seat adjustment JEEP DJ 1953 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 24 of 376

c

TUNE-UP

14011

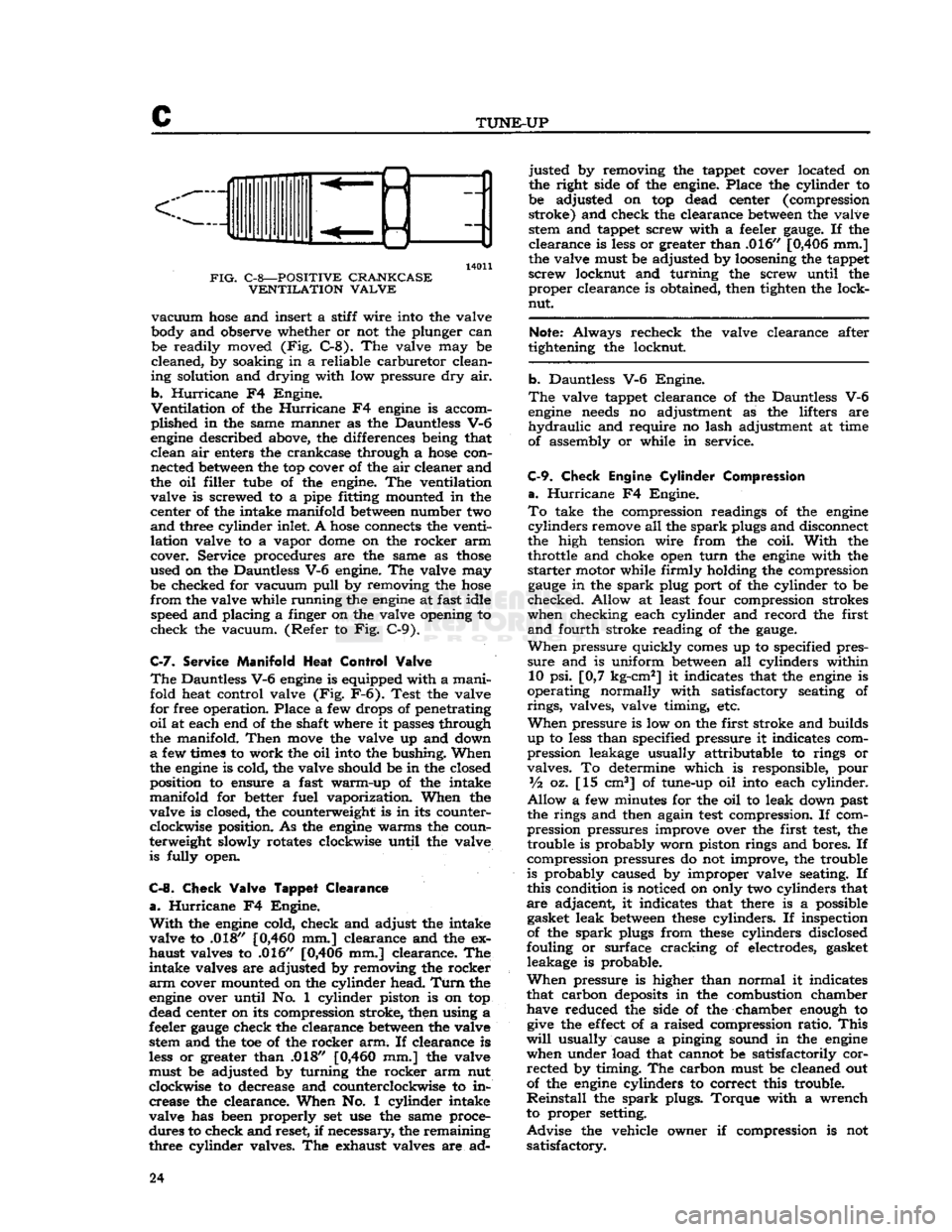

FIG.

C-8—POSITIVE CRANKCASE VENTILATION VALVE

vacuum

hose

and insert a stiff wire into the valve

body and observe whether or not the plunger can be readily moved (Fig. C-8). The valve may be

cleaned, by soaking in a reliable carburetor clean

ing solution and drying with low pressure dry air.

b.

Hurricane

F4 Engine.

Ventilation

of the

Hurricane

F4

engine

is accom

plished in the same manner as the Dauntless V-6

engine

described above, the differences being that clean air enters the crankcase through a

hose

con nected

between

the top cover of the air cleaner and

the oil filler tube of the engine. The ventilation valve is screwed to a pipe fitting mounted in the

center of the intake manifold

between

number two

and

three cylinder inlet. A

hose

connects the venti

lation valve to a vapor

dome

on the rocker arm

cover. Service procedures are the same as

those

used on the Dauntless V-6 engine. The valve may be checked for vacuum

pull

by removing the

hose

from

the valve while running the

engine

at fast idle speed and placing a finger on the valve opening to

check the vacuum. (Refer to Fig. C-9).

C-7.

Service

Manifold

Heat

Control

Valve

The

Dauntless V-6

engine

is equipped with a manifold heat control valve (Fig. F-6). Test the valve

for free operation. Place a few drops of penetrating

oil

at each end of the shaft where it passes through

the manifold.

Then

move

the valve up and down

a

few times to work the oil into the bushing. When

the

engine

is cold, the valve should be in the closed

position to ensure a fast warm-up of the intake

manifold for better fuel vaporization. When the

valve is closed, the counterweight is in its counter clockwise position. As the

engine

warms the coun

terweight slowly rotates clockwise until the valve is fully open.

C-8.

Check

Valve

Tappet

Clearance

a.

Hurricane

F4 Engine.

With

the

engine

cold, check and adjust the intake

valve to .018"

[0,460

mm.] clearance and the ex

haust valves to .016" [0,406 mm.] clearance. The

intake valves are adjusted by removing the rocker

arm

cover mounted on the cylinder head.

Turn

the

engine

over until No. 1 cylinder piston is on top

dead center on its compression stroke, then using a

feeler

gauge

check the clearance

between

the valve stem and the toe of the rocker arm. If clearance is

less

or greater than .018"

[0,460

mm.] the valve

must be adjusted by turning the rocker arm nut

clockwise to decrease and counterclockwise to in crease the clearance. When No. 1 cylinder intake

valve has been properly set use the same proce

dures to check and reset, if necessary, the remaining

three cylinder valves. The exhaust valves are ad justed by removing the tappet cover located on

the right side of the engine. Place the cylinder to

be adjusted on top dead center (compression stroke) and check the clearance

between

the valve stem and tappet screw with a feeler

gauge.

If the

clearance is

less

or greater than .016" [0,406 mm.]

the valve must be adjusted by loosening the tappet

screw locknut and turning the screw until the proper clearance is obtained, then tighten the lock-

nut.

Note:

Always recheck the valve clearance after

tightening the locknut.

b. Dauntless V-6 Engine.

The

valve tappet clearance of the Dauntless V-6

engine

needs

no adjustment as the lifters are

hydraulic

and require no lash adjustment at time

of assembly or while in service.

C-9.

Check

Engine

Cylinder

Compression

a.

Hurricane

F4 Engine.

To

take the compression readings of the

engine

cylinders

remove all the

spark

plugs and disconnect

the high tension wire from the coil.

With

the throttle and choke open

turn

the

engine

with the

starter

motor while firmly holding the compression

gauge

in the

spark

plug port of the cylinder to be

checked. Allow at least four compression strokes

when checking each cylinder and record the first

and

fourth stroke reading of the

gauge.

When

pressure quickly

comes

up to specified pres

sure

and is uniform

between

all cylinders within 10 psi. [0,7 kg-cm2] it indicates that the

engine

is

operating normally with satisfactory seating of

rings,

valves, valve timing, etc.

When

pressure is low on the first stroke and builds

up to

less

than specified pressure it indicates com

pression leakage usually attributable to rings or

valves. To determine which is responsible, pour

Vz

oz. [15 cm3] of tune-up oil into each cylinder.

Allow

a few minutes for the oil to leak down past

the rings and then again

test

compression. If com

pression pressures improve over the first

test,

the trouble is probably worn piston rings and bores. If

compression pressures do not improve, the trouble

is probably caused by improper valve seating. If

this condition is noticed on only two cylinders that

are adjacent, it indicates that there is a possible gasket leak

between

these

cylinders. If inspection

of the

spark

plugs from

these

cylinders disclosed

fouling or surface cracking of electrodes, gasket leakage is probable.

When

pressure is higher than normal it indicates

that carbon

deposits

in the combustion chamber have reduced the side of the chamber enough to

give

the

effect

of a raised compression ratio.

This

will

usually cause a pinging sound in the

engine

when under load that cannot be satisfactorily corrected by timing. The carbon must be cleaned out

of the

engine

cylinders to correct this trouble.

Reinstall

the

spark

plugs. Torque with a wrench

to proper setting.

