oil type JEEP DJ 1953 Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 266 of 376

Jl

FOUR-SPEED

TRANSMISSION

Jl-9.

TRANSMISSION

SER¥ICE

DIAGNOSIS

SYMPTOMS

Lock

In Two Gears

Slips

Out of High Gear Transmission Misaligned with Bellhousing

End

Play in Main Drive Gear Damaged Pilot Bearing or Front Bearing.

Slips Out of

Second

Worn

Gear

Weak

Poppet

Spring

PROBABLE

REMEDY

Replace

Poppet

or Shift Levers

Align Transmission Case to Bellhousing and Bellhousing to Engine

Tighten Front Retainer Replace

Replace Replace

Noise

in Low Gear

Gear

Teeth Worn. Replace Gears

Shifting

Shoe

Bent Replace

Shoe

Lack

of Lubrication Drain and Refill

Grease

Leak into Bellhousing Gasket Broken Front Bearing Retainer......... Replace Transmission Main Drive Gear Oil Seal Replace

Jl-10.

TRANSMISSION

SPECIFICATIONS

HURRICANE

F4

ENGINE

4-SPEED

Vehicle:

CJ-5,

CJ-6

Warner

T98A

Type..

• Synchronous Mesh

4 Forward — 1 Reverse

Ratios: —

First

. .

6.398

to 1

Second

3.092

to 1

Third

1.686 to 1

Fourth

1.000 to 1

7.820

to 1

DAUNTLESS

V-6

ENGINE

4-SPEED

Vehicle:

Late

CJ-5 Only

Warner

Model T-18

Type Synchromesh

4 Forward — 1 Reverse

Ratios: —

First

4.02 to 1

Second

2.41 to 1

Third

1.41 to 1

Fourth

1.00 to 1

Reverse 4.73 to 1 266

Page 277 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

m

FRONT fiXLE

Contents

SUBJECT

PAR.

GENERAL.

M-l

4-WHEEL DRIVE FRONT

AXLE.

M-2

Maintenance

Requirements M-3

FRONT AXLE REMOVAL

.M-4

AXLE

SHAFT REMOVAL

M-5

REMOVING

AND

OVERHAULING

DIFFERENTIAL

.M-6

AXLE

SHAFT UNIVERSAL JOINT SERVICE

M-7

STEERING

KNUCKLE SERVICE

M-8

Replacing

Steering

Knuckle

Oil Seal M-10

M-1. GENERAL

The

front axle for all 'Jeep* Universal models,

which

have 4-wheel drive, is described in

Par.

M-2.

The

front axle for all DJ-5, DJ-6 models, which

have 2-wheel drive, is described in

Par.

M-l5.

M-2. 4-WHEEL-DRIVE FRONT AXLE

The

front axle is a live driving unit with hypoid

type

driving gears and spherical steering knuckles mounted m pivot pins which ride on tapered roller bearings for

ease

of steering. The drive is of the

full

floating

type

through axle shafts built integrally

with

cardan cross universal joints which revolve in the steering knuckles. The steering knuckle tie rod

arm

is made integrally with the knuckle. The

knuckles

are connected by a divided tie rod to a steering bell

crank.

A steering connecting rod con

nects

the bell

crank

to the steering gear arm. The

divided

tie rod is adjustable and the

toe-in

of each

front wheel is adjusted independently.

Camber

and

SUBJECT

PAR.

REASSEMBLY

AND

BEARING PRELOAD

M-9

AXLE

SHAFT INSTALLATION

M-ll

FRONT AXLE INSTALLATION........

.M-l2

Turning

Angle Adjustment . .M-14

Steering

Tie Rod and

Beilcrank

M-l3

2-WHEEL DRIVE FRONT AXLE

M-15

Removal

of Solid

Front

Axle M-l6

Steering

Knuckle

Service M-l7

Steering

Knuckle

Pin Replacement. ......M-l8

SERVICE

DIAGNOSIS

M-19

AXLE

SPECIFICATIONS.

M-20

caster

of the front

wheels

is preset.

Camber

cannot

be altered but caster can be adjusted by installing

caster

shims

between

the axle pad and the springs.

For

information on the steering

geometry

see

"Steering

Section."

Service

procedures given in this section include

the removal, installation, disassembly and assembly

of the Model

27AF

front axle assembly, the axle

shafts, steering knuckles, and

universal

joints.

Note:

All service replacement axle assemblies are

shipped from the factory without lubricant in the

differential.

Lubricant

must be added; use grade

and

quantity as specified in the lubrication chart (Section B).

M-3.

Maintenance Requirements

A

spring-loaded breather is located on the top of

the differential housing.

Each

time the differential

lubricant

is checked, the breather should be

Page 279 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

m f. Disconnect propeller shaft from the differential

companion flange.

g.

Disconnect both front springs from front spring hangers.

h.

Remove spring clip and spring clip plates secur

ing axle to front springs.

i.

Remove front

wheels

from axle assembly.

j.

Lower

jack

slightly and

pull

axle forward from

under

vehicle.

M-5.

FRONT AXLE SHAFT REMOVAL

Refer

to Fig. M-2.

The

following procedure applies to either right or

left

front axle shaft.

Note:

Axle shafts can be removed without remov

ing the axle housing from the vehicle. Use the fol

lowing procedure.

First

raise and support front end

of vehicle, and remove front wheels.

a.

Remove drive

flange

snap

ring.

b-

Remove the hub cap with a puller as shown in

Fig.

M-3.

c.

Remove the axle shaft driving

flange

bolts.

d.

Apply the

foot

brakes and remove the axle shaft

flange

with puller W-163 as illustrated in

Fig.

M-4.

