wheel alignment JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 206 of 376

H

ELECTRICAL

SYSTEM

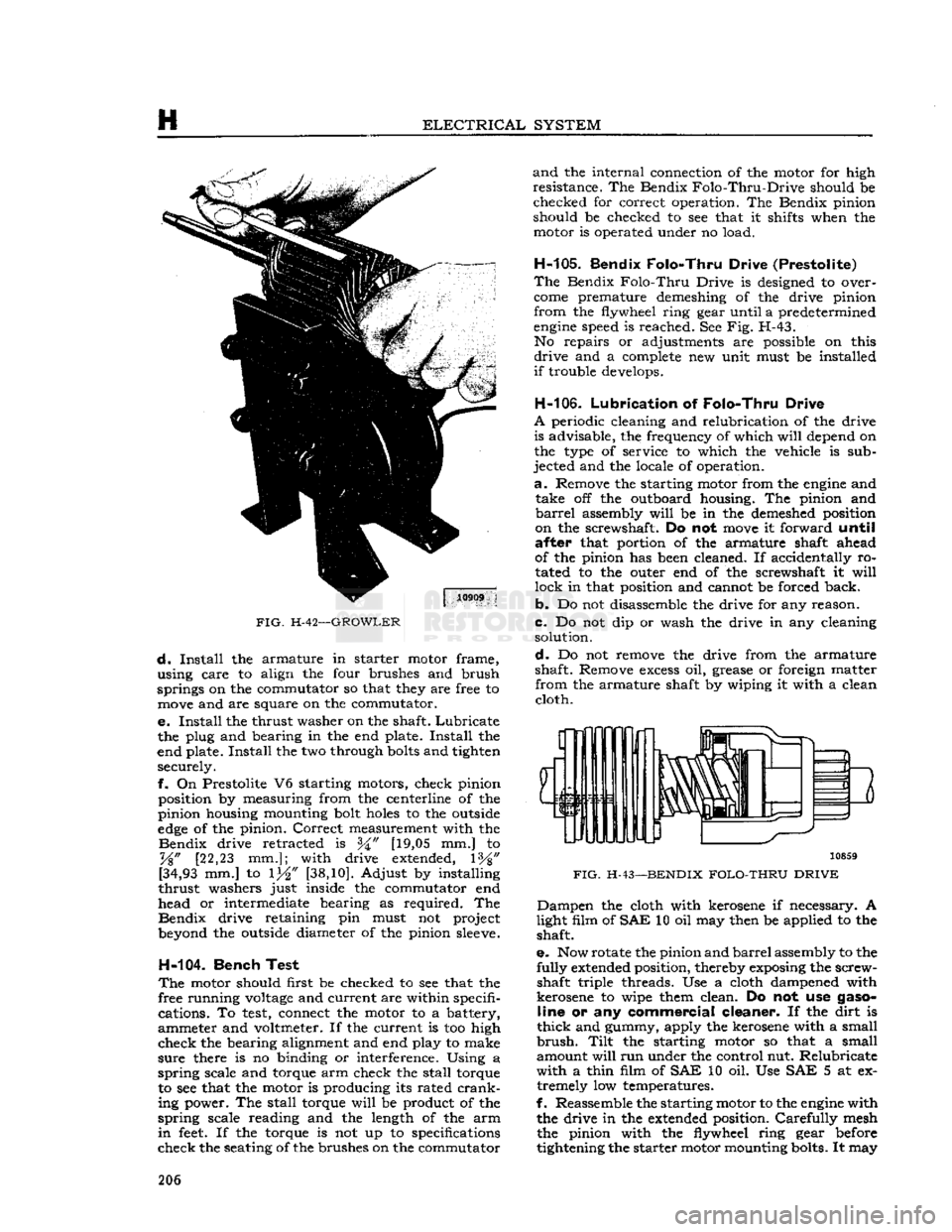

FIG.

H-42—GROWLER

d.

Install

the armature in starter motor frame,

using care to align the four brushes and brush

springs on the commutator so that they are free to

move

and are square on the commutator.

e.

Install

the thrust washer on the shaft.

Lubricate

the plug and bearing in the end plate.

Install

the

end plate.

Install

the two through

bolts

and tighten securely.

f.

On Prestolite V6 starting motors, check pinion position by measuring from the centerline of the

pinion housing mounting bolt

holes

to the outside

edge

of the pinion.

Correct

measurement with the

Bendix

drive retracted is [19,05 mm.] to

%"

[22,23 mm.]; with drive extended, 1%"

[34,93

mm.] to 1^" [38,10]. Adjust by installing

thrust

washers just inside the commutator end

head or intermediate bearing as required. The

Bendix

drive retaining pin must not project

beyond the outside diameter of the pinion

sleeve.

H-104.

Bench Test

The

motor should first be checked to see that the

free running

voltage

and current are within specifi cations. To

test,

connect the motor to a battery,

ammeter and voltmeter. If the current is too high

check

the bearing alignment and end play to make

sure

there is no binding or interference. Using a

spring

scale and torque arm check the stall torque to see that the motor is producing its rated

crank

ing power. The stall torque

will

be product of the

spring

scale reading and the length of the arm

in

feet.

If the torque is not up to specifications

check

the seating of the brushes on the commutator

and

the internal connection of the motor for high

resistance. The Bendix

Folo-Thru-Drive

should be checked for correct operation. The Bendix pinion

should be checked to see that it shifts when the motor is operated under no load.

H-105.

Bendix Folo-Thru Drive (Prestolite)

The

Bendix

Folo-Thru

Drive is designed to over

come

premature demeshing of the drive pinion

from

the flywheel ring gear until a predetermined

engine

speed is reached. See Fig. H-43. No repairs or adjustments are possible on this

drive

and a

complete

new unit must be installed

if

trouble develops.

H-106.

Lubrication

of

Folo-Thru Drive

A

periodic cleaning and relubrication of the drive is advisable, the frequency of which

will

depend on

the type of service to which the vehicle is sub

jected and the locale of operation.

a.

Remove the starting motor from the

engine

and take off the outboard housing. The pinion and

barrel

assembly

will

be in the demeshed position

on the screwshaft. Do not

move

it forward

until

after

that portion of the armature shaft ahead

of the pinion has been cleaned. If accidentally ro

tated to the outer end of the screwshaft it

will

lock

in that position and cannot be forced back.

b.

Do not disassemble the drive for any reason.

c.

Do not dip or wash the drive in any cleaning solution.

d.

Do not remove the drive from the armature

shaft. Remove

excess

oil, grease or foreign matter

from

the armature shaft by wiping it with a clean cloth.

3

10859

FIG.

H-43—BENDIX

FOLO-THRU DRIVE

Dampen

the cloth with kerosene if necessary. A

light film of

SAE

10 oil may then be applied to the shaft.

e.

Now rotate the pinion and

barrel

assembly to the

fully

extended position, thereby exposing the screw shaft triple threads. Use a cloth dampened with

kerosene to wipe them clean. Do not use

gaso

line

or any

commercial cleaner.

If the dirt is

thick

and gummy, apply the kerosene with a small

brush.

Tilt

the starting motor so that a small

amount

will

run under the control nut. Relubricate

with

a thin film of

SAE

10 oil. Use SAE 5 at ex tremely low temperatures.

f.

Reassemble the starting motor to the

engine

with the drive in the extended position.

Carefully

mesh the pinion with the flywheel ring gear before

tightening the starter motor mounting bolts. It may 206

Page 239 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

J

THREE-SPEED

TRANSMISSION

Contents

SUBJECT

PAR.

GENERAL

J-l

TRANSMISSION

SHIFTING

CONTROL.

. J-2

TRANSMISSION

REMOTE

CONTROL

ADJUSTMENT

J-3

REMOTE

CONTROL

DISASSEMBLY

J-4

REMOTE

CONTROL

REASSEMBLY.

. . . . J-5

TRANSMISSION

REMOVAL

J-6

SEPARATING

TRANSMISSION

AND

TRANSFER

CASE

J-7

SUBJECT

PAR.

DISASSEMBLY

OF

CANE

SHIFT

TRANSMISSION

J-8, J-12, J-16

Transmission

Cleaning and

Inspection J-10, J-18

Transmission

Interlocking Sleeve Inspection J-9

REASSEMBLY

OF

CANE

SHIFT

TRANSMISSION

J-ll,

J-14, J-19

SERVICE

DIAGNOSIS

J-20

TRANSMISSION

SPECIFICATIONS

J-21

J-1.

GENERAL

A

three speed synchromesh transmission is standard

equipment on all 'Jeep' Universal vehicles.

The

models T90 and T96 transmissions are used

with

the

Hurricane

F4 engine, and models

T86AA

and

T14A transmissions are used with the Daunt

less

V-6 engine. All model transmissions are similar

in

design with exception of the T14A which is a

fully

synchronized (all forward gears) transmission

with

helical drive gears throughout.