Advise

the vehicle owner if compression is not satisfactory. 24

Page 30 of 376

c

TUNE-UP

meter during this

test

Connect the red lead

tc*

dis

tributor

primary

lead at the coil as shown in Fig.

C-21.

Connect black lead to the ground.

Turn

ignition switch on; with

engine

stopped, observe

dwell

meter. If the meter reads zero,

crank

the

engine

a fraction of a revolution to

close

the

breaker

points.

Distributor

resistance is normal, if dwell meter

pointer is within range of

black

bar. Distributor resistance is high, if

dwell

meter pointer is not

within

the black bar.

Remove test lead from

distri

butor terminal of coil and

connect

to

each

of the

following points to determine

where

the excessive resistance is:

Distributor

primary

terminal

Distributor

primary

terminal in the distributor

Breaker

point bracket

Ground

side of points

Distributor

housing

Where

a noticeable change occurs in the meter

reading

in

these

steps, make the necessary correc

tion and repeat the

test.

C-l 7. Distributor

Point

Dwell

Using

a dwell tester, connect red

lead

to the

distri

butor terminal at coil. Connect black lead to

ground.

Set selector switch to the number of

cylin

ders in the

engine

being tested. Operate

engine

speed at specified rpm. and

note

readings. Cam

dwell

angle must be 30° for the Dauntless V-6

Delco equipped engine, 29° ±: 3° Prestolite equipped

engine

and 42° for the

Hurricane

F4 engine. If the dwell reading is not to specifications,

trouble could be improper point spacing, point

rubbing,

defective block or breaker arm, or mis

aligned and worn distributor cam.

Adjust

dwell

as shown in Fig. C-14 for the Delco equipped

Dauntless V-6 engine. For cam dwell adjustment

of the Prestolite equipped V6 and

Hurricane

F4 engine, refer to Par. C-10,

step

a.

Dwell

variation is determined by noting any

dwell

change as the

engine

is operated at different

speeds.

Excessive

variation indicates a change in point opening that can result from shaft or bushing wear,

or

from the distributor plate shifting because of

wear

or

looseness.

Measure

dwell variation at idle speed, using same

test

hookup for checking dwell. Increase speed to 1750 rpm.;

note

dwell reading.

Then

slowly reduce

speed to idle while observing dwell meter. Dwell

variation

should not exceed 3°. If dwell variation

exceeds

3°

between

idle speed and 1750 rpm.,

probable wear in the distributor shaft, bushings, or

breaker

plate is indicated. Distributor should then be checked more thoroughly.

C-l8. Check Ignition Wires

and

Connections

Examine

and clean the insulation on all ignition

wires

and check all connections. Wires should be

firm,

flexible, and free from roughness and minute

cracks.

Bend wires to check for brittle,

cracked,

or

loose

insulation. Since defective insulation

will

per

mit

crossfiring or missing of the engine, defective

wires

should be replaced.

C-l9. Test Ignition

Cables

To

remove cables from

spark

plugs, use

Spark

Plug

Cable

Remover

Tool

W-274.

Twist

the

boot

slightly to break the seal and, grasping the rubber

protector

boot,

lift straight up with a steady even

pull.

Do not grasp the cable and

jerk

the cable off; this

will

damage the cables. Do not use a probe

on

these

wires; puncturing them may cause a

separation in the conductor. To remove ignition cables from the distributor cap or coil tower,

loosen

the nipple first, then grasp the upper part of the nipple and the cable and gently

pull

straight up.

Test

the cable with an ohmmeter. Resistance value

per

foot

is

3000-7000

ohms. The ignition cables

can

be checked for

circuit

continuity by removing

the cable from the

spark

plug and holding the cable

end Vi" [6,35 mm.] from the engine. A strong

spark

indicates

good

conductor continuity.

When

connecting the cable to the

spark

plug, be

certain

a

good

connection is made and that the

protector

boot

fits tight on the

spark

plug. A

partially

seated cable creates an additional gap in

the

circuit

and the resulting

spark

jump

will

cause

terminal

corrosion and cable damage.

C-20. Coil

When

an ignition coil is suspected of being defec tive, it should be checked on the car. A coil may

break

down after it has reached operating tempera

ture.

It is important that the coil be at operating

temperature when

tests

are made.

Note:

The ignition coil and ballast resistor for the

V-6

engine

must be of the same manufacturer.

Ballast

resistors and ignition coils of one manufac

turer

are interchangeable with both units of the

other.

C-21.

Service Air

Cleaner

Refer

to Par.

B-2 2

for the correct service of the

air

cleaner.

C-22.

Check Fuel Lines and

Screens

Check

all fuel line connections to guard against

leakage.

Check

fuel pump filter F4

engine

and

fuel

line filter V-6 engine. Replace fuel filter if

necessary.

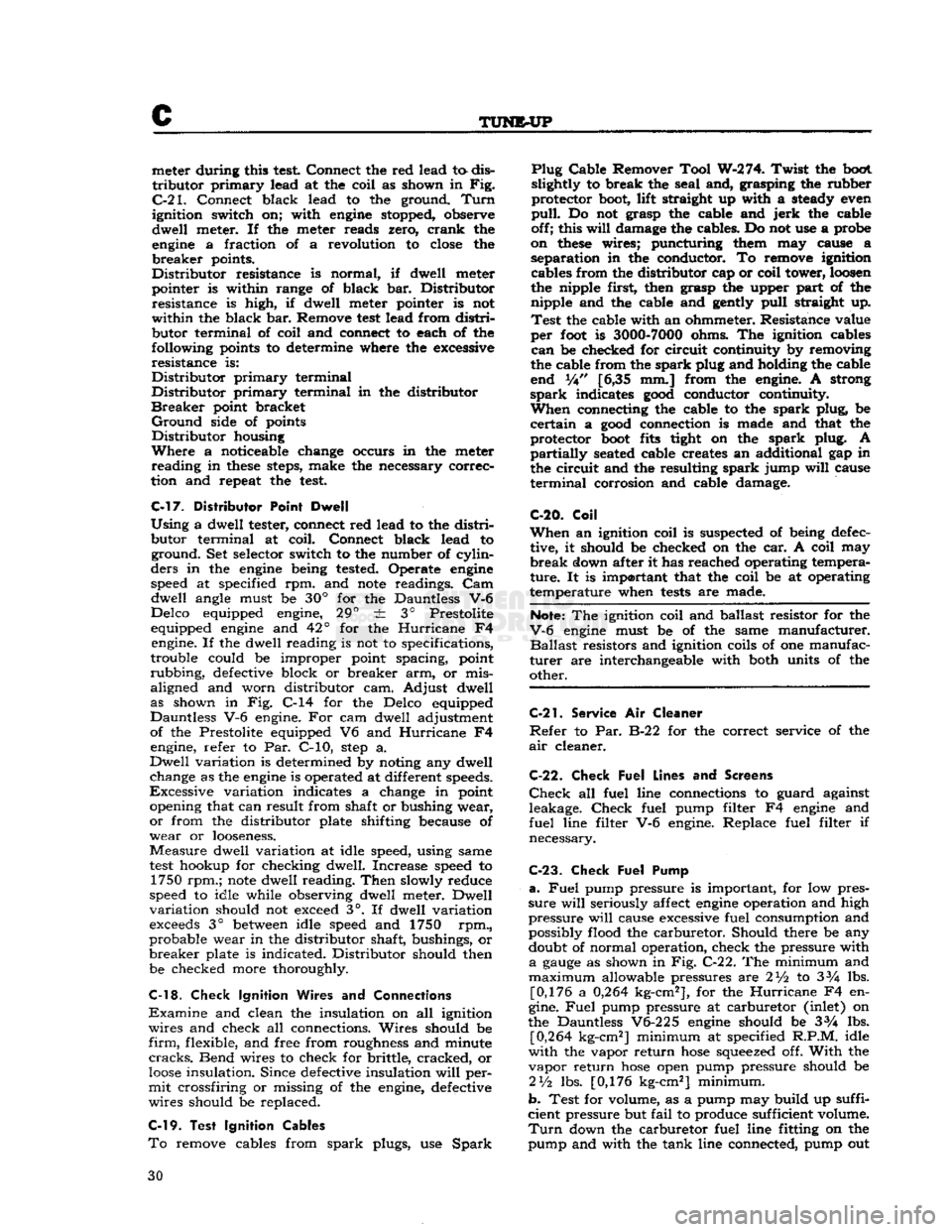

C-23. Check Fuel Pump a.

Fuel

pump pressure is important, for low pres

sure

will

seriously affect

engine

operation and high

pressure

will

cause excessive fuel consumption and

possibly flood the carburetor. Should there be any doubt of normal operation, check the pressure with

a

gauge

as shown in Fig.

C-2 2.

The minimum and

maximum

allowable pressures are 2% to 3% lbs. [0,176 a

0,264

kg-cm2], for the

Hurricane

F4 en

gine.

