ECO mode JEEP CJ 1953 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 10 of 376

B

LUBRICATION

B-2.

Special Lubricants

Special

lubricants are required for certain

lubri

cation points on the 'Jeep' Universal vehicles. The

special

lubricants are necessary for proper function ing and maintenance of the vehicle. The

Lubrica

tion

Chart

(Fig. B-l and B-2)

designates

the spe

cial

lubricating points and identifies them by type

or

part number.

B-3.

Applying

Fresh

Lubricant

When

servicing or lubricating the vehicle, it is important that all old lubricant and

dirt

be re moved from the fitting and/or plugs before servic

ing and that the recommended type of lubricant be used for the particular item being serviced.

Force

lubricant through the lube fittings until the lubricant being forced out of the joint is fresh

lubricant,

indicating that all old lubricant has

been removed.

B-4.

Engine

Lubrication

System —

Hurricane

F4 Engine

•

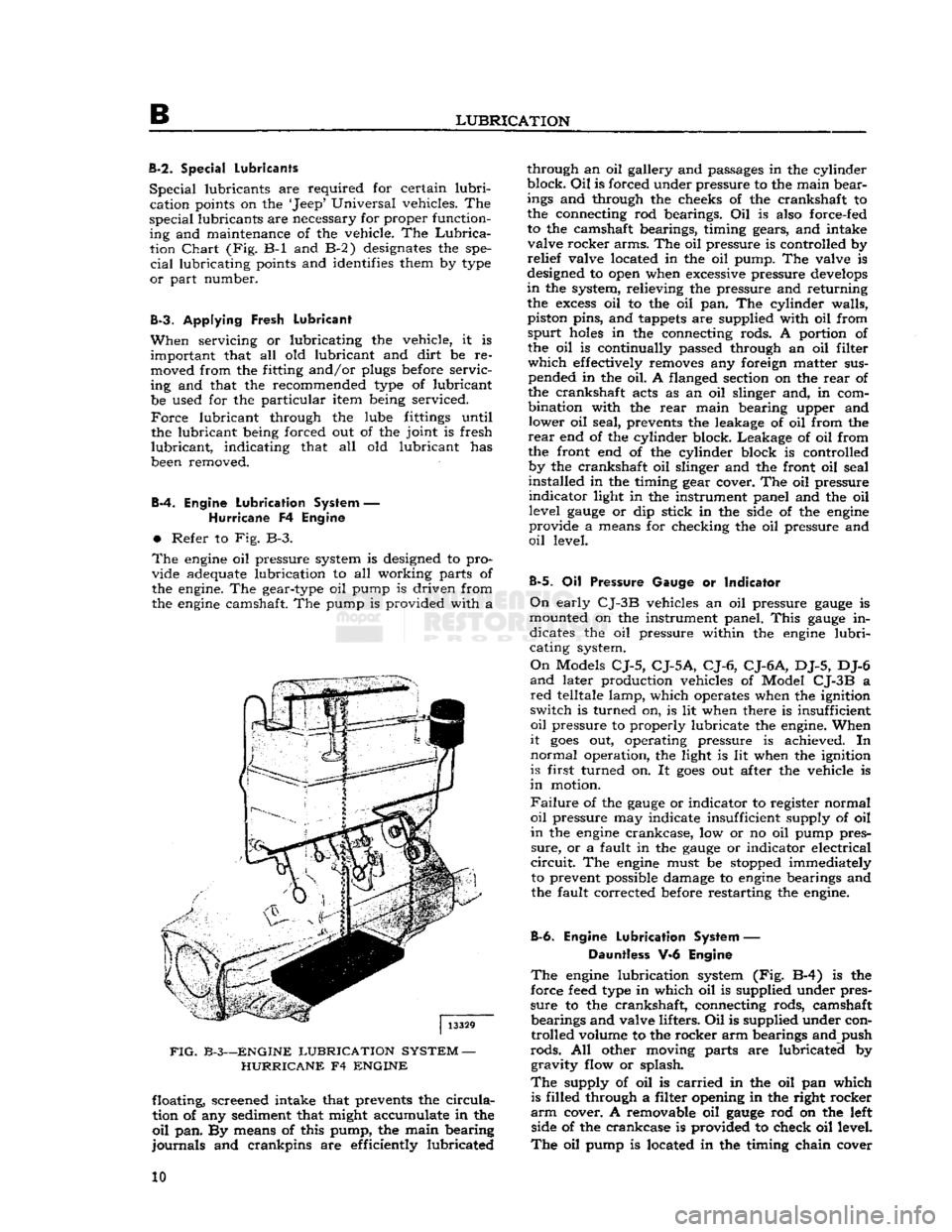

Refer to Fig. B-3.

The

engine

oil pressure system is designed to pro

vide adequate lubrication to all working parts of

the engine. The gear-type oil pump is driven from

the

engine

camshaft. The pump is provided with a

FIG.

B-3—ENGINE

LUBRICATION

SYSTEM

—

HURRICANE

F4

ENGINE

floating, screened intake that prevents the

circula

tion of any sediment that might accumulate in the

oil

pan. By means of this pump, the main bearing

journals

and crankpins are efficiently lubricated through an oil gallery and passages in the cylinder

block.

Oil

is forced under pressure to the main bear

ings and through the cheeks of the crankshaft to

the connecting rod bearings. Oil is also force-fed

to the camshaft bearings, timing gears, and intake valve rocker arms. The oil pressure is controlled by

relief

valve located in the oil pump. The valve is

designed to open when excessive pressure

develops

in

the system, relieving the pressure and returning the

excess

oil to the oil pan. The cylinder walls,

piston pins, and tappets are supplied with oil from

spurt

holes

in the connecting rods. A portion of the oil is continually passed through an oil filter

which

effectively removes any foreign matter sus pended in the oil. A flanged section on the

rear

of

the crankshaft acts as an oil slinger and, in com

bination with the

rear

main bearing upper and lower oil seal, prevents the leakage of oil from the

rear

end of the cylinder block. Leakage of oil from

the front end of the cylinder block is controlled by the crankshaft oil slinger and the front oil seal

installed in the timing gear cover. The oil pressure

indicator

light in the instrument panel and the oil level

gauge

or dip stick in the side of the

engine

provide a means for checking the oil pressure and

oil

level.

B-5.

Oil Pressure Gauge or Indicator

On

early

CJ-3B

vehicles an oil pressure

gauge

is

mounted on the instrument panel.

This

gauge

in dicates the oil pressure within the

engine

lubri

cating system.

On

Models

CJ-5,

CJ-5A,

CJ-6,

CJ-6A,

DJ-5, DJ-6

and

later production vehicles of Model

CJ-3B

a

red

telltale lamp, which operates when the ignition

switch is turned on, is lit when there is insufficient

oil

pressure to properly lubricate the engine. When

it

goes

out, operating pressure is achieved. In

normal

operation, the light is lit when the ignition

is first turned on. It

goes

out after the vehicle is

in

motion.

Failure

of the

gauge

or indicator to register normal

oil

pressure may indicate insufficient supply of oil

in

the

engine

crankcase, low or no oil pump pres

sure,

or a fault in the

gauge

or indicator electrical

circuit.

The

engine

must be stopped immediately to prevent possible damage to

engine

bearings and

the fault corrected before restarting the engine.

B-6.

Engine

Lubrication

System — Dauntless V-6 Engine

The

engine

lubrication system (Fig. B-4) is the

force

feed

type in which oil is supplied under pres

sure

to the crankshaft, connecting rods, camshaft bearings and valve lifters. Oil is supplied under controlled volume to the rocker arm bearings and push

rods.

All other moving parts are lubricated by gravity flow or splash.

The

supply of oil is

carried

in the oil pan which is filled through a filter opening in the right rocker

arm

cover. A removable oil

gauge

rod on the left side of the crankcase is provided to check oil level.

The

oil pump is located in the timing chain cover 10

Page 12 of 376

B

LUBRICATION B-3.

