brake JEEP DJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 71 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

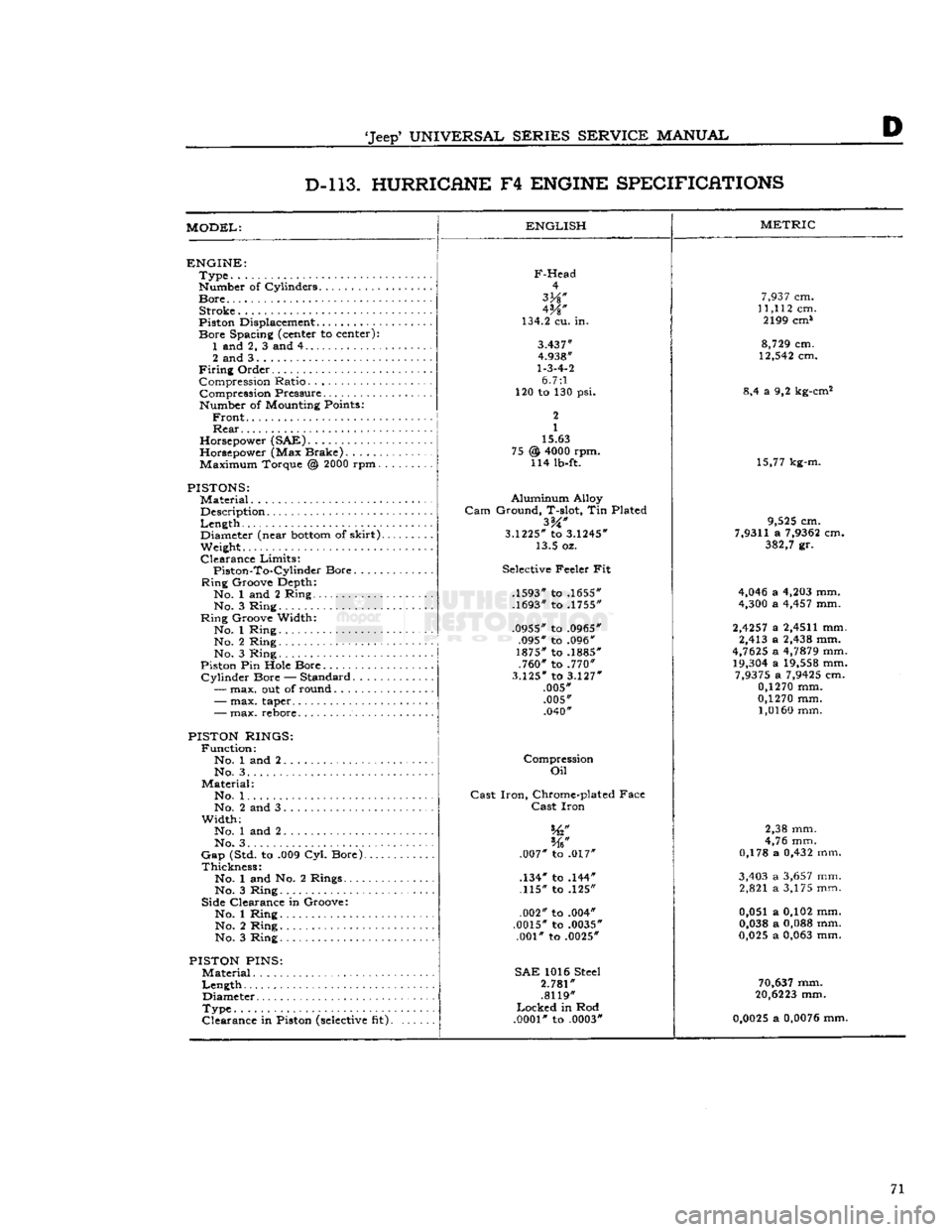

D D-l 13. HURRICANE

F4

ENGINE SPECIFICATIONS

MODEL:

ENGLISH

ENGINE:

Type

Number of Cylinders

Bore

Stroke

Piston Displacement...........

Bore

Spacing (center to center): 1 and 2, 3 and 4

2 and 3

Firing

Order Compression Ratio Compression Pressure... .

Number of Mounting Points:

Front

Rear

Horsepower (SAE)

Horsepower (Max Brake) Maximum Torque @

2000

rpm.

PISTONS:

Material

Description

Length

,.

Diameter (near

bottom

of

skirt).

Weight.

Clearance

Limits:

Piston-To-Cylindcr

Bore

Ring

Groove Depth:

No. 1 and 2 Ring No. 3 Ring

Ring

Groove Width:

No. 1 Ring No. 2 Ring

No. 3 Ring

Piston Pin Hole Bore

Cylinder

Bore — Standard.....

—

max. out of round

F-Head

4

W

134.2 cu. in.

3.437"

4.938"

1-3-4-2

6.7:1

120 to 130 psi.

2

1

15.63

@

4000

rpm. 114 lb-ft. 75

-

max. taper..

-

max. rebore.

PISTON RINGS:

Function:

No. 1 and 2 No. 3. .

Material:

No. 1. .

No. 2 and 3

Width;

No. 1 and 2

No. 3. . . .

Gap

(Std. to .009 Cyl. Bore).

Thickness:

No. 1 and No. 2 Rings....

No. 3 Ring

Side Clearance in Groove:

No. 1 Ring No. 2 Ring

No. 3 Ring

PISTON

PINS:

Material

Length

Diameter

Type

Clearance

in Piston

(selective

fit).

Aluminum

Alloy

Gam

Ground, T-slot, Tin Plated

3.1225*

to

3.1245*

13.5 oz.

Selective Feeler Fit

.1593" to .1655"

.1693" to .1755"

.0955" to .0965" .095" to .096"

1875" to .1885" .760" to .770"

3.125"

to

3.127"

.005" .005" .040"

Compression

Oil

Cast

Iron,

Chrome-plated Face

Cast

Iron

.007" to .017"

.134" to .144" .115" to .125"

.002" to .004"

.0015" to .0035" .001" to .0025"

SAE

1016 Steel

2.781"

.8119"

Locked

in Rod

.0001"

to .0003"

METRIC

7,937

cm.

11,112

cm. 2199 cm*

8,729

cm.

12,542

cm.

8,4 a 9,2 kg-cm2

15,77 kg-m.

9,525

cm.

7,9311

a

7,9362

cm.

382,7

gr.

4,046

a

4,203

mm.

4,300

a

4,457

mm.

2,4257

a

2,4511

mm. 2,413 a

2,438

mm.

4,7625

a

4,7879

mm.

19,304

a

19,558

mm.

7,9375

a

7,9425

cm.

0,1270

mm.

0,1270

mm.

1,0160

mm.

2,38 mm.

4,76 mm.

0,178 a

0,432

mm.

3,403

a

3,657

mm. 2,821 a 3,175 mm.

0,051 a 0,102 mm.

0,038

a

0,088

mm.

0,025

a

0,063

mm.

70,637

mm.

20,6223

mm.

