tow JEEP CHEROKEE 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: CHEROKEE, Model: JEEP CHEROKEE 2019Pages: 344, PDF Size: 6.35 MB

Page 206 of 344

TIRE SERVICE KIT — IF

EQUIPPED

Small punctures up to 1/4 inch (6 mm) in the

tire tread can be sealed with Tire Service Kit.

Foreign objects (e.g., screws or nails) should

not be removed from the tire. Tire Service Kit

can be used in outside temperatures down to

approximately -4°F (-20°C).

This kit will provide a temporary tire seal,

allowing you to drive your vehicle up to 100

miles (160 km) with a maximum speed of

50 mph (80 km/h).

Tire Service Kit Storage

The Tire Service Kit is stowed under the load

floor behind the rear seat.

1. Open the liftgate.

2. Lift the access cover using the load floor

handle.

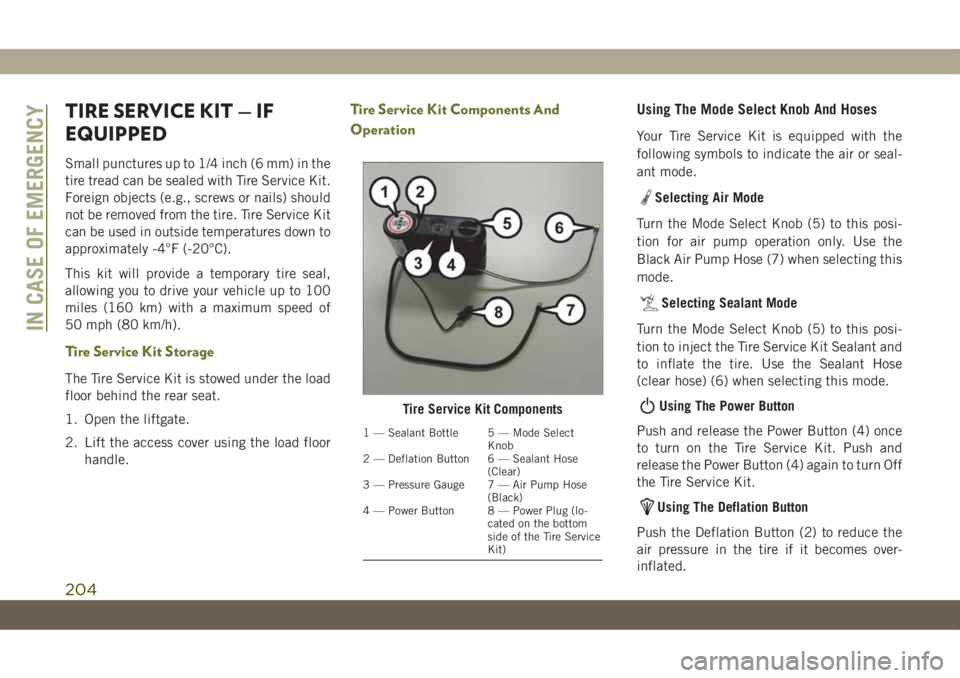

Tire Service Kit Components And

OperationUsing The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the

following symbols to indicate the air or seal-

ant mode.

Selecting Air Mode

Turn the Mode Select Knob (5) to this posi-

tion for air pump operation only. Use the

Black Air Pump Hose (7) when selecting this

mode.

Selecting Sealant Mode

Turn the Mode Select Knob (5) to this posi-

tion to inject the Tire Service Kit Sealant and

to inflate the tire. Use the Sealant Hose

(clear hose) (6) when selecting this mode.

Using The Power Button

Push and release the Power Button (4) once

to turn on the Tire Service Kit. Push and

release the Power Button (4) again to turn Off

the Tire Service Kit.

Using The Deflation Button

Push the Deflation Button (2) to reduce the

air pressure in the tire if it becomes over-

inflated.