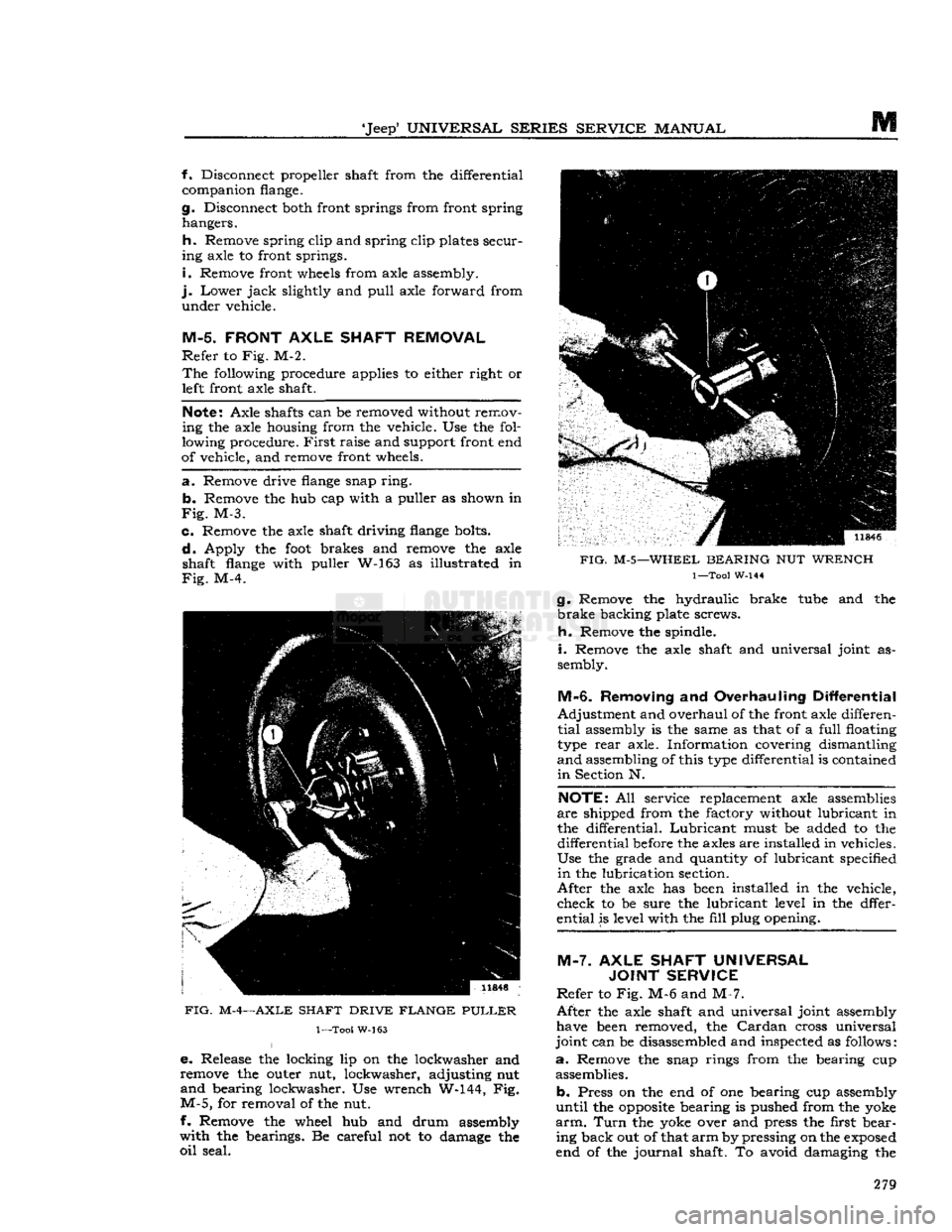

FIG.

M-4—AXLE

SHAFT

DRIVE

FLANGE

PULLER

1—Too!

W-163

e.

Release the locking lip on the lockwasher and

remove the outer nut, lockwasher, adjusting nut

and

bearing lockwasher. Use wrench W-144, Fig.

M-5,

for removal of the nut.

f- Remove the wheel hub and drum assembly

with

the bearings. Be careful not to damage the

oil

seal.

FIG.

M-5—WHEEL

BEARING

NUT

WRENCH

1—Tool

W-144

g.

Remove the hydraulic brake

tube

and the

brake

backing plate screws.

h.

Remove the spindle.

i.

Remove the axle shaft and universal joint as

sembly.

M-6.

Removing

and

Overhauling Differential

Adjustment

and overhaul of the front axle differen

tial

assembly is the same as that of a

full

floating

type

rear

axle. Information covering dismantling

and

assembling of this

type

differential is contained

in

Section N.

NOTE:

All service replacement axle assemblies

are

shipped from the factory without lubricant in

the differential.

Lubricant

must be added to the

differential

before

the axles are installed in vehicles.

Use

the grade and quantity of lubricant specified

in

the lubrication section.

After

the axle has

been

installed in the vehicle,

check

to be sure the lubricant level in the dffer-

ential

is level with the

fill

plug opening.

M-7.

AXLE SHAFT UNIVERSAL JOINT SERVICE

Refer

to Fig. M-6 and M-7.

After

the axle shaft and universal joint assembly have

been

removed, the

Cardan

cross universal

joint

can be disassembled and inspected as follows:

a.

Remove the snap rings from the bearing cup assemblies.

b.

Press on the end of one bearing cup assembly

until

the

opposite

bearing is pushed from the yoke

arm.

Turn

the yoke over and press the first bear ing back out of that

arm

by pressing on the

exposed

end of the

journal

shaft. To avoid damaging the 279

Page 282 of 376

FRONT

AXLE

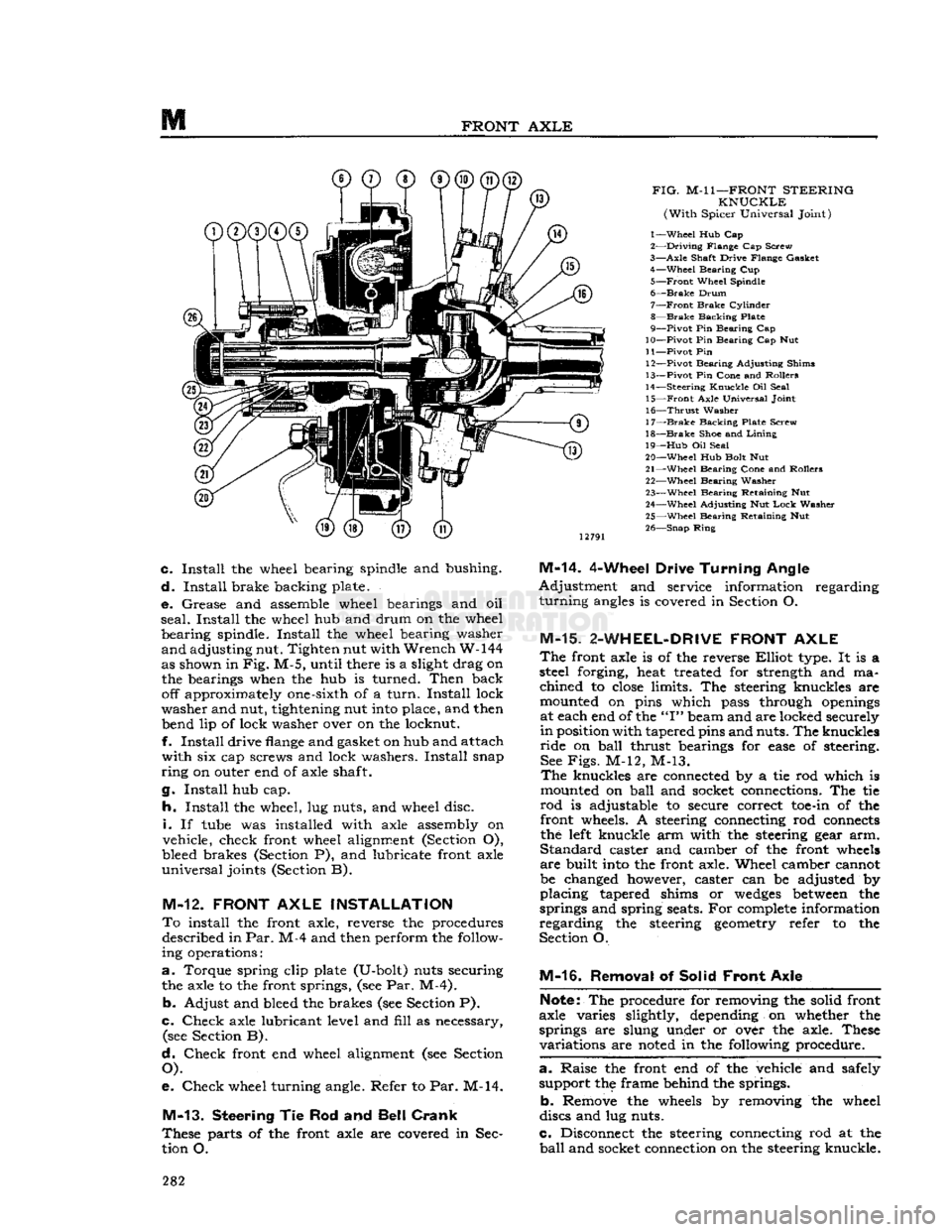

FIG.

