lights JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 174 of 376

H

ELECTRICAL

SYSTEM

the condenser. Replace the condenser. If there is

no jump to full voltage, overhaul or replace the

distributor.

k.

With the points closed, connect the voltmeter

from

a clean, paint-free

post

on the distributor

body to the negative

post

of the battery. The volt

age drop should be practically zero, a hardly

readable deflection on the voltmeter. If the volt meter registers a

voltage

drop, perform the checks

in

steps

1

and m following.

I.

Check

for

voltage

drop in the battery ground

cable.

Clean

the battery

post,

cable terminals, and contact surface on the bellhousing, or on body if

a

noticeable deflection of the voltmeter occurs,

m.

Check

for any

voltage

drop

between

the dis

tributor

body and a clean, paint-free

spot

on the

cylinder

block. If there is any

voltage

drop, remove

the distributor and clean the mounting surfaces of

distributor

body and cylinder block.

H-5.

SECONDARY

CIRCUIT

If

satisfactory ignition is not obtainable with cor

rect

point gap and tension; satisfactory condenser;

sufficient primary voltage; and correctly cleaned, gapped, and installed spark plugs; the secondary

circiut

should be investigated.

a.

Test the coil.

Bring

the coil up to operating

temperature using the coil heat feature of a coil tester, if available. Refer to the coil tester manu

facturer's

instructions for specific hook-ups for

performing the checks given in

steps

b, c, and d following.

b. Connect the positive lead of the tester to the

battery terminal of the coil primary winding.

Con

nect the tester ground lead to the coil tower. Mea

sure

the resistance of the secondary winding. If the

resistance is more than

20,000

ohms, a fault in the

secondary winding is indicated.

c.

Check

for a grounded secondary by touching the tester ground lead to the coil cover. If resistance

is not over

100,000

ohms, the secondary is grounded

to the cover.

d.

If the secondary winding is satisfactory, mea

sure

the primary current draw in accordance with

the instructions of the

test

equipment manu

facturer.

e.

Check

the secondary circuit for leakage. With the coil primary in the circuit with the breaker unit of the tester, connect a long, high-tension

test

lead

to the coil tower.

Check

the secondary circuit for

leakage by performing the checks given in

steps

f. g, h, and i following.

Note:

In the following

tests,

a slight sparking and

meter deflection

will

usually be

seen

just as contact

is made.

This

is caused by capacitance and

does

not

indicate defective insulation.

f.

Check

distributor cap. Remove the coil lead from the cap and touch the

test

lead to the center contact

inside the cap. If the meter reading drops when the contact is touched or if sparking is seen, a leakage

path is present

between

the center contact and one

of the plug towers.

This

leakage path

will

be in the

form

of a

crack

or carbon track in the cap. Discon nect the spark plug wires from the cap one at a

time and

test

each plug contact with the high-

voltage

lead and with all other plug wires con

nected. Any sparking or meter drop indicates that

a

leakage path exists

between

that particular con

tact and an adjacent one. Testing the adjacent contacts

will

determine which pair is at fault,

g-

Check

distributor rotor. Touch the

test

lead to

the spring contact in the center of the distributor

rotor.

Any leakage in the rotor insulation

between

the contact and the shaft

will

cause a drop in the meter reading and usually sparking

will

be seen.

h.

Check

spark plug wires. Disconnect the spark

plug wires from the plugs and

test

the plug terminal of each. The meter reading should not drop below

the open secondary value (value before making contact). If it

does

or if a large spark occurs when

the

test

lead and the plug wire are separated, there

is a break in the insulation on that wire.

i.

Check

the coil tower insulation. Remove the

high-tension

test

lead from the coil tower and touch

the ground lead of the coil tester to several points

around

the base of the tower. Any sparking or deflection of the meter indicates a leakage path in

the tower insulation.

H-6.

Alternator Charging System

All

Jeep

Universal

Series vehicles have, as standard

equipment a 35-amp., 12-volt, negative ground

alternator and a transistorized

voltage

regulator.

For

repairing the alternator, many of its major components are furnished as complete assemblies

including:

complete brush assembly which requires no soldering or unsoldering of leads; two complete

rectifying

diode

assemblies which eliminate the need for removing and replacing individual diodes;

a

complete isolation

diode

assembly; and a rotor assembly complete with shaft,

pole

pieces, field coil,

and

slip rings.

The

transistorized

voltage

regulator is an electronic

switching device. It

senses

the

voltage

appearing at the auxiliary terminal of the alternator and

supplies the necessary field current for maintaining the system

voltage

at the output

terminal.

The out

put current is determined by the battery electrical

load;

such as headlights, heater, etc.

The

transistorized

voltage

regulator is a sealed unit,

has no adjustments, and must be replaced as a

complete unit.

H-7.

Starting System

The

operation of the starter motor is controlled by

the ignition switch. The starter is made up of a

frame,

field coil, armature, and brushes.

The

starter solenoid electrically

closes

the circuit

between

the battery and the starter motor. When the ignition key is turned to its extreme right, the

solenoid is energized and

closes

the battery-to- starter-motor circuit.

Note:

All Jeep Universal Series vehicles have the

starter

solenoid switch secured to the starter motor

assembly. The Hurricane F4 and Dauntless V-6

engine

Prestolite starter drive is of the inertia type

(rexr

continued on

page

176) 174

Page 175 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

H

11514

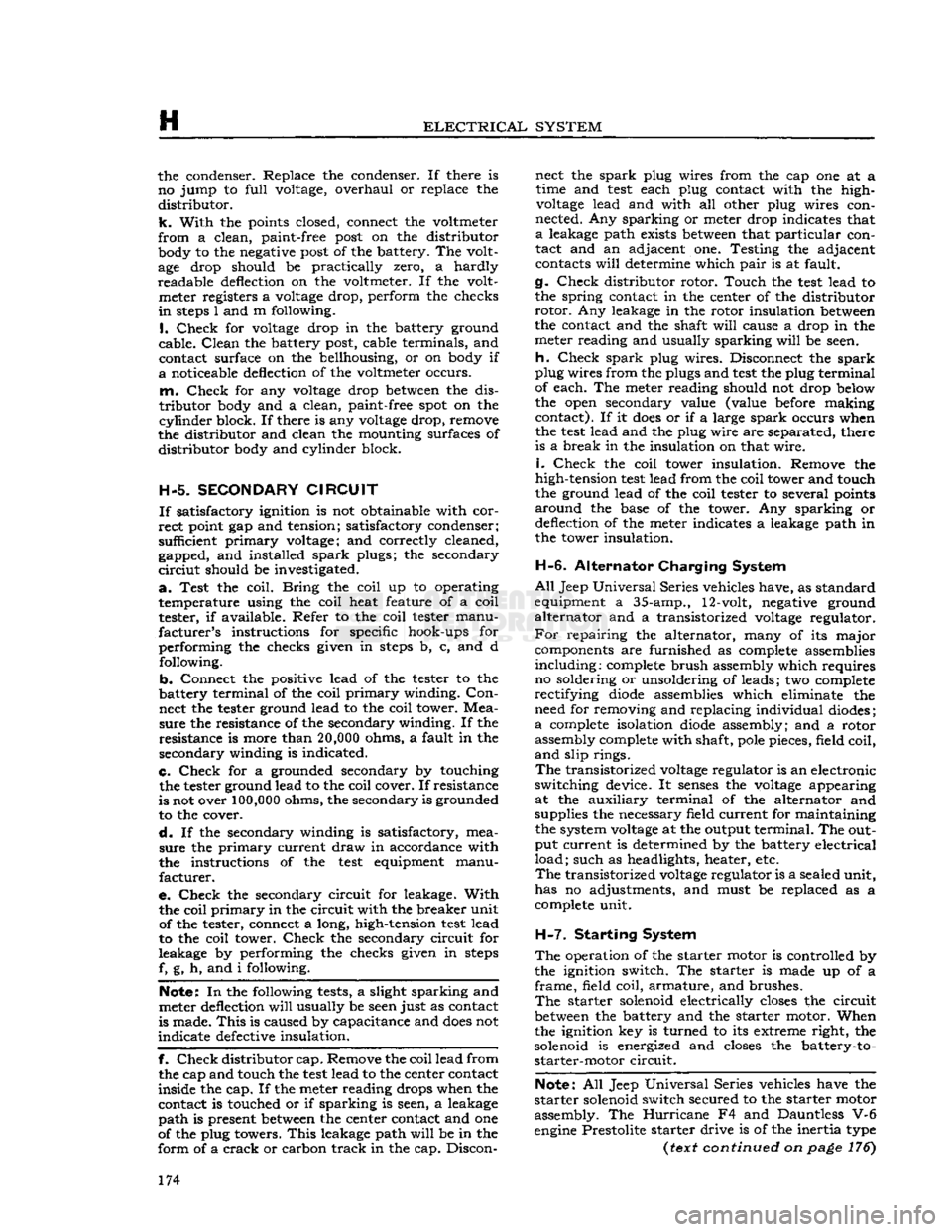

FIG.

