brake JEEP DJ 1953 Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 335 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

WHEELS

Contents

SUBJECT PAR.

GENERAL

Q-l Wheel Balancing. Q-2

WHEEL BEARING SERVICE.

......

Q-3

Checking

Front Wheel Bearings Q-4

Checking

Rear Wheel Bearings.

.......

.

Q-7

Front

Wheel Bearing Adjustment. Q-5

Rear

Wheel Bearing Adjustment — Flanged Axle Q-6

Rear

Wheel Bearing Adjustment —

Tapered

Axle Q-8 SUBJECT PAR.

REAR WHEEL

MOUNTING

.Q-9

BRAKE

DRUM

SERVICE.

......

. . .Q-10

TIRE

SERVICE.

.................

.Q-ll

Tire

Care

Q-l2

Tire

Removal and Installation. Q-l3

SPECIFICATIONS

. .Q-14

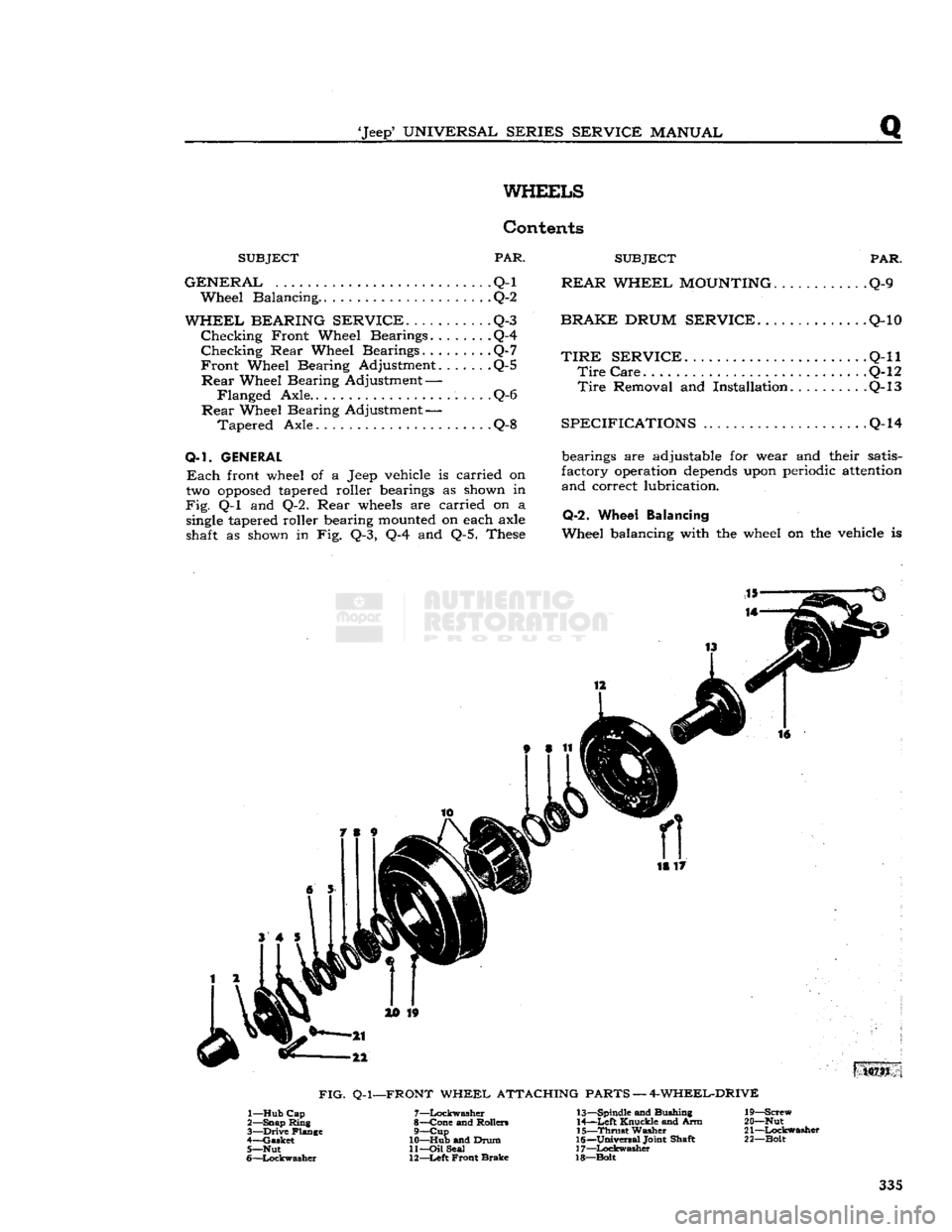

Q-l.

GENERAL

Each

front wheel of a Jeep vehicle is carried on

two

opposed

tapered roller bearings as shown in

Fig.

Q-l and Q-2. Rear

wheels

are carried on a

single

tapered roller bearing

mounted

on each axle

shaft as shown in Fig. Q-3, Q-4 and Q-5. These bearings are adjustable for wear and their satis

factory operation

depends

upon periodic

attention

and correct lubrication.

Q-2.

Wheel Balancing

Wheel balancing with the wheel on the vehicle is 18 17

10731

FIG.

