light JEEP CJ 1953 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 271 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

K

the

bottom.

Remove

rear

bearing

cone

and roller

assembly from the shaft by striking the end of the

shaft lightly against a

wooden

block,

j.

Remove the set screw in sliding gear shift fork.

Remove shift rod.

See the following paragraphs for disassembly of

the front and

rear

bearing caps.

K-4.

Front

Bearing Cap Disassembly

•

Refer to Fig. K-1, K-2.

The

front bearing cap is a separate assembly which

may

be removed for service. Should difficulty be

experienced in this section of the transfer case,

follow

the

sequence

below

for removal and dis assembly.

a.

Remove the output shaft yoke as outlined in

Par. K-3.

Remove the

poppet

balls and

move

the

front wheel drive shift rod forward as outlined in

Par.

K-3f.

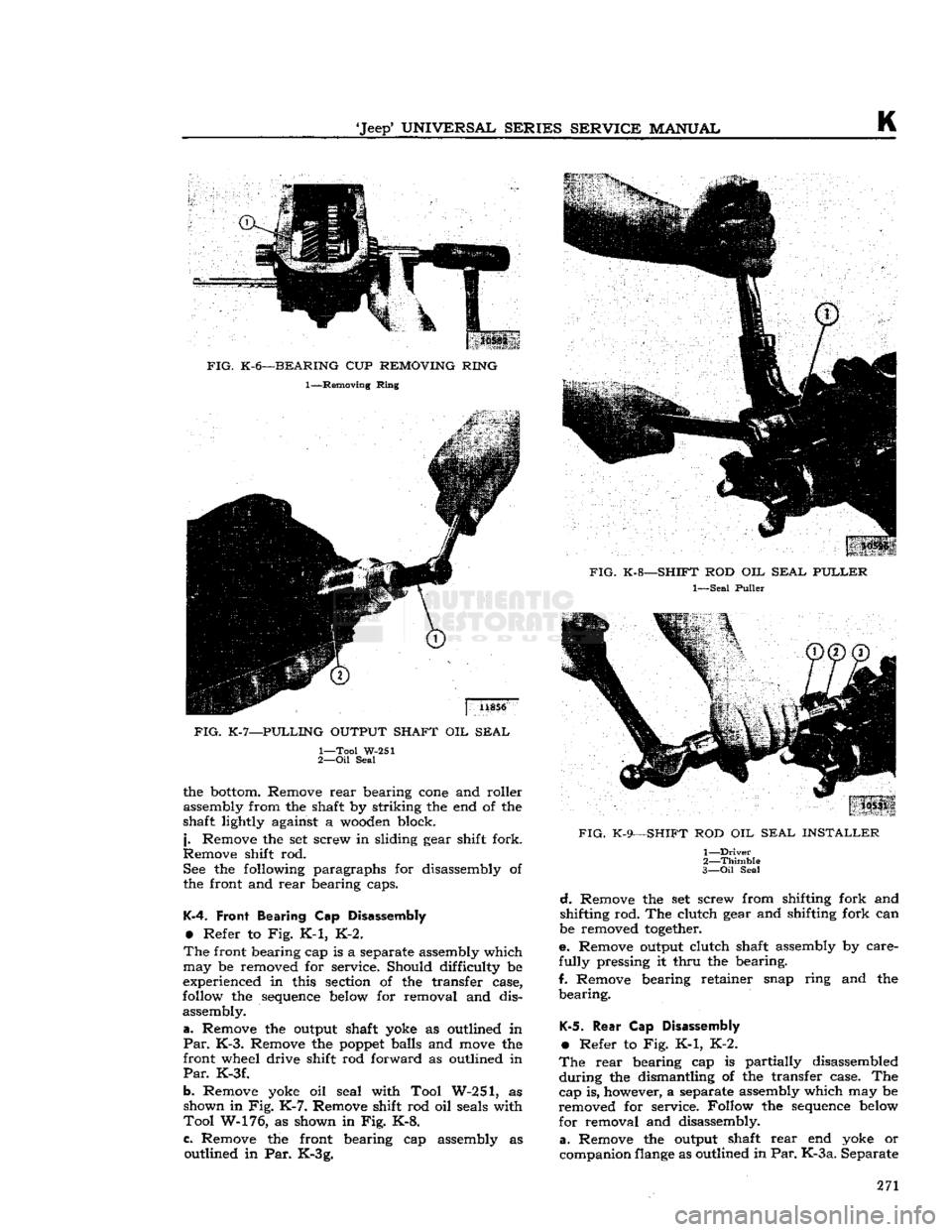

b.

Remove yoke oil seal with Tool W-251, as shown in Fig.

K-7.

Remove shift rod oil seals with

Tool

W-176, as shown in Fig. K-8.

c.

Remove the front bearing cap assembly as outlined in Par. K-3g.

FIG.

K-9—SHIFT

ROD OIL

SEAL INSTALLER

1—

Driver

2—

Thimble

3— Oil

Seal

d.

Remove the set screw from shifting fork and

shifting rod. The clutch gear and shifting fork can

be removed

together.

e. Remove output clutch shaft assembly by care

fully

pressing it

thru

the bearing.

f. Remove bearing retainer snap ring and the

bearing.

K-5.

Rear

Cap Disassembly

•

Refer to Fig. K-1, K-2.

The

rear

bearing cap is partially disassembled

during

the dismantling of the transfer case. The

cap is, however, a separate assembly which may be

removed for service. Follow the

sequence

below

for removal and disassembly,

a.

Remove the output shaft

rear

end yoke or

companion

flange

as outlined in

Par. K-3 a.

Separate 271

Page 272 of 376

K

TRANSFER

CASE

the brake drum and companion

flange

by remov

ing bolts, lockwashers, and nuts.

b.

Remove the oil seal with Tool W-251, as shown

in

Fig. K-7.

c.

Remove

speedometer

driven gear assembly.

d.

Remove the cap screws attaching the cap and

brake

backing plate to the case.

Take

precautions

not to

lose

or damage bearing adjusting shims placed

between

the cap and the transfer case

housing.

e. Separate the

rear

cap and brake backing plate

assembly. See Section P for brake service pro

cedures.

f. Remove

speedometer

driving gear.

K-6.

Transfer

Case

Reassembly

•

Refer to Fig. K-1, K-2.

Reassembly

of the transfer case is reversal of the

foregoing

procedure of disassembly. The output shaft snap ring may

best

be installed with Tool

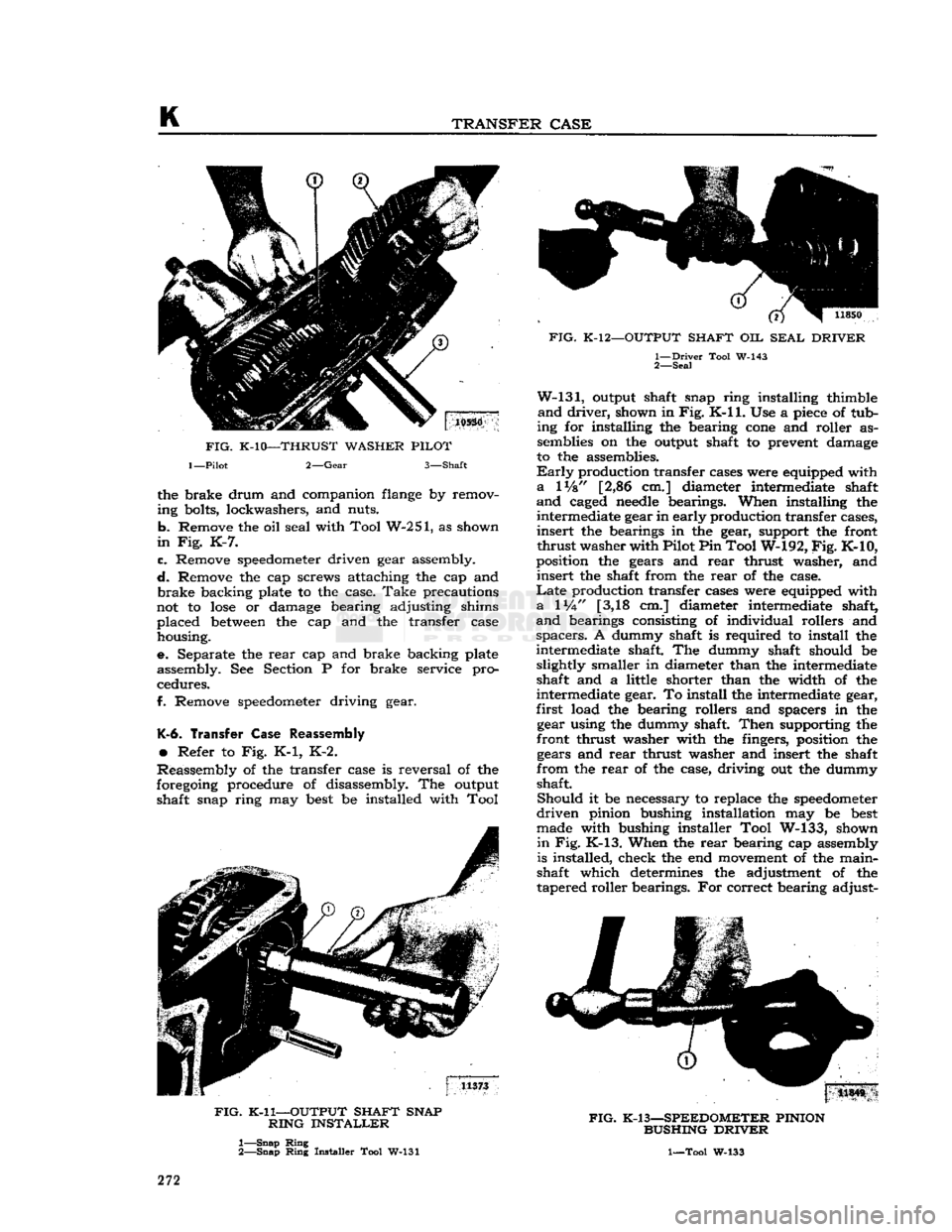

FIG.