0,0025

a

0,0076

mm. 71

Page 105 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

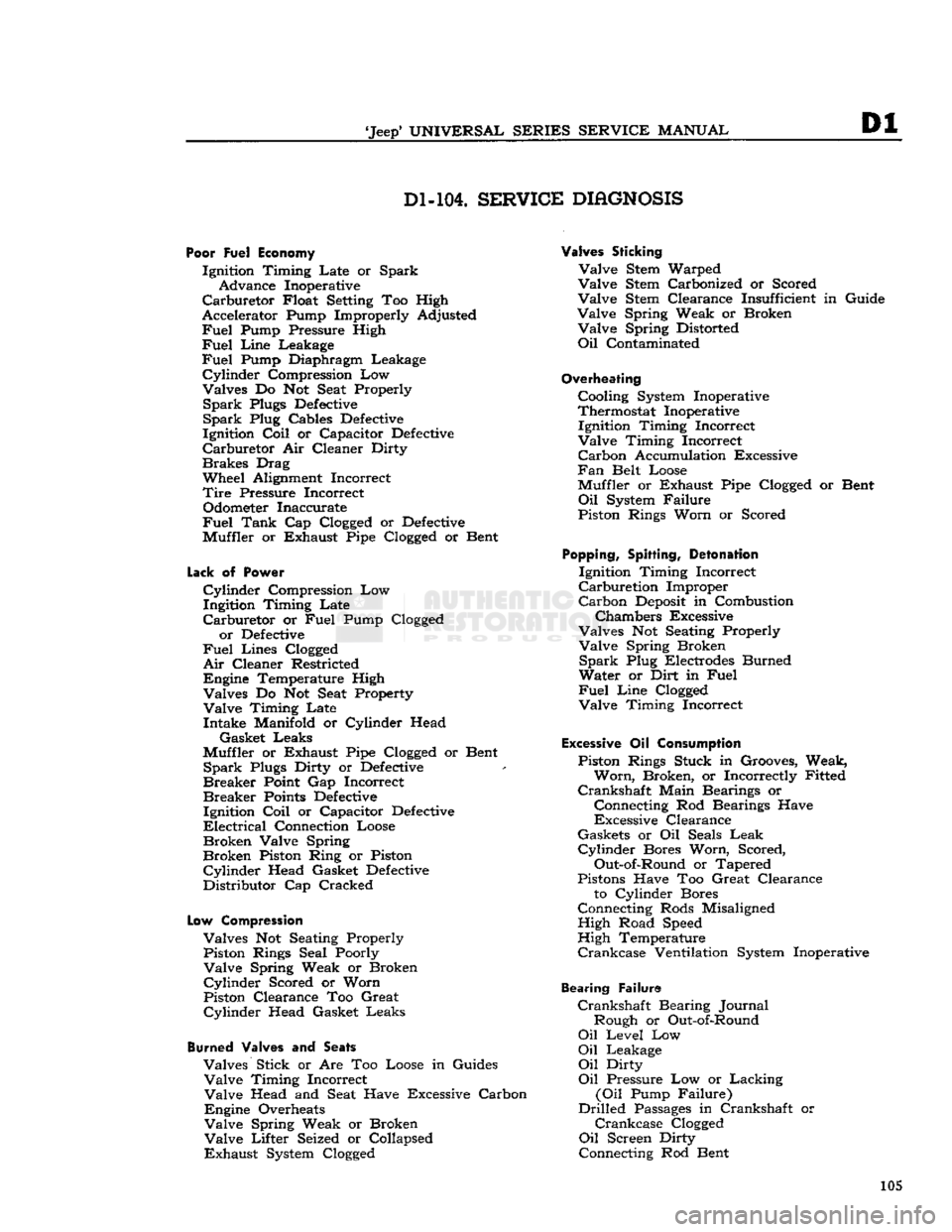

Dl-104.

SERVICE

DIAGNOSIS

Poor Fuel Economy

Ignition Timing Late or Spark Advance Inoperative

Carburetor

Float Setting Too High

Accelerator Pump Improperly Adjusted

Fuel

Pump Pressure High

Fuel

Line

Leakage

Fuel

Pump Diaphragm Leakage

Cylinder

Compression Low

Valves Do Not Seat Properly

Spark

Plugs

Defective

Spark

Plug Cables

Defective

Ignition

Coil

or Capacitor

Defective

Carburetor

Air Cleaner Dirty

Brakes

Drag

Wheel Alignment Incorrect

Tire

Pressure Incorrect Odometer Inaccurate

Fuel

Tank

Cap Clogged or

Defective

Muffler or Exhaust Pipe Clogged or Bent

Lack

of

Power

Cylinder

Compression Low

Ingitdon Timing Late

Carburetor

or

Fuel

Pump Clogged or

Defective

Fuel

Lines Clogged

Air

Cleaner Restricted

Engine Temperature High Valves Do Not Seat Property

Valve

Timing Late Intake Manifold or Cylinder Head

Gasket Leaks

Muffler or Exhaust Pipe Clogged or Bent

Spark

Plugs Dirty or

Defective

Breaker

Point Gap Incorrect

Breaker

Points

Defective

Ignition

Coil

or Capacitor

Defective

Electrical

Connection Loose

Broken

Valve Spring

Broken

Piston Ring or Piston

Cylinder

Head Gasket

Defective

Distributor Cap Cracked

Low

Compression

Valves Not Seating Properly Piston Rings Seal Poorly

Valve

Spring Weak or Broken

Cylinder

Scored or Worn

Piston Clearance Too Great

Cylinder

Head Gasket Leaks

Burned

Valves and

Seats

Valves Stick or Are Too Loose in Guides

Valve

Timing Incorrect

Valve

Head and Seat Have Excessive Carbon

Engine Overheats

Valve

Spring Weak or Broken

Valve

Lifter Seized or Collapsed

Exhaust

System Clogged

Valves Sticking

Valve

Stem Warped

Valve

Stem Carbonized or Scored

Valve

Stem Clearance Insufficient in Guide

Valve

Spring Weak or Broken

Valve

Spring Distorted

Oil

Contaminated

Overheating

Cooling System Inoperative

Thermostat Inoperative Ignition Timing Incorrect

Valve

Timing Incorrect

Carbon

Accumulation Excessive

Fan

Belt Loose

Muffler or Exhaust Pipe Clogged or Bent

Oil

System Failure

Piston Rings Worn or Scored

Popping,

Spitting,

Detonation

Ignition Timing Incorrect

Carburetion

Improper

Carbon

Deposit

in Combustion

Chambers Excessive

Valves Not Seating Properly

Valve

Spring Broken

Spark

Plug Electrodes Burned

Water or Dirt in

Fuel

Fuel

Line

Clogged

Valve

Timing Incorrect

Excessive

Oil

Consumption

Piston Rings Stuck in Grooves, Weak,

Worn,

Broken, or Incorrectly Fitted

Crankshaft

Main Bearings or

Connecting Rod Bearings Have

Excessive Clearance

Gaskets or Oil Seals

Leak

Cylinder

Bores Worn, Scored,

Out-of-Round or Tapered

Pistons Have Too Great Clearance to Cylinder Bores

Connecting Rods Misaligned High Road Speed

High Temperature

Crankcase

Ventilation System Inoperative

Bearing Failure

Crankshaft

Bearing Journal Rough or Out-of-Round

Oil

Level Low

Oil

Leakage

Oil

Dirty

Oil

Pressure Low or Lacking

(Oil

Pump Failure)

