recommended oil JEEP COMPASS 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: COMPASS, Model: JEEP COMPASS 2020Pages: 328, PDF Size: 8.85 MB

Page 58 of 328

GETTING TO KNOW YOUR INSTRUMENT PANEL

56

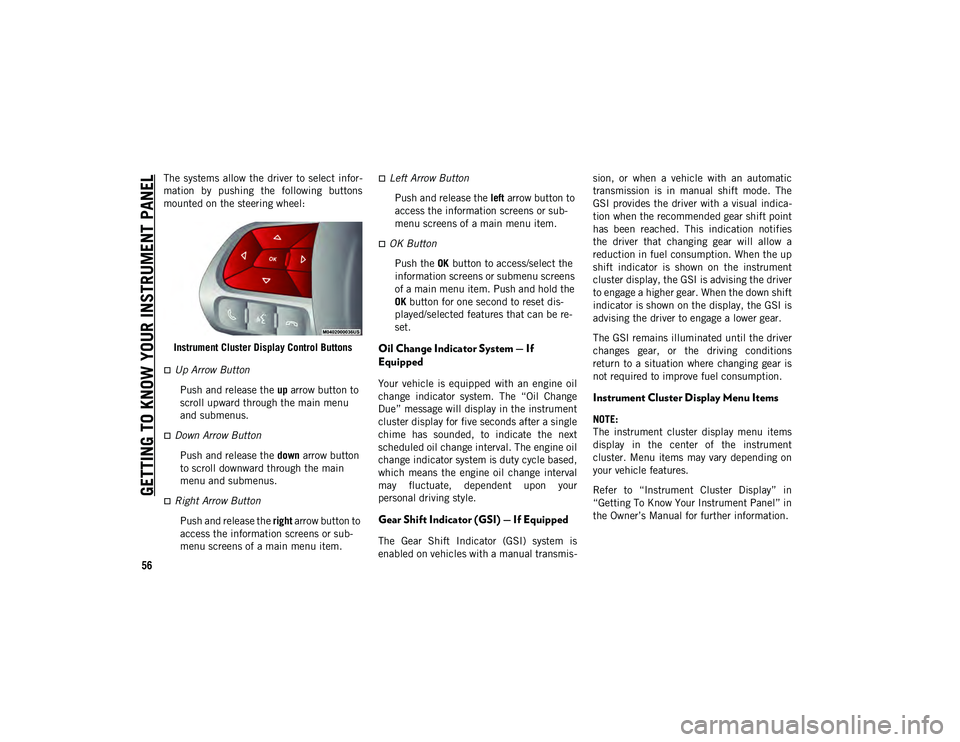

The systems allow the driver to select infor-

mation by pushing the following buttons

mounted on the steering wheel:

Instrument Cluster Display Control Buttons

Up Arrow Button Push and release the up arrow button to

scroll upward through the main menu

and submenus.

Down Arrow Button

Push and release the down arrow button

to scroll downward through the main

menu and submenus.

Right Arrow Button

Push and release the right arrow button to

access the information screens or sub -

menu screens of a main menu item.

Left Arrow Button

Push and release the left arrow button to

access the information screens or sub -

menu screens of a main menu item.

OK Button

Push the OK button to access/select the

information screens or submenu screens

of a main menu item. Push and hold the

OK button for one second to reset dis -

played/selected features that can be re -

set.

Oil Change Indicator System — If

Equipped

Your vehicle is equipped with an engine oil

change indicator system. The “Oil Change

Due” message will display in the instrument

cluster display for five seconds after a single

chime has sounded, to indicate the next

scheduled oil change interval. The engine oil

change indicator system is duty cycle based,

which means the engine oil change interval

may fluctuate, dependent upon your

personal driving style.

Gear Shift Indicator (GSI) — If Equipped

The Gear Shift Indicator (GSI) system is

enabled on vehicles with a manual transmis -sion, or when a vehicle with an automatic

transmission is in manual shift mode. The

GSI provides the driver with a visual indica

-

tion when the recommended gear shift point

has been reached. This indication notifies

the driver that changing gear will allow a

reduction in fuel consumption. When the up

shift indicator is shown on the instrument

cluster display, the GSI is advising the driver

to engage a higher gear. When the down shift

indicator is shown on the display, the GSI is

advising the driver to engage a lower gear.

The GSI remains illuminated until the driver

changes gear, or the driving conditions

return to a situation where changing gear is

not required to improve fuel consumption.