Q-l—FRONT

WHEEL ATTACHING PARTS — 4-WHEEL-DRIVE 1— Hub Cap

2— Snap Ring

3—

Drive

Flange

4— Gasket 5— Nut

6—

Lockwasher

7—

Lockwasher

8— Cone and Rollers 9—

Cup

10— Hub and Drum 11—

Oil

Seal

12—

Left

Front Brake 13— Spindle and Bushing

14—

Left

Knuckle and Arm

15—

Thrust

Washer

16—

Universal

Joint Shaft

17—

Lockwasher

18—Bolt 19— Screw

20— Nut

21—

Lockwasher

22— Bolt 335

Page 336 of 376

Q

WHEELS

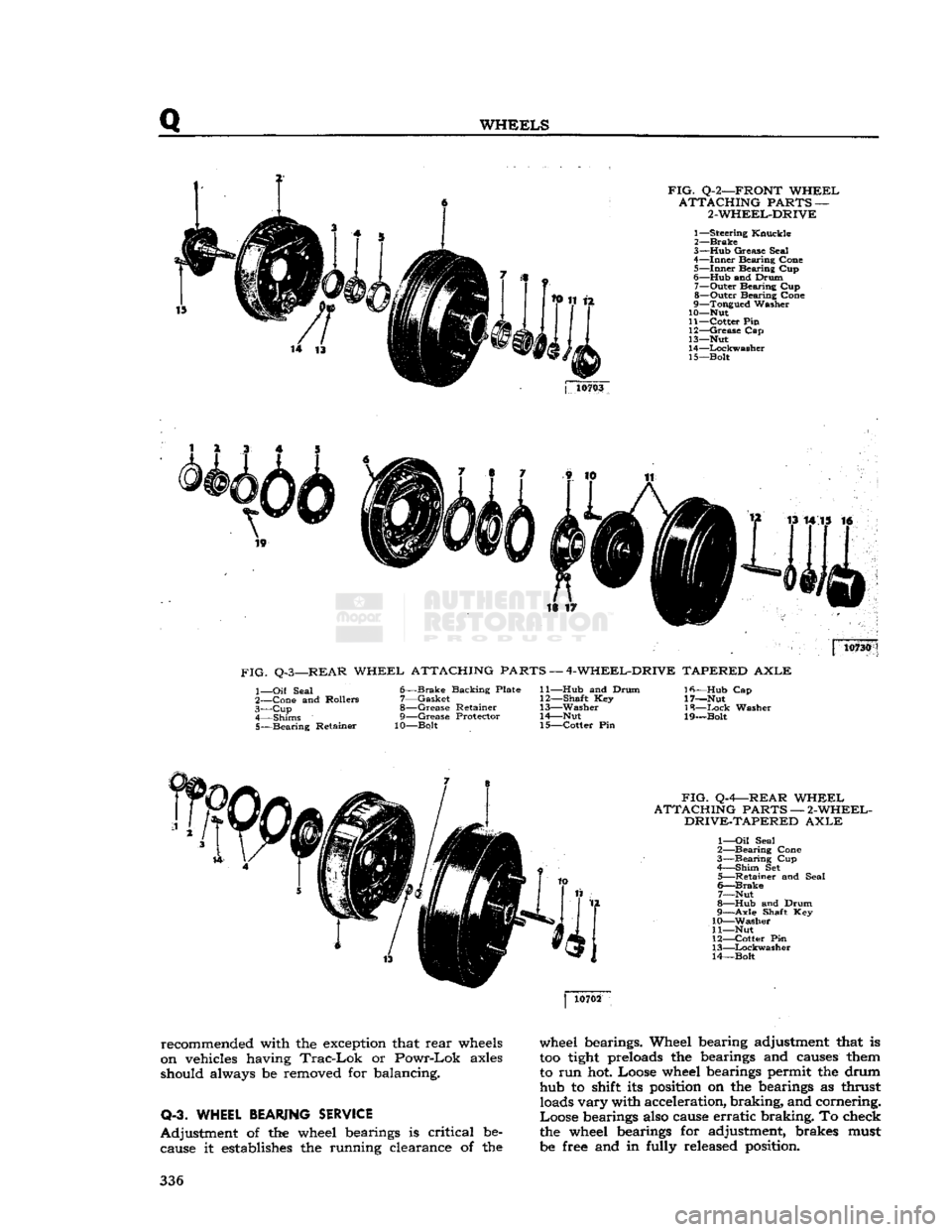

FIG.

Q-2—FRONT

WHEEL

ATTACHING

PARTS —

2-WHEEL-DRIVE

1—

Steering

Knuckle

2—

Brake

3— Hub

Grease

Seal

4—

Inner

Bearing

Cone

5—

Inner

Bearing

Cup

6—

Hub

and

Drum

7—

Outer

Bearing

Cup

8—

Outer

Bearing

Cone

9—

Tongued

Washer

10— Nut

11—

Cotter

Pin

12—

Grease

Cap

13— Nut

14—

Lockwasher

15—

Bolt

j

10703

is ir 10730

FIG.

Q-3—REAR

WHEEL

ATTACHING PARTS —

4-WHEEL-DRIVE

TAPERED

AXLE

1—

Oil

Seal

2—

Cone

and

Rollers

3— Cup

4—

Shims

5—

Bearing

Retainer

6—

Brake

Backing

Plate

7—

Gasket

8—

Grease

Retainer

9—

Grease

Protector

10—Bolt

11— Hub

and

Drum

12—

Shaft

Key

13—

Washer

14—

Nut

15—

Cotter

Pin

Ifi—Hub

Cap

17—Nut

18—

Ixick

Washer

19—Bolt

FIG.

Q-4—REAR

WHEEL

ATTACHING

PARTS —

2-WHEEL-

DRIVE-TAPERED

AXLE

1—

Oil

Seal

2—

Bearing

Cone

3—

Bearing

Cup

4—

Shim

Set

5—

Retainer

and

Seal

6—

Brake

7—

Nut

8—

Hub

and

Drum

9—

Axle

Shaft Key

10—

Washer

11— Nut

12—

Cotter

Pin

13—

Lockwasher

14—

Bolt

recommended with the exception that

rear

wheels

on vehicles having

Trac-Lok

or

Powr-Lok

axles

should always be removed for balancing.

Q-3. WHEEL

BEARING

SERVICE

Adjustment

of the wheel bearings is

critical

be cause it establishes the running clearance of the wheel bearings. Wheel bearing adjustment that is

too

tight

preloads the bearings and causes them

to run hot. Loose wheel bearings permit the drum hub to shift its position on the bearings as thrust loads

vary

with acceleration,

braking,

and cornering.

Loose

bearings also cause

erratic

braking.

To check

the wheel bearings for adjustment, brakes must

be free and in fully released position. 336

Page 337 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

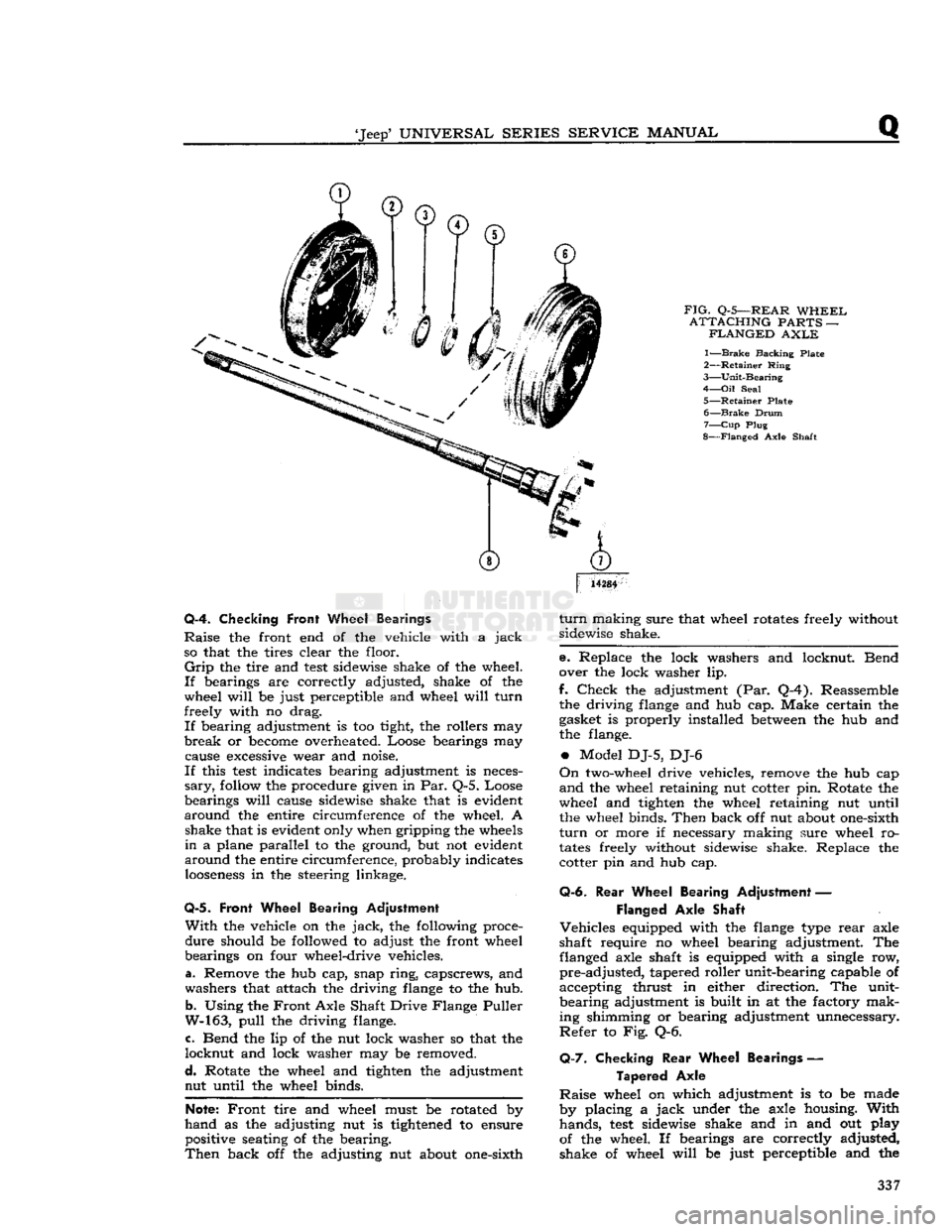

FIG.

Q-5—REAR

WHEEL

ATTACHING

PARTS —

FLANGED

AXLE

1—

Brake

Backing Plate

2—

Retainer

Ring

3—

Unit-Bearing

4—

Oil

Seal

5—

Retainer

Plate 6—

Brake

Drum

7—

Cup

Plug

8—

Flanged

Axle Shaft

14284

Q-4. Checking

Front

Wheel Bearings

Raise

the front end of the vehicle with a

jack

so that the tires clear the floor.

