JEEP COMPASS 2021 Owner handbook (in English)

Manufacturer: JEEP, Model Year: 2021, Model line: COMPASS, Model: JEEP COMPASS 2021Pages: 328, PDF Size: 8.85 MB

Page 191 of 328

189

JACKING AND TIRE

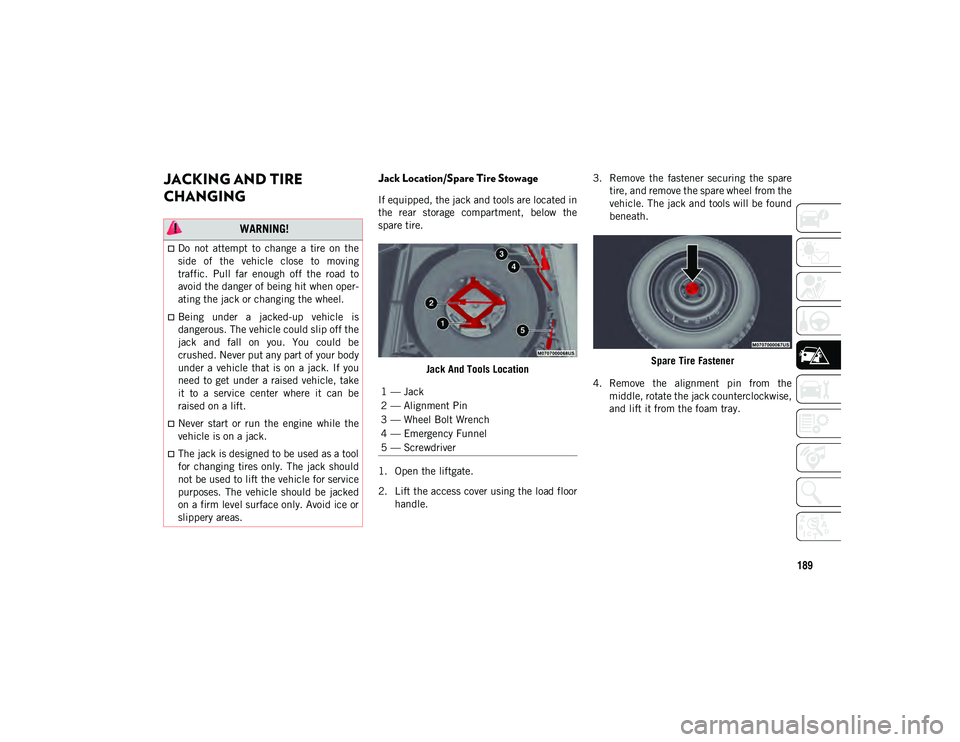

CHANGING Jack Location/Spare Tire Stowage

If equipped, the jack and tools are located in

the rear storage compartment, below the

spare tire.Jack And Tools Location

1. Open the liftgate.

2. Lift the access cover using the load floor handle. 3. Remove the fastener securing the spare

tire, and remove the spare wheel from the

vehicle. The jack and tools will be found

beneath.

Spare Tire Fastener

4. Remove the alignment pin from the middle, rotate the jack counterclockwise,

and lift it from the foam tray.

WARNING!

Do not attempt to change a tire on the

side of the vehicle close to moving

traffic. Pull far enough off the road to

avoid the danger of being hit when oper -

ating the jack or changing the wheel.

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

Never start or run the engine while the

vehicle is on a jack.