M-l

1—FRONT

STEERING

KNUCKLE

(With

Spicer Universal Joint)

1—

Wheel

Hub Cap

2—

Driving

Flange Cap Screw

3—

Axle

Shaft Drive Flange Gasket 4—

Wheel

Bearing Cup

5—

Front

Wheel Spindle

6—

Brake

Drum

7—

Front

Brake

Cylinder

8—

Brake

Backing Plate

9—

Pivot

Pin Bearing Cap

10—

Pivot

Pin Bearing Cap Nut

11—

Pivot

Pin 12—

Pivot

Bearing Adjusting Shims

13—

Pivot

Pin Cone and Rollers

14—

Steering

Knuckle

Oil Seal 15—

Front

Axle Universal Joint

16—

Thrust

Washer

17—

Brake

Backing Plate Screw

18—

Brake

Shoe and

Lining

19—

Hub

Oil Seal

20—

Wheel

Hub Bolt Nut

21—

Wheel

Bearing Cone and Rollers 22—

Wheel

Bearing Washer

23—

Wheel

Bearing Retaining Nut

24—

Wheel

Adjusting Nut

Lock

Washer

25—

Wheel

Bearing Retaining Nut

26—

Snap

Ring

c.

Install

the wheel bearing spindle and bushing.

d.

Install

brake backing plate.

e.

Grease and assemble wheel bearings and oil

seal.

Install

the wheel hub and drum on the wheel

bearing

spindle.

Install

the wheel bearing washer

and

adjusting nut. Tighten nut with

Wrench

W-144

as shown in

Fig.

M-5, until there is a slight drag on the bearings when the hub is turned.

Then

back off approximately one-sixth of a

turn.

Install

lock

washer

and nut, tightening nut

into

place, and then bend lip of lock washer over on the locknut.

f.

Install

drive

flange

and gasket on hub and attach

with

six cap screws and lock washers.

Install

snap

ring

on outer end of axle shaft.

g.

Install

hub cap.

h.

Install

the wheel, lug nuts, and wheel disc.

i.

If

tube

was installed with axle assembly on

vehicle, check front wheel alignment (Section O),

bleed brakes (Section P), and lubricate front axle

universal

joints (Section B).

M-12.

FRONT

AXLE

INSTALLATION

To

install the front axle, reverse the procedures described in

Par.

M-4 and then perform the follow

ing operations:

a.

Torque spring clip plate (U-bolt) nuts securing the axle to the front springs, (see Par. M-4).

b.

Adjust and bleed the brakes (see Section P).

c.

Check

axle lubricant level and

fill

as necessary, (see Section B).

d.

Check

front end wheel alignment (see Section

O).

e.

Check

wheel turning angle. Refer to Par. M-14.

M-13.

Steering

Tie Rod and

Bell Crank

These

parts of the front axle are covered in Sec

tion O.

M-14.

4-Wheel Drive

Turning

Angle

Adjustment

and service information regarding

turning

angles

is covered in Section O.

M-15.

2-WHEEL-DRIVE

FRONT

AXLE

The

front axle is of the reverse

Elliot

type. It is a

steel forging, heat treated for strength and ma

chined

to

close

limits. The steering knuckles are

mounted on pins which pass through

openings

at each end of the

"I"

beam and are locked securely

in

position with tapered pins and nuts. The knuckles

ride

on

ball

thrust bearings for

ease

of steering. See

Figs.

M-12, M-13.

The

knuckles are connected by a tie rod which is

mounted on

ball

and socket connections. The tie

rod

is adjustable to secure correct

toe-in

of the front wheels. A steering connecting rod

connects

the

left

knuckle arm with the steering gear arm.

Standard

caster and camber of the front

wheels

are

built

into

the front axle. Wheel camber cannot

be changed however, caster can be adjusted by

placing

tapered shims or

wedges

between

the

springs and spring seats. For

complete

information

regarding

the steering

geometry

refer to the

Section O.

M-16.

Removal of Solid

Front

Axle

Note:

The procedure for removing the solid front

axle varies slightly, depending on whether the

springs are slung under or over the axle. These

variations

are

noted

in the following procedure.

a. -

Raise the front end of the vehicle and safely support the frame behind the springs.

b.

Remove the

wheels

by removing the wheel

discs and lug nuts.

c.

Disconnect the steering connecting rod at the

ball

and socket connection on the steering knuckle. 282

Page 290 of 376

N

REAR

AXLE

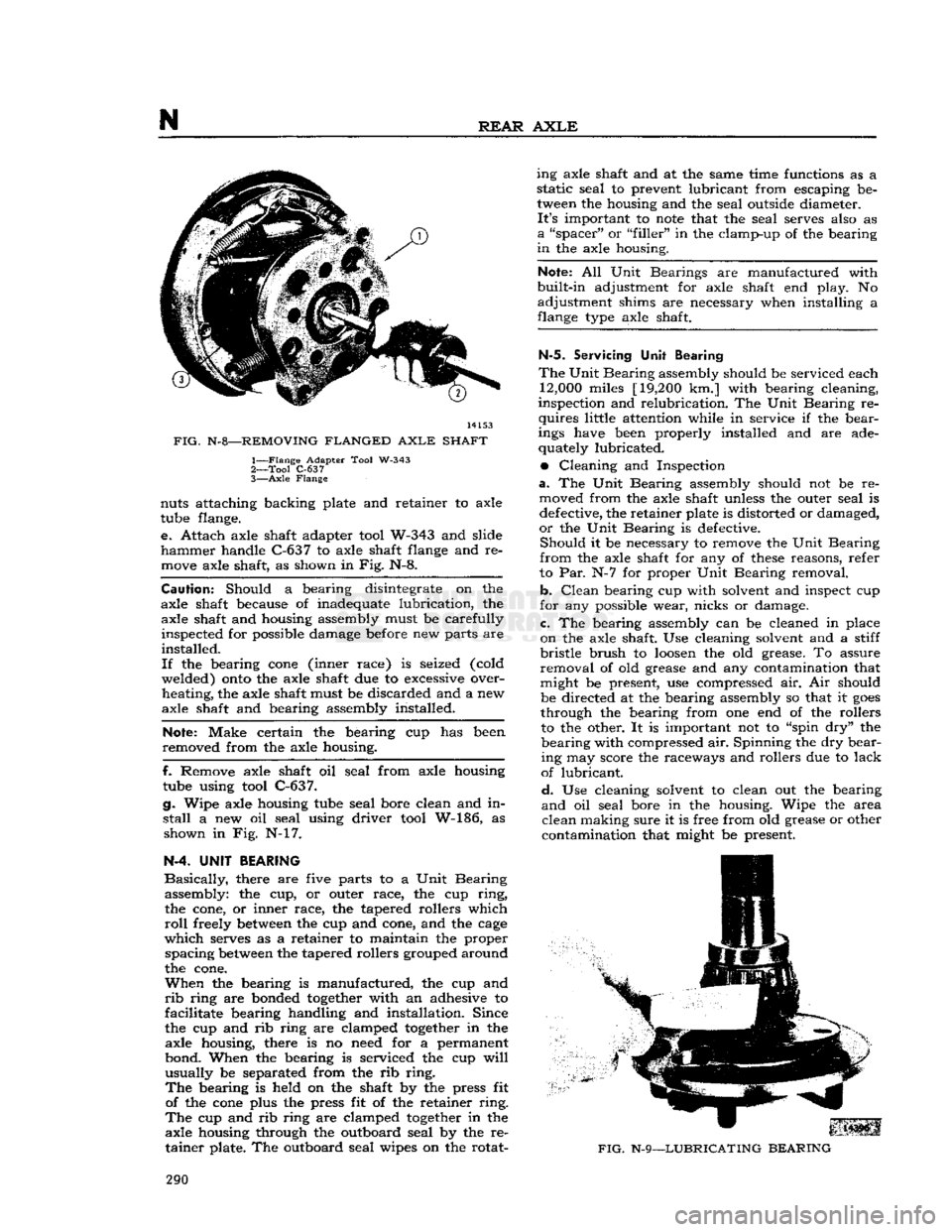

14153

FIG.