Grip

the tire and

test

sidewise shake of the wheel.

If

bearings are correctly adjusted, shake of the

wheel

will

be just perceptible and wheel

will

turn

freely with no drag.

If

bearing adjustment is too tight, the rollers may

break

or

become

overheated. Loose bearings may cause

excessive

wear and noise.

If

this

test

indicates bearing adjustment is neces

sary,

follow

the procedure given in Par. Q-5. Loose

bearings

will

cause sidewise shake that is evident

around

the entire circumference of the wheel. A shake that is evident only when gripping the

wheels

in

a plane parallel to the ground, but not evident

around

the entire circumference, probably indicates

looseness

in the steering linkage.

Q-5.

Front Wheel Bearing Adjustment

With

the vehicle on the

jack,

the following proce

dure

should be followed to adjust the front wheel

bearings on four wheel-drive vehicles.

a. Remove the hub cap, snap

ring,

capscrews, and

washers that attach the driving

flange

to the hub.

b.

Using the

Front

Axle Shaft Drive Flange Puller

W-163,

pull

the driving flange.

c. Bend the lip of the nut lock washer so that the

locknut

and lock washer may be removed.

d.

Rotate the wheel and tighten the adjustment nut until the wheel binds.

Note:

Front

tire and wheel must be rotated by

hand

as the adjusting nut is

tightened

to ensure positive seating of the bearing.

Then

back off the adjusting nut about one-sixth

turn

making sure that wheel rotates freely without

sidewise shake.

e. Replace the lock washers and locknut. Bend

over the lock washer lip.

f.

Check

the adjustment (Par. Q-4). Reassemble the driving

flange

and hub cap. Make certain the

gasket is properly installed

between

the hub and

the flange.

•

Model DJ-5, DJ-6

On

two-wheel drive vehicles, remove the hub cap

and

the wheel retaining nut cotter pin. Rotate the

wheel and tighten the wheel retaining nut until the wheel binds.

Then

back off nut about one-sixth

turn

or more if necessary making sure wheel ro

tates

freely without sidewise shake. Replace the cotter pin and hub cap.

Q-6.

Rear

Wheel Bearing Adjustment —

Flanged

Axle Shaft

Vehicles

equipped with the

flange

type

rear

axle

shaft require no wheel bearing adjustment. The flanged axle shaft is equipped with a single row,

pre-adjusted,

tapered roller unit-bearing capable of

accepting thrust in either direction. The unit-

bearing

adjustment is built in at the factory mak

ing shimming or bearing adjustment unnecessary.

Refer

to Fig. Q-6.

Q-7.

Checking

Rear

Wheel Bearings —

Tapered

Axle

Raise

wheel on which adjustment is to be made

by placing a

jack

under the axle housing.

With

hands,

test

sidewise shake and in and out play

of the wheel. If bearings are correctly adjusted,

shake of wheel

will

be just perceptible and the 337

Page 338 of 376

Q

WHEELS

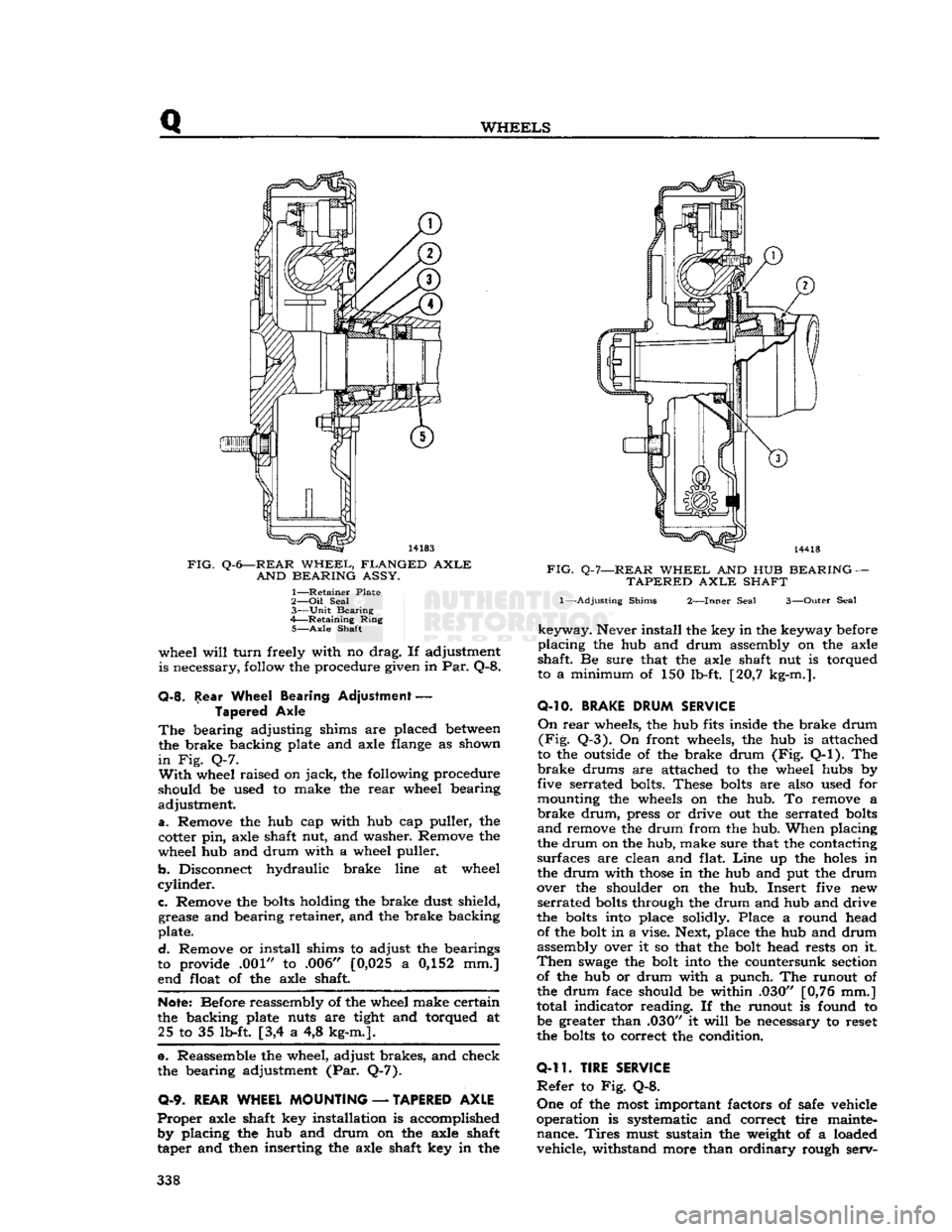

FIG.

Q-6—REAR

WHEEL,

FLANGED

AXLE

AND

BEARING

ASSY.

1—

Retainer

Plate

2— Oil

Seal

3—

Unit

Bearing

4—

Retaining

Ring

5—

Axle

Shaft

wheel

will

turn

freely with no drag. If adjustment

is necessary, follow the procedure given in Par. Q-8.

Q-8.

Rear Wheel Bearing Adjustment

—

Tapered Axle

The

bearing adjusting shims are placed

between

the brake backing plate and axle flange as shown

in

Fig. Q-7.

With

wheel raised on

jack,

the following procedure

should be used to make the

rear

wheel bearing

adjustment.

a.

Remove the hub cap with hub cap puller, the

cotter pin, axle shaft nut, and washer. Remove the

wheel hub and drum with a wheel puller.

b.

Disconnect hydraulic brake line at wheel

cylinder.

c.

Remove the

bolts

holding the brake dust shield, grease and bearing retainer, and the brake backing

plate.

d.

Remove or install shims to adjust the bearings

to provide .001" to .006" [0,025 a 0,152 mm.]

end float of the axle shaft.