Drilled

Passages

in Crankshaft or

Crankcase

Clogged

Oil

Screen Dirty

Connecting Rod Bent 105

Page 106 of 376

Dl

DAUNTLESS

V-6

ENGINE

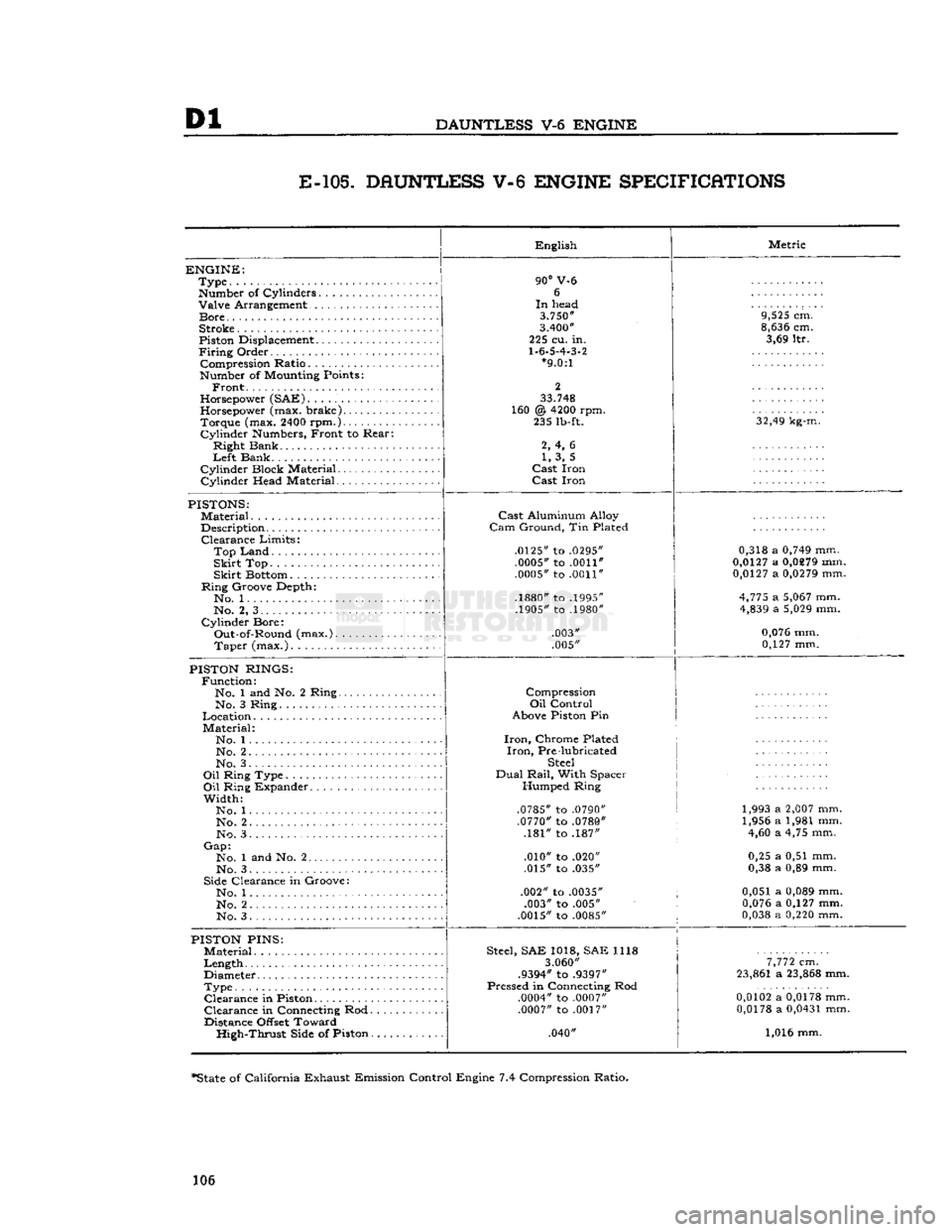

E-105.

DAUNTLESS V-6 ENGINE SPECIFICATIONS

ENGINE:

Type

Number

of Cylinders Valve Arrangement

Bore

Stroke

Piston

Displacement

Firing

Order Compression Ratio

Number

of

Mounting

Points:

Front.

Horsepower

(SAE)

Horsepower

(max. brake) Torque (max.

2400

rpm.)

Cylinder

Numbers,

Front to Rear:

Right Bank

Left

Bank

Cylinder Block Material

Cylinder Head Material English

90°

V-6 6

In

head

3.750"

3.400"

225 cu. in.

1.6.5.4.3.2

*9.0:1

2

33.748

160 @

4200

rpm. 235

lb-ft.

2, 4, 6 1, 3, 5

Cast

Iron

Cast

Iron Metric

9,525

cm.

8,636

cm. 3,69 ltr.

32,49

kg-m.

PISTONS:

Material

Description Clearance Limits:

Top

Land

Skirt

Top

Skirt

Bottom

Ring Groove Depth*. No. 1

No. 2, 3

Cylinder Bore: Out-of-Round (max.). Taper (max.)

Cast

Aluminum Alloy

Cam

Ground, Tin Plated

.0125"

to

.0295" .0005"

to

.0011"

.0005"

to

.0011"

.1880"

to

.1995"

.1905"

to

.1980"

.003"

.005" 0,318 a

0,749

mm.

0,0127

a

0,0279

mm.

0,0127

a

0,0279

mm.

4,775

a

5,067

mm.

4,839

a

5,029

mm.

0,076

mm. 0,127 mm.

PISTON

RINGS:

Function: No. 1 and No. 2 Ring.. No. 3 Ring

Location

Material: No. 1...

No. 2 No. 3.

Oil

Ring Type

Oil

Ring Expander

Width: No. 1

No. 2. .

No. 3

Gap:

No. 1 and No. 2

No. 3

Side

Clearance in Groove: No. 1

No. 2

No. 3 Compression

Oil

Control

Above

Piston

Pin

Iron,

Chrome Plated

Iron,

Pre lubricated

Steel

Dual

Rail,

With Spacer Humped Ring

.0785"

to

.0790" .0770"

to

.0780"

.181" to .187"

.010" to .020"

.015" to .035"

.002" to

.0035"

.003" to .005"

.0015"

to

.0085"

1,993 a

2,007

mm.

1,956 a 1,981 mm. 4,60 a 4,75 mm.

0,25 a 0,51 mm.

0,38 a 0,89 mm.

0,051 a

0,089

mm.

0,076

a 0,127 mm.

0,038

a

0,220

mm.

PISTON

PINS:

Material

Length

Diameter

Type Clearance in

Piston

Clearance in

Connecting

Rod.

Distance

Offset

Toward High-Thrust

Side

of Piston.

Steel,

SAE 1018, SAE 1118

3.060"

.9394"

to

.9397"

Pressed in

Connecting

Rod

.0004"

to

.0007" .0007"

to

.0017"

.040"

7,772

cm.

23,861

a

23,868

mm.

0,0102

a

0,0178

mm.

0,0178

a

0,0431

mm.

1,016 mm.

*State

of California Exhaust Emission Control Engine 7.4 Compression Ratio.

106

Page 134 of 376

E

FUEL

SYSTEM

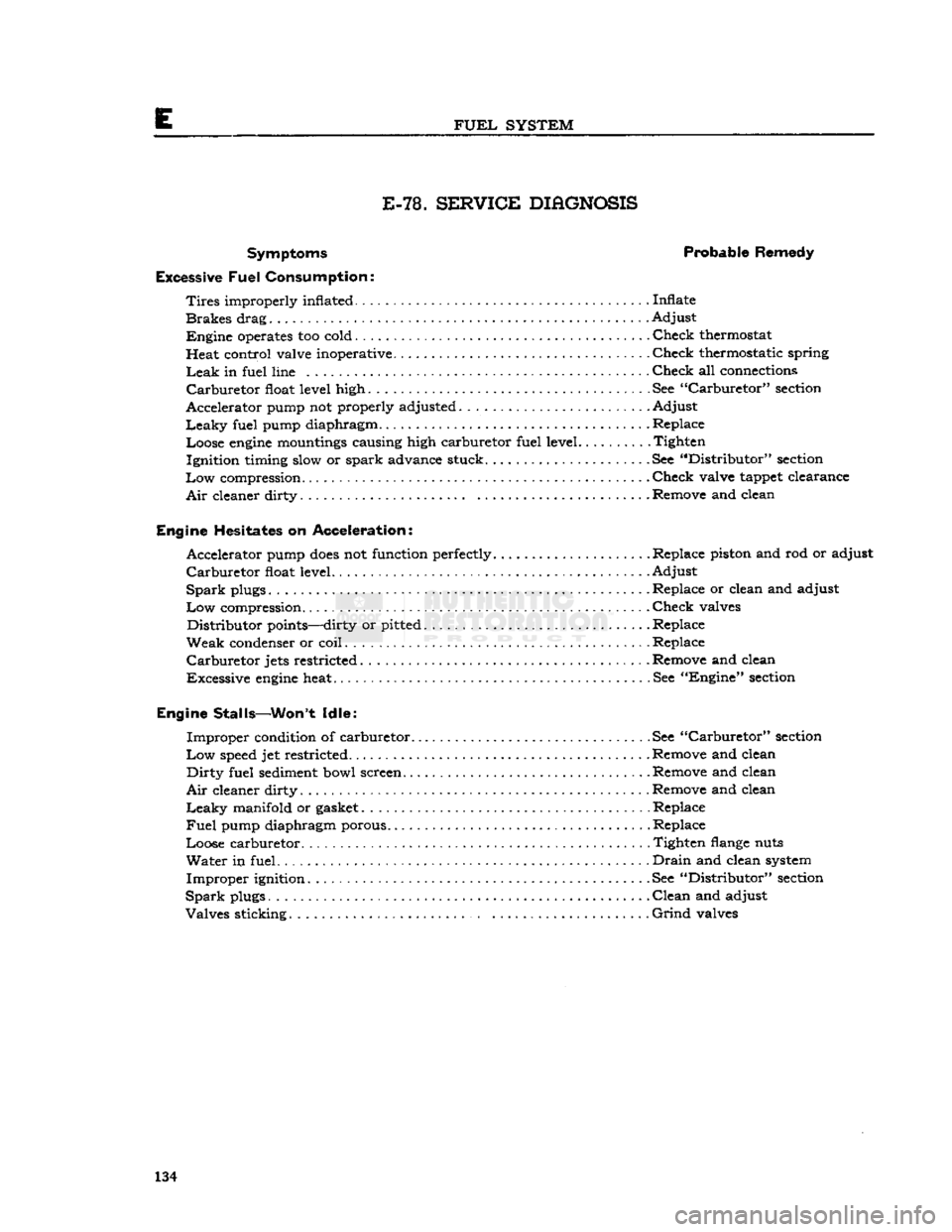

E-78. SERVICE DIHGNOSIS

Symptoms Probable Remedy

Excessive

Fuel

Consumption:

Tires

improperly inflated Inflate

Brakes

drag Adjust

Engine

operates too cold Check thermostat

Heat control valve inoperative Check thermostatic spring

Leak

in fuel line Check all connections

Carburetor

float level high. See

"Carburetor"

section

Accelerator pump not properly adjusted Adjust

Leaky

fuel pump diaphragm Replace

Loose

engine

mountings causing high carburetor fuel level Tighten Ignition timing slow or spark advance stuck See "Distributor" section

Low

compression. Check valve tappet clearance

Air

cleaner dirty

.