N-8—REMOVING FLANGED

AXLE

SHAFT

1—

Flange

Adapter Tool W-343

2—

Tool

C-637

3—

Axle

Flange nuts attaching backing plate and retainer to axle

tube flange.

e. Attach axle shaft adapter tool W-343 and slide

hammer

handle C-637 to axle shaft flange and re

move

axle shaft, as shown in Fig. N-8.

Caution:

Should a bearing disintegrate on the

axle shaft because of inadequate lubrication, the axle shaft and housing assembly must be carefully inspected for possible damage before new parts are

installed.

If

the bearing

cone

(inner race) is seized (cold

welded)

onto

the axle shaft due to excessive over heating, the axle shaft must be discarded and a new

axle shaft and bearing assembly installed.

Note:

Make certain the bearing cup has been

removed from the axle housing.

f. Remove axle shaft oil seal from axle housing tube using tool C-637.

g. Wipe axle housing tube seal bore clean and in

stall

a new oil seal using driver tool W-186, as shown in Fig. N-l7.

N-4.

UNIT BEARING

Basically,

there are five parts to a Unit Bearing assembly: the cup, or outer race, the cup

ring,

the cone, or inner race, the tapered rollers which

roll

freely

between

the cup and cone, and the

cage

which

serves as a retainer to maintain the proper spacing

between

the tapered rollers grouped around

the cone.

When

the bearing is manufactured, the cup and

rib

ring are bonded

together

with an adhesive to

facilitate bearing handling and installation. Since the cup and rib ring are clamped

together

in the axle housing, there is no need for a permanent

bond. When the bearing is serviced the cup

will

usually

be separated from the rib

ring.

The

bearing is held on the shaft by the press fit of the

cone

plus the press fit of the retainer

ring.

The

cup and rib ring are clamped

together

in the axle housing through the outboard seal by the re

tainer

plate. The outboard seal wipes on the rotat ing axle shaft and at the same time functions as a

static seal to prevent lubricant from escaping be

tween the housing and the seal outside diameter.

It's

important to

note

that the seal serves also as

a

"spacer" or "filler" in the clamp-up of the bearing

in

the axle housing.

Note:

All Unit Bearings are manufactured with

built-in

adjustment for axle shaft end play. No adjustment shims are necessary when installing a

flange type axle shaft.

N-5.

Servicing Unit Bearing

The

Unit

Bearing

assembly should be serviced each

12,000

miles [

19,200

km.] with bearing cleaning,

inspection and relubrication. The Unit Bearing re

quires

little attention while in service if the bear

ings have been properly installed and are ade

quately lubricated.

•

Cleaning and Inspection

a.

The Unit Bearing assembly should not be re moved from the axle shaft unless the outer seal is defective, the retainer plate is distorted or damaged,

or

the Unit Bearing is defective.

Should

it be necessary to remove the Unit Bearing

from

the axle shaft for any of

these

reasons, refer

to Par. N-7 for proper Unit Bearing removal.

b.

Clean

bearing cup with solvent and inspect cup

for any possible wear, nicks or damage.

c.

The bearing assembly can be cleaned in place

on the axle shaft. Use cleaning solvent and a stiff

bristle

brush to

loosen

the old grease. To assure

removal

of old grease and any contamination that

might be present, use compressed air. Air should be directed at the bearing assembly so that it

goes

through the bearing from one end of the rollers to the other. It is important not to "spin dry" the

bearing

with compressed

air.

Spinning the dry bearing may score the raceways and rollers due to

lack

of lubricant.

d.

Use cleaning solvent to clean out the bearing

and

oil seal bore in the housing. Wipe the area

clean

making sure it is free from old grease or other

contamination that might be present.

FIG.