SERVICE

MAINTENANCE

SCHEDULE

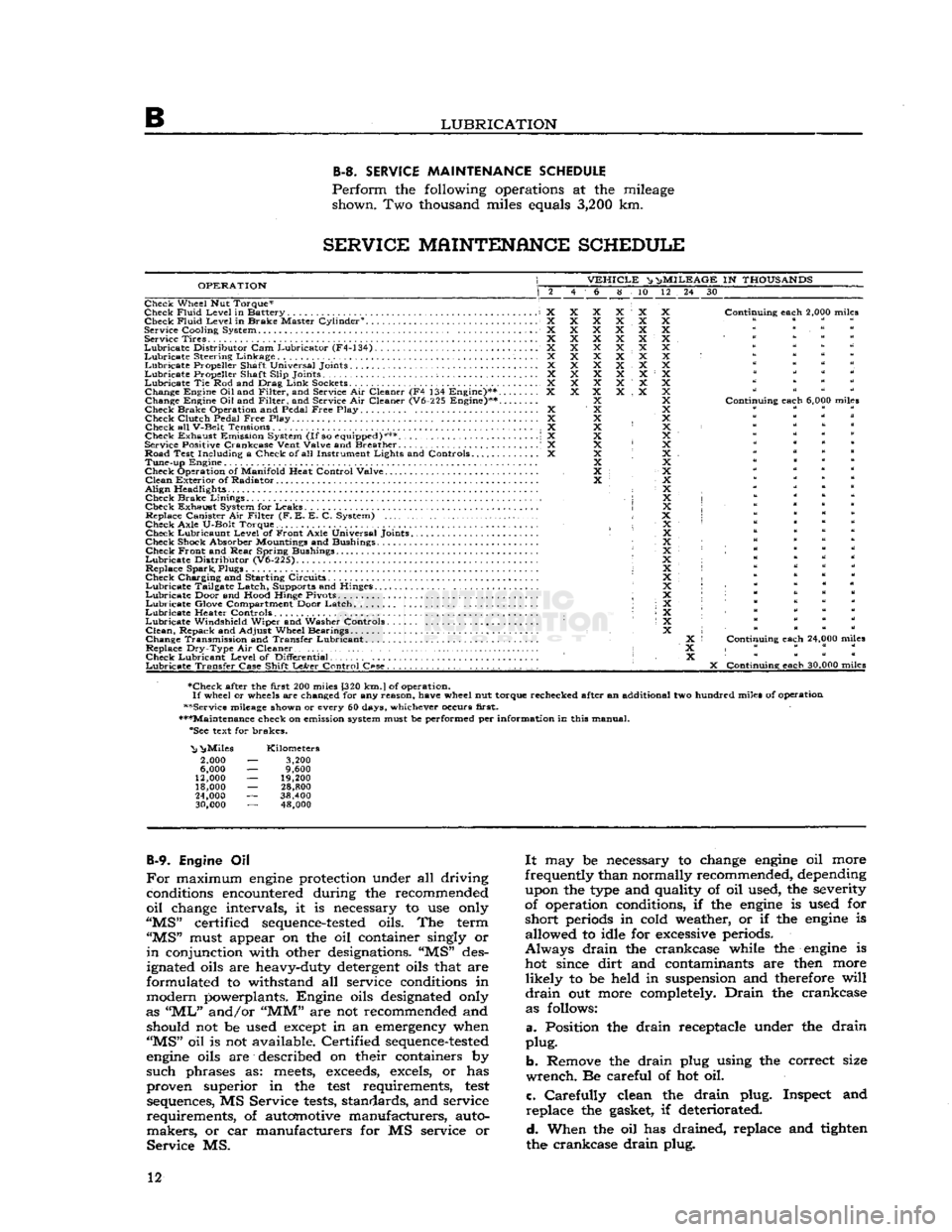

Perform

the following operations at the mileage shown. Two thousand miles equals

3,200

km.

SERVICE

MAINTENANCE

SCHEDULE

OPERATION

VEHICLE

^ n>

MILEAGE

IN

THOUSANDS

6 8 10 12 24 30

Check Wheel Nut Torque*

Check

Fluid

Level

in Battery X Check

Fluid

Level

in Brake Master Cylinder0. X

Service

Cooling

System X Service Tires X

Lubricate

Distributor

Cam Lubricator (F4-134) X

Lubricate

Steering Linkage X

Lubricate

Propeller Shaft Universal Joints X

Lubricate

Propeller Shaft

Slip

Joints ; X

Lubricate

Tie Rod and Drag

Link

Sockets................................... X Change Engine

Oil

and

Filter,

and Service Air Cleaner (F4 134 Engine)** X

Change Engine Oil and

Filter,

and Service Air Cleaner (V6-225 Engine)**....

Check Brake Operation and Pedal

Free

Play X Check

Clutch

Pedal

Free

Play. .... X

Check all

V-Belt

Tensions X

Check Exhaust Emission System

(If

so equipped)*** \ X

Service Positive

Crankcase

Vent

Valve

and Breather . .' X

Road Test

Including

a Check of all Instrument

Lights

and Controls X Tune-up Engine

Check Operation of

Manifold

Heat

Control

Valve

Clean

Exterior of Radiator

Align

Headlights • Check Brake

Linings

,

Check Exhaust System for Leaks Replace Canister Air

Filter

(F. E. E. C. System)

Check

Axle

U-Bolt

Torque. Check Lubricaunt

Level

of Front

Axle

Universal Joints

Check Shock Absorber Mountings and Bushings Check Front and

Rear

Spring Bushings

Lubricate

Distributor

(V6-225).

Replace Spark, Plugs

Check Charging and Starting Circuits

Lubricate

Tailgate Latch, Supports and Hinges.

Lubricate

Door and

Hood

Hinge Pivots ;

Lubricate

Glove Compartment Door Latch

Lubricate

Heater Controls •

Lubricate

Windshield

Wiper and Washer Controls

Clean,

Repack and

Adjust

Wheel Bearings

Change Transmission and Transfer Lubricant. .

Replace

Dry-Type

Air Cleaner • Check Lubricant

Level

of

Differential

Lubricate

Transfer

Case

Shift

LeArer

Control

C«se.

. , . . . . . . . .

Continuing

each

2,000 miles

Continuing

each

6,000 miles

Continuing

each

24,000 miles

X

Continuing

each

30,000 miles

•Check after the

first

200 miles [320

km.

J

of operation.

If

wheel or wheels are changed for any

reason,

have

wheel nut torque rechecked after an additional two hundred miles of operation

••Service mileage shown or every 60 days, whichever occurs

first.

•••Maintenance check on emission system must be performed per

information

in this manual. "See text for brakes.

"Nj

^Miles

2,000

6,000

12,000

18,000

24,000

30,000

Kilometers

3,200

9,600

19,200

28,800

38,400 48,000

B-9.

Engine Oil

For

maximum

engine

protection under all driving conditions encountered during the recommended

oil

change intervals, it is necessary to use only

"MS"

certified

sequence-tested

oils. The term

"MS"

must appear on the oil container singly or

in

conjunction with other designations. "MS" des

ignated oils are heavy-duty detergent oils that are

formulated to withstand all service conditions in

modern powerplants. Engine oils designated only

as

"ML"

and/or

"MM"

are not recommended and should not be used except in an emergency when

"MS"

oil is not available. Certified

sequence-tested

engine

oils are described on their containers by

such

phrases as:

meets,

exceeds,

excels, or has

proven superior in the

test

requirements,

test

sequences, MS Service

tests,

standards, and service

requirements,

of automotive manufacturers, auto

makers,

or car manufacturers for MS service or

Service

MS.

It

may be necessary to change

engine

oil more

frequently than normally recommended, depending upon the type and quality of oil used, the severity

of operation conditions, if the

engine

is used for

short

periods in cold weather, or if the

engine

is allowed to idle for excessive periods.

Always

drain

the crankcase while the

engine

is hot since

dirt

and contaminants are then more

likely

to be held in suspension and therefore

will

drain

out more completely.

Drain

the crankcase as follows:

a.

Position the

drain

receptacle under the

drain

plug.

b.

Remove the

drain

plug using the correct size

wrench.

Be careful of hot oil.

c.

Carefully

clean the

drain

plug. Inspect and

replace

the gasket, if deteriorated.

d.

When the oil has drained, replace and tighten

the crankcase

drain

plug. 12

Page 15 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

B

solvent.

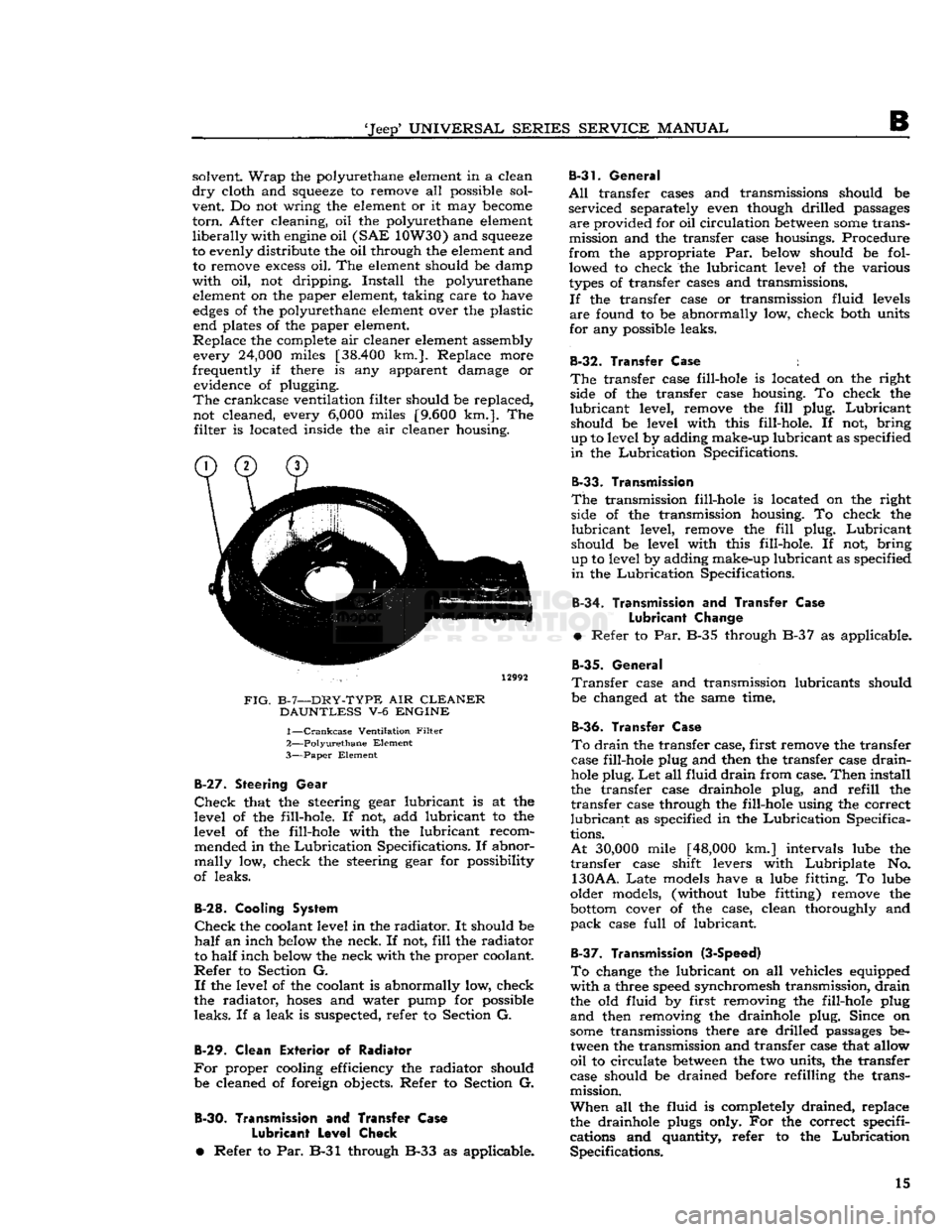

Wrap

the polyurethane element in a clean

dry

cloth and

squeeze

to remove all possible sol

vent. Do not wring the element or it may

become

torn.