K-11—OUTPUT

SHAFT

SNAP

RING

INSTALLER

1—

Snap

Ring

2—

Snap

Ring

Installer Tool W-131

FIG.

K-12—OUTPUT

SHAFT

OIL

SEAL

DRIVER

1—

Driver

Tool W-143

2—

Seal

W-131,

output shaft snap ring installing thimble

and

driver,

shown in

Fig.

K-ll.

Use a

piece

of tub

ing for installing the bearing

cone

and roller as semblies on the output shaft to prevent damage

to the assemblies.

Early

production transfer cases were equipped with

a

lVs" [2,86 cm.] diameter intermediate shaft

and

caged

needle

bearings. When installing the intermediate gear in early production transfer cases,

insert

the bearings in the gear, support the front

thrust

washer with Pilot Pin Tool W-192,

Fig.

K-10,

position the gears and

rear

thrust washer, and

insert

the shaft from the

rear

of the case.

Late

production transfer cases were equipped with

a

1

Vi"

[3,18 cm.] diameter intermediate shaft,

and

bearings consisting of individual rollers and

spacers.

A dummy shaft is required to install the

intermediate shaft. The dummy shaft should be slightly smaller in diameter than the intermediate

shaft and a little shorter than the width of the

intermediate gear. To install the intermediate gear,

first

load the bearing rollers and spacers in the gear using the dummy shaft.

Then

supporting the

front thrust washer with the fingers, position the gears and

rear

thrust washer and insert the shaft

from

the

rear

of the case, driving out the dummy

shaft.

Should

it be necessary to replace the

speedometer

driven

pinion bushing installation may be

best

made with bushing installer Tool W-133, shown

in

Fig. K-13. When the

rear

bearing cap assembly

is installed, check the end

movement

of the main-

shaft which determines the adjustment of the

tapered roller bearings. For correct bearing adjust-

|

11S4S

FIG.

K-13—SPEEDOMETER

PINION

BUSHING

DRIVER

1—Tool W-133

272

Page 276 of 376

L

PROPELLER

SHAFTS

AND

UNIVERSAL JOINTS

move

the snap rings, pinch the ends

together

with

a

pair

of pliers. If the rings do not readily snap

out of the groove, tap the end of the bearing lightly

which

will

relieve pressure against the rings.

After

removing the snap rings, press on the end of

one bearing until the

opposite

bearing is pushed

from

the yoke arm.

Turn

the joint over and press

the first bearing back out of that arm by pressing

on the

exposed

end of the

journal

shaft. Use a

soft

ground drift with a flat face about [0,8 mm.]

smaller

in diameter than the

hole

in the yoke arm

and

drive it out, otherwise there is danger of damaging the bearing.

Repeat

this operation for the other two bearings,

then lift out

journal

assembly by sliding it to one

side.

L-4.

Snap

Ring

Type Assembly

Wash

all parts in cleaning solvent and inspect the

parte

after cleaning. Replace any parts that indicate

extensive

wear.

It is advisable to install new gaskets

on the

journal

assembly regardless of the condition of the old gaskets. Make certain that the grease

channel

in each

journal

trunnion is open.

Pack

the bearing

cones

one-third

full

of lubricant

and

install the rollers.

Draw

the bearings into the end yoke arm and seat

them firmly against the bearing shoulders. Hold

the bearings in a vertical position to prevent the

needles

from dropping out until the joint is as sembled. If the joint binds when assembled, tap

the arms lightly to relieve any pressure on the bear

ings at the end of the

journal.

L-5.

U-Bolt

Type Disassembly

Removal

of the attaching "U"-bolt releases one set

of bearing races. Slide the propeller shaft into the

yoke flange to remove them using care not to

lose

the rollers.

After

the removal of the one set of bearing races,

release the other set by removing the snap rings

in

the

sleeve

yoke by pinching the ends

together

with

a

pair

of pliers. Should the rings

fail

to snap

readily

from the groove, tap the end of the bearing

lightly,

which

will

relieve the pressure against them.

Press

on the end of one bearing, until the

opposite

bearing

is pushed out of the yoke arm.

Turn

the

universal

joint over and press the first bearing out

by pressing on the

exposed

end of the

journal

as

sembly. Use a

soft

ground drift with a flat face about

\{i

[0,8 mm.] smaller in diameter than the

hole

in the yoke

arm

and drive out the bearing.

Lift

the

journal

out by sliding to one side.

Clean

all

parts

and check for wear.

L-6.

U-Bolt Type Assembly

Wash

all parts in cleaning solvent and inspect the

parts

after cleaning. Replace any parts that indicate

extensive

wear.

It is advisable to install new gaskets

on the

journal

assembly regardless of the condition

of the old gaskets. Make certain that the grease

channel

in each

journal

trunnion is open.

Pack

the bearing

cones

one-third

full

of lubricant

and

install the rollers.

Draw

the bearings into the end yoke arm and seat

them firmly against the bearing shoulders. Hold the

bearings in a vertical position to prevent the

needles

from dropping out until the joint is as

sembled. If the joint binds when assembled, tap the arms lightly to relieve any pressure on the

bearings at the end of the

journal.

Tighten the

U-bolts equally. U-bolt torque wrench reading is 15 to 20 lb-ft. [2,07 a 2,76 kg-m.].

When

installing the assembly in the vehicle be sure

that the arrows on the propeller shaft and yoke

sleeve

are in alignment as shown in Fig. L-2, or

that the unmarked joints are aligned with the yokes in the same parallel plane.