The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

1 — Jack

2 — Alignment Pin

3 — Wheel Bolt Wrench

4 — Emergency Funnel

5 — Screwdriver

2020_JEEP_M6_UG_UK.book Page 189

Page 192 of 328

IN CASE OF EMERGENCY

190(Continued)

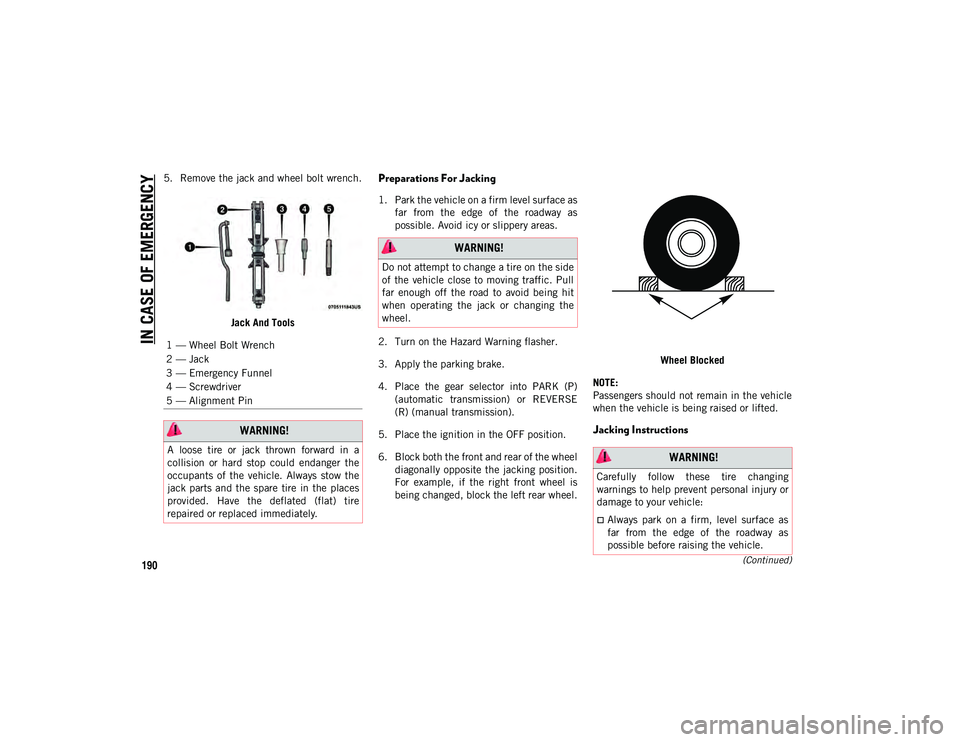

5. Remove the jack and wheel bolt wrench.Jack And ToolsPreparations For Jacking

1. Park the vehicle on a firm level surface asfar from the edge of the roadway as

possible. Avoid icy or slippery areas.

2. Turn on the Hazard Warning flasher.

3. Apply the parking brake.

4. Place the gear selector into PARK (P) (automatic transmission) or REVERSE

(R) (manual transmission).

5. Place the ignition in the OFF position.

6. Block both the front and rear of the wheel diagonally opposite the jacking position.

For example, if the right front wheel is

being changed, block the left rear wheel. Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being raised or lifted.

Jacking Instructions

1 — Wheel Bolt Wrench

2 — Jack

3 — Emergency Funnel

4 — Screwdriver

5 — Alignment Pin

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire

repaired or replaced immediately.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic. Pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

WARNING!

Carefully follow these tire changing

warnings to help prevent personal injury or

damage to your vehicle:

Always park on a firm, level surface as

far from the edge of the roadway as

possible before raising the vehicle.

2020_JEEP_M6_UG_UK.book Page 190

Page 193 of 328

191(Continued)