The

transmission assembly is attached to the

rear

face of the flywheel bell housing and is supported on a rubber insulator at the frame center cross member which forms the

rear

engine

support.

All

4-wheel-drive vehicles are equipped with a

transfer

case attached to the

rear

of the transmission.

Transfer

case service and repair procedures

are

described in Section

K.

Models

CJ-5A,

and

CJ-6A

are equipped with the

same transmission, but with a remote control shift.

Models DJ-5 and DJ-6 are equipped with a similar

transmission,

however, the construction is

some

what different because it is not designed to receive a transfer case for four-wheel drive.

For

DJ-5 and DJ-6 2WD vehicles, the trans mission repair procedures begin with Par. J-12.

J-2.

TRANSMISSION SHIFTING CONTROL

The

shift of the three-speed transmission is smooth

and

positive. The cane control lever shifts the trans

mission gears direct from the shift control housing

mounted to the top side of the transmission housing.

The

remote control lever shifts the transmission

gears through remote control rods attached to the

adjusting

levers of the shift shafts protruding from the left side of the transmission housing. Poppet

balls and springs retain the transmission gears in mesh and an interlocking mechanism prevents

shifting into two gears at the same time.

J-3.

Transmission Remote Control Adjustment

•

Early

CJ-5A,

CJ-6A

First

disconnect the transmission shift rods from the remote control levers.

Check

for binding of

the remote control shaft on the steering column

and

make the necessary corrections to eliminate any binding condition.

If

the shift is not smooth and positive, first make

sure

the gears are in neutral position then remove

the shift rods at the transmission by removing

clevis pins, Fig. J-l No. 17, and slip a short piece

of snug fitting 34" [6,35 mm.] aligning rod, through

the gearshift levers and housing as shown in insert

drawing.

This

places the clutch and shift lever assemblies

in

the neutral position. Adjust the shift rod yokes

at the transmission end, so clevis pins can be in stalled freely without moving the shift levers on the

transmission after which remove alignment pin.

If

shifting from first to second is difficult or trans

mission hangs in first gear, shorten the low and

reverse shift rod one

turn

at a time until the con

dition is corrected. Usually three turns are re

quired.

Should

the fault continue after completing the above adjustment, check further as outlined below.

First

remove the lubricating fitting. Use a narrow

feeler

gauge

which

will

enter the opening for the

lubricator

and check the clearance

between

the

faces of the shifting clutches.

This

clearance should

be .015" to .031", [W to W]

[0,397-0,794

mm.]. If

this clearance is greater the assembly must be removed for adjustment. The shift dog, which

engages

the clutch slots, should not have more than .009" [0,229 mm.] clearance in the slots. If the clear

ance

between

the clutch

grooves

and cross pins is

too great,

these

parts must be replaced.

J-4.

Removal

of

Remote Control

m

Early

CJ-5A,

CJ-6A

•

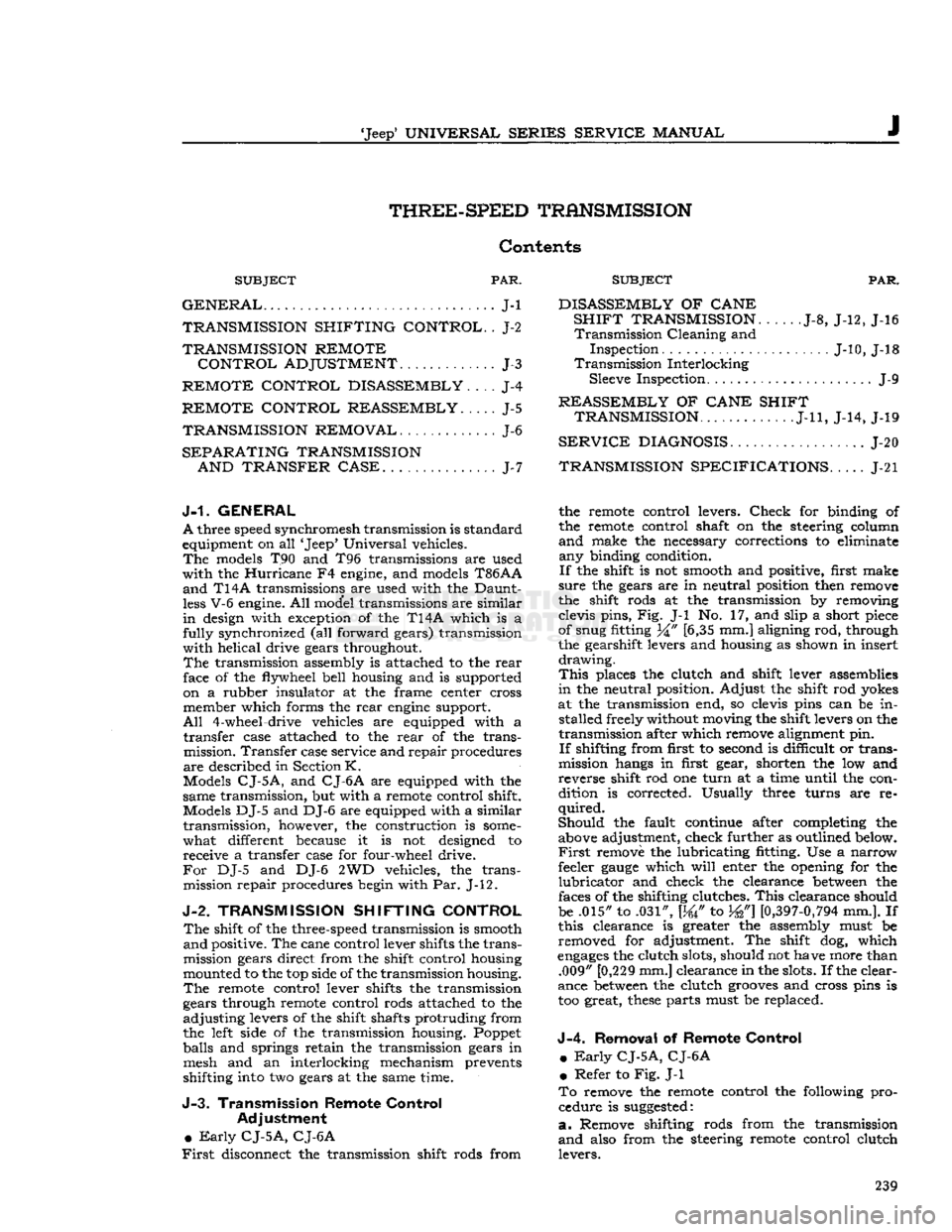

Refer to Fig. J-l

To

remove the remote control the following pro cedure is

suggested:

a.

Remove shifting rods from the transmission

and

also from the steering remote control clutch levers. 239

Page 240 of 376

THREE-SPEED

TRANSMISSION

FIG.

J-l—TRANSMISSION

REMOTE

CONTROL

CJ-5

A,

CJ-6A

1— Stop Screw

2—

Bias

Spring

3—

Gearshift

Lever

4—

Lever

Ball

5—

Steering

Wheel 6—

Horn

Button 7—

Column

and Bearing

8—

End

Huts

9—

Shift

Rod

Ends

10—

Shift

Rod

11—

Shift

Rod

12—

Cross-Shift

Bracket

13—

Control

Shaft

14—

Lubrication

Fitting

15—

Lever

and

Clutch

16—

Adjusting

Yoke

17—

Aligning

Rod 11706

b.

Remove gearshift lever fulcrum pin and the

gearshift lever.

c.

Remove plates on the toe board at the steer

ing

post.

d.

Remove two screws holding remote control

housing to the steering

post

and lift the housing

from

the positioning pin.

e.

Remove the assembly down through the floor

pan.

f. Remove the lower clutch and shift lever from the housing by turning counterclockwise.

g. Remove upper clutch and shift lever in the same

manner.

h. Wash all parts in a suitable cleaning solution.

J-5.

Reassembly of

Remote

Control

•

Refer to

Fig.

J-l

Check

clearance of shift dog which

engages

in slot

of clutches, and if found to be greater than .009" [0,229 mm.] clearance, replace the worn parts.

Assemble upper clutch lever assembly in housing

making

sure that the alignment

hole

in the housing

faces toward the engine.

Turn

the upper lever as

sembly in as far as it

will

go and then back off one

full

turn

until the

hole

in the clutch lever aligns

with

hole

in the housing.

Assemble the lower clutch lever assembly in hous ing until faces of clutches contact then back off

not more than one-half

turn

which should bring

the aligning

hole

in the lever in line with the

hole

in

the housing. If the one-half

turn

does

not bring

the alignment

hole

in proper position, it

will

be

necessary to grind off (square with axis not to exceed .015") [0,397 mm.] the face of the lower

clutch;

in other words, backing off not more than

one-half

turn

from face to face contact

gives

the

proper

clearance of .015" to .031"

[0,397-0,794

mm.]

between

the two clutches.

Assemble the unit to the steering

post

in reverse

order

of dismantling and adjust remote control

rods.