N-9—LUBRICATING BEARING

290

Page 294 of 376

N

REAR AXLE

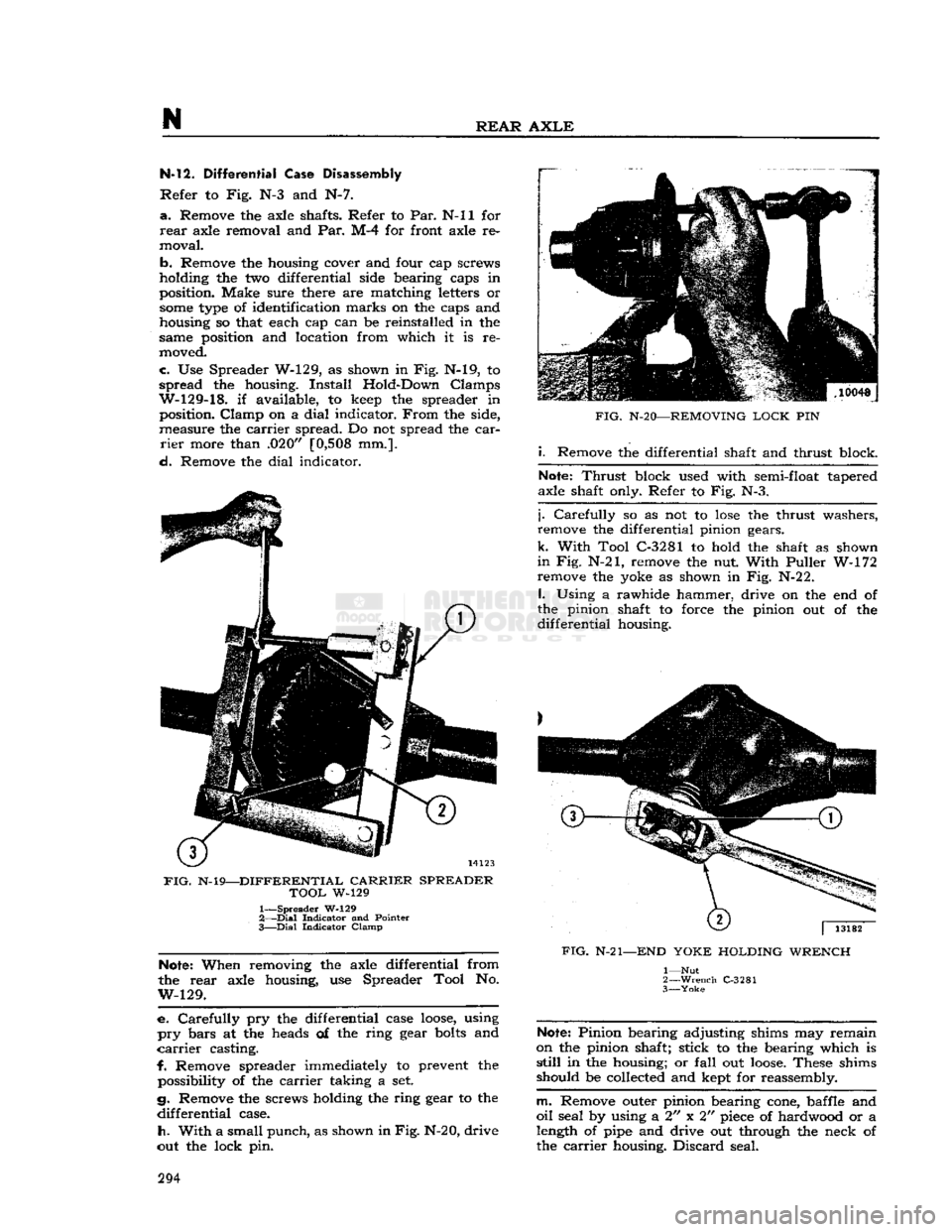

N-l2.

Differential Case

Disassembly

Refer

to

Fig.

N-3 and N-7.

a.

Remove

the

axle shafts. Refer

to

Par.

N-ll for

rear

axle removal

and

Par.

M-4 for

front axle

re

moval.

b.

Remove

the

housing cover

and

four

cap

screws

holding

the two

differential side bearing caps

in

position. Make sure there

are

matching letters

or

some

type

of

identification marks

on the

caps

and

housing

so

that each

cap can be

reinstalled

in the

same position

and

location from which

it is re

moved.

c.

Use

Spreader W-129,

as

shown

in

Fig. N-l9,

to

spread

the

housing.

Install

Hold-Down Clamps

W-129-18.

if

available,

to

keep

the

spreader

in

position.

Clamp

on a

dial

indicator.

From

the

side,

measure

the

carrier

spread.

Do not

spread

the

car

rier

more than

.020"

[0,508

mm.].

d.

Remove

the

dial

indicator.

FIG.

N-19—DIFFERENTIAL

CARRIER

SPREADER

TOOL

W-129

1—

Spreader

W-129

2—

Dial

Indicator

and

Pointer

3—

Dial

Indicator

Clamp

Note:

When removing

the

axle differential from

the

rear

axle housing,

use

Spreader Tool

No.

W-129.

e.

Carefully

pry the

differential case

loose,

using

pry

bars

at the

heads

of the

ring gear

bolts

and

carrier

casting.

f.

Remove spreader immediately

to

prevent

the

possibility

of the

carrier

taking

a set.

g. Remove

the

screws holding

the

ring gear

to the

differential

case.

h.

With

a

small punch,

as

shown in

Fig.

N-20, drive

out

the

lock

pin.

FIG.

N-20—REMOVING

LOCK

PIN

i.

Remove

the

differential shaft

and

thrust block.

Note:

Thrust

block used with semi-float tapered

axle shaft only. Refer

to

Fig.

N-3.

j.

Carefully

so as not to

lose

the

thrust washers,

remove

the

differential pinion gears.

k.

With

Tool C-3281

to

hold

the

shaft

as

shown

in

Fig.

N-21,

remove

the nut.

With

Puller

W-172

remove

the

yoke

as

shown

in

Fig. N-2

2.

I.

Using

a

rawhide hammer, drive

on the end of

the pinion shaft

to

force

the

pinion

out of the

differential

housing.

FIG.

N-21—END

YOKE

HOLDING WRENCH

1— Nut

2—

Wrench

C-3281

3—

Yoke

Note:

Pinion bearing adjusting shims

may

remain

on

the

pinion shaft; stick

to the

bearing which

is

still

in the

housing;

or

fall

out

loose.

These shims

should

be

collected

and

kept

for

reassembly.

m.

Remove outer pinion bearing

cone,

baffle

and

oil

seal

by

using

a 2" x 2"

piece

of

hardwood

or a

length

of

pipe

and

drive

out

through

the

neck

of

the

carrier

housing.

Discard

seal. 294

Page 301 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

N

13189

FIG.

N-36—PINION

SHAFT OIL

SEAL

INSTALLER

1—Tool

W-147

p.

Remove

the

sleeve

previously installed in

place

of

the yoke. Install the oil

seal

with

Tool

W-147 shown in Fig. N-36.

q. Install the yoke

with

Flange

Installer W-162,

as shown in Fig. N-3 7.

r.

Install pinion nut and cotter pin.

s. Install axle

shafts

and housing cover.

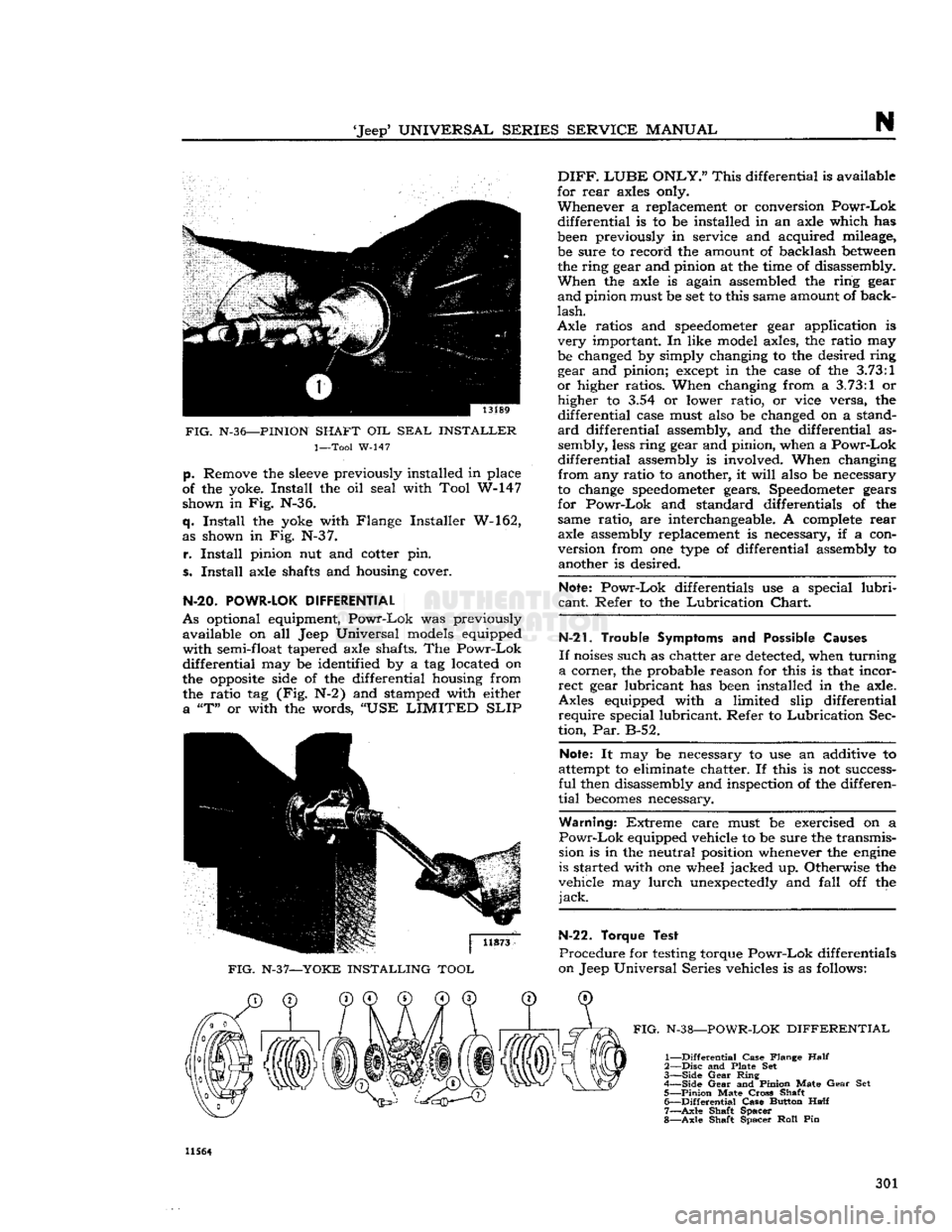

N-20.

