oil type JEEP DJ 1953 Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 226 of 376

![JEEP DJ 1953 Workshop Manual

I

CLUTCH 1-1.

GENERAL

The

clutch on current Jeep vehicles is either

Auburn

or Borg and Beck manufactured. Vehicles

equipped with F4-134

engines

have an

Auburn

9.25" [23,4 cm.] single JEEP DJ 1953 Workshop Manual

I

CLUTCH 1-1.

GENERAL

The

clutch on current Jeep vehicles is either

Auburn

or Borg and Beck manufactured. Vehicles

equipped with F4-134

engines

have an

Auburn

9.25" [23,4 cm.] single](/img/16/57041/w960_57041-225.png)

I

CLUTCH 1-1.

GENERAL

The

clutch on current 'Jeep' vehicles is either

Auburn

or Borg and Beck manufactured. Vehicles

equipped with F4-134

engines

have an

Auburn

9.25" [23,4 cm.] single plate dry-disc clutch. The

pressure plate has three coil pressure springs and

three levers or fingers.

The

V6-225

engine

is equipped with a 10.4" [26,4

cm.] Borg and Beck single plate dry-disc clutch.

The

pressure plate utilizes either a finger-type

diaphragm spring, or a coil

type

spring pressure plate for clutch release.

The

driven plates of all

models

are built with

vibra

tion damper springs and have two flexible facings

which

provide

smooth

engagement

of the

engine

power.

Early

'Jeep' vehicles equipped with a Dauntless

V-6

engine

use a 10.4" [26,4 cm.] single plate, dry-

disc clutch, incorporating a diaphram-type spring assembly.

The

clutch is of the centrifugal single dry disc

type

and

consists of the clutch disc, pressure plate and

the clutch release bearing.

The

clutch is actuated by a clutch pedal and a

series of mechanical linkage.

When

the clutch pedal is in the

engaged

position,

the clutch disc facings are clamped

between

the

friction surface of the

engine

flywheel and the face of the clutch pressure plate, thereby connect

ing

engine

power to the transmission. Depressing

the clutch pedal actuates the clutch release shaft

fork

which

moves

the clutch release bearing against

the clutch fingers.

This,

in

turn,

moves

the pressure

plate away from the clutch disc. Since the disc is splined to the transmission input shaft, the clutch

disc and transmission input shaft

will

stop

when

the clutch is disengaged, thereby disconnecting

engine

power from the transmission.

1-2.

Clutch

Maintenance

To

obtain normal life and satisfactory performance

from any clutch it must be correctly operated and

properly maintained. Two conditions which shorten

clutch life are continuous operation of the clutch

release bearing and clutch slippage.

The

clutch release bearing is

designed

for inter

mittent use. If run continuously the bearing

lubri

cant

will

become

exhausted causing the bearing to

become

dry, noisy, or

will

seize, resulting in clutch

finger or diaphragm wear. The clutch must be properly adjusted so that the release bearing is

free of the clutch fingers or diaphragm at all times,

except

when the clutch pedal is depressed.

Excessive

clutch slippage

often

occurs when the

vehicle is overloaded, the vehicle load is applied

too quickly, or when the pressure of the clutch fingers or diaphragm is only partially applied to the clutch plate.

Friction

between

the clutch facing

and

flywheel produces

excessive

heat causing

burned,

glazed and worn linings, resulting in shortened clutch life. Avoid clutch slippage under

heavy loads by using a lower gear or reducing the load.

1-3.

Clutch

Pedal

Linkage

and Adjustment

Adjust

the clutch pedal free travel whenever the clutch

does

not

disengage

properly, or when new

clutch parts are installed. Improper adjustment of

the clutch pedal free travel is one of the

most

fre

quent causes of clutch failure and can be a con tributing factor in

some

transmission failures.

As

the clutch facings wear the free travel of the clutch pedal diminishes. When sufficient wear oc

curs

the pedal clearance must be adjusted.

Two

types

of clutch linkage have

been

used on Jeep vehicles, a cross shaft

tube

and lever

type

shown in Fig. 1-1, and a clutch control cable

type

shown in Fig. 1-2. The clutch pedal adjustment

procedures for both

type

linkages are as follows.

•

Cross

Shaft

Lever

and Tube Type

Refer

to Fig. 1-1.

Note:

Two different

Clutch

Control

Lever

and

Tube

Assemblies have

been

installed on 'Jeep*

Universal

vehicles equipped with a V-6

engine

and

T14A

transmission.

Should difficulty in shifting the transmission be

noted, check the length of the clutch release pedal

rod,

item (16) in Fig. 1-1. Measure the distance

between

the centerlines of the cotter key holes.

FIG.

1-2—CLUTCH

LINKAGE AND

ADJUSTMENT,

CONTROL

CABLE TYPE

A—Top

View,

Cable

to

Clutch

Fork

1—

Retracting

Spring

(Clutch

Fork)

2—

Clutch

Fork

3—

Ball

Adjusting Nut

4—

Lock

Nut 5—

Clutch

Cable

B—Side

View,

Cable

to

Clutch

Pedal 6—

Clutch

Cable

Support

Bracket

7—

Clutch

Cable

Housing

8—

Anchor

Bracket-to-Frame Side

Rail

9—

Retracting

Spring

(Clutch

Pedal)

10—Clutch

Pedal Assembly

*

© © ©

1437S

226

Page 227 of 376

![JEEP DJ 1953 Workshop Manual

Jeep

UNIVERSAL SERIES SERVICE

MANUAL

The

correct distance should be 10%"

[26,04

cm.].

If

the length of the clutch release pedal rod is

other than

10

W

[26,04

cm.], the vheicle is eq JEEP DJ 1953 Workshop Manual

Jeep

UNIVERSAL SERIES SERVICE

MANUAL

The

correct distance should be 10%"

[26,04

cm.].

If

the length of the clutch release pedal rod is

other than

10

W

[26,04

cm.], the vheicle is eq](/img/16/57041/w960_57041-226.png)

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

The

correct distance should be 10%"

[26,04

cm.].

If

the length of the clutch release pedal rod is

other than

10

W

[26,04

cm.], the vheicle is equipped with the early

type

Clutch

Control

Lever

and

Tube Assembly, which should be removed, and^trie latest

designed

parts should be installed.

The

free pedal clearance is adjusted by lengthening

or shortening the" clutch fork cable. To make this adjustment,

loosen

the jam nut on the cable clevis

and

lengthen or shorten the cable to obtain %"

[19,05

mm.] free travel at the pedal pad, then

tighten the jam unit.

•

Clutch

Control Cable Type

Refer

to Fig. 1-2.

a.

With the clutch pedal pad against the floor

panel, (pedal up, clutch

engaged)

adjust ball ad

justing nut until slack is removed from the cable

and

the clutch throwout bearing contacts the clutch

pressure plate, release levers or diaphragm plate.

b. Back-off ball adjusting nut 2

V2

turns to obtain

approximately %"

[19,05

mm.] free travel.

Lock

hex nut.

FIG.

1-3—AUBURN

CLUTCH

ASSEMBLY —

HURRICANE F4 ENGINE 1—

Driven

Plate and Hub

2—

Pressure

Plate

3—

Pivot Pin

4—

Bracket

5—

Spring

Cup 6—

Pressure

Spring 7— Release

Lever

8—

Return

Spring

9—

Adjusting

Screw

10—

Jam

Nut 11—

Washer

Note:

Some older 'Jeep' vehicles may

develop

side

movement

of the clutch and brake pedals resulting

from wear of the pedals, shafts, and bushings. One way to

compensate

for this wear is to install a pedal

slack

adjuster kit 1-4.

CLUTCH

—

HURRICANE

F4

ENGINE

•

Auburn

Vehicles equipped with the Hurricane F4

engine

have a 9.25" [23,4 cm.] driven plate. The auburn clutch driving (pressure) plate assembly (Fig. 1-3)

has three pressure springs and three levers or

fingers.

1-5.