After

assembly, if the shift dog catches on the

edge

of the slot in the clutch when moving the lever up

and

down, disconnect the shift rod at the

transmission

end and either lengthen or shorten it

slightly to correct this condition.

J-6.

TRANSMISSION

REMOVAL

The

following repair procedures given in Par. J-7

through J-ll for the standard

3-speed

transmission

apply

in general to all models listed. Minor dif

ferences

between

models that affect the procedure

are

noted. Procedure for the optional

4-speed

transmission

begins

with Section

J-l.

Removal

is as follows:

a.

Drain

the transmission and transfer case. Re place the

drain

plugs.

b.

Remove the floor pan inspection plate.

c.

Remove the shift lever and shift housing as sembly and its gasket from the transmission. On 240

Page 278 of 376

M

FRONT

AXLE

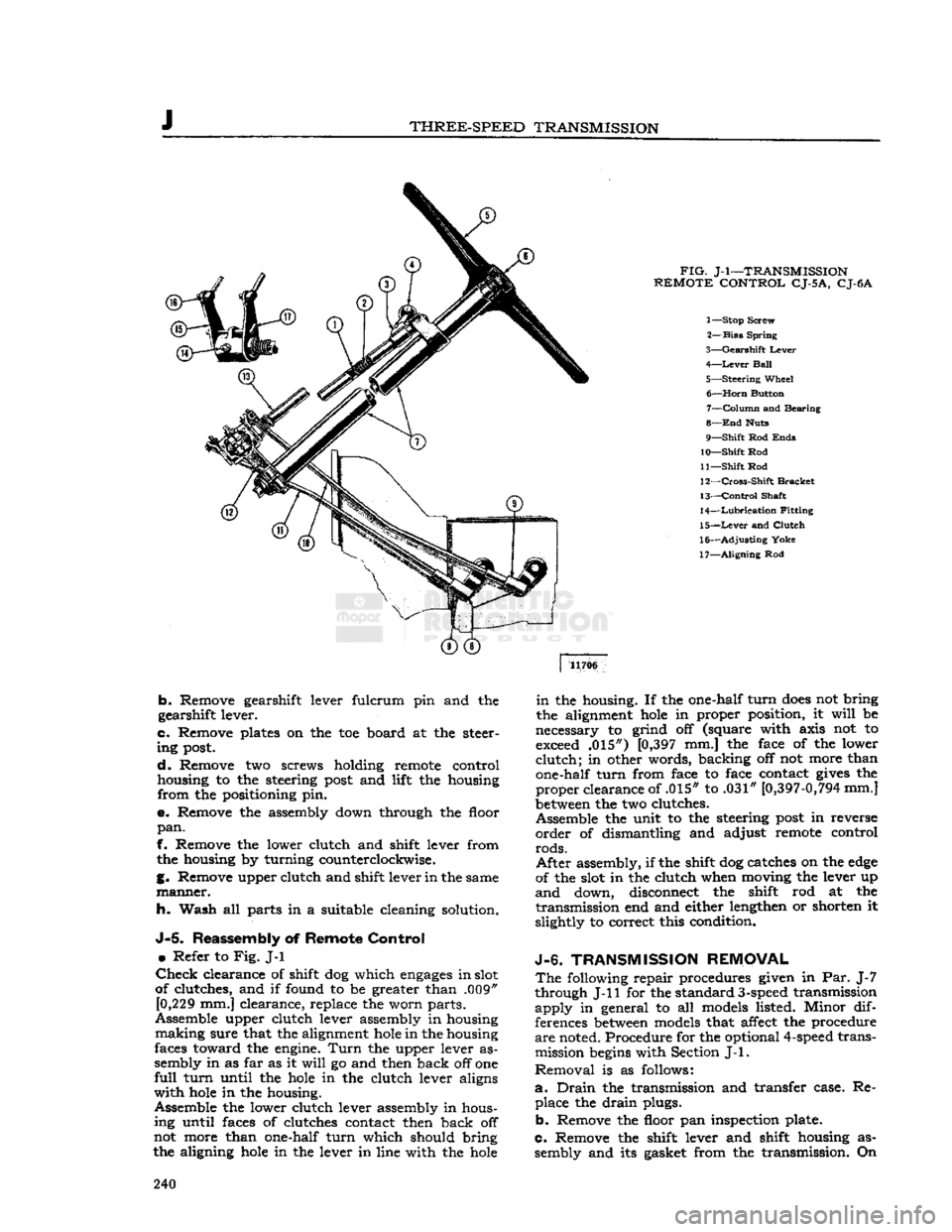

1— Nut

2—

Lock

Washer

3—

Bearing

Lock

Washer

4—

Wheel

Bearing Cup 5—

Cone

and Rollers

6—

Oil

Seal 7— Spindle

8— Spindle Bushing

9—

Filler

Plug

10—

Right

Knuckle and Arm

11— Shims

12— Pivot Pin

13—

Lock

Washer

14—

Cap

Screw

15— Nut

16—

Washer

17—

Universal

Joint Yoke

18—

Oil

Seal

19—

Oil

Slinger

FIG.

M-2—FRONT

AXLE

20—

Cone

and Rollers

21—

Bearing

Cup

22—

Right

Axle Shaft with Universal Joint

23—

Knuckle

Oil Seal Retainer

24— Housing Breather 25—

Front

Axle Housing

26—

Axle

Shaft with Universal Joint

27—

Oil

Seal

28—

Axle

Shaft Guide

29—

Shim

Pack

30—

Bearing

Cup

31—

Cone

and Rollers

32—

Ring

Gear

and Pinion

33—

Thrust

Washer

34—

Thrust

Washer

35—

Differential

Gears

36— Housing Cover Gasket

37— Housing Cover

38—

Fill

Plug 39—

Screw

and

Lock

Washer

40—

Bearing

Cup

41—

Cone

and Rollers

42— Shims

43—

Lock

Pin

44—

Pinion

Shaft

45—

Differential

Case

47— Bolts

48— Nut

49—

Oil

Seal and Backing Ring

50—

Thrust

Washer

51— Snap Ring

52— Stop Bolt

53— Nut 54—

Bearing

Cup

55—

Cone

and Rollers

56—

Gasket

checked, making sure it is clean and open.

The

front wheel bearings should be checked every

12,000

miles. Refer to Section Q. Front wheel toe-

in

is adjustable by lengthening or shortening the

tie rod. However, standard caster and camber of

the front

wheels

are built

into

the axle. Wheel

caster can be adjusted by placing tapered shim

plates or

wedges

between

the springs and spring

seats

welded to the axle housing. Steering

geometry

and

front wheel adjustments are discussed in Sec tion O.

The

axle housing should be checked periodically

for weld cracks and/or other damage that may cause misalignment of the front

wheels

or

loss

of lubricant. The spring clips (U-bolts) should be

inspected and torqued every

12,000

miles. Torque (spring clip) nuts 45 to 50 lb-ft. [6,2 a 6,9 kg-m.].

M-4. FRONT

AXLE

REMOVAL

a.

Raise front end of vehicle

arid

safely support the frame by placing stands under the frame at

the rear of the front spring rear hangers.

b. Place

jack

under front axle housing and relieve

axle

weight

from the springs.

c. Disconnect shock absorbers from spring clip plates.