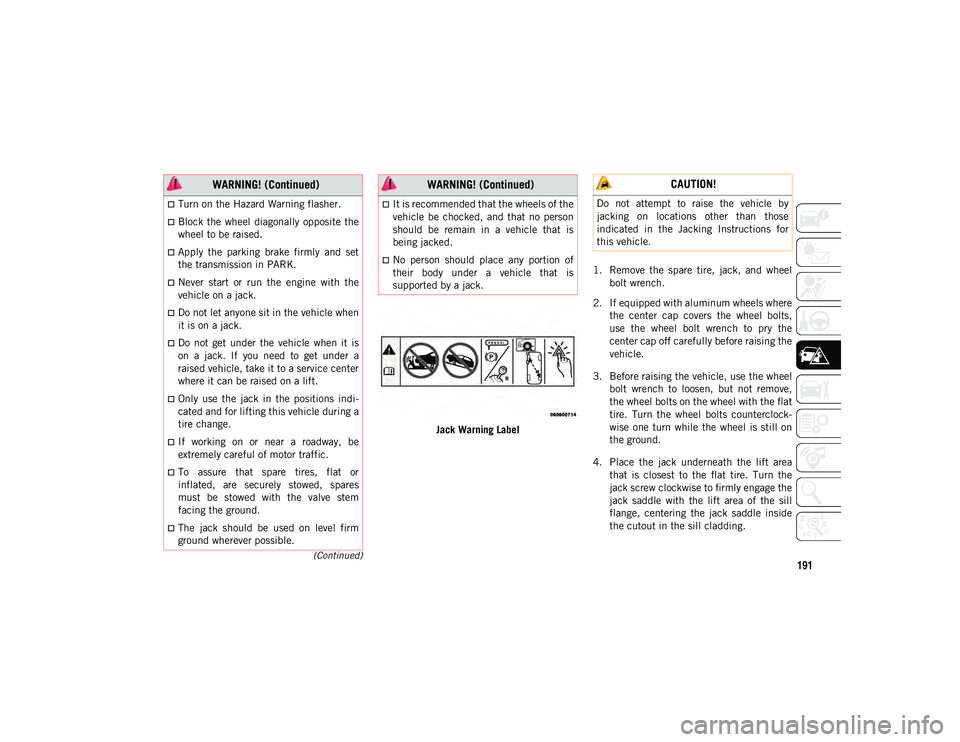

Jack Warning Label1. Remove the spare tire, jack, and wheel

bolt wrench.

2. If equipped with aluminum wheels where the center cap covers the wheel bolts,

use the wheel bolt wrench to pry the

center cap off carefully before raising the

vehicle.

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove,

the wheel bolts on the wheel with the flat

tire. Turn the wheel bolts counterclock -

wise one turn while the wheel is still on

the ground.