After cleaning, oil the polyurethane element

liberally

with

engine

oil

(SAE

10W30) and

squeeze

to evenly distribute the oil through the element and to remove

excess

oil. The element should be damp

with

oil, not dripping.

Install

the polyurethane element on the paper element, taking care to have

edges

of the polyurethane element over the plastic end plates of the paper element.

Replace

the complete air cleaner element assembly every

24,000

miles

[38.400

km.]. Replace more

frequently if there is any apparent damage or evidence of plugging.

The

crankcase ventilation filter should be replaced, not cleaned, every

6,000

miles

[9.600

km.]. The

filter

is located inside the air cleaner housing.

12992

FIG.

B-7—DRY-TYPE

AIR

CLEANER DAUNTLESS

V-6

ENGINE

1—

Crankcase

Ventilation

Filter

2—

Polyurethane

Element

3—

Paper

Element

B-27.

Steering

Gear

Check

that the steering gear lubricant is at the

level of the fill-hole. If not, add lubricant to the

level of the fill-hole with the lubricant recom mended in the

Lubrication

Specifications. If abnor

mally

low, check the steering gear for possibility

of leaks.

B-28.

Cooling System

Check

the coolant level in the

radiator.

It should be

half

an inch below the neck. If not,

fill

the radiator

to

half

inch below the neck with the proper coolant.

Refer

to Section G.

If

the level of the coolant is abnormally low, check

the radiator,

hoses

and water pump for possible

leaks.

If a leak is suspected, refer to Section G.

B-29.

Clean

Exterior

of Radiator

For

proper cooling efficiency the radiator should be cleaned of foreign objects. Refer to Section G.

B-30.

Transmission

and

Transfer Case

Lubricant

Level

Cheek

•

Refer to Par. B-31 through B-33 as applicable.

B-31.

General

All

transfer cases and transmissions should be

serviced

separately even though drilled passages

are

provided for oil circulation

between

some

trans

mission and the transfer case housings. Procedure

from

the appropriate Par. below should be fol lowed to check the lubricant level of the various

types

of transfer cases and transmissions.

If

the transfer case or transmission fluid levels

are

found to be abnormally low, check both units

for any possible leaks.

B-32.

Transfer

Case

:

The

transfer case fill-hole is located on the right side of the transfer case housing. To check the

lubricant

level, remove the

fill

plug.

Lubricant

should be level with this fill-hole. If not, bring up to level by adding make-up lubricant as specified

in

the

Lubrication

Specifications.

B-33.

Transmission

The

transmission fill-hole is located on the right side of the transmission housing. To check the

lubricant

level, remove the

fill

plug.

Lubricant

should be level with this fill-hole. If not, bring

up to level by adding make-up

lubricant

as specified

in

the

Lubrication

Specifications.

B-34.

Transmission and Transfer

Case

Lubricant

Change

•

Refer to Par. B-35 through B-37 as applicable.

B-35.

General

Transfer

case and transmission lubricants should

be changed at the same time.

B-36.

Transfer

Case

To

drain

the transfer case, first remove the transfer

case fill-hole plug and then the transfer case

drain-

hole

plug. Let all fluid

drain

from case.

Then

install

the transfer case drainhole plug, and

refill

the

transfer

case through the fill-hole using the correct

lubricant

as specified in the

Lubrication

Specifica

tions.

At

30,000

mile

[48,000

km.] intervals lube the

transfer

case shift levers with

Lubriplate

No.

130AA.

Late

models have a lube fitting. To lube

older models, (without lube fitting) remove the

bottom

cover of the case, clean thoroughly and

pack

case

full

of lubricant.

B-37.

Transmission (3-Speed)

To

change the lubricant on all vehicles equipped

with

a three speed synchromesh transmission,

drain

the old fluid by first removing the fill-hole plug

and

then removing the drainhole plug. Since on

some

transmissions there are drilled passages be tween the transmission and transfer case that allow

oil

to circulate

between

the two units, the transfer

case should be drained before refilling the trans

mission.

When

all the fluid is completely drained, replace

the drainhole plugs only. For the correct specifi

cations and quantity, refer to the

Lubrication

Specifications. 15

Page 31 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

C

FIG.

C-22—-CHECKING

FUEL

PUMP

PRESSURE

—

DAUNTLESS

V-6

ENGINE a

couple of strokes to be sure the pump is primed.

Using

a half-pint

bottle

or similar measure, pump

Vi

pint [0,24 It] of fuel by cranking the

engine

with

the starter motor. Count the strokes neces

sary

to

fill

the measure. If more than 20 strokes

are

required, the fuel pump is inefficient, the tank

line is leaking air, or the fuel supply is restricted.

Check

fuel filter in the fuel tank if line is restricted.

C-24.

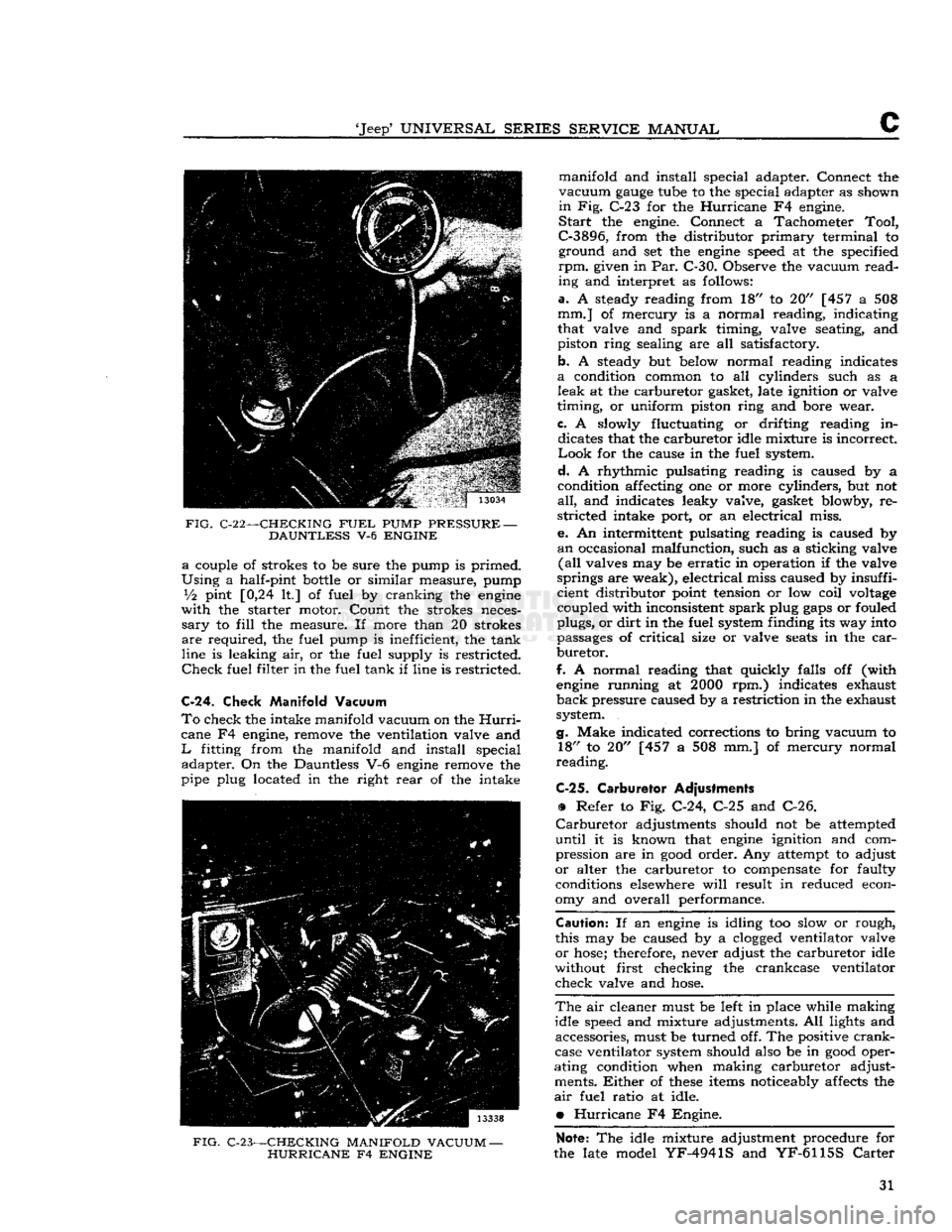

Check Manifold Vacuum

To

check the intake manifold vacuum on the

Hurri

cane F4 engine, remove the ventilation valve and

L

fitting from the manifold and install special adapter. On the Dauntless V-6

engine

remove the

pipe plug located in the right

rear

of the intake

FIG.

C-23—CHECKING MANIFOLD VACUUM

—

HURRICANE

F4

ENGINE

manifold and install special adapter. Connect the

vacuum

gauge

tube to the special adapter as shown

in

Fig. C-23 for the

Hurricane

F4 engine.

