belt JEEP CJ 1953 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 147 of 376

'Jeep'

UNIVERSAL SERIES

SERVICE

MANUAL

Fl

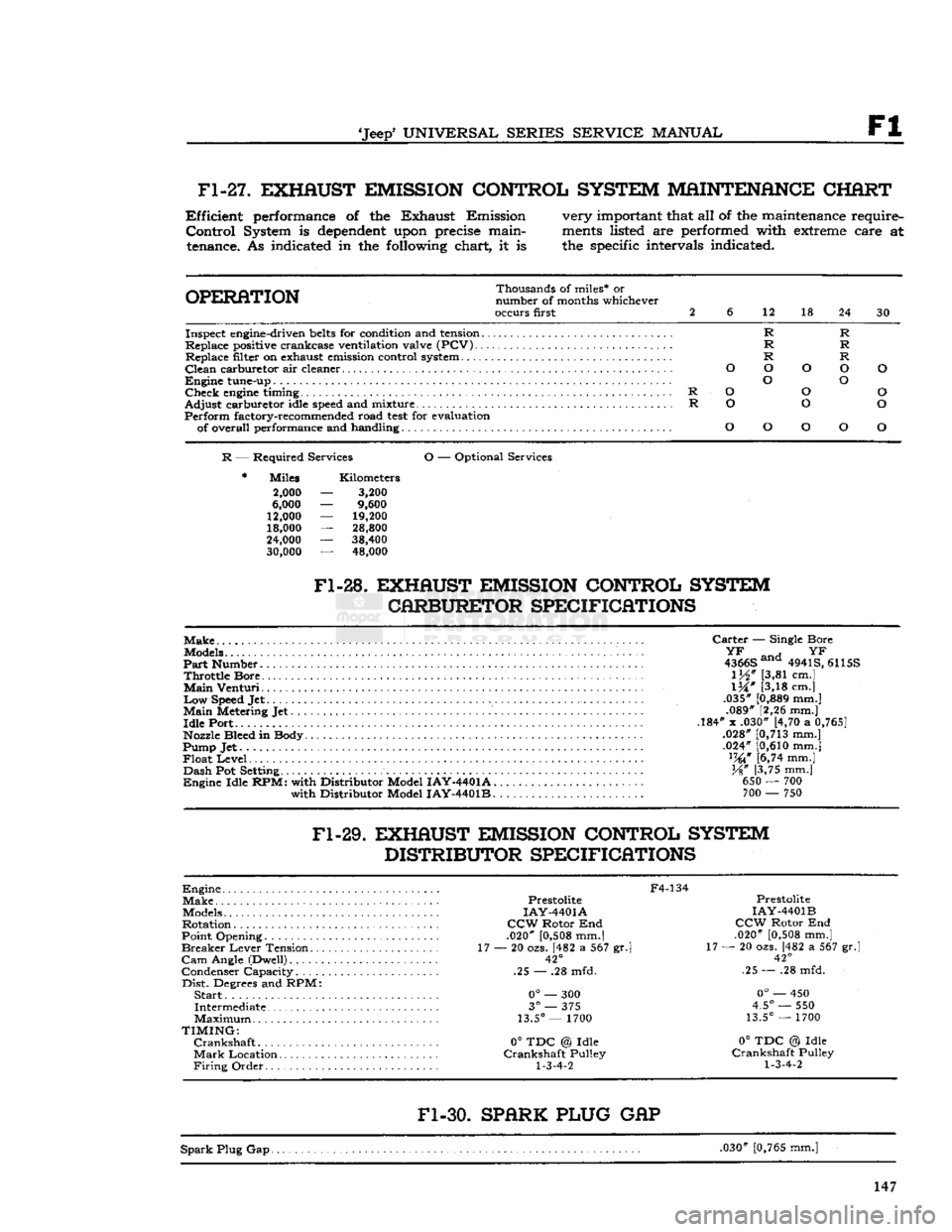

Fl-27.

EXHAUST EMISSION CONTROL SYSTEM MAINTENANCE CHART

Efficient

performance of the Exhaust Emission

Control

System is

dependent

upon precise maintenance. As indicated in the following chart, it is very important that all of the maintenance require

ments

listed are performed with extreme care at

the specific intervals indicated.

OPERATION

Thousands of miles* or

number of months whichever

occurs first 2

6

12 18

24 30

R R

R R

R R

O O o O

O

o O

R

O

o

o

R

o

o o

o

o

o

O

o

Inspect engine-driven

belts

for condition and tension...

Replace positive crankcase ventilation valve (PCV) Replace filter on exhaust emission control system

Clean

carburetor air cleaner

Engine

tune-up

Check

engine

timing

Adjust

carburetor idle

speed

and mixture

Perform

factory-recommended road

test

for evaluation of overall performance and handling

R

— Required Services

O

— Optional Services

Miles

2,000

6,000

12,000

18,000

24,000

30,000

Kilometers

3,200

9,600

19,200

28,800

38,400 48,000

Fl-28.

EXHAUST EMISSION CONTROL SYSTEM CARBURETOR SPECIFICATIONS

Make

Models

Part

Number

Throttle

Bore

Main

Venturi

Low

Speed Jet

Main

Metering Jet

Idle

Port

Nozzle Bleed in Body

Pump Jet

Float

Level

Dash

Pot Setting

Engine

Idle

RPM:

with Distributor Model

IAY-4401A.

with Distributor Model

IAY-4401B.

Carter

— Single Bore

^ an H

YF

4366S ana 4941S, 6115S

1M"

[3,81 cm.]

IX"

[3,18 cm.]

.035"

[0,889

mm.] .089" [2,26 mm.]

.184" x .030" [4,70 a

0,765]

.028"

[0,713

mm.]

.024"

[0,610

mm.] lW [6,74 mm.]

%"

[3,75 mm.] 650 — 700 700 — 750

Fl-29.

EXHAUST EMISSION CONTROL SYSTEM DISTRIBUTOR SPECIFICATIONS

Engine

Make

Models

Rotation

Point Opening

Breaker

Lever

Tension..

Cam

Angle (Dwell)

Condenser Capacity

Dist.

Degrees and RPM:

Start..

Intermediate

Maximum

TIMING:

Crankshaft

Mark

Location

Firing

Order

F4-134

Prestolite

IAY-4401A

CCW

Rotor End

.020"

[0,508

mm.|

17 — 20 ozs. [482 a 567 gr.l

42°

.25 — .28 mfd.

0°

— 300

3°

— 375

13.5°

— 1700

0°

TDC @ Idle

Crankshaft

Pulley

1-3-4-2

Prestolite

IAY-4401B

CCW

Rotor End

.020"

[0,508

mm.]

17 — 20 ozs. [482 a 567 gr.

42°

.25 — .28 mfd.

0°

— 450

4.5°

— 550

13.5°

— 1700

0°

TDC @ Idle

Crankshaft

Pulley

1-3-4-2

Fl-30.

SPARK PLUG

GAP

Spark

Plug Gap. .030"