H-2—WIRING

DIAGRAM—MODEL

CJ-3B

(Serial No.

35522

and

after)

1—

Left

Headlamp

2—

Left

Parking and Signal Lamp

3— Right Parking and Signal Lamp

4— Right Headlamp 5— Battery Ground Strap

6— Generator 7— Ignition

Coil

8— Junction Block

9—

Horn

10— Distributor

11— Battery

12—

Voltage

Regulator 13— Starting Motor

14—

Oil

Pressure Signal Switch 15— Temperature Sending Unit

16—

Solenoid

Switch 17— Foot Dimmer Switch

18—

Stop

Light Switch 19— Directional Signal Flasher

20— Fuse

21—

Light

Switch 22— Directional Signal Switch

23—

Horn

Button 24— Ignition and Starter Switch 25—Instrument Cluster

A—Upper Beam Indicator

B—Turn

Signal Indicator C—Instrument Lights

D—Oil

Pressure Indicator

E—Charging

Indicator F—Temperature Gauge

G—Fuel

Gauge

H—Instrument

Voltage

Regulator

25—Fuel Gauge Tank Unit

27—

Left

Tail

and

Stop

Lamp

28— Right

Tail

and

Stop

Lamp 175

Page 176 of 376

H

ELECTRICAL

SYSTEM

11474

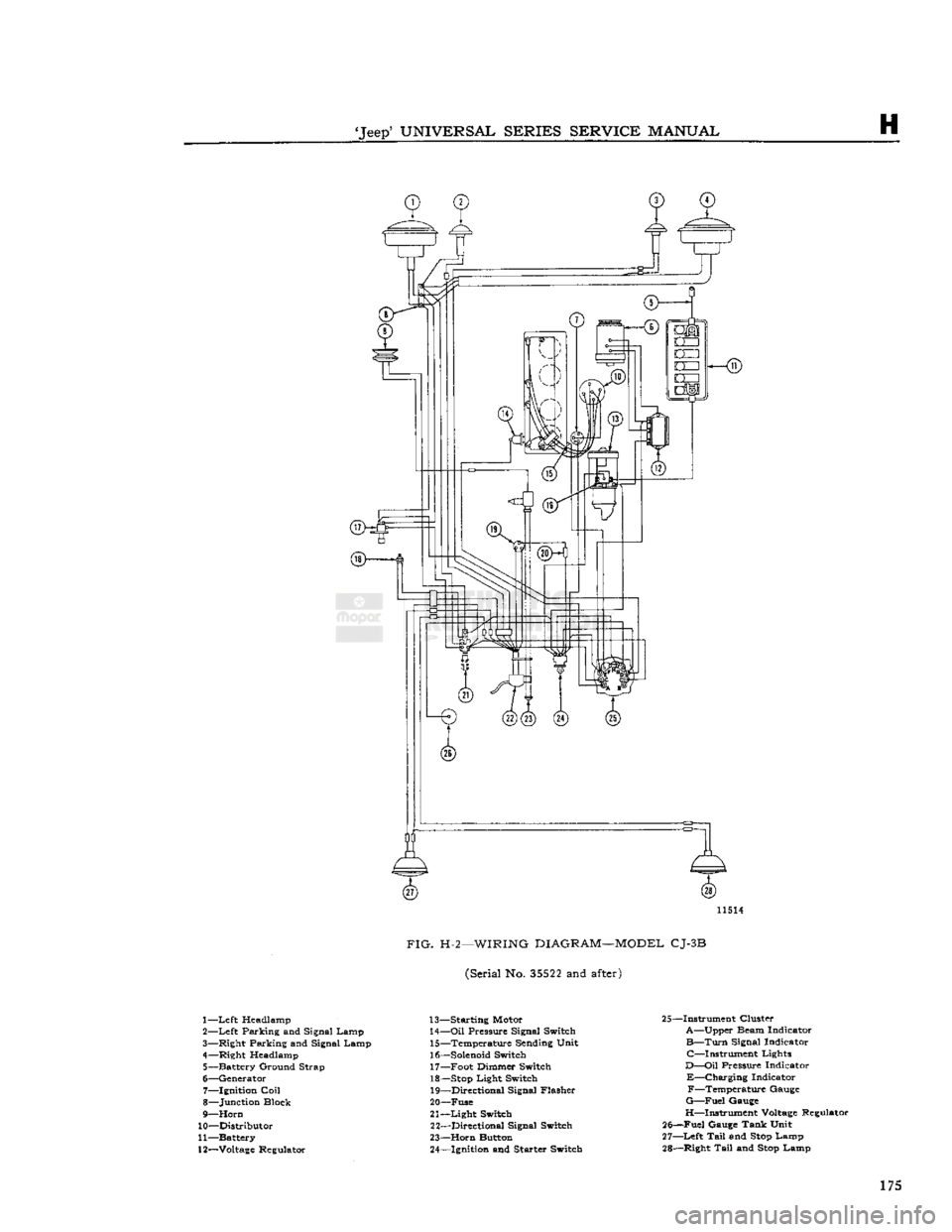

FIG.

H-3—WIRING

DIAGRAM—MODELS

CJ-5, CJ-6, DJ-5 AND DJ-6—F4

ENGINE

(Model CJ-5 after Serial No.

49248,

Model CJ-6 after Serial No.

12577)

1—

Left

Headlamp

B—Turn

Signal Indicator 17—Directional Signal Switch

2—

Left

Parking and Directional Lamp C—Instrument Lights 18—Light Switch

3— Right Parking and Directional Lamp

D—Oil

Pressure Indicator

19—Stop

Light Switch

4— Right Headlamp E—Charging Indicator 20—Foot Dimmer Switch

5— Battery Ground Cable F—Temperature Gauge 21—Directional Signal Flasher

6— Generator

G—Fuel

Gauge 22—Fuse 7— Distributor H—Instrument Voltage Regulator

23—Solenoid

Switch

8— Ignition

Coil

12—Right

Tail

and

Stop

Lamp 24—Temperature Sending Unit

9— Starting Motor 13—Left

Tail

and

Stop

Lamp 25—Oil Pressure Signal Switch

10— Voltage Regulator 14—Fuel Gauge

Tank

Unit 26—Horn

11— Instrument Cluster 15—Ignition and Starter Switch 27—Junction Block

A—Upper

Beam Indicator 16—Horn Button

whereas the Dauntless V-6

engine

Delco starter

ignition

switch. If trouble

develops

in this switch, drive is of the clutch

type.

it must be replaced.