Clutch

Removal

When

necessary to remove the clutch,

follow

the procedures outlined in Section J for the removal

of the transmission and transfer case from the vehicle. Then remove the flywheel housing and use

the following procedures for removing the clutch assembly.

Note:

The F4

engine

may be removed from the

vehicle when inspecting or replacing the clutch.

Refer

to Section D for Hurricane F4

engine

removal and then

follow

the instructions given

below

to remove the clutch assembly.

a.

Mark

the clutch pressure plate and

engine

fly

wheel with a center punch so the clutch assembly

may be installed in the same position after adjust

ments

or replacement are completed.

b. Remove the clutch pressure plate bracket

bolts

equally, a little at a time, to prevent distortion and

to relieve the clutch springs evenly.

c. Remove the pressure plate assembly and driven

plate from the flywheel.

1-6.

Clutch

Pressure Plate and Disc Inspection

Inspect the pressure plate face for

cracks,

chips,

and

warpage.

Check

the pressure plate levers for

excessive

wear and the springs for breaks. If any of the

above

conditions exist, the

complete

pressure

plate must be replaced.

Check

the clutch disc for

excessive

wear,

loose

or damaged facings, broken

vibration damper springs and evidence of grease

or oil. If any of the

above

conditions exist, replace

the clutch disc.

1-7.

Clutch

Pressure Plate Adjustment —

Auburn

The

clutch pressure plate must be checked

before

installing a new or reconditioned clutch. The proper 11339

FIG.

1-4—CHECKING

AUBURN

CLUTCH

LEVER

ADJUSTMENT

1— Adjustment Gauge

2—

Fixture

Mounting Bolt

3—

Clutch

Fixture

227

Page 229 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

I

Note:

The clutch release bearing is lubricated at

time of assembly and no attempt should be made

to lubricate it Refer to Fig. 1-23 when lubricating

the clutch throwout bearing collar. c. Reassembly

To

assemble the clutch to the flywheel, first put

a

small amount of light cup grease in the flywheel

pilot bushing, install the driven plate, with short

end of hub toward the flywheel, then place the pressure plate assembly in position.

With

a clutch

plate aligning arbor or a spare transmission main

shaft, align the driven plate splines leaving the

arbor

in position while tightening the pressure plate

screws evenly.

Next, assemble the flywheel housing to the

engine

and

reinstall the transmission and transfer case or

install

the

engine

in the vehicle, depending on the

procedure of removal. Make sure that the clutch

release bearing

carrier

return spring is hooked in place. For the remainder of the assembly reverse

the operations that were used in removing the

transmission and transfer case or the

engine

referring

to the instructions given in Section J for the transmission and Section D and Dl for the

engine.

d.

Adjust the clutch control cable so there is 3A" [19,05 mm.] free pedal travel. (Refer to Par. 1-3)

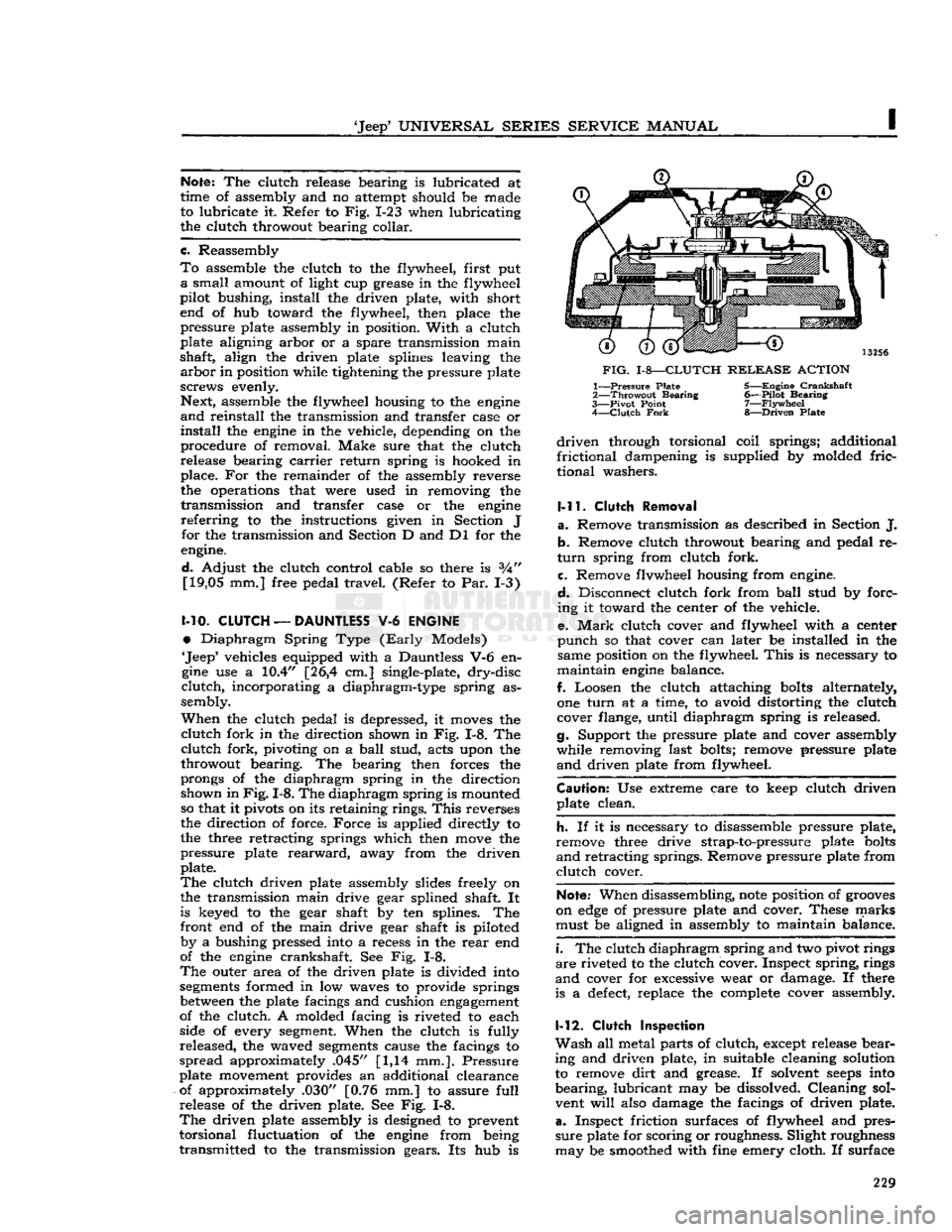

1-10.

CLUTCH

—

DAUNTLESS

V-6

ENGINE

•

Diaphragm Spring Type

(Early

Models)

*

Jeep' vehicles equipped with a Dauntless V-6 en

gine

use a 10.4" [26,4 cm.] single-plate, dry-disc

clutch,

incorporating a diaphragm-type spring as

sembly.

When

the clutch pedal is depressed, it

moves

the

clutch

fork in the direction shown in Fig. 1-8. The

clutch

fork, pivoting on a

ball

stud, acts upon the

throwout bearing. The bearing then forces the

prongs of the diaphragm spring in the direction shown in

Fig.

1-8. The diaphragm spring is mounted

so that it pivots on its retaining rings.

This

reverses

the direction of force.

Force

is applied directly to

the three retracting springs which then

move

the

pressure plate

rearward,

away from the driven plate.

The

clutch driven plate assembly slides freely on

the transmission main drive gear splined shaft. It is keyed to the gear shaft by ten splines. The

front end of the main drive gear shaft is piloted by a bushing pressed into a recess in the

rear

end

of the

engine

crankshaft. See Fig. 1-8.

The

outer area of the driven plate is divided into

segments

formed in low waves to provide springs

between

the plate facings and cushion

engagement

of the clutch. A molded facing is riveted to each

side of every

segment.

When the clutch is fully

released, the waved

segments

cause the facings to

spread

approximately .045" [1,14 mm.]. Pressure

plate movement provides an additional clearance

of approximately .030" [0.76 mm.] to assure

full

release of the driven plate. See Fig. 1-8.