[0,765

mm.] 147

Page 149 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

Fl

EXHAUST

EMISSION

CONTROL

SYSTEM

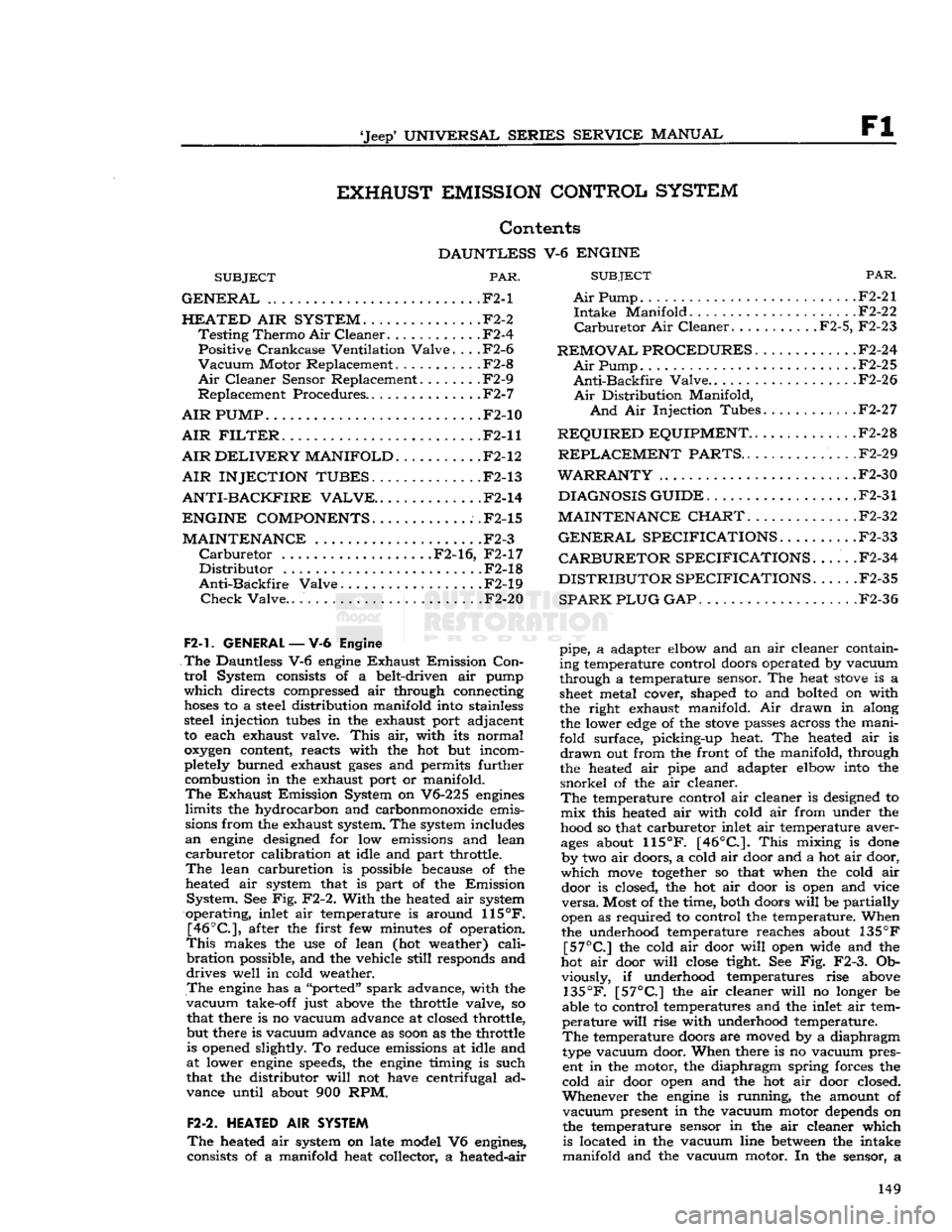

Contents

DAUNTLESS

V-6

ENGINE

SUBJECT

PAR.

GENERAL

.F2-1

HEATED

AIR

SYSTEM.

. F2-2

Testing

Thermo

Air

Cleaner

F2-4

Positive

Crankcase

Ventilation

Valve.

. . .F2-6

Vacuum

Motor Replacement . .F2-8

Air

Cleaner Sensor Replacement F2-9

Replacement Procedures F2-7

AIR

PUMP

.F2-10

AIR

FILTER.

F2-11

AIR

DELIVERY

MANIFOLD.

F2-12

AIR INJECTION TUBES.

F2-13

ANTI-BACKFIRE

VALVE..

.F2-14

ENGINE COMPONENTS

.F2-15

MAINTENANCE

.F2-3

Carburetor

F2-16, F2-17

Distributor

F2-18

Anti-Backfire

Valve . . F2-19

Check

Valve..

F2-20

F2-1.

GENERAL

—V-6

Engine

The

Dauntless V-6

engine

Exhaust

Emission

Con

trol

System consists of a belt-driven air pump

which

directs compressed air through connecting

hoses

to a steel distribution manifold into stainless steel injection

tubes

in the exhaust port adjacent

to each exhaust valve.

This

air, with its normal

oxygen

content, reacts with the hot but incom

pletely burned exhaust

gases

and permits further combustion in the exhaust port or manifold.

The

Exhaust

Emission System on V6-225

engines

limits

the hydrocarbon and carbonmonoxide emissions from the exhaust system. The system includes

an

engine

designed for low emissions and lean

carburetor

calibration at idle and part throttle.

The

lean carburetion is possible because of the

heated air system that is part of the Emission

System.

See Fig. F2-2.

With

the heated air system

operating, inlet air temperature is around

115°F.

[46°C],

after the first few minutes of operation.

This

makes the use of lean (hot weather)

cali

bration

possible, and the vehicle

still

responds and

drives

well in cold weather.

The

engine

has a "ported"

spark

advance, with the

vacuum

take-off just above the throttle valve, so that there is no vacuum advance at closed throttle,

but there is vacuum advance as

soon

as the throttle is opened slightly. To reduce emissions at idle and

at lower

engine

speeds, the

engine

timing is such

that the distributor

will

not have centrifugal ad

vance until about 900 RPM.

F2-2.

HEATED

AIR

SYSTEM

The

heated air system on late model V6 engines,

consists of a manifold heat collector, a heated-air

SUBJECT

PAR.

Air

Pump F2-21

Intake

Manifold F2-22

Carburetor

Air Cleaner F2-5, F2-23

REMOVAL PROCEDURES

F2-24

Air

Pump. F2-25

Anti-Backfire

Valve..

. . .F2-26

Air

Distribution Manifold,

And

Air Injection Tubes F2-27

REQUIRED

EQUIPMENT..

. F2-28

REPLACEMENT

PARTS..

.F2-29

WARRANTY

F2-30

DIAGNOSIS GUIDE

F2-31

MAINTENANCE CHART.

F2-32

GENERAL

SPECIFICATIONS

F2-33

CARBURETOR SPECIFICATIONS.

.... .F2-34

DISTRIBUTOR SPECIFICATIONS

. .F2-35

SPARK PLUG GAP

F2-36

pipe, a adapter elbow and an air cleaner containing temperature control doors operated by vacuum

through a temperature sensor. The heat

stove

is a

sheet

metal cover, shaped to and bolted on with

the right exhaust manifold. Air drawn in along the lower

edge

of the

stove

passes across the mani

fold surface, picking-up heat. The heated air is

drawn

out from the front of the manifold, through

the heated air pipe and adapter elbow into the

snorkel

of the air cleaner.

The

temperature control air cleaner is designed to mix this heated air with cold air from under the

hood so that carburetor inlet air temperature aver

ages

about

115°F.

[46°C.].

This

mixing is

done

by two air doors, a cold air door and a hot air door,

which

move

together

so that when the cold air door is closed, the hot air door is open and vice

versa.

Most of the time, both doors

will

be partially

open as required to control the temperature. When

the underhood temperature reaches about 135

°F

[57°C]

the cold air door

will

open wide and the

hot air door

will

close

tight See Fig. F2-3. Ob viously, if underhood temperatures rise above

135°F.

[57°C]

the air cleaner

will

no longer be

able to control temperatures and the inlet air tem

perature

will

rise with underhood temperature.

The

temperature doors are moved by a diaphragm

type vacuum door. When there is no vacuum pres ent in the motor, the diaphragm spring forces the

cold air door open and the hot air door closed.