Fuel

pump pressure at carburetor (inlet) on

the Dauntless V6-225

engine

should be 3% lbs.

[0,264

kg-cm2] minimum at specified

R.P.M.

idle

with

the vapor

return

hose

squeezed off.

With

the

vapor

return

hose

open pump pressure should be

2

V2

lbs. [0,176 kg-cm2] minimum.

b.

Test for volume, as a pump may build up suffi

cient pressure but

fail

to produce sufficient volume.

Turn

down the carburetor fuel line fitting on the

pump and with the tank line connected, pump out

30

Page 31 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

C

FIG.

C-22—-CHECKING

FUEL

PUMP

PRESSURE

—

DAUNTLESS

V-6

ENGINE a

couple of strokes to be sure the pump is primed.

Using

a half-pint

bottle

or similar measure, pump

Vi

pint [0,24 It] of fuel by cranking the

engine

with

the starter motor. Count the strokes neces

sary

to

fill

the measure. If more than 20 strokes

are

required, the fuel pump is inefficient, the tank

line is leaking air, or the fuel supply is restricted.

Check

fuel filter in the fuel tank if line is restricted.

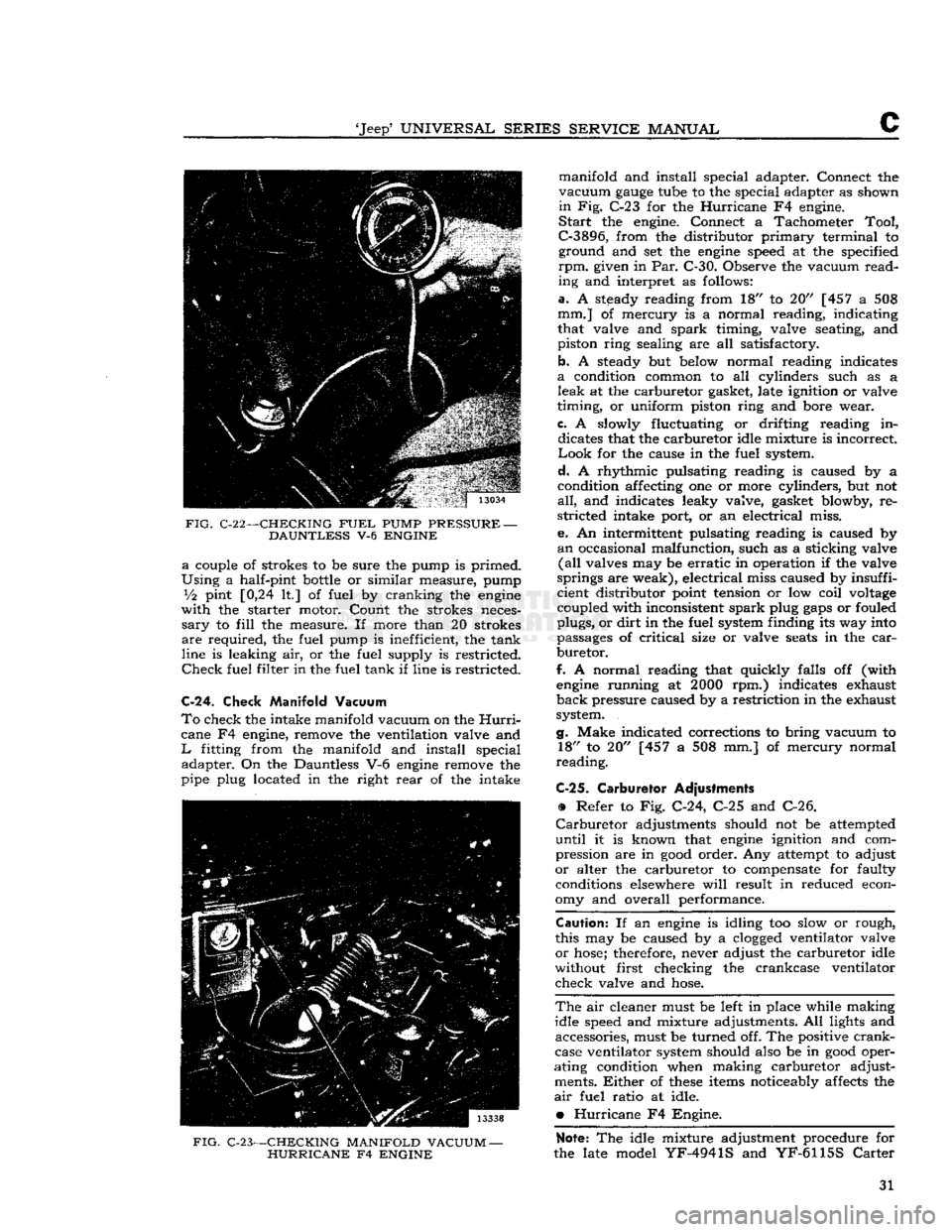

C-24.

Check Manifold Vacuum

To

check the intake manifold vacuum on the

Hurri

cane F4 engine, remove the ventilation valve and

L

fitting from the manifold and install special adapter. On the Dauntless V-6

engine

remove the

pipe plug located in the right

rear

of the intake

FIG.

C-23—CHECKING MANIFOLD VACUUM

—

HURRICANE

F4

ENGINE

manifold and install special adapter. Connect the

vacuum

gauge

tube to the special adapter as shown

in

Fig. C-23 for the

Hurricane

F4 engine.

Start

the engine. Connect a Tachometer

Tool,

C-3896,

from the distributor

primary

terminal to ground and set the

engine

speed at the specified

rpm.

given in Par. C-30. Observe the vacuum

read

ing and interpret as follows:

a.

A steady reading from 18" to 20" [457 a 508

mm.] of mercury is a normal reading, indicating

that valve and

spark

timing, valve seating, and

piston ring sealing are all satisfactory.

b. A steady but below normal reading indicates

a

condition common to all cylinders such as a

leak

at the carburetor gasket, late ignition or valve

timing, or uniform piston ring and bore wear.

c.

A slowly fluctuating or drifting reading in dicates that the carburetor idle mixture is incorrect

Look

for the cause in the fuel system.

d.

A rhythmic pulsating reading is caused by a

condition affecting one or more cylinders, but not

all,

and indicates leaky valve, gasket blowby, re

stricted intake port, or an electrical miss.

e. An intermittent pulsating reading is caused by

an

occasional malfunction, such as a sticking valve

(all

valves may be

erratic

in operation if the valve

springs are weak), electrical miss caused by insuffi

cient distributor point tension or low coil

voltage

coupled with inconsistent

spark

plug

gaps

or fouled

plugs, or

dirt

in the fuel system finding its way into

passages of

critical

size or valve

seats

in the

car

buretor.

f.

A normal reading that quickly falls off (with

engine

running at

2000

rpm.) indicates exhaust

back

pressure caused by a restriction in the exhaust

system.

g.

Make indicated corrections to bring vacuum to 18" to 20" [457 a 508 mm.] of mercury normal

reading.

C-25.

