wind JEEP GRAND CHEROKEE 2002 WJ / 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1179 of 2199

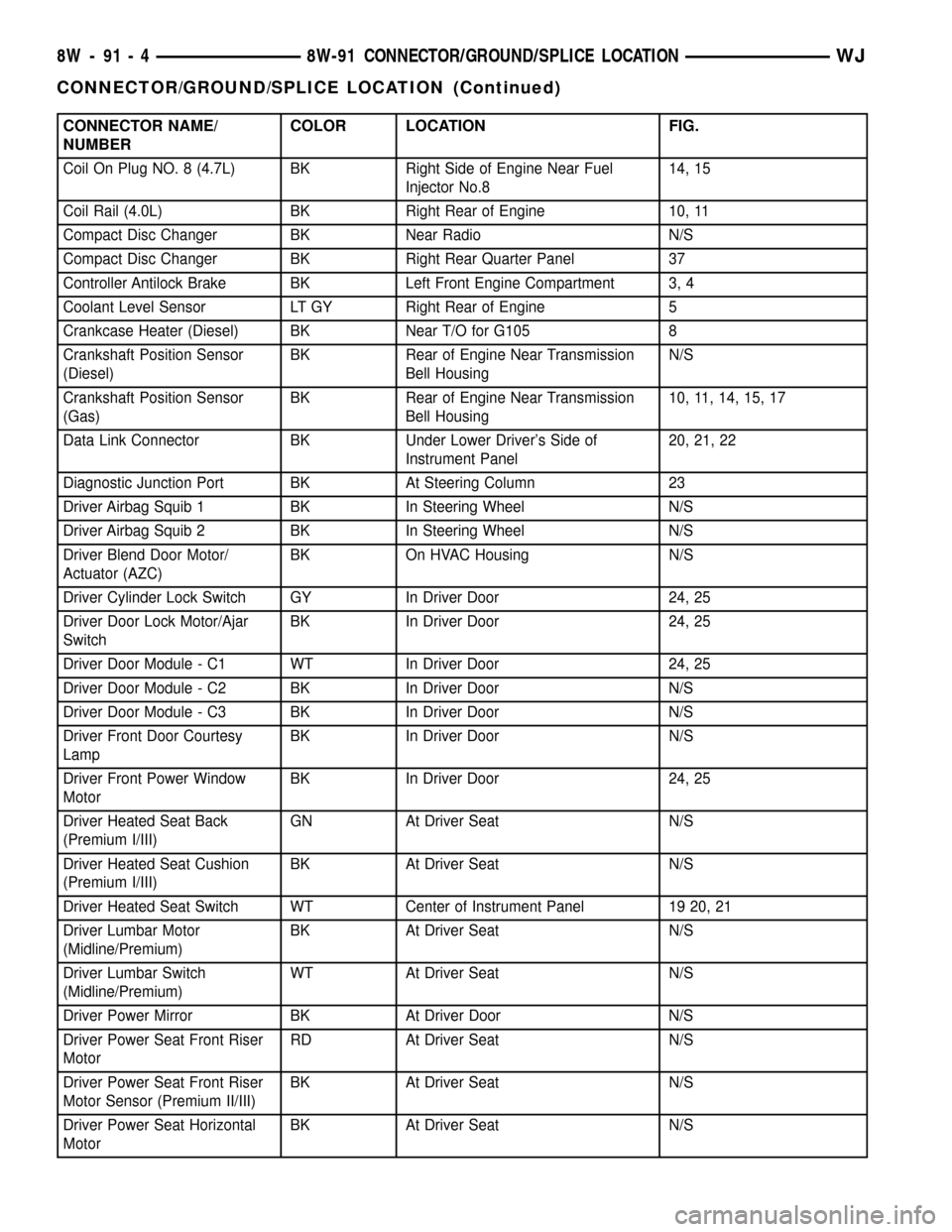

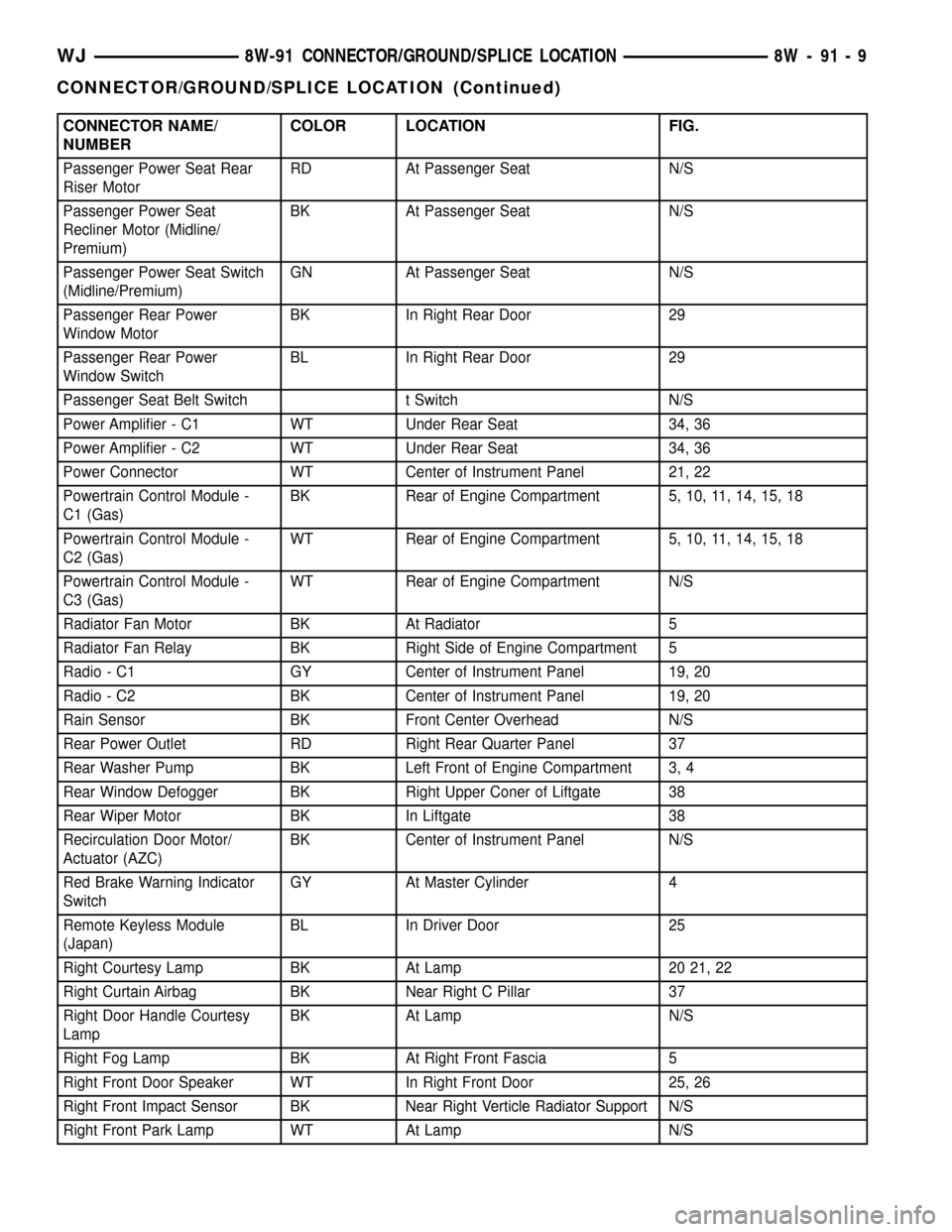

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Coil On Plug NO. 8 (4.7L) BK Right Side of Engine Near Fuel