Remove and clean

Engine

Hesitates on Acceleration: Accelerator pump

does

not function perfectly.

...................

.Replace piston and rod or adjust

Carburetor

float level. ... .Adjust

Spark

plugs Replace or clean and adjust

Low

compression Check valves

Distributor

points—dirty or pitted Replace

Weak

condenser or coil Replace

Carburetor

jets restricted Remove and clean

Excessive

engine

heat See "Engine" section

Engine

Stalls—Won't Idle:

Improper

condition of carburetor See

"Carburetor"

section

Low

speed

jet restricted Remove and clean

Dirty

fuel sediment bowl screen Remove and clean

Air

cleaner dirty Remove and clean

Leaky

manifold or gasket Replace

Fuel

pump diaphragm porous. Replace

Loose carburetor. Tighten

flange

nuts

Water

in fuel

Drain

and clean system

Improper

ignition. .See "Distributor" section

Spark

plugs Clean and adjust

Valves

sticking.

Grind

valves 134

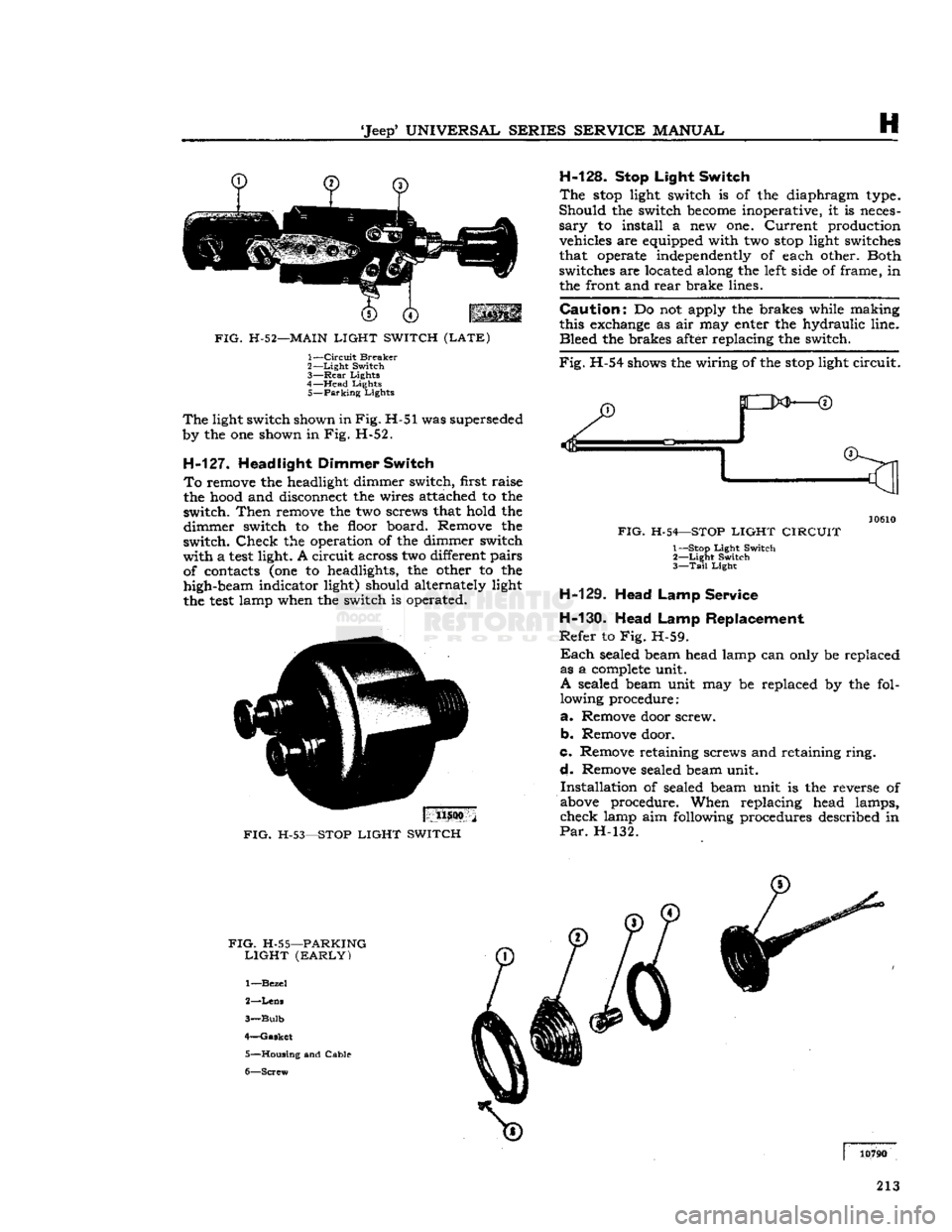

Page 213 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

H

FIG.

H-52—MAIN

LIGHT SWITCH (LATE)

1—

Circuit

Breaker

2—

Light

Switch

3—

Rear

Lights

4—

Head

Lights

5—

Parking

Lights

The

light switch shown in

Fig.

H-51 was superseded

by the one shown in

Fig.

H-52.

H-127.

Headlight Dimmer Switch To

remove the headlight dimmer switch, first raise

the hood and disconnect the wires attached to the

switch.

Then

remove the two screws that hold the

dimmer

switch to the floor board. Remove the

switch.

Check

the operation of the dimmer switch

with

a

test

light. A

circuit

across two different pairs of contacts (one to headlights, the other to the

high-beam indicator light) should alternately light

the

test

lamp when the switch is operated.

H-128.

Stop Light Switch

The

stop

light switch is of the diaphragm type.

Should

the switch

become

inoperative, it is neces

sary

to install a new one.

Current

production vehicles are equipped with two

stop

light switches

that operate independently of each other. Both

switches are located along the

left

side of frame, in the front and

rear

brake lines.

Caution:

Do not apply the brakes while making

this exchange as air may enter the hydraulic line.

Bleed

the brakes after replacing the switch.

Fig.

H-54 shows the wiring of the

stop

light

circuit.

11500

FIG.

H-53—STOP

LIGHT SWITCH

FIG.

H-54—STOP

LIGHT CIRCUIT

1— Stop

Light

Switch

2—

Light

Switch

3—

Tail

Light

H-129. Head Lamp Service

H-130.

Head Lamp Replacement

Refer

to Fig. H-59.

Each

sealed beam head lamp can only be replaced as a

complete

unit.

A

sealed beam unit may be replaced by the fol lowing procedure:

a.

Remove door screw.

b.

Remove door.

c.

Remove retaining screws and retaining

ring.

d.

Remove sealed beam unit.

Installation

of sealed beam unit is the reverse of

above procedure. When replacing head lamps,

check

lamp aim following procedures described in

Par.

H-132.

FIG.