Carburetor Adjustments

•

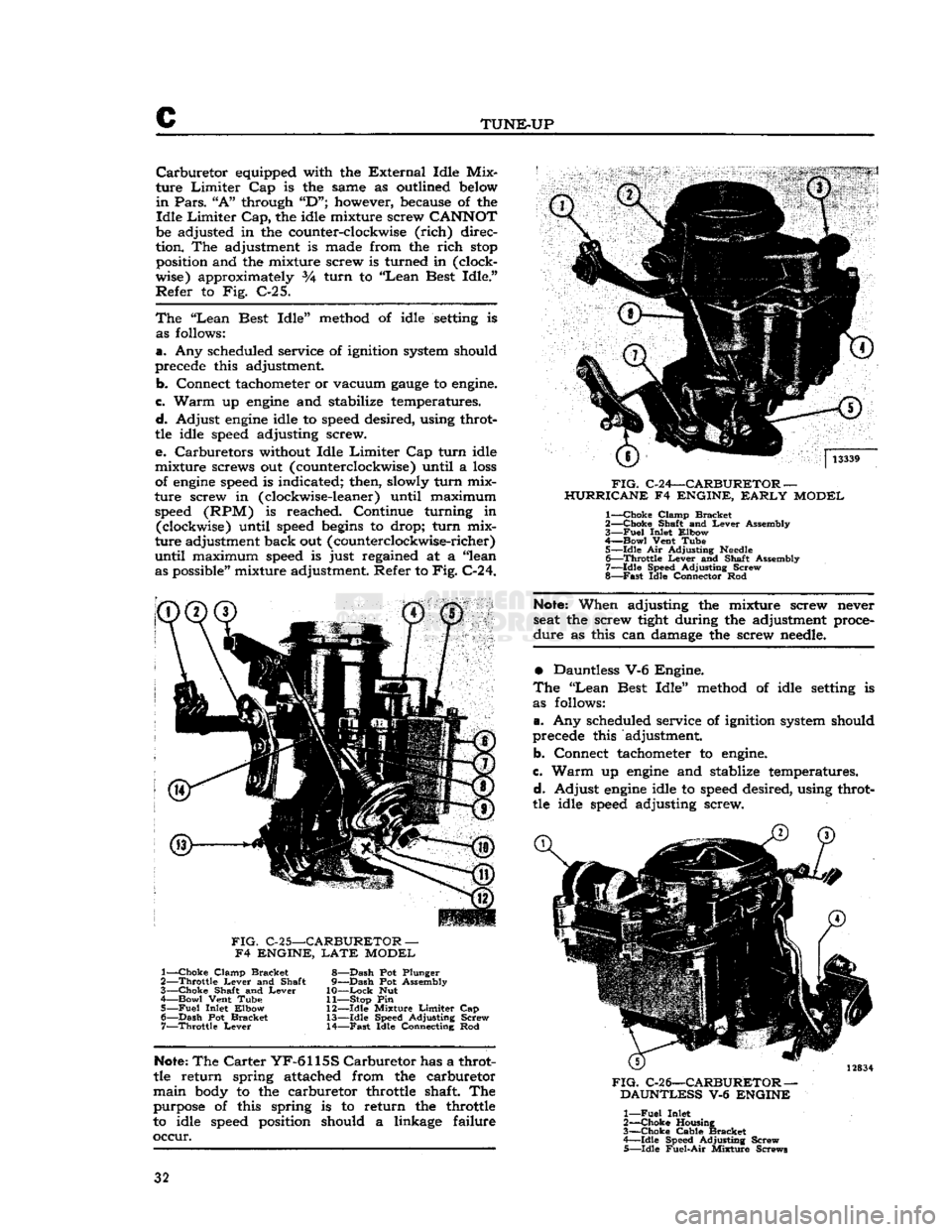

Refer to Fig. C-24, C-25 and C-26.

Carburetor

adjustments should not be attempted

until

it is known that

engine

ignition and com

pression are in

good

order. Any attempt to adjust

or

alter the carburetor to compensate for faulty conditions elsewhere

will

result in reduced econ

omy and overall performance.

Caution:

If an

engine

is idling too slow or rough,

this may be caused by a

clogged

ventilator valve

or

hose;

therefore, never adjust the carburetor idle

without first checking the crankcase ventilator

check valve and

hose.

The

air cleaner must be left in place while making

idle speed and mixture adjustments. All lights and accessories, must be turned off. The positive

crank

case ventilator system should also be in

good

oper

ating condition when making carburetor adjust ments.

Either

of

these

items noticeably affects the

air

fuel ratio at idle.

•

Hurricane

F4 Engine.

Note:

The idle mixture adjustment procedure for

the late model

YF-4941S

and

YF-6115S

Carter

31

Page 32 of 376

c

TUNE-UP

Carburetor

equipped with the

External

Idle Mix

ture

Limiter

Cap is the same as outlined below

in

Pars.

"A"

through

"D";

however, because of the

Idle

Limiter

Cap,

the idle mixture screw

CANNOT

be adjusted in the counter-clockwise

(rich)

direc

tion. The adjustment is made from the

rich

stop

position and the mixture screw is turned in (clock

wise) approximately 3A turn to

"Lean

Best Idle."

Refer

to Fig. C-25.

The

"Lean

Best Idle" method of idle setting is as follows:

a.

Any scheduled service of ignition system should

precede this adjustment.

b.

Connect tachometer or vacuum

gauge

to engine.

c.

Warm

up

engine

and stabilize temperatures.

d.

Adjust

engine

idle to speed desired, using throt

tle idle speed adjusting screw.

e.

Carburetors without Idle

Limiter

Cap turn idle

mixture screws out (counterclockwise) until a

loss

of

engine

speed is indicated; then, slowly turn mix

ture screw in (clockwise-leaner) until maximum speed (RPM) is reached. Continue turning in (clockwise) until speed

begins

to drop; turn mix

ture adjustment back out (counterclockwise-richer)

until

maximum speed is just regained at a "lean as possible" mixture adjustment. Refer to

Fig.

C-24.

FIG.

C-24—CARBURETOR —

HURRICANE F4 ENGINE,

EARLY

MODEL 1—

Choke

Clamp Bracket

2—

Choke

Shaft and

Lever

Assembly

3—

Fuel

Inlet Elbow

4—

Bowl

Vent Tube 5— idle Air Adjusting

Needle

6—

Throttle

Lever

and Shalt Assembly

7—

Idle

Speed Adjusting Screw

8—

Fast

Idle Connector Rod

FIG.

C-25—CARBURETOR —

F4 ENGINE,

LATE

MODEL 1—

Choke

Clamp Bracket

2—

Throttle

Lever

and Shaft

3—

Choke

Shaft and

Lever

4 Bowl Vent Tube 5—

Fuel

Inlet Elbow 6—

Dash

Pot Bracket 7—

Throttle

Lever

8—

Dash

Pot Plunger

9—

Dash

Pot Assembly

10—

Lock

Nut

11— Stop Pin

12—

Idle

Mixture

Limiter

Cap 13—

Idle

Speed Adjusting Screw

14—

Fast

Idle Connecting Rod

Note:

When adjusting the mixture screw never

seat the screw tight during the adjustment proce

dure

as this can damage the screw needle.

•

Dauntless V-6 Engine.

The

"Lean

Best Idle" method of idle setting is

as follows:

a.

Any scheduled service of ignition system should

precede this adjustment.

b. Connect tachometer to engine.

c.

Warm

up

engine

and stablize temperatures.

d.

Adjust

engine

idle to speed desired, using throt

tle idle speed adjusting screw.

Note:

The

Carter

YF-6115S

Carburetor

has a throt

tle return spring attached from the carburetor

main

body to the carburetor throttle shaft The purpose of this spring is to return the throttle

to idle speed position should a linkage failure

occur.

FIG.

C-26—CARBURETOR —

DAUNTLESS V-6 ENGINE 1—

Fuel

Inlet

2—

-Choke

Housing

3—

Choke

Cable Bracket

4—

Idle

Speed Adjusting Screw

5—

Idle

Fuel-Air

Mixture Screws 32

Page 37 of 376

'Jeep9

UNIVERSAL SERIES SERVICE

MANUAL

D HURRICANE

F4

ENGINE

Contents

SUBJECT

PAR.

GENERAL...

D-l Description D-2

Engine

Ground Strap D-4

Engine

Mountings D-3

ENGINE REMOVAL

D-5

ENGINE DISASSEMBLY

D-6

Camshaft

.......

D-28

Clutch

D-24

Crankshaft.

D-26

Crankshaft

Pulley. D-l2

Cylinder

Head. .D-17

Distributor.

.D-13

Exhaust

Manifold D-8

Exhaust

Valves and Springs D-2

7

Flywheel.

. D-25

Front

End Plate D-23

Oil

Filler

Tube D-9

Oil

Gallery Plugs D-30

Oil

Pan. . ...D-19

Oil

Pump D-l4

Piston and Connecting Rods. . . D-20

Ream

Cylinder Bore Ridges. D-l8

Rocker

Arm Assemblies D-l6 Thermostat D-ll

Timing

Gear

Cover . . D-21

Timing

Gears D-22

Valve

Tappets D-29

Ventilation Valve D-l5

Water

Outlet Fitting D-10

Water

Pump D-7

ENGINE INSPECTION

AND

REPAIR.

.D-31

Camshaft

and Bearings. D-51

Camshaft

End-Play

. . .D-53

Camshaft

Front Bearing Replacement..... D-52

Checking

Connecting Rod

Crank

Pins D-42

Checking

Crankshaft Alignment .

.

D-40

Checking

Main Bearing Journals. D-41

Cleaning.

. D-33 Connecting Rod Bearing Inspection D-48

Connecting Rod Bearings D-47 Connecting Rod Side Play D-50

Core

Hole Expansion Plug D-72

Crankshaft

.

.

D-38, 39

Crankshaft

Main Bearing Inspection D-44

Crankshaft

Main Bearings D-43

Crankshaft

Rear

Bearing Seal D-63

Cylinder

Block D-32

Cylinder

Bores D-35

Cylinder

Head. . . D-73

Exhaust

Valve Seat Insert Replacement. .

.

D-60

Fitting

Crankshaft Main Bearings

Using

Plastigage

D-45

Fitting

Crankshaft Main Bearings

Using

Shim Stock D-46

Floating

Oil Intake D-64

Flywheel.

. . .D-67

Flywheel

Housing D-71

SUBJECT

FAR.

