light JEEP COMPASS 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: COMPASS, Model: JEEP COMPASS 2019Pages: 362, PDF Size: 6.23 MB

Page 207 of 362

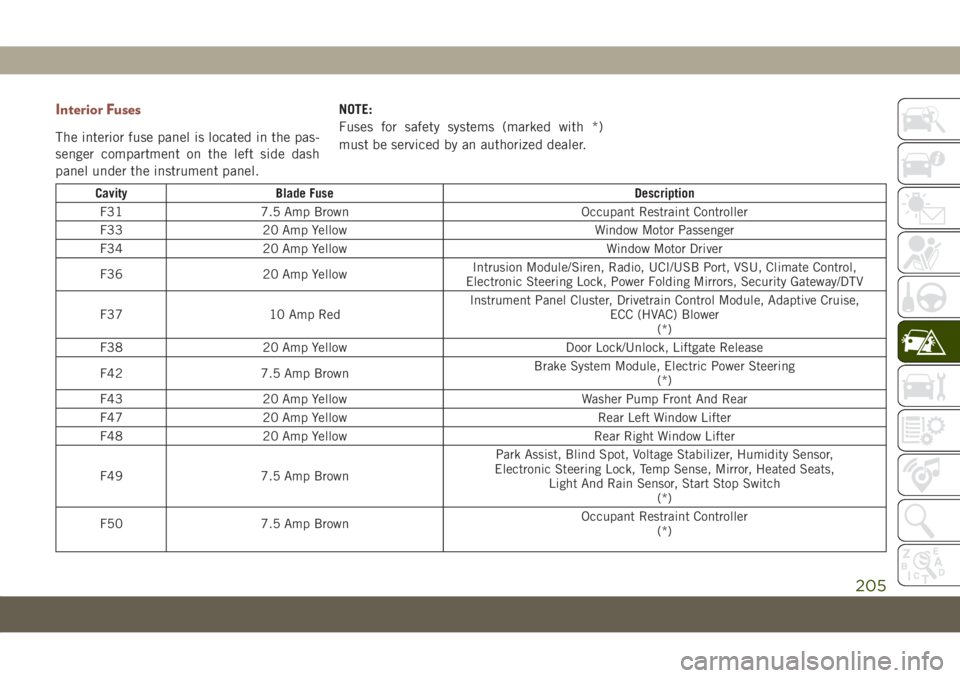

Interior Fuses

The interior fuse panel is located in the pas-

senger compartment on the left side dash

panel under the instrument panel.NOTE:

Fuses for safety systems (marked with *)

must be serviced by an authorized dealer.

Cavity Blade Fuse Description

F31 7.5 Amp Brown Occupant Restraint Controller

F33 20 Amp Yellow Window Motor Passenger

F34 20 Amp Yellow Window Motor Driver

F36 20 Amp YellowIntrusion Module/Siren, Radio, UCI/USB Port, VSU, Climate Control,

Electronic Steering Lock, Power Folding Mirrors, Security Gateway/DTV

F37 10 Amp RedInstrument Panel Cluster, Drivetrain Control Module, Adaptive Cruise,

ECC (HVAC) Blower

(*)

F38 20 Amp Yellow Door Lock/Unlock, Liftgate Release

F42 7.5 Amp BrownBrake System Module, Electric Power Steering

(*)

F43 20 Amp Yellow Washer Pump Front And Rear

F47 20 Amp Yellow Rear Left Window Lifter

F48 20 Amp Yellow Rear Right Window Lifter

F49 7.5 Amp BrownPark Assist, Blind Spot, Voltage Stabilizer, Humidity Sensor,

Electronic Steering Lock, Temp Sense, Mirror, Heated Seats,

Light And Rain Sensor, Start Stop Switch

(*)

F50 7.5 Amp BrownOccupant Restraint Controller

(*)