Start

the engine. Connect a Tachometer

Tool,

C-3896,

from the distributor

primary

terminal to ground and set the

engine

speed at the specified

rpm.

given in Par. C-30. Observe the vacuum

read

ing and interpret as follows:

a.

A steady reading from 18" to 20" [457 a 508

mm.] of mercury is a normal reading, indicating

that valve and

spark

timing, valve seating, and

piston ring sealing are all satisfactory.

b. A steady but below normal reading indicates

a

condition common to all cylinders such as a

leak

at the carburetor gasket, late ignition or valve

timing, or uniform piston ring and bore wear.

c.

A slowly fluctuating or drifting reading in dicates that the carburetor idle mixture is incorrect

Look

for the cause in the fuel system.

d.

A rhythmic pulsating reading is caused by a

condition affecting one or more cylinders, but not

all,

and indicates leaky valve, gasket blowby, re

stricted intake port, or an electrical miss.

e. An intermittent pulsating reading is caused by

an

occasional malfunction, such as a sticking valve

(all

valves may be

erratic

in operation if the valve

springs are weak), electrical miss caused by insuffi

cient distributor point tension or low coil

voltage

coupled with inconsistent

spark

plug

gaps

or fouled

plugs, or

dirt

in the fuel system finding its way into

passages of

critical

size or valve

seats

in the

car

buretor.

f.

A normal reading that quickly falls off (with

engine

running at

2000

rpm.) indicates exhaust

back

pressure caused by a restriction in the exhaust

system.

g.

Make indicated corrections to bring vacuum to 18" to 20" [457 a 508 mm.] of mercury normal

reading.

C-25.

Carburetor Adjustments

•

Refer to Fig. C-24, C-25 and C-26.

Carburetor

adjustments should not be attempted

until

it is known that

engine

ignition and com

pression are in

good

order. Any attempt to adjust

or

alter the carburetor to compensate for faulty conditions elsewhere

will

result in reduced econ

omy and overall performance.

Caution:

If an

engine

is idling too slow or rough,

this may be caused by a

clogged

ventilator valve

or

hose;

therefore, never adjust the carburetor idle

without first checking the crankcase ventilator

check valve and

hose.

The

air cleaner must be left in place while making

idle speed and mixture adjustments. All lights and accessories, must be turned off. The positive

crank

case ventilator system should also be in

good

oper

ating condition when making carburetor adjust ments.

Either

of

these

items noticeably affects the

air

fuel ratio at idle.

•

Hurricane

F4 Engine.

Note:

The idle mixture adjustment procedure for

the late model

YF-4941S

and

YF-6115S

Carter

31

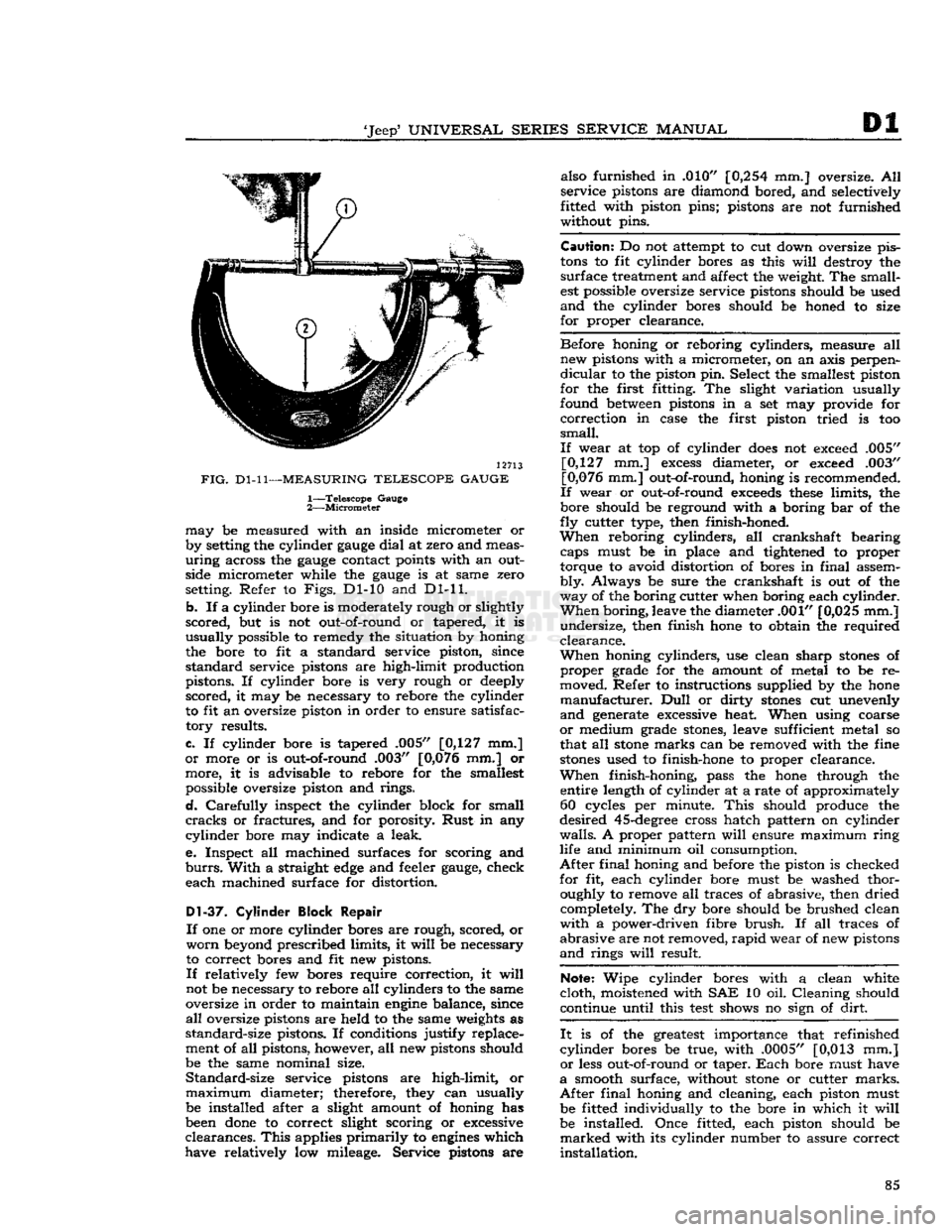

Page 85 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

12713

FIG.

Dl-11—MEASURING

TELESCOPE GAUGE

1—

Telescope

Gauge

2—

Micrometer

may

be measured with an inside micrometer or

by setting the cylinder

gauge

dial

at zero and meas

uring

across the

gauge

contact points with an outside micrometer while the

gauge

is at same zero

setting. Refer to

Figs.

Dl-10 and Dl-11.

b.

If a cylinder bore is moderately rough or slightly

scored,

but is not out-of-round or tapered, it is

usually

possible to remedy the situation by honing

the bore to fit a standard service piston, since

standard

service pistons are high-limit production

pistons. If cylinder bore is very rough or deeply

scored,

it may be necessary to rebore the cylinder

to fit an oversize piston in order to ensure satisfac

tory

results.

c.

If cylinder bore is tapered .005" [0,127 mm.]

or

more or is out-of-round .003" [0,076 mm.] or

more,

it is advisable to rebore for the smallest possible oversize piston and rings.

d.

Carefully

inspect the cylinder block for small

cracks

or fractures, and for porosity.

Rust

in any

cylinder

bore may indicate a leak.

e.

Inspect all machined surfaces for scoring and

burrs.

With

a straight

edge

and feeler

gauge,

check

each

machined surface for distortion.

D1-37.

Cylinder Block Repair

If

one or more cylinder bores are rough, scored, or

worn

beyond prescribed limits, it

will

be necessary

to correct bores and fit new pistons.

If

relatively few bores require correction, it

will

not be necessary to rebore all cylinders to the same

oversize in order to maintain

engine

balance, since

all

oversize pistons are held to the same weights as

standard-size

pistons. If conditions justify replace

ment of all pistons, however, all new pistons should

be the same nominal size.

Standard-size

service pistons are high-limit, or

maximum

diameter; therefore, they can usually be installed after a slight amount of honing has

been

done

to correct slight scoring or excessive

clearances.

This

applies

primarily

to

engines

which

have relatively low mileage. Service pistons are also furnished in .010"

[0,254

mm.] oversize. All

service

pistons are diamond bored, and selectively

fitted with piston pins; pistons are not furnished

without pins.

Caution:

Do not attempt to cut down oversize pis

tons

to fit cylinder bores as this

will

destroy the

surface

treatment and affect the weight. The small

est possible oversize service pistons should be used

and

the cylinder bores should be honed to size

for

proper clearance.

Before

honing or reboring cylinders, measure all new pistons with a micrometer, on an axis perpen

dicular

to the piston pin. Select the smallest piston

for

the first fitting. The slight variation usually

found between pistons in a set may provide for

correction

in case the first piston tried is too

small.

If

wear at top of cylinder

does

not exceed .005" [0,127 mm.]

excess

diameter, or exceed .003"

[0,076 mm.] out-of-round, honing is recommended.

If

wear or out-of-round

exceeds

these

limits, the

bore should be reground with a boring bar of the

fly

cutter type, then finish-honed.

When

reboring cylinders, all crankshaft bearing caps must be in place and tightened to proper

torque to avoid distortion of bores in

final

assem

bly.

Always be sure the crankshaft is out of the

way

of the boring cutter when boring each cylinder.

When

boring, leave the diameter .001" [0,025 mm.]

undersize,

then finish hone to obtain the required

clearance.

When

honing cylinders, use clean sharp

stones

of

proper

grade for the amount of metal to be re

moved. Refer to instructions supplied by the hone

manufacturer.