Tire Service Kit Components

1 — Sealant Bottle 5 — Mode Select

Knob

2 — Deflation Button 6 — Sealant Hose

(Clear)

3 — Pressure Gauge 7 — Air Pump Hose

(Black)

4 — Power Button 8 — Power Plug (lo-

cated on the bottom

side of the Tire Service

Kit)

IN CASE OF EMERGENCY

204

Page 207 of 344

Tire Service Kit Usage Precautions

• Replace the Tire Service Kit Sealant Bottle

(1) and Sealant Hose (6) prior to the expi-

ration date (printed at the lower right hand

corner on the bottle label) to assure opti-

mum operation of the system.

NOTE:

Refer to section “(F) Sealant Bottle And Hose

Replacement” in “Sealing A Tire With Tire

Service Kit” in this section.

• The Sealant Bottle (1) and Sealant Hose (6)

are a one tire application use and need to

be replaced after each use. Always replace

these components immediately at your

original equipment vehicle dealer.

• When the Tire Service Kit sealant is in a

liquid form, clean water and a damp cloth

will remove the material from the vehicle or

tire and wheel components. Once the seal-

ant dries, it can easily be peeled off and

properly discarded.• For optimum performance, make sure the

valve stem on the wheel is free of debris

before connecting the Tire Service Kit.

• You can use the Tire Service Kit air pump to

inflate bicycle tires. The kit also comes with

two needles, located in the Accessory Stor-

age Compartment (on the bottom of the air

pump) for inflating sport balls, rafts, or

similar inflatable items. However, use only

the Air Pump Hose (7) and make sure the

Mode Select Knob (5) is in the Air Mode

when inflating such items to avoid injecting

sealant into them. The Tire Service Kit

Sealant is only intended to seal punctures

less than 1/4 inch (6 mm) diameter in the

tread of your vehicle.

• Do not lift or carry the Tire Service Kit by the

hoses.

WARNING!

• Do not attempt to seal a tire on the side

of the vehicle closest to traffic. Pull far

enough off the road to avoid the danger

of being hit when using the Tire Service

Kit.

WARNING!

• Do not use Tire Service Kit or drive the

vehicle under the following circum-

stances:

– If the puncture in the tire tread is

approximately 1/4 inch (6 mm) or

larger.

– If the tire has any sidewall damage.

– If the tire has any damage from

driving with extremely low tire pres-

sure.

– If the tire has any damage from

driving on a flat tire.

– If the wheel has any damage.

– If you are unsure of the condition of

the tire or the wheel.

• Keep Tire Service Kit away from open

flames or heat source.

• A loose Tire Service Kit thrown forward in

a collision or hard stop could endanger

the occupants of the vehicle. Always

stow the Tire Service Kit in the place

provided. Failure to follow these warn-

ings can result in injuries that are seri-

ous or fatal to you, your passengers, and

others around you.

205

Page 216 of 344

NOTE:

Push the “ESC Off” switch (if necessary), to

place the Electronic Stability Control (ESC)

system in “Partial Off” mode, before rocking

the vehicle. Refer to “Electronic Brake Con-

trol System” in “Safety” for further informa-

tion. Once the vehicle has been freed, push

the "ESC Off" switch again to restore “ESC

On” mode.WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even failure,

of the axle and tires. A tire could explode

and injure someone. Do not spin your

vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you

are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

TOWING A DISABLED

VEHICLE

This section describes procedures for towing

a disabled vehicle using a commercial towing

service.