Note:

Before reassembly of the wheel make certain

the backing plate nuts are tight and torqued at 25 to 35 lb-ft [3,4 a 4,8 kg-m.].

e. Reassemble the wheel, adjust brakes, and check

the bearing adjustment (Par. Q-7).

0-9.

REAR WHEEL MOUNTING

—

TAPERED AXLE

Proper

axle shaft key installation is accomplished by placing the hub and drum on the axle shaft

taper and then inserting the axle shaft key in the

FIG.

Q-7—REAR

WHEEL

AND HUB

BEARING

—

TAPERED

AXLE

SHAFT

1—-Adjusting

Shims

2—Inner

Seal

3—Outer

Seal

keyway.

Never install the key in the keyway before

placing

the hub and drum assembly on the axle

shaft. Be sure that the axle shaft nut is torqued

to a minimum of 150 lb-ft. [20,7 kg-m.].

O-10.

BRAKE

DRUM

SERVICE

On

rear

wheels, the hub fits inside the brake drum

(Fig.

Q-3). On front wheels, the hub is attached

to the outside of the brake drum (Fig. Q-l). The

brake

drums are attached to the wheel hubs by

five serrated bolts. These

bolts

are also used for

mounting the wheels on the hub. To remove a

brake

drum,

press or drive out the serrated

bolts

and

remove the drum from the hub. When placing

the drum on the hub, make sure that the contacting

surfaces are clean and flat.

Line

up the

holes

in

the drum with

those

in the hub and put the drum

over the shoulder on the hub. Insert five new

serrated

bolts

through the drum and hub and drive

the

bolts

into place solidly. Place a round head of the bolt in a vise. Next, place the hub and drum

assembly over it so that the bolt head rests on it.

Then

swage

the bolt into the countersunk section of the hub or drum with a punch. The runout of

the drum face should be within .030" [0,76 mm.]

total indicator reading. If the runout is found to be greater than .030" it

will

be necessary to reset

the

bolts

to correct the condition.

0-11.

TIRE SERVICE

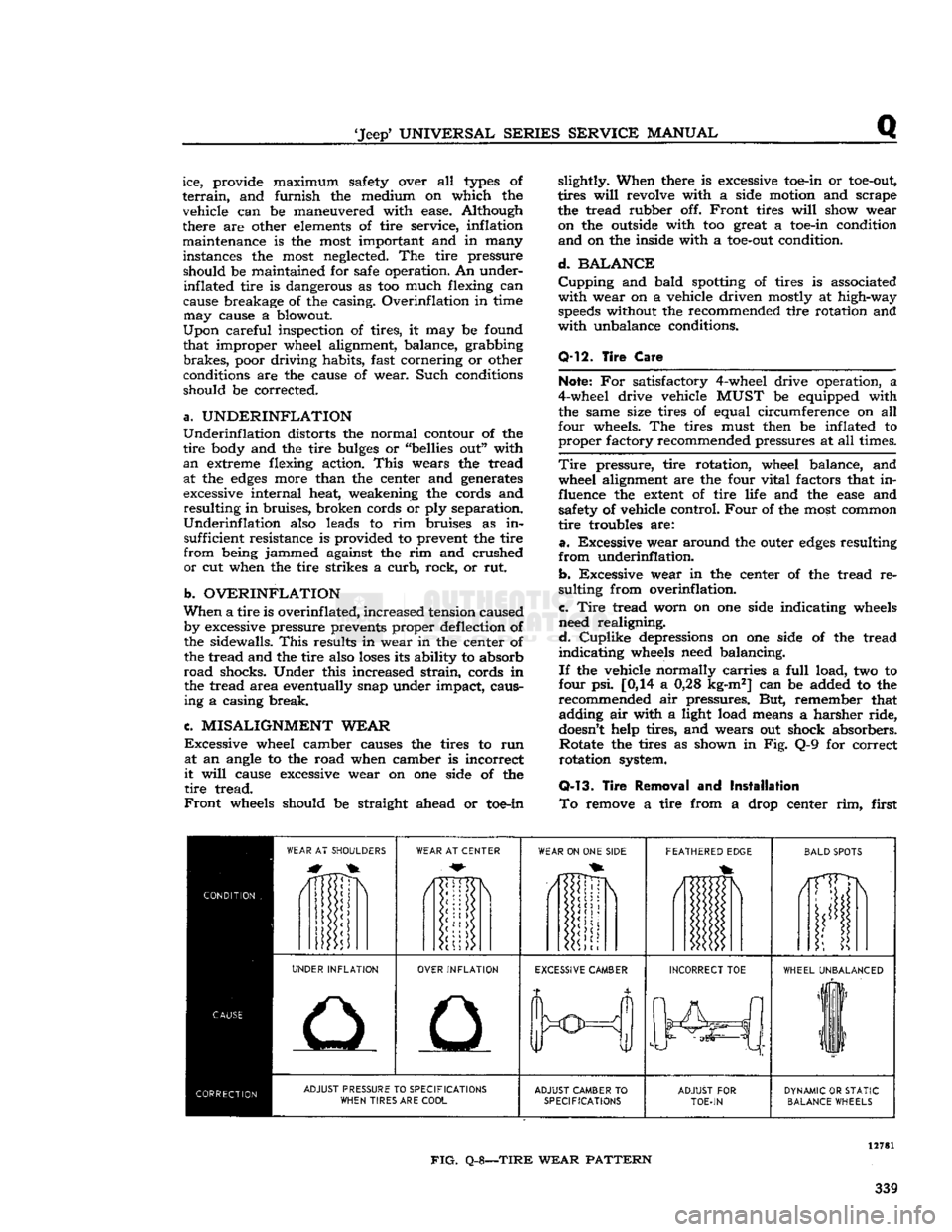

Refer

to Fig. Q-8.

One

of the most important factors of safe vehicle

operation is systematic and correct tire mainte nance.

Tires

must sustain the weight of a loaded vehicle, withstand more than ordinary rough serv- 338

Page 339 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

Q

ice, provide maximum safety over all

types

of

terrain,

and furnish the medium on which the

vehicle can be maneuvered with ease. Although

there are other

elements

of tire service, inflation maintenance is the most important and in many

instances the most neglected. The tire pressure should be maintained for safe operation. An under- inflated tire is dangerous as too much flexing can

cause breakage of the casing. Overinflation in time

may

cause a blowout.

Upon

careful inspection of tires, it may be found

that improper wheel alignment, balance, grabbing

brakes,

poor driving habits, fast cornering or other

conditions are the cause of wear. Such conditions

should be corrected.

a.

UNDERINFLATION

Underinflation

distorts the normal contour of the

tire

body and the tire

bulges

or "bellies out" with

an

extreme flexing action.

This

wears the tread at the

edges

more than the center and generates

excessive internal heat, weakening the cords and

resulting

in bruises, broken cords or ply separation.

Underinflation

also leads to rim bruises as in sufficient resistance is provided to prevent the tire

from

being jammed against the rim and crushed

or

cut when the tire strikes a

curb,

rock, or rut.

b.

OVERINFLATION

When

a tire is

overinf

lated,

increased tension caused by excessive pressure prevents proper deflection of

the sidewalls.

This

results in wear in the center of the tread and the tire also

loses

its ability to absorb

road

shocks. Under this increased

strain,

cords in the tread area eventually snap under impact, causing a casing break.

c.

MISALIGNMENT

WEAR

Excessive

wheel camber causes the tires to run at an angle to the road when camber is incorrect

it

will

cause excessive wear on one side of the

tire

tread.

Front

wheels should be straight ahead or toe-in slightly. When there is excessive toe-in or

toe-out,

tires

will

revolve with a side motion and scrape

the tread rubber off.

Front

tires

will

show wear on the outside with too great a toe-in condition

and

on the inside with a

toe-out

condition.

d.

BALANCE

Cupping

and bald spotting of tires is associated

with

wear on a vehicle driven mostly at high-way

speeds

without the recommended tire rotation and

with

unbalance conditions.