POWR-LOK

DIFFERENTIAL

As

optional equipment, Powr-Lok was previously available on all

Jeep

Universal

models

equipped

with

semi-float

tapered

axle

shafts.

The Powr-Lok

differential

may be identified by a tag located on

the opposite

side

of the differential housing

from

the ratio tag (Fig. N-2) and

stamped

with

either a "T" or

with

the words, "USE

LIMITED

SLIP

FIG.

N-37—YOKE INSTALLING TOOL

DIFF.

LUBE

ONLY."

This differential is available

for

rear

axles

only.

Whenever a

replacement

or conversion Powr-Lok

differential

is to be installed in an axle which has

been

previously in

service

and acquired mileage, be

sure

to record the amount of backlash

between

the ring

gear

and pinion at the time of

disassembly.

When the axle is again

assembled

the ring

gear

and pinion must be set to this

same

amount of

back

lash.

Axle

ratios and

speedometer

gear

application is very important. In

like

model

axles,

the ratio may

be

changed

by simply changing to the desired ring

gear

and pinion;

except

in the

case

of the

3.73:1

or higher ratios. When changing

from

a

3.73:1

or higher to 3.54 or lower ratio, or vice

versa,

the

differential

case

must

also

be

changed

on a

stand

ard differential

assembly,

and the differential as sembly,

less

ring

gear

and pinion, when a Powr-Lok

differential

assembly

is involved. When changing

from

any ratio to

another,

it

will

also

be

necessary

to

change

speedometer

gears.

Speedometer

gears

for

Powr-Lok and

standard

differentials of the

same

ratio, are

interchangeable.

A complete

rear

axle

assembly

replacement

is

necessary,

if a con

version

from

one type of differential

assembly

to

another

is desired.

Note: Powr-Lok differentials use a special

lubri

cant.

Refer to the Lubrication Chart.

N-21.

Trouble Symptoms and

Possible

Causes

If

noises

such

as

chatter

are

detected,

when turning

a corner, the probable

reason

for this is that incor

rect

gear

lubricant has

been

installed in the axle.

Axles

equipped

with

a

limited

slip differential require special lubricant. Refer to Lubrication

Sec

tion,

Par. B-52.

Note: It may be

necessary

to use an additive to

attempt to eliminate

chatter.

If this is not

success

ful

then

disassembly

and inspection of the differen

tial

becomes

necessary.

Warning:

Extreme

care

must be exercised on a

Powr-Lok

equipped vehicle to be

sure

the transmis

sion is in the neutral position

whenever

the

engine

is

started

with

one wheel jacked up. Otherwise the

vehicle may lurch unexpectedly and

fall

off the

jack.

N-22. Torque Test

Procedure

for testing torque Powr-Lok differentials

on

Jeep

Universal

Series

vehicles is as follows:

FIG.

N-38—POWR-LOK DIFFERENTIAL

1—

Differential

Case Flange

Half

2—

Disc

and Plate Set

3—

Side

Gear

Ring

4— Side

Gear

and Pinion Mate

Gear

Set

5—

Pinion

Mate

Cross

Shaft 6—

Differential

Case Button

Half

7—

Axle

Shaft Spacer

8—

Axle

Shaft Spacer

Roll

Pin 11564

301

Page 314 of 376

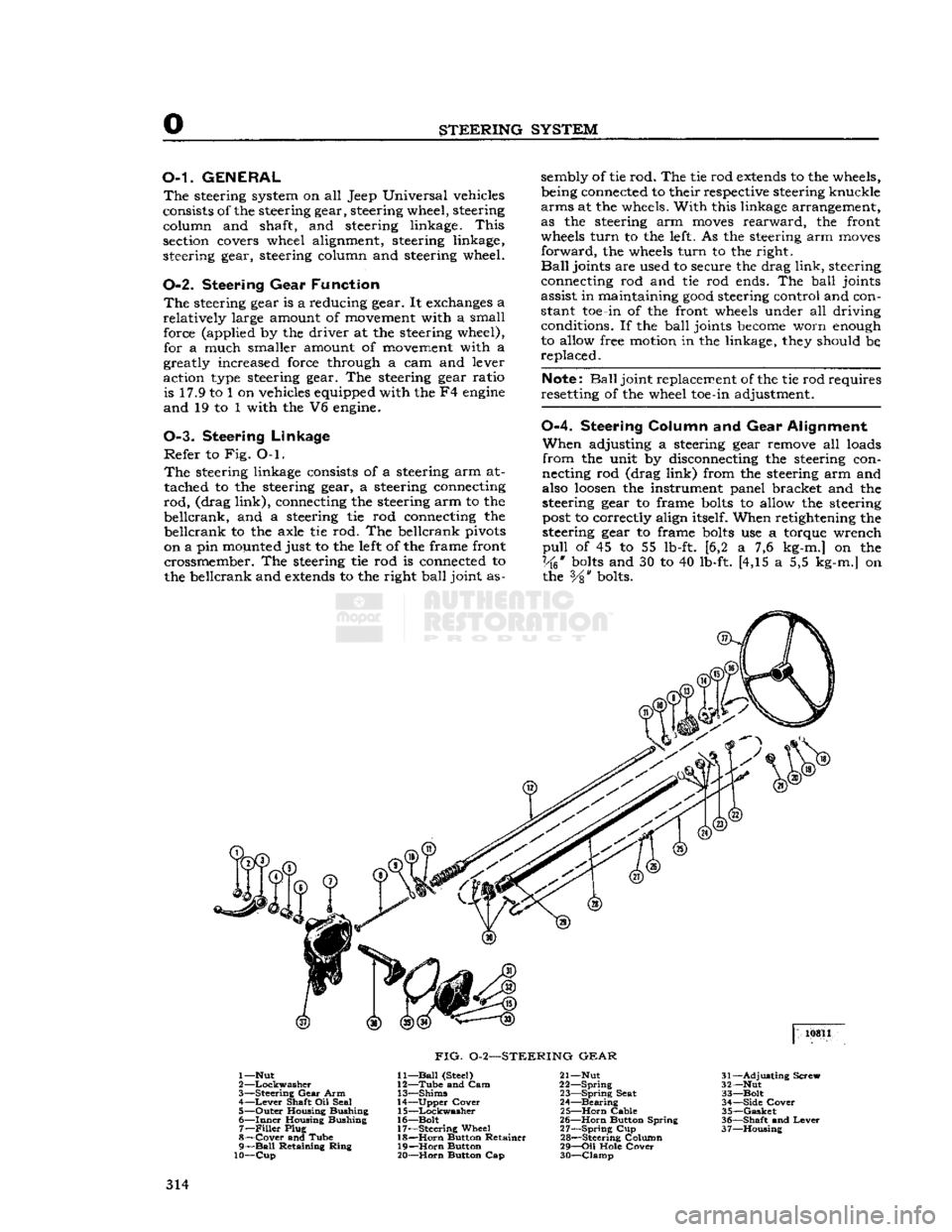

STEERING

SYSTEM

O-L

GENERAL

The

steering system on all Jeep Universal vehicles

consists of the steering gear, steering wheel, steering column and shaft, and steering linkage.