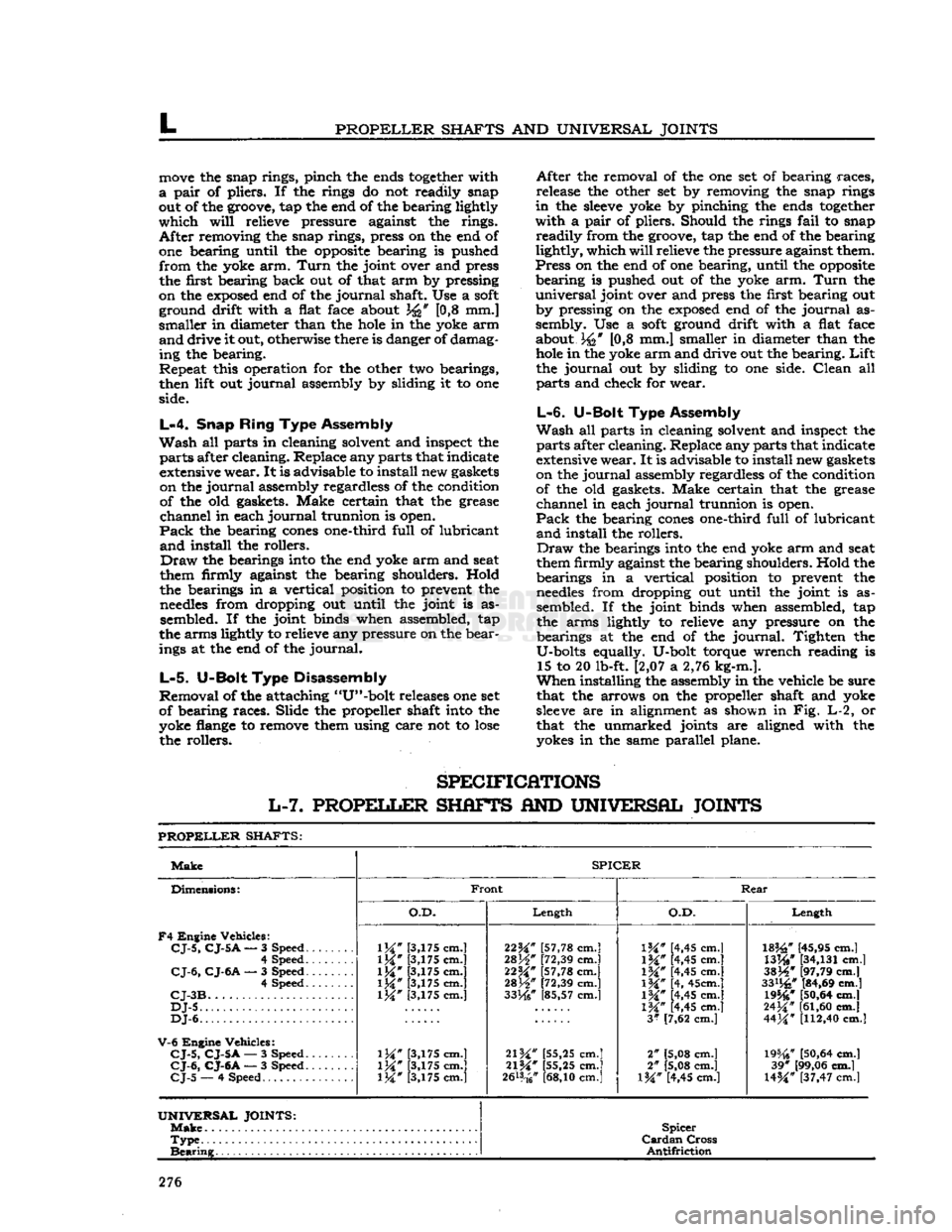

SPECIFICATIONS

L-7.

PROPELLER

SHAFTS

AND

UNIVERSAL JOINTS

PROPELLER

SHAFTS:

Make

SPICER

Dimensions:

F4

Engine Vehicles:

CJ-5,

CJ-5

A

— 3 Speed.

......

4 Speed

CJ-6,

CJ-6A

— 3 Speed 4 Speed

CJ-3B

DJ-5

DJ-6.

V-6

Engine Vehicles:

CJ-5,

CJ-5A

— 3 Speed.

CJ-6,

CJ-6A

— 3 Speed.

CJ-5

— 4 Speed

Front

Rear

Dimensions:

F4

Engine Vehicles:

CJ-5,

CJ-5

A

— 3 Speed.

......

4 Speed

CJ-6,

CJ-6A

— 3 Speed 4 Speed

CJ-3B

DJ-5

DJ-6.

V-6

Engine Vehicles:

CJ-5,

CJ-5A

— 3 Speed.

CJ-6,

CJ-6A

— 3 Speed.

CJ-5

— 4 Speed

O.D.

Length

O.D.

Length

Dimensions:

F4

Engine Vehicles:

CJ-5,

CJ-5

A

— 3 Speed.

......

4 Speed

CJ-6,

CJ-6A

— 3 Speed 4 Speed

CJ-3B

DJ-5

DJ-6.

V-6

Engine Vehicles:

CJ-5,

CJ-5A

— 3 Speed.

CJ-6,

CJ-6A

— 3 Speed.

CJ-5

— 4 Speed

1M"

[3,175 cm.]

1M*

[3,175 cm.]

\W

[3,175 cm.]

1M*

[3,175 cm.] [3,175 cm.]

\W

[3,175 cm.]

\W

[3,175 cm.] [3,175 cm.] 22^" [57,78 cm.]

28H"

[72,39 cm.]

22M*

[57,78 cm.]

mW

[72,39 cm.]

33He"

[85,57 cm.]

21W

[55,25 cm.]

21%"

[55,25 cm.]

2&*

cm.]

IK"

[4,45 cm.]

1M#

[4,45 cm.]

\%"

[4,45 cm.]

\%"

[4, 45cm.]

IW

[4,45 cm.]

1M*

[4,45 cm.]

3*

[7,62 cm.]

2" [5,08 cm.]

2" [5,08 cm.]

l%" [4,45 cm.]

182£"

[45,95 cm.]

WW

[34,131

cm.]

3SJ4*

[97,79 cm.]

33%"

[84,69 cm.] 19546*

[50,64

cm.]

24^"

[61,60

cm.]

44M*

[112,40

cm.]

19%?

[50,64

cm.] 39* [99,06 cm.]

U%"

[37,47 cm.l

UNIVERSAL

JOINTS:

Make

Spicer

Cardan

Cross

Antifriction

Type

Spicer

Cardan

Cross

Antifriction

Bearing

Spicer

Cardan

Cross

Antifriction

276

Page 279 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

m f. Disconnect propeller shaft from the differential

companion flange.

g.

Disconnect both front springs from front spring hangers.

h.

Remove spring clip and spring clip plates secur

ing axle to front springs.

i.

Remove front

wheels

from axle assembly.

j.

Lower

jack

slightly and

pull

axle forward from

under

vehicle.

M-5.

FRONT AXLE SHAFT REMOVAL

Refer

to Fig. M-2.

The

following procedure applies to either right or

left

front axle shaft.

Note:

Axle shafts can be removed without remov

ing the axle housing from the vehicle. Use the fol

lowing procedure.

First

raise and support front end

of vehicle, and remove front wheels.

a.

Remove drive

flange

snap

ring.

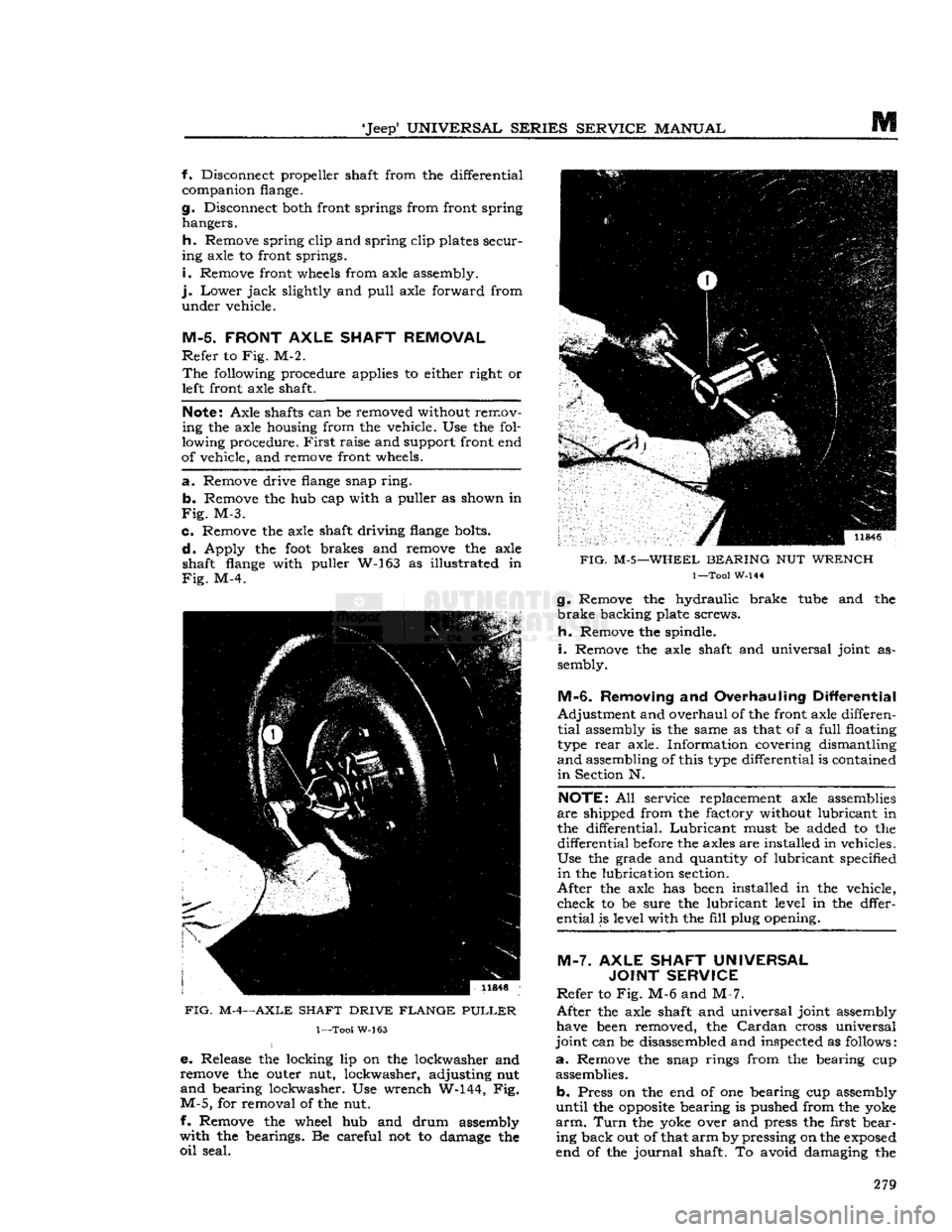

b-

Remove the hub cap with a puller as shown in

Fig.