Q-12.

Tire

Care

Note;

For satisfactory 4-wheel drive operation, a

4-wheel drive vehicle

MUST

be equipped with the same size tires of equal circumference on all

four wheels. The tires must then be inflated to

proper

factory recommended pressures at all times.

Tire

pressure, tire rotation, wheel balance, and wheel alignment are the four vital factors that in

fluence the

extent

of tire life and the

ease

and safety of vehicle control.

Four

of the most common

tire

troubles are:

a.

Excessive wear around the outer

edges

resulting

from

underinflation.

b.

Excessive wear in the center of the tread re

sulting from overinflation.

c.

Tire

tread worn on one side indicating wheels

need realigning.

d.

Cuplike

depressions on one side of the tread

indicating

wheels need balancing.

If

the vehicle normally carries a

full

load, two to

four psi. [0,14 a 0,28 kg-m2] can be added to the

recommended air pressures. But, remember that adding air with a light load means a harsher ride,

doesn't

help tires, and wears out shock absorbers. Rotate the tires as shown in Fig. Q-9 for correct

rotation system.

Q-13.

Tire

Removal

and

Installation

To

remove a tire from a drop center rim, first

WEAR

AT SHOULDERS

WEAR

AT CENTER

WEAR

ON ONE

SIDE

FEATHERED

EDGE

BALD

SPOTS

/1TTDN

i

UNDER

INFLATION

OVER

INFLATION

EXCESSIVE

CAMBER

INCORRECT

TOE

WHEEL

UNBALANCED

liF

11

ADJUST

PRESSURE TO

SPECIFICATIONS

WHEN

TIRES ARE

COOL

ADJUST

CAMBER

TO

SPECIFICATIONS

ADJUST

FOR

TOE-IN

DYNAMIC

OR

STATIC

BALANCE

WHEELS

FIG.

Q-8—TIRE

WEAR

PATTERN

339

Page 351 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

T

BODY

Contents

SUBJECT

PAR.

Brake

and

Clutch

Pedal Pads T-7

Canvas

Tops T-5

Care

of

Fabric

Tops. : T-6

Front

Seat Adjustment. . . T-8

Passenger Seat Safety

Catch

. .T-9

Windshield

T-2, T-3

Windshield

Glass and Weatherstrip T-4

T-1.

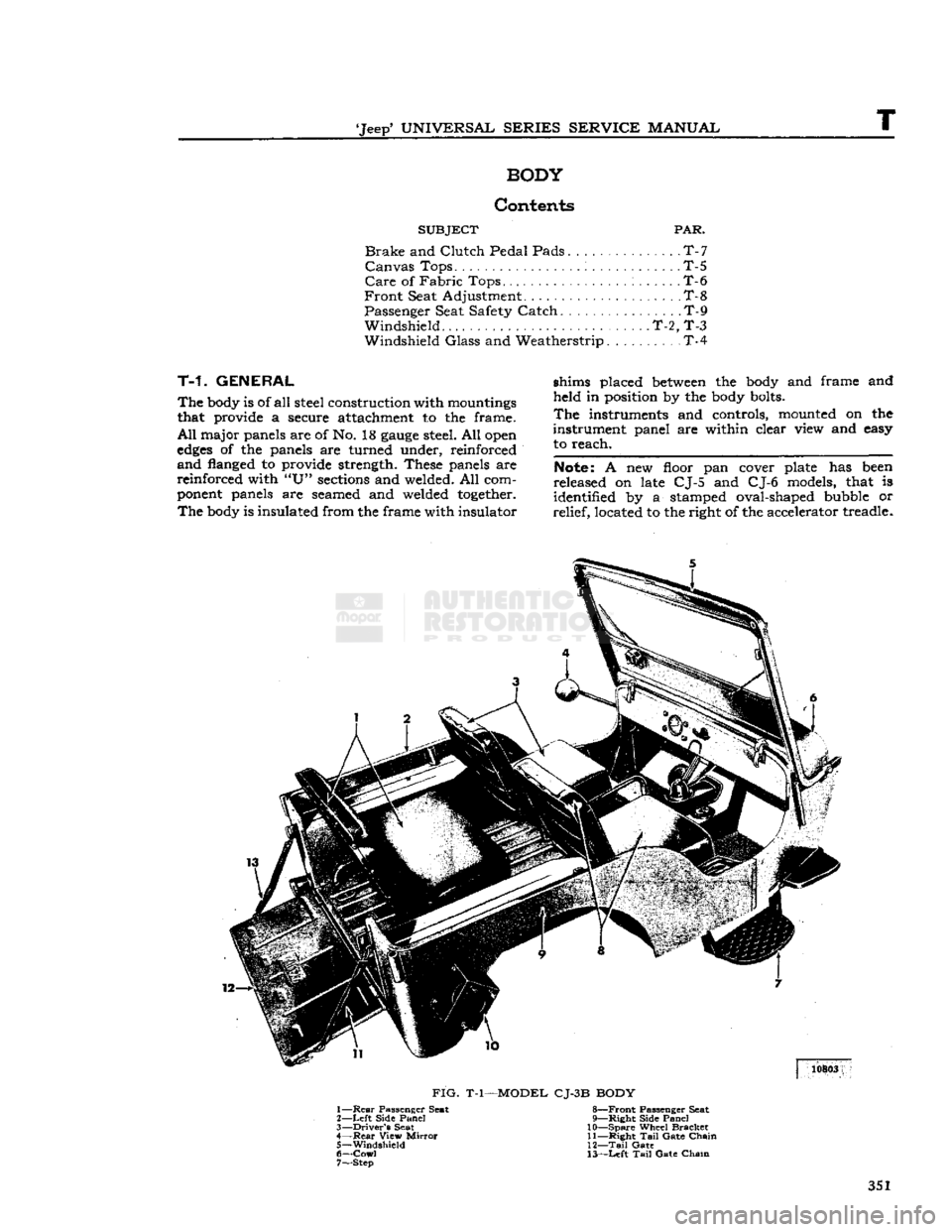

GENERAL

The

body

is of

all

steel construction with mountings

that provide a secure attachment to the frame.

All

major panels are of No. 18

gauge

steel. All

open

edges

of the panels are turned under, reinforced

and

flanged to provide strength. These panels are reinforced with

"U"

sections

and welded. All com

ponent

panels are seamed and welded

together.

The

body

is insulated from the frame with insulator shims placed

between

the

body

and frame and

held in position by the

body

bolts.

The

instruments and controls, mounted on the

instrument panel are within clear view and easy

to reach.

Note:

A new floor pan cover plate has

been

released on late CJ-5 and CJ-6 models, that is

identified by a stamped oval-shaped bubble or

relief, located to the right of the accelerator treadle.

FIG.

T-l—MODEL CJ-3B BODY

1—

Rear

Passenger Seat 8—Front Passenger Seat

2—

Left

Side

Panel

9—Right Side

Panel

3—

Driver's

Seat 10—Spare Wheel

Bracket

4—

Rear

View

Mirror

11—Right

Tail

Gate

Chain

5—

Windshield

12—Tail

Gate

6—

Cowl

13—Left

Tail

Gate

Chain

7— Step

351

Page 354 of 376

T

BODY

from the windshield wiper vacuum fitting. On

late

models

disconnect electrical wires from wiper

motor. Unlatch the two windshield clamps on each

side

of the windshield.

Fold

the windshield forward

until

the

slot

in the windshield

hinges

aligns with the flat

side

of the pin in the

body

hinges.

Slip wind

shield off the pins and remove from

body.

T-4.

Windshield Glass

The

windshield

glass

is mounted in a rubber

weatherstrip which in turn

mounts

in the frame. A

rubber

locking strip, which

holds

the

glass

firmly in

the frame, is inserted in a moulded

groove

around

the rear

face

of the weatherstrip as shown in Fig.

T-2.

To remove the

glass

it is necessary to first

remove the locking strip which may be pried out

with a screwdriver or similar

tool.