205

Page 209 of 362

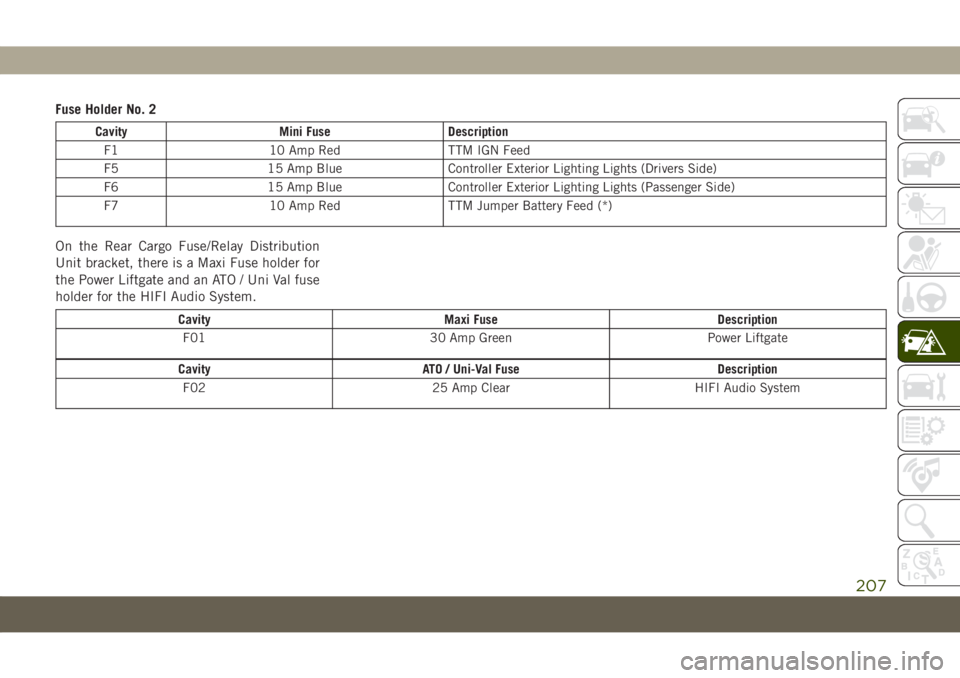

Fuse Holder No. 2

Cavity Mini Fuse Description

F1 10 Amp Red TTM IGN Feed

F5 15 Amp Blue Controller Exterior Lighting Lights (Drivers Side)

F6 15 Amp Blue Controller Exterior Lighting Lights (Passenger Side)

F7 10 Amp Red TTM Jumper Battery Feed (*)

On the Rear Cargo Fuse/Relay Distribution

Unit bracket, there is a Maxi Fuse holder for

the Power Liftgate and an ATO / Uni Val fuse

holder for the HIFI Audio System.

Cavity Maxi Fuse Description

F01 30 Amp Green Power Liftgate

Cavity ATO / Uni-Val Fuse Description

F02 25 Amp Clear HIFI Audio System

207

Page 214 of 362

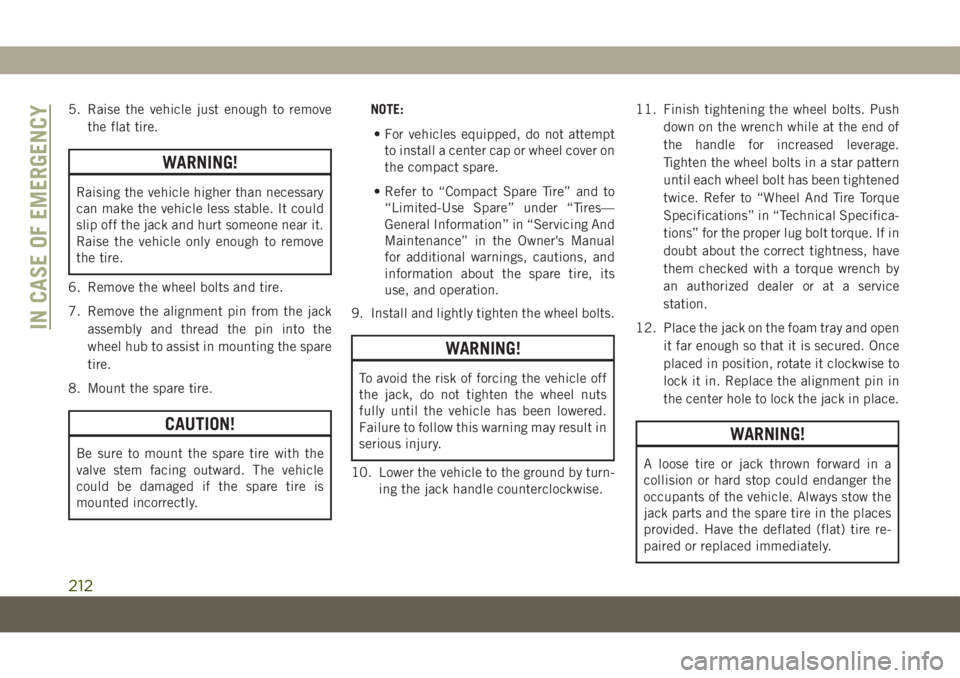

5. Raise the vehicle just enough to remove

the flat tire.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack

assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

8. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.NOTE:

• For vehicles equipped, do not attempt

to install a center cap or wheel cover on

the compact spare.

• Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires—

General Information” in “Servicing And

Maintenance” in the Owner's Manual

for additional warnings, cautions, and

information about the spare tire, its

use, and operation.

9. Install and lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

10. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.11. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica-

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

them checked with a torque wrench by

an authorized dealer or at a service

station.

12. Place the jack on the foam tray and open

it far enough so that it is secured. Once

placed in position, rotate it clockwise to

lock it in. Replace the alignment pin in

the center hole to lock the jack in place.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

IN CASE OF EMERGENCY

212

Page 215 of 362

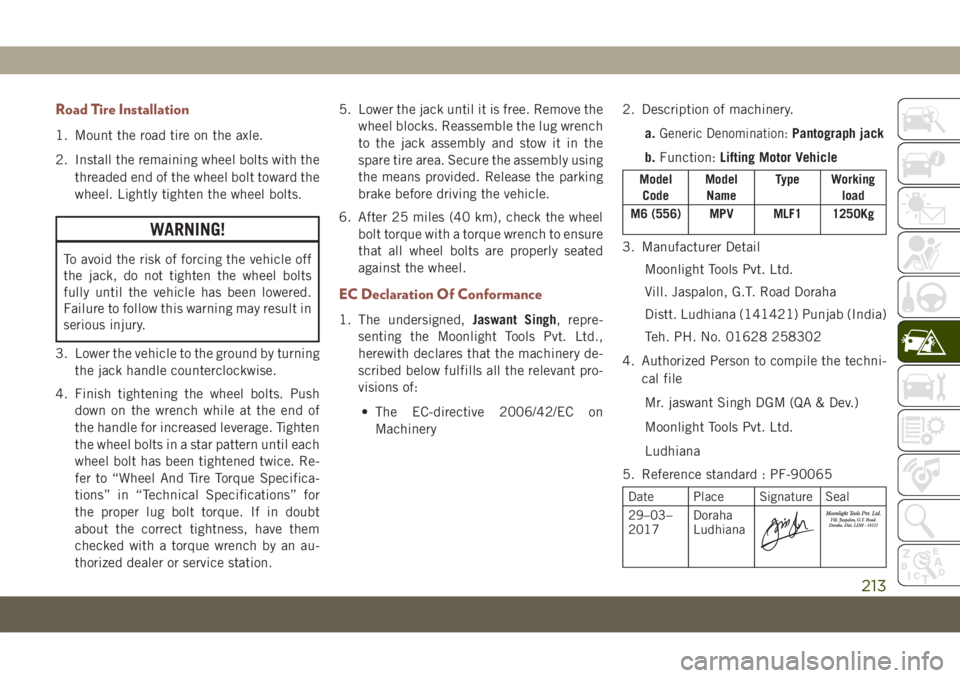

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the

threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage. Tighten

the wheel bolts in a star pattern until each

wheel bolt has been tightened twice. Re-

fer to “Wheel And Tire Torque Specifica-

tions” in “Technical Specifications” for

the proper lug bolt torque. If in doubt

about the correct tightness, have them

checked with a torque wrench by an au-

thorized dealer or service station.5. Lower the jack until it is free. Remove the

wheel blocks. Reassemble the lug wrench

to the jack assembly and stow it in the

spare tire area. Secure the assembly using

the means provided. Release the parking

brake before driving the vehicle.

6. After 25 miles (40 km), check the wheel

bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

EC Declaration Of Conformance

1. The undersigned,Jaswant Singh, repre-

senting the Moonlight Tools Pvt. Ltd.,

herewith declares that the machinery de-

scribed below fulfills all the relevant pro-

visions of:

• The EC-directive 2006/42/EC on

Machinery2. Description of machinery.

a.