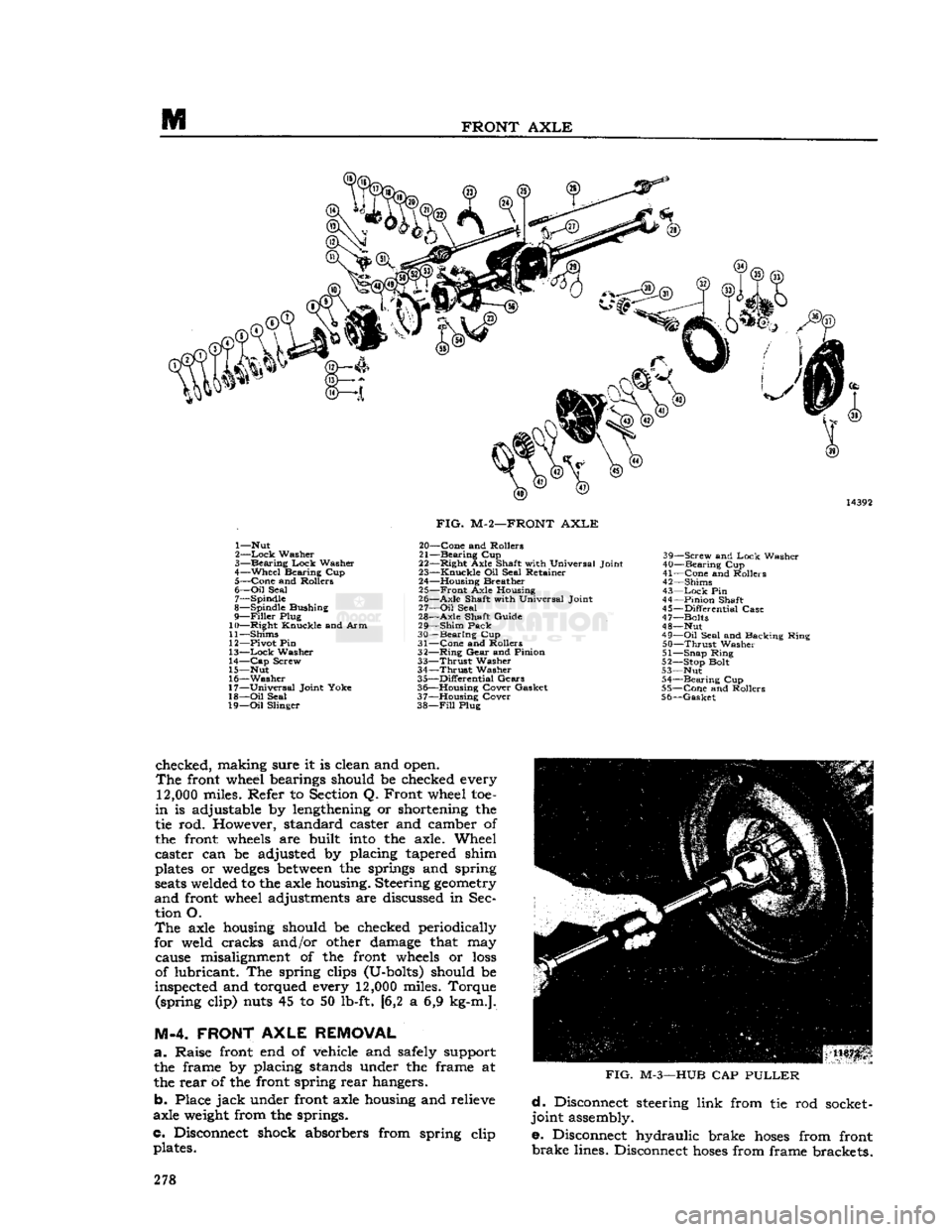

FIG.

M-3—HUB

CAP

PULLER

d.

Disconnect steering link from tie rod socket-

joint assembly.

e. Disconnect hydraulic brake

hoses

from front

brake

lines. Disconnect

hoses

from frame brackets. 278

Page 282 of 376

FRONT

AXLE

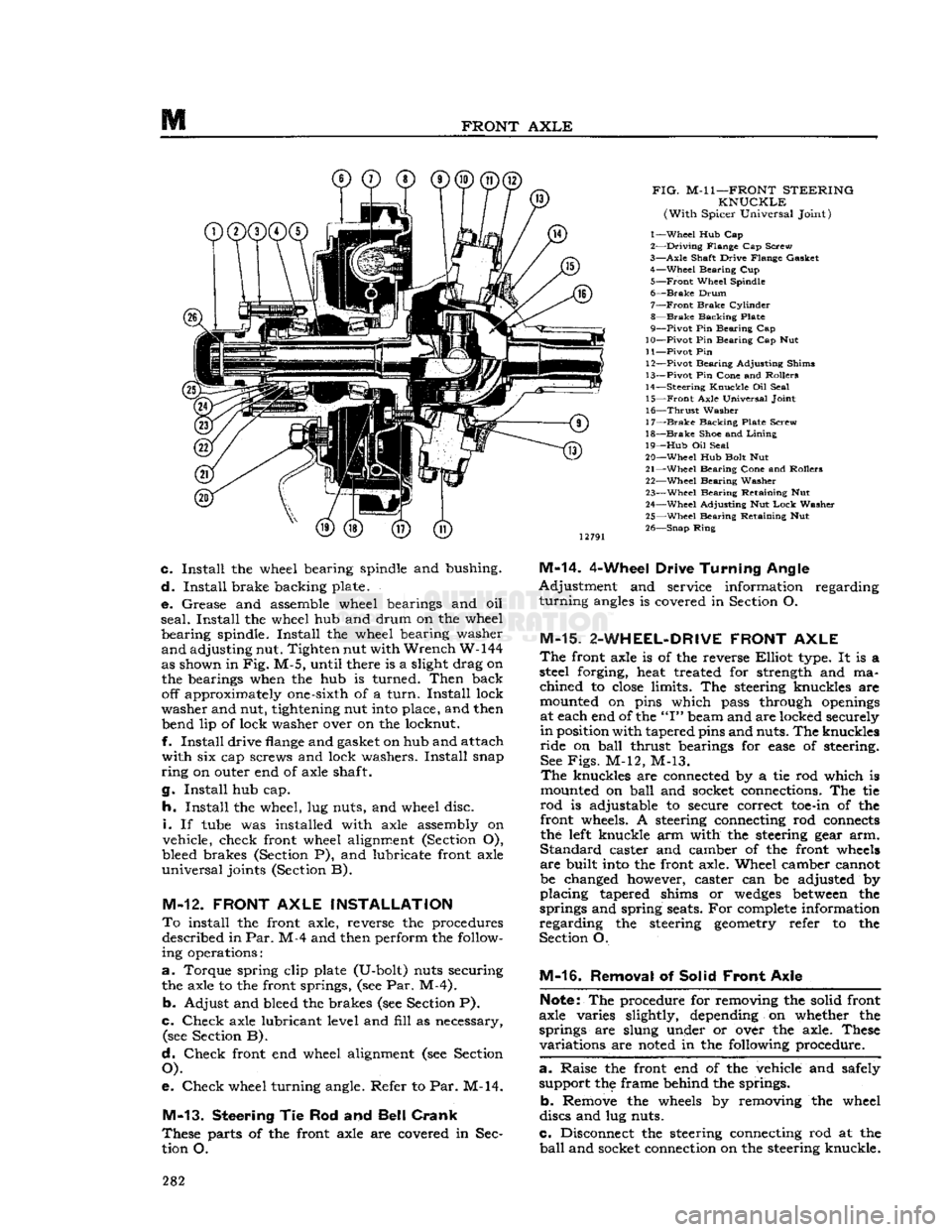

FIG.

M-l

1—FRONT

STEERING

KNUCKLE

(With

Spicer Universal Joint)

1—

Wheel

Hub Cap

2—

Driving

Flange Cap Screw

3—

Axle

Shaft Drive Flange Gasket 4—

Wheel

Bearing Cup

5—

Front

Wheel Spindle

6—

Brake

Drum

7—

Front

Brake

Cylinder

8—

Brake

Backing Plate

9—

Pivot

Pin Bearing Cap

10—

Pivot

Pin Bearing Cap Nut

11—

Pivot

Pin 12—

Pivot

Bearing Adjusting Shims

13—

Pivot

Pin Cone and Rollers

14—

Steering

Knuckle

Oil Seal 15—

Front

Axle Universal Joint

16—

Thrust

Washer

17—

Brake

Backing Plate Screw

18—

Brake

Shoe and

Lining

19—

Hub

Oil Seal

20—

Wheel

Hub Bolt Nut

21—

Wheel

Bearing Cone and Rollers 22—

Wheel

Bearing Washer

23—

Wheel

Bearing Retaining Nut

24—

Wheel

Adjusting Nut

Lock

Washer

25—

Wheel

Bearing Retaining Nut

26—

Snap

Ring

c.

Install

the wheel bearing spindle and bushing.

d.

Install

brake backing plate.

e.

Grease and assemble wheel bearings and oil

seal.

Install

the wheel hub and drum on the wheel

bearing

spindle.

Install

the wheel bearing washer

and

adjusting nut. Tighten nut with

Wrench

W-144

as shown in

Fig.

M-5, until there is a slight drag on the bearings when the hub is turned.

Then

back off approximately one-sixth of a

turn.

Install

lock

washer

and nut, tightening nut

into

place, and then bend lip of lock washer over on the locknut.

f.

Install

drive

flange

and gasket on hub and attach

with

six cap screws and lock washers.

Install

snap

ring

on outer end of axle shaft.

g.

Install

hub cap.

h.

Install

the wheel, lug nuts, and wheel disc.

i.

If

tube

was installed with axle assembly on

vehicle, check front wheel alignment (Section O),

bleed brakes (Section P), and lubricate front axle

universal

joints (Section B).

M-12.

FRONT

AXLE

INSTALLATION

To

install the front axle, reverse the procedures described in

Par.

M-4 and then perform the follow

ing operations:

a.

Torque spring clip plate (U-bolt) nuts securing the axle to the front springs, (see Par. M-4).

b.

Adjust and bleed the brakes (see Section P).

c.

Check

axle lubricant level and

fill

as necessary, (see Section B).

d.

Check

front end wheel alignment (see Section

O).

e.

Check

wheel turning angle. Refer to Par. M-14.

M-13.

Steering

Tie Rod and

Bell Crank

These

parts of the front axle are covered in Sec

tion O.

M-14.

4-Wheel Drive

Turning

Angle

Adjustment

and service information regarding

turning

angles

is covered in Section O.