Installation is,

obvious.

T-5.

Canvas Tops

Canvas

tops

are available in

Half

Tops and

Full

Tops.

Installation instructions are provided with

each canvas top kit for each model vehicle.

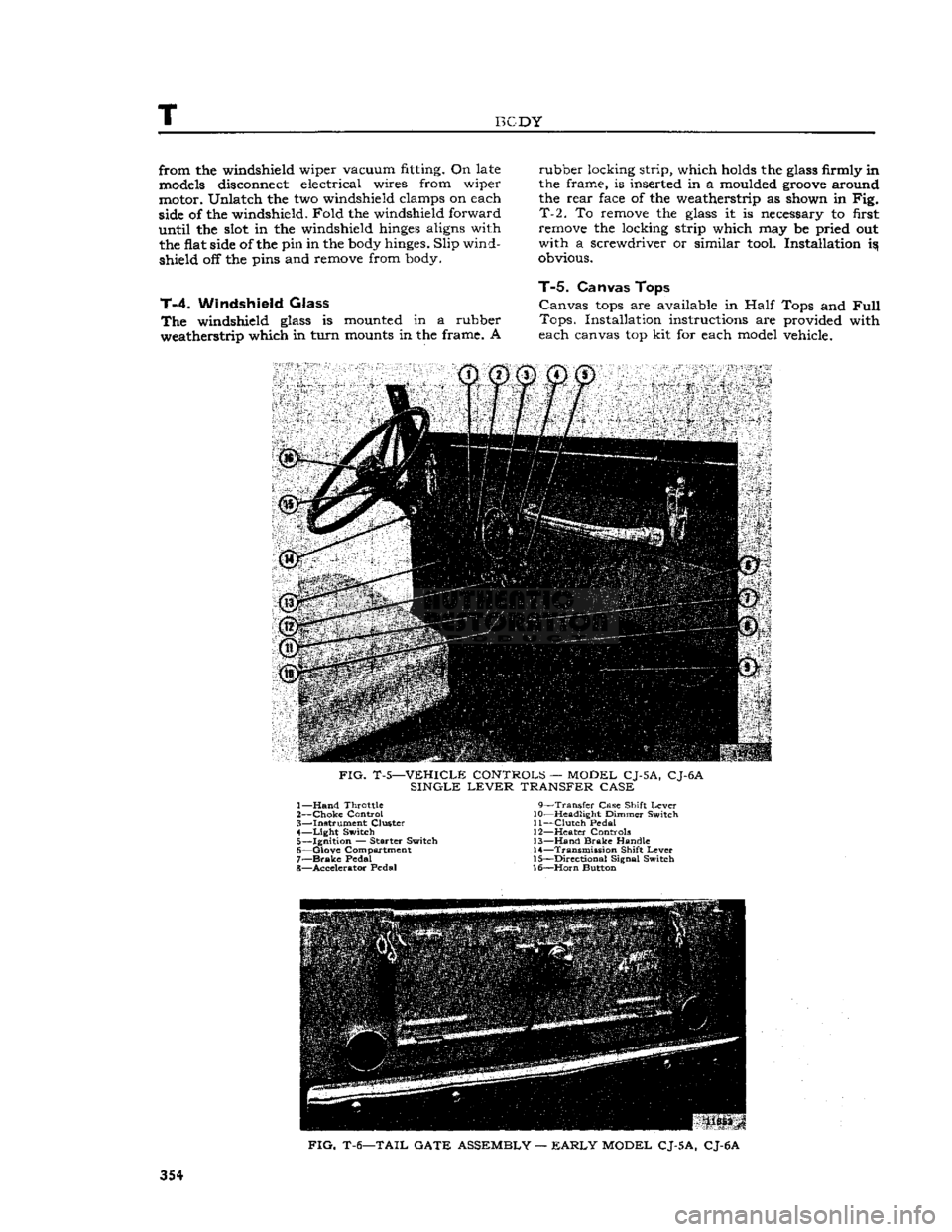

FIG.

T-5—VEHICLE CONTROLS — MODEL CJ-5A, CJ-6A

SINGLE

LEVER

TRANSFER CASE 1—

Hand

Throttle 9—Transfer Case Shift

Lever

2—

Choke

Control 10—Headlight Dimmer Switch

3— Instrument Cluster 11—Clutch Pedal 4—

Light

Switch 12—Heater Controls 5— Ignition — Starter Switch 13—Hand

Brake

Handle

6— Glove Compartment 14—Transmission Shift

Lever

7—

Brake

Pedal 15—Directional Signal Switch

8— Accelerator Pedal 16—Horn Button

FIG.

T-6—TAIL GATE ASSEMBLY —

EARLY

MODEL CJ-5A, CJ-6A

354

Page 355 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

T

FIG.

T-7—TAIL

GATE

ASSEMBLY

—

LATE

MODEL

CJ-5, CJ-6

T-6.

Care

of

Fabric

Tops

Remove fabric

tops

from their protective covering

immediately after they are received. Store in a

dry,

clean,

airy

place. If the material is damp, the

top should be installed on the vehicle immediately

and

washed with a mild soap; then

give

the top a

quick

and thorough rinsing.

T-7.

Brake

and

Clutch Pedal Pads

A

clutch and brake pedal pad cover has been re leased which has a .44" [11,18 mm.]

groove

molded into the back side of the pad cover. When installing,

the grooved opening is located down and to the

bottom

of the pedal. See Fig. T-ll. The purpose of the

groove

concerns models not listed in this

manual.

The pedal pad cover formerly used is

FIG.

