ESP JEEP CJ 1953 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 21 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

FIG.

C-3—SETTING SPARK PLUG

GAP

1—Wire

Gauge 2—Spark Plug

c.

Blow out all carbon and

dirt

from each

spark

plug hole with compressed air. If compressed air is

not available, start the engine and accelerate to 1000 rpm. to blow out the carbon and

dirt.

Stop

the engine.

d.

Remove the plugs carefully with a

spark

plug

wrench.

e. Inspect the plugs for serviceability. Especially

check

for burned and eroded electrodes, blistering

of porcelain at the firing tip, cracked porcelain, or

black

deposits and fouling. These conditions in

dicate that the plugs have not been operating at

the correct temperature. Replace bad or worn plugs

in

sets.

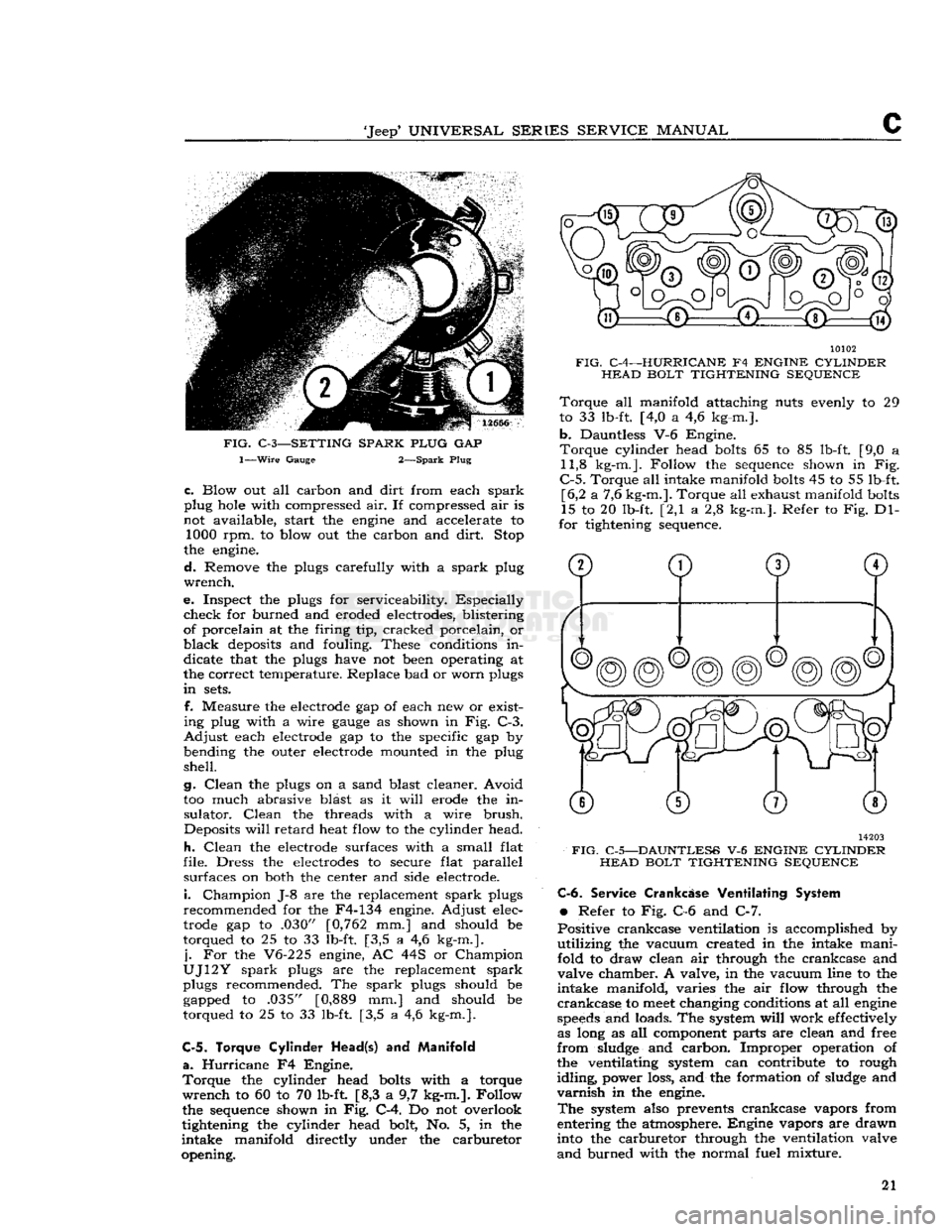

f. Measure the electrode gap of each new or exist

ing plug with a wire

gauge

as shown in Fig. C-3.

Adjust

each electrode gap to the specific gap by

bending the outer electrode mounted in the plug

shell.

g.

Clean

the plugs on a sand blast cleaner. Avoid

too much abrasive blast as it

will

erode the in

sulator.

Clean

the threads with a wire

brush.

Deposits

will

retard

heat flow to the cylinder head.

h.

Clean

the electrode surfaces with a small flat

file. Dress the electrodes to secure flat parallel surfaces on both the center and side electrode.

i.

Champion J-8 are the replacement

spark

plugs

recommended for the F4-134 engine. Adjust elec

trode gap to .030" [0,762 mm.] and should be

torqued to 25 to 33 lb-ft. [3,5 a 4,6 kg-m.].

j.

For the V6-225 engine, AC 44S or Champion

UJ12Y

spark

plugs are the replacement

spark

plugs recommended. The

spark

plugs should be gapped to .035" [0,889 mm.] and should be

torqued to 25 to 33 lb-ft. [3,5 a 4,6 kg-m.].

C-5. Torque Cylinder

Head(s)

and

Manifold

a.

Hurricane

F4 Engine.

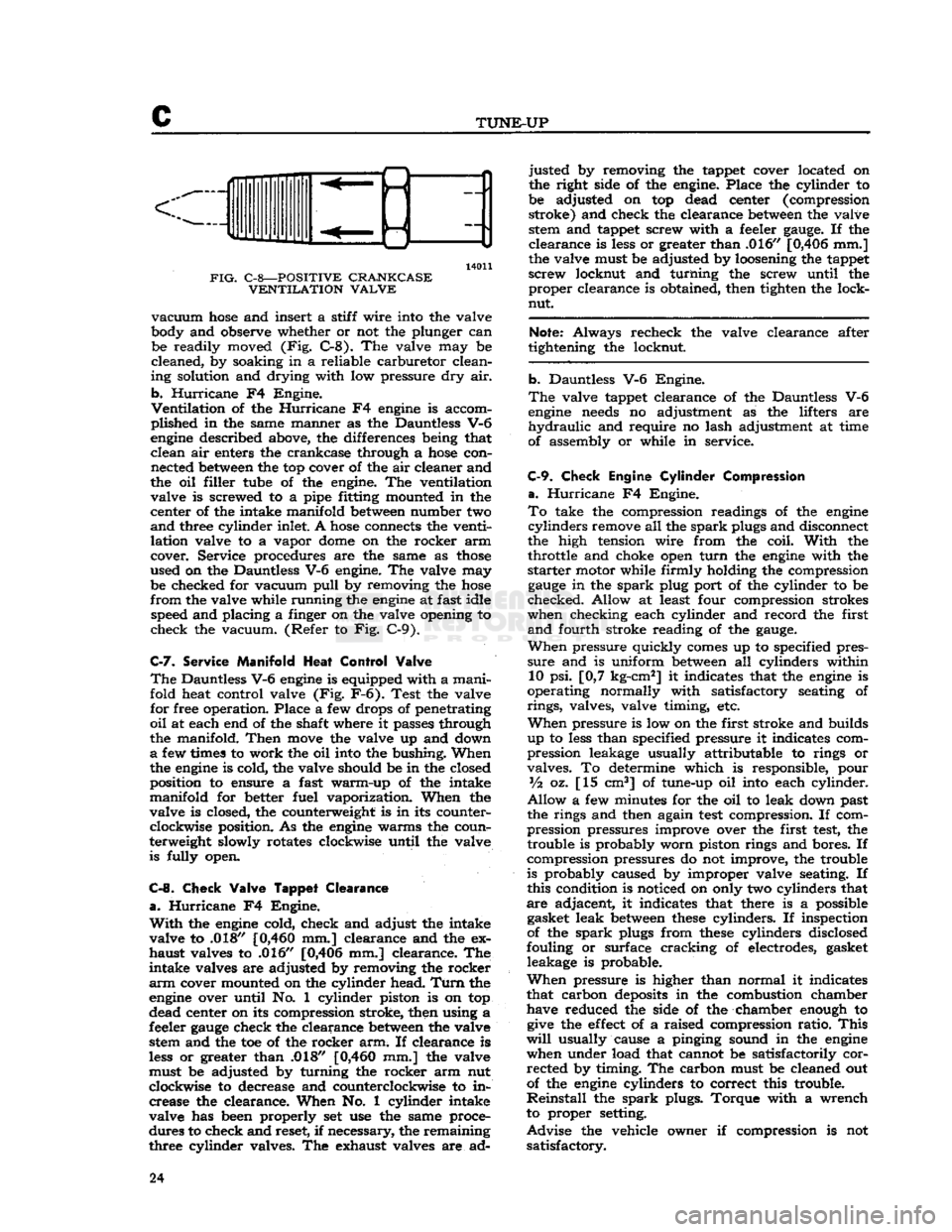

Torque

the cylinder head bolts with a torque

wrench

to 60 to 70 lb-ft [8,3 a 9,7 kg-m.]. Follow

the sequence shown in Fig. C-4. Do not overlook

tightening the cylinder head bolt, No. 5, in the

intake

manifold directly under the carburetor

opening. 10102

FIG.