Dull

or dirty

stones

cut unevenly

and

generate excessive heat. When using coarse

or

medium grade

stones,

leave sufficient metal so

that all

stone

marks can be removed with the fine

stones

used to finish-hone to proper clearance.

When

finish-honing, pass the hone through the entire length of cylinder at a rate of approximately 60 cycles per minute.

This

should produce the

desired

45-degree

cross hatch pattern on cylinder

walls.

A proper pattern

will

ensure maximum

ring

life and minimum oil consumption.

After

final

honing and before the piston is checked

for

fit, each cylinder bore must be washed thor oughly to remove all traces of abrasive, then dried completely. The dry bore should be brushed clean

with

a power-driven fibre

brush.

If all traces of

abrasive

are not removed,

rapid

wear of new pistons

and

rings

will

result.

Note:

Wipe cylinder bores with a clean white

cloth,

moistened with SAE 10 oil. Cleaning should

continue until this

test

shows no sign of

dirt.

It

is of the greatest importance that refinished

cylinder

bores be true, with .0005" [0,013 mm.]

or

less out-of-round or taper.

Each

bore must have

a

smooth surface, without

stone

or cutter

marks.

After

final

honing and cleaning, each piston must be fitted individually to the bore in which it

will

be installed. Once fitted, each piston should be

marked

with its cylinder number to assure correct

installation.

85

Page 113 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

E

there is a relief valve that

opens

to reduce high

(dangerous) pressures in the fuel tank. In con

junction

with the pressure relief valve there is a

vacuum

relief valve to

stop

collapse of the fuel

tank

in case of a plugged system or failure of the demand valve. When replacing the gas cap, the

same type must be used as originally installed.

E-8.

System Inspection Test

The

fuel emission vent system should be checked

carefully

to ensure the absence of any leaks to the

atmosphere of either liquid or vapor which might

affect the accuracy, safety, or performance of the control system.

To

assure that the sealed system has been properly

installed,

the following

test

procedure has been

developed.

Disconnect the vent line from the fuel tank system

to the activated charcoal canister, induce l/i p.s.i.

air

pressure. If this pressure can be maintained for

a

few seconds the vent system is assured to be sealed. DO NOT add air pressure to the canister

because damage can occur to the demand valve if

care

is not taken.

E-9.

Servicing the System

Periodic

Maintenance — Replace carbon canister filter at

12,000

miles

[19,200

km.] or 12 month intervals (more

often

for operation in dusty areas).

This

is the only regular maintenance service

required.

Canister

Filter

Replacement — Disconnect

hoses

from

top of canister, remove canister from mount

-

t

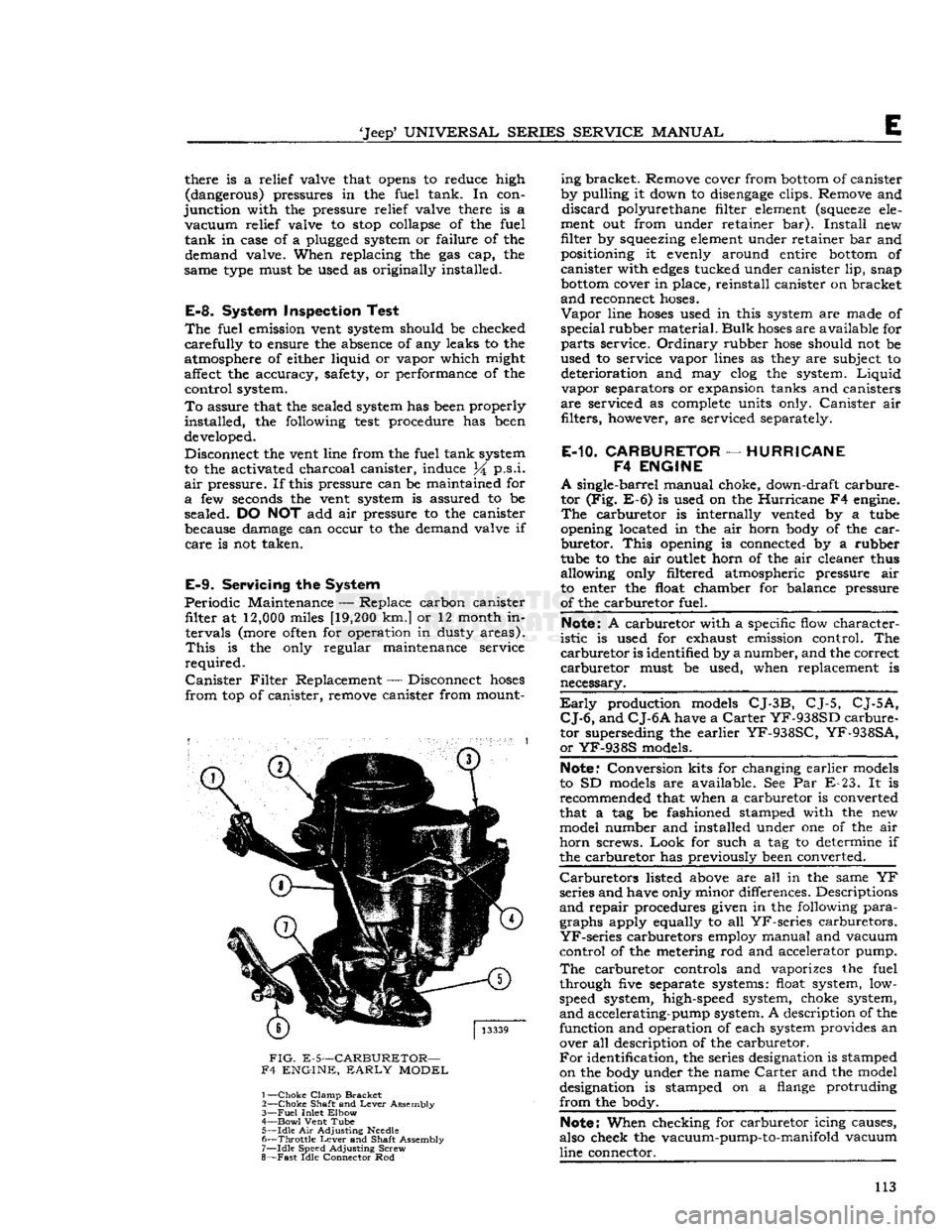

FIG.

E-5—CARBURETOR—

F4 ENGINE,

EARLY

MODEL

1—

Choke

Clamp

Bracket

2—

Choke

Shaft and

Lever

Assembly

3—

Fuel

Inlet

Elbow

4—

Bowl

Vent Tube 5—

Idle

Air Adjusting

Needle

6—

Throttle

Lever

and Shaft Assembly

7—

Idle

Speed Adjusting Screw

8—

Fast

Idle Connector Rod ing bracket. Remove cover from

bottom

of canister

by pulling it down to

disengage

clips. Remove and

discard

polyurethane filter element

(squeeze

ele

ment out from under retainer bar).

Install

new

filter by squeezing element under retainer bar and positioning it evenly around entire

bottom

of

canister with

edges

tucked under canister lip, snap

bottom

cover in place, reinstall canister on bracket

and

reconnect

hoses.

Vapor

line

hoses

used in this system are made of

special

rubber material.

Bulk

hoses

are available for

parts

service.

Ordinary

rubber

hose

should not be

used to service vapor lines as they are subject to deterioration and may clog the system.

Liquid

vapor separators or expansion tanks and canisters

are

serviced as complete units only.

Canister

air filters, however, are serviced separately.

E-10.

CARBURETOR

—

HURRICANE

F4

ENGINE

A

single-barrel manual choke, down-draft carbure

tor (Fig. E-6) is used on the

Hurricane

F4 engine.

The

carburetor is internally vented by a tube

opening located in the air horn body of the

car

buretor.

This

opening is connected by a rubber

tube to the air

outlet

horn of the air cleaner thus

allowing only filtered atmospheric pressure air

to enter the float chamber for balance pressure

of the carburetor fuel.

Note:

A carburetor with a specific flow character

istic

is used for exhaust emission control. The

carburetor

is identified by a number, and the correct

carburetor

must be used, when replacement is

necessary.

Early

production models

CJ-3B,

CJ-5,

CJ-5A,

CJ-6,

and

CJ-6A

have a

Carter

YF-938SD

carbure

tor superseding the earlier

YF-938SC,

YF-938SA,

or

YF-938S

models.

Note."

Conversion kits for changing earlier models

to SD models are available. See Par E-23. It is recommended that when a carburetor is converted

that a tag be fashioned stamped with the new model number and installed under one of the air

horn

screws.

Look

for such a tag to determine if

the carburetor has previously been converted.

Carburetors

listed above are all in the same YF

series and have only minor differences. Descriptions

and

repair procedures given in the following

para

graphs apply equally to all

YF-series

carburetors.

YF-series

carburetors employ manual and vacuum

control of the metering rod and accelerator pump.

The

carburetor controls and vaporizes the fuel

through five separate systems: float system, low-

speed system, high-speed system, choke system,

and

accelerating-pump system. A description of the function and operation of each system provides an over all description of the carburetor.

For

identification, the series designation is stamped

on the body under the name

Carter

and the model

designation is stamped on a flange protruding

from

the body.