Flywheel

Inspection. D-6 8

Flywheel

Pilot Bushing D-70 Inspection D-3 4

Inspection of Valves, Springs and Guides. .D-57

Installing

Connecting Rod Bearings....... D-49

Oil

Pan D-66

Oil

Pump D-65

Piston Ring Application

Chart

D-3 7

Pistons, Rings, and Connecting Rods..... D-36

Refacing

Valves

.

D-58

Ring

Gear

Replacement D-69

Rocker

Arm Shaft Disassembly. D-75, 76

Rocker

Arm Shaft Reassembly.

.

D-77

Rocker

Arms D-74

Tappets and Cover. . D-62

Timing

Gears and Cover D-54, 55

Valve

Guide Replacement D-61

Valve

Seat Inspection and Refacing D-59

Valve,

Springs and Guides D-56

ENGINE REASSEMBLY

D-78

Camshaft

and

Thrust

Plate .D-81

Camshaft

Timing

Gear

D-91

Check

Crankshaft

End-Play.

............D-83

Clutch.

...D-89

Crankshaft

and Bearings................ D-82

Crankshaft

Pulley D-96

Crankshaft

Rear

Bearing Seal.. .

.

D-85

Crankshaft

Timing

Gear

D-84

Cylinder

Head D-98

Distributor

D-l

00

Flywheel

®. . .. D-87

Flywheel

Housing D-88

Front

End Plate D-86

Manifold.......

D-101

Oil

Filler

Tube D-102

Oil

Gallery Plug. D-79

Oil

Pan. D-97

Oil

Pump D-93

Pistons and Connecting Rods D-95

Rocker

Arm Assembly D-99

Spark

Plugs. .D-100

Tappets D-80

Timing

Gear

Cover D-94

Timing

Gear

Oil Jet D-92

Valves

and Springs ... D-90

Water

Outlet Fitting D-104

Water

Pump D-103

ENGINE INSTALLATION.

............D-105

FINAL IN-VEHICLE

ADJUSTMENTS.

.D-106

Check

Valve Timing . . D-109

Crankcase

Ventilation Valve. D-l 10

Oil

Filter

, . .

...D-lll

Valve

Adjustment D-107

Valve

Adjustment Procedure D-l08

SERVICE

DIAGNOSIS

D-112

SPECIFICATIONS D-l

13 37

Page 54 of 376

D

HURRICANE

F4

ENGINE

against the hub of the crankshaft pulley.

Timing

gears are accessible for inspection or replacement

with

the

engine

installed in the vehicle after re moving the radiator, belt drive pulley, and timing

cover.

Should

it be necessary to replace the timing gears, attention must be given to the end float of both

the camshaft and crankshaft and to the running

clearance

of both gears. It is also advisable to

check

both the oil jet and oil passage to the

crank

shaft front bearing to be sure that they are clear.

D-55.

Inspection and

Repair

Check

the general condition of both gears and

inspect for evidence of excessive wear. Replace

excessively worn or damaged gears. Inspect the

cover and replace if bent or damaged. It is recom mended that the crankshaft oil seal in the cover

be replaced when the cover is removed to ensure a

good

seal around the crankshaft. To replace this

seal

with the

engine

in the vehicle

requires

removing

the radiator and water pump.

D-56.

Valves, Springs, and Guides

The

exhaust valves seat on the top of the cylinder

block

with the

stems

extending down through

replaceable valve guides. The exhaust valves are actuated by the camshaft through exhaust valve

tappets. The exhaust valve springs are assembled

and

locked on the lower end of the exhaust valve

stems. The retaining locks are the split type, which

fit in a recess on the valve

stems

and into the taper

in

the valve spring retainers.

Adjustment

of exhaust valves is by means of the

adjusting

screw threaded into the upper end of the

exhaust valve tappets. An exhaust valve rotator used as a valve spring retainer is installed on the

lower end of the exhaust valve.

This

valve rotator,

known

as "Roto Cap", is a spring-loaded

ball

bearing

device. On each lift, or opening stroke of

a

valve, the rotator

gives

the valve a slight positive

clockwise rotation.

The

intake valves operate in valve

guides

in the

cylinder

head and are actuated by rocker arms.

The

rocker arms are actuated by valve push rods

and

the intake valve tappets. The intake valve

springs,

the intake valve spring retainers, and the

intake

valve spring retainer locks make up the

remainder

of the valve operating parts. An intake

valve spring retainer oil seal which encircles the

upper

end of the intake valve

between

the valve

locks and the upper end of the valve spring re

tainer,

controls the passage of oil along the valve

stem and guide.

Note:

When

engine

trouble indicates defective

valves as a possible source of trouble, also check

all

vacuum line connections for possible leaks.

D-57.

Inspection of Valves, Springs,

and

Guides

Clean

the valves on a wire wheel, making sure that

all

carbon is removed from the top and the under

side of the heads and that all gum and varnish

deposits

are removed from the stems.

Polish

the valve

stems

with steel wool or crocus

cloth.

Visually

inspect all valves for warpage,

cracks,

or excessive burning and discard if one of

these

conditions exists. Replace any worn, pitted,

or

corroded valves that cannot be cleaned with a

wire

brush.

Replace any valves when

seats

are pitted, burned, or corroded so badly that they

cannot be cleaned up with a light refacing on a valve refacing machine.

Replace

valves with marks of scoring or abrasion visible on the stem. Replace any valves with bent

stems

which

will

be apparent when the valve is

mounted in the valve refacing machine.

Note:

Use only hard-face exhaust valves for

replacement.

Examine

the

stems

of valves which employ the

ball

bearing rotators.

Wear

marks around the

cir

cumference of the

stems

indicates that the valve is

rotating satisfactorily.

Vertical

heavy pressure

areas

indicate that the valve is not rotating and the valve spring retainer (Roto

Cap)

should be replaced

if

at fault.

Check

the diameter of the valve stem at two or three places along the length of the stem

with

a micrometer. The intake valve stem diameter is .3733" to .3738" [9,482 a

9,495

mm.]. The

exhaust valve stem diameter is .371" to .372"

[9,423

a

9,449

mm.].

Note:

Exhaust

and intake valve springs are

similar

in appearance. They must not be inter

changed as they have different spring

charac

teristics.

Wash

the valve springs thoroughly in solvent.

Visually

examine the springs and replace any that

are

deformed or obviously damaged. Examine for

corrosion

from moisture or acid etching which might

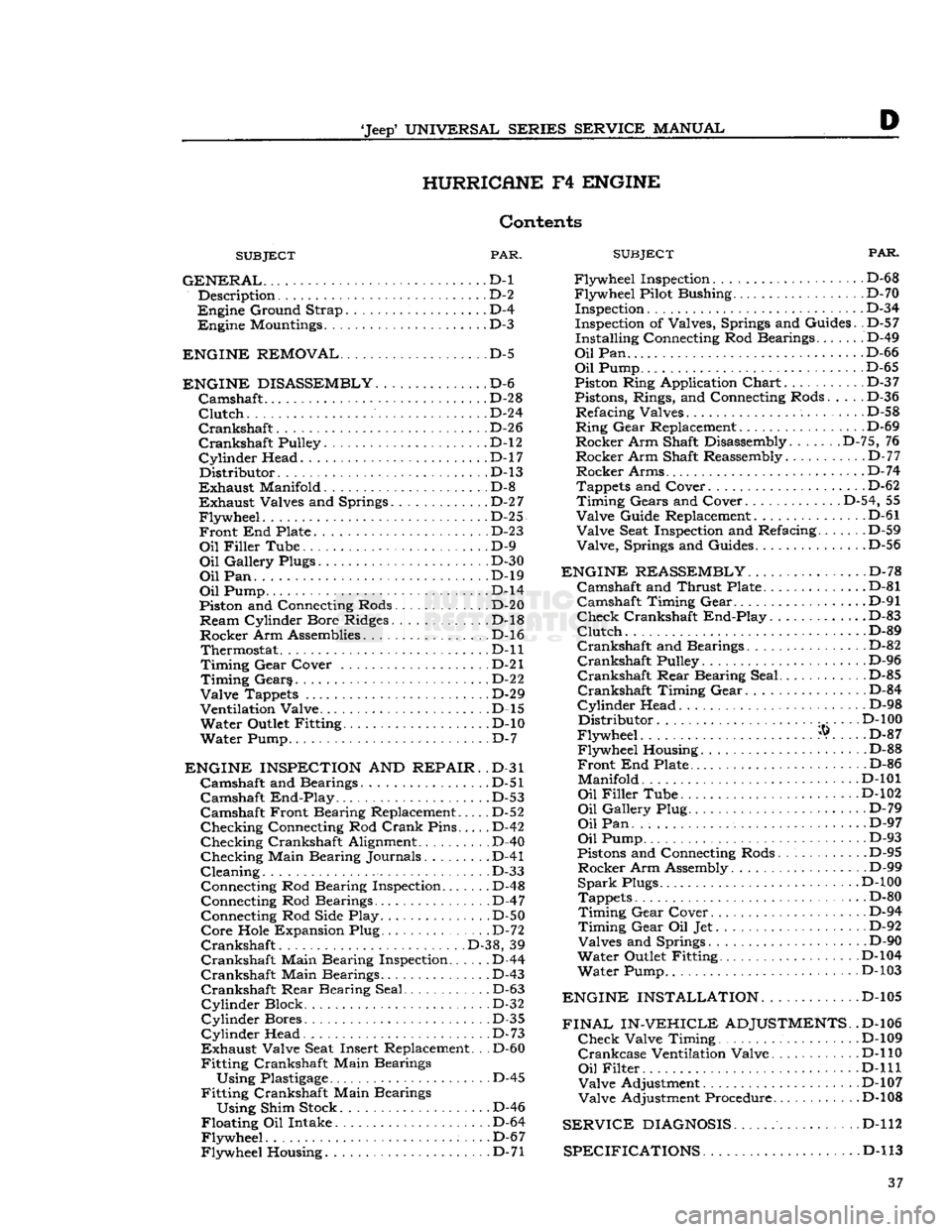

FIG.