The

ignition

switch

serves

both

to

energize

the

The

starter circuit is

opened

when the

ignition

key

ignition

system

and

also

to

engage

the starter

sole-

is allowed to return to the "Ignition On"

position.

miod switch. With the key in the vertical

position,

No repairs or adjustments can be

made

to the the electrical

system

is off. This is the

only

position

176

Page 177 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

H

12968

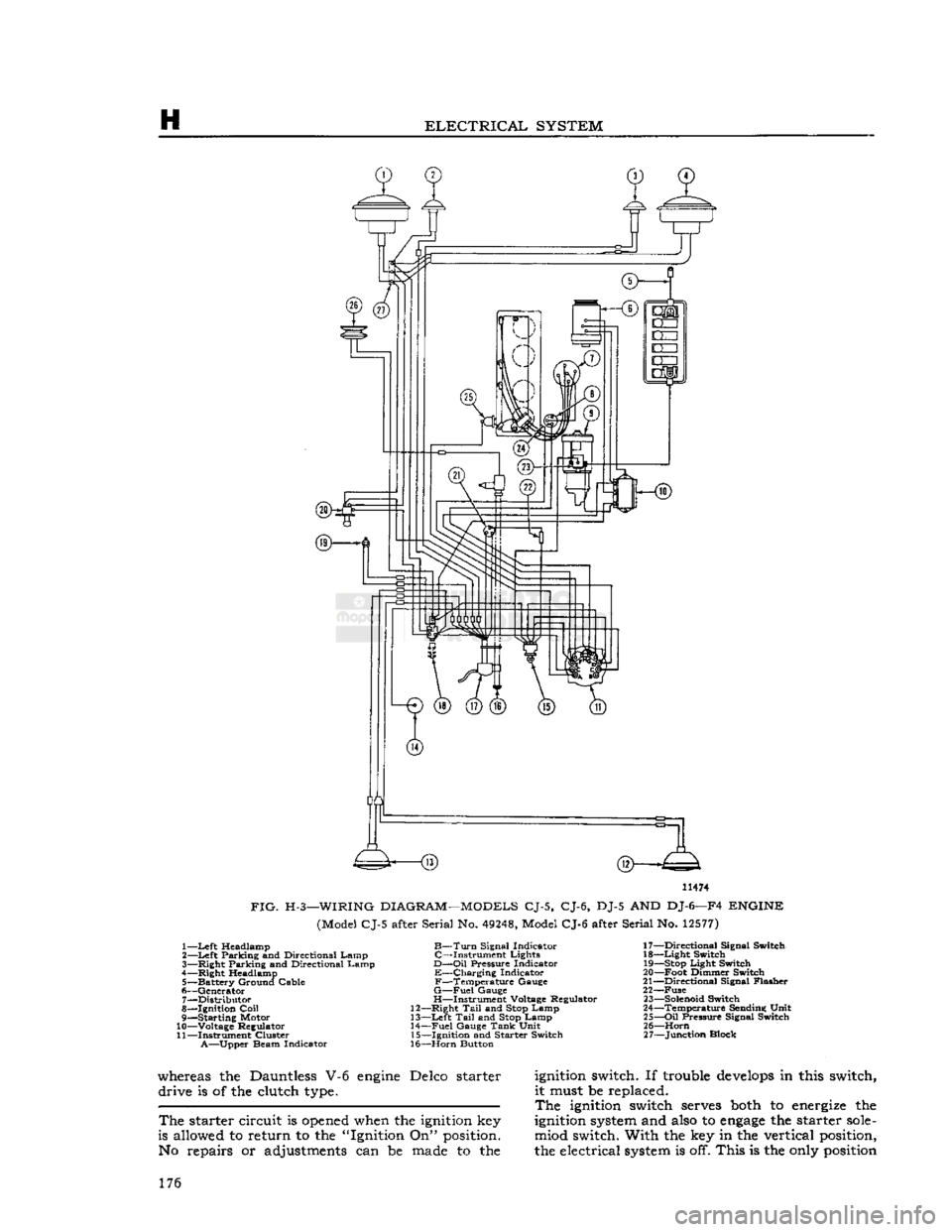

FIG.

H-4—WIRING

DIAGRAM—MODELS

CJ-5, CJ-6, DJ-5, DJ-6

LATE

F4

ENGINE

1—

Left

Headlamp

2—

Left

Parking and Signal Lamp

3— Right Parking and Signal Lamp 4— Right Headlamp

5— Generator

6— Ignition Distributor

7—

Oil

Pressure Sending Unit

8— Junction Block

9—

Horn

10— Foot Dimmer Switch 11—

Stop

Light Switch — Front

12— Temperature Sending Unit

13— Ignition

Coil

14— Starting Motor 15— Battery Ground Cable

16— Battery

17— Voltage Regulator 18—

Fuse

19— Instrument Cluster

A—Hi-Beam

Indicator

B—Auxiliary

C—Instrument

Lights

D—Oil

Pressure Indicator

E—Charging

Indicator

F—Temperature

Indicator

G—Fuel

Gauge

H—Instrument Voltage Regulator

20— Ignition and Starter Switch 21—

Flashei

(Directional Signal)

22—

Horn

Button 23— Directional Signal Switch

24— 4-Way Flasher Switch

25—

Flasher

(4-Way)

26—

Fuse

27—

Main

Light Switch 28—

Stop

Light Switch — Rear

29—

Fuel

Gauge

Tank

Unit

30—

Back-Up

Light Switch

31— Right

Tail

and

Stop

Lamp

32— Right Back-Up Lamp

33—

Left

Back-Up Lamp

34—

Left

Tail

and

Stop

Lamp

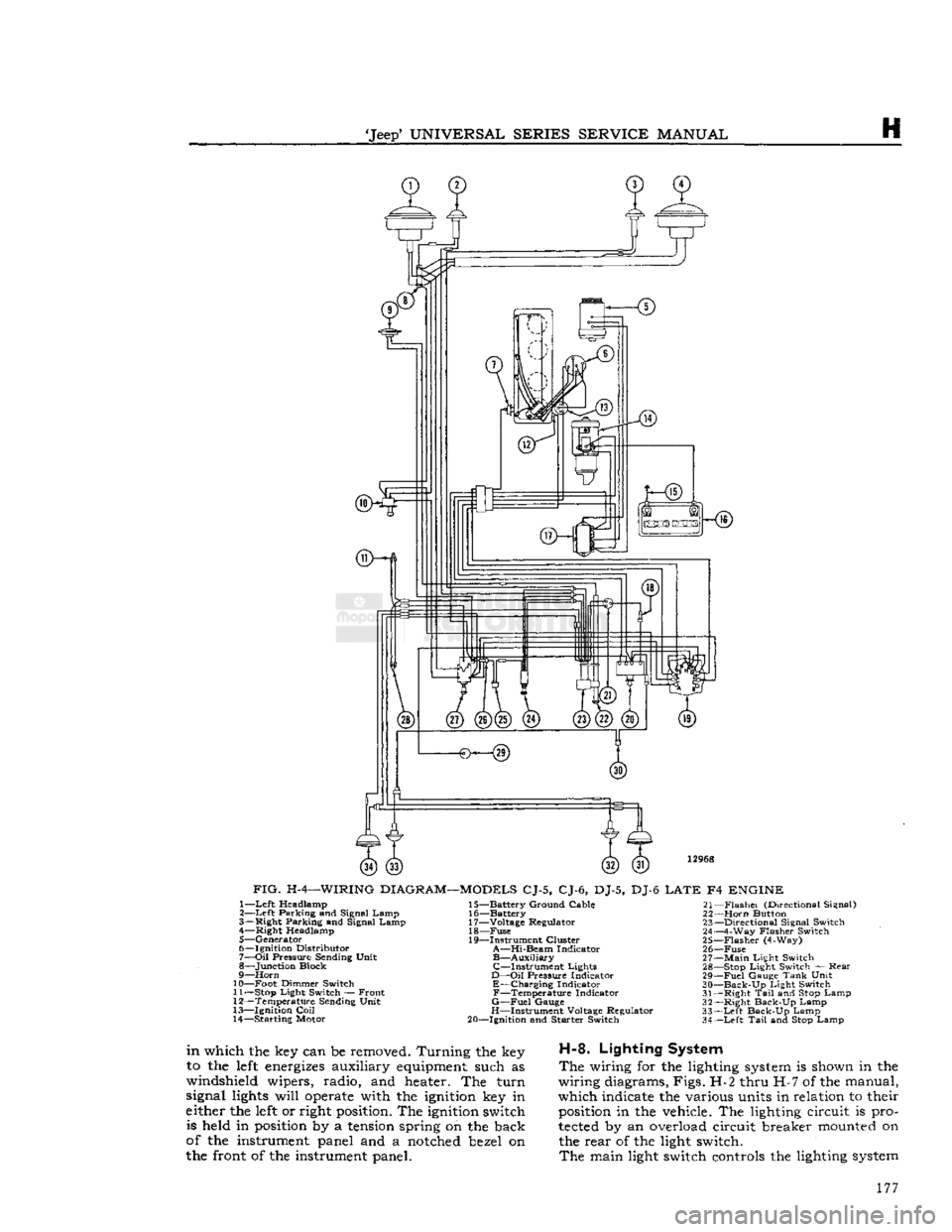

in

which the key can be removed. Turning the key

to the

left

energizes

auxiliary

equipment

such as

windshield wipers, radio, and heater. The turn

signal

lights

will

operate

with the

ignition

key in

either the

left

or right

position.