Generic Denomination:Pantograph jack

b.Function:Lifting Motor Vehicle

Model

CodeModel

NameType Working

load

M6 (556) MPV MLF1 1250Kg

3. Manufacturer Detail

Moonlight Tools Pvt. Ltd.

Vill. Jaspalon, G.T. Road Doraha

Distt. Ludhiana (141421) Punjab (India)

Teh. PH. No. 01628 258302

4. Authorized Person to compile the techni-

cal file

Mr. jaswant Singh DGM (QA & Dev.)

Moonlight Tools Pvt. Ltd.

Ludhiana

5. Reference standard : PF-90065

Date Place Signature Seal

29–03–

2017Doraha

Ludhiana

213

Page 223 of 362

CAUTION!

Do not use a portable battery booster pack

or any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

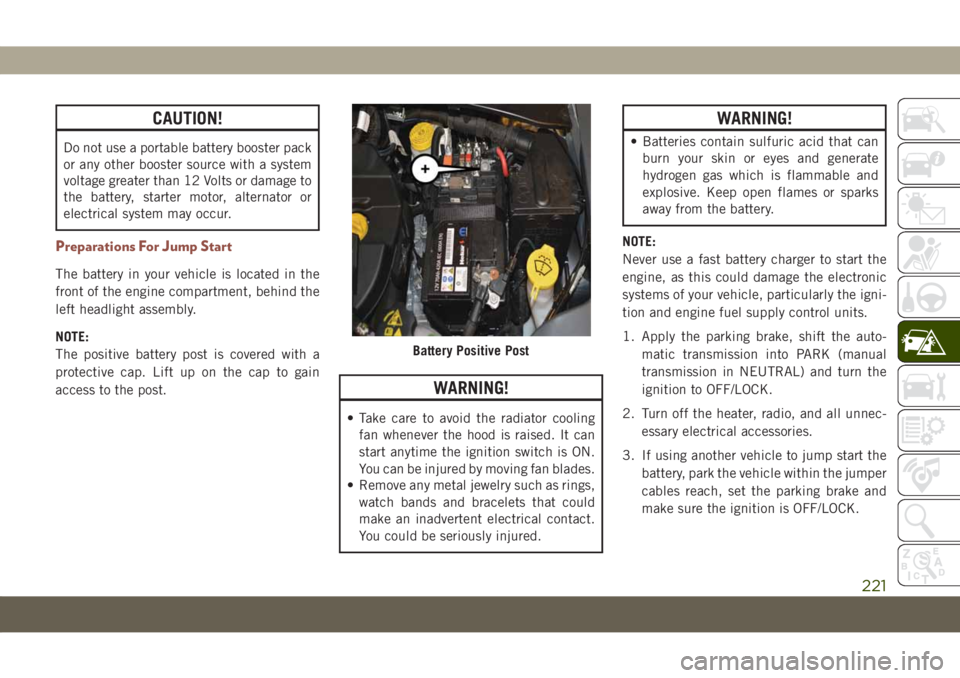

Preparations For Jump Start

The battery in your vehicle is located in the

front of the engine compartment, behind the

left headlight assembly.

NOTE:

The positive battery post is covered with a

protective cap. Lift up on the cap to gain

access to the post.

WARNING!

• Take care to avoid the radiator cooling

fan whenever the hood is raised. It can

start anytime the ignition switch is ON.

You can be injured by moving fan blades.

• Remove any metal jewelry such as rings,

watch bands and bracelets that could

make an inadvertent electrical contact.

You could be seriously injured.

WARNING!

• Batteries contain sulfuric acid that can

burn your skin or eyes and generate

hydrogen gas which is flammable and

explosive. Keep open flames or sparks

away from the battery.

NOTE:

Never use a fast battery charger to start the

engine, as this could damage the electronic

systems of your vehicle, particularly the igni-

tion and engine fuel supply control units.

1. Apply the parking brake, shift the auto-

matic transmission into PARK (manual

transmission in NEUTRAL) and turn the

ignition to OFF/LOCK.

2. Turn off the heater, radio, and all unnec-

essary electrical accessories.

3. If using another vehicle to jump start the

battery, park the vehicle within the jumper

cables reach, set the parking brake and

make sure the ignition is OFF/LOCK.