C-4—HURRICANE

F4

ENGINE CYLINDER HEAD BOLT TIGHTENING SEQUENCE

Torque

all manifold attaching nuts evenly to 29

to 33 lb-ft. [4,0 a 4,6 kg-m.].

b.

Dauntless V-6 Engine.

Torque

cylinder head bolts 65 to 85 lb-ft. [9,0 a 11,8 kg-m.]. Follow the sequence shown in Fig.

C-5.

Torque all intake manifold bolts 45 to 55 lb-ft. [6,2 a 7,6 kg-m.]. Torque all exhaust manifold bolts

15 to 20 lb-ft. [2,1 a 2,8 kg-m.]. Refer to Fig. Dl-

for tightening sequence. 14203

FIG.

C-5—DAUNTLESS

V-6

ENGINE CYLINDER HEAD BOLT TIGHTENING SEQUENCE C-6.

Service

Crankcase

Ventilating System

•

Refer to Fig. C-6 and C-7.

Positive crankcase ventilation is accomplished by

utilizing

the vacuum created in the intake mani

fold to draw clean air through the crankcase and

valve chamber. A valve, in the vacuum line to the

intake

manifold, varies the air flow through the

crankcase

to

meet

changing conditions at all engine

speeds

and loads. The system

will

work effectively as long as all component parts are clean and free

from

sludge and carbon. Improper operation of the ventilating system can contribute to rough

idling,

power loss, and the formation of sludge and

varnish

in the engine.

The

system also prevents crankcase vapors from

entering the atmosphere. Engine vapors are drawn

into the carburetor through the ventilation valve

and

burned with the normal fuel mixture. 21

Page 24 of 376

c

TUNE-UP

14011

FIG.

C-8—POSITIVE CRANKCASE VENTILATION VALVE

vacuum

hose

and insert a stiff wire into the valve

body and observe whether or not the plunger can be readily moved (Fig. C-8). The valve may be

cleaned, by soaking in a reliable carburetor clean

ing solution and drying with low pressure dry air.

b.

Hurricane

F4 Engine.

Ventilation

of the

Hurricane

F4

engine

is accom

plished in the same manner as the Dauntless V-6

engine

described above, the differences being that clean air enters the crankcase through a

hose

con nected

between

the top cover of the air cleaner and

the oil filler tube of the engine. The ventilation valve is screwed to a pipe fitting mounted in the

center of the intake manifold

between

number two

and

three cylinder inlet. A

hose

connects the venti

lation valve to a vapor

dome

on the rocker arm

cover. Service procedures are the same as

those

used on the Dauntless V-6 engine. The valve may be checked for vacuum

pull

by removing the

hose

from

the valve while running the

engine

at fast idle speed and placing a finger on the valve opening to

check the vacuum. (Refer to Fig. C-9).

C-7.

Service

Manifold

Heat

Control

Valve

The

Dauntless V-6

engine

is equipped with a manifold heat control valve (Fig. F-6). Test the valve

for free operation. Place a few drops of penetrating

oil

at each end of the shaft where it passes through

the manifold.

Then

move

the valve up and down

a

few times to work the oil into the bushing. When

the

engine

is cold, the valve should be in the closed

position to ensure a fast warm-up of the intake

manifold for better fuel vaporization. When the

valve is closed, the counterweight is in its counter clockwise position. As the

engine

warms the coun

terweight slowly rotates clockwise until the valve is fully open.

C-8.

Check

Valve

Tappet

Clearance

a.

Hurricane

F4 Engine.

With

the

engine

cold, check and adjust the intake

valve to .018"

[0,460

mm.] clearance and the ex

haust valves to .016" [0,406 mm.] clearance. The

intake valves are adjusted by removing the rocker

arm

cover mounted on the cylinder head.

Turn

the

engine

over until No. 1 cylinder piston is on top

dead center on its compression stroke, then using a

feeler

gauge

check the clearance

between

the valve stem and the toe of the rocker arm. If clearance is

less

or greater than .018"

[0,460

mm.] the valve

must be adjusted by turning the rocker arm nut

clockwise to decrease and counterclockwise to in crease the clearance. When No. 1 cylinder intake

valve has been properly set use the same proce

dures to check and reset, if necessary, the remaining

three cylinder valves. The exhaust valves are ad justed by removing the tappet cover located on

the right side of the engine. Place the cylinder to

be adjusted on top dead center (compression stroke) and check the clearance

between

the valve stem and tappet screw with a feeler

gauge.

If the

clearance is

less

or greater than .016" [0,406 mm.]

the valve must be adjusted by loosening the tappet

screw locknut and turning the screw until the proper clearance is obtained, then tighten the lock-

nut.

Note:

Always recheck the valve clearance after

tightening the locknut.

b. Dauntless V-6 Engine.

The

valve tappet clearance of the Dauntless V-6

engine

needs

no adjustment as the lifters are

hydraulic

and require no lash adjustment at time

of assembly or while in service.

C-9.

Check

Engine

Cylinder

Compression

a.

Hurricane

F4 Engine.

To

take the compression readings of the

engine

cylinders

remove all the

spark

plugs and disconnect

the high tension wire from the coil.

With

the throttle and choke open

turn

the

engine

with the

starter

motor while firmly holding the compression

gauge

in the

spark

plug port of the cylinder to be

checked. Allow at least four compression strokes

when checking each cylinder and record the first

and

fourth stroke reading of the

gauge.

When

pressure quickly

comes

up to specified pres

sure

and is uniform

between

all cylinders within 10 psi. [0,7 kg-cm2] it indicates that the

engine

is

operating normally with satisfactory seating of

rings,

valves, valve timing, etc.

When

pressure is low on the first stroke and builds

up to

less

than specified pressure it indicates com

pression leakage usually attributable to rings or

valves. To determine which is responsible, pour

Vz

oz. [15 cm3] of tune-up oil into each cylinder.

Allow

a few minutes for the oil to leak down past

the rings and then again

test

compression. If com

pression pressures improve over the first

test,

the trouble is probably worn piston rings and bores. If

compression pressures do not improve, the trouble

is probably caused by improper valve seating. If

this condition is noticed on only two cylinders that

are adjacent, it indicates that there is a possible gasket leak

between

these

cylinders. If inspection

of the

spark

plugs from

these

cylinders disclosed

fouling or surface cracking of electrodes, gasket leakage is probable.

When

pressure is higher than normal it indicates

that carbon

deposits

in the combustion chamber have reduced the side of the chamber enough to

give

the

effect

of a raised compression ratio.

This

will

usually cause a pinging sound in the

engine

when under load that cannot be satisfactorily corrected by timing. The carbon must be cleaned out

of the

engine

cylinders to correct this trouble.

Reinstall

the

spark

plugs. Torque with a wrench

to proper setting.

Advise

the vehicle owner if compression is not satisfactory. 24

Page 25 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

COMPRESSION PRESSURE LIMIT CHART

Maximum

Pressure

Minimum

Pressure

Maximum

Pressure

Minimum

Pressure

psi.

kg-cm2

psi.

kg-cm2

psi.

kg-cm2

psi.