M-3.

c.

Remove the axle shaft driving

flange

bolts.

d.

Apply the

foot

brakes and remove the axle shaft

flange

with puller W-163 as illustrated in

Fig.

M-4.

FIG.

M-4—AXLE

SHAFT

DRIVE

FLANGE

PULLER

1—Too!

W-163

e.

Release the locking lip on the lockwasher and

remove the outer nut, lockwasher, adjusting nut

and

bearing lockwasher. Use wrench W-144, Fig.

M-5,

for removal of the nut.

f- Remove the wheel hub and drum assembly

with

the bearings. Be careful not to damage the

oil

seal.

FIG.

M-5—WHEEL

BEARING

NUT

WRENCH

1—Tool

W-144

g.

Remove the hydraulic brake

tube

and the

brake

backing plate screws.

h.

Remove the spindle.

i.

Remove the axle shaft and universal joint as

sembly.

M-6.

Removing

and

Overhauling Differential

Adjustment

and overhaul of the front axle differen

tial

assembly is the same as that of a

full

floating

type

rear

axle. Information covering dismantling

and

assembling of this

type

differential is contained

in

Section N.

NOTE:

All service replacement axle assemblies

are

shipped from the factory without lubricant in

the differential.

Lubricant

must be added to the

differential

before

the axles are installed in vehicles.

Use

the grade and quantity of lubricant specified

in

the lubrication section.

After

the axle has

been

installed in the vehicle,

check

to be sure the lubricant level in the dffer-

ential

is level with the

fill

plug opening.

M-7.

AXLE SHAFT UNIVERSAL JOINT SERVICE

Refer

to Fig. M-6 and M-7.

After

the axle shaft and universal joint assembly have

been

removed, the

Cardan

cross universal

joint

can be disassembled and inspected as follows:

a.

Remove the snap rings from the bearing cup assemblies.

b.

Press on the end of one bearing cup assembly

until

the

opposite

bearing is pushed from the yoke

arm.

Turn

the yoke over and press the first bear ing back out of that

arm

by pressing on the

exposed

end of the

journal

shaft. To avoid damaging the 279

Page 281 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

M

If

the joint binds when assembled, tap the yoke

lightly to relieve any pressure on the bearings at the end of the

journal.

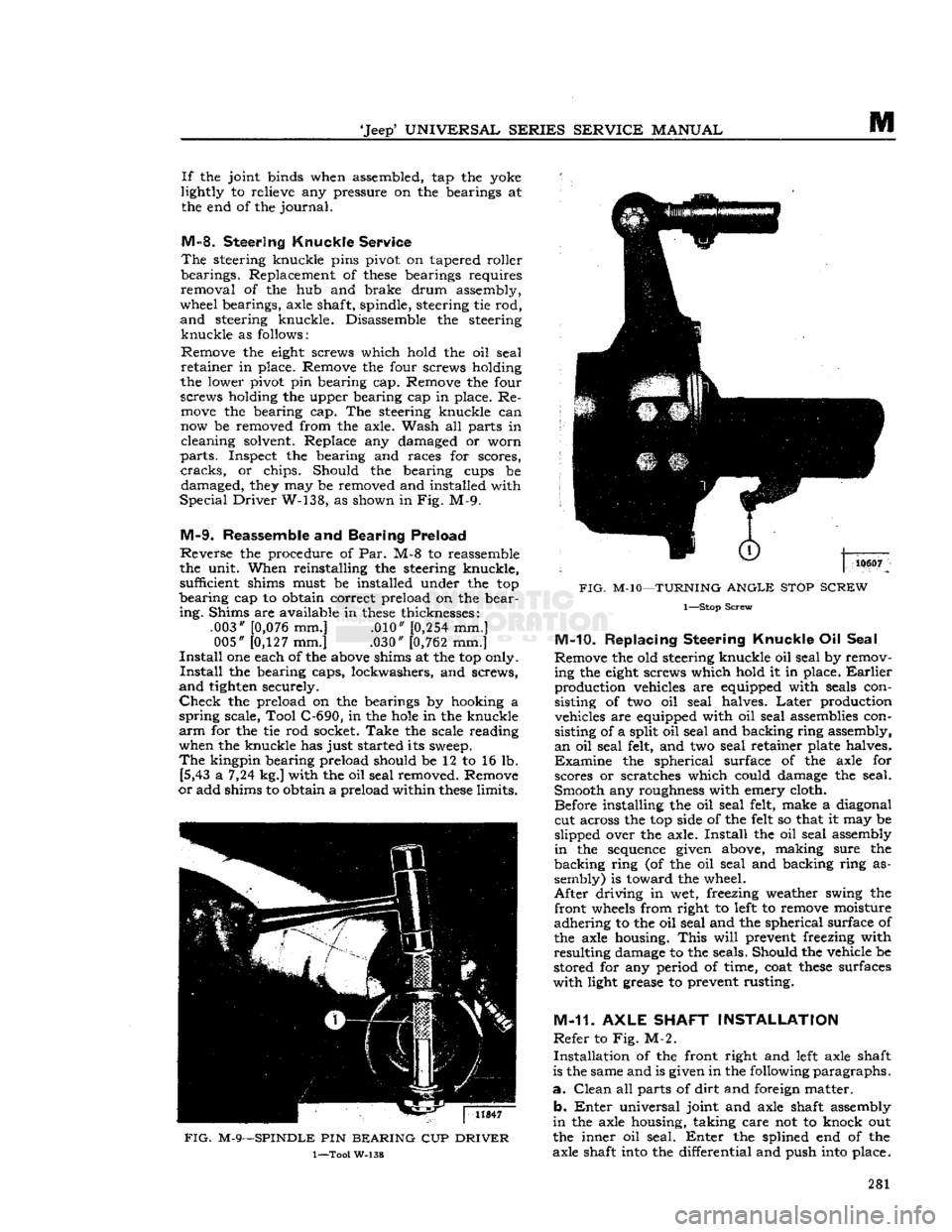

M-8-

Steering

Knuckle

Service

The

steering knuckle pins pivot on tapered roller

bearings. Replacement of

these

bearings requires

removal

of the hub and brake drum assembly,

wheel bearings, axle shaft, spindle, steering tie rod,

and

steering knuckle. Disassemble the steering

knuckle

as follows:

Remove the

eight

screws which hold the oil seal

retainer

in place. Remove the four screws holding

the lower pivot pin bearing cap. Remove the four screws holding the upper bearing cap in place. Re

move

the bearing cap. The steering knuckle can

now be removed from the axle. Wash all parts in cleaning solvent. Replace any damaged or worn

parts.

Inspect the bearing and races for scores,

cracks,

or chips. Should the bearing cups be damaged,

they

may be removed and installed with

Special

Driver

W-138, as shown in Fig. M-9.

M-9.

Reassemble

and

Bearing Preload

Reverse

the procedure of Par. M-8 to reassemble

the unit. When reinstalling the steering knuckle, sufficient shims must be installed under the top

bearing

cap to obtain correct preload on the bear

ing.

Shims are available in

these

thicknesses: .003"

[0,076

mm.] .010"

[0,254

mm.] 005"

[0,127

mm.] .030"

[0,762

mm.]

Install

one each of the

above

shims at the top only.

Install

the bearing caps, lockwashers, and screws,

and

tighten securely.

Check

the preload on the bearings by hooking a

spring

scale, Tool C-690, in the

hole

in the knuckle

arm

for the tie rod socket.

Take

the scale reading when the knuckle has just started its

sweep.

The

kingpin bearing preload should be 12 to 16 lb. [5,43 a 7,24 kg.] with the oil seal removed. Remove

or

add shims to obtain a preload within

these

limits.

FIG.

M-9—SPINDLE

PIN

BEARING

CUP

DRIVER

1—Tool

W-138

FIG.

M-10—TURNING

ANGLE

STOP

SCREW

1—Stop

Screw

M-10.

Replacing Steering

Knuckle

Oil Seal

Remove the old steering knuckle oil seal by remov ing the

eight

screws which hold it in place.

Earlier

production vehicles are equipped with seals con sisting of two oil seal halves.

Later

production vehicles are equipped with oil seal assemblies con

sisting of a split oil seal and backing ring assembly,

an

oil seal felt, and two seal retainer plate halves.

Examine

the spherical surface of the axle for scores or scratches which could damage the seal.

Smooth any roughness with emery cloth. Before installing the oil seal felt, make a diagonal

cut across the top side of the

felt

so that it may be

slipped over the axle.

Install

the oil seal assembly

in

the

sequence

given above, making sure the

backing

ring (of the oil seal and backing ring as

sembly) is toward the wheel.