The

driven plate assembly is designed to prevent

torsional fluctuation of the

engine

from being

transmitted to the transmission gears. Its hub is

FIG.

1-8—CLUTCH

RELEASE

ACTION

1—

Pressure

Plate 5—Engine

Crankshaft

2—

Throwout

Bearing

6—Pilot

Bearing

3—

Pivot

Point

7—Flywheel

4—

Clutch

Fork

8—Driven

Plate

driven

through torsional coil springs; additional

frictional

dampening is supplied by molded

fric-

tional washers.

1-11.

Clutch

Removal

a.

Remove transmission as described in Section J. b. Remove clutch throwout bearing and pedal re

turn

spring from clutch fork.

c. Remove flvwheel housing from engine.

d.

Disconnect clutch fork from

ball

stud by forc

ing it toward the center of the vehicle.

e.

Mark

clutch cover and flywheel with a center

punch

so that cover can later be installed in the same position on the flywheel.

This

is necessary to

maintain

engine

balance.

f. Loosen the clutch attaching

bolts

alternately,

one

turn

at a time, to avoid distorting the clutch

cover flange, until diaphragm spring is released.

g. Support the pressure plate and cover assembly

while removing last bolts; remove pressure plate

and

driven plate from flywheel.

Caution:

Use extreme care to keep clutch driven plate clean.

h.

If it is necessary to disassemble pressure plate,

remove three drive strap-to-pressure plate

bolts

and

retracting springs. Remove pressure plate from

clutch

cover.

Note:

When disassembling,

note

position of

grooves

on

edge

of pressure plate and cover. These marks must be aligned in assembly to maintain balance.

i.

The clutch diaphragm spring and two pivot rings

are

riveted to the clutch cover. Inspect spring, rings

and

cover for excessive wear or damage. If there

is a

defect,

replace the complete cover assembly.

1-12.

Clutch

inspection

Wash

all metal parts of clutch, except release bear

ing and driven plate, in suitable cleaning solution to remove

dirt

and grease. If solvent

seeps

into

bearing,

lubricant may be dissolved. Cleaning sol

vent

will

also damage the facings of driven plate,

a.

Inspect friction surfaces of flywheel and pres

sure

plate for scoring or roughness. Slight roughness

may be smoothed with fine emery cloth. If surface 229

Page 230 of 376

CLUTCH

is deeply scored or grooved, the part should be

replaced.

b. Inspect driven plate for wear or damage to fac

ings,

loose

rivets, broken or

loose

torsion springs,

and

flattened cushion springs. If facings are worn

near

rivets or are oily, replace the plate assembly.

A

slight amount of oil on clutch facings

will

cause

clutch

grab and chatter; excessive oil on facings

will

cause slippage. It is not practical to remove

oil

with solvents or by buffing since oil

will

con

tinue to bleed from facing material when hot. If

oil

is found on driven plate facings, examine trans

mission drainback hole, pilot bushing,

engine

rear

main

bearing and other points of possible oil leakage. Test the fit of driven plate hub on trans

mission main drive gear for an easy sliding fit.

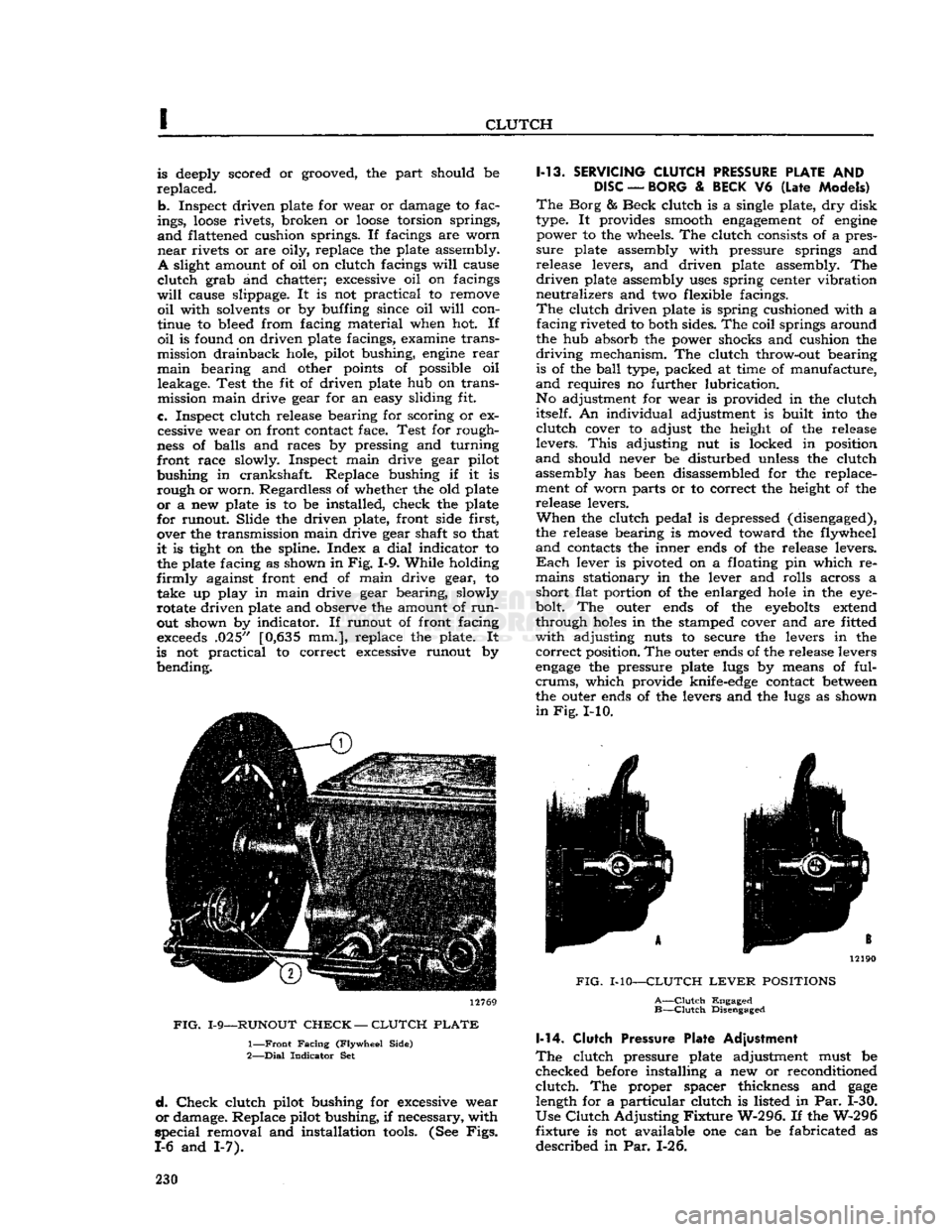

c. Inspect clutch release bearing for scoring or ex cessive wear on front contact face. Test for rough

ness

of balls and races by pressing and turning

front race slowly. Inspect main drive gear pilot

bushing in crankshaft. Replace bushing if it is rough or worn. Regardless of whether the old plate

or

a new plate is to be installed, check the plate

for runout. Slide the driven plate, front side first,

over the transmission main drive gear shaft so that

it

is tight on the spline. Index a

dial

indicator to the plate facing as shown in

Fig.

1-9. While holding

firmly

against front end of main drive gear, to take up play in main drive gear bearing, slowly

rotate driven plate and observe the amount of

run

out shown by indicator. If runout of front facing

exceeds

.025" [0,635 mm.], replace the plate. It

is not practical to correct excessive runout by bending. 12769

FIG.

1-9—RUNOUT

CHECK

—

CLUTCH

PLATE

1—

Front

Facing

(Flywheel

Side)

2—

Dial

Indicator

Set

d.

Check

clutch pilot bushing for excessive wear

or

damage. Replace pilot bushing, if necessary, with

special

removal and installation

tools.