Note:

When checking for carburetor icing causes,

also check the vacuum-pump-to-manifold vacuum

line connector. 113

Page 114 of 376

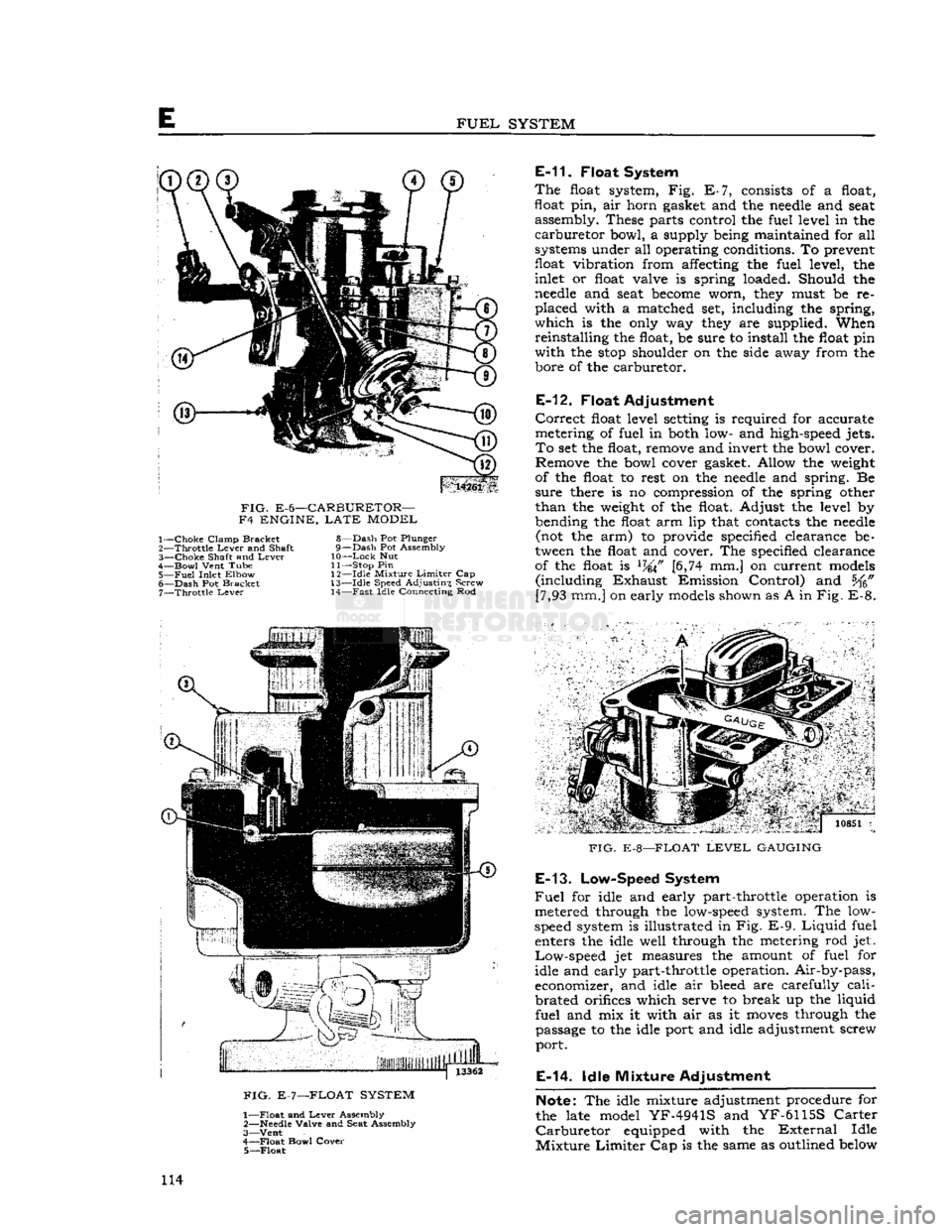

FUEL

SYSTEM

14261

FIG.

E-6—CARBURETOR—

F4 ENGINE,

LATE

MODEL 1—

Choke

Clamp Bracket

2—

Throttle

Lever

and Shaft

3—

Choke

Shaft and

Lever

4—

Bowl

Vent Tube

5—

Fuel

Inlet Elbow

6—

Dash

Pot Bracket 7—

Throttle

Lever

8—

Dash

Pot Plunger

9—

Dash

Pot Assembly

10—

Lock

Nut

11— Stop Pin

1

2—Idle Mixture

Limiter

Cap

13—

Idle

Speed Adjusting Screw 14—

Fast

Idle Connecting Rod

E-11.

Float System

The

float system, Fig. E-7, consists of a float,

float

pin,

air horn gasket and the

needle

and seat assembly. These parts control the fuel level in the

carburetor

bowl, a supply being maintained for all

systems under all operating conditions. To prevent

float

vibration

from affecting the fuel level, the

inlet or float valve is spring loaded. Should the

needle

and seat

become

worn, they must be re

placed

with a matched set, including the spring,

which

is the only way they are supplied. When

reinstalling

the float, be sure to install the float pin

with

the

stop

shoulder on the side away from the bore of the carburetor.

E-12.

Float Adjustment

Correct

float level setting is required for accurate

metering of fuel in both low- and high-speed jets.

To

set the float, remove and invert the bowl cover. Remove the bowl cover gasket. Allow the weight

of the float to rest on the

needle

and spring. Be

sure

there is no compression of the spring other

than

the weight of the float. Adjust the level by

bending the float arm lip that contacts the

needle

(not the arm) to provide specified clearance be

tween the float and cover. The specified clearance of the float is

L74\F

[6,74 mm.] on current models

(including

Exhaust

Emission Control) and [7,93 mm.] on early models shown as A in

Fig.

E-8.

FIG.

E-7—FLOAT SYSTEM

1—

Float

and

Lever

Assembly

2—

Needle

Valve and Seat Assembly

3—

Vent

4—

Float

Bowl Cover 5—

Float

7 '.. j

io8Si

i

FIG.

E-8—FLOAT

LEVEL

GAUGING

E-13.

Low-Speed System

Fuel

for idle and early part-throttle operation is

metered through the low-speed system. The low-

speed system is illustrated in Fig.

E-9.

Liquid

fuel enters the idle well through the metering rod jet.

Low-speed

jet measures the amount of fuel for

idle and early part-throttle operation. Air-by-pass,

economizer, and idle air bleed are carefully

cali

brated

orifices which serve to break up the liquid

fuel

and mix it with air as it

moves

through the passage to the idle port and idle adjustment screw

port.

E-14.

Idle Mixture Adjustment

Note:

The idle mixture adjustment procedure for

the late model

YF-4941S

and

YF-6115S

Carter

Carburetor

equipped with the

External

Idle

Mixture

Limiter

Cap is the same as outlined below 114

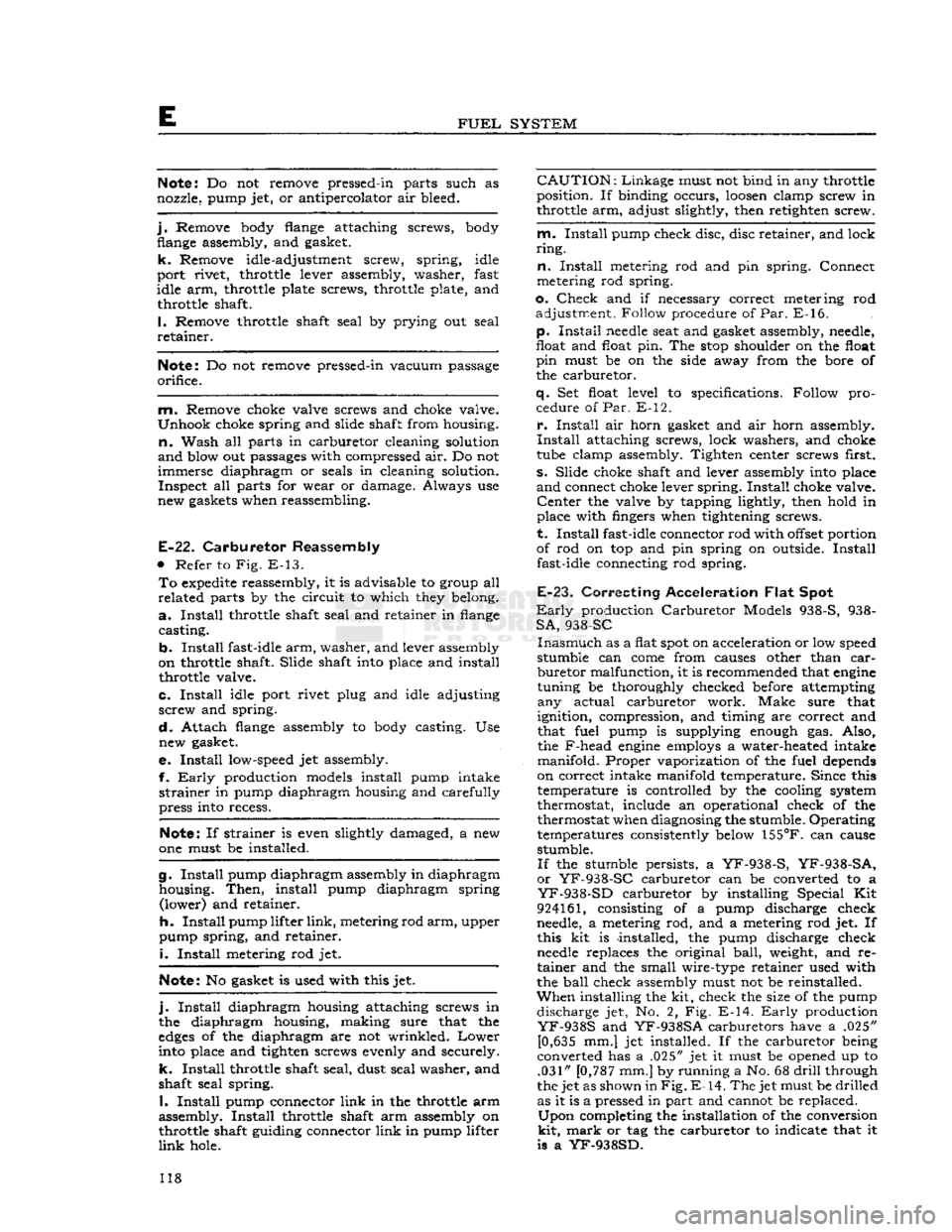

Page 118 of 376

E

FUEL

SYSTEM

Note:

Do not remove pressed-in parts such as

nozzle, pump jet, or antipercolator air bleed.

j.