After

driving in wet, freezing weather swing the

front

wheels

from right to

left

to remove moisture

adhering

to the oil seal and the spherical surface of

the axle housing.

This

will

prevent freezing with

resulting

damage to the seals. Should the vehicle be

stored for any period of time, coat

these

surfaces

with

light grease to prevent rusting.

M-11.

AXLE

SHAFT

INSTALLATION

Refer

to Fig. M-2.

Installation

of the front right and

left

axle shaft

is the same and is given in the following

paragraphs.

a.

Clean

all parts of

dirt

and foreign matter.

b.

Enter

universal joint and axle shaft assembly

in

the axle housing, taking care not to knock out

the inner oil seal.

Enter

the splined end of the

axle shaft

into

the differential and push

into

place. 281

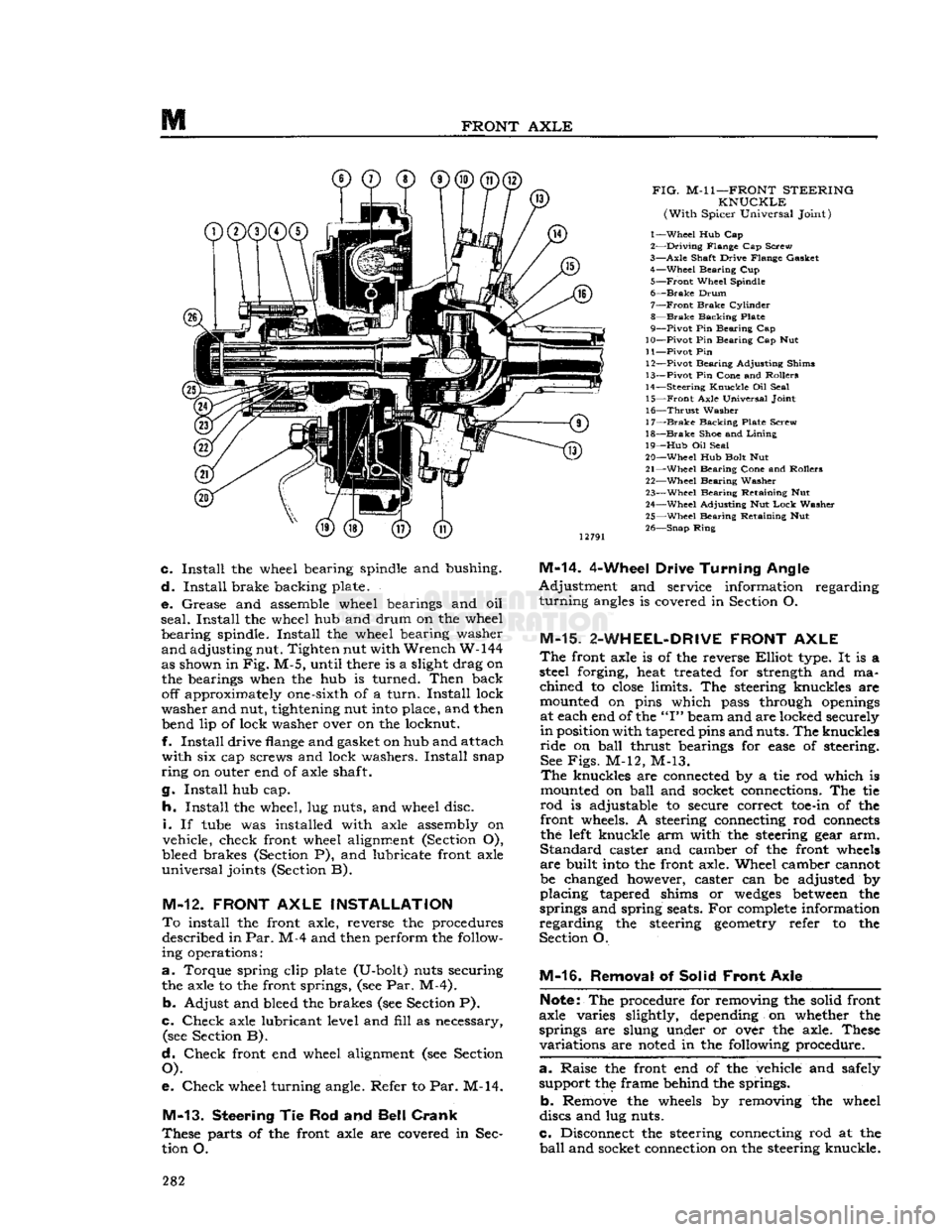

Page 282 of 376

FRONT

AXLE

FIG.

M-l

1—FRONT

STEERING

KNUCKLE

(With

Spicer Universal Joint)

1—

Wheel

Hub Cap

2—

Driving

Flange Cap Screw

3—

Axle

Shaft Drive Flange Gasket 4—

Wheel

Bearing Cup

5—

Front

Wheel Spindle

6—

Brake

Drum

7—

Front

Brake

Cylinder

8—

Brake

Backing Plate

9—

Pivot

Pin Bearing Cap

10—

Pivot

Pin Bearing Cap Nut

11—

Pivot

Pin 12—

Pivot

Bearing Adjusting Shims

13—

Pivot

Pin Cone and Rollers

14—

Steering

Knuckle

Oil Seal 15—

Front

Axle Universal Joint

16—

Thrust

Washer

17—

Brake

Backing Plate Screw

18—

Brake

Shoe and

Lining

19—

Hub

Oil Seal

20—

Wheel

Hub Bolt Nut

21—

Wheel

Bearing Cone and Rollers 22—

Wheel

Bearing Washer

23—

Wheel

Bearing Retaining Nut

24—

Wheel

Adjusting Nut

Lock

Washer

25—

Wheel

Bearing Retaining Nut

26—

Snap

Ring

c.

Install

the wheel bearing spindle and bushing.

d.

Install

brake backing plate.

e.

Grease and assemble wheel bearings and oil

seal.

Install

the wheel hub and drum on the wheel

bearing

spindle.

Install

the wheel bearing washer

and

adjusting nut. Tighten nut with

Wrench

W-144

as shown in

Fig.

M-5, until there is a slight drag on the bearings when the hub is turned.

Then

back off approximately one-sixth of a

turn.

Install

lock

washer

and nut, tightening nut

into

place, and then bend lip of lock washer over on the locknut.

f.

Install

drive

flange

and gasket on hub and attach

with

six cap screws and lock washers.

Install

snap

ring

on outer end of axle shaft.

g.

Install

hub cap.

h.

Install

the wheel, lug nuts, and wheel disc.

i.

If

tube

was installed with axle assembly on

vehicle, check front wheel alignment (Section O),

bleed brakes (Section P), and lubricate front axle

universal

joints (Section B).

M-12.

FRONT

AXLE

INSTALLATION

To

install the front axle, reverse the procedures described in

Par.

M-4 and then perform the follow

ing operations:

a.

Torque spring clip plate (U-bolt) nuts securing the axle to the front springs, (see Par. M-4).

b.

Adjust and bleed the brakes (see Section P).

c.

Check

axle lubricant level and

fill

as necessary, (see Section B).

d.

Check

front end wheel alignment (see Section

O).

e.

Check

wheel turning angle. Refer to Par. M-14.

M-13.

Steering

Tie Rod and

Bell Crank

These

parts of the front axle are covered in Sec

tion O.

M-14.

4-Wheel Drive

Turning

Angle

Adjustment

and service information regarding

turning

angles

is covered in Section O.

M-15.

2-WHEEL-DRIVE

FRONT

AXLE

The

front axle is of the reverse

Elliot

type. It is a

steel forging, heat treated for strength and ma

chined

to

close

limits. The steering knuckles are

mounted on pins which pass through

openings

at each end of the

"I"

beam and are locked securely

in

position with tapered pins and nuts. The knuckles

ride

on

ball

thrust bearings for

ease

of steering. See

Figs.

M-12, M-13.

The

knuckles are connected by a tie rod which is

mounted on

ball

and socket connections. The tie

rod

is adjustable to secure correct

toe-in

of the front wheels. A steering connecting rod

connects

the

left

knuckle arm with the steering gear arm.

Standard

caster and camber of the front

wheels

are

built

into

the front axle. Wheel camber cannot

be changed however, caster can be adjusted by

placing

tapered shims or

wedges

between

the

springs and spring seats. For

complete

information

regarding

the steering

geometry

refer to the

Section O.

M-16.

Removal of Solid

Front

Axle

Note:

The procedure for removing the solid front

axle varies slightly, depending on whether the

springs are slung under or over the axle. These

variations

are

noted

in the following procedure.

a. -

Raise the front end of the vehicle and safely support the frame behind the springs.

b.

Remove the

wheels

by removing the wheel

discs and lug nuts.

c.

Disconnect the steering connecting rod at the

ball

and socket connection on the steering knuckle. 282

Page 292 of 376

N

REAR

AXLE

FIG.