Instrument Cluster Display Menu Items

NOTE:

The instrument cluster display menu items

display in the center of the instrument

cluster. Menu items may vary depending on

your vehicle features.

Refer to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” in

the Owner’s Manual for further information.

2020_JEEP_M6_UG_UK.book Page 56

Page 132 of 328

SAFETY

130

Periodic Safety Checks You Should Make

Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones,

nails, glass, or other objects lodged in the

tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts,

cracks, and bulges. Check the wheel nuts for

tightness. Check the tires (including spare)

for proper cold inflation pressure.

Lights

Have someone observe the operation of

brake lights and exterior lights while you

work the controls. Check turn signal and high

beam indicator lights on the instrument

panel.

Door Latches

Check for proper closing, latching, and

locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid

leaks. Also, if gasoline fumes are detected or

if fuel, or brake fluid leaks are suspected, the

cause should be located and corrected

immediately.

NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These

objects could change the position of the

floor mat and may cause interference

with the accelerator, brake, or clutch

pedals.

If the vehicle carpet has been removed

and re-installed, always properly attach

carpet to the floor and check the floor

mat fasteners are secure to the vehicle

carpet. Fully depress each pedal to

check for interference with the acceler-

ator, brake, or clutch pedals then

re-install the floor mats.

It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat

has been properly installed and is

secured to your vehicle using the floor

mat fasteners by lightly pulling mat.

WARNING! (Continued)

2020_JEEP_M6_UG_UK.book Page 130

Page 202 of 328

IN CASE OF EMERGENCY

200

After Driving:

Pull over to a safe location. Refer to “When-

ever You Stop To Use Tire Service Kit” in this

section before continuing.

1. Uncoil the Sealant Hose, and then remove the cap from the fitting at the end

of the hose.

2. Place the Tire Service Kit flat on the ground next to the deflated tire.

3. Remove the cap from the valve stem, and then screw the fitting at the end of the

Sealant Hose onto the valve stem.

4. Uncoil the power plug and insert the plug into the vehicle's 12 Volt power outlet. 5. Uncoil the Hose and screw the fitting at

the end of the hose onto the valve stem.

6. Turn the Mode Select Knob and turn to the Air Mode position.

7. Check the pressure in the tire by reading the Pressure Gauge.

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not

attempt to drive the vehicle further. Call for

assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button to turn on Tire Service Kit and inflate the tire to the cold

tire inflation pressure found on the tire

and loading information label located in

the driver-side door opening.

NOTE:

If the tire becomes over-inflated, push the

Deflation Button to reduce the tire pressure

to the recommended inflation pressure

before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve

stem and unplug from 12 Volt outlet. 3. Place the Tire Service Kit in its proper

storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an

authorized dealer or tire service center.

5. Remove the Speed Limit sticker from the steering wheel after the tire has been

repaired.

6. Replace the Sealant Bottle at an autho -

rized dealer as soon as possible. Refer to

“Sealant Bottle Replacement”.

NOTE:

When having the tire serviced, advise the

authorized dealer or service center that the

tire has been sealed using the Tire Service

Kit.

WARNING!

The Tire Service Kit is not a permanent flat

tire repair. Have the tire inspected and

repaired or replaced after using the Tire

Service Kit. Do not exceed 50 mph

(80 km/h) until the tire is repaired or

replaced. Failure to follow this warning

can result in injuries that are serious or

fatal to you, your passengers, and others

around you. Have the tire checked as soon

as possible at an authorized dealer.

WARNING!

You must always indicate that the tire was

repaired using the Tire Service Kit. Give

the booklet to the technicians who will be

handling the tire that was treated using

the Tire Service Kit.

2020_JEEP_M6_UG_UK.book Page 200

Page 219 of 328

217

Heavy Duty Use Of Vehicle

**** Change the engine oil and engine oil

filter at every 4500 miles (7,500 km) or

12 months if using your vehicle under any of

the following severe duty conditions:

Stop and go driving.

Driving in dusty conditions.

Short trips of less than 10 miles (16 km).

Trailer towing.

Taxi, police, or delivery service (commer-

cial service).

Off-road or desert operation.

Diesel Engines

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is

time to take your vehicle in for engine oil

replacement.

Based on engine operation conditions, the oil

change indicator message will illuminate.

This means that service is required for your

vehicle. Operating conditions such as

frequent short-trips, trailer tow, extremely

hot or cold ambient temperatures will influ -ence when the “Oil Change Required”

message is displayed. Severe Operating

Conditions can cause the change oil

message to illuminate as earlier than speci

-

fied. Have your vehicle serviced as soon as

possible, within the next 500 miles

(805 km).