Injector No.814, 15

Coil Rail (4.0L) BK Right Rear of Engine 10, 11

Compact Disc Changer BK Near Radio N/S

Compact Disc Changer BK Right Rear Quarter Panel 37

Controller Antilock Brake BK Left Front Engine Compartment 3, 4

Coolant Level Sensor LT GY Right Rear of Engine 5

Crankcase Heater (Diesel) BK Near T/O for G105 8

Crankshaft Position Sensor

(Diesel)BK Rear of Engine Near Transmission

Bell HousingN/S

Crankshaft Position Sensor

(Gas)BK Rear of Engine Near Transmission

Bell Housing10, 11, 14, 15, 17

Data Link Connector BK Under Lower Driver's Side of

Instrument Panel20, 21, 22

Diagnostic Junction Port BK At Steering Column 23

Driver Airbag Squib 1 BK In Steering Wheel N/S

Driver Airbag Squib 2 BK In Steering Wheel N/S

Driver Blend Door Motor/

Actuator (AZC)BK On HVAC Housing N/S

Driver Cylinder Lock Switch GY In Driver Door 24, 25

Driver Door Lock Motor/Ajar

SwitchBK In Driver Door 24, 25

Driver Door Module - C1 WT In Driver Door 24, 25

Driver Door Module - C2 BK In Driver Door N/S

Driver Door Module - C3 BK In Driver Door N/S

Driver Front Door Courtesy

LampBK In Driver Door N/S

Driver Front Power Window

MotorBK In Driver Door 24, 25

Driver Heated Seat Back

(Premium I/III)GN At Driver Seat N/S

Driver Heated Seat Cushion

(Premium I/III)BK At Driver Seat N/S

Driver Heated Seat Switch WT Center of Instrument Panel 19 20, 21

Driver Lumbar Motor

(Midline/Premium)BK At Driver Seat N/S

Driver Lumbar Switch

(Midline/Premium)WT At Driver Seat N/S

Driver Power Mirror BK At Driver Door N/S

Driver Power Seat Front Riser

MotorRD At Driver Seat N/S

Driver Power Seat Front Riser

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Horizontal

MotorBK At Driver Seat N/S

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1180 of 2199

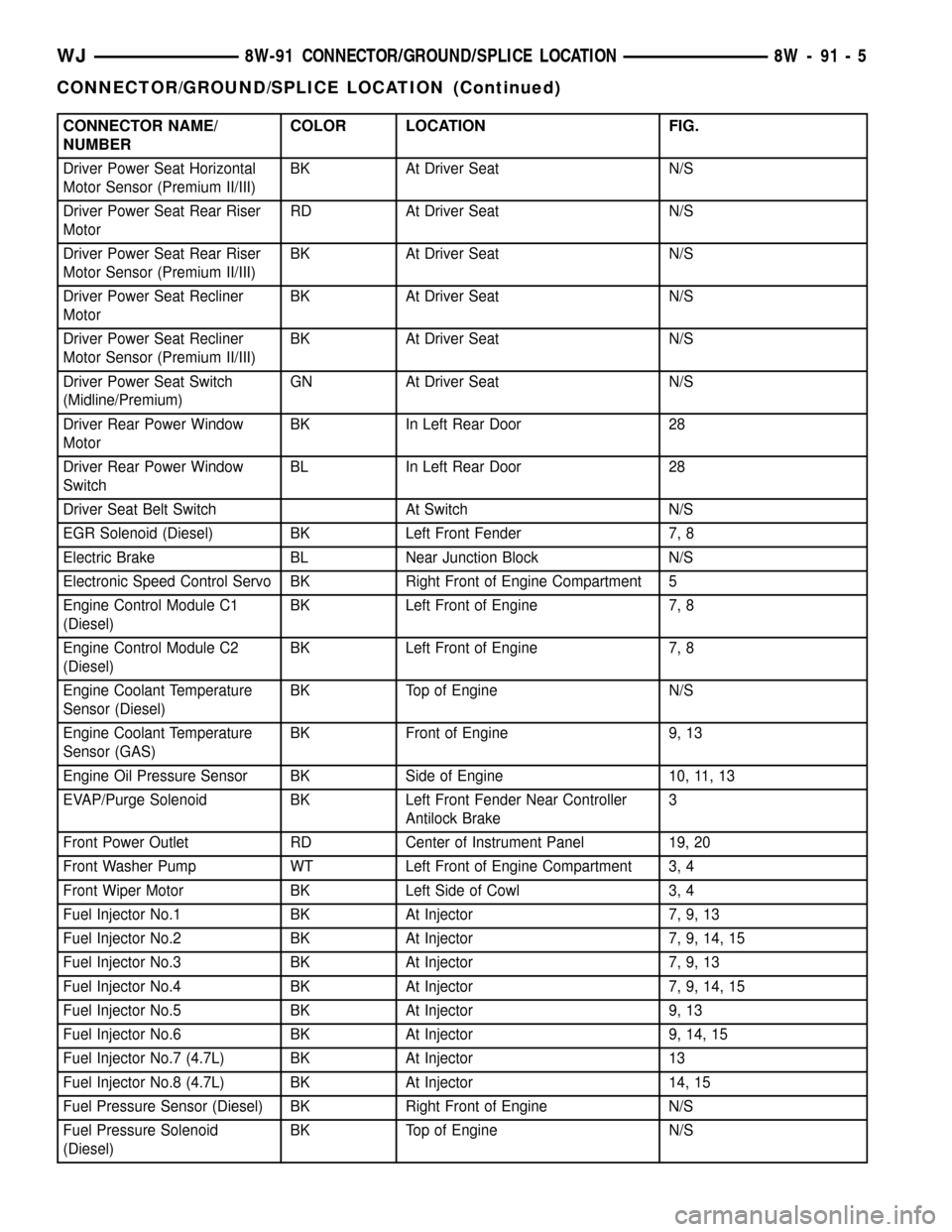

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Driver Power Seat Horizontal

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Rear Riser

MotorRD At Driver Seat N/S

Driver Power Seat Rear Riser

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Recliner

MotorBK At Driver Seat N/S

Driver Power Seat Recliner

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Switch

(Midline/Premium)GN At Driver Seat N/S

Driver Rear Power Window

MotorBK In Left Rear Door 28

Driver Rear Power Window

SwitchBL In Left Rear Door 28

Driver Seat Belt Switch At Switch N/S

EGR Solenoid (Diesel) BK Left Front Fender 7, 8

Electric Brake BL Near Junction Block N/S

Electronic Speed Control Servo BK Right Front of Engine Compartment 5

Engine Control Module C1

(Diesel)BK Left Front of Engine 7, 8

Engine Control Module C2

(Diesel)BK Left Front of Engine 7, 8

Engine Coolant Temperature

Sensor (Diesel)BK Top of Engine N/S

Engine Coolant Temperature

Sensor (GAS)BK Front of Engine 9, 13

Engine Oil Pressure Sensor BK Side of Engine 10, 11, 13

EVAP/Purge Solenoid BK Left Front Fender Near Controller

Antilock Brake3

Front Power Outlet RD Center of Instrument Panel 19, 20

Front Washer Pump WT Left Front of Engine Compartment 3, 4

Front Wiper Motor BK Left Side of Cowl 3, 4

Fuel Injector No.1 BK At Injector 7, 9, 13

Fuel Injector No.2 BK At Injector 7, 9, 14, 15

Fuel Injector No.3 BK At Injector 7, 9, 13

Fuel Injector No.4 BK At Injector 7, 9, 14, 15

Fuel Injector No.5 BK At Injector 9, 13

Fuel Injector No.6 BK At Injector 9, 14, 15

Fuel Injector No.7 (4.7L) BK At Injector 13

Fuel Injector No.8 (4.7L) BK At Injector 14, 15

Fuel Pressure Sensor (Diesel) BK Right Front of Engine N/S

Fuel Pressure Solenoid

(Diesel)BK Top of Engine N/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 5