H-55—PARKING

LIGHT (EARLY)

1—

Bezel

2—

Lens

3—

Bulb

4—

Gasket

5—

Housing

and Cable

6—

Screw

213

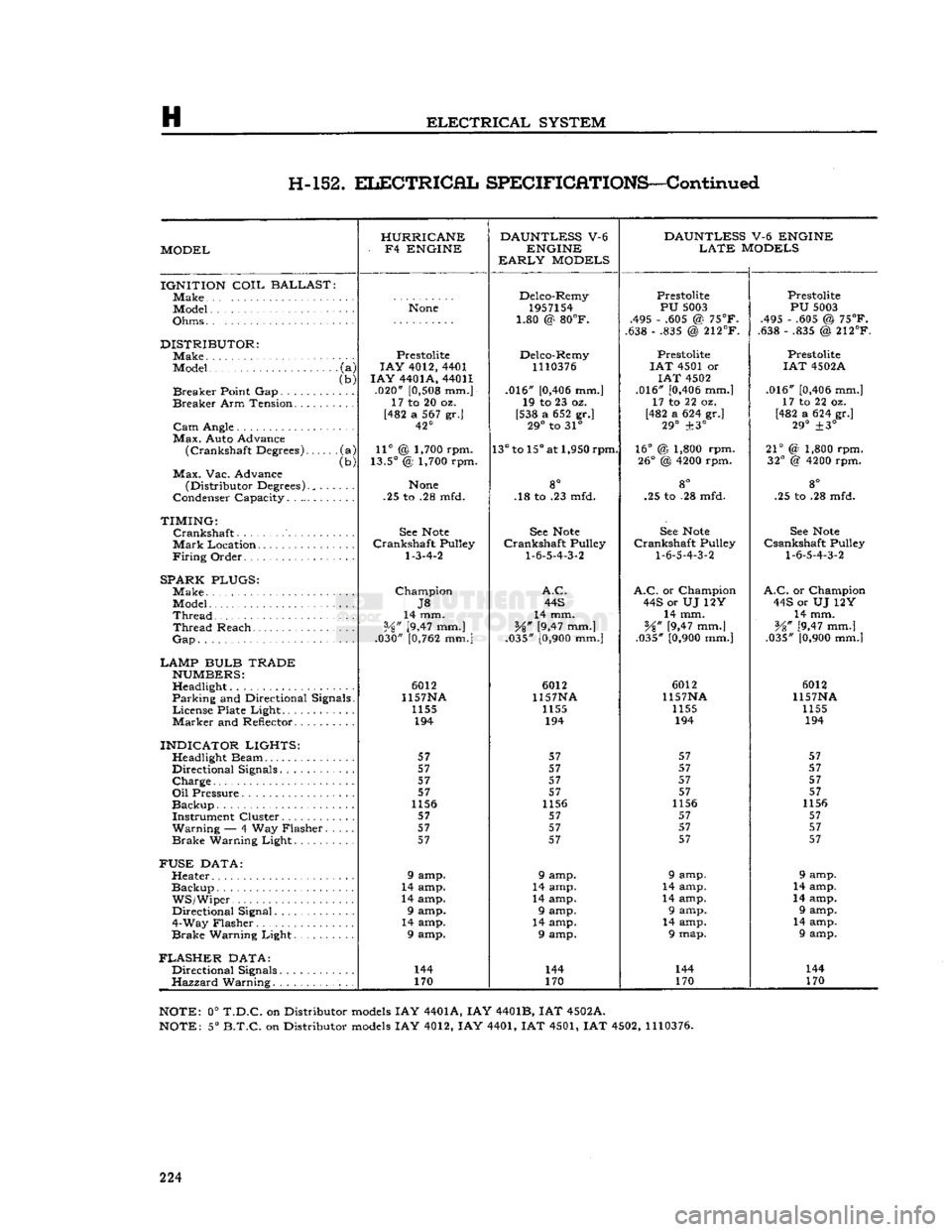

Page 224 of 376

H

ELECTRICAL

SYSTEM

H-152.

ELECTRICAL

SPECIFICATIONS—Continued

HURRICANE DAUNTLESS

V-6

DAUNTLESS

V-6 ENGINE

MODEL -

F4

ENGINE

ENGINE

LATE

MODELS

EARLY

MODELS

IGNITION

COIL

BALLAST

]Make Delco-Remy

Prestolite Prestolite

Model

None

1957154

PU

5003

PU

5003

Ohms • • 1.80 @

80°F.

.495 - .605 @

75°F.

.495 - .605 @

75°F.

1.80 @

80°F.

.638 - .835 @

212°F.

.638 - .835 @

212°F.

DISTRIBUTOR:

Prestolite Delco-Remy Prestolite Prestolite

Model

•

(a)

LAY

4012, 4401

1110376

I

AT

4501 or

IAT

4502A

(b)

I

AY

4401A, 44011

IAT

4502

Breaker

Point Gap (b)

.020"

[0,508

mm.] .016"

[0,406

mm.] .016"

[0,406

mm.]

.016"

[0,406

mm.]

Breaker

Arm Tension. ..... 17 to 20 oz.

19 to 23 oz. 17 to 22 oz. 17 to 22 oz.

[482 a 567 gr.] [538 a 652 gr.] [482 a 624 gr.]

[482 a 624 gr.]

42° 29°

to 31°

29°

±3°

29°

±3°

Max.

Auto Advance

(Crankshaft

Degrees) •(a)

11°

@ 1,700 rpm.

13°

to

15°

at 1,950 rpm.

16°

@ 1,800 rpm.

21°

(2 1,800 rpm.

(Crankshaft

Degrees)

(b)

13.5°

@ 1,700 rpm.

26°

@

4200

rpm.

32°

@

4200

rpm.

Max.

Vac. Advance go

(Distributor Degrees)., . .

None

8° 8°

go

Condenser Capacity. . .25 to .28 mfd. .18 to .23 mfd. .25 to .28 mfd. .25 to .28 mfd.

TIMING:

Crankshaft

See

Note

See

Note

See

Note

See

Note

Mark

Location............

Crankshaft

Pulley

Crankshaft

Pulley

Crankshaft

Pulley

Csankshaft

Pulley

Firing

Order

1-3-4-2

1-6-5-4-3-2

1-6-5-4-3-2 1-6-5-4-3-2

SPARK PLUGS:

Make

Champion

A.C. A.C.

or Champion

A.C.

or Champion

J8

44S

44S or UJ 12Y 44S or UJ 12Y

Thread

14 mm.

14 mm. 14 mm. 14 mm.

Thread

Reach

Vz"

[9,47 mm.]

%"

[9,47 mm.]

¥%"

[9,47 mm.]

V8" [9,47 mm.]

Gap

.030"

[0,762

mm.]

.035"

[0,900

mm.] .035"

[0,900

mm.] .035"

[0,900

mm.|

LAMP BULB TRADE

NUMBERS:

Headlight 6012

6012 6012 6012

Parking

and Directional Signals. 1157NA

1157NA 1157NA 1157NA

License

Plate Light........ 1155

1155 1155 1155

Marker

and Reflector 194

194 194 194

INDICATOR LIGHTS:

57 57 57 57

Directional Signals........ 57

57 57 57

Charge

57

57 57 57

57 57 57 57

1156 1156 1156 1156

Instrument Cluster 57 57 57 57

Warning

— 4 Way Flasher. . 57

57 57 57

Brake

Warning Light 57

57 57 57

FUSE

DATA:

Heater 9 amp. 9 amp. 9 amp. 9 amp.

Backup

14 amp. 14 amp. 14 amp. 14 amp.

WS/Wiper.

14 amp. 14 amp. 14 amp. 14 amp.

Directional Signal 9 amp. 9 amp. 9 amp. 9 amp.

4-Way Flasher 14 amp. 14 amp. 14 amp. 14 amp.

Brake

Warning Light 9 amp. 9 amp. 9 map. 9 amp.

FLASHER

DATA:

Directional Signals. 144

144 144 144

Hazzard

Warning. 170

170 170 170

NOTE:

0°

T.D.C.

on Distributor

models

IAY 4401A, IAY 4401B, IAT 4502A.

NOTE:

5°

B.T.C.

on Distributor

models

IAY 4012, IAY 4401, IAT 4501, IAT 4502,

1110376.

224

Page 227 of 376

![JEEP DJ 1953 User Guide

Jeep

UNIVERSAL SERIES SERVICE

MANUAL

The

correct distance should be 10%"

[26,04

cm.].