(See

Figs.

1-6 and 1-7). 1-13.

SERVICING

CLUTCH

PRESSURE

PLATE

AND

DISC

—

BORG

&

BECK

V6

(Late

Models)

The

Borg & Beck clutch is a single plate, dry disk

type. It provides smooth

engagement

of

engine

power to the wheels. The clutch consists of a pres

sure

plate assembly with pressure springs and

release levers, and driven plate assembly. The

driven

plate assembly

uses

spring center vibration

neutralizes and two flexible facings.

The

clutch driven plate is spring cushioned with a facing riveted to both sides. The coil springs around

the hub absorb the power shocks and cushion the

driving

mechanism. The clutch throw-out bearing is of the

ball

type, packed at time of manufacture,

and

requires no further lubrication.

No adjustment for wear is provided in the clutch itself. An individual adjustment is built into the

clutch

cover to adjust the height of the release

levers.

This

adjusting nut is locked in position

and

should never be disturbed unless the clutch assembly has been disassembled for the replace

ment of worn parts or to correct the height of the release levers.

When

the clutch pedal is depressed (disengaged),

the release bearing is moved toward the flywheel

and

contacts the inner ends of the release levers.

Each

lever is pivoted on a floating pin which re

mains stationary in the lever and rolls across a short flat portion of the enlarged

hole

in the eye-

bolt. The outer ends of the

eyebolts

extend

through

holes

in the stamped cover and are fitted

with

adjusting nuts to secure the levers in the

correct

position. The outer ends of the release levers

engage

the pressure plate lugs by means of ful-

crums,

which provide knife-edge contact

between

the outer ends of the levers and the lugs as shown

in

Fig.

I-10. 12190

FIG.

MO—CLUTCH

LEVER

POSITIONS

A—Clutch

Engaged

B—Clutch

Disengaged 1-14.

Clutch

Pressure Plate Adjustment

The

clutch pressure plate adjustment must be

checked before installing a new or reconditioned

clutch.

The proper spacer thickness and

gage

length for a particular clutch is listed in Par. 1-30.

Use

Clutch

Adjusting

Fixture

W-296. If the W-296

fixture is not available one can be fabricated as

described in Par. 1-26. 230

Page 235 of 376

![JEEP DJ 1953 Workshop Manual

Jeep

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

sta JEEP DJ 1953 Workshop Manual

Jeep

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

sta](/img/16/57041/w960_57041-234.png)

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

stamped thereon.

c.

From

flat bar stock at least Vfe" [3 mm.] thick,

make a

gauge

as shown in Fig. 1-22. Harden, grind

to size, and stamp sizes on the

gauge.

1-27.

Clutch Installation

a.

Very

sparingly, apply wheel bearing lubricant

to inner surface of pilot bushing in crankshaft.

Caution:

If

excessive

lubricant is applied to pilot bushing, it

will

run out on face of flywheel when

hot and

ruin

the driven plate facings.

b. Make sure that splines in the driven plate hub

are

clean; apply a light coat of lubricant to splines

of hub and transmission drive gear shaft. Slide plate over gear shaft several times; remove plate

from shaft and wipe off

excess

lubricant.

Caution:

Driven plate facings must be kept clean

and

dry.

c.

Fill

groove

in throwout bearing collar with wheel bearing lubricant. See Fig. 1-23. Make sure

that front bearing retainer of transmission is clean;

apply a light coat of wheel bearing lubricant. Slide

throwout bearing over bearing retainer several times. Remove bearing from retainer and wipe off

excess

lubricant.

12736

FIG.

1-23—LUBRICATION

POINTS

—

CLUTCH

THROWOUT

BEARING

COLLAR

1—Coat

This

Groove 2—Pack

This

Recess

d.

Clean

and apply wheel bearing lubricant to ball

stud in flywheel housing and to the

seat

in clutch

fork.

e.

If disassembled, install pressure plate in the cover assembly, lining up the

groove

on its

edge

with the

groove

on the

edge

of the cover.

Install

pressure plate retracting springs, and the three

drive

strap-to-pressure plate

bolts

and lock washers.

Torque

bolts

11 lb-ft. [1,51 kg-m.].

Note:

The diaphragm

type

clutch assembly is fac

tory calibrated and requires no adjustment

before

installation. Refer to Par. 1-14 to adjust Borg and

Beck

coil spring

type

clutch assembly.

f.

Install

the pressure plate and driven plate on

flywheel. Support both assemblies with a spare

main

drive gear.

Note:

Be certain that

mark

on clutch cover is

aligned with the

mark

made on the flywheel during

clutch removal.

g.

Install

clutch attaching

bolts

and tighten alter nately so that clutch is drawn squarely

into

position

on flywheel.

Each

bolt

must be

tightened

one turn at a time to avoid bending the clutch cover flange.

Torque

bolts

30 to 40 lb-ft. [4,1 a 5,5 kg-m.].

h.

Lubricate

the ball stud and clutch fork with

wheel bearing lubricant and install clutch fork.

Note:

Be certain that fork retaining spring is

tight

on pivot ball stud.

i.

Install

flywheel housing on

engine

cylinder

block.

Caution:

Be certain that dowel pins are installed

in

cylinder block.

j.

Lubricate

the recess on the inside of the throw-

out bearing collar. Be careful not to use too much

lubricant.

See Fig. 1-23.

Caution:

Make certain that the lips of the spring

retainer (attached to the clutch fork) are in

groove

of the bearing. See Fig. 1-24.

k.

Install

throwout bearing assembly and connect

clutch linkage.

I.

Install

transmission as described in Section J. m. Adjust clutch for %"

[19,05

mm.] free travel,

see

Par.