To help you have the best driving experience

possible, the manufacturer has identified the

specific vehicle maintenance service inter -

vals that are required to keep your vehicle

operating properly and safely.

The manufacturer recommends that these

maintenance intervals be performed at your

selling dealer. The technicians at your deal -

ership know your vehicle best, and have

access to factory trained information,

genuine Mopar parts, and specially designed

electronic and mechanical tools that can

help prevent future costly repairs.

The maintenance intervals shown should be

performed as indicated in this section. NOTE:

The actual interval for changing engine oil

and replacing the engine oil filter depends

on the vehicle usage conditions, and is

signaled by the warning light or message in

the instrument panel. In any case, it must

never exceed 12,000 miles (20,000km) or 1

year.

Flush and replace the engine coolant at

120 months or 150,000 miles (240,000 km)

whichever comes first.

Areas that are not dusty: recommended

maximum distance 75,000 mi

(120,000 km). The belt must be replaced

every 6 years, regardless of distance trav-

elled. Dusty areas and/or heavy conditions

(severe weather conditions, very low or very

high temperatures for extended periods,

urban driving, long periods of idling): the

recommended maximum distance is

37,500 mi (60,000 km). The belt must be

replaced every 4 years, regardless of

distance travelled.

2020_JEEP_M6_UG_UK.book Page 217

Page 223 of 328

221

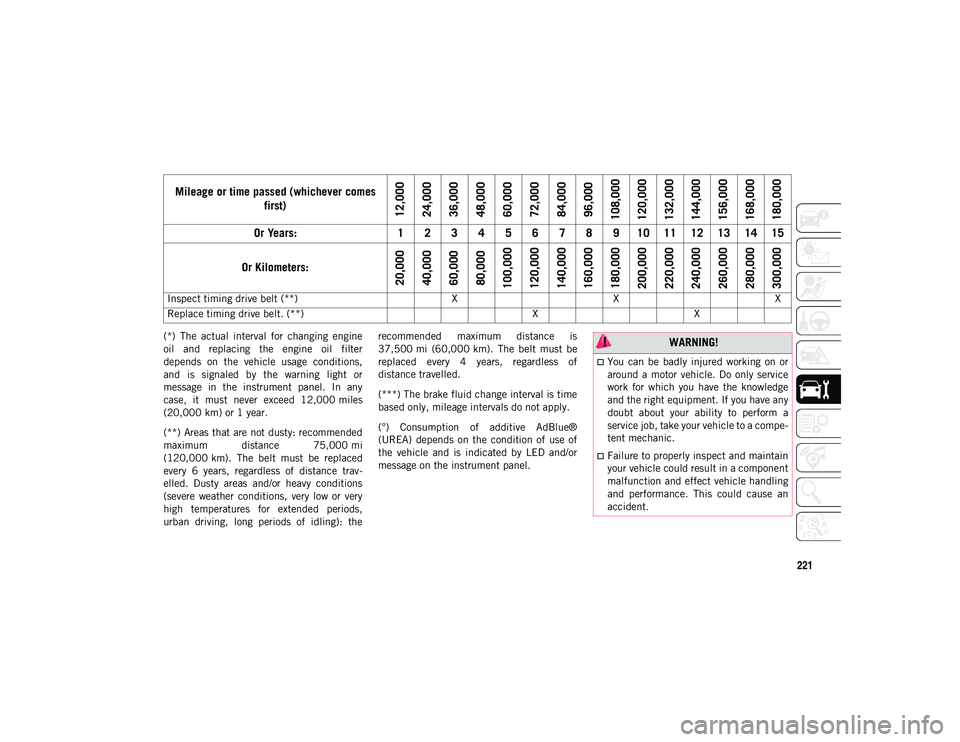

(*) The actual interval for changing engine

oil and replacing the engine oil filter

depends on the vehicle usage conditions,

and is signaled by the warning light or

message in the instrument panel. In any

case, it must never exceed 12,000 miles

(20,000 km) or 1 year.

(**) Areas that are not dusty: recommended

maximum distance 75,000 mi

(120,000 km). The belt must be replaced

every 6 years, regardless of distance trav-

elled. Dusty areas and/or heavy conditions

(severe weather conditions, very low or very

high temperatures for extended periods,

urban driving, long periods of idling): the recommended maximum distance is

37,500 mi (60,000 km). The belt must be

replaced every 4 years, regardless of

distance travelled.