If

the length of the clutch release pedal rod is

other than

10

W

[26,04

cm.], the vheicle is eq JEEP DJ 1953 User Guide

Jeep

UNIVERSAL SERIES SERVICE

MANUAL

The

correct distance should be 10%"

[26,04

cm.].

If

the length of the clutch release pedal rod is

other than

10

W

[26,04

cm.], the vheicle is eq](/img/16/57041/w960_57041-226.png)

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

The

correct distance should be 10%"

[26,04

cm.].

If

the length of the clutch release pedal rod is

other than

10

W

[26,04

cm.], the vheicle is equipped with the early

type

Clutch

Control

Lever

and

Tube Assembly, which should be removed, and^trie latest

designed

parts should be installed.

The

free pedal clearance is adjusted by lengthening

or shortening the" clutch fork cable. To make this adjustment,

loosen

the jam nut on the cable clevis

and

lengthen or shorten the cable to obtain %"

[19,05

mm.] free travel at the pedal pad, then

tighten the jam unit.

•

Clutch

Control Cable Type

Refer

to Fig. 1-2.

a.

With the clutch pedal pad against the floor

panel, (pedal up, clutch

engaged)

adjust ball ad

justing nut until slack is removed from the cable

and

the clutch throwout bearing contacts the clutch

pressure plate, release levers or diaphragm plate.

b. Back-off ball adjusting nut 2

V2

turns to obtain

approximately %"

[19,05

mm.] free travel.

Lock

hex nut.

FIG.

1-3—AUBURN

CLUTCH

ASSEMBLY —

HURRICANE F4 ENGINE 1—

Driven

Plate and Hub

2—

Pressure

Plate

3—

Pivot Pin

4—

Bracket

5—

Spring

Cup 6—

Pressure

Spring 7— Release

Lever

8—

Return

Spring

9—

Adjusting

Screw

10—

Jam

Nut 11—

Washer

Note:

Some older 'Jeep' vehicles may

develop

side

movement

of the clutch and brake pedals resulting

from wear of the pedals, shafts, and bushings. One way to

compensate

for this wear is to install a pedal

slack

adjuster kit 1-4.

CLUTCH

—

HURRICANE

F4

ENGINE

•

Auburn

Vehicles equipped with the Hurricane F4

engine

have a 9.25" [23,4 cm.] driven plate. The auburn clutch driving (pressure) plate assembly (Fig. 1-3)

has three pressure springs and three levers or

fingers.

1-5.

Clutch

Removal

When

necessary to remove the clutch,

follow

the procedures outlined in Section J for the removal

of the transmission and transfer case from the vehicle. Then remove the flywheel housing and use

the following procedures for removing the clutch assembly.

Note:

The F4

engine

may be removed from the

vehicle when inspecting or replacing the clutch.

Refer

to Section D for Hurricane F4

engine

removal and then

follow

the instructions given

below

to remove the clutch assembly.

a.

Mark

the clutch pressure plate and

engine

fly

wheel with a center punch so the clutch assembly

may be installed in the same position after adjust

ments

or replacement are completed.

b. Remove the clutch pressure plate bracket

bolts

equally, a little at a time, to prevent distortion and

to relieve the clutch springs evenly.

c. Remove the pressure plate assembly and driven

plate from the flywheel.

1-6.

Clutch

Pressure Plate and Disc Inspection

Inspect the pressure plate face for

cracks,

chips,

and

warpage.

Check

the pressure plate levers for

excessive

wear and the springs for breaks. If any of the

above

conditions exist, the

complete

pressure

plate must be replaced.

Check

the clutch disc for

excessive

wear,

loose

or damaged facings, broken

vibration damper springs and evidence of grease

or oil. If any of the

above

conditions exist, replace

the clutch disc.

1-7.

Clutch

Pressure Plate Adjustment —

Auburn

The

clutch pressure plate must be checked

before

installing a new or reconditioned clutch. The proper 11339

FIG.

1-4—CHECKING

AUBURN

CLUTCH

LEVER

ADJUSTMENT

1— Adjustment Gauge

2—

Fixture

Mounting Bolt

3—

Clutch

Fixture

227

Page 241 of 376

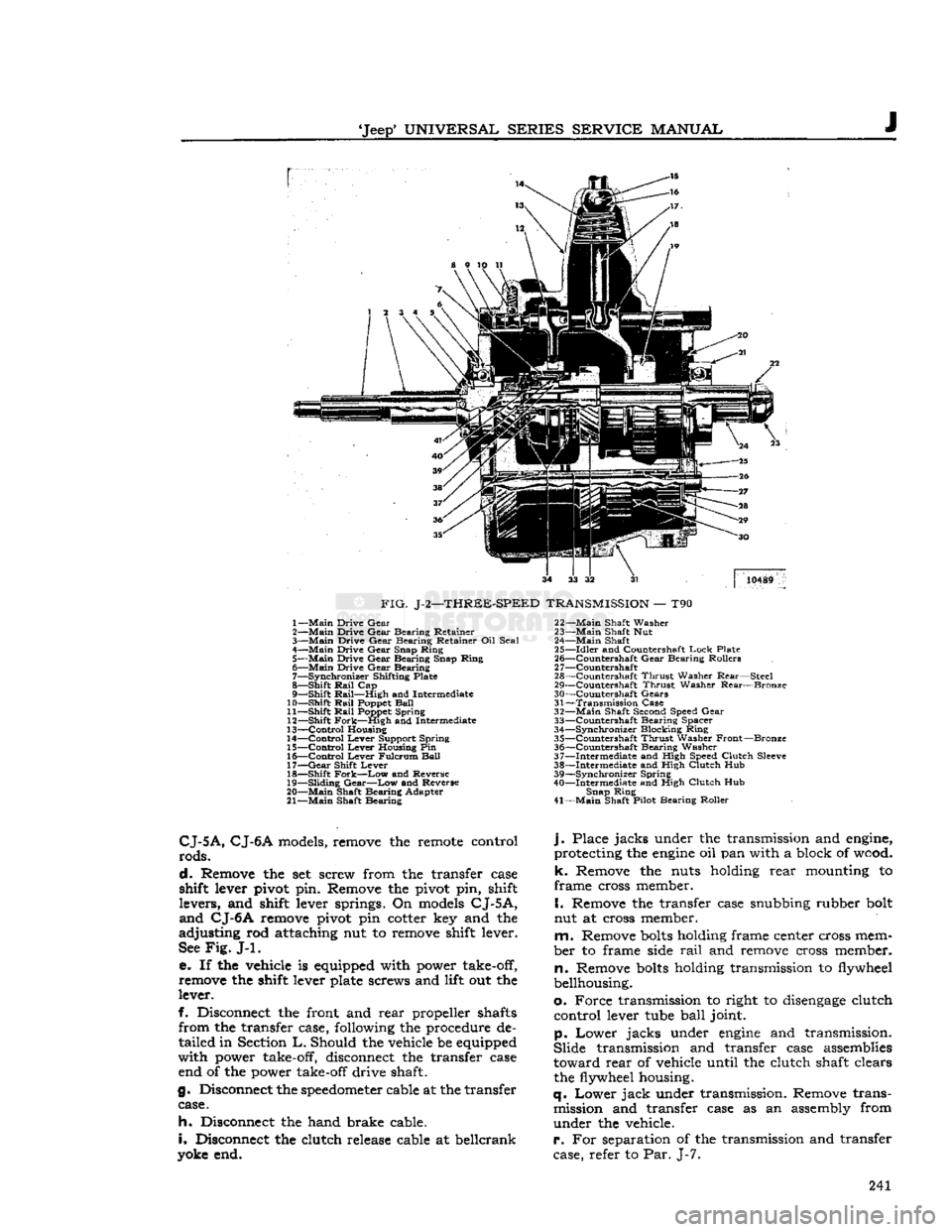

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

J

10489

FIG.