1-3. 235

Page 237 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

I

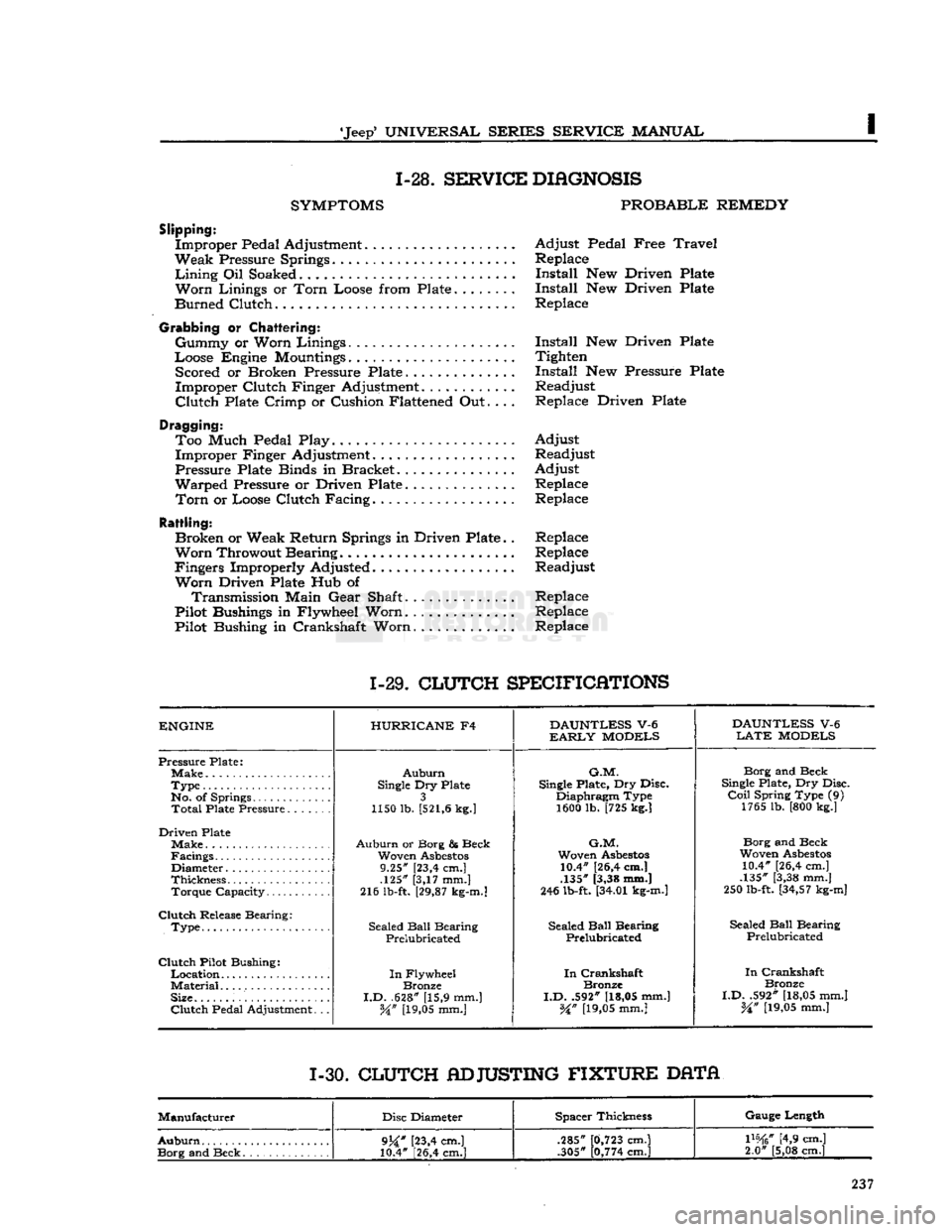

1-28.

SERVICE

DIAGNOSIS

SYMPTOMS

PROBABLE

REMEDY

Slipping:

Improper Pedal Adjustment Adjust Pedal Free

Travel

Weak Pressure Springs Replace

Lining

Oil Soaked Install New Driven Plate

Worn

Linings or

Torn

Loose from Plate Install New Driven Plate

Burned Clutch Replace

Grabbing

or

Chattering:

Gummy or Worn Linings Install New Driven Plate

Loose Engine

Mountings

Tighten Scored or Broken Pressure Plate Install New Pressure Plate

Improper Clutch Finger Adjustment............ Readjust

Clutch

Plate Crimp or Cushion Flattened Out.... Replace Driven Plate

Dragging: Too Much Pedal Play. Adjust Improper Finger Adjustment. Readjust

Pressure Plate Binds in Bracket Adjust

Warped Pressure or Driven Plate Replace

Torn

or Loose Clutch Facing. Replace

Rattling:

Broken or Weak Return Springs in Driven Plate.. Replace

Worn

Throwout Bearing Replace

Fingers Improperly Adjusted Readjust

Worn

Driven Plate Hub of Transmission Main Gear Shaft.............. Replace

Pilot Bushings in Flywheel Worn.

.............

Replace

Pilot Bushing in Crankshaft Worn Replace

1-29.

CLUTCH

SPECIFICATIONS

ENGINE

HURRICANE

F4

DAUNTLESS

V-6

DAUNTLESS

V-6

EARLY

MODELS

LATE

MODELS

Pressure Plate;

Auburn

G.M.

Borg and Beck

Type

Single

Dry Plate

Single

Plate, Dry Disc.

Single

Plate, Dry Disc.

No. of Springs 3 Diaphragm Type

Coil

Spring Type (9)

Total

Plate Pressure 1150 lb.

[521,6

kg.]

1600 lb. [725 kg.] 1765 lb. [800 kg.]

Driven Plate Make

Auburn

or Borg & Beck

G.M.

Borg and Beck

Facings Woven

Asbestos

Woven

Asbestos

Woven

Asbestos

Diameter 9.25" [23,4 cm.] 10.4" [26,4 cm.]

10.4" [26,4 cm.]

Thickness .125" [3,17 mm.] .135" [3,38 mm.]

.135" [3,38 mm.]

Torque Capacity 216 lb-ft.

[29,87

kg-m.]

246 lb-ft.

[34.01

kg-m.]

250 lb-ft.

[34,57

kg-m]

Clutch

Release Bearing: Sealed

Ball

Bearing

.

Type Sealed

Ball

Bearing Sealed

Ball

Bearing Sealed

Ball

Bearing

.

Type

Prelubricated Prelubricated

Prelubricated

Clutch

Pilot Bushing:

In

Crankshaft

In

Flywheel

In

Crankshaft

In

Crankshaft

Material

Bronze Bronze

Bronze

Size.

I.D.

.628" [15,9 mm.]

I.D.

.592"

[18,05

mm.]

I.D.

.592"

[18,05

mm.]

Clutch

Pedal Adjustment. .. W

[19,05

mm.]

%n

[19,05

mm.]

%n

[19,05

mm.]

1-30.

CLUTCH

ADJUSTING

FIXTURE

DATA

Manufacturer Disc Diameter Spacer Thickness Gauge Length

Auburn

9j£"

[23,4 cm.]

10.4" [26,4 cm.] .285"

.305"

0,723

cm.]

0,774

cm.]

mtf

[4,9 cm.]

2.0" [5,08 cm.]

9j£"

[23,4 cm.]

10.4" [26,4 cm.] .285"

.305"

0,723

cm.]

0,774

cm.]

mtf

[4,9 cm.]

2.0" [5,08 cm.]

Page 248 of 376

J

THREE-SPEED

TRANSMISSION

before

the unit is installed in the vehicle. When

doing this, use care that the countershaft and

reverse

idler shaft lock plate shown in Fig. J-8

is correctly positioned in the recess in the transfer case housing.

Three

\

Y%"

long [2,86 cm.] screws and

two 1" long [2,54 cm.] screws are used to attach the

transfer

case housing to the transmission housing.

Install

the 1" long [2,54 cm.] screws in the lower

left

and lower right mounting holes.