Whenever

the

engine

is running, the amount of

vacuum

present in the vacuum motor depends on

the temperature sensor in the air cleaner which is located in the vacuum line

between

the intake

manifold and the vacuum motor. In the sensor, a 149

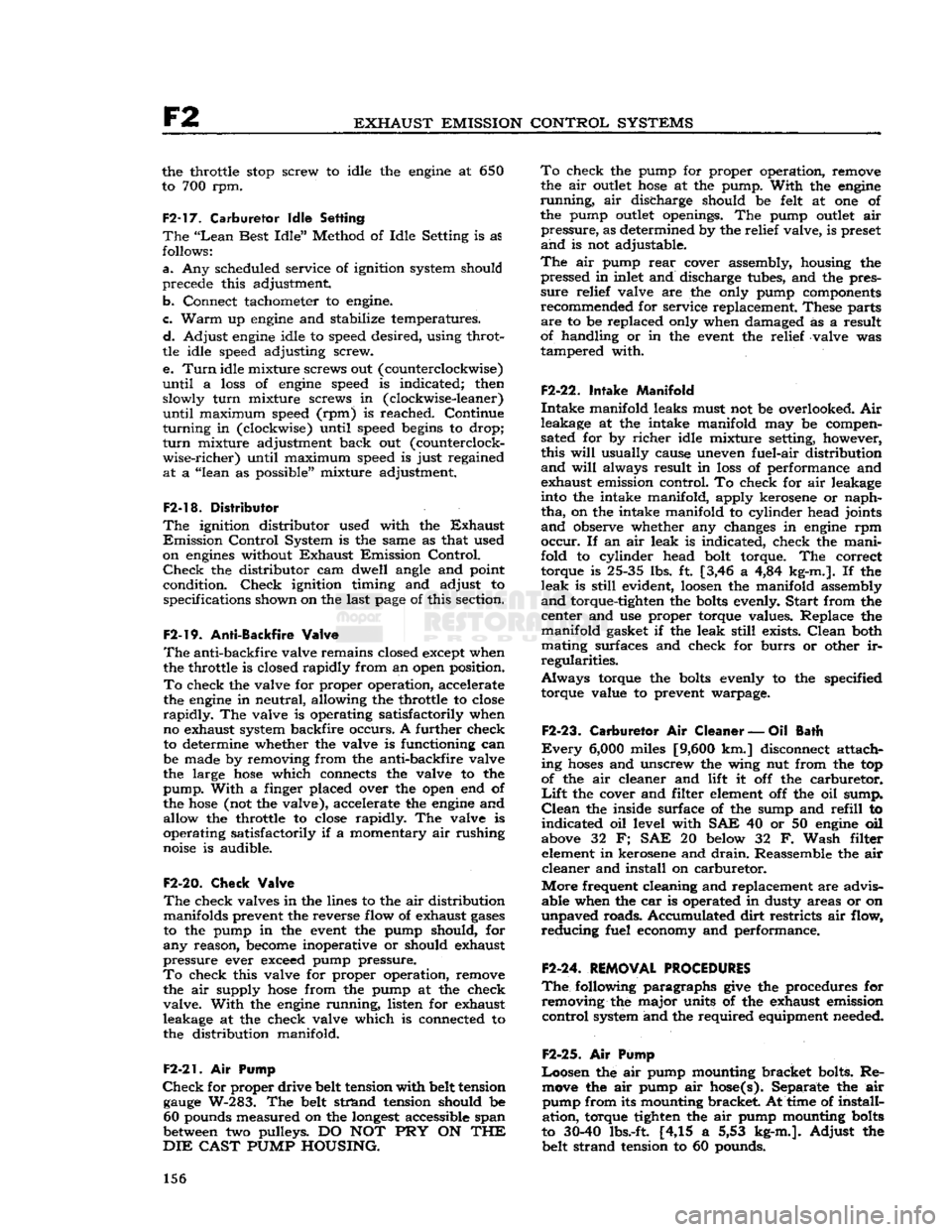

Page 156 of 376

F2

EXHAUST EMISSION CONTROL SYSTEMS

the throttle

stop

screw to idle the

engine

at 650

to 700 rpm.

F2-17. Carburetor Idle Setting

The

"Lean

Best

Idle"

Method of Idle Setting is as

follows:

a.

Any scheduled service of ignition system should

precede this adjustment

b.

Connect tachometer to engine.

c.

Warm

up

engine

and stabilize temperatures.

d.

Adjust

engine

idle to speed desired, using throt

tle idle speed adjusting screw.

e.

Turn

idle mixture screws out (counterclockwise)

until

a

loss

of

engine

speed is indicated; then slowly

turn

mixture screws in (clockwise-leaner)

until

maximum speed (rpm) is reached. Continue

turning

in (clockwise) until speed begins to drop;

turn

mixture adjustment back out (counterclock

wise-richer)

until maximum speed is just regained

at

a "lean as possible" mixture adjustment.

F2-18. Distributor

The

ignition distributor used with the

Exhaust

Emission

Control

System is the same as that used

on

engines

without

Exhaust

Emission

Control.

Check

the distributor cam dwell angle and point

condition.

Check

ignition timing and adjust to specifications shown on the last

page

of this section.

F2-19.

Anti-Backfire

Valve

The

anti-backfire valve remains closed except when

the throttle is closed rapidly from an open position.

To

check the valve for proper operation, accelerate

the

engine

in neutral, allowing the throttle to close

rapidly.

The valve is operating satisfactorily when

no exhaust system backfire occurs. A further check

to determine whether the valve is functioning can

be made by removing from the anti-backfire valve

the large

hose

which connects the valve to the

pump.

With

a finger placed over the open end of

the

hose

(not the valve), accelerate the

engine

and allow the throttle to close rapidly. The valve is

operating satisfactorily if a momentary air rushing

noise is audible.

F2-20.

Check

Valve

The

check valves in the lines to the air distribution manifolds prevent the reverse flow of exhaust

gases

to the pump in the event the pump should, for

any

reason,

become

inoperative or should exhaust

pressure

ever exceed pump pressure.

To

check this valve for proper operation, remove the air supply

hose

from the pump at the check

valve.

With

the

engine

running, listen for exhaust

leakage at the check valve which is connected to

the distribution manifold.

F2-21.

Air

Pump

Check

for proper drive belt tension with belt tension

gauge

W-283. The belt strand tension should be 60 pounds measured on the

longest

accessible span

between two pulleys. DO NOT PRY ON THE

DIE

CAST

PUMP

HOUSING. To

check the pump for proper operation, remove

the air

outlet

hose

at the pump.

With

the

engine

running,

air discharge should be felt at one of

the pump

outlet

openings. The pump

outlet

air

pressure,

as determined by the relief valve, is preset

and

is not adjustable.

The

air pump

rear

cover assembly, housing the pressed in inlet and discharge tubes, and the pres

sure

relief valve are the only pump components

recommended for service replacement. These parts

are

to be replaced only when damaged as a result

of handling or in the event the relief valve was

tampered with.

F2-22.

Intake Manifold

Intake

manifold leaks must not be overlooked. Air

leakage at the intake manifold may be compen

sated for by

richer

idle mixture setting, however, this

will

usually cause uneven fuel-air distribution

and

will

always result in

loss

of performance and

exhaust emission control. To check for air leakage

into the intake manifold, apply kerosene or naph

tha,

on the intake manifold to cylinder head joints

and

observe whether any changes in

engine

rpm

occur.

If an air leak is indicated, check the mani

fold to cylinder head bolt torque. The correct torque is 25-35 lbs. ft. [3,46 a 4,84 kg-m.]. If the

leak

is

still

evident,

loosen

the manifold assembly

and

torque-tighten the bolts evenly.

Start

from the center and use proper torque values. Replace the

manifold

gasket if the leak

still

exists.

Clean

both

mating surfaces and check for

burrs

or other ir

regularities.

Always

torque the bolts evenly to the specified

torque value to prevent warpage.

F2-23.

Carburetor

Air

Cleaner

—Oil

Bath

Every

6,000

miles [9,600 km.] disconnect attach

ing

hoses

and unscrew the wing nut from the top

of the air cleaner and lift it off the carburetor.

Lift

the cover and filter element off the oil sump.

Clean

the inside surface of the sump and

refill

to

indicated

oil level with SAE 40 or 50

engine

oil

above 32 F; SAE 20 below 32 F.

Wash

filter element in kerosene and

drain.

Reassemble the air

cleaner

and install on carburetor.

More

frequent cleaning and replacement are advis able when the car is operated in dusty areas or on

unpaved

roads. Accumulated

dirt

restricts air flow,

reducing

fuel economy and performance.

F2-24.

REMOVAL PROCEDURES

The

following paragraphs

give

the procedures for removing the major units of the exhaust emission

control

system and the required equipment needed.

F2-2S.

Air

Pump

Loosen

the air pump mounting bracket bolts. Re move the air pump air hose(s). Separate the air pump from its mounting bracket. At time of install

ation,

torque tighten the air pump mounting bolts

to

30-40

lbs.-ft [4,15 a 5,53 kg-m.].