Battery Positive Post

221

Page 233 of 362

SCHEDULED SERVICING

Correct servicing is crucial for guaranteeing a

long life for the car under the best conditions.

For this reason, Jeep has planned a series of

checks and services at fixed distance inter-

vals and, where provided, at fixed time inter-

vals, as described in the Scheduled Servicing

plan. To keep the car’s efficiency in tip-top

condition, in the following Scheduled Service

plan pages a few additional checks are listed

that should be carried out more frequently

with respect to the normal coupon redemp-

tion schedule. Scheduled Servicing is offered

by all authorized dealerships according to

fixed time or mileage intervals. If, during

each operation, in addition to the ones sched-

uled, the need arises for further replace-

ments or repairs, these may be carried out

with the owner's explicit agreement only.

The technicians at your dealership know your

vehicle best, and have access to factory trained

information, genuine Mopar parts, and specially

designed electronic and mechanical tools that

can help prevent future costly repairs. If your car

is used frequently for towing, the interval be-

tween one scheduled servicing operation and

the next should be reduced. More frequentmaintenance may be needed for vehicles in

severe operating conditions, such as dusty areas

and very short trip driving.

NOTE:

Scheduled Servicing interventions are set out

by the Manufacturer. Failure to have them

carried out may invalidate the warranty. It is

advised to inform an authorized dealership of

any small operating irregularities without

waiting for the next service.

1.4L Gasoline Engine

NOTE:

Under no circumstances should oil change

intervals exceed 9,000 miles (15,000 km) or

12 months, whichever comes first.

Once A Month Or Before A Long Trip

• Check engine oil level.

• Check windshield washer fluid level.

• Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.

•

Check the fluid levels of the coolant reservoir

and brake master cylinder, fill as needed.

• Check function of all interior and exterior

lights.

At Each Oil Change

• Change oil and filter.

• Rotate the tires.Rotate at the first sign of

irregular wear, even if it occurs before the oil

indicator system turns on.

• Inspect battery and clean and tighten ter-

minals as required.

• Inspect brake pads, shoes, rotors, drums,

hoses and park brake.

• Inspect engine cooling system protection

and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty

or off-road conditions.

Refer to the “Maintenance Plan” on the fol-

lowing page for the required maintenance

intervals.

CAUTION!

Failure to perform the required maintenance

items may result in damage to the vehicle.

231

Page 237 of 362

WARNING!

• You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge

and the right equipment. If you have any

doubt about your ability to perform a

service job, take your vehicle to a com-

petent mechanic.

• Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an

accident.

Heavy Duty Use Of Vehicle

**** Change the engine oil and engine oil

filter at every 4500 miles (7,500 km) or

12 months if using your vehicle under any of

the following severe duty conditions:

• Stop and go driving.

• Driving in dusty conditions.

• Short trips of less than 10 miles (16 km).

• Trailer towing.• Taxi, police, or delivery service (commercial

service).

• Off-road or desert operation.

Diesel Engines

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is

time to take your vehicle in for engine oil

replacement.

Based on engine operation conditions, the oil

change indicator message will illuminate.

This means that service is required for your

vehicle. Operating conditions such as fre-

quent short-trips, trailer tow, extremely hot or

cold ambient temperatures will influence

when the “Oil Change Required” message is

displayed. Severe Operating Conditions can

cause the change oil message to illuminate

as earlier than specified. Have your vehicle

serviced as soon as possible, within the next

500 miles (805 km).To help you have the best driving experience

possible, the manufacturer has identified the

specific vehicle maintenance service inter-

vals that are required to keep your vehicle

operating properly and safely.

The manufacturer recommends that these

maintenance intervals be performed at your

selling dealer. The technicians at your deal-

ership know your vehicle best, and have ac-

cess to factory trained information, genuine

Mopar parts, and specially designed elec-

tronic and mechanical tools that can help

prevent future costly repairs.

The maintenance intervals shown should be

performed as indicated in this section.

NOTE:

•The actual interval for changing engine oil

and replacing the engine oil filter depends on

the vehicle usage conditions, and is signaled

by the warning light or message in the instru-

ment panel. In any case, it must never exceed

12,000 miles (20,000km) or 1 year.