M-15.

2-WHEEL-DRIVE

FRONT

AXLE

The

front axle is of the reverse

Elliot

type. It is a

steel forging, heat treated for strength and ma

chined

to

close

limits. The steering knuckles are

mounted on pins which pass through

openings

at each end of the

"I"

beam and are locked securely

in

position with tapered pins and nuts. The knuckles

ride

on

ball

thrust bearings for

ease

of steering. See

Figs.

M-12, M-13.

The

knuckles are connected by a tie rod which is

mounted on

ball

and socket connections. The tie

rod

is adjustable to secure correct

toe-in

of the front wheels. A steering connecting rod

connects

the

left

knuckle arm with the steering gear arm.

Standard

caster and camber of the front

wheels

are

built

into

the front axle. Wheel camber cannot

be changed however, caster can be adjusted by

placing

tapered shims or

wedges

between

the

springs and spring seats. For

complete

information

regarding

the steering

geometry

refer to the

Section O.

M-16.

Removal of Solid

Front

Axle

Note:

The procedure for removing the solid front

axle varies slightly, depending on whether the

springs are slung under or over the axle. These

variations

are

noted

in the following procedure.

a. -

Raise the front end of the vehicle and safely support the frame behind the springs.

b.

Remove the

wheels

by removing the wheel

discs and lug nuts.

c.

Disconnect the steering connecting rod at the

ball

and socket connection on the steering knuckle. 282

Page 302 of 376

N

REAR

AXLE a.

Place the transmission in neutral.

b.

Raise one wheel off the floor and place a block

in

front and at the

rear

of the

opposite

wheel.

c.

Apply a torque wrench to the axle shaft nut of

the elevated wheel.

d.

Turn

wheel with torque wrench. Disregard

breakaway

torque and observe torque required to

continuously

turn

wheel smoothly. Torque should

read

40 lb-ft [5,53 kg-m.] or more.

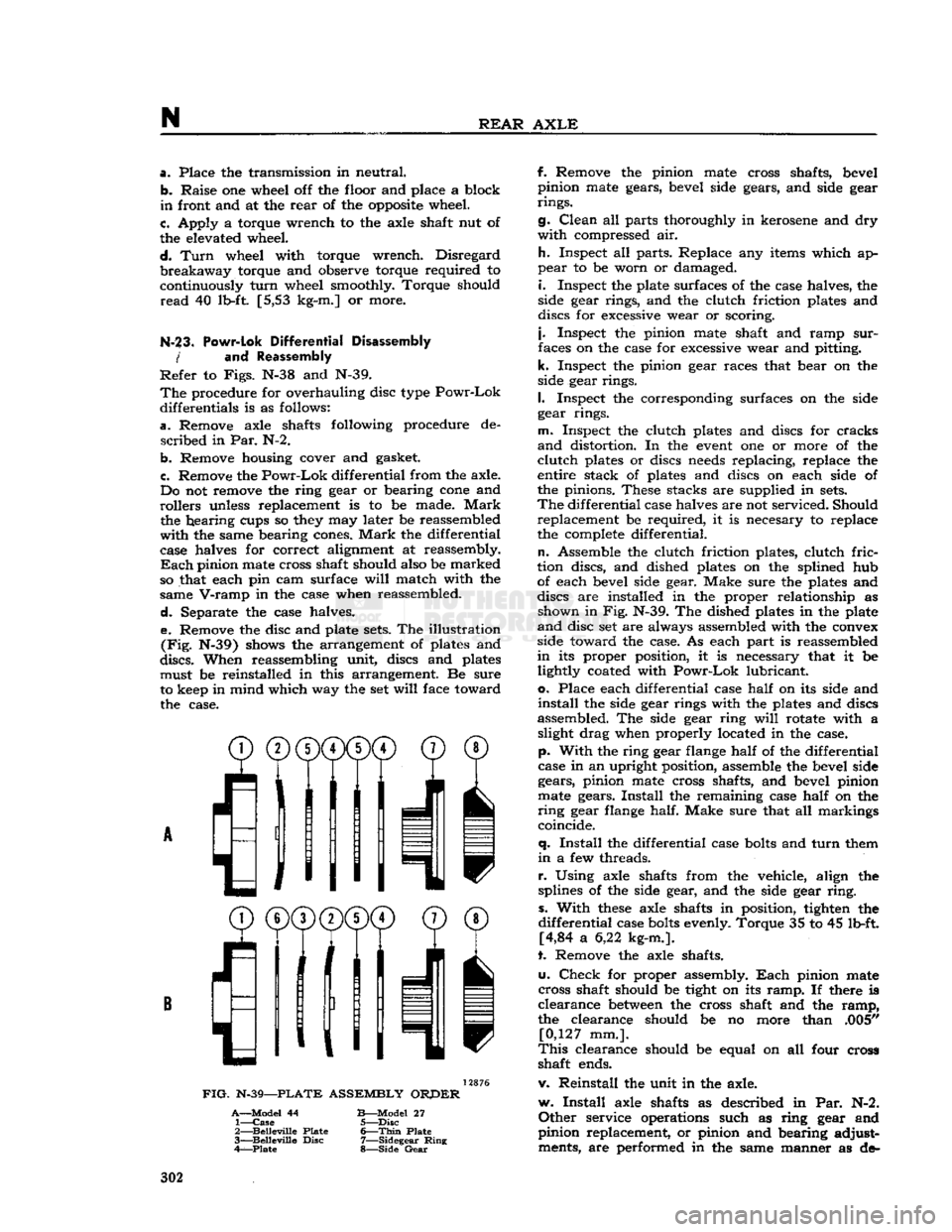

N-23. Powr-Lok

Differential Disassembly

/

and Reassembly

Refer

to

Figs.

N-38 and N-39.

The

procedure for overhauling disc type

Powr-Lok

differentials is as follows:

a.

Remove axle shafts following procedure de

scribed

in Par. N-2.

b.

Remove housing cover and gasket.

c.

Remove the

Powr-Lok

differential from the axle.

Do not remove the ring gear or bearing

cone

and

rollers

unless replacement is to be made.

Mark

the hearing cups so they may later be reassembled

with

the same bearing cones.

Mark

the differential

case halves for correct alignment at reassembly.

Each

pinion mate cross shaft should also be marked

so that each pin cam surface

will

match with the

same

V-ramp

in the case when reassembled.

d.

Separate the case halves. e. Remove the disc and plate

sets.

The illustration

(Fig.

N-39) shows the arrangement of plates and

discs.

When reassembling unit, discs and plates must be reinstalled in this arrangement. Be sure

to keep in mind which way the set

will

face toward the case.

^®(j)(j)CD©

® /'Ml

I

11

11 v

FIG.

N-39—PLATE

ASSEMBLY

ORPER

A—Model

44

B—Model

27 1—

Case

5—Disc

2—

Belleville

Plate

6—Thin

Plate

3—

Belleville

Disc

7—Sidegear

Ring

4—Plate

8—Side

Gear

f. Remove the pinion mate cross shafts, bevel

pinion mate gears, bevel side gears, and side gear

rings.

g.

Clean

all parts thoroughly in kerosene and dry

with

compressed air.

h.

Inspect all parts. Replace any items which ap

pear

to be worn or damaged.

i.

Inspect the plate surfaces of the case halves, the

side gear rings, and the clutch friction plates and

discs for excessive wear or scoring.

j.

Inspect the pinion mate shaft and ramp

sur

faces on the case for excessive wear and pitting,

k.

Inspect the pinion gear races that bear on the

side gear rings.

I.

Inspect the corresponding surfaces on the side

gear rings.

m.

Inspect the clutch plates and discs for cracks

and

distortion. In the

event

one or more of the

clutch

plates or discs

needs

replacing, replace the

entire stack of plates and discs on each side of

the pinions. These stacks are supplied in

sets.

The

differential case halves are not serviced. Should replacement be required, it is necesary to replace

the complete differential.

n.

Assemble the clutch friction plates, clutch

fric

tion discs, and dished plates on the splined hub of each bevel side gear. Make sure the plates and

discs are installed in the proper relationship as shown in Fig. N-39. The dished plates in the plate

and

disc set are always assembled with the convex

side toward the case. As each part is reassembled

in

its proper position, it is necessary that it be lightly coated with

Powr-Lok

lubricant,

o.

Place each differential case

half

on its side and

install

the side gear rings with the plates and discs

assembled. The side gear ring

will

rotate with a slight drag when properly located in the case,

p.

With

the ring gear flange

half

of the differential

case in an upright position, assemble the bevel side gears, pinion mate cross shafts, and bevel pinion

mate gears.

Install

the remaining case

half

on the

ring

gear flange half. Make sure that all markings

coincide.

q.

Install

the differential case

bolts

and

turn

them

in

a few threads.

r.

Using axle shafts from the vehicle, align the

splines of the side gear, and the side gear

ring,

s.