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1181 of 2199

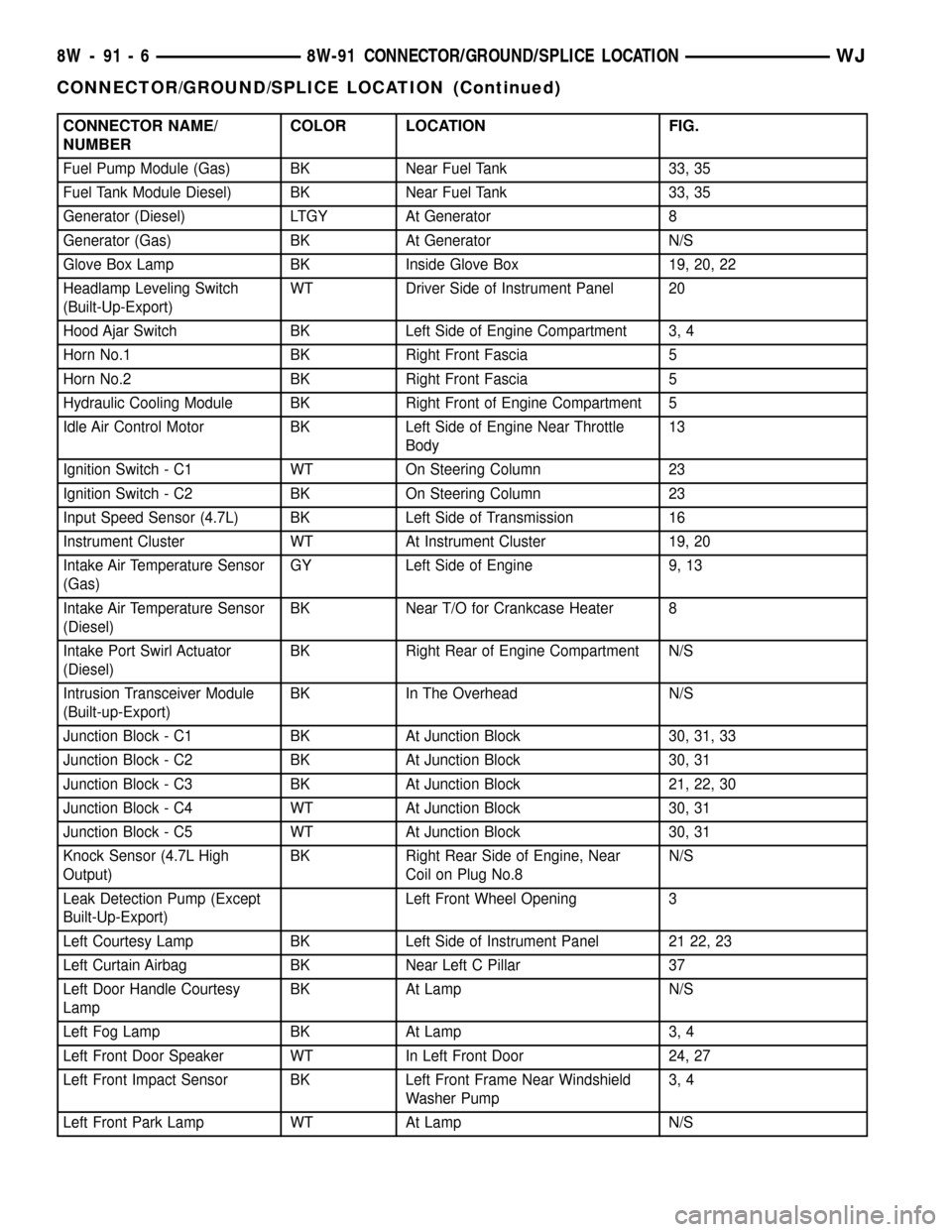

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Fuel Pump Module (Gas) BK Near Fuel Tank 33, 35