N-l3—NOTCHING

BEARING

RETAINING

RING

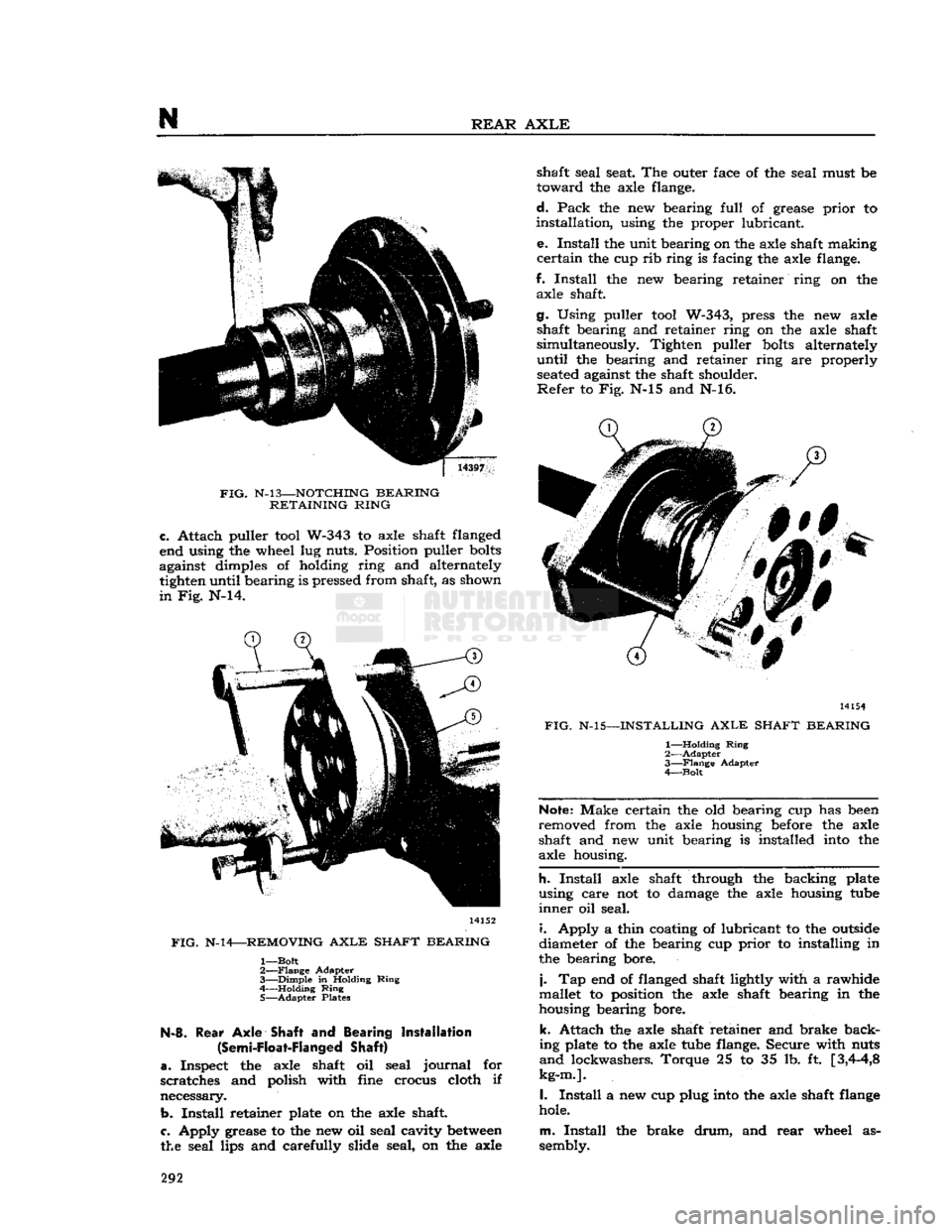

c.

Attach puller

tool

W-343 to axle shaft flanged

end using the wheel lug nuts. Position puller

bolts

against dimples of holding ring and alternately tighten until bearing is pressed from shaft, as shown

in

Fig. N-14. 14152

FIG.

N-14—REMOVING

AXLE

SHAFT

BEARING

1—

Bolt

2—

Flange

Adapter

3—

Dimple

in Holding

Ring

4 Holding

Ring

5—

Adapter

Plates N-8.

Rear

Axle

Shaft and Bearing Installation

(Semi-Float-Flanged

Shaft)

a.

Inspect the axle shaft oil seal

journal

for

scratches and polish with fine crocus cloth if

necessary.

b.

Install

retainer plate on the axle shaft

c.

Apply grease to the new oil seal cavity

between

the seal lips and carefully slide seal, on the axle shaft seal seat. The outer face of the seal must be

toward

the axle flange.

d.

Pack

the new bearing

full

of grease

prior

to

installation,

using the proper lubricant.

e.

Install

the unit bearing on the axle shaft making

certain

the cup rib ring is facing the axle flange.

f.

Install

the new bearing retainer ring on the axle shaft.

g. Using puller

tool

W-343, press the new axle shaft bearing and retainer ring on the axle shaft

simultaneously. Tighten puller

bolts

alternately

until

the bearing and retainer ring are properly

seated

against the shaft shoulder.

Refer

to Fig. N-15 and N-16. 14154

FIG.

N-15—INSTALLING

AXLE

SHAFT

BEARING

1—

Holding

Ring

2—

Adapter

3—

Flange

Adapter

4—

Bolt

Note:

Make certain the old bearing cup has

been

removed from the axle housing

before

the axle

shaft and new unit bearing is installed

into

the

axle housing.

h.

Install

axle shaft through the backing plate

using care not to damage the axle housing

tube

inner

oil seal.

i.

Apply a thin coating of lubricant to the

outside

diameter of the bearing cup

prior

to installing in

the bearing bore.

j.

Tap end of flanged shaft lightly with a rawhide

mallet to position the axle shaft bearing in the

housing bearing bore.

k.

Attach the axle shaft retainer and brake back

ing plate to the axle

tube

flange. Secure with nuts

and

lockwashers. Torque 25 to 35 lb. ft

[3,4-4,8

kg-m.].

I.

Install

a new cup plug

into

the axle shaft

flange

hole.

m.

Install

the brake

drum,

and

rear

wheel as

sembly. 292

Page 299 of 376

'Jeep9

UNIVERSAL

SERIES SERVICE

MANUAL

N

c.

Check

side gear clearance as described in Par.

N-18.

d.

Examine contacting surfaces of ring gear and

differential case for

burrs

or foreign matter.

e.

Assemble ring gear on differential case with assembly

hole

on each lined up.

f.

Tap ring gear

into

place with mallet.

g.

Install

ring gear screws. Torque 35 to 55 lb-ft. [4,84 a 7,60 kg-m.].