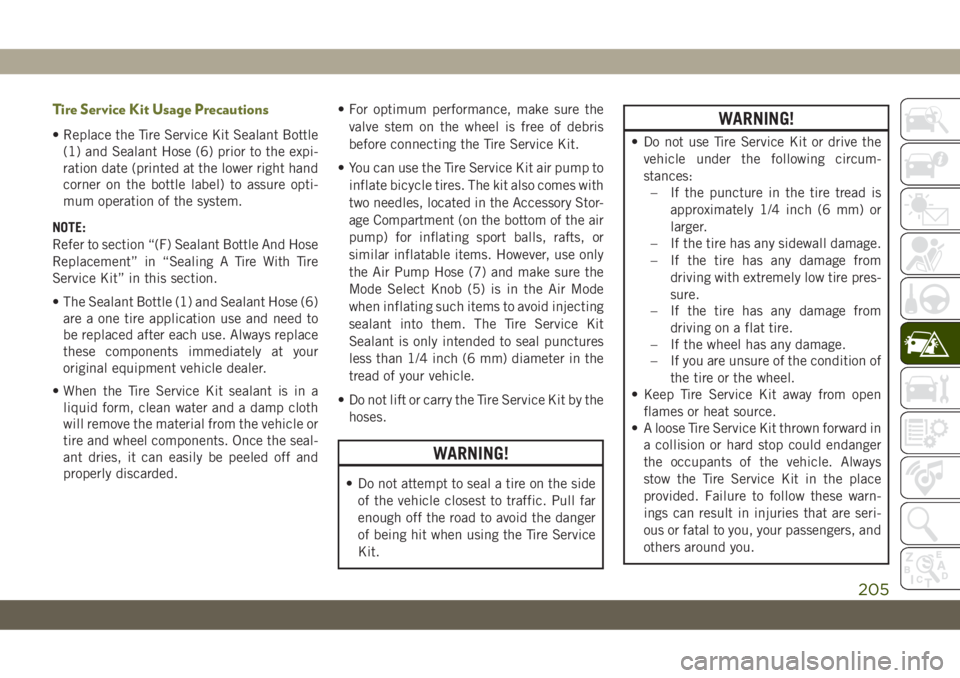

Towing Condition Wheels OFF The

GroundFWD MODELS 4X4 MODELS

Flat Tow NONENOT ALLOWED NOT ALLOWED

Wheel Lift Or Dolly TowRearNOT ALLOWED NOT ALLOWED

Front OKNOT ALLOWED

FlatbedALL BEST METHOD ONLY METHOD

Proper towing or lifting equipment is required

to prevent damage to your vehicle. Use only

tow bars and other equipment designed for

this purpose, following equipment manufac-

turer’s instructions. Use of safety chains is

mandatory. Attach a tow bar or other towingdevices to main structural members of the

vehicle, not to bumpers or associated brack-

ets. State and local laws regarding vehicles

under tow must be observed.

IN CASE OF EMERGENCY

214

Page 217 of 344

NOTE:

• You must ensure that the Auto Park Brake

feature is disabled before towing this ve-

hicle, to avoid inadvertent Electric Park

Brake engagement. The Auto Park Brake

feature is enabled or disabled via the cus-

tomer programmable features in the

Uconnect Settings.

• Vehicles with a discharged battery or total

electrical failure when the electric park

brake (EPB) is engaged, will need a wheel

dolly or jack to raise the rear wheels off the

ground when moving the vehicle onto a

flatbed.

If you must use the accessories (wipers, de-

frosters, etc.) while being towed, the ignition

must be in the ON/RUN mode, not the ACC

mode.

Note that the Safehold feature will engage

the Electric Park Brake whenever the driver's

door is opened (if the battery is connected,

ignition is ON, transmission is not in PARK,

and brake pedal is released). If you are towing

this vehicle with the ignition in the ON/RUNmode, you must manually disable the Elec-

tric Park Brake each time the driver's door is

opened, by pressing the brake pedal and then

releasing the EPB.

If the vehicle’s battery is discharged, refer to

“Gear Selector Override” in this section for

instructions on shifting the automatic trans-

mission out of PARK so that the vehicle can

be moved.

CAUTION!

• Do not use sling-type equipment when

towing. Vehicle damage may occur.

• When securing the vehicle to a flatbed

truck, do not attach to front or rear

suspension components. Damage to

your vehicle may result from improper

towing.

• Ensure that the Electric Park Brake is

released, and remains released, while

being towed.