The

ignition

switch is held in

position

by a

tension

spring on the back

of the instrument panel and a

notched

bezel on

the front of the instrument panel.

H-8.

Lighting System

The

wiring for the lighting

system

is shown in the

wiring diagrams, Figs. H-2 thru H-7 of the manual,

which indicate the various units in relation to their

position

in the vehicle. The lighting circuit is pro

tected

by an overload circuit breaker

mounted

on the rear of the light switch.

The

main light switch controls the lighting

system

177

Page 178 of 376

H

ELECTRICAL

SYSTEM

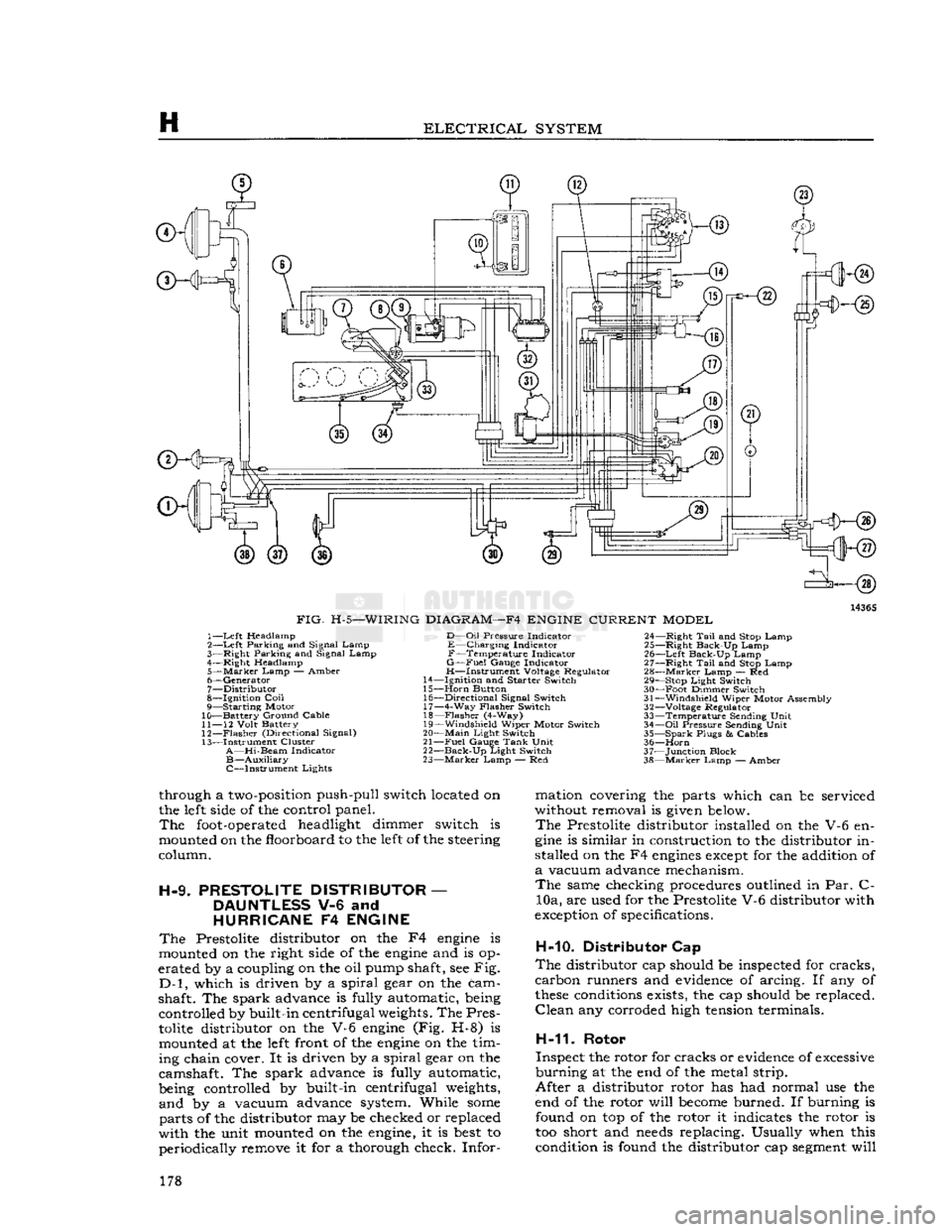

14365

FIG.

H-5—WIRING

DIAGRAM—F4

ENGINE

CURRENT

MODEL

1—

Left

Headlamp

2—

Left

Parking and Signal Lamp

3—

Right

Parking and Signal Lamp

4—

Right

Headlamp

5—

Marker

Lamp

— Amber

6—

Generator

7—

Distributor

8—

Ignition

Coil

9— Starting Motor

10— Battery Ground Cable

11—

12

Volt

Battery

12—

Flasher

(Directional Signal)

13— Instrument Cluster

A—Hi-Beam

Indicator

B—Auxiliary

C—Instrument Lights

D—Oil

Pressure

Indicator

E—Charging Indicator

F—Temperature Indicator

G—Fuel

Gauge

Indicator

H—Instrument Voltage Regulator

14—

Ignition

and

Starter

Switch

15—

Horn

Button 16—

Directional

Signal Switch 17— 4-Way

Flasher

Switch

18—

Flasher

(4-Way)

19—

Windshield

Wiper Motor Switch

20—

Main

Light

Switch

21—

Fuel

Gauge

Tank

Unit

22—

Back-Up

Light

Switch

23—

Marker

Lamp — Red 24—

Right

Tail

and Stop Lamp

25—

Right

Back-Up Lamp

26—

Left

Back-Up Lamp

27—

Right

Tail

and Stop Lamp

28—

Marker

Lamp — Red 29— Stop

Light

Switch

30— Foot Dimmer Switch

31—

Windshield

Wiper Motor Assembly

32—

Voltage Regulator

33— Temperature Sending

Unit

34—

Oil

Pressure

Sending

Unit

35— Spark

Plugs

&

Cables

36—

Horn

37— Junction Block

38—

Marker

Lamp — Amber

through a

two-position

push-pull switch located on

the

left

side

of the control panel.

The

foot-operated

headlight dimmer switch is

mounted on the floorboard to the

left

of the steering

column.

H-9.

PRESTOLITE

DISTRIBUTOR

—

DAUNTLESS

V-6 and

HURRICANE

F4

ENGINE

The

Prestolite distributor on the F4

engine

is

mounted on the right

side

of the

engine

and is op

erated by a coupling on the oil pump shaft, see Fig.

D-l,

which is driven by a spiral gear on the cam

shaft. The spark advance is fully automatic, being controlled by built-in centrifugal

weights.

The Pres

tolite

distributor on the V-6

engine

(Fig. H-8) is mounted at the

left

front of the

engine

on the tim

ing chain cover. It is driven by a spiral gear on the

camshaft. The spark advance is fully automatic,

being controlled by built-in centrifugal

weights,

and by a vacuum advance system. While

some

parts of the distributor may be checked or replaced

with the unit mounted on the

engine,

it is

best

to periodically remove it for a thorough check. Infor mation covering the parts which can be serviced

without removal is

given

below.

The

Prestolite distributor installed on the V-6 en

gine

is similar in construction to the distributor in

stalled on the F4

engines

except

for the addition of

a

vacuum advance mechanism.

The

same checking procedures outlined in Par. C- 10a, are used for the Prestolite V-6 distributor with

exception

of specifications.

H-10. Distributor Cap

The

distributor cap should be inspected for cracks,

carbon runners and

evidence

of arcing. If any of

these

conditions

exists, the cap should be replaced.

Clean

any corroded high

tension

terminals.

H-11.

Rotor

Inspect the rotor for cracks or

evidence

of

excessive

burning at the end of the metal strip.