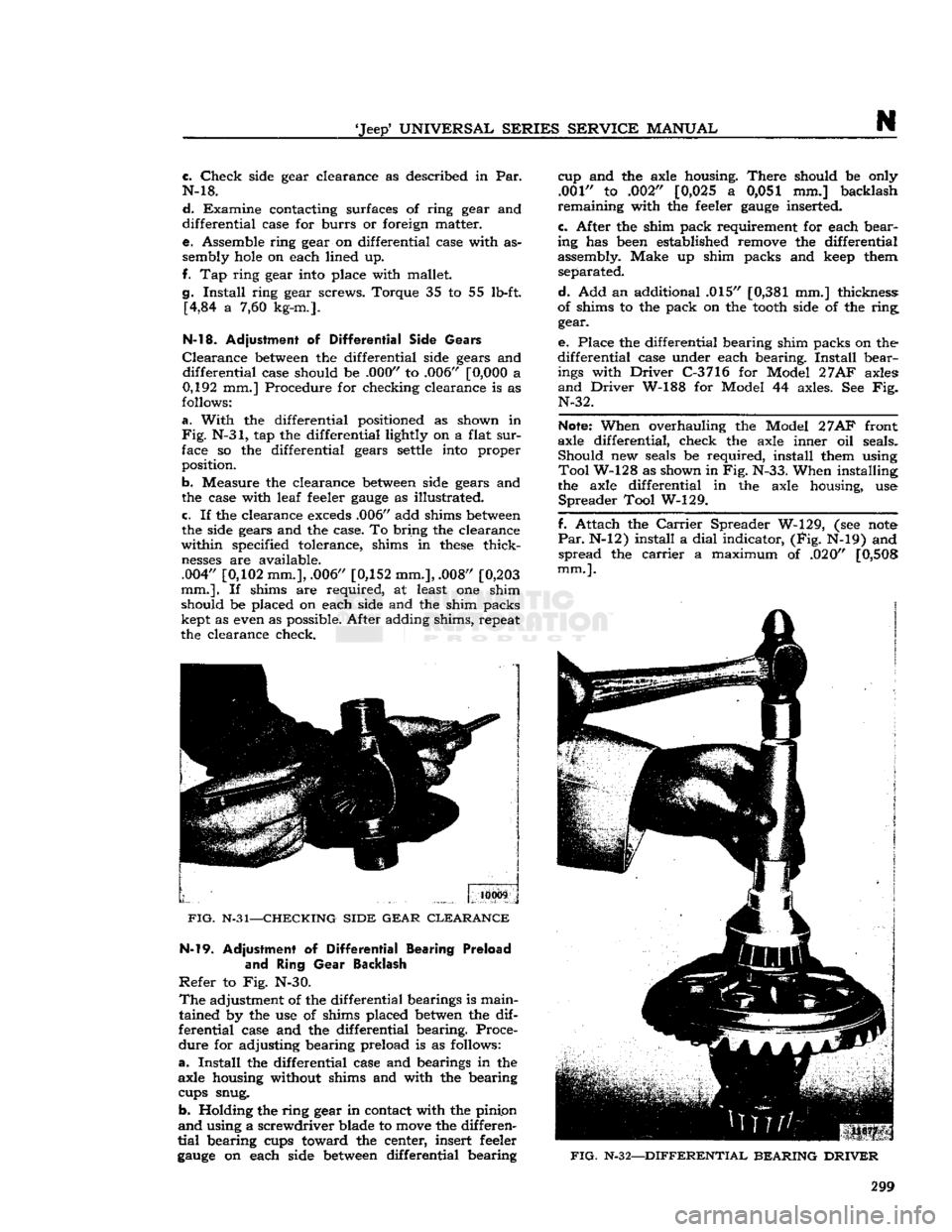

N-18.

Adjustment

of

Differential

Side

Gears

Clearance

between

the differential side gears and differential case should be .000" to .006"

[0,000

a

0,192 mm.] Procedure for checking clearance is as

follows:

a.

With

the differential positioned as shown in

Fig.

N-31, tap the differential lightly on a flat

sur

face so the differential gears

settle

into

proper

position.

b. Measure the clearance

between

side gears and

the case with leaf feeler

gauge

as illustrated. c. If the clearance

exceds

.006" add shims

between

the side gears and the case. To bring the clearance

within specified tolerance, shims in

these

thick

nesses

are available.

.004"

[0,102

mm.], .006"

[0,152

mm.], .008"

[0,203

mm.].

If shims are required, at least one shim

should be placed on each side and the shim packs kept as even as possible. After adding shims, repeat

the clearance check.

10009

FIG.

N-31—CHECKING SIDE GEAR CLEARANCE N-l9.

Adjustment of

Differential

Bearing Preload

and

Ring

Gear

Backlash

Refer

to Fig. N-30.

The

adjustment of the differential bearings is main

tained by the use of shims placed

betwen

the dif

ferential case and the differential bearing. Proce

dure for adjusting bearing preload is as follows:

a.

Install

the differential case and bearings in the

axle housing without shims and with the bearing

cups snug.

b. Holding the ring gear in contact with the pinipn

and

using a screwdriver blade to

move

the differen

tial

bearing cups toward the center, insert feeler

gauge

on each side

between

differential bearing cup and the axle housing.

There

should be only

.001" to .002"

[0,025

a 0,051 mm.] backlash

remaining with the feeler

gauge

inserted.

c.

After the shim pack requirement for each bear

ing has

been

established remove the differential

assembly. Make up shim packs and

keep

them separated.

d.

Add an additional .015"

[0,381

mm.] thickness:

of shims to the pack on the

tooth

side of the ring gear.

e.

Place the differential bearing shim packs on the

differential case under each bearing.

Install

bear

ings

with

Driver

C-3716 for Model

27AF

axles

and

Driver

W-188 for Model 44 axles. See Fig. N-32.

Note:

When overhauling the Model

27AF

front

axle differential, check the axle inner oil seals. Should new seals be required, install them using

Tool

W-128 as shown in Fig. N-33. When installing

the axle differential in the axle housing, use

Spreader

Tool W-129.

f. Attach the

Carrier

Spreader W-129, (see

note

Par.

N-12) install a

dial

indicator, (Fig. N-19) and spread the

carrier

a maximum of .020"

[0,508

mm.].

FIG.

N-32—DIFFERENTIAL BEARING DRIVER

299

Page 302 of 376

N

REAR

AXLE a.

Place the transmission in neutral.

b.

Raise one wheel off the floor and place a block

in

front and at the

rear

of the

opposite

wheel.

c.

Apply a torque wrench to the axle shaft nut of

the elevated wheel.

d.

Turn

wheel with torque wrench. Disregard

breakaway

torque and observe torque required to

continuously

turn

wheel smoothly. Torque should

read

40 lb-ft [5,53 kg-m.] or more.

N-23. Powr-Lok

Differential Disassembly

/

and Reassembly

Refer

to

Figs.

N-38 and N-39.

The

procedure for overhauling disc type

Powr-Lok

differentials is as follows:

a.

Remove axle shafts following procedure de

scribed

in Par. N-2.

b.

Remove housing cover and gasket.

c.

Remove the

Powr-Lok

differential from the axle.

Do not remove the ring gear or bearing

cone

and

rollers

unless replacement is to be made.

Mark

the hearing cups so they may later be reassembled

with

the same bearing cones.

Mark

the differential

case halves for correct alignment at reassembly.

Each

pinion mate cross shaft should also be marked

so that each pin cam surface

will

match with the

same

V-ramp

in the case when reassembled.

d.

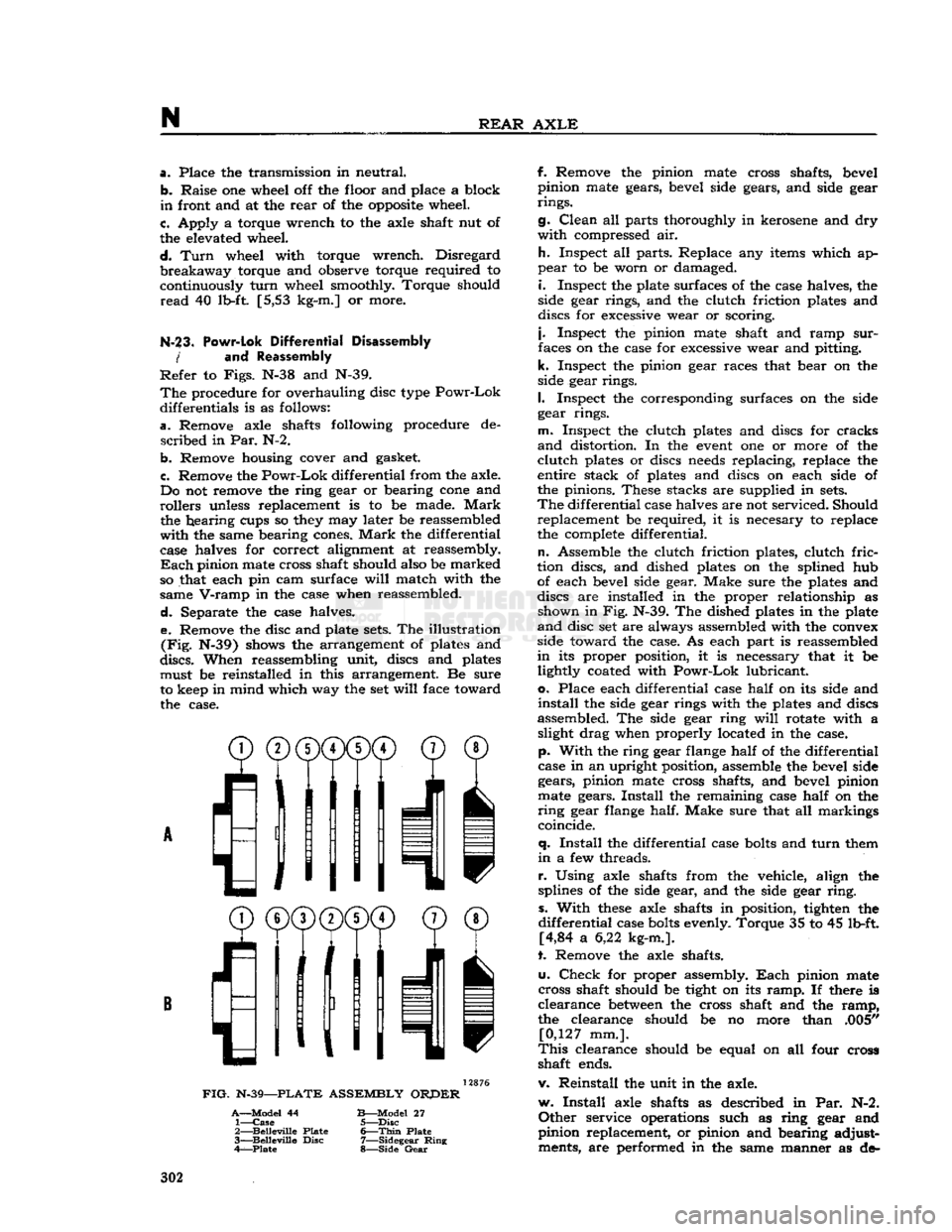

Separate the case halves. e. Remove the disc and plate

sets.