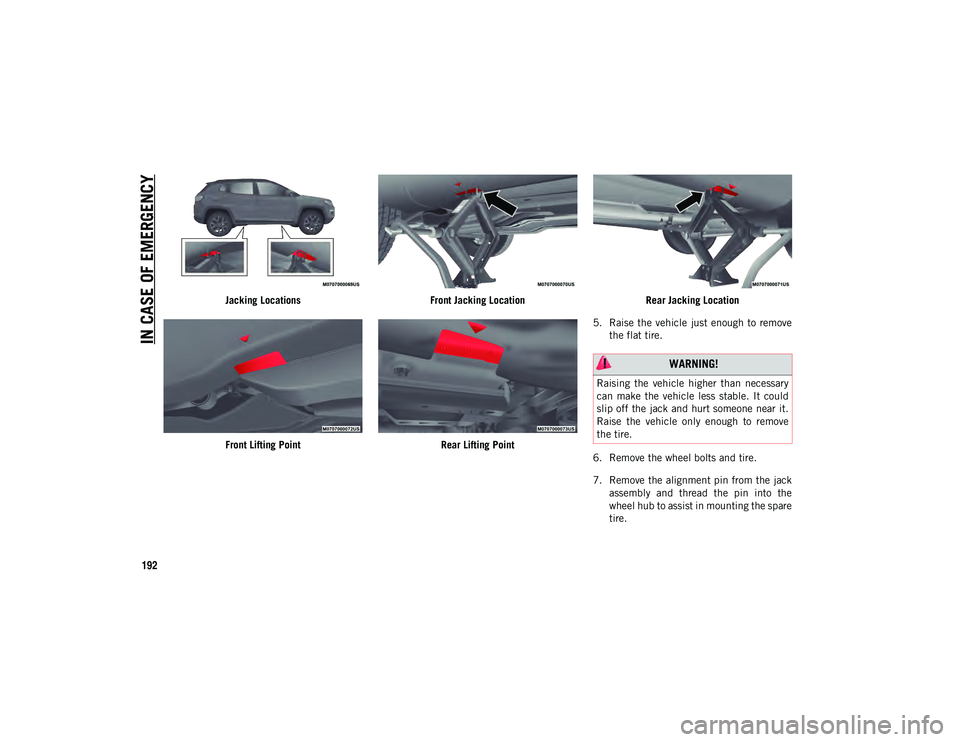

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the

jack screw clockwise to firmly engage the

jack saddle with the lift area of the sill

flange, centering the jack saddle inside

the cutout in the sill cladding.

Turn on the Hazard Warning flasher.

Block the wheel diagonally opposite the

wheel to be raised.

Apply the parking brake firmly and set

the transmission in PARK.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when

it is on a jack.

Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

Only use the jack in the positions indi -

cated and for lifting this vehicle during a

tire change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or

inflated, are securely stowed, spares

must be stowed with the valve stem

facing the ground.

The jack should be used on level firm

ground wherever possible.

WARNING! (Continued)

It is recommended that the wheels of the

vehicle be chocked, and that no person

should be remain in a vehicle that is

being jacked.

No person should place any portion of

their body under a vehicle that is

supported by a jack.

WARNING! (Continued) CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those

indicated in the Jacking Instructions for

this vehicle.

2020_JEEP_M6_UG_UK.book Page 191

Page 194 of 328

IN CASE OF EMERGENCY

192

Jacking LocationsFront Lifting Point Front Jacking Location

Rear Lifting Point Rear Jacking Location

5. Raise the vehicle just enough to remove the flat tire.

6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

2020_JEEP_M6_UG_UK.book Page 192

Page 195 of 328

193

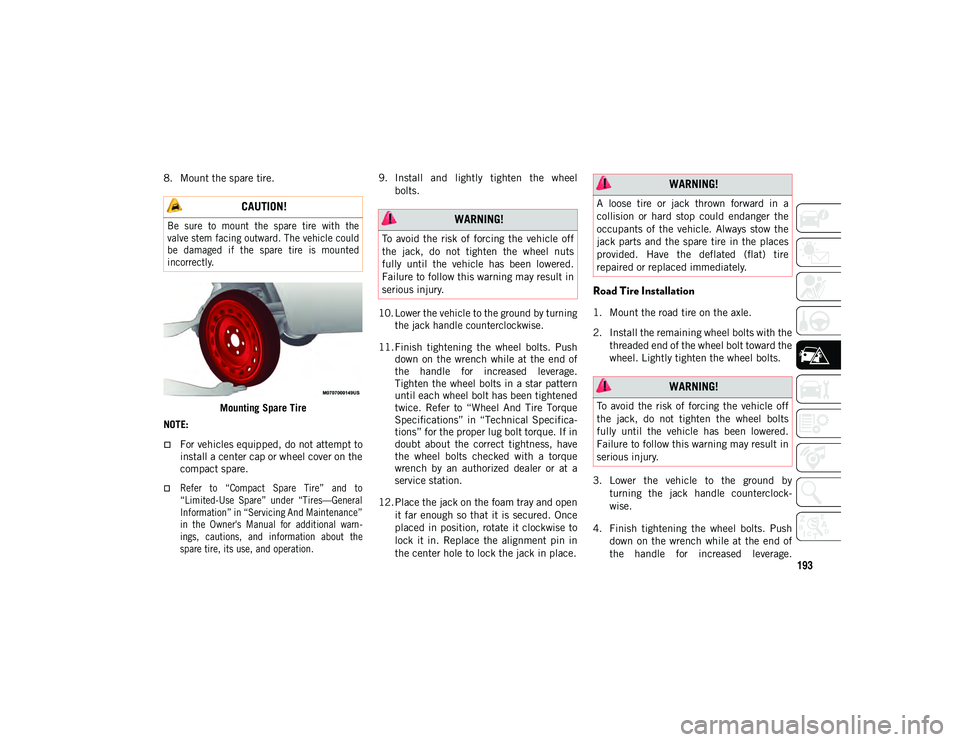

8. Mount the spare tire.Mounting Spare Tire

NOTE:

For vehicles equipped, do not attempt to install a center cap or wheel cover on the

compact spare.

Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires—General

Information” in “Servicing And Maintenance”

in the Owner's Manual for additional warn- ings, cautions, and information about thespare tire, its use, and operation.

9. Install and lightly tighten the wheel

bolts.

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica -

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

the wheel bolts checked with a torque

wrench by an authorized dealer or at a

service station.

12. Place the jack on the foam tray and open it far enough so that it is secured. Once

placed in position, rotate it clockwise to

lock it in. Replace the alignment pin in

the center hole to lock the jack in place.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with thethreaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

3. Lower the vehicle to the ground by turning the jack handle counterclock -

wise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of

the handle for increased leverage.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle could

be damaged if the spare tire is mounted

incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire

repaired or replaced immediately.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

2020_JEEP_M6_UG_UK.book Page 193

Page 196 of 328

IN CASE OF EMERGENCY

194

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica-

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.

5. Lower the jack until it is free. Remove the wheel blocks. Reassemble the lug

wrench to the jack assembly and stow it

in the spare tire area. Secure the

assembly using the means provided.

Release the parking brake before driving

the vehicle.

6. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to

ensure that all wheel bolts are properly

seated against the wheel.

EC Declaration Of Conformance

1. The undersigned, Jaswant Singh, repre-

senting the Moonlight Tools Pvt. Ltd.,

herewith declares that the machinery

described below fulfills all the relevant

provisions of:

The EC-directive 2006/42/EC on Machinery 2. Description of machinery.

a. Generic Denomination: Pantograph

jack

b. Function: Lifting Motor Vehicle

3. Manufacturer Detail Moonlight Tools Pvt. Ltd.

Vill. Jaspalon, G.T. Road Doraha

Distt. Ludhiana (141421) Punjab (India)

Teh. PH. No. 01628 258302

4. Authorized Person to compile the tech -

nical file

Mr. Jaswant Singh DGM (QA & Dev.)

Moonlight Tools Pvt. Ltd.

Ludhiana

5. Reference standard: PF-90065 NOTE:

This declaration becomes invalid, if tech

-

nical or operational modifications are intro -

duced without the manufacture’s consent.

Follow operational manual and instructions

for use.