kg-cm2

134 9,42 101 7,10

188

13,22 141

9,91

136 9,56 102 7,17 190

13,36 142

9,98

138 9,70 104 7,31 192

13,50 144 10,12

140 9,84 105 7,38 194

13,64 145

10,19

142 9,98 107 7,52 196

13,78 147 10,33

144 10,12 108 7,59 198

13,92

148 10,40

146 10,26 110 7,73 200

14,06 150 10,55

148 10,40 111 7,80

202

14,20 151

10,62

150 10,55 113 7,94 204

14,34 153

10,76

152 10,68 114 8,01 206

14,48 154 10,83

154 10,83

115 8,08 208

14,62 156

10,97

156 10,97 117 8,23

210

14,76 157 11,04

158 11,11 118 8,30 212

14,90

158 11,11

160 11,25 120

8,44 214

15,04 160

11,25

162 11,39 121 8,51 216

15,18 162 11,39

164 11,53

123 8,65 218

15,32 163

11,46

166 11,67 124 8,72 220

15,46 165 11,60

168 11,81 126 8,86 222

15,61 166

11,67

170 11,95 127 9,83 224

15,75 168 11,81

172 12,09 129 9,07 226

15,89 169

11,88

174 12,23 131 9,21 228

16,03 171 12,02

176 12,37 132 9,28 230

16,17 172

12,09

178 12,51 133 9,35 232

16,31

174 12,23

180 12,65 135 9,49

234

16,45 175 12,30

182 12,79 136 9,56 236

16,59 177 12,44

184 12,94 138 9,70

238

16,73 178 12,51

186 13,08 140 9,84

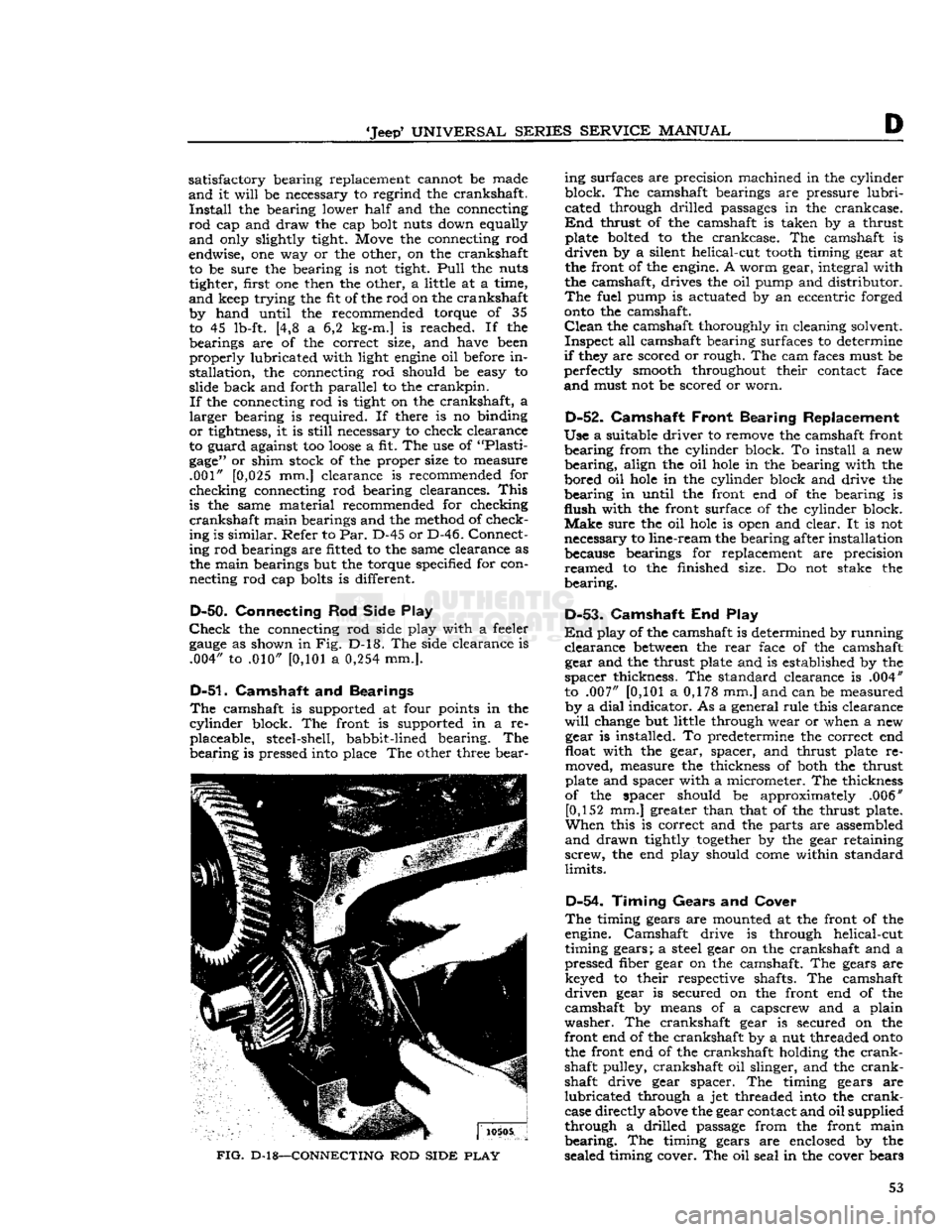

b.

Dauntless V-6 Engine.

To

check the

engine

cylinder compression use the

following procedures:

Firmly

insert compression

gauge

in

spark

plug

port

(Fig.

C-10).

Crank

engine

through at least four

compression strokes to obtain highest possible

reading.

Check

compression of each cylinder. Repeat com

pression check and record highest reading obtained on each cylinder during the two pressure checks.

Note:

The recorded compression pressures are to

be considered normal if the lowest reading cylinder

is more than seventy-five percent of the highest

reading

cylinder. See the following example and

the "Compression Pressure

Limit

Chart".

Example:

Cylinder

No. 1 2 3 4 5 6

Pressure

(psi.) 129 135 140 121 120 100

Seventy-five percent of 140 (highest) is 105.

Thus,

Cylinder

No. 6 is

less

than seventy-five percent

of

Cylinder

No. 3.

This

condition, accompanied by low speed missing, indicates an improperly seated

valve or worn or broken piston

ring.

If

one or more cylinders read low, inject about

a

tablespoon of

engine

oil on top of pistons in low

reading

cylinders through

spark

plug port. Repeat compression check on

these

cylinders.

If

compression improves considerably, rings are

worn.

If compression

does

not improve, valves are

sticking

or seating poorly.

If

two adjacent cylinders indicate low compression

and

injecting oil

does

not increase compression, the

cause may be a head gasket leak

between

the

cylinders.

Engine coolant and/or oil in cylinders could result from this

defect.

FIG.

C-10—CHECKING ENGINE CYLINDER

COMPRESSION

—

DAUNTLESS

V-6

ENGINE

FIG.

C-l

1—CONTACT

POINTS

MATERIAL

TRANSFER

25

Page 53 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

D

satisfactory bearing replacement cannot be made

and

it

will

be necessary to regrind the crankshaft.

Install

the bearing lower

half

and the connecting

rod

cap and draw the cap bolt nuts down equally

and

only slightly tight. Move the connecting rod

endwise, one way or the other, on the crankshaft to be sure the bearing is not tight.

Pull

the nuts tighter, first one then the other, a little at a time,

and

keep trying the fit of the rod on the crankshaft by hand until the recommended torque of 35 to 45 lb-ft. [4,8 a 6,2 kg-m.] is reached. If the

bearings are of the correct size, and have been

properly

lubricated with light

engine

oil before in

stallation,

the connecting rod should be easy to

slide back and forth parallel to the

crankpin.

If

the connecting rod is tight on the crankshaft, a

larger

bearing is required. If there is no binding

or

tightness, it is

still

necessary to check clearance

to guard against too

loose

a fit. The use of "Plasti

gage"

or shim stock of the proper size to measure .001" [0,025 mm.] clearance is recommended for

checking

connecting rod bearing clearances.

This

is the same material recommended for checking

crankshaft

main bearings and the method of check

ing is

similar.

Refer to

Par.

D-45 or D-46. Connect

ing rod bearings are fitted to the same clearance as the main bearings but the torque specified for con

necting rod cap

bolts

is different.

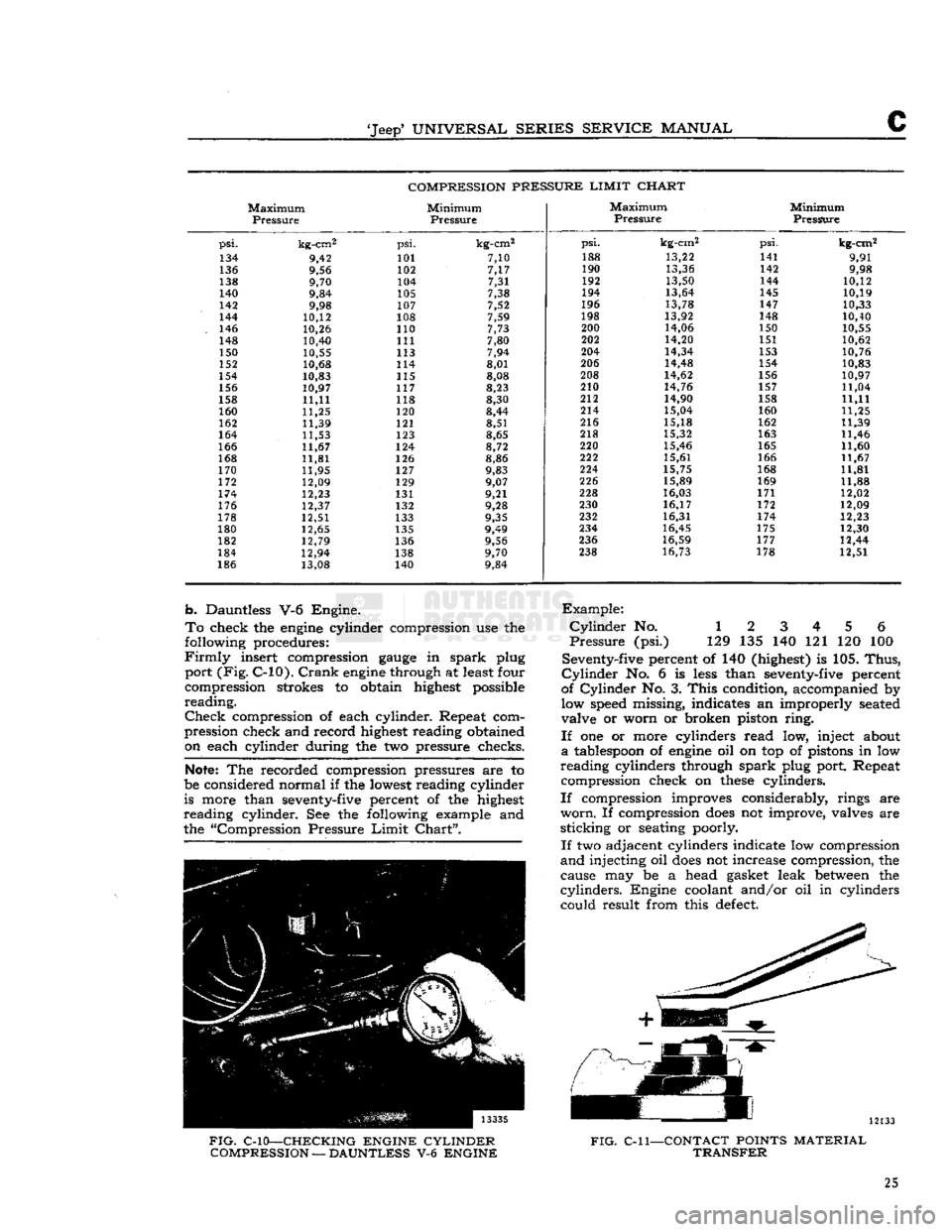

D-50.