The illustration

(Fig.

N-39) shows the arrangement of plates and

discs.

When reassembling unit, discs and plates must be reinstalled in this arrangement. Be sure

to keep in mind which way the set

will

face toward the case.

^®(j)(j)CD©

® /'Ml

I

11

11 v

FIG.

N-39—PLATE

ASSEMBLY

ORPER

A—Model

44

B—Model

27 1—

Case

5—Disc

2—

Belleville

Plate

6—Thin

Plate

3—

Belleville

Disc

7—Sidegear

Ring

4—Plate

8—Side

Gear

f. Remove the pinion mate cross shafts, bevel

pinion mate gears, bevel side gears, and side gear

rings.

g.

Clean

all parts thoroughly in kerosene and dry

with

compressed air.

h.

Inspect all parts. Replace any items which ap

pear

to be worn or damaged.

i.

Inspect the plate surfaces of the case halves, the

side gear rings, and the clutch friction plates and

discs for excessive wear or scoring.

j.

Inspect the pinion mate shaft and ramp

sur

faces on the case for excessive wear and pitting,

k.

Inspect the pinion gear races that bear on the

side gear rings.

I.

Inspect the corresponding surfaces on the side

gear rings.

m.

Inspect the clutch plates and discs for cracks

and

distortion. In the

event

one or more of the

clutch

plates or discs

needs

replacing, replace the

entire stack of plates and discs on each side of

the pinions. These stacks are supplied in

sets.

The

differential case halves are not serviced. Should replacement be required, it is necesary to replace

the complete differential.

n.

Assemble the clutch friction plates, clutch

fric

tion discs, and dished plates on the splined hub of each bevel side gear. Make sure the plates and

discs are installed in the proper relationship as shown in Fig. N-39. The dished plates in the plate

and

disc set are always assembled with the convex

side toward the case. As each part is reassembled

in

its proper position, it is necessary that it be lightly coated with

Powr-Lok

lubricant,

o.

Place each differential case

half

on its side and

install

the side gear rings with the plates and discs

assembled. The side gear ring

will

rotate with a slight drag when properly located in the case,

p.

With

the ring gear flange

half

of the differential

case in an upright position, assemble the bevel side gears, pinion mate cross shafts, and bevel pinion

mate gears.

Install

the remaining case

half

on the

ring

gear flange half. Make sure that all markings

coincide.

q.

Install

the differential case

bolts

and

turn

them

in

a few threads.

r.

Using axle shafts from the vehicle, align the

splines of the side gear, and the side gear

ring,

s.

With

these

axle shafts in position, tighten the

differential

case

bolts

evenly. Torque 35 to 45 lb-ft. [4,84 a 6,22 kg-m.].

t. Remove the axle shafts.

u.

Check

for proper assembly.

Each

pinion mate

cross shaft should be tight on its

ramp.

If there is

clearance

between

the cross shaft and the

ramp,

the clearance should be no more than .005" [0,127 mm.].

This

clearance should be equal on all four cross

shaft ends.

v. Reinstall the unit in the axle.

w.

Install

axle shafts as described in Par. N-2.

Other

service operations such as ring gear and

pinion replacement, or pinion and bearing adjust ments, are performed in the same manner as de- 302

Page 303 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

N

scribed

in

Pars.

N-ll through N-l9 for standard

axles, with the exception of the following torque

recommendations. Torque the differential case

bearing

cap screws 70 to 90 lb-ft. [9,7 a 12,4 kg-m.]

and

the cover screws 15 to 25 lb-ft. [2,1 a 3,4

kg-m.].

The ring gear screws on axles with Powr-

Lok

differentials should be torqued as follows:

Model

30 and 44 axles 35 to 55 lb-ft. [4,84 a 7,60 kg-m.].

N-24. TRAC-LOK DIFFERENTIAL

As

optional equipment

Trac-Lok

Model 44 differen

tial

is available on all Jeep Universal vehicles equipped with semi-float flanged axle shafts.

A

conventional differential transmits all of the

ring

gear torque through the differential gears to the axle shafts. Torque is at all

times

equal on the axle shafts, and if one wheel slips, the other wheel

can

only put out as much torque as the slipping

wheel.

The

Trac-Lok

differential is similar,

except

that

part

of the torque from the ring gear is trans mitted through clutch packs

between

the side gears

and

differential case. The multiple disc clutches

with

radial

grooves

on the plates and concentric

grooves

on the discs are

engaged

by a preload

from

Belleville springs, plus separating forces from

the side gears as torque is applied through the

ring

gear.

The

Trac-Lok

construction permits differential action when required for turning corners and transmits equal torque to both

wheels

when driving

straight

ahead. However, when one wheel tries to spin due to leaving the ground, a patch of ice,

etc., the clutch packs automatically provide more

torque to the wheel which is not trying to spin.

It

can be

seen

then that the

Trac-Lok

differential

resists wheel spin on bumpy roads and provides

more pulling power when one wheel tries to slip.

In

many cases of differences in traction, pulling

power

will

be automatically provided until both

wheels

start to slip.

In

diagnosis of vehicle operators' complaints, it

is important to recognize two things:

a.

If, with unequal traction, both

wheels

slip, the

Trac-Lok

has

done

all it can possibly do.

b.

In extreme cases of differences in traction, the

wheel with least traction may spin after the

Trac-

Lok

has transferred as much torque as possible

to the non-slipping wheel.

N-25.

Lubrication

The

Trac-Lok

differential requires a special

lubri

cant

and ordinary multipurpose gear lubricants

MUST

NOT be used. Use only 'Jeep* Differential

Oil,

Part

No. 94557.

Trac-Lok

differential may be cleaned only by disassembling the unit and wiping with clean rags. Do not flush the

Trac-Lok

unit.

Note:

The

Trac-Lok

differential is serviced at the

same time intervals as the standard differential.

N-26.

Trouble

Symptoms

If

noises

or roughness, such as chatter, are present

in

turning corners, the probable cause is incorrect

or

contaminated lubricant.

Before any differential is removed and disassem

bled for chatter complaints, the correctness of

lubri

cant

can and should be determined.

A

complete

lubricant

drain,

and

refill

with specified

Limited

Slip Differential lubricant

will

usually

correct

chatter.

The

following procedure is recommended to ensure

complete

removal of old lubricant.

a.

Warm

the lubricant by vehicle road operation,

or

5 minutes of operation in gear at 30 mph with

both

wheels

off the ground on a hoist.

Caution:

Never place the transmission in gear with

the

engine

running when only one wheel of a

Limited

Slip Differential equipped vehicle is raised.

The

vehicle might drive itself off the

jack

and produce damage or

injury.

b.

Drain

lubricant while

warm.

Remove

drain

plug

or

cover to

drain

completely. If cover is removed,

it

may be necessary to replace gasket at this time.

c.

Refill

axle with specified

Limited

Slip Differen

tial

lubricant.

d.

Operate the vehicle for approximately ten miles

[16,09

km.], making at least ten figure 8 turns

to flush the old lubricant out of the clutch packs.

e.

Repeat

steps

b, c, and d, making sure to replace

the cover gasket if required in

step

c.

f. It is possible that slight chatter, requiring ad

ditional

vehicle operation, may remain after

step

e. If chatter persists after 100 miles

[160,9

km.]

of vehicle operation, or remains severe after

step

e above, disassembly and repair

will

be necessary.

N-27.

Unit

Inoperative

Proper

performance and capabilities of

Limited

Slip

Differentials are

often

misunderstood. No

precise

methods

of measuring

Limited

Slip Dif

ferential

performance are generally available in the field. A functioning unit can be determined by

relatively

simple vehicle operational

tests,

as

follows:

a.

Place one wheel on

good

dry pavement, and the

other on ice, mud, grease, etc.

b.

Gradually

increase

engine

rpm to obtain maxi

mum

traction

prior

to "break-a-way." The ability

to

move

the vehicle

effectively

will

demonstrate

proper

performance.

c.

If extremely slick surfaces, such as ice or grease,

are

used

some

question may exist as to proper per

formance at

step

b. In

these

extreme cases a prop

erly

performing

Limited

Slip Differential

will

pro

vide greater "pulling" power by lightly applying

the parking brake.

N-23.

Trac-Lok

Differential Disassembly

and

Reassembly

It

is recommended that the

complete

axle assembly

be removed from the vehicle, when it

becomes

necessary to remove the

Trac-Lok

from the hous

ing.

Refer to Par. N-3 and N-12 for removal of axle shafts and differential case from axle housing. 303