D-19—TESTING

VALVE

SPRING

1—

Torque

Wrench

2—

Spring

Testing

Fixture

3—

Valve

Spring

54

Page 68 of 376

D

HURRICANE

F4

ENGINE

D-101.

Install

Manifold

If

manifold studs were removed for replacement,

apply sealer on the stud threads

before

installing

a

new stud.

See Section Fl for exhaust emission controlled

engines.

Make

certain that no foreign objects are inside the manifold and that all

passages

are clear. Place a

new set of manifold

gaskets

in position on the side

of the cylinder block.

Then,

carefully slide the manifold

onto

the studs and against the cylinder block being careful not to damage the gaskets.

Torque

all manifold attaching nuts evenly 29 to

35 lb-ft. [4,0 a 4,8 kg-m.].

D-102.

Install

Oil

Filler

Tube

When

installing the oil filler tube, be sure that the

beveled lower end is away from the crankshaft.

Place a

piece

of

hard

wood

over the top of the

tube

to prevent damage to the cap gasket seat.

D-103.

Install

Water Pump

Make

certain that the mating surfaces of the water pump and the cylinder block are clean and smooth.

Install

the gasket on the

flange

of the pump and

install

the pump in position on the cylinder block.

Torque

the water pump attaching

bolts

alternately

and

evenly 12 to 17 lb-ft. [1,7 a 2,3 kg-m.].

D-104.

Install

Water Outlet Fitting

Install

the thermostat and the water

outlet

fitting.

Torque

the water

outlet

fitting attaching

bolts

20

to 25 lb-ft. [2,8 a 3,4 kg-m.].

FIG.

D-42—INSTALLING HURRICANE F4 ENGINE

IN

VEHICLE

1—

Lifting

Sling

2— Hoist

Cable

3—

Hurricane

F4 Engine

4— Dowel Bolt

5—

Flywheel

Housing

D-105.

ENGINE INSTALLATION

a.

Install

lifting sling to

engine

and using suitable hoist raise the

engine

from its blocking or stand

and

then slowly lower it

into

the

engine

compartment of the vehicle.

Note:

When installing the

Hurricane

F4 Engine,

two % x 4 inch

guide

bolts

or

dowels

should be

used to properly

guide

and align the

engine

to the

flywheel housing (See Fig. D-42).

b. Slightly tilt the

engine

downward and at the

same time slide the

engine

rearward

while lining up the transmission main gear shaft with the clutch

throw-out bearing and disc spline.

Note

:The

engine

crankshaft may have to be turned

slightly to align the transmission main gear shaft

with the clutch disc spline.

c. Remove the

guide

bolts

or

dowels

and secure

the

engine

to the housing.

d.

Secure the front

engine

mounts to the frame brackets and

bolt

ground cable to

engine.

e. Remove lifting sling from

engine.

f. Connect exhaust pipe to

engine

manifold flange.

g. Connect throttle and choke cables to carburetor.

h.

Install

fan to water pump pulley.

i.

Connect fuel pump line to main fuel line,

j.

Replace starting motor assembly. k. Connect

engine

wiring harness connectors at

front of cowl.

I.

Connect wires to starting motor assembly, water

temperature and oil pressure sending units and alternator.

NOTE:

ON

ENGINES EQUIPPED WITH EX

HAUST

EMISSION CONTROL,

REPLACE

THE

AIR

PUMP,

AIR

DISTRIBUTOR

MANI

FOLD,

AND

ANTI-BACKFIRE (DIVERTER)

VALVE.

SEE

SECTION

Fl.

m. Replace radiator and radiator grille support

rods and connect coolant

hoses

to

engine.

Note:

Replace heater

hoses

if vehicle is equipped

with hot water heater.

n. Fill

radiator with coolant and

engine

with oil

(see

Lubrication

Chart).

o.

Install

air cleaner and connect carburetor air

hose.

p. Connect battery cables and start

engine,

q.

Install

hood

and road

test

vehicle.

D-103.

FINAL

IN-VEHICLE

ADJUSTMENTS

a.

Clean

battery terminals and check battery. b.

Check

ignition terminals and check battery.

c. Service carburetor air cleaner.

d.

Service positive crankcase ventilation valve.

e.

Check

fuel lines. f. Gap and install new

spark

plugs.

g.

Check

distributor

points

and capacitor; replace

if

necessary. 68

Page 69 of 376

'Jeep9

UNIVERSAL

SERIES

SERVICE

MANUAL

h.

Check

ignition (distributor) timing; reset if

necessary.

i.

Check

carburetor

adjustments; reset if necessary,

j.

With

engine

fully warmed up, tighten cylinder

head and manifold

bolts

and nuts to specified

torque.

Check

cylinder head gaskets and

bolts

for

air

or coolant leaks.

Note:

Tightness of cylinder head

bolts

should be

checked and corrected after 500 to 600 miles [800

a

960 km.] of normal operation.

k.

Check

fan belt tension; adjust if necessary.

I.

Check

for and correct any oil leak, fuel leak or

coolant leak.

D-107.

VALVE

ADJUSTMENT

Proper

valve adjustment is important to prevent

burning

of valves and poor

engine

performance.

This

adjustment consists of obtaining a specified

lash

in the valve mechanism. The exhaust valve

tappets and the intake valve rocker arms should be adjusted to the proper clearance with the

engine

cold (at room temperature). Valve clearance can

be properly adjusted only when the tappet is on the

heel or low portion of the cam.

INTAKE

OPENS

9°

BTC?