Connecting

Rod

Side Play

Check

the connecting rod side play with a feeler

gauge

as shown in Fig. D-l8. The side clearance is .004" to .010"

[0,101

a

0,254

mm.].

D-51.

Camshaft and Bearings

The

camshaft is supported at four points in the

cylinder

block. The front is supported in a re placeable, steel-shell, babbit-lined bearing. The

bearing

is pressed into place The other three bear-

FIG.

D-18—CONNECTING

ROD

SIDE

PLAY

ing surfaces are precision machined in the cylinder

block. The camshaft bearings are pressure

lubri

cated through drilled passages in the crankcase.

End

thrust of the camshaft is taken by a thrust plate bolted to the crankcase. The camshaft is

driven

by a silent helical-cut

tooth

timing gear at

the front of the engine. A worm gear, integral with

the camshaft, drives the oil pump and distributor.

The

fuel pump is actuated by an eccentric forged

onto

the camshaft.

Clean

the camshaft thoroughly in cleaning solvent.

Inspect

all camshaft bearing surfaces to determine

if

they are scored or rough. The cam faces must be

perfectly smooth throughout their contact face

and

must not be scored or worn.

D-52.

Camshaft

Front Bearing Replacement

Use

a suitable driver to remove the camshaft front

bearing

from the cylinder block. To install a new

bearing,

align the oil

hole

in the bearing with the

bored oil

hole

in the cylinder block and drive the

bearing

in until the front end of the bearing is

flush

with the front surface of the cylinder block.

Make

sure the oil

hole

is open and clear. It is not

necessary to line-ream the bearing after installation because bearings for replacement are precision

reamed

to the finished size. Do not stake the

bearing.

D-53-

Camshaft End Play

End

play of the camshaft is determined by running

clearance

between

the

rear

face of the camshaft gear and the thrust plate and is established by the

spacer

thickness. The standard clearance is .004"

to .007"

[0,101

a 0,178 mm.] and can be measured by a

dial

indicator. As a general rule this clearance

will

change but little through wear or when a new gear is installed. To predetermine the correct end

float with the gear, spacer, and thrust plate re

moved, measure the thickness of both the thrust

plate and spacer with a micrometer. The thickness

of the spacer should be approximately .006" [0,152 mm.] greater than that of the thrust plate.

When

this is correct and the parts are assembled

and

drawn tightly

together

by the gear retaining

screw,

the end play should

come

within standard

limits.

D-54.

Timing Gears

and

Cover

The

timing gears are mounted at the front of the

engine. Camshaft drive is through helical-cut

timing gears; a steel gear on the crankshaft and a

pressed fiber gear on the camshaft. The gears are keyed to their respective shafts. The camshaft

driven

gear is secured on the front end of the

camshaft by means of a capscrew and a plain

washer.

The crankshaft gear is secured on the

front end of the crankshaft by a nut threaded

onto

the front end of the crankshaft holding the

crank

shaft pulley, crankshaft oil slinger, and the

crank

shaft drive gear spacer. The timing gears are

lubricated

through a jet threaded into the

crank

case directly above the gear contact and oil supplied

through a drilled passage from the front main

bearing.

The timing gears are enclosed by the

sealed timing cover. The oil seal in the cover bears 53

Page 55 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

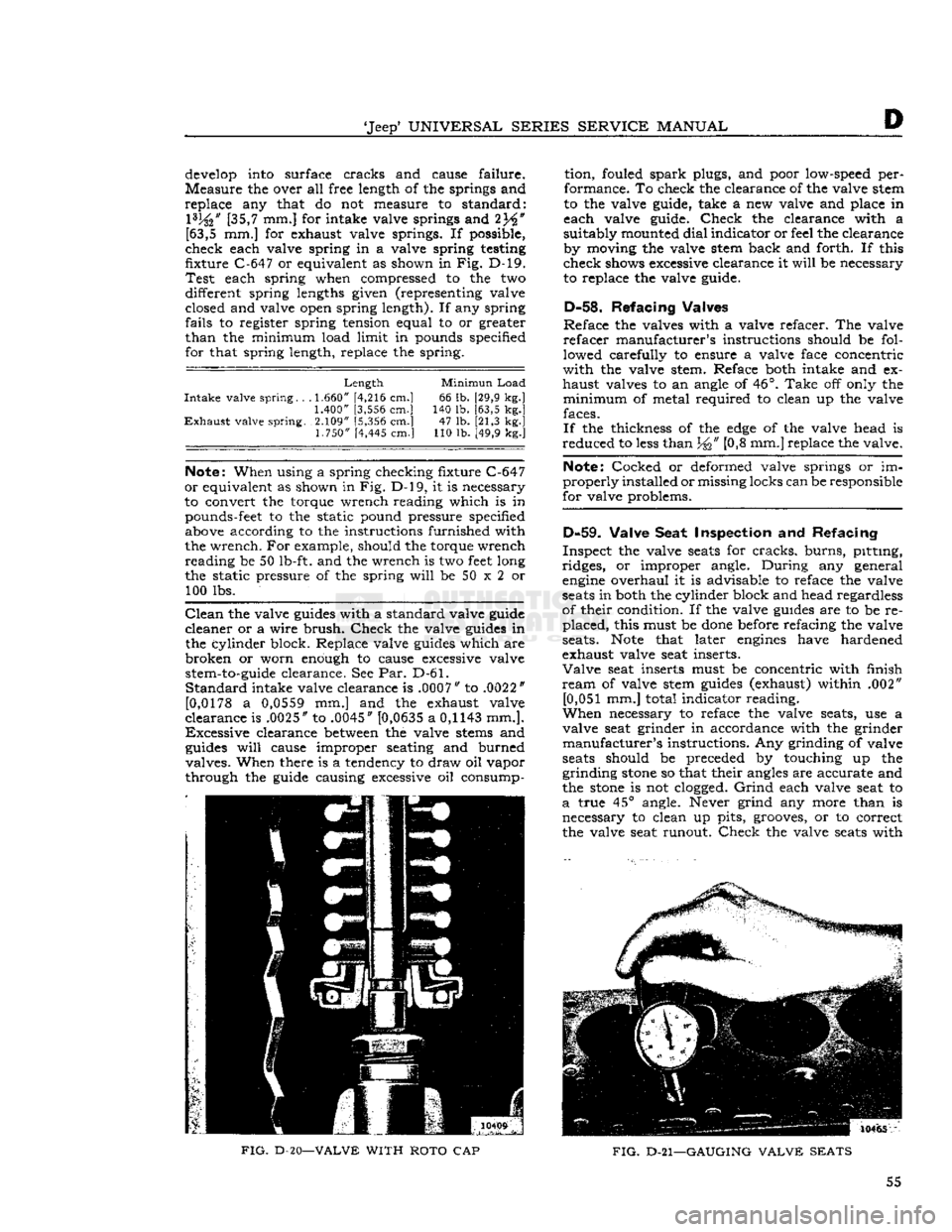

develop

into surface cracks and cause failure.

Measure

the over all free length of the springs and

replace any that do not measure to standard: 1%" [35,7 mm.] for intake valve springs and 2j^"

[63,5 mm.] for exhaust valve springs. If possible,

check each valve spring in a valve spring testing

fixture C-647 or equivalent as shown in Fig. D-l9.

Test

each spring when compressed to the two

different spring lengths given (representing valve closed and valve open spring length). If any spring

fails to register spring tension equal to or greater

than

the minimum load limit in pounds specified for that spring length, replace the spring.

Length

Minimun

Load

Intake

valve spring. . .

1.660"

[4,216 cm.] 66 lb. [29,9 kg.]

1.400"

[3,556 cm.] 140 lb. [63,5 kg.]

Exhaust

valve spring. 2.109" [5,356 cm.] 47 lb. [21,3 kg.]

1.750"

[4,445 cm.] 110 lb. [49,9 kg.]

Note:

When using a spring checking fixture C-647

or

equivalent as shown in Fig. D-l9, it is necessary

to convert the torque wrench reading which is in pounds-feet to the static pound pressure specified above according to the instructions furnished with

the wrench. For example, should the torque wrench reading be 50 lb-ft. and the wrench is two

feet

long

the static pressure of the spring

will

be 50 x 2 or 100 lbs.

Clean

the valve

guides

with a standard valve guide

cleaner or a wire

brush.

Check

the valve

guides

in the cylinder block. Replace valve

guides

which are

broken

or worn enough to cause excessive valve

stem-to-guide

clearance. See Par. D-61.

Standard

intake valve clearance is .0007" to .0022"

[0,0178

a

0,0559

mm.] and the exhaust valve

clearance is .0025" to .0045" [0,0635 a

0,1143

mm.].