With

these

axle shafts in position, tighten the

differential

case

bolts

evenly. Torque 35 to 45 lb-ft. [4,84 a 6,22 kg-m.].

t. Remove the axle shafts.

u.

Check

for proper assembly.

Each

pinion mate

cross shaft should be tight on its

ramp.

If there is

clearance

between

the cross shaft and the

ramp,

the clearance should be no more than .005" [0,127 mm.].

This

clearance should be equal on all four cross

shaft ends.

v. Reinstall the unit in the axle.

w.

Install

axle shafts as described in Par. N-2.

Other

service operations such as ring gear and

pinion replacement, or pinion and bearing adjust ments, are performed in the same manner as de- 302

Page 313 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

STEERING SYSTEM

Contents

SUBJECT

PAR.

GENERAL......

O-l

Camber

Adjustment 0-9

Caster

Adjustment. .0-10

Front

Wheel Alignment Adjustments.....

.

0-6

Front

Wheel Shimmy 0-13

Front

Wheel Turning Angle Oil

Steering Knuckle Arm O-l2

Steering

Gear

Function 0-2

Steering Linkage 0-3

Toe-in

Adjustment 0-7, 8

STEERING LINKAGE SERVICE..

O-l4

Drag

Link

or Connecting Rod O-l5

Tie

Rod 0-16

Tie

Rod Removal.. O-l7

Beilcrank

Service O-l8

SUBJECT

PAR.

STEERING GEAR SERVICE

.0-22 Reassembly of Steering

Gear

0-25 Disassembly of Steering

Gear

0-24 Installation of Steering

Gear

0-26

Removal

of Steering

Gear

0-23

Steering

Gear

Adjustment. . 0-5

STEERING

COLUMN

AND

WHEEL SERVICE.

..................

.0-20

Steering Column Adjustments 0-4

Steering Wheel Installation 0-27

Steering Wheel Removal 0-21

SERVICE

DIAGNOSIS.

. 0-28

SPECIFICATIONS.

.0-29

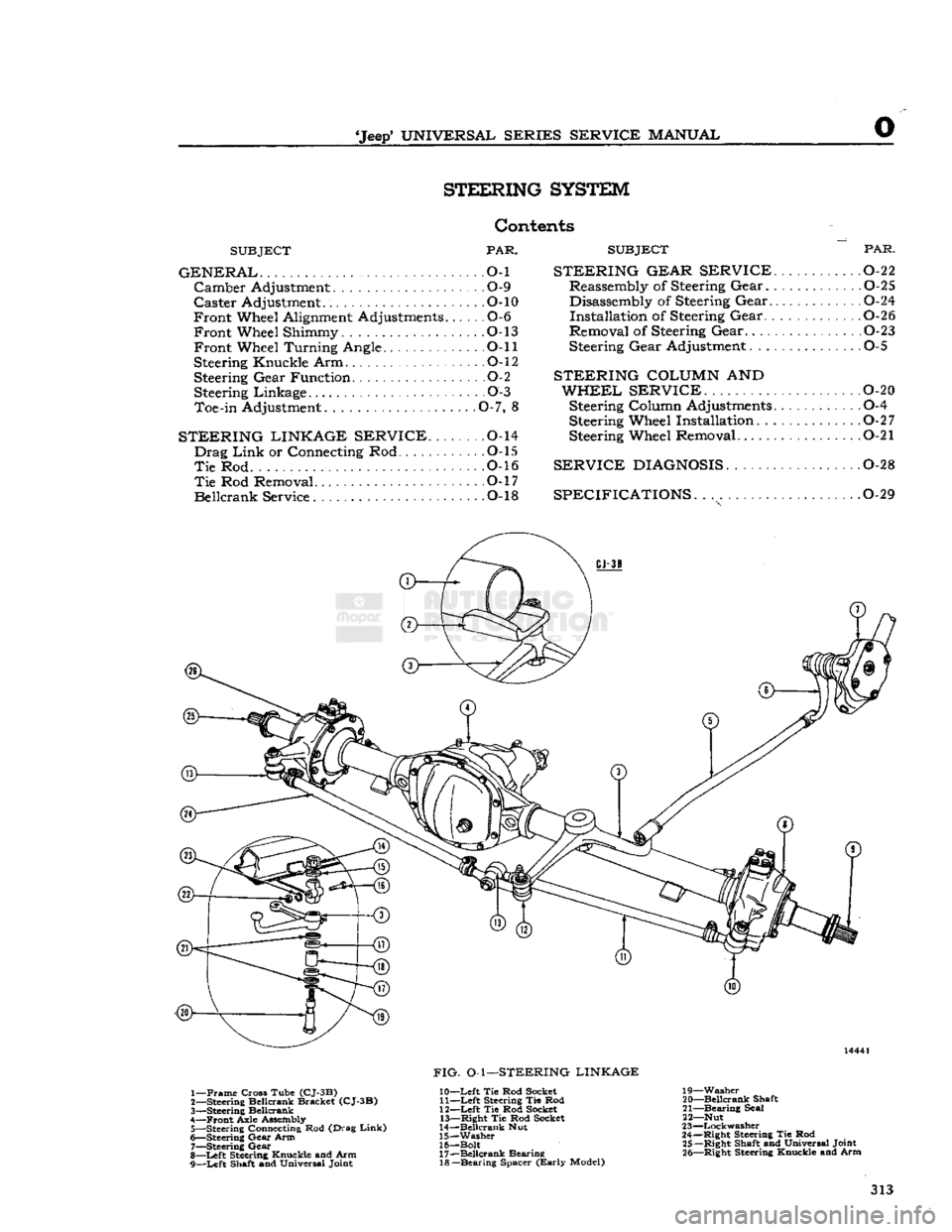

<§>-

i©1

CJ-3B

0

0 0

®

1—

Frame

Cross Tube

(CJ-3B)

2— Steering Beilcrank Bracket

(CJ-3B)

3—

Steering Beilcrank

4—

Front

Axle Assembly 5— Steering Connecting Rod (Drag

Link)

6— Steering

Gear

Arm

7—

Steering

Gear

8—

Left

Steering Knuckle and Arm

9—

Left

Shaft and Universal Joint

FIG.

O-l—STEERING LINKAGE

10—

Left

Tie Rod Socket 11—

Left

Steering Tie Rod

12—

Left

Tie Rod Socket 13—

Right

Tie Rod Socket

14—

Beilcrank

Nut

15—

Washer

16— Bolt 17—

Beilcrank

Bearing 18—

Bearing

Spacer

(Early

Model) 19—

Washer

20—

Beilcrank

Shaft

21—

Bearing

Seal

22— Nut

23—

Lockwasher

24—

Right

Steering Tie Rod 25—

Right

Shaft and Universal Joint 26—

Right

Steering Knuckle and Arm 313

Page 314 of 376

STEERING

SYSTEM

O-L

GENERAL

The

steering system on all Jeep Universal vehicles

consists of the steering gear, steering wheel, steering column and shaft, and steering linkage.

This

section covers wheel alignment, steering linkage,

steering gear, steering column and steering wheel.

0-2. Steering

Gear

Function

The

steering gear is a reducing gear. It exchanges a

relatively

large amount of movement with a small force (applied by the driver at the steering wheel), for a much smaller amount of movement with a

greatly increased force through a cam and lever

action type steering gear. The steering gear ratio is 17.9 to 1 on vehicles equipped with the F4

engine

and

19 to 1 with the V6 engine.

0-3. Steering

Linkage

Refer

to Fig. O-l.

The

steering linkage consists of a steering arm at

tached to the steering gear, a steering connecting

rod,

(drag

link),

connecting the steering arm to the

beilcrank,

and a steering tie rod connecting the

beilcrank

to the axle tie rod. The beilcrank pivots

on a pin mounted just to the left of the frame front crossmember. The steering tie rod is connected to

the beilcrank and

extends

to the right

ball

joint as sembly of tie rod. The tie rod

extends

to the wheels,

being connected to their respective steering knuckle

arms

at the wheels.

With

this linkage arrangement,

as the steering arm

moves

rearward,

the front

wheels

turn

to the left. As the steering arm

moves

forward,

the wheels

turn

to the right.

Ball

joints are used to secure the drag

link,

steering

connecting rod and tie rod ends. The

ball

joints

assist in maintaining

good

steering control and con

stant toe-in of the front wheels under all driving conditions. If the

ball

joints

become

worn enough

to allow free motion in the linkage, they should be,

replaced.

Note:

Ball

joint replacement of the tie rod requires

resetting of the wheel toe-in adjustment.

0-4.