J-2—THREE-SPEED

TRANSMISSION

— T90 1—

Main

Drive

Gear

2—

Main

Drive

Gear

Bearing

Retainer

3—

Main

Drive

Gear

Bearing

Retainer Oil

Seal

4—

Main

Drive

Gear

Snap

Ring

5—

Main

Drive

Gear

Bearing

Snap

Ring

6—

Main

Drive

Gear

Bearing

7—

Synchronizer

Shifting Plate

8—

Shift

Rail

Cap

9—

Shift

Rail—High

and Intermediate

10—

Shift

Rail

Poppet

Ball

11—

Shift

Rail

Poppet

Spring

12—

Shift

Fork—High

and Intermediate

13—

Control

Housing

14—

Control

Lever

Support

Spring

15—

Control

Lever

Housing Pin

16—

Control

Lever

Fulcrum

Ball

17—

Gear

Shift

Lever

18—

Shift

Fork—Low

and Reverse

19—

Sliding

Gear—Low

and Reverse

20—

Main

Shaft

Bearing

Adapter

21—

Main

Shaft

Bearing

22—

Main

Shaft

Washer

23—

Main

Shaft Nut

24—

Main

Shaft

25—

Idler

and Countershaft

Lock

Plate

26—

^Countershaft

Gear

Bearing

Rollers

2

7—Countershaft

28—

Countershaft

Thrust

Washer

Rear—Steel

29—

Countershaft

Thrust

Washer

Rear—Bronze

30—

Countershaft

Gears

31—

Transmission

Case

32—

Main

Shaft Second Speed

Gear

33—

Countershaft

Bearing

Spacer

34—

Synchronizer

Blocking

Ring

35—

Countershaft

Thrust

Washer

Front—Bronze

36—

Countershaft

Bearing

Washer

37—

Intermediate

and High Speed

Clutch

Sleeve

38—

Intermediate

and High

Clutch

Hub

39—

Synchronizer

Spring

40—

Intermediate

and High

Clutch

Hub

Snap

Ring

41—

Main

Shaft Pilot

Bearing

Roller

CJ-5A,

CJ-6A

models, remove the remote control

rods.

d.

Remove the set screw from the transfer case

shift lever pivot pin. Remove the pivot pin, shift

levers,

and shift lever springs. On models

CJ-5A,

and

CJ-6A

remove pivot pin cotter key and the

adjusting

rod attaching nut to remove shift lever.

See

Fig.

J-l.

e. If the vehicle is equipped with power take-off,

remove the shift lever plate screws and lift out the

lever.

f. Disconnect the front and

rear

propeller shafts

from

the transfer case, following the procedure de

tailed

in Section

L.

Should the vehicle be equipped

with

power take-off, disconnect the transfer case end of the power take-off drive shaft.

g. Disconnect the

speedometer

cable at the transfer case.

h.

Disconnect the hand brake cable.

i.

Disconnect the clutch release cable at beilcrank

yoke end.

j.

Place

jacks

under the transmission and engine,

protecting the

engine

oil pan with a block of wood,

k.

Remove the nuts holding

rear

mounting to

frame

cross member.

I.

Remove the transfer case snubbing rubber bolt

nut at cross member.

m.

Remove

bolts

holding frame center cross mem

ber

to frame side

rail

and remove cross member,

n.

Remove

bolts

holding transmission to flywheel

bellhousing.

o.

Force

transmission to right to

disengage

clutch

control

lever tube

ball

joint.

p.

Lower

jacks

under

engine

and transmission.

Slide

transmission and transfer case assemblies

toward

rear

of vehicle until the clutch shaft clears the flywheel housing.

q.

Lower

jack

under transmission. Remove trans mission and transfer case as an assembly from

under

the vehicle.

r.

For separation of the transmission and transfer

case, refer to Par. J-7. 241

Page 267 of 376

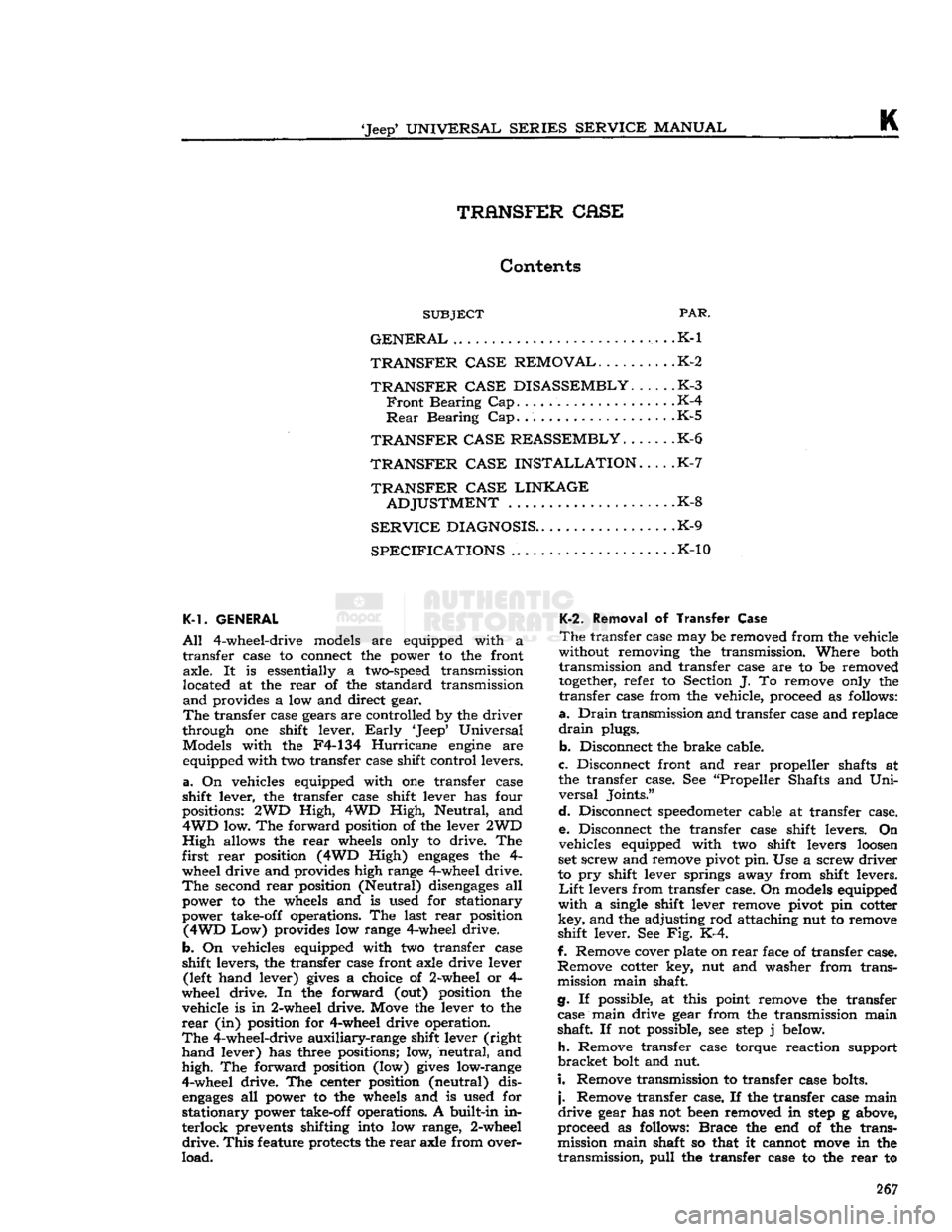

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

ft

TRANSFER CASE

Contents

SUBJECT

PAR.

GENERAL

. . .K-1

TRANSFER CASE REMOVAL

K-2

TRANSFER CASE DISASSEMBLY

K-3

Front

Bearing Cap K-4

Rear

Bearing Cap K-5

TRANSFER CASE REASSEMBLY.

. .K-6

TRANSFER CASE INSTALLATION

K-7

TRANSFER CASE LINKAGE

ADJUSTMENT

K-8

SERVICE

DIAGNOSIS

K-9

SPECIFICATIONS

.K-10

K-1. GENERAL

All

4-wheel-drive models are equipped with a

transfer

case to connect the power to the front

axle.

It is essentially a

two-speed

transmission

located at the

rear

of the standard transmission

and

provides a low and direct gear.

The

transfer case gears are controlled by the

driver

through

one shift lever.

Early

'Jeep'

Universal

Models with the F4-134

Hurricane

engine

are equipped with two transfer case shift control levers.

a.

On vehicles equipped with one transfer case

shift

lever, the transfer case shift lever has four

positions: 2WD

High,

4WD

High,

Neutral, and

4WD

low. The forward position of the lever 2WD

High

allows the

rear

wheels only to drive. The

first

rear

position (4WD High)

engages

the 4- wheel drive and provides high range 4-wheel drive.