This

section covers wheel alignment, steering linkage,

steering gear, steering column and steering wheel.

0-2. Steering

Gear

Function

The

steering gear is a reducing gear. It exchanges a

relatively

large amount of movement with a small force (applied by the driver at the steering wheel), for a much smaller amount of movement with a

greatly increased force through a cam and lever

action type steering gear. The steering gear ratio is 17.9 to 1 on vehicles equipped with the F4

engine

and

19 to 1 with the V6 engine.

0-3. Steering

Linkage

Refer

to Fig. O-l.

The

steering linkage consists of a steering arm at

tached to the steering gear, a steering connecting

rod,

(drag

link),

connecting the steering arm to the

beilcrank,

and a steering tie rod connecting the

beilcrank

to the axle tie rod. The beilcrank pivots

on a pin mounted just to the left of the frame front crossmember. The steering tie rod is connected to

the beilcrank and

extends

to the right

ball

joint as sembly of tie rod. The tie rod

extends

to the wheels,

being connected to their respective steering knuckle

arms

at the wheels.

With

this linkage arrangement,

as the steering arm

moves

rearward,

the front

wheels

turn

to the left. As the steering arm

moves

forward,

the wheels

turn

to the right.

Ball

joints are used to secure the drag

link,

steering

connecting rod and tie rod ends. The

ball

joints

assist in maintaining

good

steering control and con

stant toe-in of the front wheels under all driving conditions. If the

ball

joints

become

worn enough

to allow free motion in the linkage, they should be,

replaced.

Note:

Ball

joint replacement of the tie rod requires

resetting of the wheel toe-in adjustment.

0-4.

Steering

Column

and Gear

Alignment

When

adjusting a steering gear remove all loads

from

the unit by disconnecting the steering con

necting rod (drag

link)

from the steering arm and

also

loosen

the instrument panel bracket and the

steering gear to frame

bolts

to allow the steering

post

to correctly align itself. When retightening the

steering gear to frame

bolts

use a torque wrench

pull

of 45 to 55 lb-ft. [6,2 a 7,6 kg-m.] on the

Vk*

bolts

and 30 to 40 lb-ft. [4,15 a 5,5 kg-m.] on the

Vs"

bolts. 10811

FIG.

0-2—STEERING

GEAR

1—Nut

2

—Lockwasher

3—

Steering

Gear

Arm 4—

Lever

Shaft Oil Seal

5—

Outer

Housing Bushing

6—

Inner

Housing Bushing 7—

Filler

Plug

8—

Cover

and Tube

9—

Ball

Retaining

Ring

10—Cup

11—

Ball

(Steel)

12—

Tube

and Cam

13—

Shims

14—

Upper

Cover

15—

Lockwasher

16—

Bolt

17—

Steering

Wheel 18—

Horn

Button Retainer

19—

Horn

Button

20—

Horn

Button Cap 21— Nut

22—

Spring

23—

Spring

Seat

24—

Bearing

25—

Horn

Cable

26—

Horn

Button Spring

27—

Spring

Cup

28—

Steering Column

29—

Oil

Hole

Cover

30—

Clamp

31—

Adjusting

Screw

32— Nut

33—

Bolt

34—

Side

Cover

35—

Gasket

36—

Shaft

and

Lever

37—

Housing

314

Page 321 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

O

column assembly down through the floor pan open

ing and out from under vehicle.

0-24.

Disassembly

of

Steering

Gear

Refer

to Fig. 0-2.

When

the steering gear arm is installed on early

production vehicles, the line across the face of the

arm

and the end of the shaft should be in align ment. On later production vehicles, blind splines

on the lever shaft and in the steering gear arm en

sure

correct positioning of the arm.

a.

Remove the steering gear arm with a puller

C-3646.

Caution:

Do not use a hammer or

wedge

to re

move

the steering arm from the shaft and lever.

This

can cause damage to the shaft assembly.

b.

Loosen the lock nut and unscrew the adjusting

screw

two turns.

c.

Remove the side cover screws and washers. Re

move

the side cover and gasket.

d.

Remove lever shaft.

e.

Remove upper cover plate screws. Remove cam,

wheel tube, and bearing assembly from the housing.

f.

Clean

all parts with suitable cleaning solvent and wipe dry.

g.

After dismantling as outlined above is com

pleted, inspect cam

grooves

for wear, chipping and

scoring,

also the

ball

races on the cam ends and the

separate

ball

cups. Existence of any of

these

condi tions indicates the necessity for parts replacement.

h.

Inspect the tapered stud mounted on the lever

shaft for flat

spots

and chipping. In the case of

either, replacement is usually advisable. Inspect the

lever shaft for wear and

test

the fit of the shaft in

the bushings.

i.

Inspect condition of the oil seal at outer end of

lever shaft and the bearing at top end of steering

column.

0-25.

Reassembly

of

Steering

Gear

e Refer to Fig. 0-2.

Reassemble all parts to wheel tube in reverse order

of dismantling. Assemble cam, wheel tube and

bearing

assembly in housing, seating the lower

bearing

ball

cup in the housing.

Note:

New plastic retainer type cam bearings are

now available for the Ross steering gears. The new

bearings replace, and are interchangeable with,

the lock ring type cam bearings on gears equipped

with

early type cams.

With

adjusting shims in place, assemble upper

cover and adjust the cam bearings.

Assemble lever shaft in housing and with gasket

in

place assemble the side cover and set adjusting

screw

for a minimum backlash of the studs in the

cam

groove, with the steering gear at the center

point of travel.

When

assembling upper bearing spring and spring

seat in jacket tube make sure that the spring seat

is positioned correctly. It must be installed with

the lengthwise flange down against the bearing and

not up inside of spring coil.

0-26.

Installation

of

Steering

Gear

a.

After the gear has been properly adjusted, as

outlined in Par. 0-5, install steering gear assembly

in

chassis in the reverse order in which it was re

moved.

b.

After installing the assembly in the vehicle,

jack

up front of vehicle and place the front wheels

in

the straight ahead position.

c.

Temporarily install the steering wheel to locate

the mid-position of the steering gear. To locate the mid-position,

turn

the steering wheel as far to the

right

as possible and then

turn

in the

opposite

di

rection

as far as possible, noting the total number

of turns.

Turn

the wheel back just ^ of the total movement to place the gear in mid-position.

d.

With

the steering gear in mid-position and the

wheels in the straight ahead position install steer ing gear arm on lever shaft with the

ball

end down.

When

installed the line across the face of the arm

and

end of shaft should be in alignment.

0-27.

Steering

Wheel

Installation

•

Refer to Fig. 0-2.

a.