(***) The brake fluid change interval is time

based only, mileage intervals do not apply.

(°) Consumption of additive AdBlue®

(UREA) depends on the condition of use of

the vehicle and is indicated by LED and/or

message on the instrument panel.

Inspect timing drive belt (**)

XXX

Replace timing drive belt. (**) XX

Mileage or time passed (whichever comes

first)

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

260,000

280,000

300,000

WARNING!

You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge

and the right equipment. If you have any

doubt about your ability to perform a

service job, take your vehicle to a compe-

tent mechanic.

Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an

accident.

2020_JEEP_M6_UG_UK.book Page 221

Page 232 of 328

SERVICING AND MAINTENANCE

230

(Continued)

Cooling System Pressure Cap

The cap must be fully tightened to prevent

loss of engine coolant (antifreeze), and to

ensure that engine coolant (antifreeze) will

return to the radiator from the coolant expan-

sion bottle/recovery tank if so equipped.

The cap should be inspected and cleaned if

there is any accumulation of foreign material

on the sealing surfaces.

Brake System

In order to assure brake system performance,

all brake system components should be

inspected periodically. Refer to the “Mainte -nance Plan” in this section for the proper

maintenance intervals.

Brake Master Cylinder

The fluid in the master cylinder should be

checked when performing under hood

services or immediately if the “Brake

Warning Light” is illuminated.

Be sure to clean the top of the master

cylinder area before removing the cap. If

necessary, add fluid to bring the fluid level

up to the requirements described on the

brake fluid reservoir. With disc brakes, fluid

level can be expected to fall as the brake

pads wear. Brake fluid level should be

checked when pads are replaced. However,

low fluid level may be caused by a leak and

a checkup may be needed.

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubricants”

in “Technical Specifications” for further

information.

WARNING!

Do not open hot engine cooling system.

Never add engine coolant (antifreeze)

when the engine is overheated. Do not

loosen or remove the cap to cool an over

-

heated engine. Heat causes pressure to

build up in the cooling system. To

prevent scalding or injury, do not remove

the pressure cap while the system is hot

or under pressure.

Do not use a pressure cap other than the

one specified for your vehicle. Personal

injury or engine damage may result.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake

temperatures, excessive lining wear, and

possible brake damage. You would not

have your full braking capacity in an

emergency. WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri -

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its

performance. The proper type of brake

fluid for your vehicle is also identified on

the original factory installed hydraulic

master cylinder reservoir.

To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master

cylinder reservoir cap secured at all

times. Brake fluid in a open container

absorbs moisture from the air resulting

in a lower boiling point. This may cause

it to boil unexpectedly during hard or

prolonged braking, resulting in sudden

brake failure. This could result in a colli -

sion.

2020_JEEP_M6_UG_UK.book Page 230

Page 238 of 328

SERVICING AND MAINTENANCE

236

(Continued)

NOTE:

Wheel Valve Stem must be replaced as well

when installing new tires due to wear and

tear in existing tires.

Keep dismounted tires in a cool, dry place

with as little exposure to light as possible.

Protect tires from contact with oil, grease,

and gasoline.

Replacement Tires

The tires on your new vehicle provide a

balance of many characteristics. They should

be inspected regularly for wear and correct

cold tire inflation pressures. The manufac-

turer strongly recommends that you use tires

equivalent to the originals in size, quality

and performance when replacement is

needed. Refer to the paragraph on “Tread

Wear Indicators” in this section. Refer to the

Tire and Loading Information placard or the

Vehicle Certification Label for the size desig -

nation of your tire. The Load Index and

Speed Symbol for your tire will be found on

the original equipment tire sidewall.

It is recommended to replace the two front

tires or two rear tires as a pair. Replacing just

one tire can seriously affect your vehicle’s

handling. If you ever replace a wheel, make

sure that the wheel’s specifications match

those of the original wheels. It is recommended you contact an authorized

tire dealer or original equipment dealer with

any questions you may have on tire specifica

-

tions or capability. Failure to use equivalent

replacement tires may adversely affect the

safety, handling, and ride of your vehicle.

Tire Types

All Season Tires — If Equipped

All Season tires provide traction for all

seasons (Spring, Summer, Fall, and Winter).

Traction levels may vary between different all

season tires. All season tires can be identi -

fied by the M+S, M&S, M/S or MS designa -

tion on the tire sidewall. Use all season tires

only in sets of four; failure to do so may

adversely affect the safety and handling of

your vehicle.