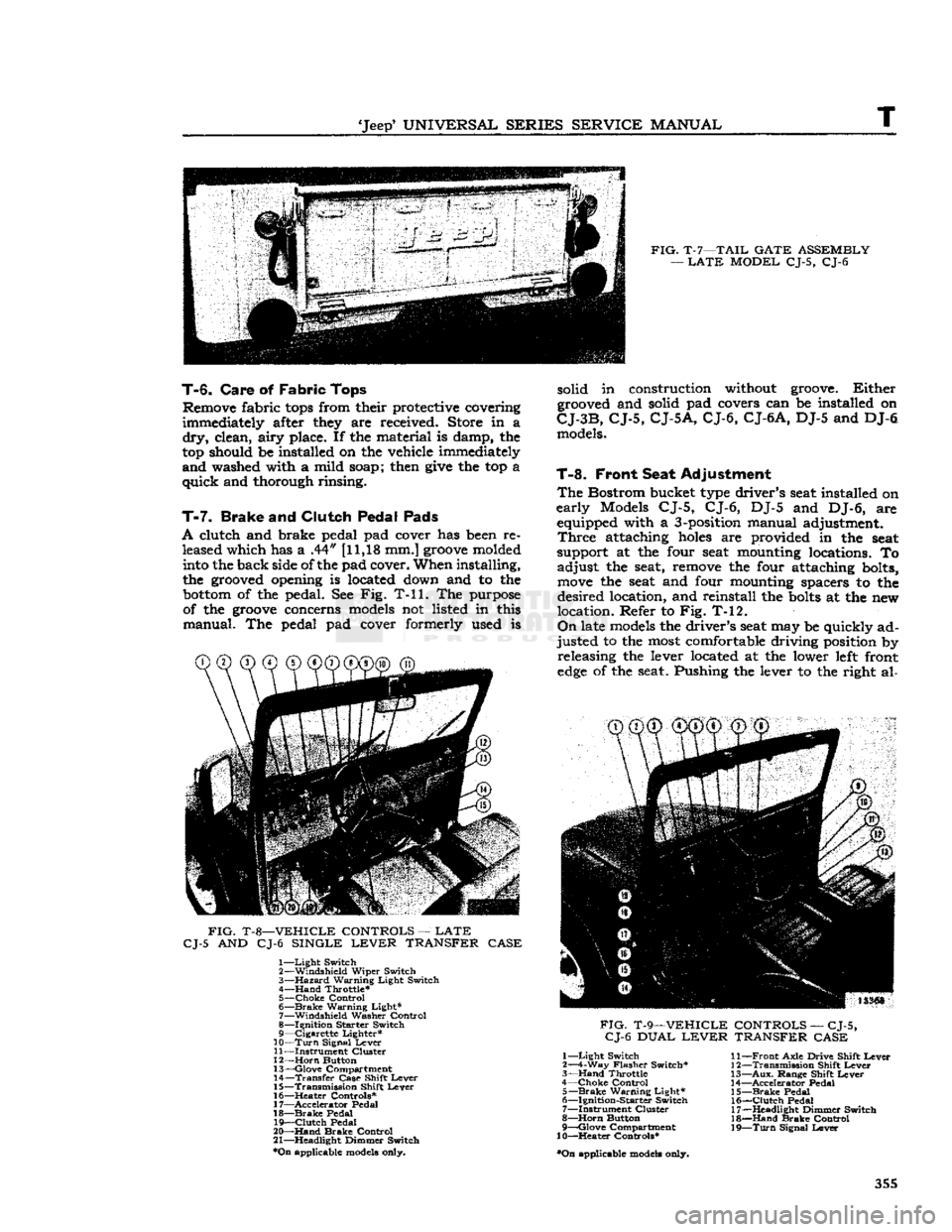

T-8—VEHICLE

CONTROLS

—

LATE

CJ-5

AND CJ-6

SINGLE

LEVER

TRANSFER

CASE

1—

Light

Switch

2—

Windshield

Wiper

Switch

3—

Hazard

Warning

Light

Switch

4—

Hand

Throttle*

5—

Choke

Control

6—

Brake

Warning

Light*

7—

Windshield

Washer

Control

8—

Ignition

Starter

Switch

9—

Cigarette

Lighter*

10—

Turn

Signal

Lever

11—

Instrument

Cluster

12—

Horn

Button

13—

Glove

Compartment

14—

Transfer

Case

Shift

Lever

15—

Transmission

Shift

Lever

16—

^Heater

Controls*

17—

Accelerator

Pedal

18—

Brake

Pedal

19—

Clutch

Pedal

20—

Hand

Brake

Control

21—

Headlight

Dimmer

Switch

*On

applicable models only. solid in construction without groove.

Either

grooved and solid pad covers can be installed on

CJ-3B,

CJ-5,

CJ-5A,

CJ-6,

CJ-6A,

DJ-5 and DJ-6 models.

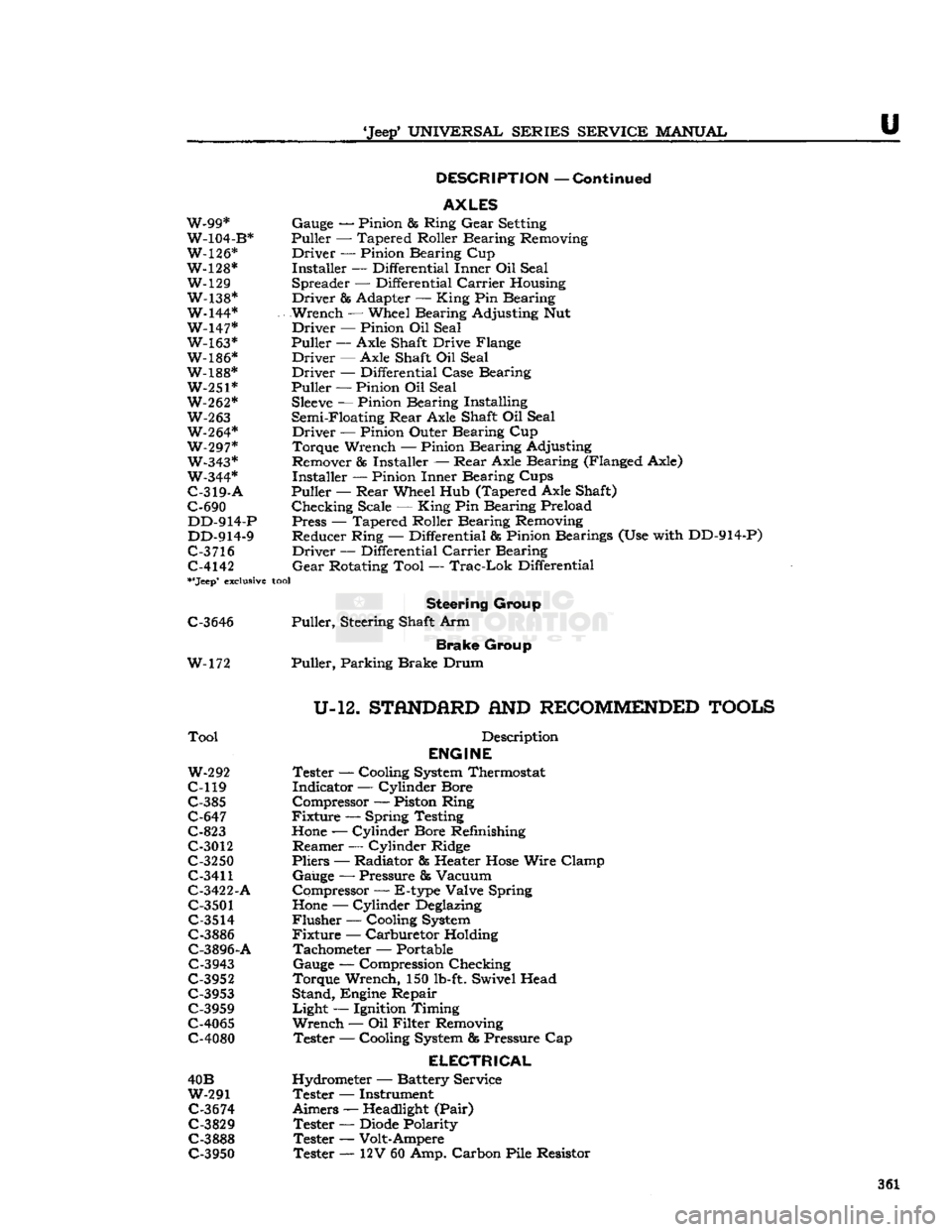

T-8.

Front Seat Adjustment

The

Bostrom bucket type driver's seat installed on

early

Models CJ-5, CJ-6, DJ-5 and DJ-6, are equipped with a 3-position manual adjustment.

Three

attaching

holes

are provided in the seat

support at the four seat mounting locations. To

adjust

the seat, remove the four attaching bolts,

move

the seat and four mounting spacers to the

desired

location, and reinstall the

bolts

at the new

location. Refer to Fig. T-12.

On

late models the driver's seat may be quickly ad

justed

to the most comfortable driving position by releasing the lever located at the lower left front

edge

of the seat. Pushing the lever to the right al-

CD CD®

®@©"®^

FIG.

T-9—VEHICLE

CONTROLS

—

CJ-5,

CJ-6

DUAL

LEVER

TRANSFER

CASE

1—

Light

Switch

2—4-Way

Flasher

Switch*

3—

Hand

Throttle

4—

Choke

Control

5—

Brake

Warning

Light*

6—

Ignition-Starter

Switch

7—

Instrument

Cluster

8—

Horn

Button

9—

Qlove

Compartment

10—Heater

Controls*

•On

applicable models only.

11—

Front

Axle

Drive

Shift

Lever

12—

Transmission

Shift

Lever

13—

Aux.

Range

Shift

Lever

14—

Accelerator

Pedal

15—

Brake

Pedal

16—

Clutch

Pedal

17—

Headlight

Dimmer

Switch

18—

Hand

Brake

Control

19—

Turn

Signal

Lever

355

Page 356 of 376

T

BODY

lows

the seat to be

moved forward

or

rearward.

Re

positioning

the

lever

to the

left

will

lock

the seat

in

the

desired position.

T-9.