Without The Key Fob

Special care must be taken when the vehicle

is towed with the ignition in the LOCK/OFF

mode. The only approved method of towing

without the key fob is with a flatbed truck.

Proper towing equipment is necessary to pre-

vent damage to the vehicle.

Front-Wheel Drive (FWD) Models

The manufacturer recommends towing your

vehicle with all four wheelsOFFthe ground

using a flatbed.

If flatbed equipment is not available, this

vehicle must be towed with the front wheels

OFF the ground (using a towing dolly, or

wheel lift equipment with the front wheels

raised).

Ensure that the Electric Park Brake is re-

leased, and remains released, while being

towed. The Electric Park Brake does not need

to be released, if all four wheels are off the

ground.

215

Page 218 of 344

CAUTION!

Towing this vehicle in violation of the

above requirements can cause severe en-

gine and/or transmission damage. Damage

from improper towing is not covered under

the New Vehicle Limited Warranty.

4x4 Models

The manufacturer requires towing with all

four wheelsOFFthe ground.

Acceptable methods are to tow the vehicle on

a flatbed, or with one end of vehicle raised

and the opposite end on a towing dolly.

CAUTION!

• Front or rear wheel lifts must not be used

(if the remaining wheels are on the

ground). Internal damage to the trans-

mission or power transfer unit will occur

if a front or rear wheel lift is used when

towing.

• Towing this vehicle in violation of the

above requirements can cause severe

transmission and/or power transfer unit

CAUTION!

damage. Damage from improper towing

is not covered under the New Vehicle

Limited Warranty.

Recovery Strap — If Equipped

Your vehicle may be included with a recovery

strap. Recovery straps do not act like tradi-

tional tow straps, chains, or winch cables.

WARNING!

Recovery straps should only be used in

emergencies to rescue stranded vehicles.

Only use Recovery straps on vehicles that

fit within the recommended GVW of your

recovery strap. Only attach recovery straps

to OE recommended anchor points or

emergency towing anchor points. Never

attach to tow ball or vehicle tie down point,

these are not designed for this purpose.

Never attach to vehicle steering, drive

train, or any other suspension compo-

nents. NEVER pull a strap over sharp

edges or abrasive surfaces that can dam-

age the recovery strap. NEVER use a dam-

WARNING!

aged strap, it has reduced strength. DO

NOT attempt to repair straps. ONLY per-

sons involved in the recovery should be in

either vehicle. No passengers. Anyone in-

side the vehicles can be struck by strap

recoil, causing serious injury. MOVE by-

standers at least 40 ft (12.2 m) from the

recovery area when using the recovery

strap.

Using Recovery Strap

1. Review all warnings and instructions first.

2. Position the recovery vehicle.

3. Connect the recovery strap.

4. Add a recovery damper or blanket.

5. Clear the danger zone.

6. Safely and slowly start pulling.

7. Disconnect the recovery strap after both

vehicles are secure and parked.

IN CASE OF EMERGENCY

216

Page 220 of 344

SCHEDULED SERVICING

Correct servicing is crucial for guaranteeing a

long life for the car under the best conditions.

For this reason, Jeep has planned a series of

checks and services at fixed distance inter-

vals and, where provided, at fixed time inter-

vals, as described in the Scheduled Servicing

plan. To keep the car’s efficiency in tip-top

condition, in the following Scheduled Service

plan pages a few additional checks are listed

that should be carried out more frequently

with respect to the normal coupon redemp-

tion schedule. Scheduled Servicing is offered

by all authorized dealerships according to

fixed time or mileage intervals. If, during

each operation, in addition to the ones

scheduled, the need arises for further re-

placements or repairs, these may be carried

out with the owner's explicit agreement only.

The technicians at your dealership know your

vehicle best, and have access to factory

trained information, genuine Mopar parts,

and specially designed electronic and me-

chanical tools that can help prevent future

costly repairs. If your car is used frequently

for towing, the interval between one sched-uled servicing operation and the next should

be reduced. More frequent maintenance may

be needed for vehicles in severe operating

conditions, such as dusty areas and very

short trip driving.