Remove body flange attaching screws, body flange assembly, and gasket.

k.

Remove idle-adjustment screw, spring, idle

port

rivet, throttle lever assembly, washer, fast

idle arm, throttle plate screws, throttle plate, and throttle shaft.

1. Remove throttle shaft seal by prying out seal

retainer.

Note:

Do not remove pressed-in vacuum passage

orifice.

m.

Remove choke valve screws and choke valve.

Unhook

choke spring and slide shaft from housing,

n.

Wash all parts in carburetor cleaning solution

and

blow out passages with compressed air. Do not immerse diaphragm or seals in cleaning solution.

Inspect

all parts for wear or damage. Always use

new gaskets when reassembling.

E-22.

Carburetor

Reassembly

•

Refer to Fig. E-13.

To

expedite

reassembly, it is advisable to group all

related

parts by the circuit to which they belong.

a.

Install

throttle shaft seal and retainer in flange casting.

b.

Install

fast-idle

arm,

washer, and lever assembly

on throttle shaft. Slide shaft into place and install throttle valve.

c.

Install

idle port rivet plug and idle adjusting

screw

and spring.

d.

Attach flange assembly to body casting. Use new gasket.

e.

Install

low-speed jet assembly.

f.

Early

production models install pump intake

strainer

in pump diaphragm housing and carefully

press into recess.

Note:

If strainer is even slightly damaged, a new

one must be installed.

g.

Install

pump diaphragm assembly in diaphragm housing.

Then,

install pump diaphragm spring

(lower)

and retainer.

h.

Install

pump lifter

link,

metering rod

arm,

upper

pump spring, and retainer.

I.

Install

metering rod jet.

Note:

No gasket is used with this jet.

j.

Install

diaphragm housing attaching screws in

the diaphragm housing, making sure that the

edges

of the diaphragm are not wrinkled.

Lower

into place and tighten screws evenly and securely,

k.

Install

throttle shaft seal, dust seal washer, and

shaft seal spring.

I.

Install

pump connector

link

in the throttle arm

assembly.

Install

throttle shaft arm assembly on

throttle shaft guiding connector

link

in pump lifter

link

hole.

CAUTION:

Linkage

must not bind in any throttle

position. If binding occurs,

loosen

clamp screw in

throttle arm, adjust slightly, then retighten screw.

m.

Install

pump check disc, disc retainer, and lock

ring.

n.

Install

metering rod and pin spring. Connect

metering rod spring.

o.

Check

and if necessary correct meter ing rod adjustment. Follow procedure of

Par.

E-16.

p.

Install

needle

seat and gasket assembly, needle,

float

and

float pin. The

stop

shoulder on the float

pin

must be on the side away from the bore of

the carburetor.

q.

Set float level to specifications. Follow pro cedure of

Par.

E-12.

r.

Install

air horn gasket and air horn assembly.

Install

attaching screws, lock washers, and choke

tube clamp assembly. Tighten center screws first,

s. Slide choke shaft and lever assembly into place

and

connect choke lever

spring.

Install

choke valve.

Center

the valve by tapping lightly, then hold in

place with fingers when tightening screws,

t.

Install

fast-idle connector rod with

offset

portion

of rod on top and pin spring on outside.

Install

fast-idle connecting rod spring.

E-23.

Correcting Acceleration

Flat

Spot

Early

production

Carburetor

Models 938-S, 938-

SA,

938-SC

Inasmuch

as a flat

spot

on acceleration or low speed

stumble can

come

from causes other than

car

buretor

malfunction, it is recommended that

engine

tuning be thoroughly checked before attempting

any

actual carburetor work. Make sure that

ignition, compression, and timing are correct and

that fuel pump is supplying enough gas. Also, the F-head

engine

employs a water-heated intake

manifold.

Proper vaporization of the fuel depends

on correct intake manifold temperature. Since this

temperature is controlled by the cooling system

thermostat, include an operational check of the

thermostat when diagnosing the stumble. Operating

temperatures consistently below

155°F.

can cause stumble.

If

the stumble persists, a

YF-938-S,

YF-938-SA,

or

YF-938-SC

carburetor can be converted to a

YF-938-SD

carburetor by installing Special Kit

924161, consisting of a pump discharge check

needle, a metering rod, and a metering rod jet. If this kit is installed, the pump discharge check

needle

replaces the original

ball,

weight, and re

tainer

and the small wire-type retainer used with

the

ball

check assembly must not be reinstalled.

When

installing the kit, check the size of the pump discharge jet, No. 2, Fig. E-14.

Early

production

YF-938S

and

YF-938SA

carburetors have a .025" [0,635 mm.] jet installed. If the carburetor being

converted has a .025" jet it must be opened up to .031" [0,787 mm.] by running a No. 68

drill

through

the jet as shown in

Fig.

E-14.

The jet must be drilled

as it is a pressed in part and cannot be replaced.

Upon

completing the installation of the conversion

kit,

mark

or tag the carburetor to indicate that it

is a

YF-938SD.

118

Page 125 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

E

is generally caused by excessive

engine

idle speed

in

combination with retarded ignition timing,

engine

heat soak or the use cf low octane fuel.

Should

engine

dieseling

(engine

running after ignition key is turned off) be experienced on V-6

engine

equipped vehicles, installation of Idle Stop

Valve

Kit

Part

No.

991722

will

correct the

difficulty.

E-43.

Fast

Idle Adjustment

No fast idle speed adjustment is required.

Fast

idle is controlled by the curb idle speed adjustment

screw.

If curb idle speed is correctly set and the choke rod is properly adjusted, fast idle speed

will

be correct;

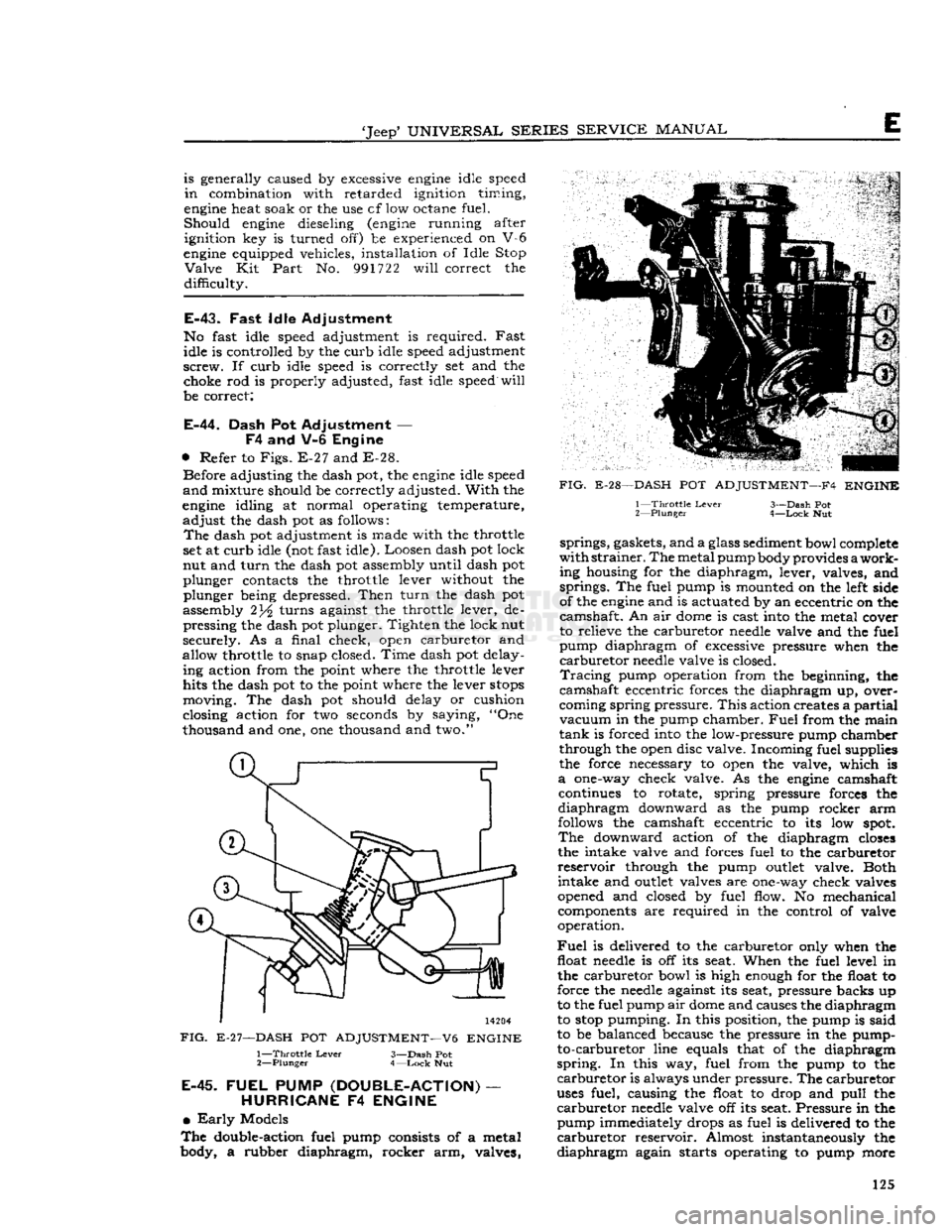

E-44.

Dash Pot Adjustment —

F4

and V-6 Engine

•

Refer to

Figs.