Excessive

clearance

between

the valve

stems

and

guides

will

cause improper seating and burned

valves. When there is a tendency to draw oil vapor

through the guide causing excessive oil consump tion, fouled

spark

plugs, and poor low-speed per

formance. To check the clearance of the valve stem

to the valve guide, take a new valve and place in

each valve guide.

Check

the clearance with a

suitably mounted

dial

indicator or feel the clearance by moving the valve stem back and forth. If this

check shows excessive clearance it

will

be necessary to replace the valve guide.

D-58.

Refacing Valves

Re

face the valves with a valve refacer. The valve

refacer

manufacturer's instructions should be fol

lowed carefully to ensure a valve face concentric

with

the valve stem. Reface both intake and ex

haust valves to an angle of 46°.

Take

off only the

minimum

of metal required to clean up the valve faces.

If

the thickness of the

edge

of the valve head is

reduced to

less

than

J^>"

[0>8 mm.] replace the valve.

Note:

Cocked or deformed valve springs or im

properly

installed or missing locks can be responsible

for valve problems.

D-59.

Valve Seat Inspection

and

Refacing

Inspect the valve

seats

for

cracks,

burns, pitting,

ridges, or improper angle.

During

any general

engine

overhaul it is advisable to reface the valve

seats

in both the cylinder block and head regardless

of their condition. If the valve

guides

are to be re placed, this must be

done

before refacing the valve

seats.

Note

that later

engines

have hardened

exhaust valve seat inserts.

Valve

seat inserts must be concentric with finish

ream

of valve stem

guides

(exhaust) within .002"

[0,051

mm.] total indicator reading.

When

necessary to reface the valve seats, use a

valve seat grinder in accordance with the grinder

manufacturer's

instructions. Any grinding of valve

seats

should be preceded by touching up the

grinding

stone

so that their angles are accurate and

the

stone

is not

clogged.

Grind

each valve seat to

a

true 45° angle. Never grind any more than is necessary to clean up pits, grooves, or to correct

the valve seat runout.

Check

the valve

seats

with

10465

FIG.

D-20—VALVE

WITH

ROTO

CAP

FIG.

D-21—GAUGING

VALVE

SEATS

55

Page 63 of 376

![JEEP CJ 1953 Service Manual

Jeep

UNIVERSAL SERIES SERVICE

MANUAL

D

is .004" to .007"

[0,102

a 0,178 mm.] as measured

by a dial indicator. Should a check

show

too little

end play, place a shim of suitable thickness

JEEP CJ 1953 Service Manual

Jeep

UNIVERSAL SERIES SERVICE

MANUAL

D

is .004" to .007"

[0,102

a 0,178 mm.] as measured

by a dial indicator. Should a check

show

too little

end play, place a shim of suitable thickness](/img/16/57040/w960_57040-62.png)

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

D

is .004" to .007"

[0,102

a 0,178 mm.] as measured

by a dial indicator. Should a check

show

too little

end play, place a shim of suitable thickness

between

the camshaft shoulder and the spacer. Too much

end play may be corrected by removing shims or

dressing off the spacer a slight amount. See Fig. D-33.

D-82. Install Crankshaft and Bearings

Fit

the three upper main bearings

into

their

respective

locations

in the cylinder block. Fit the

three lower main bearings

into

their respective

bearing caps.

NOTE:

It is

possible

to incorrectly install the front main bearing. The bearing is properly installed in

the cap with the narrower of the two radial oil

grooves

toward the front

edge

of the cap. If this

bearing is not properly installed, the oil

grooves

in

the two halves of the bearing will not match at the

parting line and premature failure of the bearing

will

result.

Lubricate

all bearing surfaces

generously

with

clean, light

engine

oil. Place the crankshaft in

position

in the cylinder block and install the main

bearing caps. Torque the

bolts

65 to 75 lb-ft.

[9,0 a 10,4 kg-m.] rotating the crankshaft after

each bearing cap is

tightened

D-83. Check Crankshaft End-Play

End

play of the crankshaft is set by the running

clearance

between

the crankshaft thrust washer

and the front

face

of the front main bearing. The

standard end play is .004" to .006"

[0,102

a 0,152

mm.] which is controlled by .002"

[0,051

mm.]

shims placed

between

the thrust washer and the

shoulder on the crankshaft. Check the end play

with a dial indicator as shown in

Fig.

D-34. If clear ance is incorrect, adjustment is made by adding or

removing shims.

Install

the thrust washer with the

beveled

inner

edge

toward the front bearing.

10668

FIG.

D-33—VALVES, CAMSHAFT,

AND

TIMING GEARS

1— Nut

2—

Left

Rocker Arm

3—

Rocker

Arm Shaft Spring

4—

Rocker

Shaft

Lock

Screw 5—

Rocker

Shaft

6— Nut 7—

Right

Rocker Arm

8—

Rocker

Arm Shaft Bracket

9—

Intake

Valve Tappet Adjusting Screw

10—

Intake

Valve Upper Retainer

Lock

11—

Oil

Seal

12—

Intake

Valve Spring Upper Retainer 13—

Intake

Valve Spring

14—

Intake

Valve Push Rod 15—

Intake

Valve

16—

Intake

Valve Tappet

17—

Camshaft

18—

Camshaft

Front Bearing

19—

Camshaft

Thrust Plate Spacer

20—

Camshaft

Thrust Plate

21— Bolt and Lockwasher

22— Bolt 13—Lockwasher

24—Camshaft

Gear

Washer 25—

Crankshaft

Gear

26—

Camshaft

Gear

27— Woodruff Key No. 9

28—

Exhaust

Valve Tappet

29— Tappet Adjusting Screw

30—

Spring

Retainer

Lock

31— Roto Cap Assembly

32—

Exhaust

Valve Spring

33—

Exhaust

Valve

34—

Rocker

Shaft Support Stud

35—

Washer

36—

Rocker

Arm Cover Stud 63

Page 66 of 376

D

HURRICANE

F4

ENGINE

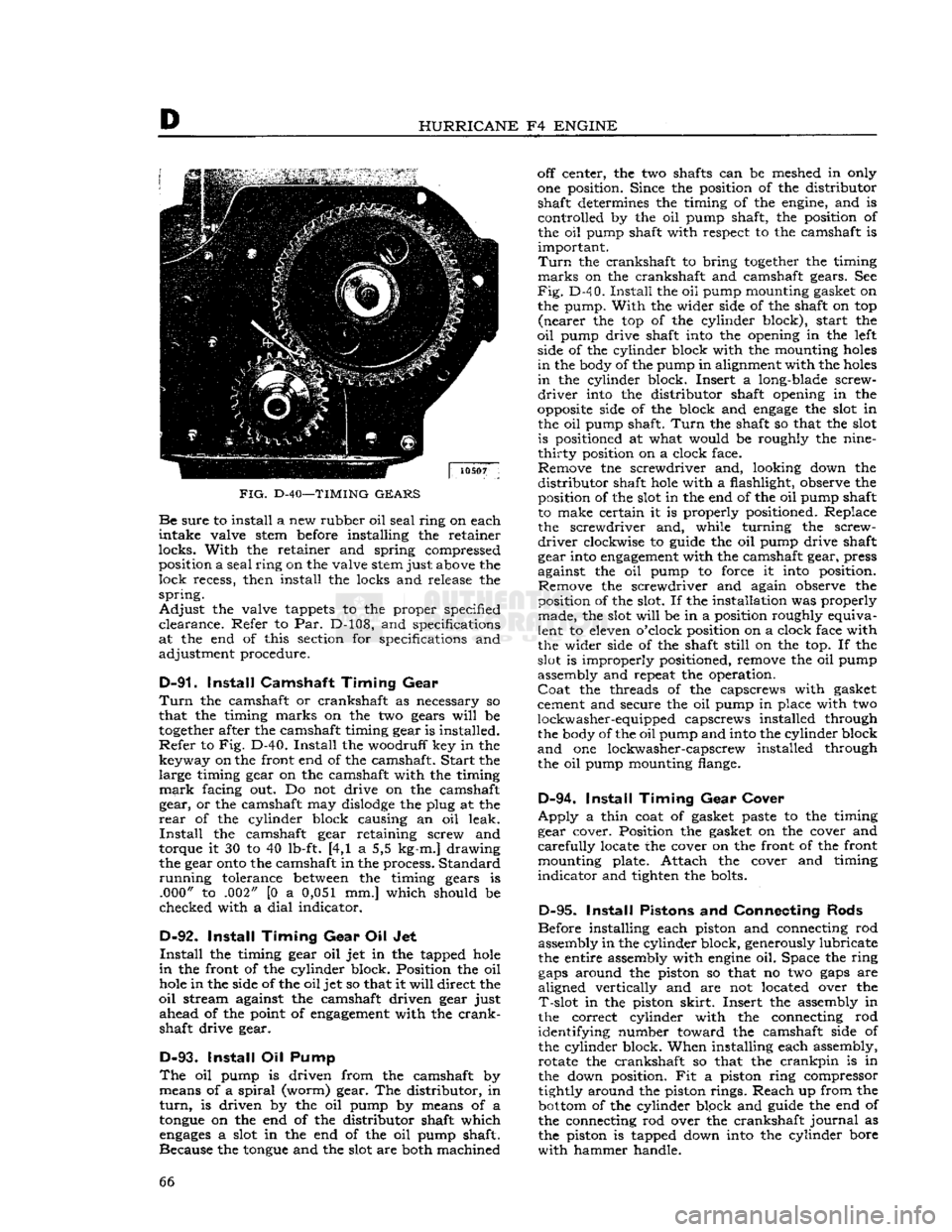

FIG.