Adjust

the

belt strand tension to 60 pounds. 156

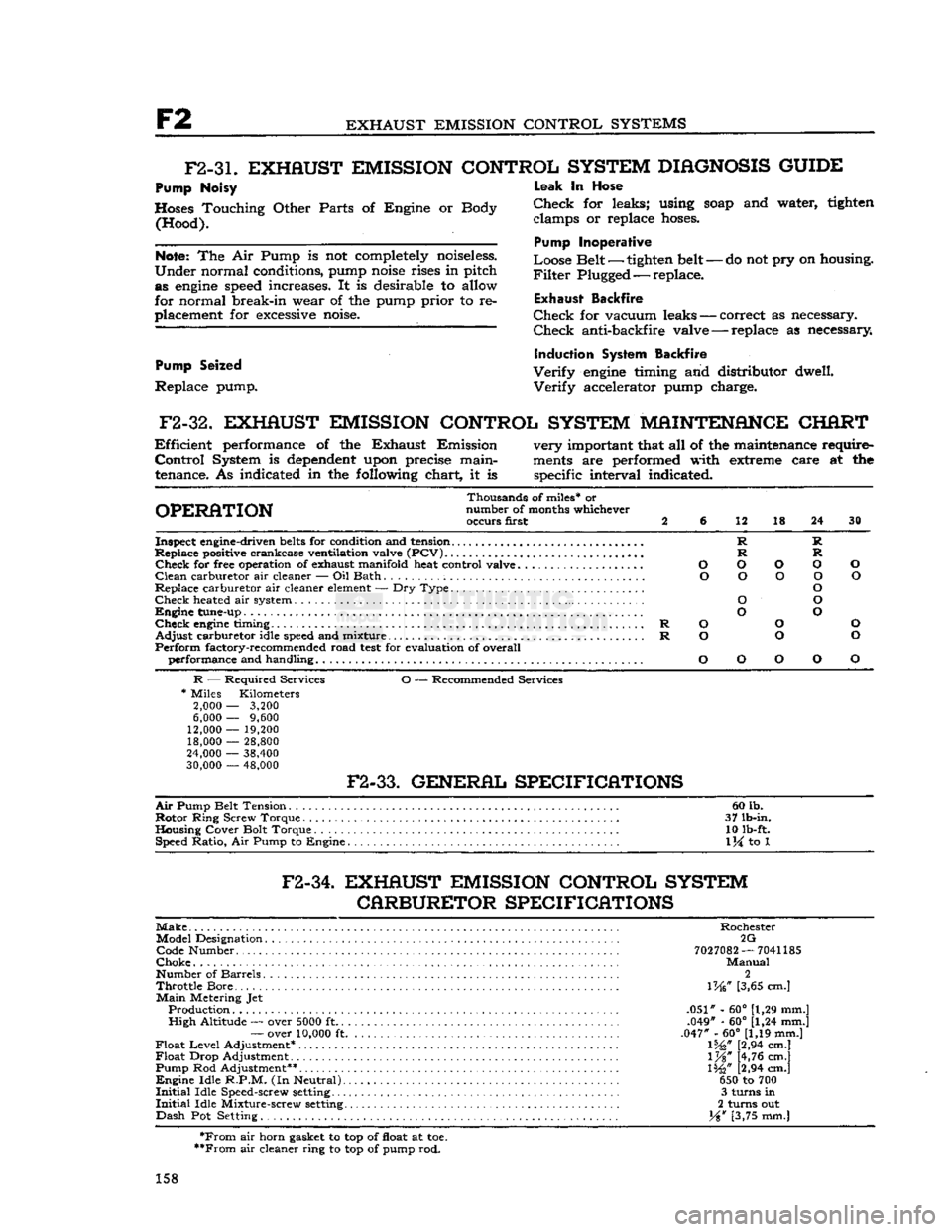

Page 158 of 376

F2

EXHAUST EMISSION CONTROL SYSTEMS

F2-3L

EXHAUST EMISSION CONTROL SYSTEM

DIAGNOSIS

GUIDE

Pump Noisy

Hoses Touching Other Parts of Engine or Body (Hood).

Note:

The Air Pump is not completely noiseless.

Under

normal conditions, pump

noise

rises in pitch as

engine

speed

increases. It is desirable to allow

for normal break-in wear of the pump prior to re

placement for

excessive

noise.

Pump Seized

Replace pump.

-

do not pry on housing.

Leak

In Hose

Check

for leaks; using

soap

and water, tighten clamps or replace

hoses.

Pump Inoperative

Loose Belt — tighten belt

-

Filter

Plugged — replace.

Exhaust

Backfire

Check

for vacuum leaks — correct as necessary.

Check

anti-backfire valve — replace as necessary

Induction System Backfire

Verify

engine

timing and distributor dwell.

Verify

accelerator pump charge.

F2-32.

EXHAUST EMISSION CONTROL SYSTEM MAINTENANCE CHART

Efficient

performance of the Exhaust Emission very important that all of the maintenance require-

Control

System is

dependent

upon precise main-

ments

are performed with extreme care at the

tenance. As indicated in the following chart, it is specific interval indicated.

Thousands of miles* or

OPERATION

number of months whichever occurs first 2 6 12 18 24 30

Inspect engine-driven

belts

for condition and tension R R

Replace positive crankcase ventilation valve

(PCV)

R R

Check

for free operation of exhaust manifold heat control valve O O O O O

Clean

carburetor air cleaner — Oil Bath O O O O O

Replace carburetor air cleaner

element

— Dry Type O

Check

heated air system O O

Engine

tune-up O O

Check

engine

timing R O O O

Adjust

carburetor idle

speed

and mixture R O O O

Perform

factory-recommended road

test

for evaluation of overall performance and handling O O O O O

R

— Required Services O — Recommended Services

*

Miles Kilometers

2,000

—

3,200

6,000

—

9,600

12,000

—

19,200 18,000

—

28,800

24,000

—

38,400

30,000

—

48,000

F2-33.

GENERAL SPECIFICATIONS

Air

Pump Belt Tension 60 lb.

Rotor

Ring Screw Torque . 37 lb-in.

Housing Cover Bolt Torque 10 lb-ft. Speed Ratio, Air Pump to Engine

1

\i to 1

F2-34.

EXHAUST EMISSION CONTROL SYSTEM CARBURETOR SPECIFICATIONS

Make

Rochester Model Designation 2G Code Number

7027082

—

7041185

Choke

Manual

Number of Barrels 2

Throttle

Bore... \W [3,65 cm.]

Main

Metering Jet Production .051" - 60° [1,29 mm.]

High

Altitude — over

5000

ft .049" - 60° [1,24 mm.]

—

over

10,000

ft .047" - 60° [1,19 mm.]

Float

Level

Adjustment* 1%," [2,94 cm.]

Float

Drop Adjustment l%" [4,76 cm.]

Pump Rod Adjustment** 1%" [2,94 cm.]

Engine

Idle

R.P.M.

(In Neutral) 650 to 700

Initial

Idle Speed-screw

setting

3 turns in

Initial

Idle Mixture-screw

setting

2 turns out

Dash

Pot Setting. Y%w [3,75 mm.]

*From

air horn gasket to top of float at toe.

**From

air cleaner ring to top of pump rod.

158

Page 161 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

COOLING

SYSTEM

Contents

SUBJECT

PAR.

GENERAL

.G-l Antifreeze Solutions. .G-l6

Cylinder

Block.

..................

.G-8

Draining

Cooling System............... G-3

Engine

Overheating..

.................

.G-19

Fan

Belt.

......... .........

.G-18

Filling

Cooling System.................

G-2

Inhibited

Coolant Solution .G-l7

Temperature

Sending Unit.

...........

.G-l0

Thermostat

.........................

G-9

RADIATOR

.G-5

Radiator

and Heater Hoses.............

G-7

SUBJECT

PAR.

Radiator

Pressure

Cap.................

G-4

Radiator

Removal and Replacement..... G-6

WATER

PUMP.

. . .G-ll

Water

Pump Disassembly. .............G-13

Water

Pump Inspection.

..............

.G-12

Water

Pump Reassembly.

.............

.G-14

Water

Pump Removal and Replacement. .G-l5

SERVICE

DIAGNOSIS.

.G-20

SPECIFICATIONS

. .G-21

ANTIFREEZE

CHART.