The

second

rear

position (Neutral)

disengages

all power to the wheels and is used for stationary

power take-off operations. The last

rear

position

(4WD

Low) provides low range 4-wheel drive.

b.

On vehicles equipped with two transfer case

shift

levers, the transfer case front axle drive lever (left hand lever)

gives

a choice of 2-wheel or 4-

wheel drive. In the forward (out) position the

vehicle is in 2-wheel drive. Move the lever to the

rear

(in) position for 4-wheel drive operation.

The

4-wheel-drive

auxiliary-range

shift lever (right

hand

lever) has three positions; low, neutral, and

high.

The forward position (low)

gives

low-range

4-wheel drive. The center position (neutral) dis

engages

all power to the wheels and is used for

stationary

power take-off operations. A built-in in

terlock

prevents shifting into low range, 2-wheel

drive.

This

feature protects the

rear

axle from over

load.

K-2.

Removal of

Transfer

Case

The

transfer case may be removed from the vehicle

without removing the transmission. Where both

transmission

and transfer case are to be removed

together,

refer to Section J. To remove only the

transfer

case from the vehicle, proceed as follows:

a.

Drain

transmission

and transfer case and replace

drain

plugs.

b.

Disconnect the brake cable.

c.

Disconnect front and

rear

propeller shafts at

the transfer case. See "Propeller Shafts and

Uni

versal

Joints."

d.

Disconnect

speedometer

cable at transfer case. e. Disconnect the transfer case shift levers. On

vehicles equipped with two shift levers

loosen

set screw and remove pivot pin. Use a screw

driver

to pry shift lever springs away from shift levers.

Lift

levers from transfer case. On models equipped

with

a single shift lever remove pivot pin cotter

key,

and the adjusting rod attaching nut to remove

shift

lever. See Fig. K-4.

f. Remove cover plate on

rear

face of transfer case.

Remove

cotter key, nut and washer from trans

mission

main shaft.

g. If possible, at this point remove the transfer case main drive gear from the transmission main

shaft.

If not possible, see

step

j below.

h.

Remove transfer case torque reaction support

bracket

bolt and nut.

i.

Remove transmission to transfer case bolts.

j.

Remove transfer case. If the transfer case main

drive

gear has not been removed in

step

g above,

proceed as follows:

Brace

the end of the trans

mission

main shaft so that it cannot

move

in the

transmission,

pull

the transfer case to the

rear

to 267

Page 268 of 376

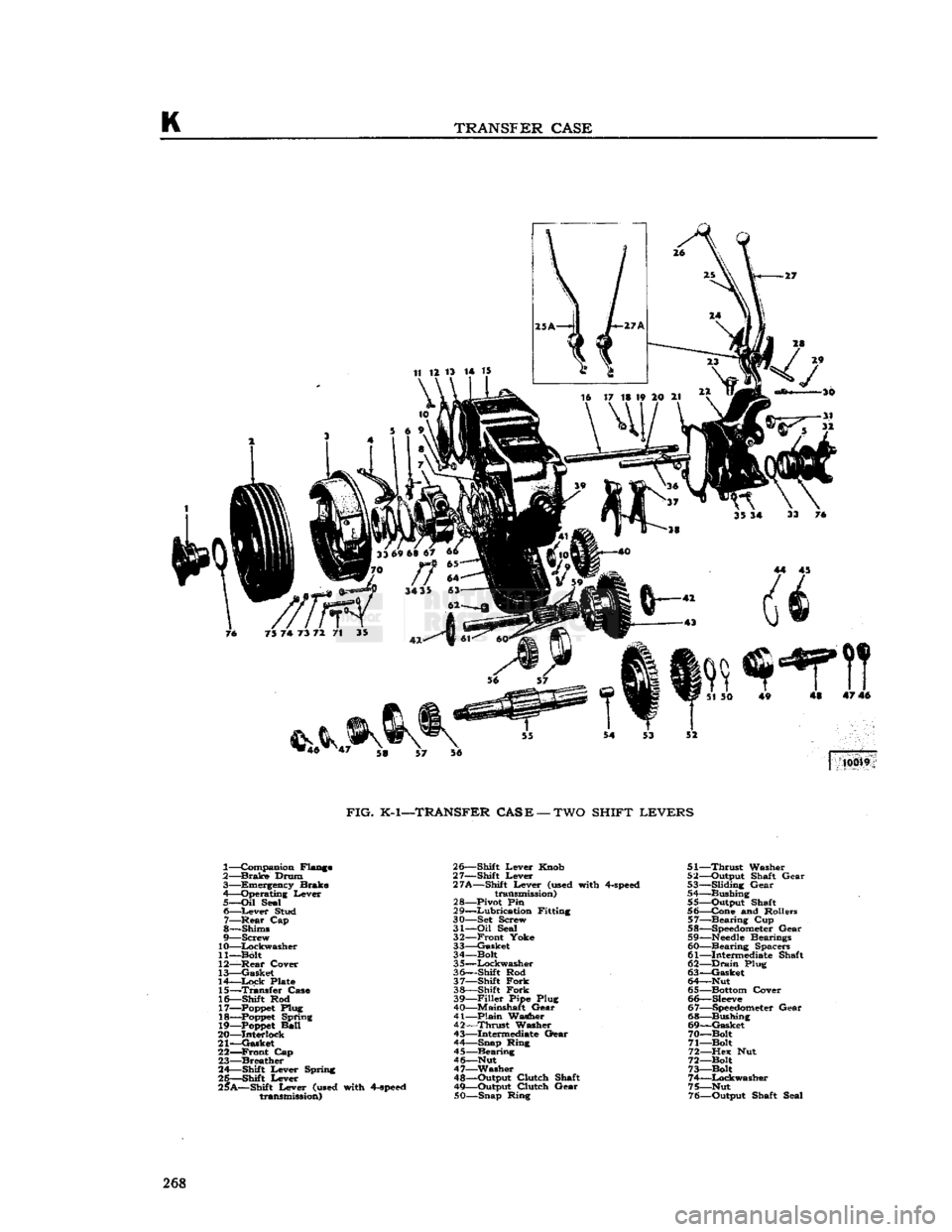

TRANSFER

CASE

FIG.

K-1—TRANSFER

CASE

—

TWO

SHIFT

LEVERS

1— Companion Flange

2—

Brake

Drum 3— Emergency Brake

4—Operating Lever

5—

Oil

Seal 6—

Lever

Stud 7—

-Rear

Cap

8— Shims

9—

Screw

10—

Lockwasher

11— Bolt

12—

-Rear

Cover

13—

Gasket

14—

Lock

Plate

15—

Transfer

Case

16— Shift Rod 17—

Poppet

Plug

18—Poppet

Spring 19—

Poppet

Ball

20— Interlock

21—Gasket 22—

Front

Cap

23—

Breather

24— Shift Lever Spring

26—Shift

Lever

25*A—Shift Lever

(used

with

4-speed

transmission) 26— Shift Lever Knob

27— Shift Lever

27A—Shift Lever

(used

with

4-speed

transmission)

28—

Pivot

Pin

29—

Lubrication

Fitting

30— Set Screw

31—

Oil

Seal 32—

Front

Yoke

33—

Gasket

34— Bolt

3

5—Lockwasher

36— Shift Rod

37—

Shift

Fork

38— Shift

Fork

39—

Filler

Pipe Plug

40—Mainshaft Gear 41— plain Washer

42—

Thrust

Washer

43—

Intermediate

Gear

44—

Snap Ring

45—

Bearing

46—

Nut 47— Washer

48— Output Clutch Shaft

49—

Output Clutch Gear

50— Snap Ring 51—

Thrust

Washer

52— Output Shaft Gear

53— Sliding Gear

54— Bushing

55— Output Shaft

56— Cone and Rollers

57—

Bearing

Cup

58—

Speedometer

Gear 59—

Needle

Bearings 60—Bearing Spacers

61—

Intermediate

Shaft

62—

Drain

Plug 63—

Gasket

64—Nut

65—

Bottom

Cover

66—

Sleeve

67—

Speedometer

Gear 68— Bushing

69—

Gasket

70— Bolt

71—Bolt

72—

Hex Nut

72— Bolt

73— Bolt

74—

Lockwasher

75— Nut

76— Output Shaft Seal 268