After a distributor rotor has had normal use the

end of the rotor will

become

burned. If burning is found on top of the rotor it indicates the rotor is

too short and

needs

replacing. Usually when this condition is found the distributor cap

segment

will 178

Page 179 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

H

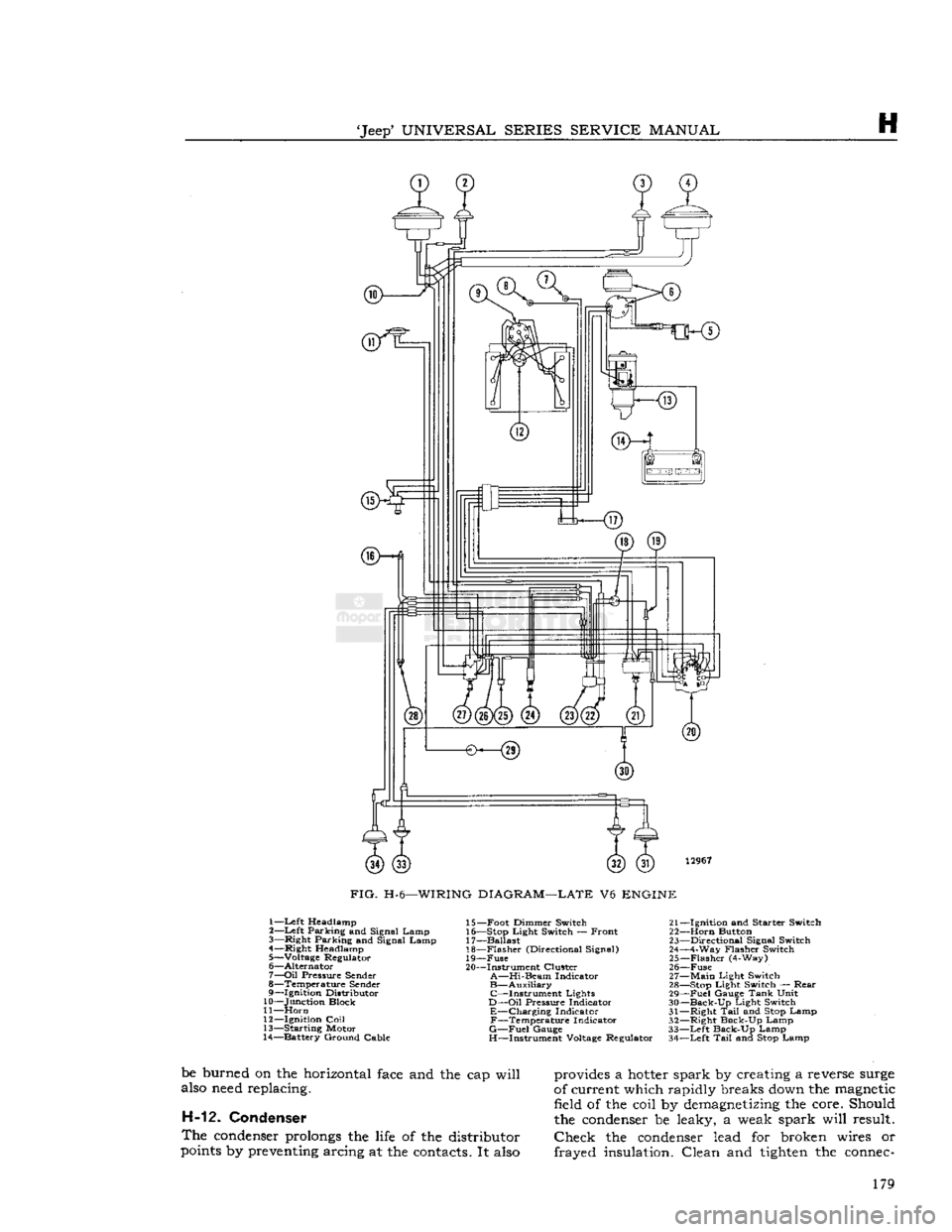

12967

FIG.

H-6—WIRING

DIAGRAM—LATE

V6

ENGINE

1—Left Headlamp

2—

Left

Parking and Signal Lamp

3—

Right

Parking and Signal Lamp

4—

Right

Headlamp

5— Voltage Regulator

6—

Alternator

7—

Oil

Pressure

Sender

8— Temperature

Sender

9—

Ignition

Distributor

10— Junction Block

11—

Horn

12—

Ignition

Coil

13— Starting Motor

14— Battery Ground Cable 15— Foot Dimmer Switch 21-

16— Stop

Light

Switch — Front 22-

17— Ballast 23-

18—

Flasher

(Directional Signal) 24-

19—

Fuse

25-

20— Instrument Cluster 26-

A—Hi-Beam

Indicator 27-

B—Auxiliary

28- C—Instrument Lights 29-

D—Oil

Pressure

Indicator 30-

E—Charging Indicator 31-F—Temperature Indicator 32-

G—Fuel

Gauge

33-

H—Instrument Voltage Regulator 34-

-Ignition

and

Starter

Switch

-Horn

Button

-Directional

Signal Switch

-4-Way

Flasher

Switch

-Flasher

(4-Way)

-Fuse

-Main

Light

Switch

-Stop

Light

Switch —

Rear

-Fuel

Gauge

Tank

Unit

-Back-Up

Light

Switch

-Right

Tail

and Stop Lamp

-Right

Back-Up Lamp

-Left

Back-Up Lamp

-Left

Tail

and Stop Lamp

be burned on the horizontal

face

and the cap will

also

need

replacing. H-12. Condenser

The

condenser

prolongs

the

life

of the distributor

points

by

preventing

arcing at the

contacts.

It

also

provides

a

hotter

spark by creating a reverse

surge

of current which rapidly breaks

down

the

magnetic

field of the coil by

demagnetizing

the core. Should

the

condenser

be leaky, a weak spark will result.

Check

the

condenser

lead for broken wires or

frayed insulation. Clean and

tighten

the

connec-

179

Page 180 of 376

H

ELECTRICAL

SYSTEM

ffKHs)

3—<§)

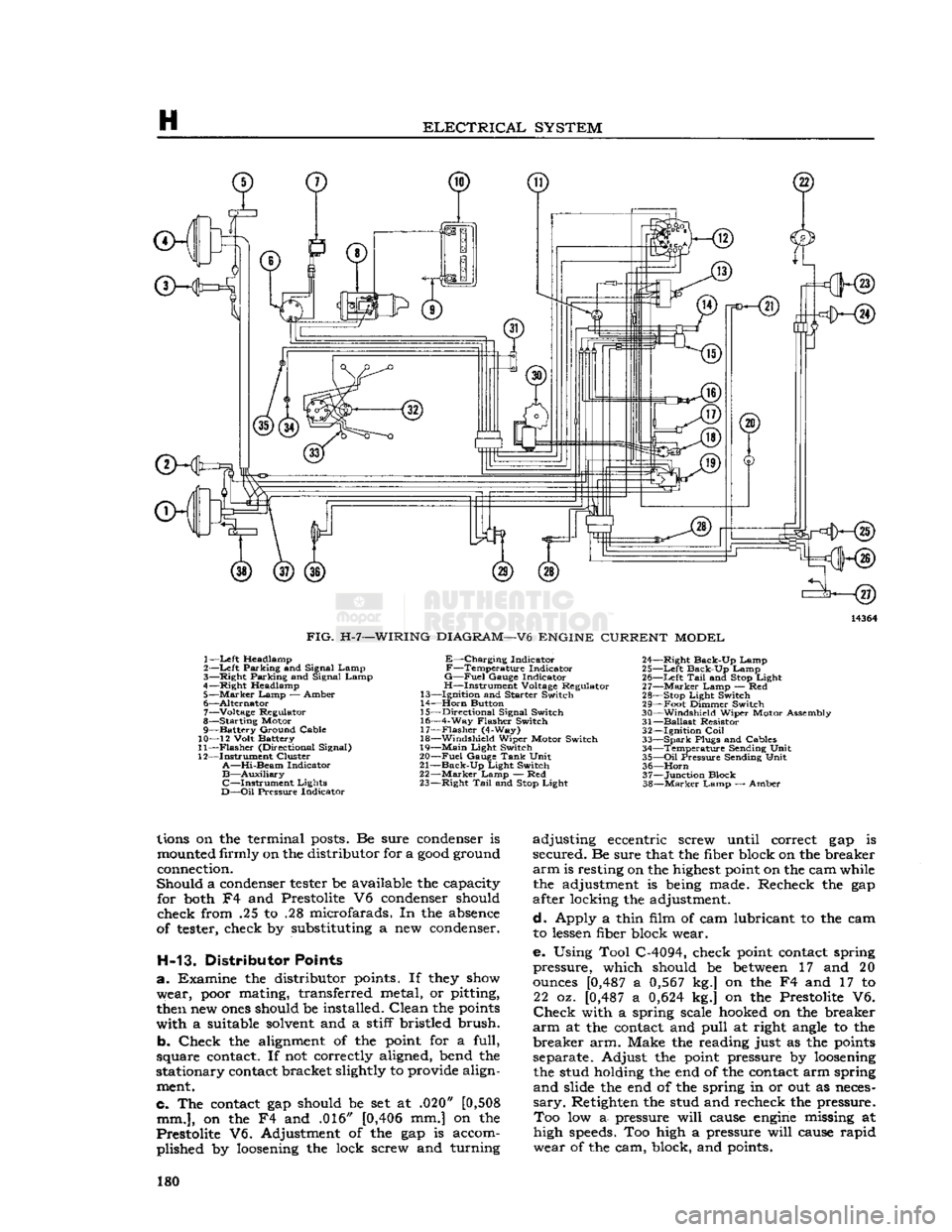

FIG.