NOTE:

Scheduled Servicing interventions are set out

by the Manufacturer. Failure to have them

carried out may invalidate the warranty. It is

advised to inform an authorized dealership of

any small operating irregularities without

waiting for the next service.

Scheduled Servicing — Gasoline Engine

The oil change indicator system will remind

you that it is time to take your vehicle in for

engine oil replacement.

An “Oil Change Required” will be displayed

in the instrument cluster and a single chime

will sound, indicating that an oil change is

necessary.

The oil change indicator message will illumi-

nate approximately 7,000 miles

(11,200 km) after the most recent oil change

was performed. Have your vehicle serviced assoon as possible, within 500 miles (800 km)

(except for 2.0L gasoline engine with GPF –

Gasoline Particulate Filter).

NOTE:

• The oil change indicator message will not

monitor the time since the last oil change.

Change your vehicle’s oil if it has been

12 months since your last oil change even

if the oil change indicator message is NOT

illuminated.

• Change your engine oil more often if you

drive your vehicle off-road for an extended

period of time (refer to the “Heavy Duty

Use” section).

• Under no circumstances should oil change

intervals exceed 7,500 miles (12,000 km)

or 12 months, whichever comes first (ex-

cept for 2.0L gasoline engine with GPF –

Gasoline Particulate Filter).

Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change.

SERVICING AND MAINTENANCE

218

Page 224 of 344

* The actual interval for changing the oil and

replacing engine oil filter depends on vehicle

usage conditions, it is signaled by the warn-

ing light or message (if equipped) in the

instrument cluster. It should not exceed

10,000 miles (16,000 km) or 12 months.

** See “Heavy Duty Use Of The Vehicle” in

this section.

*** DOT 4 brake fluid interval is time based

only, mileage intervals do not apply.

**** The spark plug change interval is mile-

age based only, yearly intervals do not apply.

***** This maintenance is recommended by

the manufacturer to the owner, but is not

required to maintain emissions warranty.

WARNING!

• You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge

and the right equipment. If you have any

doubt about your ability to perform a

service job, take your vehicle to a com-

petent mechanic.

WARNING!

• Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an

accident.

Heavy Duty Use Of Vehicle

Change the engine oil and engine oil filter at

every 4500 miles (7,500 km) or 12 months if

using your vehicle under any of the following

severe duty conditions:

• Stop and go driving.

• Driving in dusty conditions.

• Short trips of less than 10 miles (16 km).

• Trailer towing.

• Taxi, police, or delivery service (commercial

service).

• Off-road or desert operation.

Scheduled Servicing — Diesel Engine

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is

time to take your vehicle in for engine oil

replacement.

Based on engine operation conditions, the oil

change indicator message will illuminate.

This means that service is required for your

vehicle. Operating conditions such as fre-

quent short-trips, trailer tow, extremely hot or

cold ambient temperatures will influence

when the “Oil Change Required” message is

displayed. Severe Operating Conditions can

cause the change oil message to illuminate

as earlier than specified. Have your vehicle

serviced as soon as possible, within the next

500 miles (805 km).

To help you have the best driving experience

possible, the manufacturer has identified the

specific vehicle maintenance service inter-

vals that are required to keep your vehicle

operating properly and safely.