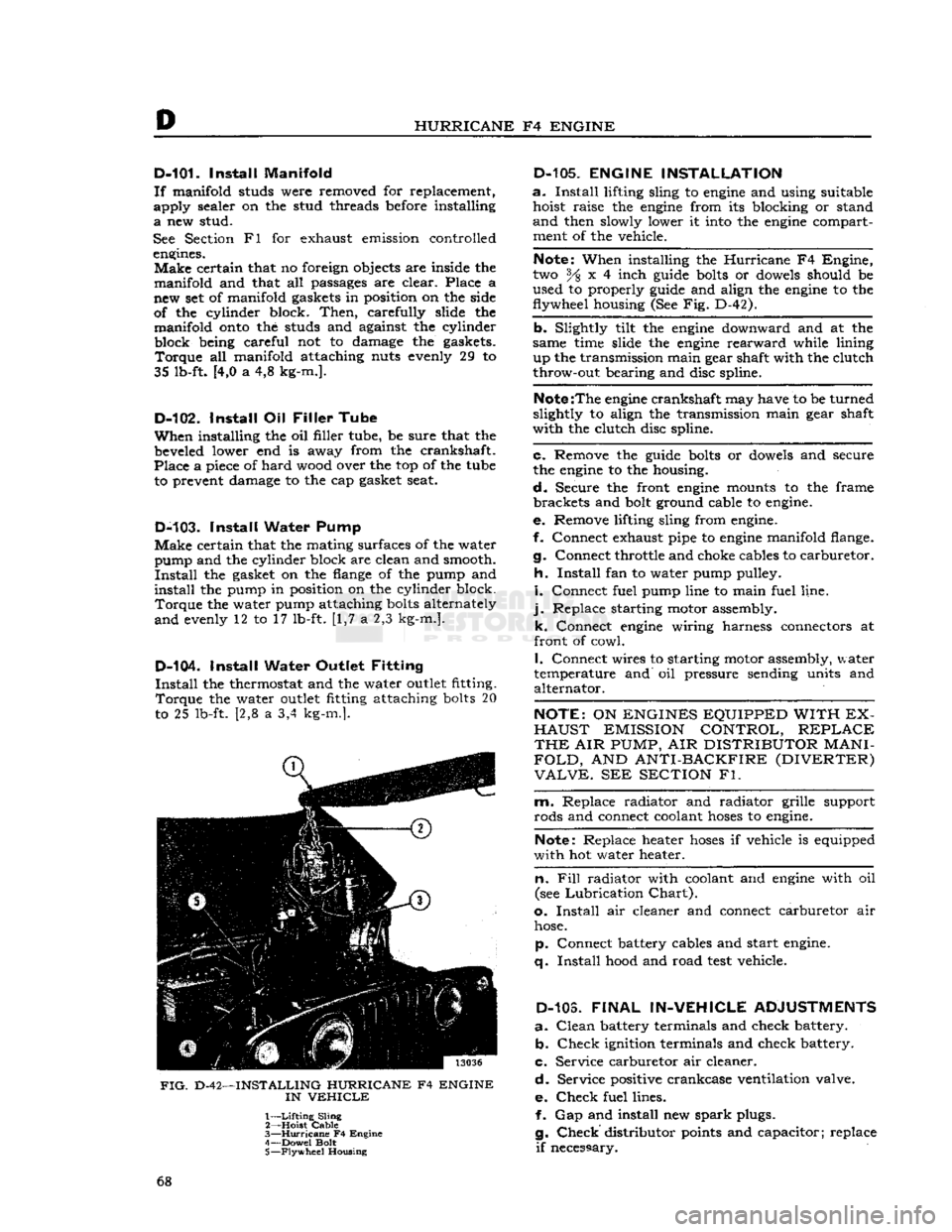

FIG.

D-43-

10270

-VALVE

TIMING

D-108. Valve Adjustment Procedure

The

exhaust valve tappets are adjusted by turning

the adjusting screw in or out of the tappet as neces

sary

to obtain the proper clearance. Where special

wrenches can be obtained, they should be used to facilitate the adjustment. The proper clearance is .016" [0,406 mm.]

between

the end of the adjusting

screw and the

bottom

of the exhaust valve.

Crank

the

engine

over to

close

a valve and check

the clearance with a feeler

gauge.

To adjust, hold

the tappet with one wrench and

turn

the adjusting

screw,

with the other.

Check

and adjust each of

the tappets in proper sequence.

Adjust

each intake valve by adjusting the rocker

arm

screw at the push rod to obtain .018" [0,457 mm.] clearance

between

the rocker arm and the

valve stem with tappet on the heel of the cam.

D-109.

Check

Valve

Timing

To

check the valve timing, carefully set the intake

valve rocker arm adjustment for No. 1 cylinder to .026"

[0,6604

mm.]

between

the rocker arm and the

valve stem. Rotate the crankshaft clockwise until

the piston in No. 1 cylinder is ready for the intake stroke. The intake valve

opens

9° before top center

(BTC).

Note

the distance

between

the

"TC"

and

"5°"

marks on the indicator on the timing gear

cover and estimate the 9° before top center position.

See

Fig.

D-43.

With

the crankshaft in this position, timing is correct if the rocker arm is just tight

against the intake valve stem. Do not overlook resetting the rocker arm adjustment to the correct

running

clearance.

D-110. Positive

Crankcase

Ventilation

Be

sure there are no air leaks at the tube connec

tions

between

the air cleaner and the oil filler tube,

and

that the oil filler tube cap gasket is in

good

condition. Always keep the cap locked securely in

place. When tuning the

engine

or grinding valves, remove the control valve and clean it thoroughly.

If

the valve is blocked with carbon, the ventilating

system

will

not operate and, should the valve

fail

to seat, it

will

be impossible to make the

engine

idle satisfactorily. Refer to Par. C-6 for servicing.

D-111. Oil

Filter

The

engine

is equipped with a throw-away type

oil

filter.

This

oil filter must be serviced periodi

cally

as outlined in the

Lubrication

Section. 69

Page 76 of 376

Dl

DAUNTLESS

V-6

ENGINE

DM.

GENERAL

This

section describes service and repair of the

Dauntless V-6 engine. The

engine

code

number shown in

Fig.

A-4 is provided to identify the Daunt

less

V6-225 engine. The meaning of the coded letters and numbers that are stamped on the right front face of the crankcase, just below the rocker

arm

cover,

between

exhaust manifold ports, is given

below.

Letter

to

Designate

Market

M

—

Military

E

—

Export

D

— Domestic

Letter

to

Designate

Year

Built

N

— 1967

P

— 1968

R

— 1969

S

— 1970

T

— 1971

Letter

to Designate

Engine

and Compression

Ratio

H—V6-225

9.0 to 1

C.R.

(2 Bbl.

Carb.)

Y—V6-225

9.0 to 1

C.R.

Marine

(Low

Profile)

(2

Bbl.Carb.)

Z—V6-225

9.0 to 1

C.R.

Marine

(High

Profile)

(2 Bbl.

Carb.)

K—V6-225

7.6 to 1

C.R.

(2 Bbl.

Carb.)

L—V6-225

7.4 to 1

C.R.

(2 Bbl.

Carb.)

Market

Domestic

—

Year

"1967"

Engine

J

Day

Plus Chg. If

Any-

Service Engine "S"

Short

Block

"R" -Oversize Bores "B"

Undersize Crank

&

"A"

Rod

Bearings

The

identifying letter or letters follow the

engine

letters are decoded as follows:

A—.010"

Undersize

Main

and Connecting Rod

Bearings

B—.010"

Oversize Pistons

AB—Combination

of A and B

S—Service

Engine

R—Short

Block

All

disassembly and assembly procedures are pre sented in logical order, assuming a complete

engine

overhaul

with

engine

removed from the vehicle.

However,

many of

these

procedures can also be

performed as on-vehicle services if vehicle or

engine

components are removed to gain access to parts

involved.

Note:

Some

engines

are equipped with an exhaust

emission control system. Service information on

the components of this system is given in sec tion F2.

Dl-2.

ENGINE

DESCRIPTION

The

Dauntless V-6

engine

has a displacement of

225 cubic inches. It has a compression ratio of

9.0 to 1, which permits use of regular-grade

gaso

line.

See

Figs.

Dl-1 and Dl-2.

The

cylinder block is made of cast

iron.

Two banks

of cylinders (three cylinders per bank) are cast at a

90-degree

angle. The lower part of the cylinder-

block

extends

below the centerline of the

crank

shaft, forming a continuous flat surface with the

rear

crankshaft main bearing cap and the timing

chain

cover.

This

design allows installation of an

oil

pan with a

one-piece

gasket. The cylinders in

the left bank (as viewed from the driver's seat) are

numbered

1-3-5,

from front to

rear.

The cylinders

in

the right bank are numbered

2-4-6,

from front

to

rear.

The

crankshaft is supported in the cylinder block

by four steel-backed full-precision bearings, all of

which

have an identical diameter.

Crankshaft

main bearings are numbered 1 to 4, front to

rear.

The

thrust

bearing is flanged to maintain crankshaft position and to compensate against crankshaft end

thrust

The No. 2 bearing is the thrust bearing.

The

crankshaft is counterbalanced by weights,

which

are cast integral with the

crank

cheeks. The

weights

are shaped to a contour which

gives

mini

mum

clearance with cylinder barrels and piston

skirts

to conserve space.

Connecting

rods have I-beam sections with

bosses

on each side. Metal is removed, as required, to secure correct weight and balance. The lower end

of each connecting rod has a steel-backed preci

sion bearing. The piston pin is a press fit into the upper end. The outer ends of the piston pin

are

a slide fit in the piston

bosses.

The

full-skirted, aluminum alloy pistons are cam ground and tin plated. Two compression rings and

one oil control ring are installed above the piston

pin.

The cast iron compression rings in the two

upper

grooves

of the piston have a

groove

or bevel cut around the inner

edge

on one side. The

top compression ring is installed with this

groove

or

bevel up. The lower compression ring is installed

with

bevel down. The oil

ring,

in the lower groove,

consists of two thin steel

rails

separated by a

spacer.

It is backed by a hump-type spring-steel

expander.

V-6

engine

cylinder heads are made of cast

iron.

Their

valve

guides

are cast integrally. Right and left cylinder heads are identical and interchange

able. In service, however, it is

good

practice to

install

the cylinder heads on the side from which

they were removed.

The

valves are in line in each head, at an angle

10°

above the centerline of the cylinder bores.

Each

valve has a spring strong enough to ensure

positive valve seating throughout the operating speed range of the engine. The valve rocker arm

mechanism is protected by a

sheet

metal cover.

This

cover is seated on a raised surface of the

cylinder

head. It is gasketed to prevent oil leaks.

The

rocker arms for each bank of cylinders are mounted on a tubular steel shaft, supported on

the cylinder head by brackets. The rocker arms

are

made of aluminum. They have inserts at the

push

rod socket and the valve stem contact face.

The

camshaft is located above the crankshaft be

tween the two cylinder banks; it is supported in

four steel-backed babbitt-metal bearings. The cam shaft is driven at one-half crankshaft speed by

sprockets and a single outside-guide type chain.