H-7—WIRING

DIAGRAM—V6

ENGINE

CURRENT

MODEL

1—

Left

Headlamp

2—Left Parking and Signal Lamp

3— Right Parking and Signal Lamp

4—Right Headlamp 5—

Marker

Lamp — Amber

6— Alternator 7— Voltage Regulator

8— Starting Motor

9— Battery Ground Cable

10— 12 Volt Battery

11—

Flasher

(Directional Signal)

12— Instrument Cluster

A—Hi-Beam

Indicator

B—Auxiliary

C—Instrument

Lights

D—Oil

Pressure Indicator

E—Charging

Indicator

F—Temperature

Indicator

G—Fuel

Gauge Indicator

H—Instrument Voltage Regulator

13— Ignition and Starter Switch

14—

Horn

Button

15— Directional Signal Switch

16— 4-Way Flasher Switch 17—

Flasher

(4-Way)

18— Windshield Wiper Motor Switch

19—

Main

Light Switch

20—

Fuel

Gauge

Tank

Unit

21—

Back-Up

Light Switch

22—

Marker

Lamp — Red

23— Right

Tail

and

Stop

Light 24— Right Back-Up Lamp

25—

Left

Back-Up Lamp 26—

Left

Tail

and

Stop

Light

27—

Marker

Lamp — Red

28—

Stop

Light Switch

29— Foot Dimmer Switch

30— Windshield Wiper Motor Assembly

31—

Ballast

Resistor 32— Ignition

Coil

33—

Spark

Plugs and Cables 34— Temperature Sending Unit

35—

Oil

Pressure Sending Unit 36—

Horn

37— Junction Block

38—

Marker

Lamp — Amber

lions

on the terminal

posts.

Be sure

condenser

is

mounted

firmly on the distributor for a

good

ground

connection.

Should a

condenser

tester

be available the capacity for

both

F4 and Prestolite V6

condenser

should

check from .25 to .28 microfarads. In the

absence

of

tester,

check by substituting a new

condenser.

H-13. Distributor Points

a. Examine the distributor

points.

If

they

show

wear,

poor

mating, transferred metal, or pitting,

then

new

ones

should be installed. Clean the

points

with a suitable

solvent

and a stiff bristled brush.

b. Check the

alignment

of the

point

for a full,

square

contact.

If not correctly aligned, bend the

stationary

contact

bracket slightly to provide align

ment.

c. The

contact

gap should be set at .020"

[0,508

mm.],

on the F4 and .016"

[0,406

mm.] on the

Prestolite V6. Adjustment of the gap is accom plished by

loosening

the lock screw and turning adjusting eccentric screw until correct gap is

secured. Be sure that the fiber block on the breaker

arm

is resting on the

highest

point

on the cam while the adjustment is

being

made. Recheck the gap

after locking the adjustment.

d. Apply a thin film of cam lubricant to the cam to

lessen

fiber block wear.

e. Using Tool C-4094, check

point

contact

spring

pressure, which should be

between

17 and 20

ounces

[0,487

a

0,567

kg.] on the F4 and 17 to 22 oz.

[0,487

a

0,624

kg.] on the Prestolite V6.

Check

with a spring scale

hooked

on the breaker

arm

at the

contact

and pull at right

angle

to the

breaker arm. Make the reading just as the

points

separate. Adjust the

point

pressure by

loosening

the stud holding the end of the

contact

arm spring

and slide the end of the spring in or out as

neces

sary.

Retighten the stud and recheck the pressure. Too low a- pressure will

cause

engine

missing at

high

speeds.

Too high a pressure will

cause

rapid

wear of the cam, block, and

points.

180

Page 188 of 376

H

ELECTRICAL

SYSTEM

colder plug may be desirable. However, under- or

over-heating is usually caused by factors other than the type of

spark

plugs and the cause should be determined before changing plugs. The design of the

engine

calls for plugs equivalent to Champion

J-8

for F4

engines

and

A.C.

44S or

UJ12Y

Champ

ion for the V6 engines, (as installed in production)

though any factor that consistently affects

engine

operating temperature may cause this requirement

to change. Overheating may be caused by in sufficient tightening of the plug in the head, which interferes with the flow of heat away from the firing

tip.

If this is the case, the plug gasket

will

show very

little flattening. Over-tightening, in

turn,

will

pro duce too easy a heat flow path and result in cold

plug operation.

This

will

be evident by excessive

flattening

and

deformation of the gasket.

Prevailing

temperatures, condition of the cooling system, and

air-fuel

mixture can affect the

engine

operating temperature and should be taken into consideration.

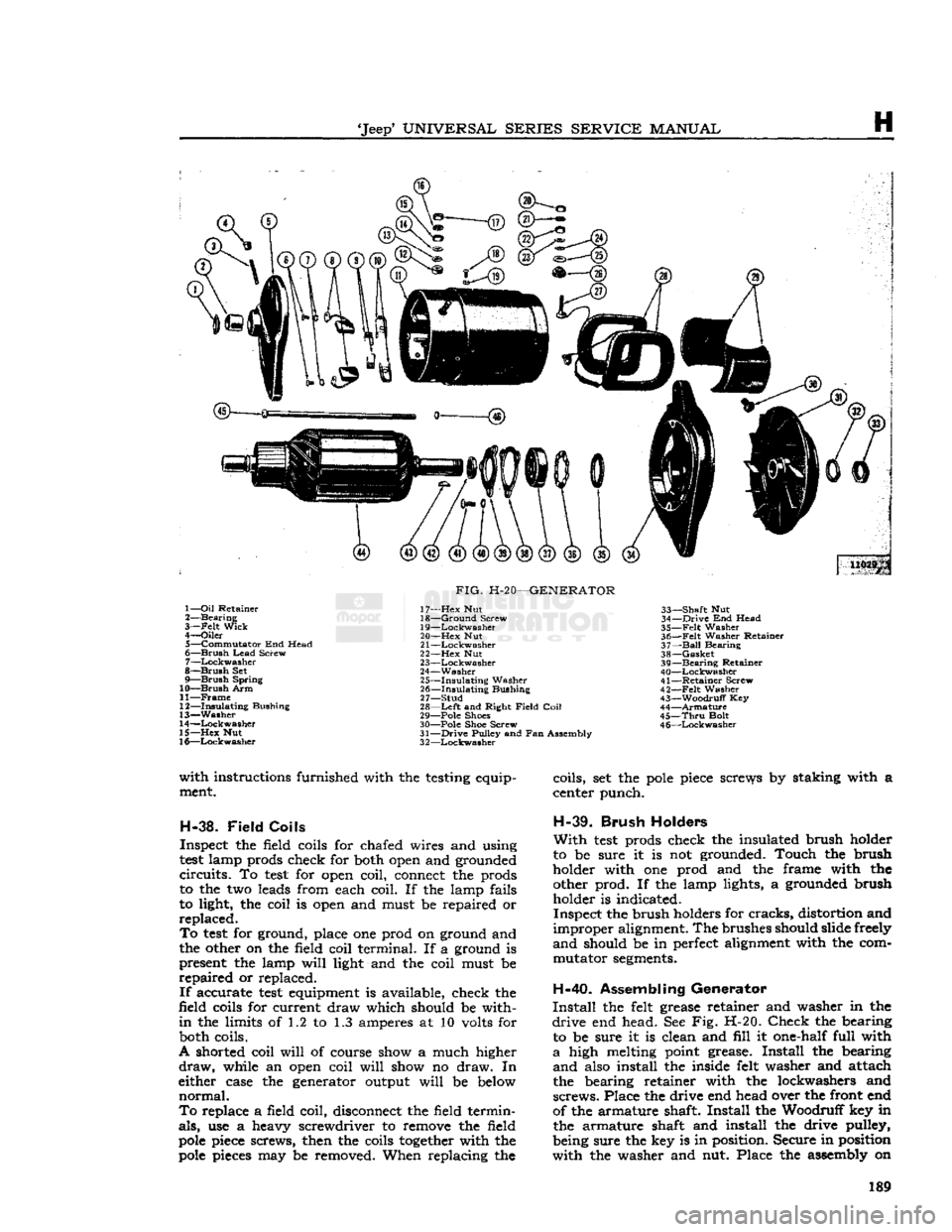

H-34.