Fuel Tank Module Diesel) BK Near Fuel Tank 33, 35

Generator (Diesel) LTGY At Generator 8

Generator (Gas) BK At Generator N/S

Glove Box Lamp BK Inside Glove Box 19, 20, 22

Headlamp Leveling Switch

(Built-Up-Export)WT Driver Side of Instrument Panel 20

Hood Ajar Switch BK Left Side of Engine Compartment 3, 4

Horn No.1 BK Right Front Fascia 5

Horn No.2 BK Right Front Fascia 5

Hydraulic Cooling Module BK Right Front of Engine Compartment 5

Idle Air Control Motor BK Left Side of Engine Near Throttle

Body13

Ignition Switch - C1 WT On Steering Column 23

Ignition Switch - C2 BK On Steering Column 23

Input Speed Sensor (4.7L) BK Left Side of Transmission 16

Instrument Cluster WT At Instrument Cluster 19, 20

Intake Air Temperature Sensor

(Gas)GY Left Side of Engine 9, 13

Intake Air Temperature Sensor

(Diesel)BK Near T/O for Crankcase Heater 8

Intake Port Swirl Actuator

(Diesel)BK Right Rear of Engine Compartment N/S

Intrusion Transceiver Module

(Built-up-Export)BK In The Overhead N/S

Junction Block - C1 BK At Junction Block 30, 31, 33

Junction Block - C2 BK At Junction Block 30, 31

Junction Block - C3 BK At Junction Block 21, 22, 30

Junction Block - C4 WT At Junction Block 30, 31

Junction Block - C5 WT At Junction Block 30, 31

Knock Sensor (4.7L High

Output)BK Right Rear Side of Engine, Near

Coil on Plug No.8N/S

Leak Detection Pump (Except

Built-Up-Export)Left Front Wheel Opening 3

Left Courtesy Lamp BK Left Side of Instrument Panel 21 22, 23

Left Curtain Airbag BK Near Left C Pillar 37

Left Door Handle Courtesy

LampBK At Lamp N/S

Left Fog Lamp BK At Lamp 3, 4

Left Front Door Speaker WT In Left Front Door 24, 27

Left Front Impact Sensor BK Left Front Frame Near Windshield

Washer Pump3, 4

Left Front Park Lamp WT At Lamp N/S

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1183 of 2199

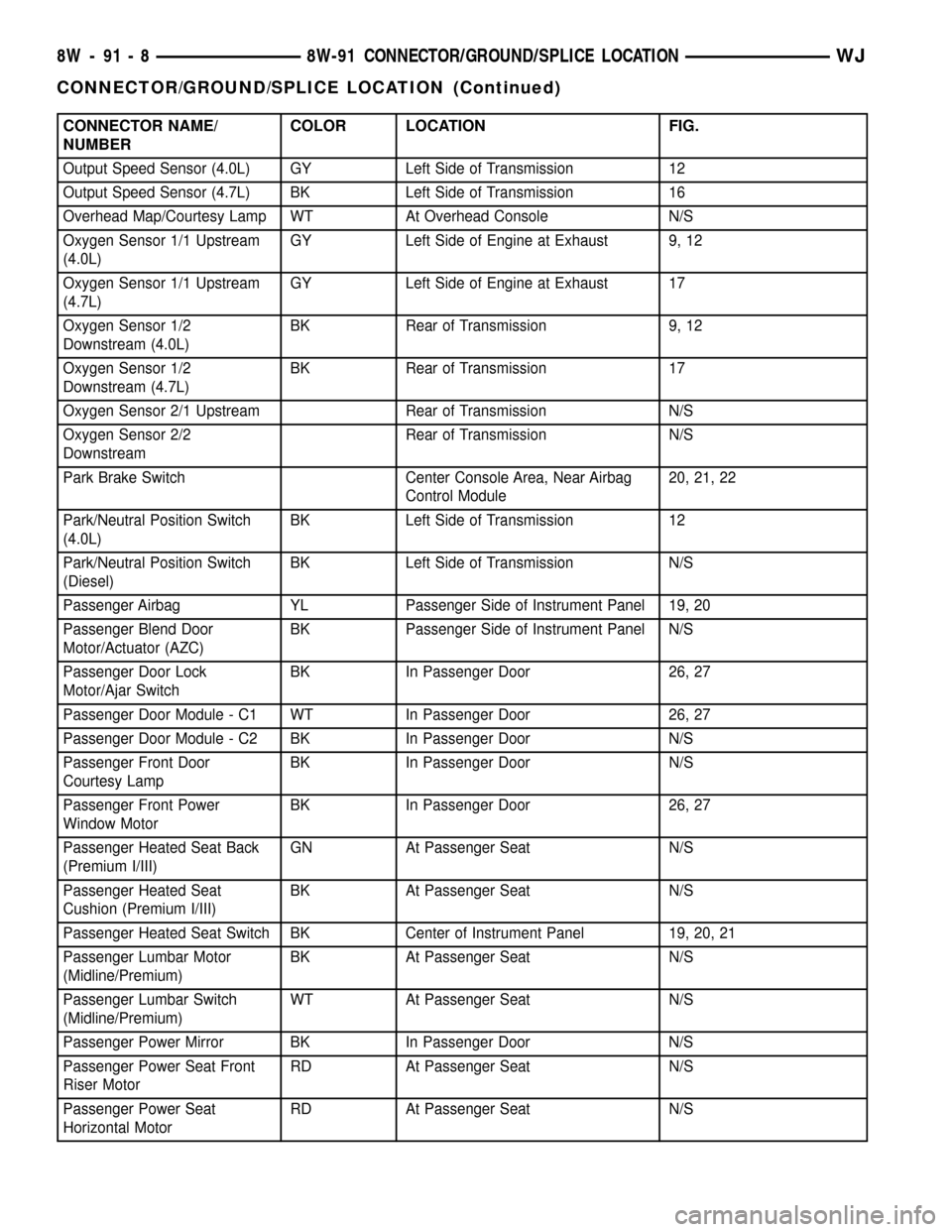

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Output Speed Sensor (4.0L) GY Left Side of Transmission 12

Output Speed Sensor (4.7L) BK Left Side of Transmission 16

Overhead Map/Courtesy Lamp WT At Overhead Console N/S

Oxygen Sensor 1/1 Upstream

(4.0L)GY Left Side of Engine at Exhaust 9, 12

Oxygen Sensor 1/1 Upstream

(4.7L)GY Left Side of Engine at Exhaust 17

Oxygen Sensor 1/2

Downstream (4.0L)BK Rear of Transmission 9, 12

Oxygen Sensor 1/2

Downstream (4.7L)BK Rear of Transmission 17

Oxygen Sensor 2/1 Upstream Rear of Transmission N/S

Oxygen Sensor 2/2

DownstreamRear of Transmission N/S

Park Brake Switch Center Console Area, Near Airbag

Control Module20, 21, 22

Park/Neutral Position Switch

(4.0L)BK Left Side of Transmission 12

Park/Neutral Position Switch

(Diesel)BK Left Side of Transmission N/S

Passenger Airbag YL Passenger Side of Instrument Panel 19, 20

Passenger Blend Door

Motor/Actuator (AZC)BK Passenger Side of Instrument Panel N/S

Passenger Door Lock

Motor/Ajar SwitchBK In Passenger Door 26, 27

Passenger Door Module - C1 WT In Passenger Door 26, 27

Passenger Door Module - C2 BK In Passenger Door N/S

Passenger Front Door

Courtesy LampBK In Passenger Door N/S

Passenger Front Power

Window MotorBK In Passenger Door 26, 27

Passenger Heated Seat Back

(Premium I/III)GN At Passenger Seat N/S

Passenger Heated Seat

Cushion (Premium I/III)BK At Passenger Seat N/S

Passenger Heated Seat Switch BK Center of Instrument Panel 19, 20, 21

Passenger Lumbar Motor

(Midline/Premium)BK At Passenger Seat N/S

Passenger Lumbar Switch

(Midline/Premium)WT At Passenger Seat N/S

Passenger Power Mirror BK In Passenger Door N/S

Passenger Power Seat Front

Riser MotorRD At Passenger Seat N/S

Passenger Power Seat

Horizontal MotorRD At Passenger Seat N/S

8W - 91 - 8 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1184 of 2199

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Passenger Power Seat Rear

Riser MotorRD At Passenger Seat N/S

Passenger Power Seat

Recliner Motor (Midline/

Premium)BK At Passenger Seat N/S

Passenger Power Seat Switch

(Midline/Premium)GN At Passenger Seat N/S

Passenger Rear Power

Window MotorBK In Right Rear Door 29

Passenger Rear Power

Window SwitchBL In Right Rear Door 29

Passenger Seat Belt Switch t Switch N/S

Power Amplifier - C1 WT Under Rear Seat 34, 36

Power Amplifier - C2 WT Under Rear Seat 34, 36

Power Connector WT Center of Instrument Panel 21, 22

Powertrain Control Module -

C1 (Gas)BK Rear of Engine Compartment 5, 10, 11, 14, 15, 18

Powertrain Control Module -

C2 (Gas)WT Rear of Engine Compartment 5, 10, 11, 14, 15, 18

Powertrain Control Module -

C3 (Gas)WT Rear of Engine Compartment N/S

Radiator Fan Motor BK At Radiator 5

Radiator Fan Relay BK Right Side of Engine Compartment 5

Radio - C1 GY Center of Instrument Panel 19, 20

Radio - C2 BK Center of Instrument Panel 19, 20

Rain Sensor BK Front Center Overhead N/S

Rear Power Outlet RD Right Rear Quarter Panel 37

Rear Washer Pump BK Left Front of Engine Compartment 3, 4

Rear Window Defogger BK Right Upper Coner of Liftgate 38

Rear Wiper Motor BK In Liftgate 38

Recirculation Door Motor/

Actuator (AZC)BK Center of Instrument Panel N/S

Red Brake Warning Indicator

SwitchGY At Master Cylinder 4

Remote Keyless Module

(Japan)BL In Driver Door 25

Right Courtesy Lamp BK At Lamp 20 21, 22

Right Curtain Airbag BK Near Right C Pillar 37

Right Door Handle Courtesy

LampBK At Lamp N/S

Right Fog Lamp BK At Right Front Fascia 5

Right Front Door Speaker WT In Right Front Door 25, 26

Right Front Impact Sensor BK Near Right Verticle Radiator Support N/S

Right Front Park Lamp WT At Lamp N/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 9