Steering

Column

and Gear

Alignment

When

adjusting a steering gear remove all loads

from

the unit by disconnecting the steering con

necting rod (drag

link)

from the steering arm and

also

loosen

the instrument panel bracket and the

steering gear to frame

bolts

to allow the steering

post

to correctly align itself. When retightening the

steering gear to frame

bolts

use a torque wrench

pull

of 45 to 55 lb-ft. [6,2 a 7,6 kg-m.] on the

Vk*

bolts

and 30 to 40 lb-ft. [4,15 a 5,5 kg-m.] on the

Vs"

bolts. 10811

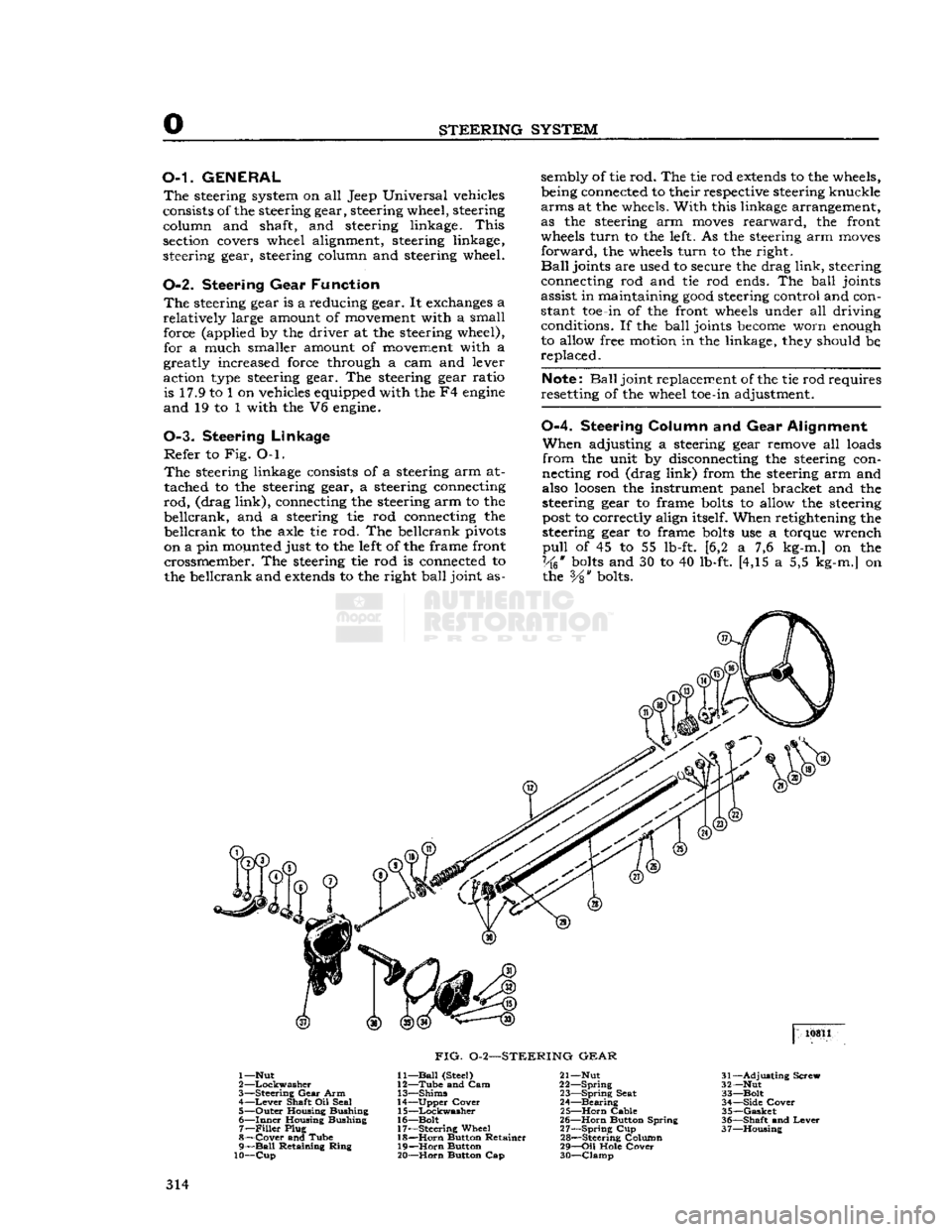

FIG.

0-2—STEERING

GEAR

1—Nut

2

—Lockwasher

3—

Steering

Gear

Arm 4—

Lever

Shaft Oil Seal

5—

Outer

Housing Bushing

6—

Inner

Housing Bushing 7—

Filler

Plug

8—

Cover

and Tube

9—

Ball

Retaining

Ring

10—Cup

11—

Ball

(Steel)

12—

Tube

and Cam

13—

Shims

14—

Upper

Cover

15—

Lockwasher

16—

Bolt

17—

Steering

Wheel 18—

Horn

Button Retainer

19—

Horn

Button

20—

Horn

Button Cap 21— Nut

22—

Spring

23—

Spring

Seat

24—

Bearing

25—

Horn

Cable

26—

Horn

Button Spring

27—

Spring

Cup

28—

Steering Column

29—

Oil

Hole

Cover

30—

Clamp

31—

Adjusting

Screw

32— Nut

33—

Bolt

34—

Side

Cover

35—

Gasket

36—

Shaft

and

Lever

37—

Housing

314

Page 315 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

O Note:

If the steering-gear-to-frame

bolts

are not

properly

torqued, they

will

eventually

loosen

dur

ing operation of the vehicle. Loose

bolts

will

result

in

elongated

bolt

holes

making maintenance of bolt torque difficult, and may allow position of the

steering columns to be misaligned. Therefore,

proper

torquing is extremely important.

Do not tighten the steering gear to dampen out

steering trouble. Adjust the steering gear only to

remove lost motion or play within the unit.

0-5. Steering

Gear

Adjustment

The

cam and lever steering gear is illustrated in

Fig.

0-2. It consists of a

spiral

cam, and a cross shaft and lever assembly with two lever studs.

When

the steering wheel is turned, the cam

moves

the studs, causing rotary movement of the cross

shaft, which in

turn

causes angular movement of

the*steering arm.

Two

adjustments of the steering gear are necessary:

up and down play of the steering shaft, and adjustment of the lever studs (tapered pins) in the

cam

groove.

Adjustment

of the

ball

thrust bearings to eliminate up and down play of the steering shaft is ac

complished by removing shims which are installed

between

the steering gear housing and the upper

cover. Before making this adjustment

loosen

the

housing side cover adjusting screw to free the pins

in

the cam groove. Loosen the housing cover to

cut and remove a shim or more as required.

Install

the screws and tighten. Adjustment should be

made to have a slight drag but allow the steering

wheel to

turn

freely with thumb and forefinger

lightly gripping the rim.

Shims

installed for adjustment are .002*, .003", and .010"

[.0508,

.0762

and .254 mm.] in thickness.

Adjustment

of the tapered pins in the cam

groove

is accomplished by adjusting screw. Unlock the

adjusting

screw and

turn

it in until a very slight

drag

is felt through the mid-position when turning

the steering wheel slowly from one extreme position

to the other.

Backlash

of the pins in the

groove

shows up as

end play of lever shaft, also as backlash of steer ing arm.

The

cam

groove

is purposely cut shallow in the

straight

ahead driving position for each pin.

This

feature permits a

close

adjustment for normal

straight

ahead driving and provides precision steer ing and permits take up of backlash at this point

after the wear occurs without causing a bind else

where.

Always

adjust within the high range through

the mid-position of pin travel. Do not adjust off

"straight

ahead" position.

Backlash

in turned posi

tions is not objectionable.

0-6.

Front

Wheel Alignment Adjustments

To

ensure correct alignment, a definite procedure

for inspection of the steering system is recom mended. It is

suggested

that the following sequence

be used:

a.

Equalize

tire pressures and level vehicle.

b.

Check

steering gear to steering column align

ment.

c.

Inspect steering knuckle pivots, spindle, and

wheel bearing

looseness.

d.

Check

wheel runout.

e.

Test wheel balance and bearing adjustment.

f.

Check

for spring sag.

g.

Inspect brakes and shock absorbers.

h.

Check

steering gear assembly adjustment and

steering connecting rod.

i.

Check

caster,

j.

Check

toe-in.

k.

Check

toe-out

on turns.

I.

Check

camber.

m.

Check

tracking of front and

rear

wheels,

n.

Check

frame alignment.

The

factors of alignment, caster, camber, and toe-

in,

are all interrelated and if one adjustment is

made, another adjustment may be affected.

There

fore, after an alignment job is completed, make a

complete recheck of all the adjustments to be sure

the

settings

are within the limit. Be sure all front

suspension and steering system nuts and

bolts

are

all

properly torqued before taking wheel alignment readings.

Proper

alignment of front wheels must be main

tained in order to ensure

ease

of steering and satisfactory tire life.

The

most important factors of front wheel alignment are wheel camber, axle caster and wheel

toe-in.

Wheel

toe-in is the distance the wheels are closer

together

at the front than at the

rear.

Wheel

camber is the amount the wheels incline out

ward

at the top from a vertical position.

Front

axle caster is the amount in

degrees

that the

steering pivot pins are tilted towards the front or

rear

of the vehicle. Positive caster is inclination of

the top of the pivot pin towards the

rear

of the ve

hicle.