..... ... .G-22

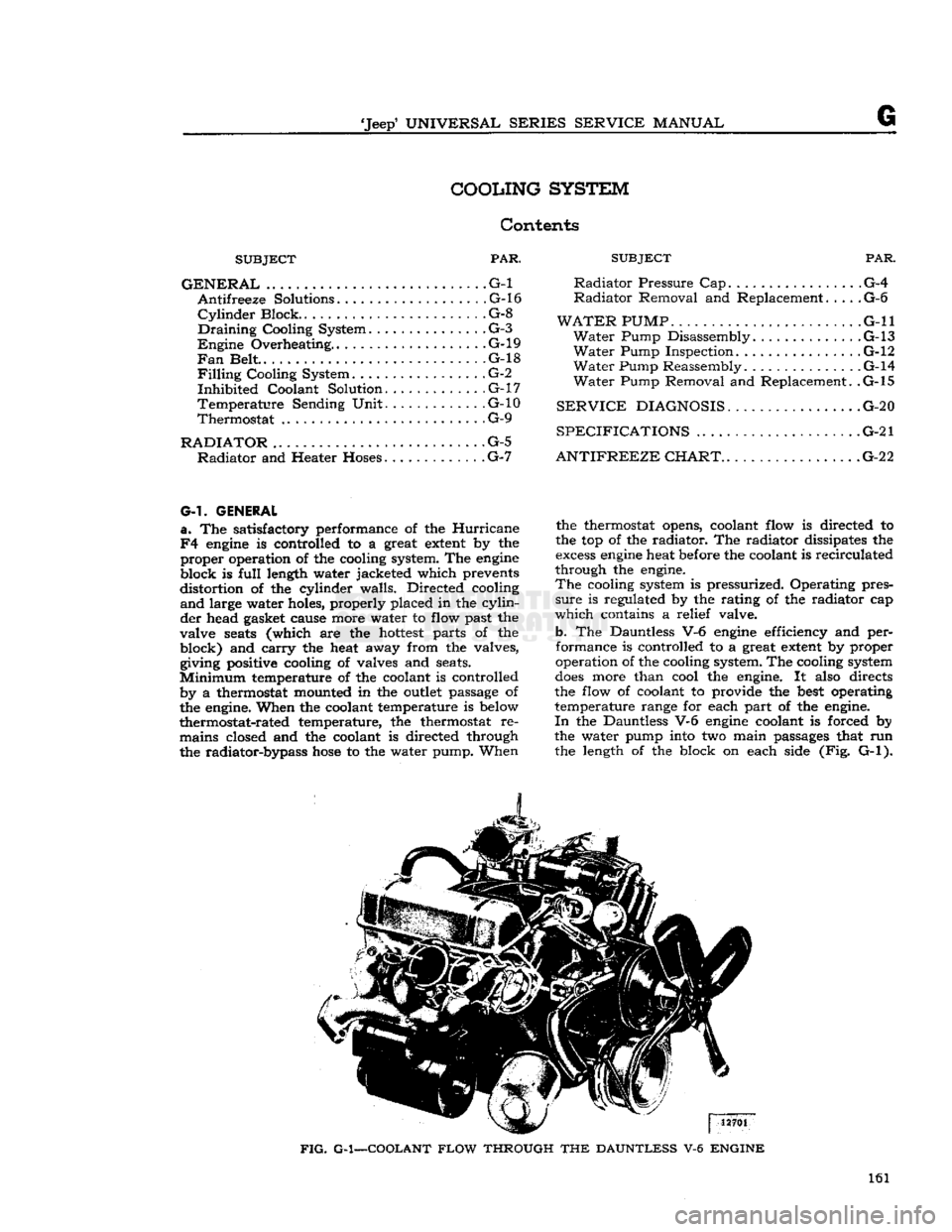

G-l. GENERAL

a.

The satisfactory performance of the Hurricane

F4

engine

is controlled to a great

extent

by the proper operation of the cooling system. The

engine

block is full length water jacketed which prevents

distortion of the cylinder walls. Directed cooling

and

large water holes, properly placed in the cylin

der head gasket cause more water to flow past the

valve

seats

(which are the

hottest

parts of the

block)

and

carry

the heat away from the valves, giving positive cooling of valves and seats.

Minimum

temperature of the coolant is controlled by a thermostat mounted in the

outlet

passage of

the engine. When the coolant temperature is below

thermostat-rated temperature, the thermostat re mains closed and the coolant is directed through

the radiator-bypass

hose

to the water pump. When the thermostat opens, coolant flow is directed to

the top of the radiator. The radiator dissipates the

excess

engine

heat before the coolant is recirculated

through the engine.

The

cooling system is pressurized. Operating pres

sure

is regulated by the rating of the radiator cap

which

contains a relief valve, b. The Dauntless V-6

engine

efficiency and performance is controlled to a great

extent

by proper

operation of the cooling system. The cooling system

does

more than cool the engine. It also directs

the flow of coolant to provide the

best

operating

temperature range for each part of the engine.

In

the Dauntless V-6

engine

coolant is forced by

the water pump into two main passages that run the length of the block on each side (Fig. G-l).

FIG.

G-1—COOLANT

FLOW

THROUGH

THE

DAUNTLESS

V-6

ENGINE

161

Page 162 of 376

COOLING

SYSTEM

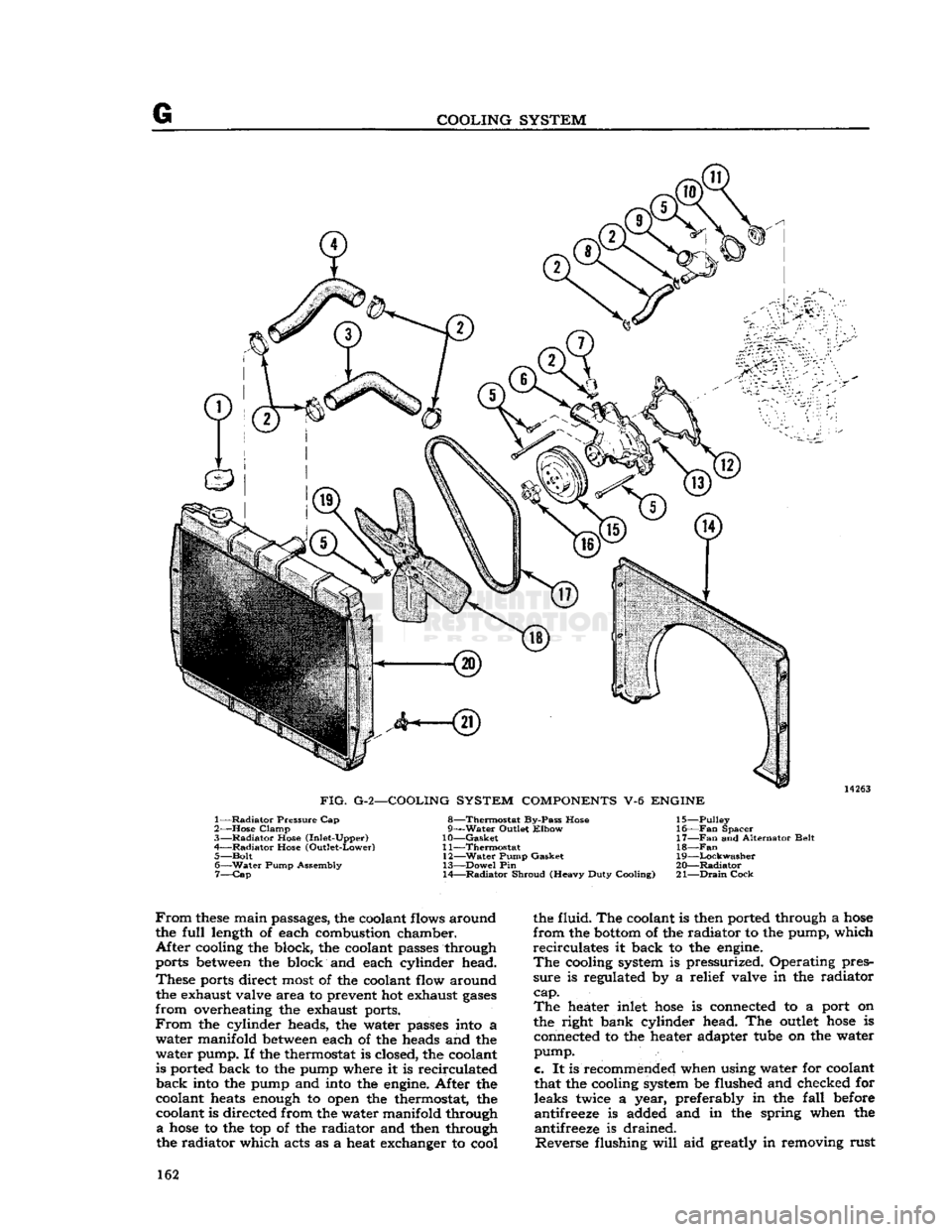

14263

FIG.

G-2—COOLING SYSTEM

COMPONENTS

V-6

ENGINE

1—

Radiator

Pressure Cap

2—

Hose

Clamp

3—

Radiator

Hose (Inlet-Upper)

4—

Radiator

Hose (Outlet-Lower) 5—

Bolt

6—

Water

Pump Assembly 7—

Cap

8—Thermostat

By-Pass Hose

g—Water Outlet

Elbow

10—

Gasket

11—

Thermostat

12—

Water

Pump Gasket

13—

Dowel

Pin

14—

Radiator

Shroud (Heavy Duty Cooling) 15—

Pulley

16—

Fan

Spacer

17—

Fan

and Alternator Belt

18—Fan

19—

Lockwasher

20—

Radiator

21—

Drain

Cock

From

these

main passages, the coolant flows around

the

full

length of each combustion chamber.

After

cooling the block, the coolant passes through

ports between the block and each cylinder head.

These

ports direct most of the coolant flow around the exhaust valve area to prevent hot exhaust

gases

from

overheating the exhaust ports.