•Flush and replace the engine coolant at

120 months or 150,000 miles (240,000 km)

whichever comes first.

235

Page 238 of 362

•Areas that are not dusty: recommended maxi-

mum distance 75,000 mi (120,000 km). The

belt must be replaced every 6 years, regard-

less of distance travelled. Dusty areas and/or

heavy conditions (severe weather conditions,

very low or very high temperatures for ex-

tended periods, urban driving, long periods of

idling): the recommended maximum distance

is 37,500 mi (60,000 km). The belt must be

replaced every 4 years, regardless of dis-

tance travelled.

Once A Month Or Before A Long Trip

• Check engine oil level.

• Check windshield washer fluid level.

• Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.

• Check the fluid levels of the coolant reser-

voir and brake master cylinder, fill as

needed.• Check function of all interior and exterior

lights.

• Control and recovery of additive level for

AdBlue Diesel emissions (UREA) (if

equipped).

At Each Oil Change

• Change the engine oil filter.

• Inspect the brake hoses and lines.

• Inspect for the presence of water in the fuel

filter/water separator unit.

Demanding Vehicle Use

• Restore additive level for AdBlue Diesel

emissions (UREA) (if equipped), when the

lamp is illuminated or the message on the

instrument panel.

CAUTION!

Failure to perform the required mainte-

nance items may result in damage to the

vehicle.

SERVICING AND MAINTENANCE

236

Page 241 of 362

(*) The actual interval for changing engine oil

and replacing the engine oil filter depends on

the vehicle usage conditions, and is signaled

by the warning light or message in the instru-

ment panel. In any case, it must never exceed

12,000 miles (20,000 km) or 1 year.

(**) Areas that are not dusty: recommended

maximum distance 75,000 mi

(120,000 km). The belt must be replaced

every 6 years, regardless of distance trav-

elled. Dusty areas and/or heavy conditions

(severe weather conditions, very low or very

high temperatures for extended periods, ur-

ban driving, long periods of idling): the rec-

ommended maximum distance is 37,500 mi

(60,000 km). The belt must be replaced

every 4 years, regardless of distance trav-

elled.

(***) The brake fluid change interval is time

based only, mileage intervals do not apply.

(°) Consumption of additive AdBlue (UREA)

depends on the condition of use of the ve-

hicle and is indicated by LED and/or message

on the instrument panel.WARNING!

• You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge

and the right equipment. If you have any

doubt about your ability to perform a

service job, take your vehicle to a com-

petent mechanic.

• Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an

accident.

239

Page 250 of 362

WARNING!

• Do not open hot engine cooling system.

Never add engine coolant (antifreeze)

when the engine is overheated. Do not

loosen or remove the cap to cool an

overheated engine. Heat causes pres-

sure to build up in the cooling system. To

prevent scalding or injury, do not remove

the pressure cap while the system is hot

or under pressure.

• Do not use a pressure cap other than the

one specified for your vehicle. Personal

injury or engine damage may result.

Brake System

In order to assure brake system performance,

all brake system components should be in-

spected periodically. Refer to the “Mainte-

nance Plan” in this section for the proper

maintenance intervals.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake tem-

peratures, excessive lining wear, and pos-

sible brake damage. You would not have

your full braking capacity in an emergency.

Brake Master Cylinder

The fluid in the master cylinder should be

checked when performing under hood ser-

vices or immediately if the “Brake Warning

Light” is illuminated.

Be sure to clean the top of the master cylin-

der area before removing the cap. If neces-

sary, add fluid to bring the fluid level up to

the requirements described on the brake

fluid reservoir. With disc brakes, fluid level

can be expected to fall as the brake pads

wear. Brake fluid level should be checked

when pads are replaced. However, low fluid

level may be caused by a leak and a checkup

may be needed.

Use only manufacturer's recommended brake

fluid. Refer to “Fluids And Lubricants” in

“Technical Specifications” for further information.

WARNING!

• Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri-

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its per-

formance. The proper type of brake fluid

for your vehicle is also identified on the

original factory installed hydraulic mas-

ter cylinder reservoir.

• To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master cylin-

der reservoir cap secured at all times.

Brake fluid in a open container absorbs

moisture from the air resulting in a lower

boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake fail-

ure. This could result in a collision.

SERVICING AND MAINTENANCE

248