Zero caster is the vertical position of the

pivot pin. Negative or reverse caster is the in

clination

of the top of the pin towards the front

of the vehicle.

These

points should be checked at regular inter

vals,

particularly when the front axle has been

subjected to a heavy impact. When checking wheel alignment, it is important that wheel bearings and

knuckle

bearings be in proper adjustment. Loose bearings

will

affect instrument readings when

checking

the camber, pivot pin inclination and

toe-in.

To

accurately check camber and caster, use a wheel

aligning fixture.

Camber

and caster of the front

wheels are both preset.

Camber

cannot be altered

but caster can be adjusted by installing caster shims

between

the axle pad and the springs. Wheel toe-in

may

be adjusted. To measure wheel toe-in, use a

wheel aligning fixture or follow the procedure given

in Par.

0-8.

0-7.

Front Wheel Toe-in

Toe-in

as illustrated in

Fig.

0-3, is necessary to

off

set the

effect

of camber as shown in Fig. Q-4. 315

Page 318 of 376

o

STEERING

SYSTEM

10

FIG.

0-7—STEERING

CONNECTING

ROD

(DRAG

LINK)

10696

1—Cotter Pin

2>—Large

Plug

3—

Ball

Seat

4—

Ball

Seat Spring 5—

Spring

Plug

shaft,

tightness

of the steering gear in the frame,

tightness

of steering gear arm, adjustment of the

steering connecting rod and condition of the steer ing tie rod

ball

joint ends. Adjust the steering con

necting rod (drag

link)

to maximum safe

tightness

at both ends. Examine the steering beilcrank bearings, the shaft in the mounting bracket, and

the mounting bracket on the frame cross member,

k.

Check

front axle caster.

This

should be the same

on both sides, otherwise a locking brake may be

indicated

causing a twisting action of the axle.

Correct

caster is shown in specifications at the end

of this section.

I.

Check

the front wheel toe-in. See Specifications,

m.

Check

wheel

toe-out

on turns.

This

gives

you

an

indication of the proper angularity of the steer

ing knuckle arms and tells whether or not they have been bent and require replacing. These may be checked by comparing them with new parts. If

an

arm is bent, check for a bent tie rod.

n.

Check

wheel camber.

This

should be the same

on both wheels as shown on the Specifications,

o.

Check

the king pin inclination. See Specifica tions.

p.

Check

the tracking of the front axle and frame

alignment, which may be incorrect due to an accident.

0-14.

STEERING

LINKAGE

SERVICE

The

steering linkage must maintain constant toe-

in

and

good

steering control under all driving

conditions.

This

requires

ball

joints at each end

of the tie rods and steering connecting rod. All

joints in the steering linkage must be kept well

lubricated

for easy operation and long life. Should

the joints be worn, allowing excessive free motion

in

the linkage, the joints must be replaced. When

ever

ball

joints are replaced, toe-in must be reset. Because

some

members of the steering system may

have

become

bent or distorted, a periodic inspection

should be made.

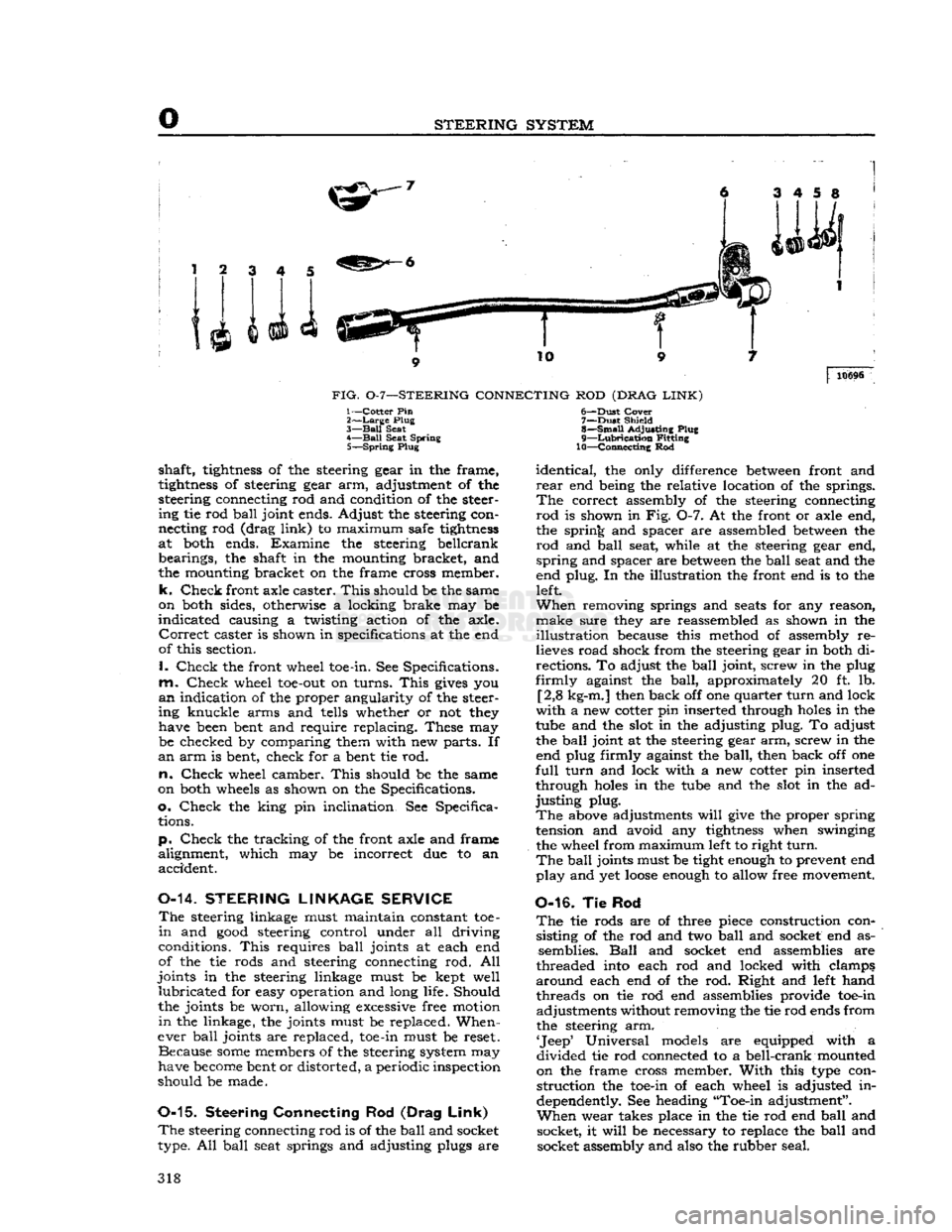

0-15.

Steering Connecting

Rod

(Drag

Link)

The

steering connecting rod is of the

ball

and socket

type. All

ball

seat springs and adjusting plugs are 6—

-Dust

Cover

7—

Dust

Shield

8—

Small

Adjusting Plug

9—

Lubrication

Fitting

10—Connecting Rod

identical,

the only difference

between

front and

rear

end being the relative location of the springs.

The

correct assembly of the steering connecting

rod

is shown in Fig. 0-7. At the front or axle end,

the spring and spacer are assembled

between

the

rod

and

ball

seat, while at the steering gear end,

spring

and spacer are

between

the

ball

seat and the

end plug. In the illustration the front end is to the left.

When

removing springs and

seats

for any reason,

make

sure they are reassembled as shown in the

illustration

because this method of assembly re

lieves road shock from the steering gear in both di

rections. To adjust the

ball

joint, screw in the plug

firmly

against the

ball,

approximately 20 ft. lb. [2,8 kg-m.] then back off one quarter

turn

and lock

with

a new cotter pin inserted through

holes

in the

tube and the slot in the adjusting plug. To adjust the

ball

joint at the steering gear arm, screw in the end plug firmly against the

ball,

then back off one

full

turn

and lock with a new cotter pin inserted

through

holes

in the tube and the slot in the ad

justing

plug.

The

above adjustments

will

give

the proper spring

tension and avoid any

tightness

when swinging

the wheel from maximum left to right

turn.

The

ball

joints must be tight enough to prevent end

play

and yet

loose

enough to allow free movement.

0-16. Tie Rod

The

tie rods are of three piece construction consisting of the rod and two

ball

and socket end as semblies.

Ball

and socket end assemblies are

threaded into each rod and locked with clamps,

around

each end of the rod. Right and left hand threads on tie rod end assemblies provide toe-in adjustments without removing the tie rod ends from

the steering arm.

'Jeep'

Universal models are equipped with a

divided

tie rod connected to a bell-crank mounted

on the frame cross member.

With

this type con

struction

the toe-in of each wheel is adjusted in

dependently. See heading "Toe-in adjustment".

When

wear takes place in the tie rod end

ball

and socket, it

will

be necessary to replace the

ball

and socket assembly and also the rubber seal. 318