SERVICING AND MAINTENANCE

222

Page 227 of 344

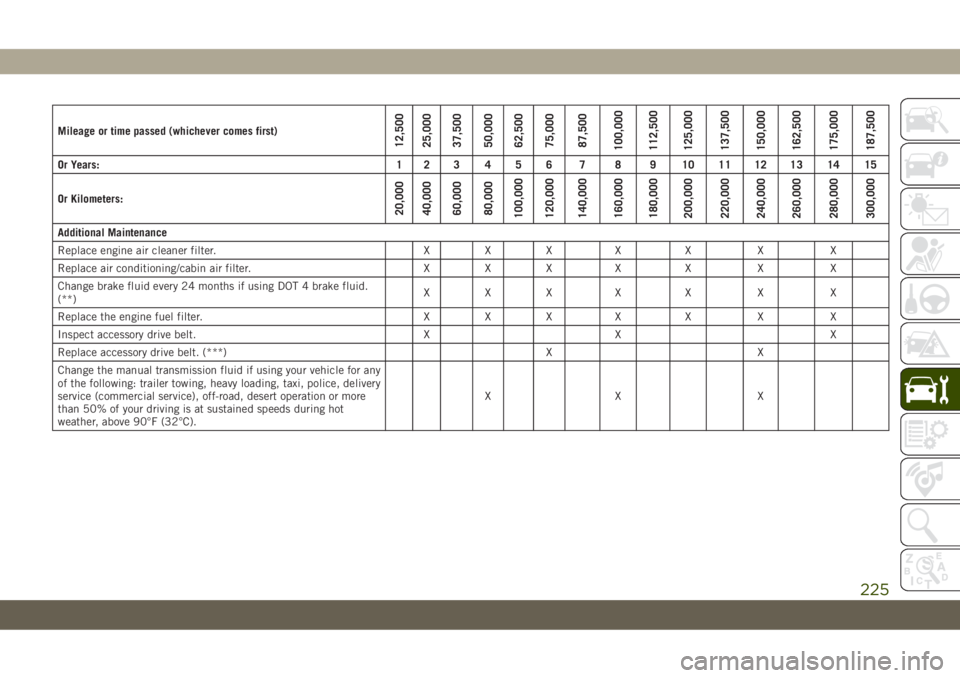

Mileage or time passed (whichever comes first)12,500

25,000

37,500

50,000

62,500

75,000

87,500

100,000

112,500

125,000

137,500

150,000

162,500

175,000

187,500

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

260,000

280,000

300,000

Additional Maintenance

Replace engine air cleaner filter. X X X X X X X

Replace air conditioning/cabin air filter. X X X X X X X

Change brake fluid every 24 months if using DOT 4 brake fluid.

(**)XXX X X X X

Replace the engine fuel filter. X X X X X X X

Inspect accessory drive belt. X X X

Replace accessory drive belt. (***) X X

Change the manual transmission fluid if using your vehicle for any

of the following: trailer towing, heavy loading, taxi, police, delivery

service (commercial service), off-road, desert operation or more

than 50% of your driving is at sustained speeds during hot

weather, above 90°F (32°C).XX X

225

Page 234 of 344

WARNING!

matically and may start at any time,

whether the engine is running or not.

• When working near the radiator cooling

fan, turn the ignition to the OFF mode.

The fan is temperature controlled and

can start at any time the ignition is in the

ON mode.

Engine Coolant Checks

Check the engine coolant (antifreeze) protec-

tion every 12 months (before the onset of

freezing weather, where applicable). If the

engine coolant (antifreeze) is dirty, the sys-

tem should be drained, flushed, and refilled

with fresh OAT coolant (conforming to

MS.90032) by an authorized dealer. Check

the front of the A/C condenser for any accu-

mulation of bugs, leaves, etc. If dirty, clean

by gently spraying water from a garden hose

vertically down the face of the condenser.

Check the engine cooling system hoses for

brittle rubber, cracking, tears, cuts, and

tightness of the connection at the coolant

recovery bottle and radiator. Inspect the en-tire system for leaks. DO NOT REMOVE THE

COOLANT PRESSURE CAP WHEN THE

COOLING SYSTEM IS HOT.

Adding Washer Fluid

The windshield and rear window washers

share the same fluid reservoir. The fluid res-

ervoir is located in the front of the engine

compartment. Be sure to check the fluid level

in the reservoir at regular intervals. Fill the

reservoir with windshield washer solvent (not

radiator antifreeze) and operate the system

for a few seconds to flush out the residual

water.