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

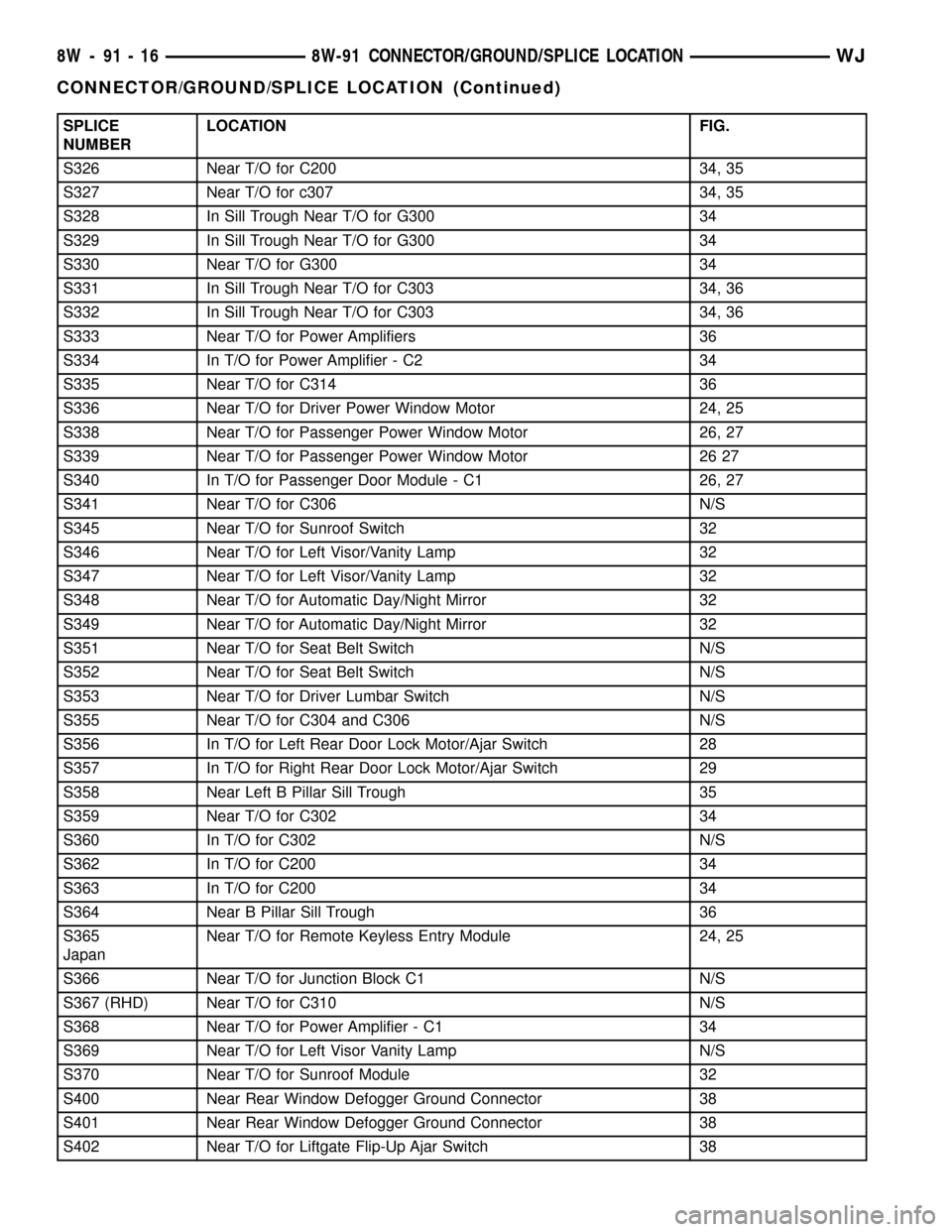

Page 1191 of 2199

SPLICE

NUMBERLOCATION FIG.

S326 Near T/O for C200 34, 35

S327 Near T/O for c307 34, 35

S328 In Sill Trough Near T/O for G300 34

S329 In Sill Trough Near T/O for G300 34

S330 Near T/O for G300 34

S331 In Sill Trough Near T/O for C303 34, 36

S332 In Sill Trough Near T/O for C303 34, 36

S333 Near T/O for Power Amplifiers 36

S334 In T/O for Power Amplifier - C2 34

S335 Near T/O for C314 36

S336 Near T/O for Driver Power Window Motor 24, 25

S338 Near T/O for Passenger Power Window Motor 26, 27

S339 Near T/O for Passenger Power Window Motor 26 27

S340 In T/O for Passenger Door Module - C1 26, 27

S341 Near T/O for C306 N/S

S345 Near T/O for Sunroof Switch 32

S346 Near T/O for Left Visor/Vanity Lamp 32

S347 Near T/O for Left Visor/Vanity Lamp 32

S348 Near T/O for Automatic Day/Night Mirror 32

S349 Near T/O for Automatic Day/Night Mirror 32

S351 Near T/O for Seat Belt Switch N/S

S352 Near T/O for Seat Belt Switch N/S

S353 Near T/O for Driver Lumbar Switch N/S

S355 Near T/O for C304 and C306 N/S

S356 In T/O for Left Rear Door Lock Motor/Ajar Switch 28

S357 In T/O for Right Rear Door Lock Motor/Ajar Switch 29

S358 Near Left B Pillar Sill Trough 35

S359 Near T/O for C302 34

S360 In T/O for C302 N/S

S362 In T/O for C200 34

S363 In T/O for C200 34

S364 Near B Pillar Sill Trough 36

S365

JapanNear T/O for Remote Keyless Entry Module 24, 25

S366 Near T/O for Junction Block C1 N/S

S367 (RHD) Near T/O for C310 N/S

S368 Near T/O for Power Amplifier - C1 34

S369 Near T/O for Left Visor Vanity Lamp N/S

S370 Near T/O for Sunroof Module 32

S400 Near Rear Window Defogger Ground Connector 38

S401 Near Rear Window Defogger Ground Connector 38

S402 Near T/O for Liftgate Flip-Up Ajar Switch 38

8W - 91 - 16 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1355 of 2199

REMOVAL

NOTE: To remove the crankshaft from the engine,

the engine must be removed from the vehicle.

(1) Remove the engine. (Refer to 9 - ENGINE -

REMOVAL).

(2) Remove the engine oil pump.(Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - REMOVAL).

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when removing oil pan.

Gasket can not be removed with oil pan.

(3) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

(4) Remove the oil pump pickup tube and oil pan

gasket /windage tray.