From

the cylinder heads, the water passes into a

water

manifold between each of the heads and the

water

pump. If the thermostat is closed, the coolant

is ported back to the pump where it is recirculated

back

into the pump and into the engine. After the

coolant heats enough to open the thermostat, the coolant is directed from the water manifold through

a

hose

to the top of the radiator and then through

the radiator which acts as a heat exchanger to cool the fluid. The coolant is then ported through a

hose

from

the bottom of the radiator to the pump, which

recirculates

it back to the engine.

The

cooling system is pressurized. Operating pres

sure

is regulated by a relief valve in the radiator

cap. The

heater inlet

hose

is connected to a port on

the right bank cylinder head. The outlet

hose

is connected to the heater adapter tube on the water

pump.

c.

It is recommended when using water for coolant

that the cooling system be flushed and checked for leaks twice a year, preferably in the

fall

before

antifreeze is added and in the spring when the antifreeze is drained.

Reverse

flushing

will

aid greatly in removing rust 162

Page 167 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

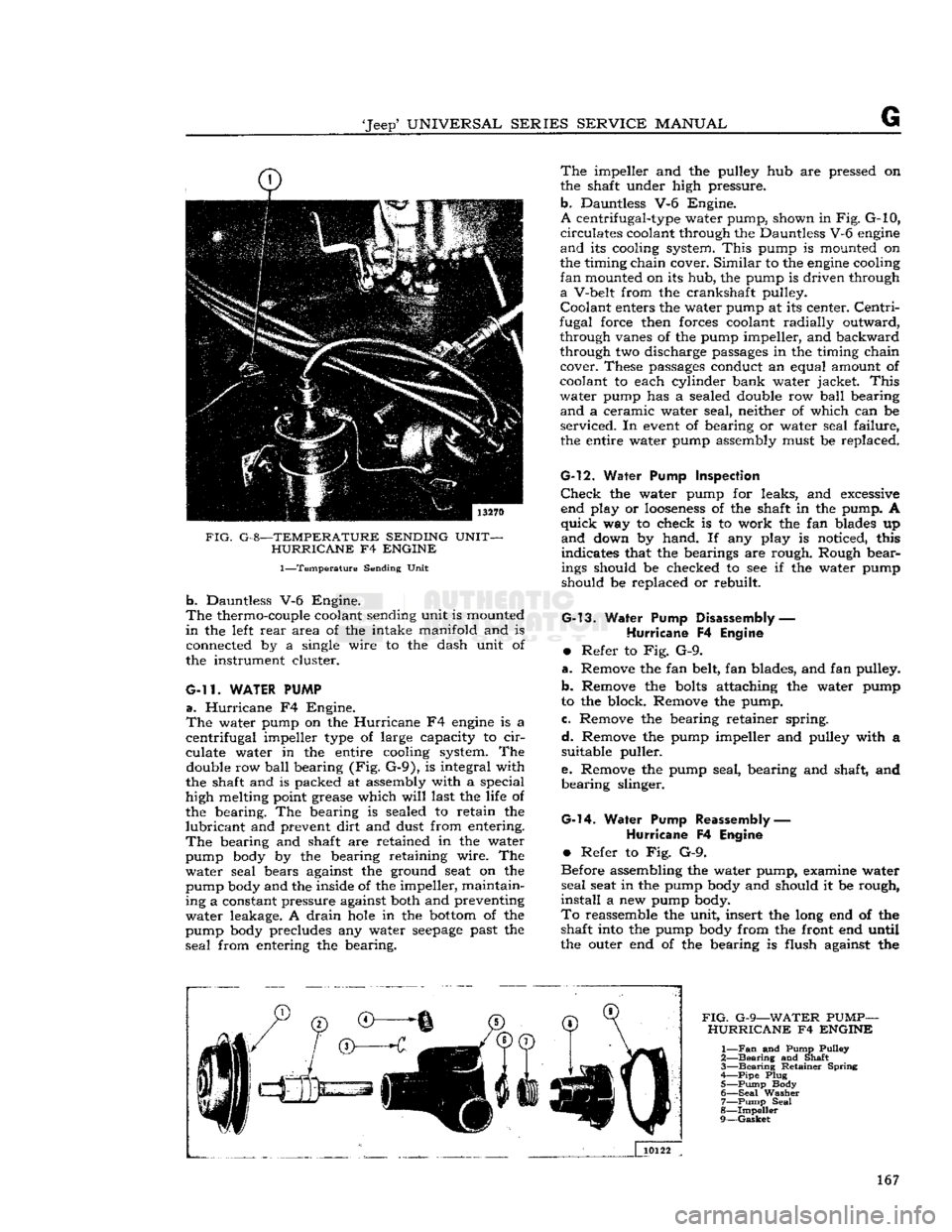

FIG.

G-8—TEMPERATURE SENDING UNIT- HURRICANE

F4

ENGINE

1—Temperature

Sending Unit

b.

Dauntless V-6 Engine.

The

thermo-couple coolant sending unit is mounted

in

the left

rear

area of the intake manifold and is

connected by a single wire to the dash unit of

the instrument cluster.

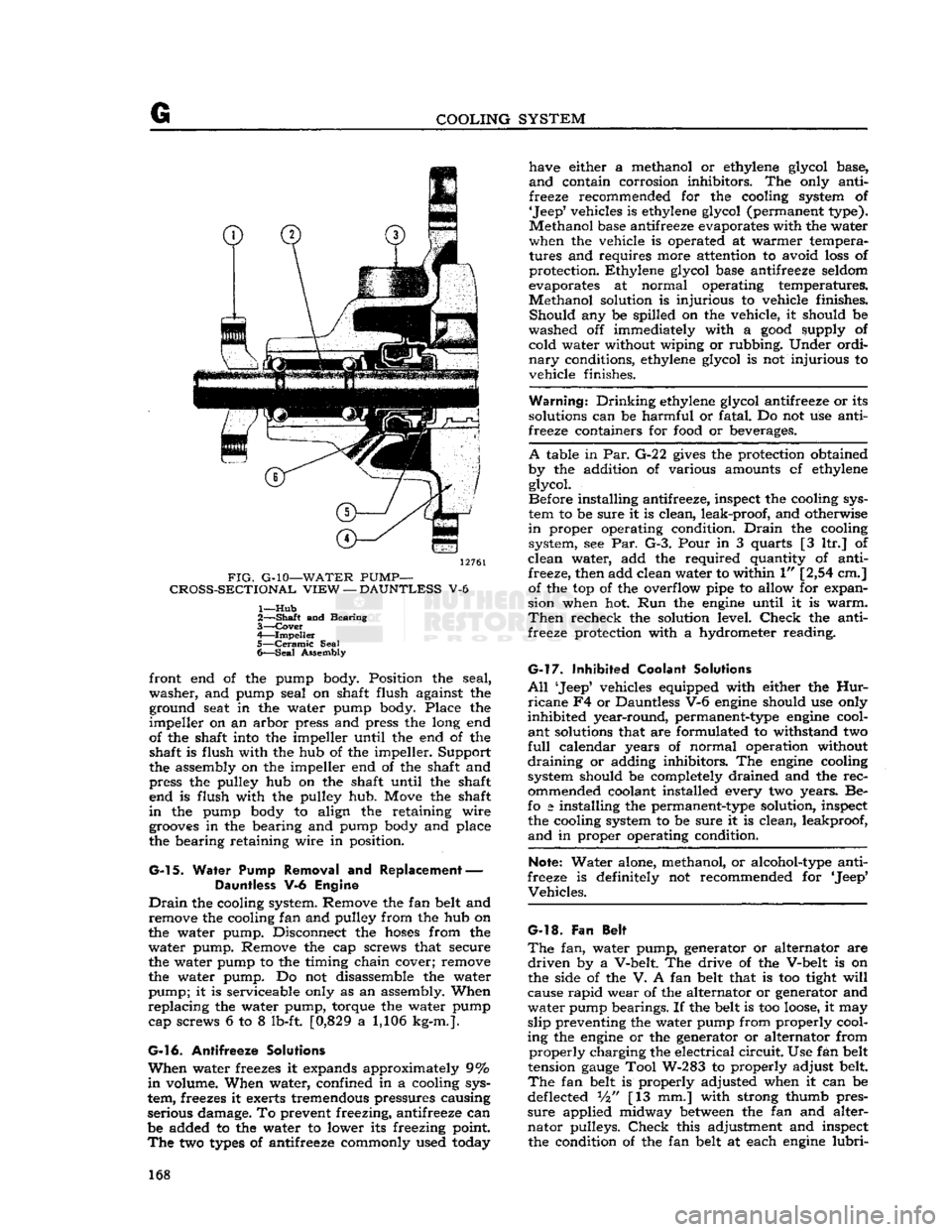

G-ll.