D-40—TIMING

GEARS Be

sure

to install a new rubber oil

seal

ring on each

intake

valve stem before installing the retainer

locks.

With

the retainer and spring compressed position a

seal

ring

on the valve stem just above the

lock

recess, then install the locks and release the

spring.

Adjust

the valve tappets to the proper specified

clearance.

Refer to Par. D-108, and specifications

at the end of this section for specifications and

adjustment procedure.

D-91.

Install

Camshaft

Timing

Gear

Turn

the camshaft or crankshaft as necessary so

that the timing marks on the two gears

will

be

together

after the camshaft timing gear is installed.

Refer

to Fig. D-40.

Install

the woodruff key in the key way on the front end of the camshaft.

Start

the large timing gear on the camshaft with the timing

mark

facing out. Do not drive on the camshaft gear, or the camshaft may

dislodge

the plug at the

rear

of the cylinder block causing an oil leak.

Install

the camshaft gear retaining screw and

torque it 30 to 40 lb-ft. [4,1 a 5,5 kg-m.] drawing

the gear

onto

the camshaft in the process. Standard

running

tolerance

between

the timing gears is .000" to .002" [0 a 0,051 mm.] which should be

checked with a

dial

indicator.

D-92.

Install

Timing

Gear

Oil Jet

Install

the timing gear oil jet in the tapped

hole

in

the front of the cylinder block. Position the oil

hole

in the side of the oil jet so that it

will

direct the

oil

stream against the camshaft driven gear just

ahead

of the point of

engagement

with the

crank

shaft drive gear.

D-93.

Install

Oil Pump

The

oil pump is driven from the camshaft by means of a

spiral

(worm) gear. The distributor, in

turn,

is driven by the oil pump by means of a

tongue

on the end of the distributor shaft which

engages

a slot in the end of the oil pump shaft.

Because the

tongue

and the slot are both machined off center, the two shafts can be meshed in only

one position. Since the position of the distributor shaft determines the timing of the engine, and is

controlled by the oil pump shaft, the position of the oil pump shaft with respect to the camshaft is

important.

Turn

the crankshaft to bring

together

the timing

marks

on the crankshaft and camshaft gears. See

Fig.

D-4 0.

Install

the oil pump mounting gasket on

the pump.

With

the wider side of the shaft on top

(nearer

the top of the cylinder block), start the

oil

pump drive shaft into the opening in the left side of the cylinder block with the mounting

holes

in

the body of the pump in alignment with the

holes

in

the cylinder block. Insert a long-blade screw

driver

into the distributor shaft opening in the

opposite

side of the block and

engage

the slot in the oil pump shaft.

Turn

the shaft so that the slot is positioned at what would be roughly the nine-

thirty

position on a clock face. Remove tne screwdriver and, looking down the

distributor

shaft

hole

with a flashlight, observe the position of the slot in the end of the oil pump shaft

to make certain it is properly positioned. Replace the screwdriver and, while turning the screw

driver

clockwise to guide the oil pump drive shaft

gear into

engagement

with the camshaft gear, press

against the oil pump to force it into position. Remove the screwdriver and again observe the

position of the slot. If the installation was properly made, the slot

will

be in a position roughly equiva

lent to eleven o'clock position on a clock face with

the wider side of the shaft

still

on the top. If the

slot is improperly positioned, remove the oil pump

assembly and repeat the operation.

Coat

the threads of the capscrews with gasket

cement and secure the oil pump in place with two

lockwasher-equipped capscrews installed through the body of the oil pump and into the cylinder block

and

one lockwasher-capscrew installed through

the oil pump mounting flange.

D-94.

Install

Timing

Gear

Cover

Apply

a thin coat of gasket paste to the timing

gear cover. Position the gasket on the cover and

carefully

locate the cover on the front of the front mounting plate. Attach the cover and timing

indicator

and tighten the bolts.

D-95.

Install

Pistons and Connecting Rods

Before installing each piston and connecting rod assembly in the cylinder block, generously lubricate

the entire assembly with

engine

oil. Space the ring

gaps

around the piston so that no two

gaps

are

aligned vertically and are not located over the

T-slot

in the piston

skirt.

Insert the assembly in

the correct cylinder with the connecting rod

identifying number toward the camshaft side of

the cylinder block. When installing each assembly, rotate the crankshaft so that the

crankpin

is in

the down position. Fit a piston ring compressor

tightly around the piston rings. Reach up from the

bottom

of the cylinder block and guide the end of

the connecting rod over the crankshaft

journal

as

the piston is tapped down into the cylinder bore

with

hammer handle. 66

Page 79 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

Dl

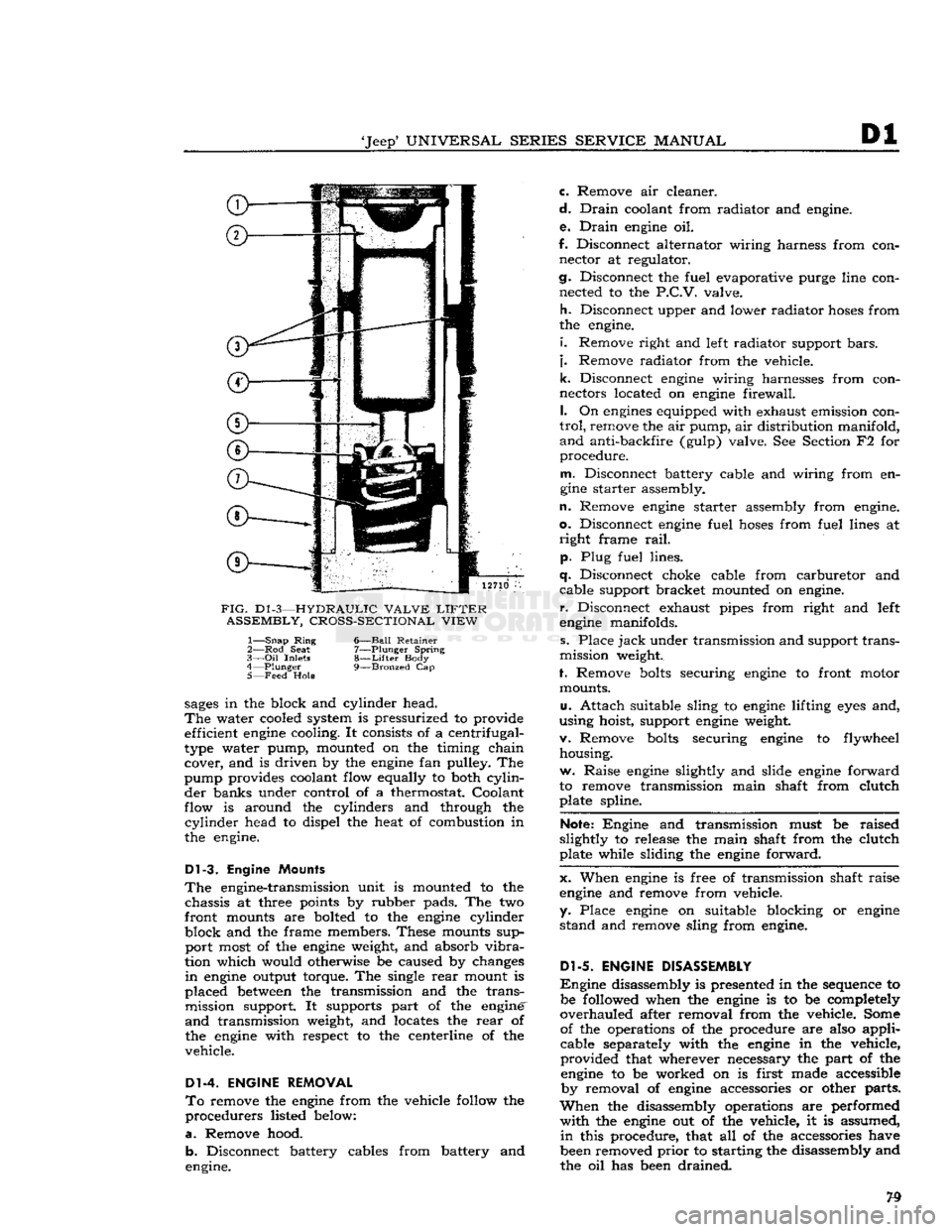

12710

FIG.

D1

-3—HYDRAULIC VALVE

LIFTER

ASSEMBLY, CROSS-SECTIONAL VIEW

1—

Snap

Ring

6—Ball Retainer

2— Rod

Seat

7—Plunger Spring

3—

Oil

Inlets

8—Lifter

Body

4—

Plunger

9—Bronzed

Cap

5— Feed

Hole

sages

in the block and cylinder head.

The

water cooled system is pressurized to provide efficient

engine

cooling. It consists of a centrifugal-

type water pump, mounted on the timing chain cover, and is driven by the

engine

fan pulley. The

pump provides coolant flow equally to both

cylin

der banks under control of a thermostat. Coolant

flow is around the cylinders and through the

cylinder

head to dispel the heat of combustion in

the engine.

Dl-3.