German Translation

Model

Code Model

Name Type Working

load

M6 (556) MPV MLF1 1250Kg

Date Place

Signature Seal

29–03–

2017 Doraha

Ludhiana

2020_JEEP_M6_UG_UK.book Page 194

Page 197 of 328

195

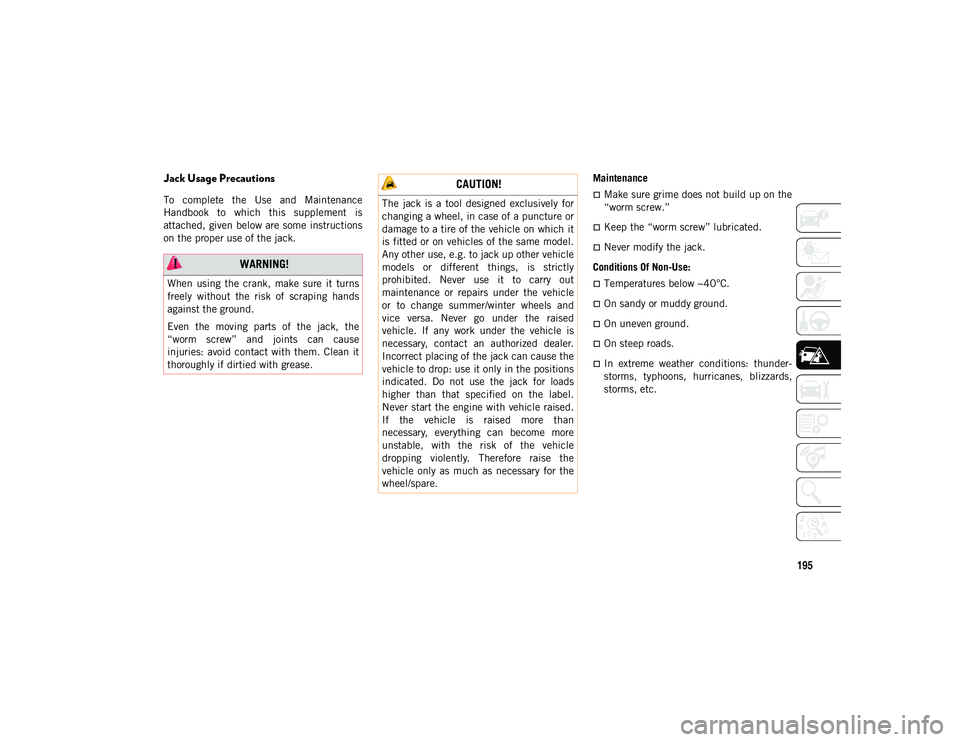

Jack Usage Precautions

To complete the Use and Maintenance

Handbook to which this supplement is

attached, given below are some instructions

on the proper use of the jack.MaintenanceMake sure grime does not build up on the

“worm screw.”

Keep the “worm screw” lubricated.

Never modify the jack.

Conditions Of Non-Use:

Temperatures below −40°C.

On sandy or muddy ground.

On uneven ground.

On steep roads.

In extreme weather conditions: thunder -

storms, typhoons, hurricanes, blizzards,

storms, etc.

WARNING!

When using the crank, make sure it turns

freely without the risk of scraping hands

against the ground.

Even the moving parts of the jack, the

“worm screw” and joints can cause

injuries: avoid contact with them. Clean it

thoroughly if dirtied with grease.

CAUTION!

The jack is a tool designed exclusively for

changing a wheel, in case of a puncture or

damage to a tire of the vehicle on which it

is fitted or on vehicles of the same model.

Any other use, e.g. to jack up other vehicle

models or different things, is strictly

prohibited. Never use it to carry out

maintenance or repairs under the vehicle

or to change summer/winter wheels and

vice versa. Never go under the raised

vehicle. If any work under the vehicle is

necessary, contact an authorized dealer.

Incorrect placing of the jack can cause the

vehicle to drop: use it only in the positions

indicated. Do not use the jack for loads

higher than that specified on the label.

Never start the engine with vehicle raised.

If the vehicle is raised more than

necessary, everything can become more

unstable, with the risk of the vehicle

dropping violently. Therefore raise the

vehicle only as much as necessary for the

wheel/spare.

2020_JEEP_M6_UG_UK.book Page 195

Page 198 of 328

IN CASE OF EMERGENCY

196

NOTE:

The jack requires no adjustment.

The jack cannot be repaired, and in the

event of a fault, it must be replaced by

another genuine one.

No tool other than its cranking device may

be fitted on the jack.

TIRE SERVICE KIT — IF

EQUIPPED

Your vehicle may be equipped with a Tire

Service Kit. Small punctures up to 1/4 inch

(6 mm) in the tire tread can be sealed with

Tire Service Kit. Foreign objects (e.g., screws

or nails) should not be removed from the tire.