WATER PUMP

a.

Hurricane

F4 Engine.

The

water pump on the

Hurricane

F4

engine

is a

centrifugal

impeller type of large capacity to

cir

culate water in the entire cooling system. The double row

ball

bearing (Fig. G-9), is integral with

the shaft and is packed at assembly with a special

high melting point grease which

will

last the life of

the bearing. The bearing is sealed to retain the

lubricant

and prevent

dirt

and dust from entering.

The

bearing and shaft are retained in the water

pump body by the bearing retaining wire. The

water

seal bears against the ground seat on the

pump body and the inside of the impeller, maintain

ing a constant pressure against both and preventing

water

leakage. A

drain

hole

in the

bottom

of the

pump body precludes any water

seepage

past the

seal

from entering the bearing.

The

impeller and the pulley hub are pressed on

the shaft under high pressure,

b.

Dauntless V-6 Engine.

A

centrifugal-type water pump, shown in

Fig.

G-10,

circulates

coolant through the Dauntless V-6

engine

and

its cooling system.

This

pump is mounted on

the timing chain cover.

Similar

to the

engine

cooling

fan

mounted on its hub, the pump is driven through

a

V-belt from the crankshaft pulley.

Coolant

enters the water pump at its center.

Centri

fugal force then forces coolant radially outward, through vanes of the pump impeller, and backward

through two discharge passages in the timing chain cover. These passages conduct an equal amount of

coolant to each cylinder bank water jacket.

This

water

pump has a sealed double row

ball

bearing

and

a ceramic water seal, neither of which can be

serviced.

In

event

of bearing or water seal failure, the entire water pump assembly must be replaced.

G-l2.

Water

Pump Inspection

Check

the water pump for leaks, and excessive end play or

looseness

of the shaft in the pump. A

quick

way to check is to work the fan blades up

and

down by hand. If any play is noticed, this

indicates that the bearings are rough. Rough bearings should be checked to see if the water pump

should be replaced or rebuilt.

G-13.

Water Pump

Disassembly

—

Hurricane

F4

Engine

•

Refer to Fig. G-9.

a.

Remove the fan belt, fan blades, and fan pulley.

b.

Remove the

bolts

attaching the water pump

to the block. Remove the pump.

c.

Remove the bearing retainer spring.

d.

Remove the pump impeller and pulley with a suitable puller.

e.

Remove the pump seal, bearing and shaft, and

bearing

slinger.

G-l4.

Water Pump Reassembly

—

Hurricane

F4

Engine

•

Refer to Fig. G-9.

Before assembling the water pump, examine water

seal

seat in the pump body and should it be rough,

install

a new pump body.

To

reassemble the unit, insert the long end of the shaft into the pump body from the front end until

the outer end of the bearing is flush against the

FIG.

G-9—WATER

PUMP-

HURRICANE

F4

ENGINE

1—

Fan

and Pump Pulley

2—

Bearing

and Shaft

3—

Bearing

Retainer Spring

A—Pipe

Plug 5—

Pump

Body

6—

Seal

Washer 7—

Pump

Seal

8—

Impeller

9—

Gasket

167

Page 168 of 376

G

COOLING SYSTEM

12761

FIG.

G-10—WATER

PUMP—

CROSS-SECTIONAL

VIEW

—

DAUNTLESS

V-6

1—

Hub

2—

—Shaft

and Bearing

3—

Cover

4—

Impeller

5—

Ceramic

Seal

6—

Seal

Assembly front end of the pump body. Position the seal,

washer,

and pump seal on shaft flush against the ground seat in the water pump body. Place the

impeller

on an arbor press and press the long end

of the shaft into the impeller until the end of the shaft is flush with the hub of the impeller. Support

the assembly on the impeller end of the shaft and

press the pulley hub on the shaft until the shaft end is flush with the pulley hub. Move the shaft

in

the pump body to align the retaining wire

grooves

in the bearing and pump body and place

the bearing retaining wire in position.

G-l

5. Water Pump Removal and Replacement — Dauntless V-6 Engine

Drain

the cooling system. Remove the fan belt and remove the cooling fan and pulley from the hub on

the water pump. Disconnect the

hoses

from the

water

pump. Remove the cap screws that secure

the water pump to the timing chain cover; remove

the water pump. Do not disassemble the water

pump;

it is serviceable only as an assembly. When

replacing

the water pump, torque the water pump cap screws 6 to 8 lb-ft. [0,829 a 1,106 kg-m.].

G-16.

Antifreeze Solutions

When

water freezes it expands approximately 9%

in

volume. When water, confined in a cooling sys

tem, freezes it exerts tremendous pressures causing

serious damage. To prevent freezing, antifreeze can

be added to the water to lower its freezing point.

The

two

types

of antifreeze commonly used today have either a methanol or ethylene glycol base,

and

contain corrosion inhibitors. The only anti

freeze recommended for the cooling system of

'Jeep'

vehicles is ethylene glycol (permanent type).

Methanol

base antifreeze evaporates with the water

when the vehicle is operated at warmer tempera

tures and requires more attention to avoid

loss

of

protection. Ethylene glycol base antifreeze seldom

evaporates at normal operating temperatures.

Methanol

solution is injurious to vehicle finishes.

Should

any be spilled on the vehicle, it should be

washed off immediately with a

good

supply of cold water without wiping or rubbing. Under ordi

nary

conditions, ethylene glycol is not injurious to

vehicle finishes.

Warning.*

Drinking

ethylene glycol antifreeze or its

solutions can be harmful or fatal. Do not use anti

freeze containers for

food

or beverages.

A

table in Par.

G-2

2

gives

the protection obtained

by the addition of various amounts cf ethylene glycol.

Before installing antifreeze, inspect the cooling sys

tem to be sure it is clean, leak-proof, and otherwise

in

proper operating condition.

Drain

the cooling system, see Par. G-3. Pour in 3 quarts [3 ltr.] of

clean

water, add the required quantity of anti freeze, then add clean water to within 1" [2,54 cm.] of the top of the overflow pipe to allow for expan

sion when hot. Run the

engine

until it is

warm.

Then

recheck the solution level.

Check

the anti

freeze protection with a hydrometer reading.

G-l7.

Inhibited Coolant Solutions

All

'Jeep5 vehicles equipped with either the

Hur

ricane

F4 or Dauntless V-6

engine

should use only

inhibited

year-round, permanent-type

engine

cool

ant

solutions that are formulated to withstand two

full

calendar years of normal operation without

draining

or adding inhibitors. The

engine

cooling

system should be completely drained and the

rec

ommended coolant installed every two years. Be-

fo

a

installing the permanent-type solution, inspect the cooling system to be sure it is clean, leakproof,

and

in proper operating condition.

Note:

Water alone, methanol, or alcohol-type anti

freeze is definitely not recommended for 'Jeep*

Vehicles.

G-l8.

Fan Belt

The

fan, water pump, generator or alternator are

driven

by a V-belt. The drive of the V-belt is on

the side of the V. A fan belt that is too tight

will

cause

rapid

wear of the alternator or generator and

water

pump bearings. If the belt is too

loose,

it may

slip

preventing the water pump from properly cool

ing the

engine

or the generator or alternator from

properly

charging the electrical

circuit.

Use fan belt

tension

gauge

Tool W-283 to properly adjust belt.

The

fan belt is properly adjusted when it can be

deflected Vi" [13 mm.] with strong thumb pres

sure

applied midway

between

the fan and alter

nator

pulleys.

Check

this adjustment and inspect the condition of the fan belt at each

engine

lubri-

168

Page 169 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

G

cation period. It is

good

preventive maintenance to

replace a badly frayed, worn or cracked fan belt

before it breaks in operation.

To

replace the fan belt,

loosen

the attaching

bolts

at each generator or alternator brace-to-engine mounting and pivot the alternator or generator to

ward

the

engine

to gain slack needed to install the new belt Remove the old belt. Position the new

belt over the fan pulley, over the crankshaft pulley,

then over the generator or alternator pulley.

Pull

the generator or alternator away from the

engine

until

belt tension is

firm.

Then tighten the generator

or

alternator mounting

bolts

and check the tension

as indicated above. Reset the generator or alternator as necessary for correct belt tension.

Finally,

torque

the generator or alternator mounting

bolts

25 to 35 lb-ft. [3,4 a 4,8 kg-m.].

Note:

On the Dauntless V-6

engine

when adjusting

the fan belt tension, the alternator mounting

bolts

should be torqued 30 to 40 lb-ft. [4,14 to 5,53

kg-m.].