Passenger

Seat

Safety

Catch

Thejfront

passenger seat on

late model vehicles

is

provided

with

a

safety

catch, located

at the

left

rear

base of the seat. To

tilt

the seat

forward,

first

release

the

catch

by

pulling

upwards

on the

catch lever. 11213

.

FIG.

T-ll—CLUTCH

AND

BRAKE PEDAL

PAD

FIG.

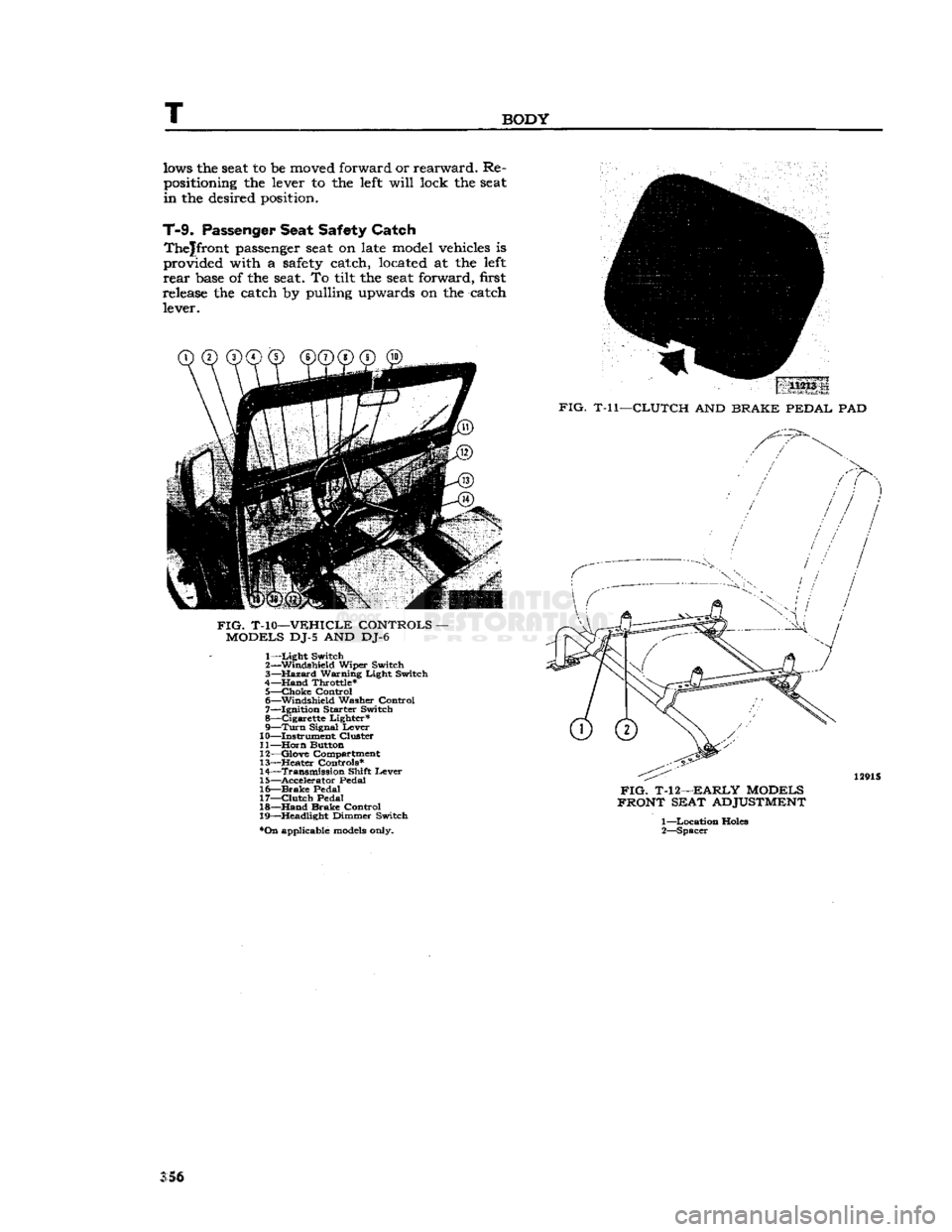

T-10—VEHICLE CONTROLS

-

MODELS

DJ-5 AND DJ-6 1—

Light

Switch

2— Windshield Wiper Switch

3—

Hazard

Warning Light Switch

4—Hand Throttle*

5—

choke

Control

6— Windshield

Washer

Control

7— Ignition

Starter

Switch

8— Cigarette Lighter* 9—

Turn

Signal Lever

10— Instrument Cluster

11—

Horn

Button

12— Glove Compartment

13—

Heater

Controls*

14— Transmission Shift Lever

15— Accelerator

Pedal

16—

Brake

Pedal

17—

Clutch

Pedal

18—

Hand

Brake Control

19— Headlight Dimmer Switch

*On

applicable

models

only.

FIG.

T-12—EARLY MODELS

FRONT SEAT

ADJUSTMENT

1—

Location Holes

2— Spacer

S5§

Page 361 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

U

DESCRIPTION

—

Continued

AXLES

W-99* Gauge — Pinion & Ring

Gear

Setting

W-104-B* Puller — Tapered Roller Bearing Removing

W-126* Driver — Pinion Bearing Cup

W-128* Installer — Differential Inner Oil Seal W-129 Spreader — Differential

Carrier

Housing

W-138* Driver & Adapter —

King

Pin Bearing

W-144* Wrench — Wheel Bearing Adjusting Nut W-147* Driver — Pinion Oil Seal W-163* Puller

—-

Axle Shaft Drive Flange

W-186* Driver — Axle Shaft Oil Seal

W-188* Driver — Differential Case Bearing W-251* Puller — Pinion Oil Seal

W-262*

Sleeve

— Pinion Bearing Installing

W-263

Semi-Floating

Rear

Axle Shaft Oil Seal W-264* Driver — Pinion Outer Bearing Cup

W-297* Torque Wrench — Pinion Bearing Adjusting W-343* Remover

85

Installer —

Rear

Axle Bearing (Flanged Axle)

W-344* Installer — Pinion Inner Bearing Cups

C-319-A

Puller —

Rear

Wheel Hub (Tapered Axle Shaft)

C-690 Checking Scale —

King

Pin Bearing Preload DD-914-P Press — Tapered Roller Bearing Removing

DD-914-9 Reducer Ring — Differential & Pinion Bearings (Use with DD-914-P)

C-3

716 Driver — Differential

Carrier

Bearing C-4142

Gear

Rotating Tool —

Trac-Lok

Differential

**Jeep*

exclusive

tool

Steering

Group

C-3646 Puller, Steering Shaft Arm

Brake

Group

W-172 Puller, Parking Brake Drum

U-12.

STflNDfiRD

AND

RECOMMENDED

TOOLS

Tool

Description

ENGINE

W-292

Tester — Cooling

System

Thermostat

C-119 Indicator — Cylinder Bore C-385 Compressor — Piston Ring

C-647 Fixture — Spring Testing

C-823

Hone

— Cylinder Bore Refinishing

C-3012 Reamer — Cylinder Ridge

C-3250 Pliers — Radiator fis Heater

Hose

Wire Clamp

C-3411

Gauge — Pressure & Vacuum

C-3422-A Compressor — E-type Valve Spring

C-3501

Hone

— Cylinder

Deglazing

C-3514

Flusher — Cooling

System

C-3886 Fixture — Carburetor Holding C-3896-A Tachometer — Portable

C-3943 Gauge — Compression Checking

C-3952 Torque Wrench, 150

lb-ft.

Swivel Head C-3953 Stand, Engine Repair

C-3959 Light — Ignition Timing

C-4065 Wrench — Oil Filter Removing

C-4080 Tester — Cooling

System

fig

Pressure Cap

ELECTRICAL

40B Hydrometer — Battery Service

W-291 Tester — Instrument

C-3674

Aimers —

Headlight

(Pair)

C-3829 Tester —

Diode

Polarity

C-3888 Tester — Volt-Ampere C-3950 Tester — 12V 60 Amp. Carbon Pile Resistor 361