Tire Service Kit can be used in outside

temperatures down to approximately -4°F

(-20°C). This kit will provide a temporary tire

seal, allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed

of 50 mph (80 km/h).Tire Service Kit Storage

The Tire Service Kit is stowed under the load

floor behind the rear seat.

1. Open the liftgate.

2. Lift the access cover using the load floor

handle.

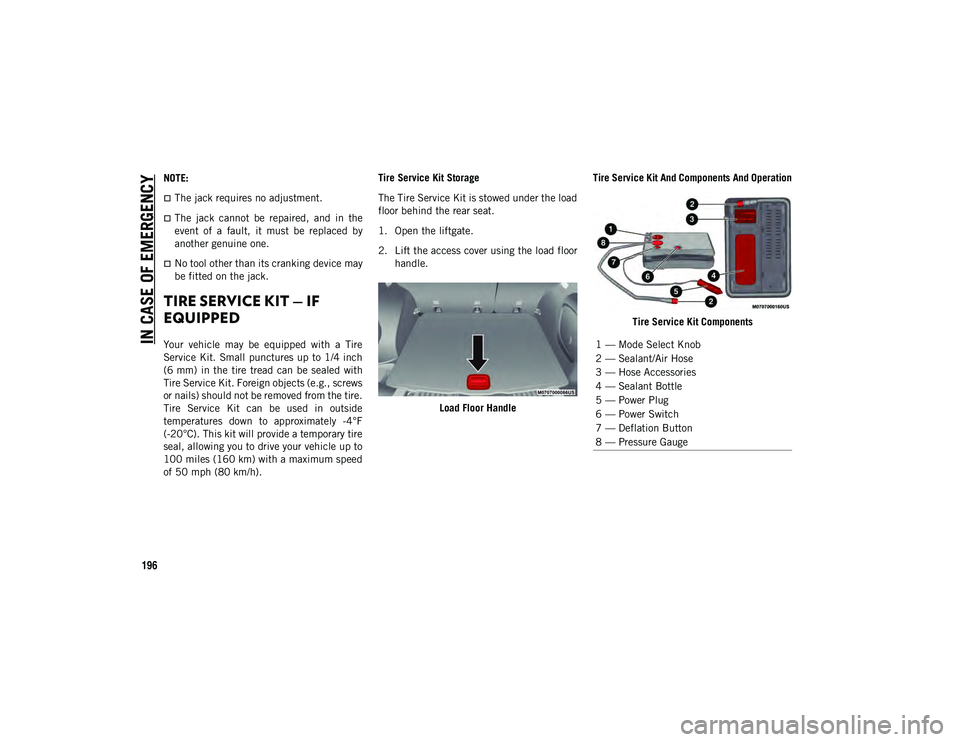

Load Floor Handle Tire Service Kit And Components And Operation

Tire Service Kit Components1 — Mode Select Knob

2 — Sealant/Air Hose

3 — Hose Accessories

4 — Sealant Bottle

5 — Power Plug

6 — Power Switch

7 — Deflation Button

8 — Pressure Gauge

2020_JEEP_M6_UG_UK.book Page 196

Page 199 of 328

197

(Continued)

Using The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the

following symbols to indicate the air or

sealant mode.

Selecting Air Mode

Push in the Mode Select Knob and turn

to this position for air pump operation on -

ly.

Selecting Sealant Mode

Push in the Mode Select Knob and turn

to this position to inject the Tire Service

Kit Sealant and to inflate the tire.

Using The Power Button

Push and release the Power Button once

to turn the Tire Service Kit on. Push and

release the Power Button again to turn

the Tire Service Kit off.

Using The Deflation Button

Push the Deflation Button to reduce the

air pressure in the tire if it becomes over

inflated. Tire Service Kit Usage Precautions

Replace the Tire Service Kit Sealant

Bottle prior to the expiration date (printed

at the lower right hand corner on the bottle

label) to assure optimum operation of the

system. Refer to “Sealant Bottle Replace-

ment” in this section.