(5) Remove the bedplate mounting bolts. Note the

location of the three stud bolts for installation.

(6) Remove the connecting rods from the crank-

shaft.

CAUTION: The bedplate to cylinder block mating

surface is a critical sealing surface. Do not pry on

or damage this surface in anyway.

NOTE: The bedplate contains the lower main bear-

ing halves. Use care when handling bedplate as not

to drop or damage bearing halves. Installing main

bearing halves in the wrong position will cause

sever damage to the crankshaft.

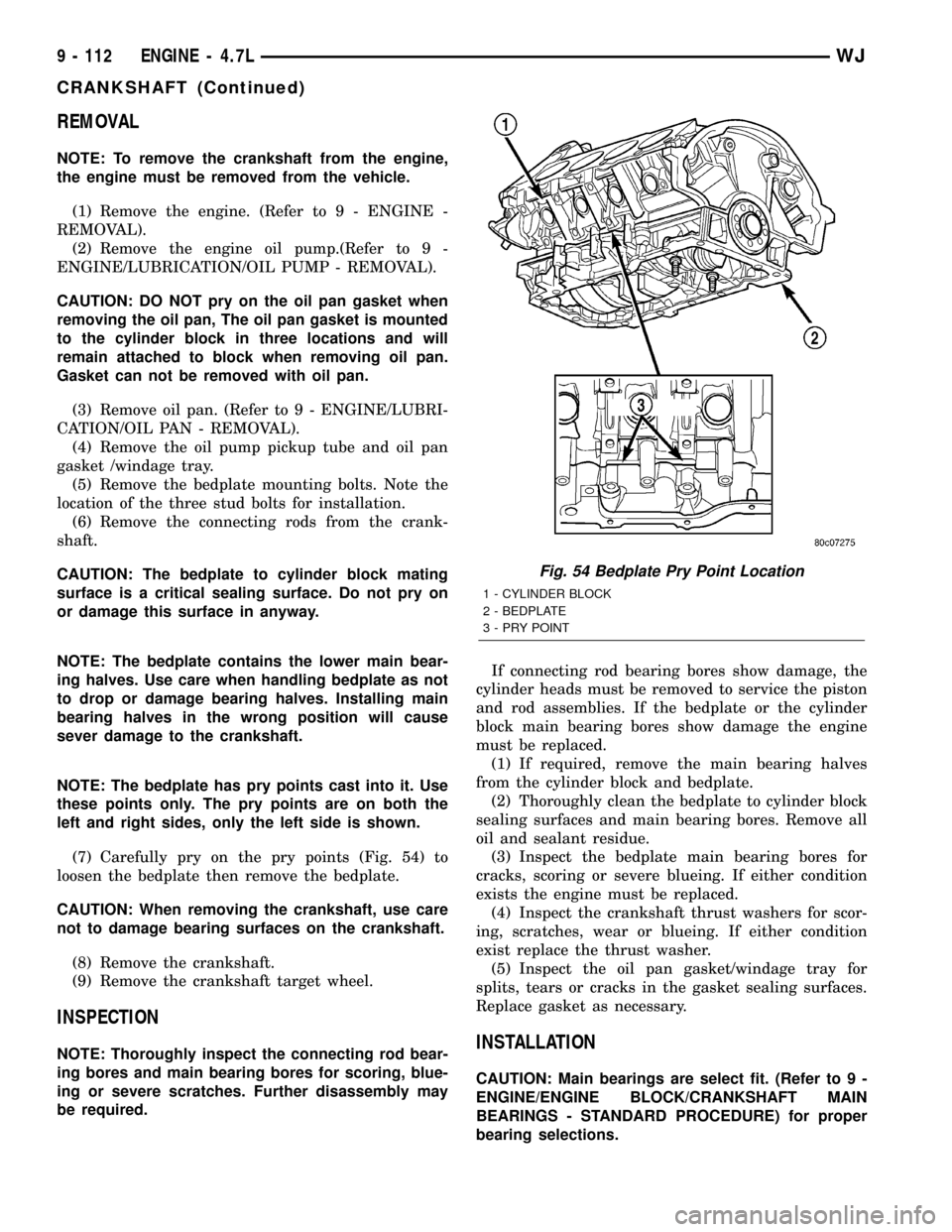

NOTE: The bedplate has pry points cast into it. Use

these points only. The pry points are on both the

left and right sides, only the left side is shown.

(7) Carefully pry on the pry points (Fig. 54) to

loosen the bedplate then remove the bedplate.

CAUTION: When removing the crankshaft, use care

not to damage bearing surfaces on the crankshaft.

(8) Remove the crankshaft.

(9) Remove the crankshaft target wheel.

INSPECTION

NOTE: Thoroughly inspect the connecting rod bear-

ing bores and main bearing bores for scoring, blue-

ing or severe scratches. Further disassembly may

be required.If connecting rod bearing bores show damage, the

cylinder heads must be removed to service the piston

and rod assemblies. If the bedplate or the cylinder

block main bearing bores show damage the engine

must be replaced.

(1) If required, remove the main bearing halves

from the cylinder block and bedplate.

(2) Thoroughly clean the bedplate to cylinder block

sealing surfaces and main bearing bores. Remove all

oil and sealant residue.

(3) Inspect the bedplate main bearing bores for

cracks, scoring or severe blueing. If either condition

exists the engine must be replaced.

(4) Inspect the crankshaft thrust washers for scor-

ing, scratches, wear or blueing. If either condition

exist replace the thrust washer.

(5) Inspect the oil pan gasket/windage tray for

splits, tears or cracks in the gasket sealing surfaces.

Replace gasket as necessary.INSTALLATION

CAUTION: Main bearings are select fit. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) for proper

bearing selections.

Fig. 54 Bedplate Pry Point Location

1 - CYLINDER BLOCK

2 - BEDPLATE

3 - PRY POINT

9 - 112 ENGINE - 4.7LWJ

CRANKSHAFT (Continued)