Install

steering wheel and spring on shaft.

Align

scribe marks on shaft and hub of wheel.

b.

Install

steering shaft nut and torque 20 to 25

lb-ft. [2,8 a 3,4 kg-m.].

c.

Install

horn cap. Test horn.

321

Page 329 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

P

FIG.

P-9—WHEEL HUB OIL

SEAL

DRIVER

•

Removing the

Rear

Brake

Shoes.

•

Refer to Fig. P-ll.

a.

Using Tool C-3785 or equivalent remove the

upper linkage rod and brake

shoe

return springs.

b. Remove the brake

shoe

retainer, spring and pins.

c. Remove the anchor pin plate and tilt the brake

shoe

assembly out from the backing plate.

d.

On vehicles without a transmission brake,

spread the anchor

ends

of the primary and second

ary

shoes

and remove the parking brake strut and

spring.

e. On vehicles without a transmission brake, dis

engage

the parking brake cable from the parking

brake

lever and remove the brake assembly.

f. Overlap the anchor

ends

of the primary and

secondary

shoes

and remove the adjusting screw,

adjusting lever, lower return spring, and linkage

rods.

P-17. Inspection

Inspect the oil seals in the wheel hubs. If the con

dition of any oil seal is doubtful, replace it. Install

the oil seal with an oil seal driver as shown in Fig.

P-9.

Brake

shoes

may be distorted by improper lining installation and linings should be ground true. For

this reason it is recommended that new or re

placement

shoe

and lining assemblies be installed.

Using

brake drum micrometer C-3920 or equi

valent, check all drums. Should a brake drum be rough and scored, it may be reconditioned by grinding or turning in a lathe. Do not remove more

than .030"

[0,762

mm.] thickness of metal .060" [1,52 mm.] overall diameter. If a drum is recon

ditioned in this manner, either the correct factory-

supplied, oversize lining .030"

[0,762

mm.] must be

installed or a shim equal in thickness to the metal

removed must be placed

between

the lining and

shoe

so that the arc of the lining

will

be the same

as that of the drum.

If

it is found when

wheels

are removed that there

is brake fluid leakage at any of the wheel cylinders, it

will

be necessary to replace or recondition the

wheel cylinder (Par. P-21) and bleed the brake lines (Par. P-7).

Whenever the brake lining is replaced in one front

or one rear wheel, be sure to perform the same

operation in the

opposite

front or rear wheel, us

ing the same brake lining part number. Otherwise, unequal brake action

will

result.

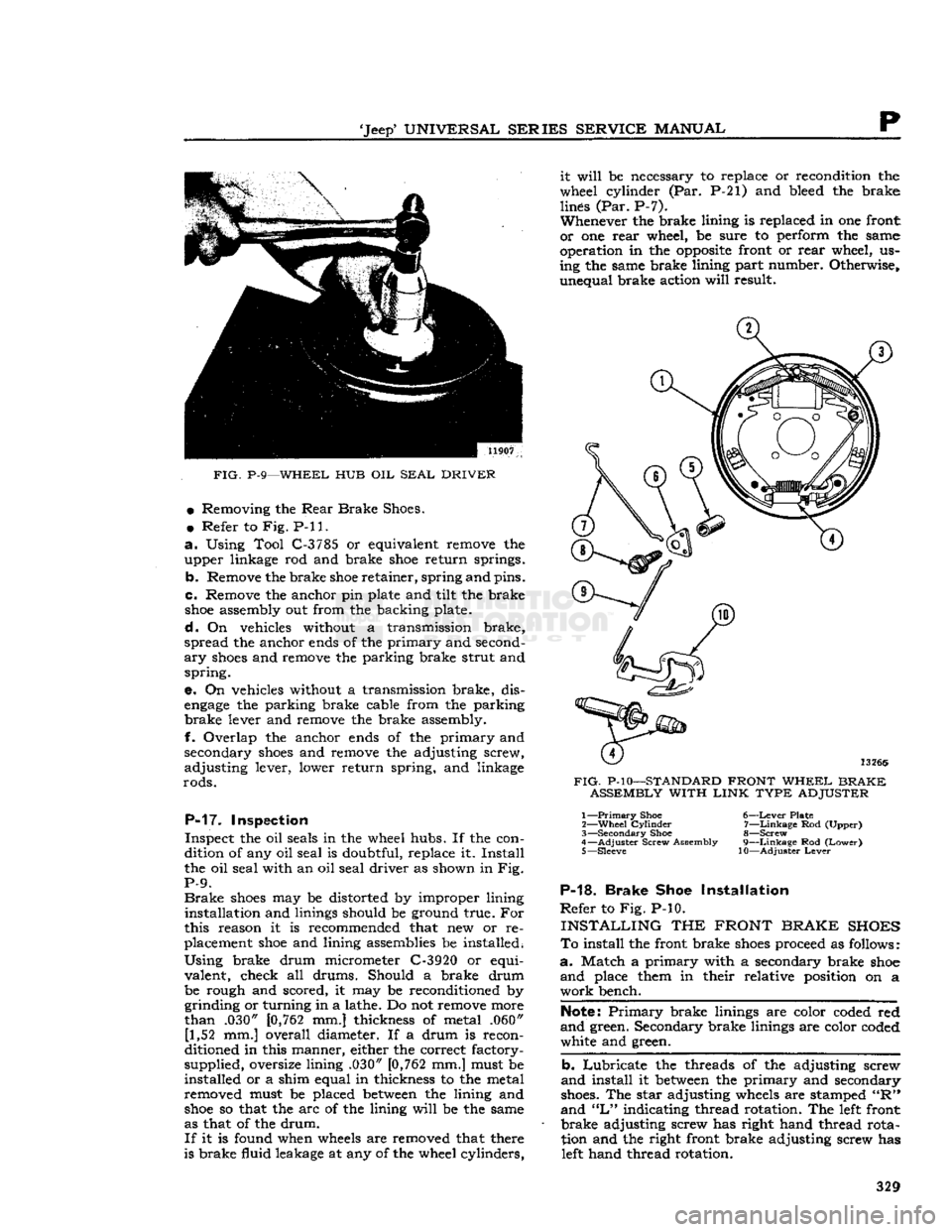

FIG.

P-10—STANDARD

FRONT

WHEEL

BRAKE

ASSEMBLY

WITH

LINK

TYPE

ADJUSTER 1—

Primary

Shoe

6—Lever

Plate

2—

Wheel

Cylinder

7—Linkage Rod (Upper)

3—

Secondary

Shoe 8—Screw

4—

Adjuster

Screw Assembly 9—Linkage Rod

(Lower)

5— Sleeve 10—Adjuster

Lever

P-18.

Brake

Shoe Installation

Refer

to Fig. P-10.

INSTALLING

THE

FRONT

BRAKE

SHOES

To

install the front brake

shoes

proceed as follows:

a.

Match a primary with a secondary brake

shoe

and

place them in their relative position on a

work

bench.

Note:

Primary

brake linings are color coded red

and

green. Secondary brake linings are color coded

white and green.

b. Lubricate the threads of the adjusting screw

and

install it

between

the primary and secondary

shoes.

The star adjusting

wheels

are stamped "R"

and

"L"

indicating thread rotation. The

left

front

brake

adjusting screw has right hand thread rota

tion and the right front brake adjusting screw has

left

hand thread rotation. 329