GENERATOR

— F4

ENGINE

The

generator is an air-cooled, two-brush unit

which

cannot be adjusted to increase or decrease output. For replacement,

voltage

regulator and generator must be matched for

voltage

and capa

city,

polarity, and common source of manufacture.

Otherwise,

either a

loss

of ampere capacity or a

burned

out generator

will

result. Generators for

these

vehicles are 12-volt. Par. H-l explains the 12-volt system. Refer to the specifications at the

end of this section for information on correct generator rating for a specific model series.

The

circuit

breaker,

voltage

regulator, and current-

limiting

regulator are built into one combination

unit.

Because the regulator and battery are part

of the generator

circuit,

the output of the generator

depends upon the

state

of charge and temperature

of the battery.

With

a discharged battery, the

output

will

be high, decreasing proportionally as the battery

becomes

charged. For service informa

tion covering current regulator see Par. H-41.

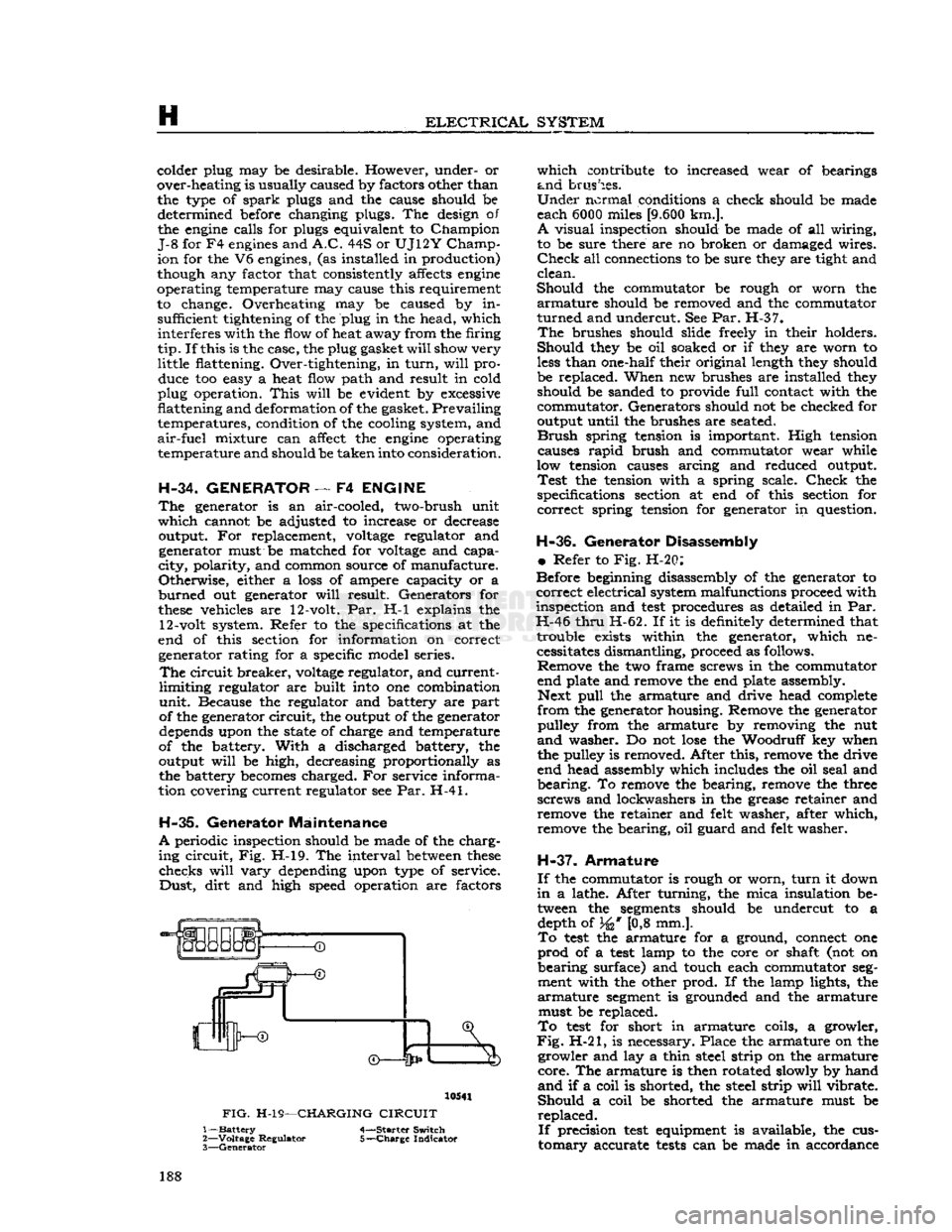

H-36.

Generator

Maintenance

A

periodic inspection should be made of the charg

ing

circuit,

Fig. H-l9. The interval

between

these

checks

will

vary

depending upon type of service.

Dust,

dirt

and high speed operation are factors 10541

FIG.

H-19—CHARGING

CIRCUIT

1—

Battery

4-—Starter Switch

2—

Voltage

Regulator 5-—Charge Indicator

3—

Generator

which

contribute to increased wear of bearings

and

brushes.

Under

normal conditions a check should be made

each 6000 miles

[9.600

km.].

A

visual inspection should be made of all wiring,

to be sure there are no broken or damaged wires.

Check

all connections to be sure they are tight and

clean.

Should

the commutator be rough or worn the

armature

should be removed and the commutator

turned

and undercut. See Par. H-37.

The

brushes should slide freely in their holders.

Should

they be oil soaked or if they are worn to

less

than one-half their original length they should

be replaced. When new brushes are installed they should be sanded to provide

full

contact with the

commutator. Generators should not be checked for

output until the brushes are seated.

Brush

spring tension is important. High tension causes

rapid

brush and commutator wear while

low tension causes arcing and reduced output.

Test

the tension with a spring scale.

Check

the

specifications section at end of this section for

correct

spring tension for generator in question.

H-36.

Generator Disassembly

•

Refer to Fig. H-20:

Before beginning disassembly of the generator to

correct

electrical system malfunctions proceed with

inspection and

test

procedures as detailed in Par.

H-46

thru

H-62. If it is definitely determined that trouble exists within the generator, which necessitates dismantling, proceed as follows. Remove the two frame screws in the commutator

end plate and remove the end plate assembly. Next

pull

the armature and drive head complete

from

the generator housing. Remove the generator pulley from the armature by removing the nut

and

washer. Do not

lose

the Woodruff key when

the pulley is removed. After this, remove the drive

end head assembly which includes the oil seal and

bearing.

To remove the bearing, remove the three

screws and lockwashers in the grease retainer and remove the retainer and felt washer, after which,

remove the bearing, oil guard and felt washer.

H-37.

Armature

If

the commutator is rough or worn,

turn

it down

in

a lathe. After turning, the mica insulation be tween the

segments

should be undercut to a depth of 34* [0,8 mm.].

To

test

the armature for a ground, connect one

prod

of a

test

lamp to the core or shaft (not on

bearing

surface) and touch each commutator

seg

ment with the other prod. If the lamp lights, the

armature

segment

is grounded and the armature must be replaced.

To

test

for short in armature coils, a growler,

Fig.

H-21, is necessary. Place the armature on the growler and lay a thin steel strip on the armature

core.

The armature is then rotated slowly by hand

and

if a coil is shorted, the steel strip

will

vibrate.

Should

a coil be shorted the armature must be

replaced.