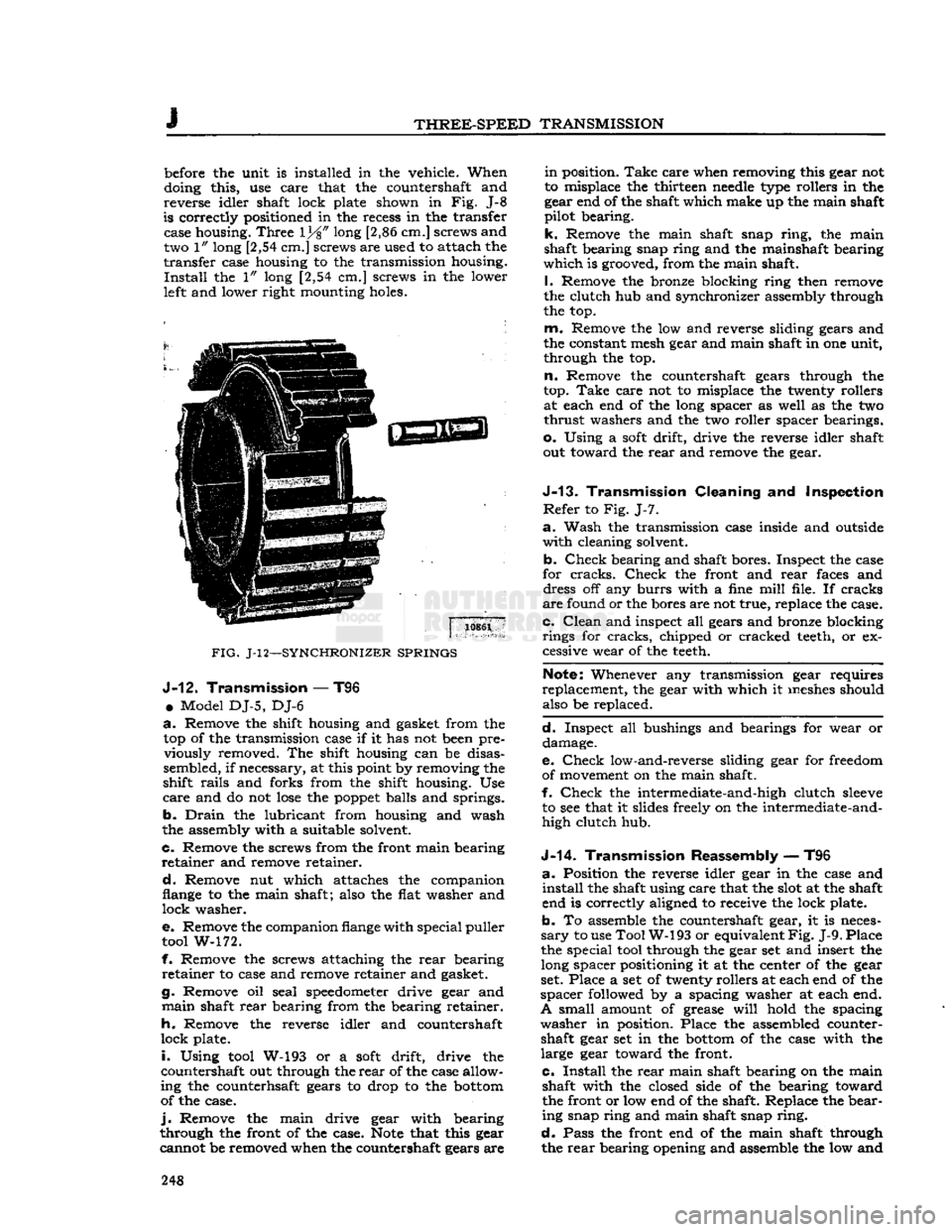

FIG.

J-12—SYNCHRONIZER

SPRINGS

J-12.

Transmission — T96

•

Model DJ-5, DJ-6

a.

Remove the shift housing and gasket from the top of the transmission case if it has not

been

pre viously removed. The shift housing can be disas

sembled, if necessary, at this point by removing the

shift

rails

and forks from the shift housing. Use

care

and do not

lose

the

poppet

balls and springs.

b.

Drain

the lubricant from housing and wash

the assembly with a suitable solvent.

c.

Remove the screws from the front main bearing

retainer

and remove retainer.

d.

Remove nut which attaches the companion

flange

to the main shaft; also the flat washer and

lock

washer.

e.

Remove the companion

flange

with special puller

tool

W-172.

f. Remove the screws attaching the

rear

bearing

retainer

to case and remove retainer and gasket.

g. Remove oil seal

speedometer

drive gear and

main

shaft

rear

bearing from the bearing retainer.

h.

Remove the reverse idler and countershaft

lock

plate.

i.

Using

tool

W-193 or a

soft

drift, drive the

countershaft out through the

rear

of the case allow

ing the counterhsaft gears to drop to the

bottom

of the case.

j.

Remove the main drive gear with bearing

through the front of the case.

Note

that this gear cannot be removed when the countershaft gears are

in

position.

Take

care when removing this gear not

to misplace the thirteen

needle

type

rollers in the

gear end of the shaft which make up the main shaft

pilot bearing.

k.

Remove the main shaft snap

ring,

the main

shaft bearing snap ring and the mainshaft bearing

which

is grooved, from the main shaft.

I.

Remove the bronze blocking ring then remove

the clutch hub and synchronizer assembly through

the top.

m.

Remove the low and reverse sliding gears and

the constant mesh gear and main shaft in one unit,

through the top.

n.

Remove the countershaft gears through the

top.

Take

care not to misplace the twenty rollers at each end of the long spacer as well as the two

thrust

washers and the two roller spacer bearings,

o.

Using a

soft

drift, drive the reverse idler shaft

out toward the

rear

and remove the gear.

J-13.

Transmission Cleaning and Inspection

Refer

to Fig. J-7.

a.

Wash the transmission case inside and

outside

with

cleaning solvent.

b.

Check

bearing and shaft bores. Inspect the case

for

cracks.

Check

the front and

rear

faces

and dress off any

burrs

with a fine

mill

file. If cracks

are

found or the bores are not true, replace the case.

c.

Clean

and inspect all gears and bronze blocking

rings

for

cracks,

chipped or cracked

teeth,

or ex

cessive wear of the

teeth.

Note:

Whenever any transmission gear requires

replacement, the gear with which it

meshes

should also be replaced.

d.

Inspect all bushings and bearings for wear or damage.

e.

Check

low-and-reverse sliding gear for freedom

of

movement

on the main shaft.

f.

Check

the intermediate-and-high clutch

sleeve

to see that it slides freely on the intermediate-and-

high clutch hub.

J-14. Transmission Reassembly

—-

T96

a.

Position the reverse idler gear in the case and

install

the shaft using care that the

slot

at the shaft

end is correctly aligned to receive the lock plate.

b.

To assemble the countershaft gear, it is neces

sary

to use Tool W-193 or equivalent

Fig. J-9.

Place

the special

tool

through the gear set and insert the

long spacer positioning it at the center of the gear

set. Place a set of twenty rollers at each end of the

spacer

followed by a spacing washer at each end.

A

small amount of grease

will

hold the spacing

washer

in position. Place the assembled counter shaft gear set in the

bottom

of the case with the

large gear toward the front.

C*

Install

the

rear

main shaft bearing on the main shaft with the closed side of the bearing toward

the front or low end of the shaft. Replace the bear

ing snap ring and main shaft snap

ring,

d.

Pass the front end of the main shaft through the

rear

bearing opening and assemble the low and 248

Page 249 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

reverse sliding gear on the shaft with the shifting

fork

groove

toward the rear.

e. Assemble the

second

speed

gear on the shaft

with the

teeth

which

engage

in the clutch

sleeve

toward the front of the case.

f.

Next,

assemble

the synchronizer unit. The as sembly

sequence

of the synchronizer is shown in

Fig.

J-12.

First

install the two springs in the high

and intermediate clutch hub. These springs must

be installed with the spring

tension

opposed.

Place the right lipped end of a spring in a

slot

of the

hub and place the spring in the hub.

Turn

the hub

around and make exactly the same installation

with the other spring starting with the same

slot.

Fig.

J-5. Install the three synchronized shifting

plates

in the three

slots

in the hub with the

smooth

side

of the

plates

out. Hold the

plates

in

position

and slip the

second

and direct

speed

clutch

sleeve

over the hub. Install the two blocking rings one

one each

side

of the hub.

g. Place

some

heavy

grease

in the main shaft

pilot and

position

the thirteen

needle

type

roller bearings.

h.

Install the main drive gear. If the bearing has

been

removed,

note

that the closed

side

is assembled

toward the inside of the case.

i.

Enter

the main shaft bearing in the case and

assemble

the shaft in position.

j.

Install the front bearing retainer. k. For

ease

in installing the countershaft, turn the

transmission case over to allow the gears to mesh.