Engine Mounts

The

engine-transmission unit is mounted to the chassis at three points by rubber pads. The two

front mounts are bolted to the

engine

cylinder

block and the frame members. These mounts sup port most of the

engine

weight, and absorb

vibra

tion which would otherwise be caused by changes

in

engine

output torque. The single

rear

mount is

placed

between

the transmission and the trans mission support. It supports part of the engine'

and

transmission weight, and locates the

rear

of

the

engine

with respect to the centerline of the

vehicle.

Dl-4. ENGINE REMOVAL

To

remove the

engine

from the vehicle follow the

procedurers listed below:

a.

Remove hood. b. Disconnect battery cables from battery and

engine. c. Remove air cleaner.

d.

Drain

coolant from radiator and engine.

e.

Drain

engine

oil.

f. Disconnect alternator wiring harness from con nector at regulator.

cj.

Disconnect the fuel evaporative purge line con nected to the

P.C.V.

valve.

h.

Disconnect upper and lower radiator

hoses

from

the engine.

i.

Remove right and left radiator support

bars,

j.

Remove radiator from the vehicle.

k.

Disconnect

engine

wiring harnesses from con

nectors located on

engine

firewall.

I.

On

engines

equipped with exhaust emission con

trol,

remove the air pump, air distribution manifold,

and

anti-backfire (gulp) valve. See Section F2 for

procedure.

m.

Disconnect battery cable and wiring from en

gine

starter assembly.

n.

Remove

engine

starter assembly from engine,

o.

Disconnect

engine

fuel

hoses

from fuel lines at

right

frame

rail,

p. Plug fuel lines.

q.

Disconnect choke cable from carburetor and cable support bracket mounted on engine,

r.

Disconnect exhaust pipes from right and left

engine

manifolds.

s. Place

jack

under transmission and support trans

mission weight.

f. Remove

bolts

securing

engine

to front motor mounts.

u.

Attach suitable sling to

engine

lifting

eyes

and,

using hoist, support

engine

weight.

v. Remove

bolts

securing

engine

to flywheel housing.

w. Raise

engine

slightly and slide

engine

forward

to remove transmission main shaft from clutch plate spline.

Note:

Engine and transmission must be raised

slightly to release the main shaft from the clutch

plate while sliding the

engine

forward.

x. When

engine

is free of transmission shaft raise

engine

and remove from vehicle,

y. Place

engine

on suitable blocking or

engine

stand and remove sling from engine.

Dl-5.

ENGINE DISASSEMBLY

Engine

disassembly is presented in the sequence to be followed when the

engine

is to be completely

overhauled after removal from the vehicle. Some of the operations of the procedure are also applicable separately with the

engine

in the vehicle,

provided that wherever necessary the part of the

engine

to be worked on is first made accessible by removal of

engine

accessories or other parts.

When

the disassembly operations are performed

with

the

engine

out of the vehicle, it is assumed,

in

this procedure, that all of the accessories have

been removed

prior

to starting the disassembly and

the oil has been drained.

Page 86 of 376

Dl

DAUNTLESS

V-6

ENGINE

Dl-38.

Crankshaft

Cleaning

Clean

the crankshaft thoroughly with a suitable

cleaning solvent.

Clean

drilled oil

passages

in its

journals

with a small rifle brush to remove all

sludge

or gum deposits; dry

passages

with com

pressed air.

Dl-39.

Crankshaft

Inspection

and

Repair

If

the crankshaft has not

been

removed from the

cylinder

block for inspection, disconnect two con necting rods at a time from crankshaft. Inspect

the bearings and crankpin journals. While turning

crankshaft,

it is necessary to temporarily reconnect

the rods to crankshaft to avoid possibility of dam aging the journals through contact with uncon

nected rods.

Inspect the crankpins visually for excessive or ir

regular

wear, and for scoring. Use an

outside

micrometer to check crankpins for out-of-round.

Standard

crankpin

diameter is

2.0000"

[5,080

cm.].

If

crankpins are more than .0015"

[0,0381

mm.]

out-of-round, new bearings cannot be

expected

to

have satisfactory life.

If

the crankshaft has

been

removed from the

cyl

inder

block for inspection support it on V-blocks

at its main bearing journals 1 and 4. Inspect the

main

bearing journals visually for excessive or ir

regular

wear, and for scoring. Standard main bear

ing

journal

diameter is 2.4995"

[6,349

cm.].

Total

indicator readings at each

journal

should not ex

ceed .003"

[0,076

mm.].

Check

run out at all four journals and

note

high

spot

(maximum eccentricity) of each

journal.

High

spot

of each

journal

should

come

at the same

angular

location. If high

spots

do not coincide,

crankshaft

is misaligned and unsatisfactory for

service.

If

crankpin or main bearing journals are scored,

ridged, or out-of-round, the crankshaft must be replaced or reground to a standard undersize bear

ing diameter to ensure satisfactory life of bearings. Slight roughness can be removed with a fine grit

polishing cloth thoroughly

wetted

with

engine

oil.

Burrs

can

be

honed with a fine oil

stone,

so long as

bearing clearances

will

remain within specified

limits.

Dl-40.

Crankshaft

Main

Bearings

A

crankshaft bearing consists of two halves which

are

neither alike nor interchangeable. One half is

carried

in the corresponding main bearing cap; the

other half is located

between

the crankshaft and

cylinder

block. The upper (cylinder block) half

of the bearing is grooved to supply oil to the con necting rod bearings, while the lower (bearing cap)

half

of the bearing is not grooved. The two bearing

halves must not be interchanged. All crankshaft

bearings

except

the thrust bearing and the

rear

main

bearing are identical. The thrust bearing (No. 2) is longer and it is flanged to take

crank

shaft end thrust. When the bearing halves are

placed in cylinder block and bearing cap, the

ends

extend slightly beyond the parting surfaces. When

cap

bolts

are tightened, the halves are clamped

tightly in place to ensure positive seating and to

prevent turning. The

ends

of bearing halves must never be filed flush with parting surface of

crank

case or bearing cap.

Crankshaft

bearings are the precision type which

do not require reaming to size or other fitting.

Shims

are not provided for adjustment since worn

bearings are readily replaced with new bearings of proper size. Bearings for service replacement are

furnished

in standard size and undersizes. Under no circumstances should crankshaft bearing caps

be filed to adjust for wear in old bearings.

Dl-41.

Crankshaft

Main

Bearing

Cleaning

and

Inspection

Clean

main bearing surfaces. Inspect the bearings

visually

for excessive or uneven wear, scoring, and

flaking.

Visibly worn or damaged bearings must

be replaced. It is necessary to check

radial

clear ance of each new or used crankshaft main bearing

before installation.

This

can be

done

by either of two methods, which are described in

Pars.

Dl-42

and

Dl-43.

a.

The desired

radial

clearance of a new bearing

is .0005" to .0021"

[0,0127

a

0,0534

mm.].

b. Replacement bearings are furnished in standard

size, and in several undersizes, including undersizes

for reground journals. If a new bearing is to be installed, try a standard size; then try each under

size in turn until one is found that

meets

the

specified clearance limits.

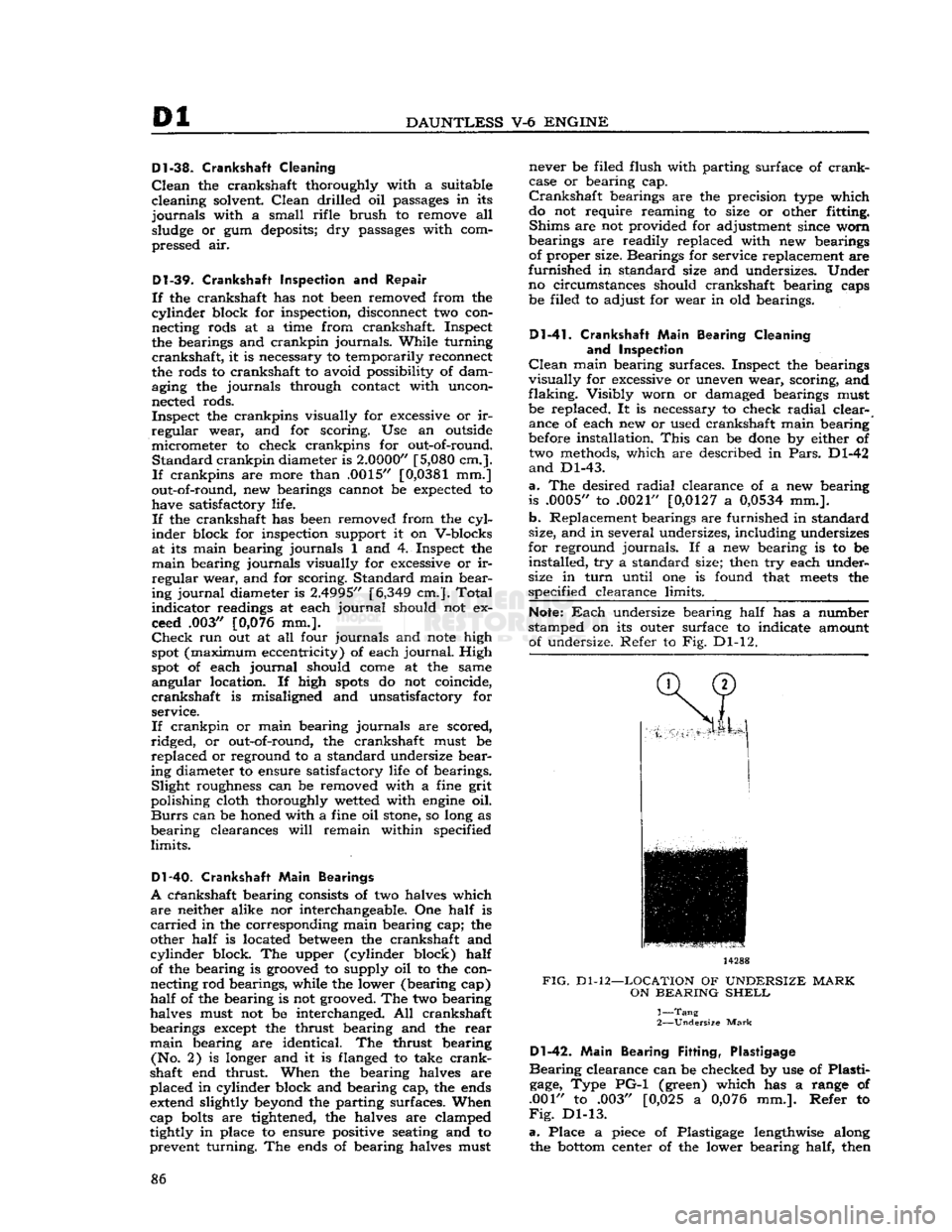

Note:

Each

undersize bearing half has a number

stamped on its outer surface to indicate amount of undersize. Refer to Fig. Dl-12. 14288

FIG.

Dl-12—LOCATION

OF

UNDERSIZE

MARK

ON

BEARING

SHELL

1—

Tang

2—

Undersize

Mark

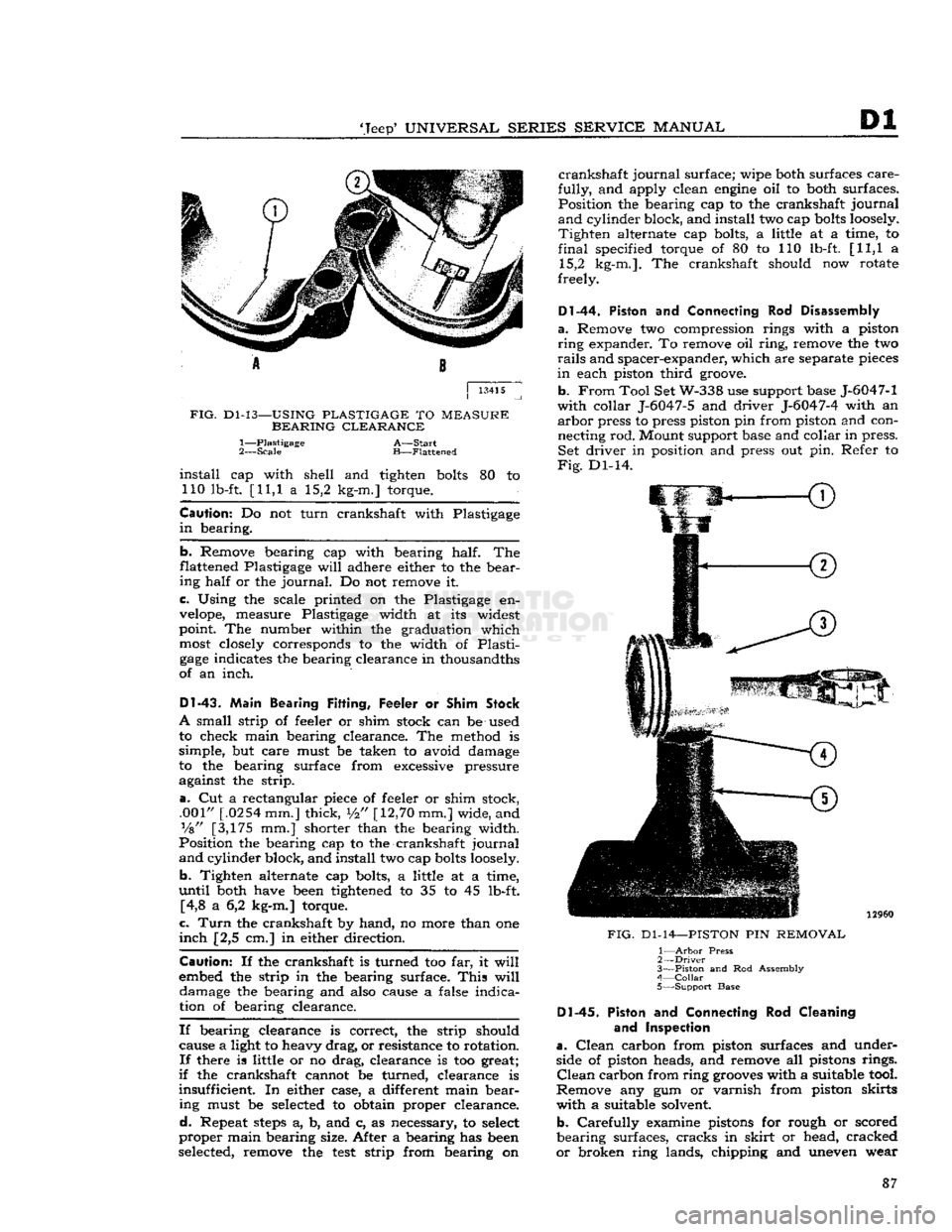

Dl-42.

Main

Bearing

Fitting,

Plastigage

Bearing

clearance can be checked by use of Plasti

gage,

Type PG-1 (green) which has a range of

.001" to .003" [0,025 a

0,076

mm.]. Refer to

Fig.

Dl-13.

a.

Place a piece of Plastigage lengthwise along the

bottom

center of the lower bearing half, then 86

Page 87 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

A 8

j

13415

FIG.

Dl-13—USING

PLASTIGAGE

TO

MEASURE

BEARING CLEARANCE

1— Plastigage

A—Start

2—

Scale

B—Flattened

install

cap with shell and tighten

bolts

80 to 110 lb-ft. [11,1 a 15,2 kg-m.] torque.

Caution:

Do not turn crankshaft with Plastigage

in

bearing.

b.

Remove bearing cap with bearing half. The

flattened Plastigage

will

adhere either to the bear ing half or the

journal.

Do not remove it.

c. Using the scale printed on the Plastigage en

velope,

measure Plastigage width at its widest

point. The number within the graduation which

most

closely corresponds to the width of Plasti

gage

indicates the bearing clearance in thousandths

of an inch.

DI-43.

Main Bearing

Fitting,

Feeler or

Shim

Stock

A

small strip of feeler or shim stock can be used

to check main bearing clearance. The method is

simple, but care must be taken to avoid damage

to the bearing surface from excessive pressure against the strip.

a.

Cut a rectangular piece of feeler or shim stock, .001"

[.0254

mm.] thick,

i/2"

[12,70

mm.] wide, and

Vs"

[3,175 mm.] shorter than the bearing width.

Position the bearing cap to the crankshaft journal

and

cylinder block, and install two cap

bolts

loosely.

b.

Tighten alternate cap bolts, a little at a time,

until

both have

been

tightened to 35 to 45 lb-ft. [4,8 a 6,2 kg-m.] torque.

c.

Turn

the crankshaft by hand, no more than one

inch

[2,5 cm.] in either direction.

Caution:

If the crankshaft is turned too far, it

will

embed the strip in the bearing surface.

This

will

damage the bearing and also cause a false indication of bearing clearance.

If

bearing clearance is correct, the strip should cause a light to heavy drag, or resistance to rotation.

If

there is little or no drag, clearance is too great;

if

the crankshaft cannot be turned, clearance is

insufficient. In either case, a different main bear ing must be

selected

to obtain proper clearance.

d.

Repeat

steps

a, b, and c, as necessary, to

select

proper main bearing size. After a bearing has

been

selected, remove the

test

strip from bearing on

crankshaft

journal surface; wipe both surfaces care

fully,

and apply clean

engine

oil to both surfaces. Position the bearing cap to the crankshaft journal

and

cylinder block, and install two cap

bolts

loosely.

Tighten

alternate cap bolts, a little at a time, to

final

specified torque of 80 to 110 lb-ft. [11,1 a 15,2 kg-m.]. The crankshaft should now rotate

freely.

Dl-44.

Piston

and

Connecting

Rod

Disassembly

a.

Remove two compression rings with a piston

ring

expander. To remove oil ring, remove the two

rails

and spacer-expander, which are separate

pieces

in

each piston third

groove.

b.

From

Tool Set W-338 use support base J-6047-1

with collar J-6047-5 and driver J-6047-4 with an

arbor

press to press piston pin from piston and con

necting rod. Mount support base and collar in press. Set driver in position and press out pin. Refer to

Fig.

Dl-14.

FIG.

Dl-14—PISTON

PIN

REMOVAL

1—

Arbor

Press

2—

Driver

3—

Piston

and Rod Assembly

4—

Collar

•

5—Support Base Dl-45.

Piston

and

Connecting

Rod

Cleaning

and Inspection

a.

Clean

carbon from piston surfaces and under

side of piston heads, and remove all pistons rings.

Clean

carbon from ring

grooves

with a suitable tool.

Remove any gum or varnish from piston skirts with a suitable solvent.

b.

Carefully examine pistons for rough or scored

bearing surfaces, cracks in

skirt

or head, cracked

or

broken ring lands, chipping and uneven wear 87