WARNING!

Do not use a tire, wheel size, load rating,

or speed rating other than that specified

for your vehicle. Some combinations of

unapproved tires and wheels may change

suspension dimensions and performance

characteristics, resulting in changes to

steering, handling, and braking of your

vehicle. This can cause unpredictable

handling and stress to steering and

suspension components. You could lose

control and have a collision resulting in

serious injury or death. Use only the tire

and wheel sizes with load ratings

approved for your vehicle.

Never use a tire with a smaller load index

or capacity, other than what was origi -

nally equipped on your vehicle. Using a

tire with a smaller load index could result

in tire overloading and failure. You could

lose control and have a collision.

Failure to equip your vehicle with tires

having adequate speed capability can

result in sudden tire failure and loss of

vehicle control.

CAUTION!

Replacing original tires with tires of a

different size may result in false

speedometer and odometer readings.

WARNING! (Continued)

2020_JEEP_M6_UG_UK.book Page 236

Page 246 of 328

244

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA

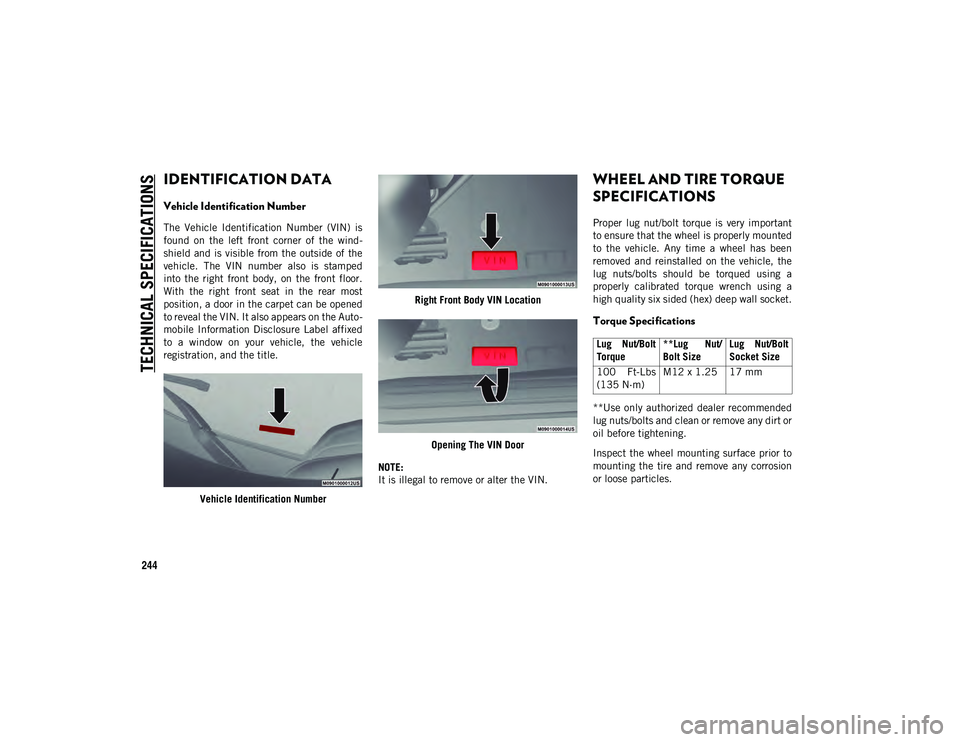

Vehicle Identification Number

The Vehicle Identification Number (VIN) is

found on the left front corner of the wind-

shield and is visible from the outside of the

vehicle. The VIN number also is stamped

into the right front body, on the front floor.

With the right front seat in the rear most

position, a door in the carpet can be opened

to reveal the VIN. It also appears on the Auto -

mobile Information Disclosure Label affixed

to a window on your vehicle, the vehicle

registration, and the title.

Vehicle Identification Number Right Front Body VIN Location

Opening The VIN Door

NOTE:

It is illegal to remove or alter the VIN.

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important

to ensure that the wheel is properly mounted

to the vehicle. Any time a wheel has been

removed and reinstalled on the vehicle, the

lug nuts/bolts should be torqued using a

properly calibrated torque wrench using a

high quality six sided (hex) deep wall socket.

Torque Specifications

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Lug Nut/Bolt

Torque **Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs

(135 N·m) M12 x 1.25 17 mm

2020_JEEP_M6_UG_UK.book Page 244