Page 1357 of 2199

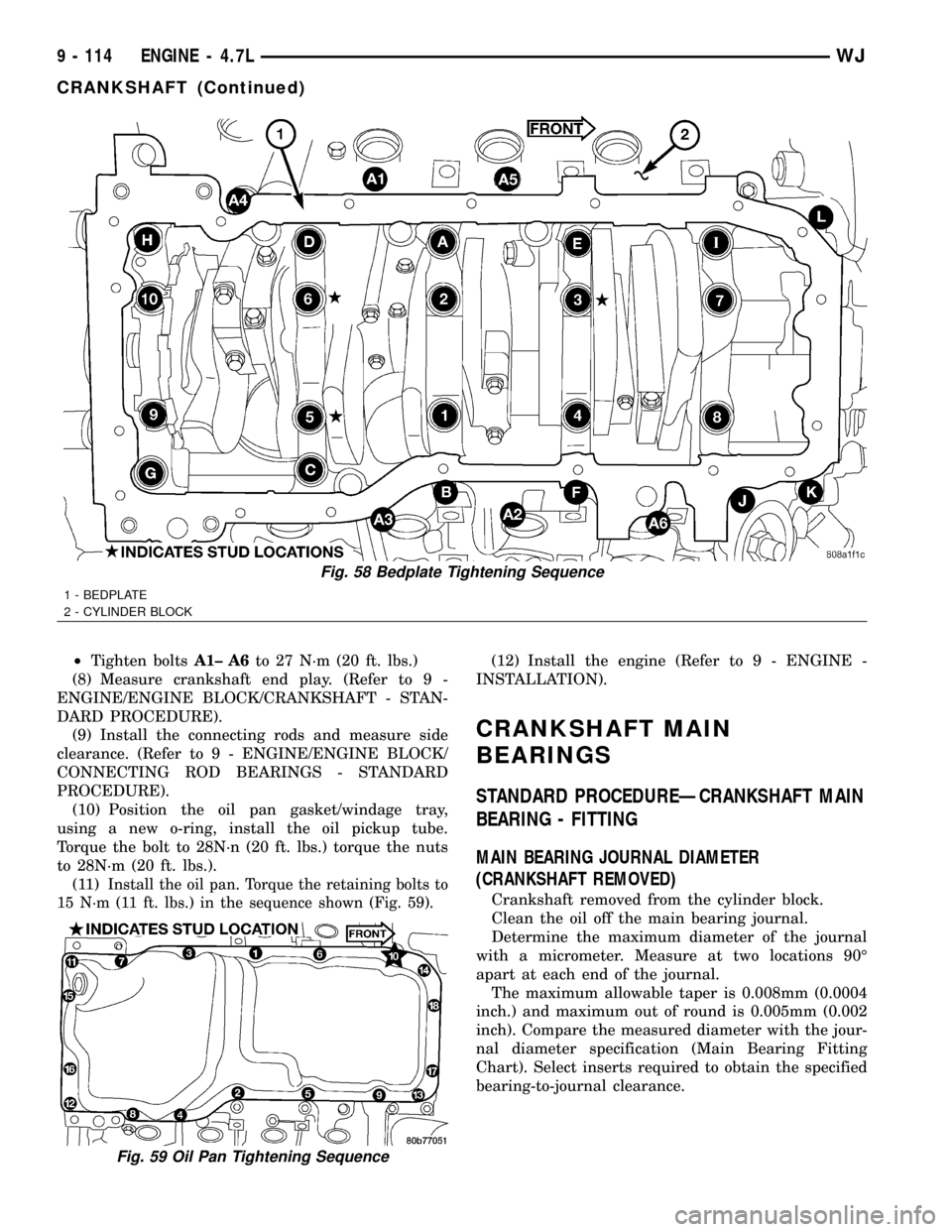

²Tighten boltsA1± A6to 27 N´m (20 ft. lbs.)

(8) Measure crankshaft end play. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT - STAN-

DARD PROCEDURE).

(9) Install the connecting rods and measure side

clearance. (Refer to 9 - ENGINE/ENGINE BLOCK/

CONNECTING ROD BEARINGS - STANDARD

PROCEDURE).

(10) Position the oil pan gasket/windage tray,

using a new o-ring, install the oil pickup tube.

Torque the bolt to 28N´n (20 ft. lbs.) torque the nuts

to 28N´m (20 ft. lbs.).

(11)

Install the oil pan. Torque the retaining bolts to

15 N´m (11 ft. lbs.) in the sequence shown (Fig. 59).

(12) Install the engine (Refer to 9 - ENGINE -

INSTALLATION).

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDUREÐCRANKSHAFT MAIN

BEARING - FITTING

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Crankshaft removed from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

Fig. 58 Bedplate Tightening Sequence

1 - BEDPLATE

2 - CYLINDER BLOCK

Fig. 59 Oil Pan Tightening Sequence

9 - 114 ENGINE - 4.7LWJ

CRANKSHAFT (Continued)

Page 1361 of 2199

FLEX PLATE

REMOVAL

(1) Remove the transmission.

(2) Remove the bolts and flexplate.

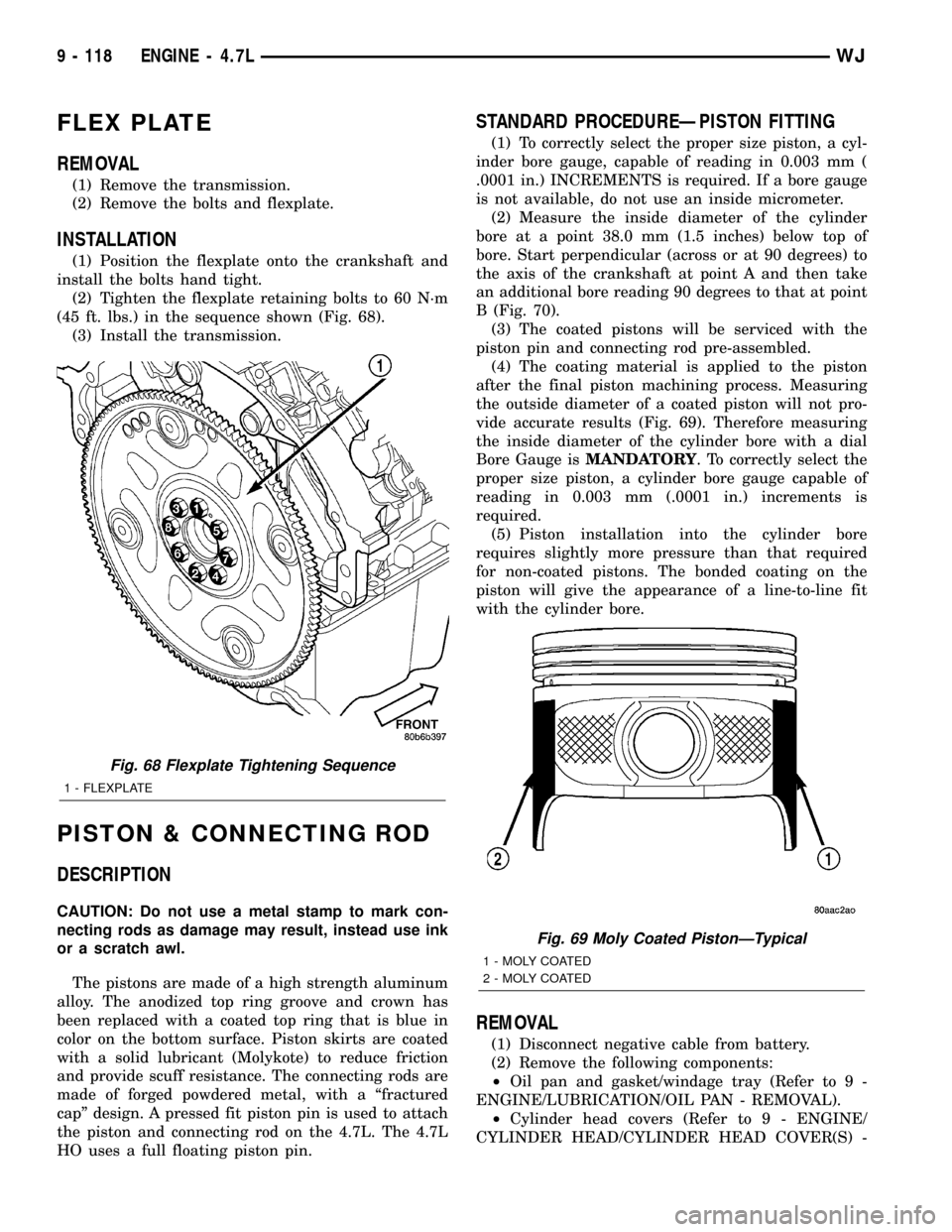

INSTALLATION

(1) Position the flexplate onto the crankshaft and

install the bolts hand tight.