When refilling the washer fluid reservoir, take

some washer fluid and apply it to a cloth or

towel and wipe clean the wiper blades, this

will help blade performance.

To prevent freeze-up of your windshield

washer system in cold weather, select a solu-

tion or mixture that meets or exceeds the

temperature range of your climate. This rat-

ing information can be found on most washer

fluid containers.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite

and burn you. Care must be exercised

when filling or working around the washer

solution.

CAUTION!

Do not travel with the windshield washer

fluid reservoir empty: the windshield

washer is essential for improving visibility.

Repeated operation of the system without

fluid could damage or cause rapid deterio-

ration of some system components.

Brake System

In order to assure brake system performance,

all brake system components should be in-

spected periodically. Refer to the “Mainte-

nance Plan” in this section for the proper

maintenance intervals.

SERVICING AND MAINTENANCE

232

Page 238 of 344

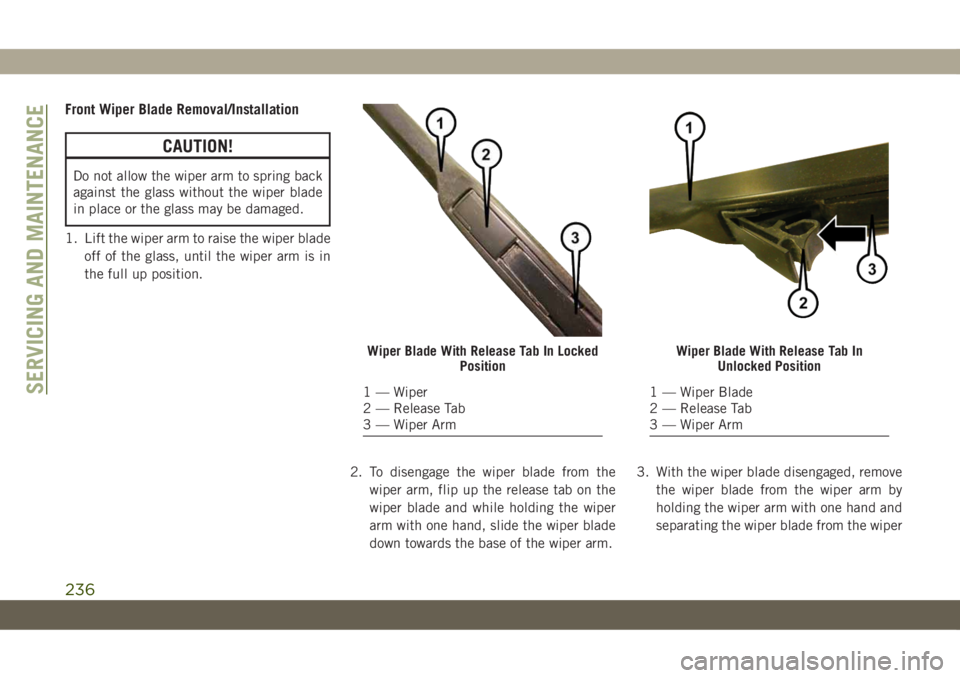

Front Wiper Blade Removal/Installation

CAUTION!

Do not allow the wiper arm to spring back

against the glass without the wiper blade

in place or the glass may be damaged.

1. Lift the wiper arm to raise the wiper blade

off of the glass, until the wiper arm is in

the full up position.

2. To disengage the wiper blade from the

wiper arm, flip up the release tab on the

wiper blade and while holding the wiper

arm with one hand, slide the wiper blade

down towards the base of the wiper arm.3. With the wiper blade disengaged, remove

the wiper blade from the wiper arm by

holding the wiper arm with one hand and

separating the wiper blade from the wiper

Wiper Blade With Release Tab In Locked

Position

1 — Wiper

2 — Release Tab

3 — Wiper Arm

Wiper Blade With Release Tab In

Unlocked Position

1 — Wiper Blade

2 — Release Tab

3 — Wiper ArmSERVICING AND MAINTENANCE

236