With

the countershaft thrust washers correctly

positioned,

start the countershaft through the rear

of the case with the lock plate

slot

toward the rear

and the

slot

in alignment with the

slot

in the

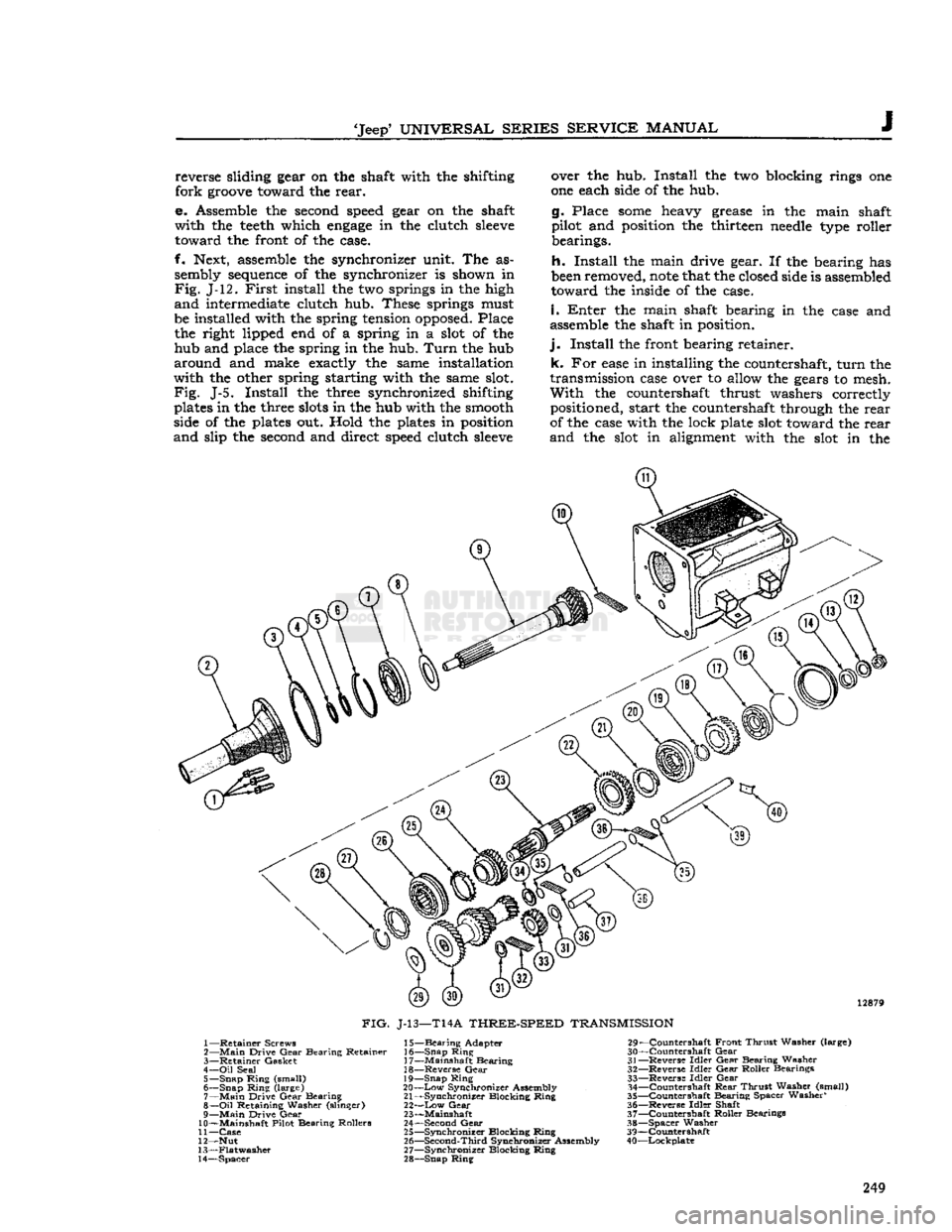

12879

FIG.

J-13—T14A

THREE-SPEED

TRANSMISSION

1—

Retainer

Screws

2—

Main

Drive

Gear

Bearing Retainer

3—

Retainer

Gasket

4—

Oil

Seal 5— Snap Ring (small)

6— Snap Ring (large) 7—

Main

Drive

Gear

Bearing

8—

Oil

Retaining Washer (slinger)

9—

Main

Drive

Gear

10— Mainshaft Pilot Bearing Rollers

11—

Case

12— Nut

13—

Flatwasher

14— Spacer 15—

Bearing

Adapter

16— Snap Ring

17—

Mainshaft Bearing

18— Reverse

Gear

19— Snap Ring

20—

Low

Synchronizer Assembly 21— Synchronizer Blocking Ring 22—

Low

Gear

23— Mainshaft

24— Second

Gear

25— Synchronizer Blocking Ring

26—

Second-Third

Synchronizer Assembly

27— Synchronizer Blocking Ring

28— Snap Ring 29— Countershaft Front Thrust Washer (large)

30— Countershaft

Gear

31— Reverse Idler

Gear

Bearing Washer

32— Reverse Idler

Gear

Roller Bearings 33— Reverse Idler

Gear

34— Countershaft

Rear

Thrust Washer (small)

35— Countershaft Bearing Spacer Washer* 36— Reverse Idler Shaft

37— Countershaft Roller Bearings

38— Spacer Washer

39— Countershaft

40—

Lockplate

249

Page 256 of 376

THREE-SPEED

TRANSMISSION

ing

snap

ring.

Care should be taken to

install

the

proper

snap

ring

at

these

locations.

fl.

Install

the mainshaft rear bearing

adapter,

spacer,

transfer

case

drive

gear,

flat

washer, and

nut.

Torque nut 130 to 170

lb-ft.

[17,9 a 23,5

kg-m.].

Refer to Fig. J-15.

o. Check the main drive bearing retainer oil seal.

If

seal is

worn

or damaged it must be replaced.

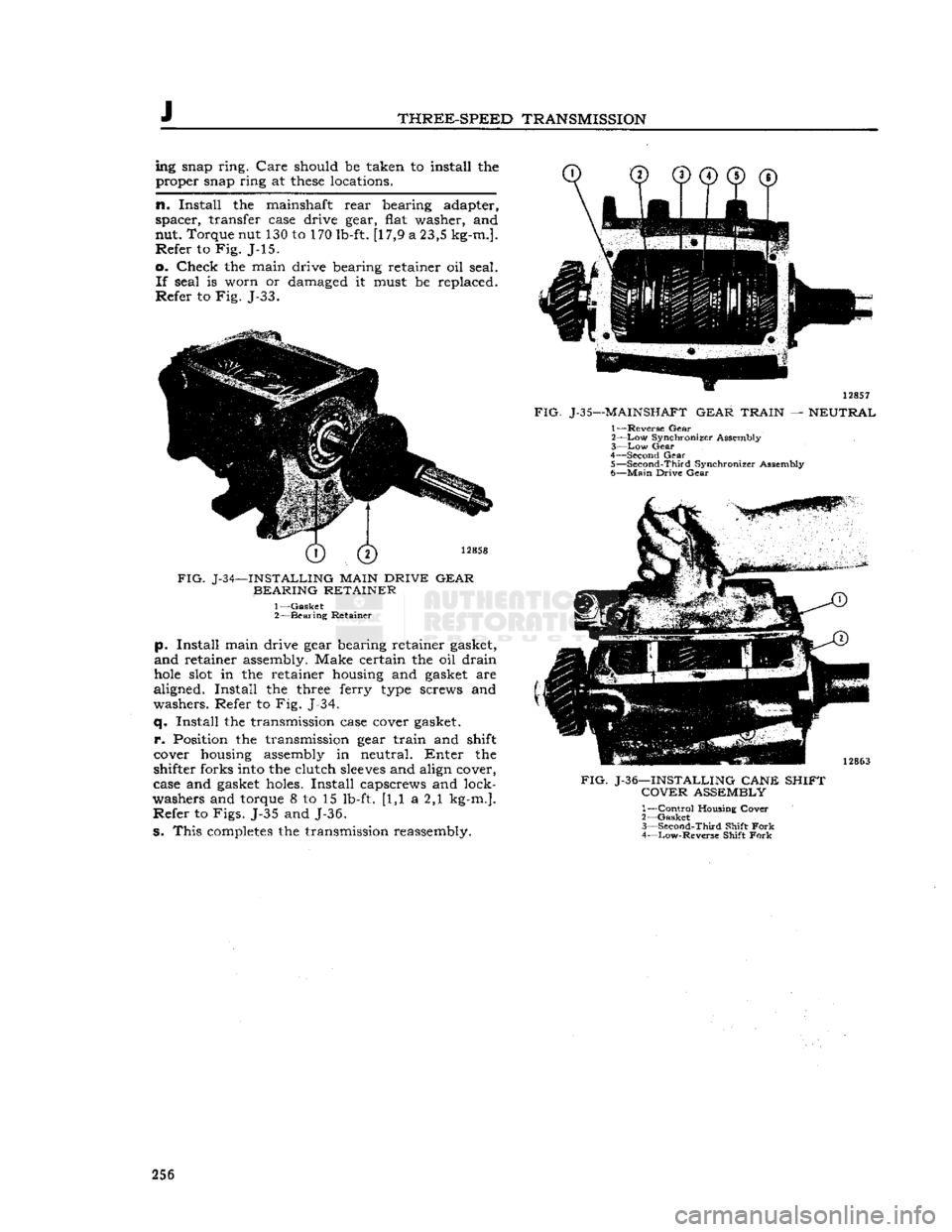

Refer to Fig. J-33. 12858

FIG.