E-27 and E-28. Before adjusting the dash pot, the

engine

idle speed

and

mixture should be correctly adjusted.

With

the

engine

idling at normal operating temperature,

adjust

the dash pot as follows:

The

dash pot adjustment is made with the throttle

set at curb idle (not fast idle). Loosen dash pot lock

nut and

turn

the dash pot assembly until dash pot

plunger contacts the throttle lever without the plunger being depressed.

Then

turn

the dash pot

assembly 2turns against the throttle lever, de pressing the dash pot plunger. Tighten the lock nut

securely. As a final check, open carburetor and

allow throttle to snap closed. Time dash pot delay ing action from the point where the throttle lever

hits the dash pot to the point where the lever

stops

moving. The dash pot should delay or cushion

closing action for two seconds by saying, "One

thousand and one, one thousand and two."

14204

FIG.

E-27—DASH

POT

ADJUSTMENT—V6

ENGINE

1—

Throttle

Lever

3—Dash Pot

2—

Plunger

4—Lock

Nut

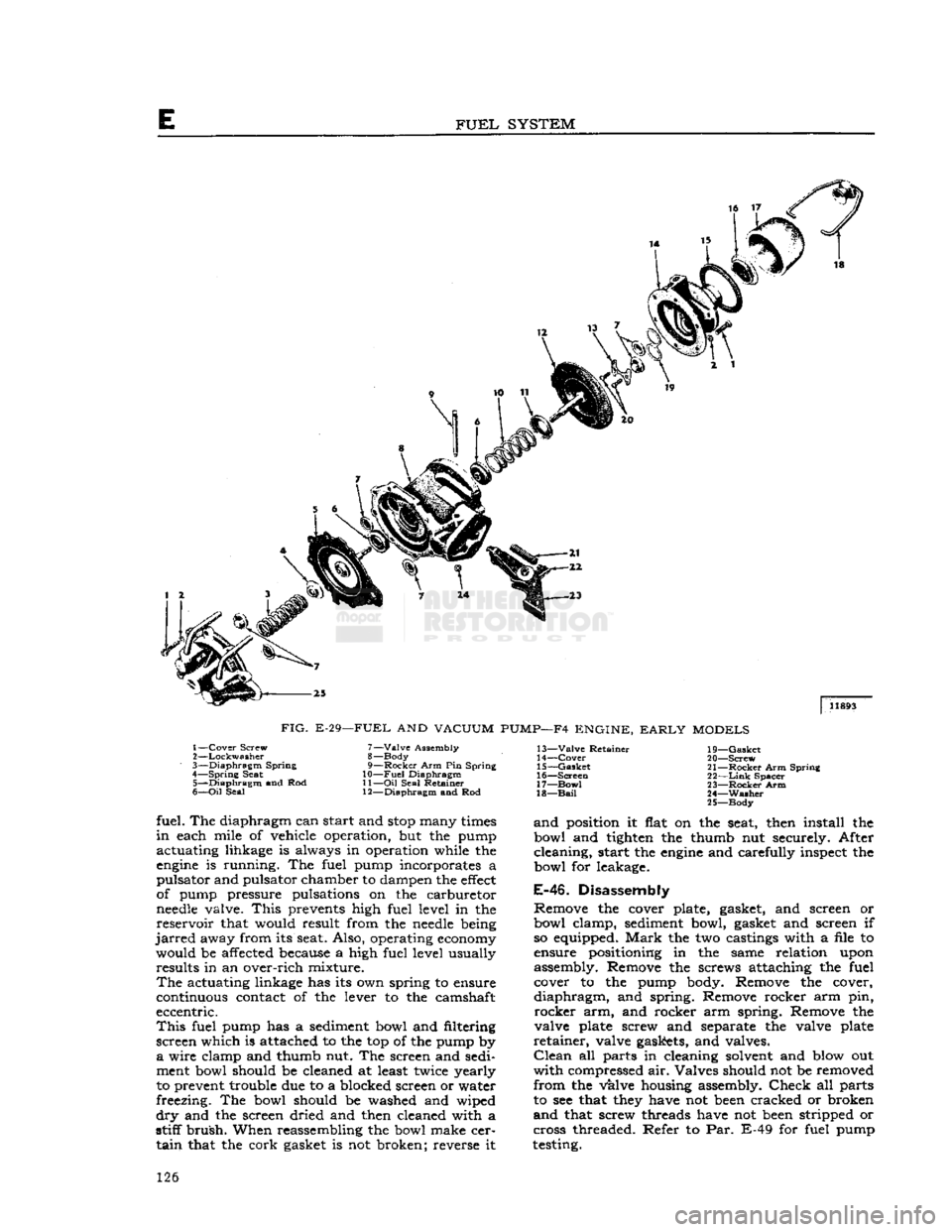

E-45.

FUEL

PUMP

(DOUBLE-ACTION)

—

HURRICANE

F4

ENGINE

•

Early

Models

The

double-action fuel pump consists of a metal

body, a rubber diaphragm, rocker arm, valves,

FIG.

E-28—DASH

POT

ADJUSTMENT—F4

ENGINE

1—

Throttle

Lever

3—Dash Pot

2—

Plunger

4—Lock

Nut springs, gaskets, and a glass sediment bowl complete

with

strainer.

The

metal pump body provides

a

work

ing housing for the diaphragm, lever, valves, and springs. The fuel pump is mounted on the left side

of the

engine

and is actuated by an eccentric on the

camshaft. An air

dome

is cast into the metal cover

to relieve the carburetor

needle

valve and the fuel

pump diaphragm of excessive pressure when the

carburetor

needle

valve is closed.

Tracing

pump operation from the beginning, the

camshaft eccentric forces the diaphragm up, over

coming spring pressure.

This

action creates a

partial

vacuum

in the pump chamber.

Fuel

from the main

tank

is forced into the low-pressure pump chamber

through the open disc valve. Incoming fuel supplies

the force necessary to open the valve, which is

a

one-way check valve. As the

engine

camshaft continues to rotate, spring pressure forces the

diaphragm

downward as the pump rocker arm

follows the camshaft eccentric to its low

spot.

The

downward action of the diaphragm

closes

the intake valve and forces fuel to the carburetor

reservoir

through the pump

outlet

valve. Both intake and

outlet

valves are one-way check valves

opened and closed by fuel flow. No mechanical components are required in the control of valve

operation.

Fuel

is delivered to the carburetor only when the float

needle

is off its seat. When the fuel level in the carburetor bowl is high enough for the float to

force the

needle

against its seat, pressure backs up

to the fuel pump air

dome

and causes the diaphragm

to

stop

pumping. In this position, the pump is said

to be balanced because the pressure in the pump- to-carburetor line equals that of the diaphragm

spring.

In this way, fuel from the pump to the

carburetor

is always under pressure. The carburetor

uses

fuel, causing the float to drop and

pull

the

carburetor

needle

valve off its seat. Pressure in the pump immediately drops as fuel is delivered to the

carburetor

reservoir. Almost instantaneously the

diaphragm

again starts operating to pump more 125

Page 126 of 376

FUEL

SYSTEM

|

11893

FIG.

E-29—FUEL

AND

VACUUM

PUMP—F4

ENGINE,

EARLY

MODELS

1—

Cover

Screw

2—

Lockwasher

3—

Diaphragm

Spring

4—

Spring

Seat 5—

Diaphragm

and Rod

6—

Oil

Seal 7—

Valve

Assembly

8— Body

9—

Rocker

Arm Pin Spring

10—

Fuel

Diaphragm

11—

Oil

Seal Retainer

12—

Diaphragm

and Rod 13—

Valve

Retainer

14—

Cover

15—

Gasket

16—

Screen

17—

Bow!

18—

Bail

19—

Gasket

20—

Screw

21—

Rocker

Arm Spring

22—

Link

Spacer

23—

Rocker

Arm

24—

Washer

25—

Body

fuel. The diaphragm can start and

stop

many

times

in

each mile of vehicle operation, but the pump

actuating lihkage is always in operation while the

engine

is running. The fuel pump incorporates a

pulsator and pulsator chamber to dampen the

effect

of pump pressure pulsations on the carburetor

needle

valve.

This

prevents high fuel level in the

reservoir

that would result from the

needle

being

jarred

away from its seat. Also, operating

economy

would be affected because a high fuel level usually results in an over-rich mixture.

The

actuating linkage has its own spring to ensure

continuous contact of the lever to the camshaft

eccentric.

This

fuel pump has a sediment bowl and filtering

screen which is attached to the top of the pump by

a

wire clamp and thumb nut. The screen and sedi

ment bowl should be cleaned at least twice yearly

to prevent trouble due to a blocked screen or water

freezing. The bowl should be washed and wiped

dry

and the screen dried and then cleaned with a

stiff

brush.

When reassembling the bowl make cer

tain

that the cork gasket is not broken; reverse it

and

position it flat on the seat, then install the

bowl and tighten the thumb nut securely. After

cleaning, start the

engine

and carefully inspect the

bowl for leakage.

E-46.

Disassembly

Remove the cover plate, gasket, and screen or

bowl clamp, sediment bowl, gasket and screen if so equipped.

Mark

the two castings with a file to

ensure positioning in the same relation upon

assembly. Remove the screws attaching the fuel cover to the pump body. Remove the cover,

diaphragm,

and spring. Remove rocker arm pin,

rocker

arm, and rocker arm spring. Remove the

valve plate screw and separate the valve plate

retainer,

valve gaskets, and valves.

Clean

all parts in cleaning solvent and blow out

with

compressed air. Valves should not be removed

from

the valve housing assembly.

Check

all parts

to see that

they

have not

been

cracked or broken

and

that screw threads have not

been

stripped or

cross threaded. Refer to Par. E-49 for fuel pump

testing. 126