If a fan belt tension

gauge

(W-283) is

avail

able, proper tension should be 80 pounds [36,2 kg.].

G-l

9. Engine Overheating

An

engine

will

not be damaged by high coolant

temperatures unless the coolant boils. The pres

surized

cooling system on the 'Jeep' vehicles raises the boiling point of the coolant solution. Should

overheating be encountered, and the fault is be

lieved to be in the cooling system check for the

following:

a.

Proper coolant level. See

Filling

Cooling Sys

tem Par. G-2.

b. Poor air flow.

Check

for dirty radiator core. (See Radiator Par. G-5).

Check

for faulty belt

pulley operation, worn or

loose

fan belt, or dam aged fan.

Clean,

repair, replace or adjust as neces

sary.

c. Foaming coolant.

Check

for air leaks at water

pump,

hose

connection and filler cap. Tighten, re

pair

or replace as necessary.

d.

Surging or "after boil".

Check

pressure cap and

replace if valves or gasket are faulty.

e.

External

leaks.

Check

the following for leaks:

Hoses and clamps, water pump, radiator, head gas

ket, core plugs and drain cocks, as well as the cylin der head or block for

cracks.

f.

Internal

leaks.

Check

for faulty head gasket,

cracked

cylinder head or block.

g. Poor coolant flow.

Check

hose

condition, water pump, fan belt, and repair or replace as necessary. Inspect block for rust or scale, and clean and flush

the system, if necessary.

h.

Check

the temperature

gauge.

169

Page 170 of 376

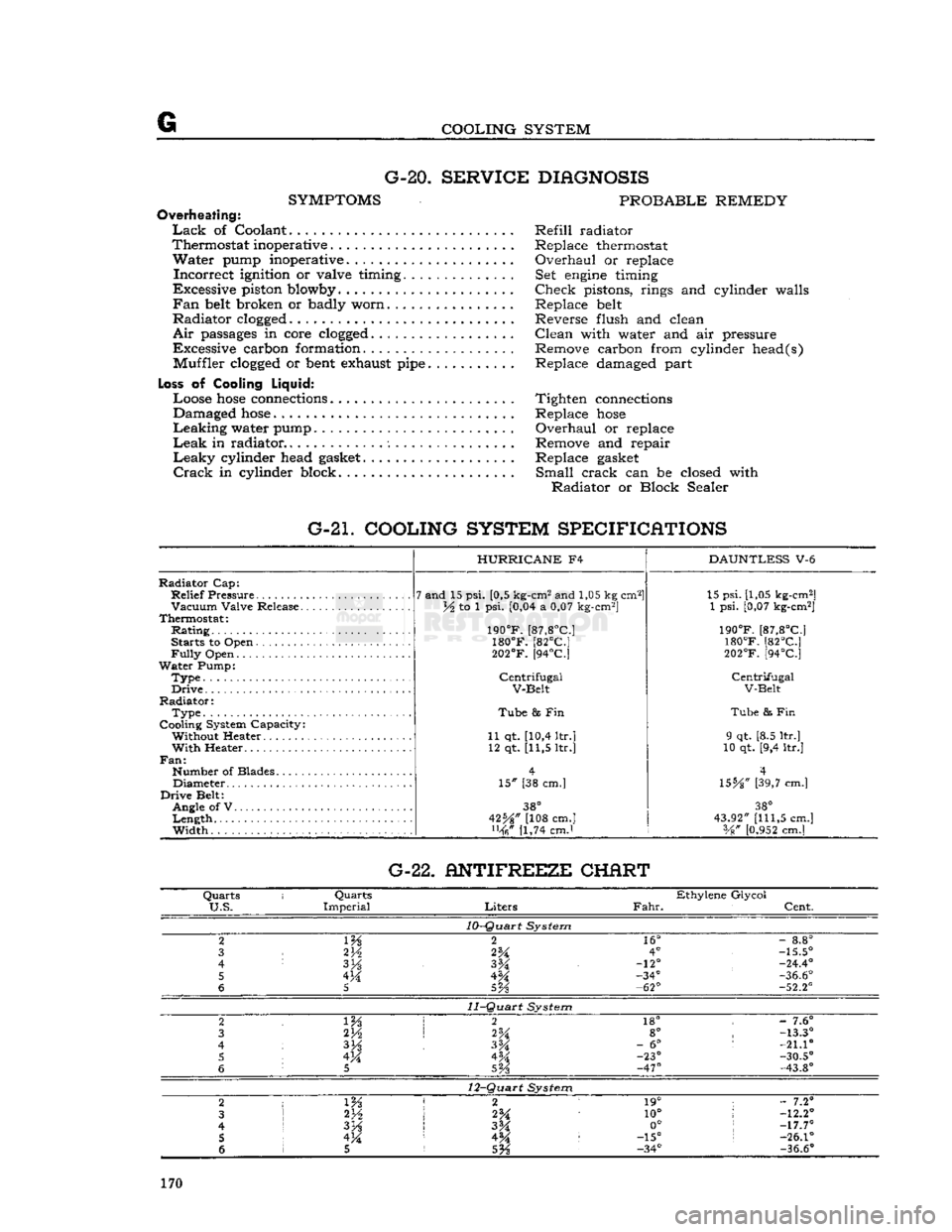

G

COOLING SYSTEM G-20.

SERVICE DIAGNOSIS

SYMPTOMS

PROBABLE REMEDY

Overheating:

Lack

of Coolant Refill radiator

Thermostat inoperative . Replace thermostat

Water

pump inoperative. Overhaul or replace

Incorrect

ignition or valve timing. Set

engine

timing

Excessive piston blowby Check pistons, rings and cylinder walls

Fan

belt

broken or badly worn Replace

belt

Radiator

clogged

Reverse flush and clean

Air

passages

in core

clogged

Clean with water and air pressure

Excessive carbon formation. Remove carbon from cylinder head(s) Muffler

clogged

or

bent

exhaust

pipe

Replace damaged part

Loss

of Cooling

Liquid:

Loose

hose

connections

Tighten

connections

Damaged

hose

Replace

hose

Leaking

water pump Overhaul or replace

Leak

in radiator Remove and repair

Leaky

cylinder head

gasket

Replace

gasket

Crack

in cylinder block. Small crack can be closed with

Radiator

or Block Sealer

G-21. COOLING SYSTEM SPECIFICATIONS

Radiator

Cap:

Relief

Pressure

Vacuum

Valve Release.

Thermostat:

Rating

Starts to Open

Fully

Open

Water

Pump:

Type.

Drive

Radiator:

Type

Cooling System Capacity: Without Heater

With

Heater..

Fan:

Number of Blades Diameter

Drive

Belt: Angle of V

Length

Width

HURRICANE

F4

7 and 15 psi. [0,5 kg-cm2 and 1,05 kg cm2]

lA to 1 psi. [0,04 a 0,07 kg-cm2]

190°F.

[87,8°C]

180°F.

[82°C]

202°F.

[94°C]

Centrifugal

V-Belt

Tube

8s Fin

11 qt. [10,4 ltr.] 12 qt. [11,5 ltr.]

15" [38 cm.]

38°

42%" [108 cm.] [1,74 cmJ

DAUNTLESS

V-6 15 psi. [1,05 kg-cm2]

1 psi. [0,07 kg-cm2]

190°F.

[87,8°C]

180°F.

[82°C]

202°F.

[94°C]

Centrifugal

V-Belt

Tube

& Fin

9 qt. [8.5 ltr.]

10 qt. [9,4 ltr.]

4

\SbA"

[39,7 cm.]

38°

43.92"

[111,5

cm.] Vg"

[0.952

cm.] G-22. ANTIFREEZE CHERT

Quarts

i

Quarts

Ethylene Glycol

U.S.

Imperial

Liters

Fahr.

Cent.

10-Quart

System

2

m

2

16°

-

8.8°

3

2V2

2%

4°

-15.5°

4

3H

-12°

-24.4°

5 4M -34°

-36.6°

6

5

5Vs

-62°

-52.2°

11-Quart

System

2 2

18° -

7.6°

3 2H

2%

8°

-13.3°

4

3%

-

6°

:

-21.10

5 4M 4M -23°

-30.5°

6

5

SVs

-47°

-43.8°

12-Quart

System

2

1 m 2 1

19° ;

- 7.2°

3

2*A

10°

!

-12.2°

4

I

3H

3M 0°

;

-17.7°

5 !

4M 4^ :

-15°

s

-26.1°

6 1 5

5%

-34°

-36.6°

170