J-34—INSTALLING

MAIN

DRIVE GEAR BEARING RETAINER

-Gasket

-Bearing

Retainer

p.

Install

main drive

gear

bearing retainer gasket,

and retainer assembly. Make certain the oil drain

hole

slot in the retainer housing and gasket are

aligned.

Install

the three

ferry

type screws and

washers. Refer to Fig. J-34.

q.

Install

the transmission

case

cover gasket,

p.

Position the transmission

gear

train

and

shift

cover housing assembly in neutral. Enter the

shifter

forks

into

the

clutch

sleeves

and

align

cover,

case

and gasket holes.

Install

capscrews and

lock

washers

and torque 8 to 15

lb-ft.

[1,1 a 2,1

kg-m.].

Refer to Figs. J-35 and J-36.

S.

This completes the transmission reassembly. 12857

FIG.

J-35—MAINSHAFT

GEAR TRAIN

—

NEUTRAL

1— Reverse Gear

2— Low

Synchronizer Assembly

3— Low

Gear

4— Second Gear

5—

Second-Third

Synchronizer Assembly

6—

Main

Drive

Gear

FIG.

J-36—INSTALLING CANE SHIFT

COVER

ASSEMBLY

1—

Control

Housing'

Cover•''

2—

Gasket

3—

Second-Third

Shift

Fork

4— Low-Reverse

Shift

Fork 256

Page 257 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

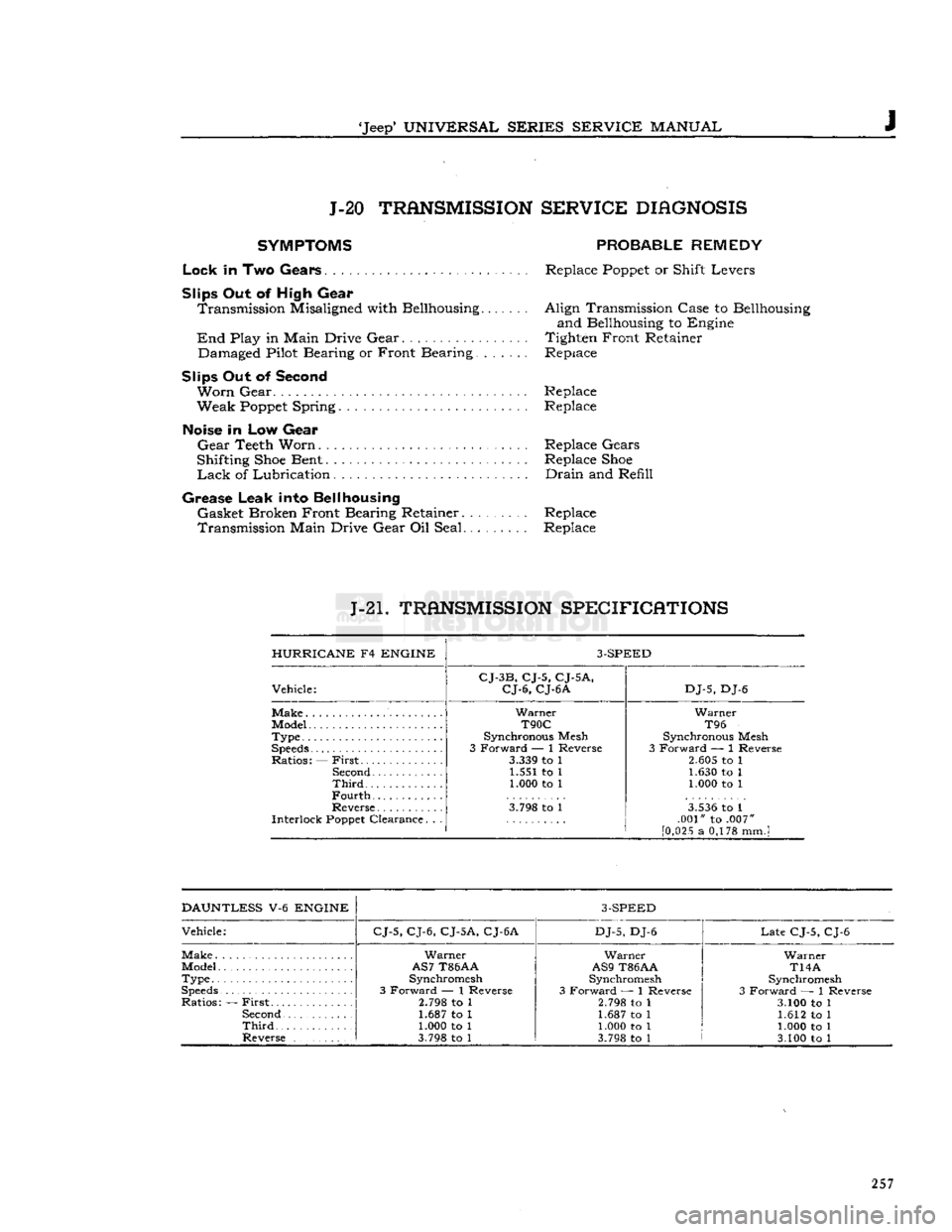

J J-20

TRANSMISSION

SERVICE

DIAGNOSIS

SYMPTOMS

PROBABLE

REMEDY

Lock

in Two

Gears

Replace

Poppet

or Shift Levers

Slips

Out of High Gear Transmission Misaligned with Bellhousing

End

Play in Main Drive Gear Damaged Pilot Bearing or Front Bearing.

Slips

Out of Second

Worn

Gear Replace

Weak

Poppet

Spring Replace

Noise

in Low Gear

Gear

Teeth Worn Replace Gears

Shifting

Shoe

Bent Replace

Shoe

Lack

of Lubrication Drain and Refill

Grease

Leak into Bellhousing Gasket Broken Front Bearing Retainer Replace

Transmission Main Drive Gear Oil Seal Replace Align Transmission Case to Bellhousing

and Bellhousing to Engine

Tighten Front Retainer

Replace

J-21.

TRANSMISSION

SPECIFICATIONS

HURRICANE

F4

ENGINE

3-SPEED

Vehicle:

CJ-3B,

CJ-5,

CJ-5A,

CJ-6,

CJ-6A

DJ-5,

DJ-6

Make

Type

Speeds

Ratios: —

First

Second

Third

Fourth

Warner

T90C

Synchronous Mesh

3 Forward — 1 Reverse

3.339

to 1 1.551 to 1 1.000 to 1

Warner

T96

Synchronous Mesh

3 Forward — 1 Reverse

2.605

to 1 1.630 to 1

1.000 to 1

Reverse

Interlock

Poppet

Clearance. . .

3.798

to 1

3.536

to 1

.001" to .007"

[0,025

a 0,178 mmJ

DAUNTLESS

V-6

ENGINE

3-SPEED

Vehicle:

CJ-5,

CJ-6,

CJ-5A,

CJ-6A

DJ-5,

DJ-6

Late

CJ-5, CJ-6

Make

Warner

Warner Warner

Model

AS7

T86AA

AS9

T86AA

T14A

Type..

Synchromesh

Synchromesh Synchromesh

Speeds

3 Forward — 1 Reverse 3 Forward — 1 Reverse 3 Forward — 1 Reverse

Ratios: —

First

2.798

to 1

2.798

to 1

3.100 to 1

Second

1.687 to 1 1.687 to 1 1.612 to 1

Third

1.000 to 1

1.000 to 1 1.000 to 1

Reverse

3.798

to 1

3.798

to 1 3.100 to 1 257