Hydraulic

valve lifters and

one-piece

push rods operate overhead rocker arms and valves of both

banks

of cylinders from a single camshaft.

This

system requires no lash adjustment during assem

bly

or in service.

In

addition to its normal function of a cam follower,

each hydraulic valve lifter also serves as an auto- 76

Page 86 of 376

Dl

DAUNTLESS

V-6

ENGINE

Dl-38.

Crankshaft

Cleaning

Clean

the crankshaft thoroughly with a suitable

cleaning solvent.

Clean

drilled oil

passages

in its

journals

with a small rifle brush to remove all

sludge

or gum deposits; dry

passages

with com

pressed air.

Dl-39.

Crankshaft

Inspection

and

Repair

If

the crankshaft has not

been

removed from the

cylinder

block for inspection, disconnect two con necting rods at a time from crankshaft. Inspect

the bearings and crankpin journals. While turning

crankshaft,

it is necessary to temporarily reconnect

the rods to crankshaft to avoid possibility of dam aging the journals through contact with uncon

nected rods.

Inspect the crankpins visually for excessive or ir

regular

wear, and for scoring. Use an

outside

micrometer to check crankpins for out-of-round.

Standard

crankpin

diameter is

2.0000"

[5,080

cm.].

If

crankpins are more than .0015"

[0,0381

mm.]

out-of-round, new bearings cannot be

expected

to

have satisfactory life.

If

the crankshaft has

been

removed from the

cyl

inder

block for inspection support it on V-blocks

at its main bearing journals 1 and 4. Inspect the

main

bearing journals visually for excessive or ir

regular

wear, and for scoring. Standard main bear

ing

journal

diameter is 2.4995"

[6,349

cm.].

Total

indicator readings at each

journal

should not ex

ceed .003"

[0,076

mm.].

Check

run out at all four journals and

note

high

spot

(maximum eccentricity) of each

journal.

High

spot

of each

journal

should

come

at the same

angular

location. If high

spots

do not coincide,

crankshaft

is misaligned and unsatisfactory for

service.

If

crankpin or main bearing journals are scored,

ridged, or out-of-round, the crankshaft must be replaced or reground to a standard undersize bear

ing diameter to ensure satisfactory life of bearings. Slight roughness can be removed with a fine grit

polishing cloth thoroughly

wetted

with

engine

oil.

Burrs

can

be

honed with a fine oil

stone,

so long as

bearing clearances

will

remain within specified

limits.

Dl-40.

Crankshaft

Main

Bearings

A

crankshaft bearing consists of two halves which

are

neither alike nor interchangeable. One half is

carried

in the corresponding main bearing cap; the

other half is located

between

the crankshaft and

cylinder

block. The upper (cylinder block) half

of the bearing is grooved to supply oil to the con necting rod bearings, while the lower (bearing cap)

half

of the bearing is not grooved. The two bearing

halves must not be interchanged. All crankshaft

bearings

except

the thrust bearing and the

rear

main

bearing are identical. The thrust bearing (No. 2) is longer and it is flanged to take

crank

shaft end thrust. When the bearing halves are

placed in cylinder block and bearing cap, the

ends

extend slightly beyond the parting surfaces. When

cap

bolts

are tightened, the halves are clamped

tightly in place to ensure positive seating and to

prevent turning. The

ends

of bearing halves must never be filed flush with parting surface of

crank

case or bearing cap.

Crankshaft

bearings are the precision type which

do not require reaming to size or other fitting.

Shims

are not provided for adjustment since worn

bearings are readily replaced with new bearings of proper size. Bearings for service replacement are

furnished

in standard size and undersizes. Under no circumstances should crankshaft bearing caps

be filed to adjust for wear in old bearings.

Dl-41.

Crankshaft

Main

Bearing

Cleaning

and

Inspection

Clean

main bearing surfaces. Inspect the bearings

visually

for excessive or uneven wear, scoring, and

flaking.

Visibly worn or damaged bearings must

be replaced. It is necessary to check

radial

clear ance of each new or used crankshaft main bearing

before installation.

This

can be

done

by either of two methods, which are described in

Pars.

Dl-42

and

Dl-43.

a.

The desired

radial

clearance of a new bearing

is .0005" to .0021"

[0,0127

a

0,0534

mm.].

b. Replacement bearings are furnished in standard

size, and in several undersizes, including undersizes

for reground journals. If a new bearing is to be installed, try a standard size; then try each under

size in turn until one is found that

meets

the

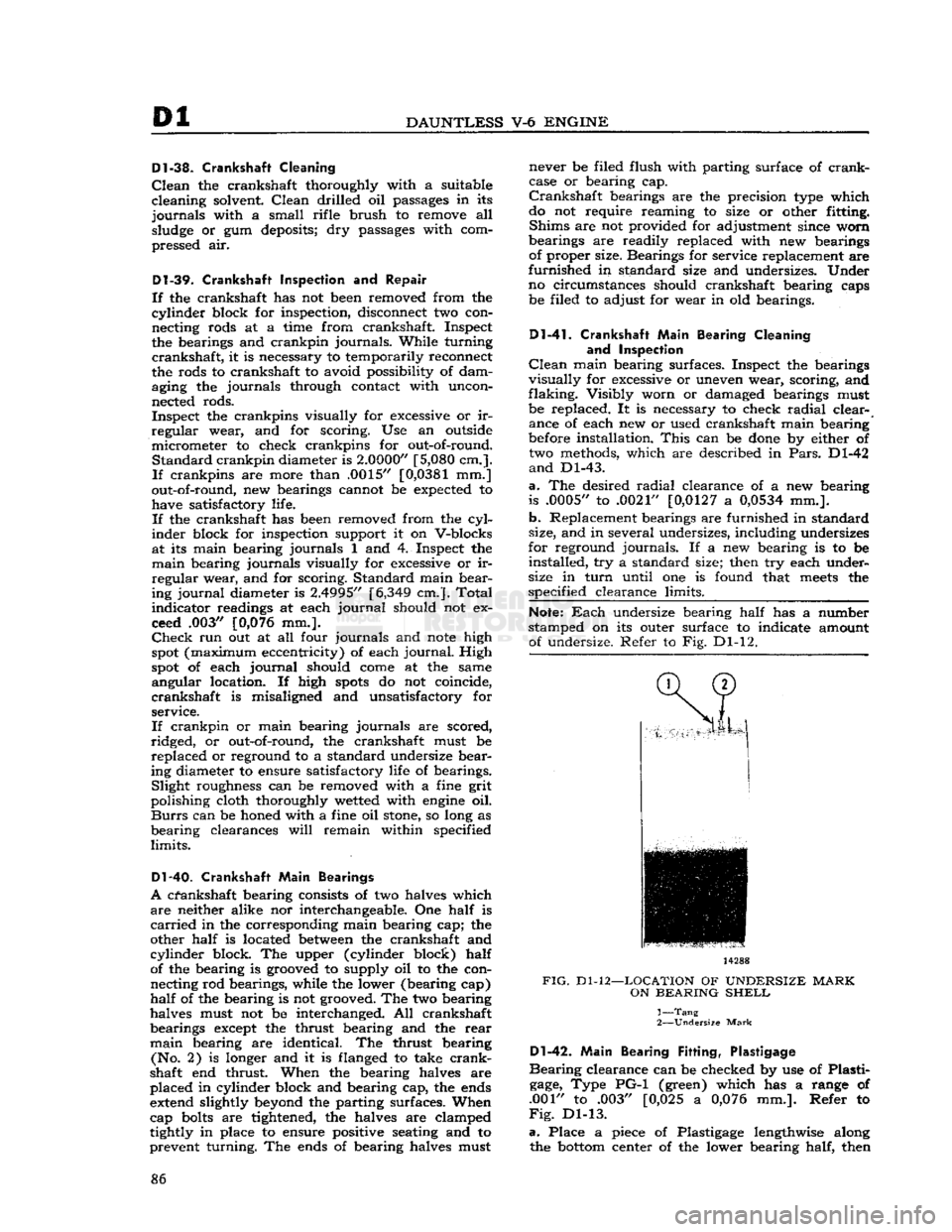

specified clearance limits.

Note:

Each

undersize bearing half has a number

stamped on its outer surface to indicate amount of undersize. Refer to Fig. Dl-12. 14288

FIG.

Dl-12—LOCATION

OF

UNDERSIZE

MARK

ON

BEARING

SHELL

1—

Tang

2—

Undersize

Mark

Dl-42.

Main

Bearing

Fitting,

Plastigage

Bearing

clearance can be checked by use of Plasti

gage,

Type PG-1 (green) which has a range of

.001" to .003" [0,025 a

0,076

mm.]. Refer to

Fig.

Dl-13.

a.

Place a piece of Plastigage lengthwise along the

bottom

center of the lower bearing half, then 86