If

precision

test

equipment is available, the cus

tomary

accurate

tests

can be made in accordance 188

Page 189 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

H

U029p 1—

Oil

Retainer

2—

Bearing

3—

-Felt

Wick

4—

Oiler

5—

Commutator

End Head

6—

Brush

Lead

Screw

7—

Lockwasher

8—

Brush

Set

9—

Brush

Spring

10—

Brush

Arm

11—

Frame

12—

Insulating

Bushing

13—

Washer

14—

Lockwasher

15—

Hex

Nut

16—

Lockwasher

FIG.

H-20—GENERATOR

17—

Hex

Nut

18—

Ground

Screw

19—

Lockwasher

20—

Hex

Nut

21

—Lockwasher

22—

Hex

Nut

23—

Lockwasher

24—

Washer

25—

Insulating

Washer

26—

Insulating

Bushing

27—

Stud

28—

Left

and Right

Field

Coil

29— Pole Shoes

30— Pole Shoe Screw

31—

Drive

Pulley and Fan Assembly

3

2—Lockwasher

33—

Shaft

Nut

34—

Drive

End Head

35—

Felt

Washer

36—

Felt

Washer Retainer

37—

Ball

Bearing

38—

Gasket

39—

Bearing

Retainer

40—

Lockwasher

41—

Retainer

Screw

42—

-Felt

Washer

43—

Woodruff

Key

44—

Armature

45—

Thru

Bolt

4

6—Lockwasher

with

instructions furnished with the testing equip ment.

H-38.

Field

Coils

Inspect the field coils for chafed wires and using

test

lamp prods check for both open and grounded

circuits.

To

test

for open coil, connect the prods

to the two leads from each coil. If the lamp fails

to light, the coil is open and must be repaired or

replaced.

To

test

for ground, place one prod on ground and

the other on the field coil terminal. If a ground is present the lamp

will

light and the coil must be

repaired

or replaced.

If

accurate

test

equipment is available, check the

field coils for current draw which should be with

in

the limits of 1.2 to 1.3 amperes at 10 volts for both coils.

A shorted coil

will

of course show a much higher

draw,

while an open coil

will

show no draw. In

either case the generator output

will

be below

normal.

To

replace a field coil, disconnect the field termin

als,

use a heavy screwdriver to remove the field

pole

piece screws, then the coils

together

with the

pole

pieces may be removed. When replacing the coils, set the

pole

piece screws by staking with a

center punch.

H-39.

Brush

Holders

With

test

prods check the insulated brush holder

to be sure it is not grounded. Touch the brush

holder with one prod and the frame with the other prod. If the lamp lights, a grounded brush holder is indicated.

Inspect the brush holders for

cracks,

distortion and

improper

alignment. The brushes should slide freely

and

should be in perfect alignment with the com mutator

segments.

H-40.

Assembling Generator

Install

the felt grease retainer and washer in the

drive

end head. See Fig. H-20.

Check

the bearing to be sure it is clean and

fill

it one-half full with

a

high melting point grease.

Install

the bearing

and

also install the inside felt washer and attach

the bearing retainer with the lockwashers and

screws.

Place the drive end head over the front end

of the armature shaft.

Install

the Woodruff key in the armature shaft and install the drive pulley,

being sure the key is in position. Secure in position

with

the washer and nut. Place the assembly on 189

Page 191 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

H

long as the circuit values allow the voltage to build

up to the operating voltage.

The

electromagnet of the voltage regulator unit has

a

winding of many turns of fine wire and is con

nected across the charging circuit so that the sys tem voltage controls the amount of magnetism.

The

contacts of the voltage regulator unit are con

nected in the generator field circuit so that the field

circuit

is completed through the contacts when they

are

closed and through a resistor when the contacts

are

opened.

When

the voltage rises to a predetermined value

there is sufficient magnetism created by the regu

lator

winding to

pull

the

armature

down.

This

opens

the contacts and inserts resistance in the field

cir

cuit

of the generator thus reducing the

field

current.

The

generated voltage immediately drops, which

reduces the

pull

on the

armature

to the point where

the spring closes the contacts. The output again

rises

and the cycle is repeated.

These

cycles occur at high enough frequencies to

hold the generated voltage at a constant value and

will

continue as long as the voltage of the circuit

is high enough to keep the voltage regulator unit

in

operation.

With

the addition of a current load great enough to lower the battery voltage below

the operating voltage of the unit, the contacts

will

remain

closed and the generator

will

maintain a

charging

rate as limited by its speed or the current

limiting

regulator.

Due

to the

effect

of heat on the operating

charac

teristics of regulator windings it is necessary to

compensate for the changes in coil resistance when

the regulator is operating under varying tempera

ture

conditions.

This

is accomplished through the

use of a nickel iron magnetic by-pass on the volt

age regulator unit.

This

shunt by-passes

some

of

the magnetic flux when the unit is cold and allows most of the flux to act on the armature when the

unit

is hot.

Thus

when the coil is hot and not as

efficient, the magnetic shunt reduces the amount of flux needed to vibrate the armature.

The

compensation is usually more than enough to

offset

the changes in regulator coil resistance due

to heat. The excess compensation allows the regu

lator

to operate at higher voltage under cold

operating conditions than under hot conditions.

This

is necessary as it requires a higher voltage to charge a battery with its internal resistance in

creased

by low temperatures.

H-45.

Current-Limiting

Regulator

The

function of the current-limiting regulator is to limit the output of the generator to its maxi

mum

safe output.

The

electromagnet of the current regulator unit

consists of

a

winding of heavy

wire

that is connected

in

series with the generator output. When the gen

erator

output reaches a predetermined value, the

current

in the winding produces enough magnetism

to overcome the spring tension and

pull

the

arma

ture

down.

This

opens

the contacts and inserts re

sistance in the field circuit of the generator.

With

the field current reduced by the resistance, the

generator output falls and there is no longer enough

magnetism to hold the contacts open. As soon as

the spring closes the contacts, the output rises and the cycle is repeated. These cycles occur at high

enough frequencies to limit the output to a mini

mum

fluctuation.

H-46.

Preliminary Inspection

a.

Wiring—Check

the wiring to see that it is prop

erly

connected to the generator.

b.

Generator

Performance—Make

sure the genera

tor operates correctly without the regulator in the

circuit.

Remove the armature and battery leads

from

the regulator and connect an ammeter be

tween them. Remove the field lead from the regu

lator

and while operating at idle speed touch the

field

lead

to the regulator base. Increase the speed slowly noting the charging rate.

CAUTION:

Do not increase the output above

the rated output of the generator.

If

the generator output

will

not build up inspect

the wiring harness for shorts and

opens

and remove the generator for an overhaul. To check the genera

tor circuit when a suitable ammeter is unavailable,

Fig.

H-19, disconnect the armature cable at the

regulator.

Connect one lead of

a

12v

test

lamp to the regulator terminal marked "armature" and with

the engine running, ground the other lead. Should

the

test

light

fail

to

burn

there is a fault either in the generator or regulator. To localize the fault, discon

nect both the

"Field"

and

"Armature"

cables at the generator. Connect a wire from the

"Field"

ter

minal

to ground and use a 60 watt, 110 volt

test

lamp

to ground the

"Armature"

terminal. If the

generator is charging satisfactorily the

test

lamp

will

glow

at approximately 1500 rpm. engine speed

and

the fault

will

be definitely localized in the

regulator.

c.

Incorrect Regulator—Make sui he regulator

is the correct type for use with the generator.

d.

Battery—Check

the specific gravity and termi

nal

voltage of the battery. If the \ ttery is not up

to specifications substitute temporarily

for

test

pur

poses

a fully charged battery of the same type and

capacity.

e. High Resistance Connections—Inspect the

wir

ing between the generator, regulator and battery for broken wires and high resistance connections.

Pay

special attention to the ground connections at

all

three units. Connect a reliable ammeter with 1-ampere graduations in series with the regulator

B-terminal

and the lead removed from this

terminal.

Run

the generator at a medium speed and

turn

on the lights or accessories until the ammeter shows a 10-ampere charging rate. At this charging rate

measure the voltage drop between the following

points using an accurate voltmeter graduated in

,1-volt divisions. The voltmeter should not show

a

reading above the maximum noted.

Generator

"A" terminal to regulator

"A"

terminal

—.1-volt maximum.

Generator

"F"

terminal to regulator

"F"

terminal

—.05-volt maximum.

Battery

terminal to regulator "B" terminal— .1-volt maximum.

Regulator

ground screw to generator frame— .03-volt maximum. 191