The Sealant Bottle is a one tire application

use and needs to be replaced after each

use. Always replace these components

immediately from an authorized dealer.

When the Tire Service Kit sealant is in a

liquid form, clean water, and a damp cloth

will remove the material from the vehicle

or tire and wheel components. Once the

sealant dries, it can easily be peeled off

and properly discarded.

For optimum performance, make sure the

valve stem on the wheel is free of debris

before connecting the Tire Service Kit.

You can use the Tire Service Kit air pump

to inflate bicycle tires. The kit also comes

with two needles, located in the Accessory

Storage Compartment (on the bottom of

the air pump) for inflating sport balls,

rafts, or similar inflatable items. However,

use only the Air Pump and make sure the

Mode Select Knob is in the Air Mode when inflating such items to avoid injecting

sealant into them. The Tire Service Kit

Sealant is only intended to seal punctures

less than 1/4 inch (6 mm) diameter in the

tread of your vehicle.

Do not lift or carry the Tire Service Kit by

the hoses.

WARNING!

Do not attempt to seal a tire on the side

of the vehicle closest to traffic. Pull far

enough off the road to avoid the danger

of being hit when using the Tire Service

Kit.

Do not use Tire Service Kit or drive the

vehicle under the following circum

-

stances:

If the puncture in the tire tread is approximately 1/4 inch (6 mm) orlarger.

If the tire has any sidewall damage.

If the tire has any damage from driving with extremely low tire pres-

sure.

If the tire has any damage from driving on a flat tire.

2020_JEEP_M6_UG_UK.book Page 197

Page 200 of 328

IN CASE OF EMERGENCY

198

(Continued)

Sealing A Tire With Tire Service Kit

Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn onthe vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that

is near to the ground. This will allow the

Tire Service Kit Hose to reach the valve

stem and keep the Tire Service Kit flat on

the ground. This will provide the best

positioning of the kit when injecting the

sealant into the deflated tire and running

the air pump. Move the vehicle as neces -

sary to place the valve stem in this posi -

tion before proceeding. 3. Place the transmission in PARK and

cycle the ignition in the OFF position.

4. Apply the parking brake.

Setting Up To Use Tire Service Kit:

1. Uncoil the Sealant Hose and then remove the cap from the fitting at the end of the

hose.

2. Place the Tire Service Kit flat on the ground next to the deflated tire.

3. Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose onto the valve stem.

4. Uncoil the Power Plug and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:

Do not remove foreign objects (e.g., screws

or nails) from the tire.

Injecting Tire Service Kit Sealant Into The

Deflated Tire:

1. Always start the vehicle before turning the Tire Service Kit on.

2. Ensure the Mode Select Knob is to the Sealant Mode position.

If the wheel has any damage.

If you are unsure of the condition ofthe tire or the wheel.

Keep Tire Service Kit away from open

flames or heat source.

A loose Tire Service Kit thrown forward in

a collision or hard stop could endanger

the occupants of the vehicle. Always

stow the Tire Service Kit in the place

provided. Failure to follow these warn -

ings can result in injuries that are serious

or fatal to you, your passengers, and

others around you.

Take care not to allow the contents of

Tire Service Kit to come in contact with

hair, eyes, or clothing. Tire Service Kit

sealant is harmful if inhaled, swallowed,

or absorbed through the skin. It causes

skin, eye, and respiratory irritation.

Flush immediately with plenty of water if

there is any contact with eyes or skin.

Change clothing as soon as possible, if

there is any contact with clothing.

WARNING! (Continued)

Tire Service Kit Sealant solution

contains latex. In case of an allergic

reaction or rash, consult a physician

immediately. Keep Tire Service Kit out

of reach of children. If swallowed, rinse

mouth immediately with plenty of water

and drink plenty of water. Do not induce

vomiting! Consult a physician immedi -

ately.

WARNING! (Continued)

2020_JEEP_M6_UG_UK.book Page 198