(2) Tighten the flexplate retaining bolts to 60 N´m

(45 ft. lbs.) in the sequence shown (Fig. 68).

(3) Install the transmission.

PISTON & CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark con-

necting rods as damage may result, instead use ink

or a scratch awl.

The pistons are made of a high strength aluminum

alloy. The anodized top ring groove and crown has

been replaced with a coated top ring that is blue in

color on the bottom surface. Piston skirts are coated

with a solid lubricant (Molykote) to reduce friction

and provide scuff resistance. The connecting rods are

made of forged powdered metal, with a ªfractured

capº design. A pressed fit piston pin is used to attach

the piston and connecting rod on the 4.7L. The 4.7L

HO uses a full floating piston pin.

STANDARD PROCEDUREÐPISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (

.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 70).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled.

(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not pro-

vide accurate results (Fig. 69). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the following components:

²Oil pan and gasket/windage tray (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - REMOVAL).

²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

Fig. 68 Flexplate Tightening Sequence

1 - FLEXPLATE

Fig. 69 Moly Coated PistonÐTypical

1 - MOLY COATED

2 - MOLY COATED

9 - 118 ENGINE - 4.7LWJ

Page 1364 of 2199

²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

²Oil pan and gasket/windage tray. (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(11) Fill crankcase with proper engine oil to cor-

rect level.

(12) Connect negative cable to battery.

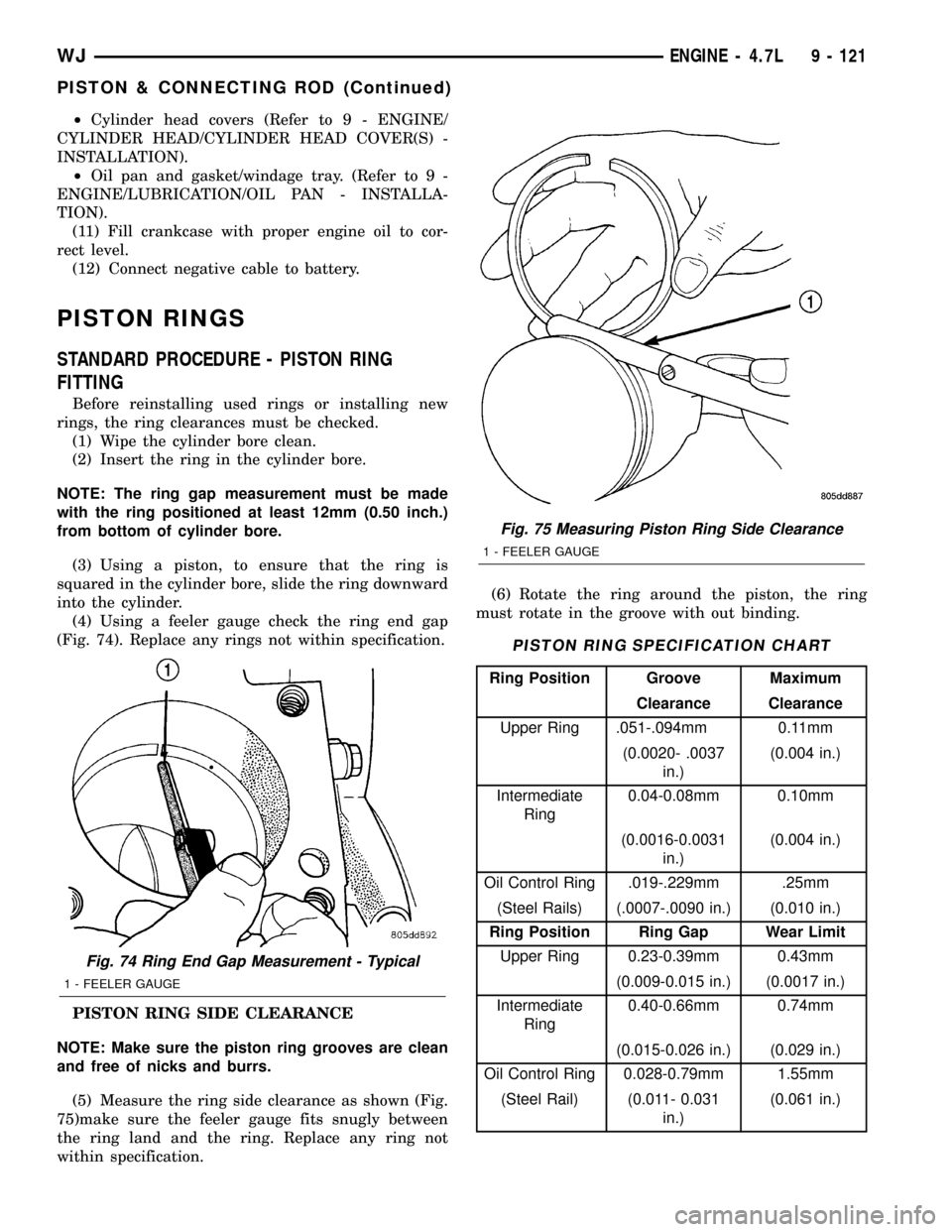

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING

Before reinstalling used rings or installing new

rings, the ring clearances must be checked.

(1) Wipe the cylinder bore clean.

(2) Insert the ring in the cylinder bore.

NOTE: The ring gap measurement must be made

with the ring positioned at least 12mm (0.50 inch.)

from bottom of cylinder bore.

(3) Using a piston, to ensure that the ring is

squared in the cylinder bore, slide the ring downward

into the cylinder.

(4) Using a feeler gauge check the ring end gap

(Fig. 74). Replace any rings not within specification.

PISTON RING SIDE CLEARANCE

NOTE: Make sure the piston ring grooves are clean

and free of nicks and burrs.

(5) Measure the ring side clearance as shown (Fig.

75)make sure the feeler gauge fits snugly between

the ring land and the ring. Replace any ring not

within specification.(6) Rotate the ring around the piston, the ring

must rotate in the groove with out binding.

PISTON RING SPECIFICATION CHART

Ring Position Groove Maximum

Clearance Clearance

Upper Ring .051-.094mm 0.11mm

(0.0020- .0037

in.)(0.004 in.)

Intermediate

Ring0.04-0.08mm 0.10mm

(0.0016-0.0031

in.)(0.004 in.)

Oil Control Ring .019-.229mm .25mm

(Steel Rails) (.0007-.0090 in.) (0.010 in.)

Ring Position Ring Gap Wear Limit

Upper Ring 0.23-0.39mm 0.43mm

(0.009-0.015 in.) (0.0017 in.)

Intermediate

Ring0.40-0.66mm 0.74mm

(0.015-0.026 in.) (0.029 in.)

Oil Control Ring 0.028-0.79mm 1.55mm

(Steel Rail) (0.011- 0.031

in.)(0.061 in.)

Fig. 74 Ring End Gap Measurement - Typical

1 - FEELER GAUGE

Fig. 75 Measuring Piston Ring Side Clearance

1 - FEELER GAUGE

WJENGINE - 4.7L 9 - 121

PISTON & CONNECTING ROD (Continued)