fluid JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1482 of 2199

(8) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

gauge.

(9) Shut off the engine and check the fluid level,

add fluid as necessary. Start engine again and let

idle.

(10) The initial pressure reading should be

345-552 kPa (50-80 psi). If pressure is higher inspect

the hoses for restrictions and repair as necessary.

(11) Increase the engine speed to 1500 RPM and

read the flow meter. The reading should be 2.4 - 2.8

GPM, if the reading is below this specification the

pump should be replaced.

CAUTION: This next step involves testing maximum

pump pressure output and flow control valve oper-

ation. Do not leave valve closed for more than three

seconds as the pump could be damaged.

(12) Close valve fully three times for three seconds

and record highest pressure indicated each time.All

three readings must be at pump relief pressure

specifications and within 345 kPa (50 psi) of

each other.

²Pressures above specifications but not within

345 kPa (50 psi) of each other, replace pump.

²Pressures within 345 kPa (50 psi) of each other

but below specifications, replace pump.

CAUTION: Do not force the pump to operate against

the stops for more than 2 to 4 seconds at a time

because, pump damage will result.

(13) Open the test valve and turn the steering

wheel to the extreme left and right positions against

the stops. Record the highest pressure reading at

each position. Compare readings to the pump specifi-

cations chart. If pressures readings are not within 50

psi. of each other, the gear is leaking internally and

must be repaired.

GEAR INLET SPECIFICATIONS 4.0L & 4.7L

ENGINERELIEF

PRESSURE 50FLOW RATE

(GPM)

4.0L 9653 kPa (1400 psi)

1500 RPM 2.4 - 2.8

GPM

4.7L 9653 kPa (1450 psi)

PUMP MOTOR SPECIFICATIONS 4.7L

ENGINERELIEF

PRESSURE 50FLOW RATE

(GPM)

4.7L 9653 kPa (1900 psi)1100 RPM 2.4-2.8

GPM Minium

@ 200 psi

DIAGNOSIS AND TESTING - 4.7L -

HYDRAULIC

The following procedures are used to test the oper-

ation of the power steering and hydraulic fan sys-

tems on the vehicle. This test will provide the gallons

per minute (GPM) or flow rate of the power steering

pump along with any maximum relief pressure. Per-

form test anytime a power steering system problem

is present. This test will determine if the power

steering pump, hydraulic fan, and power steering

gear are not functioning properly. It will also deter-

mine if the flow coming out of the hydraulic fan

motor is sufficient for the power steering gear. The

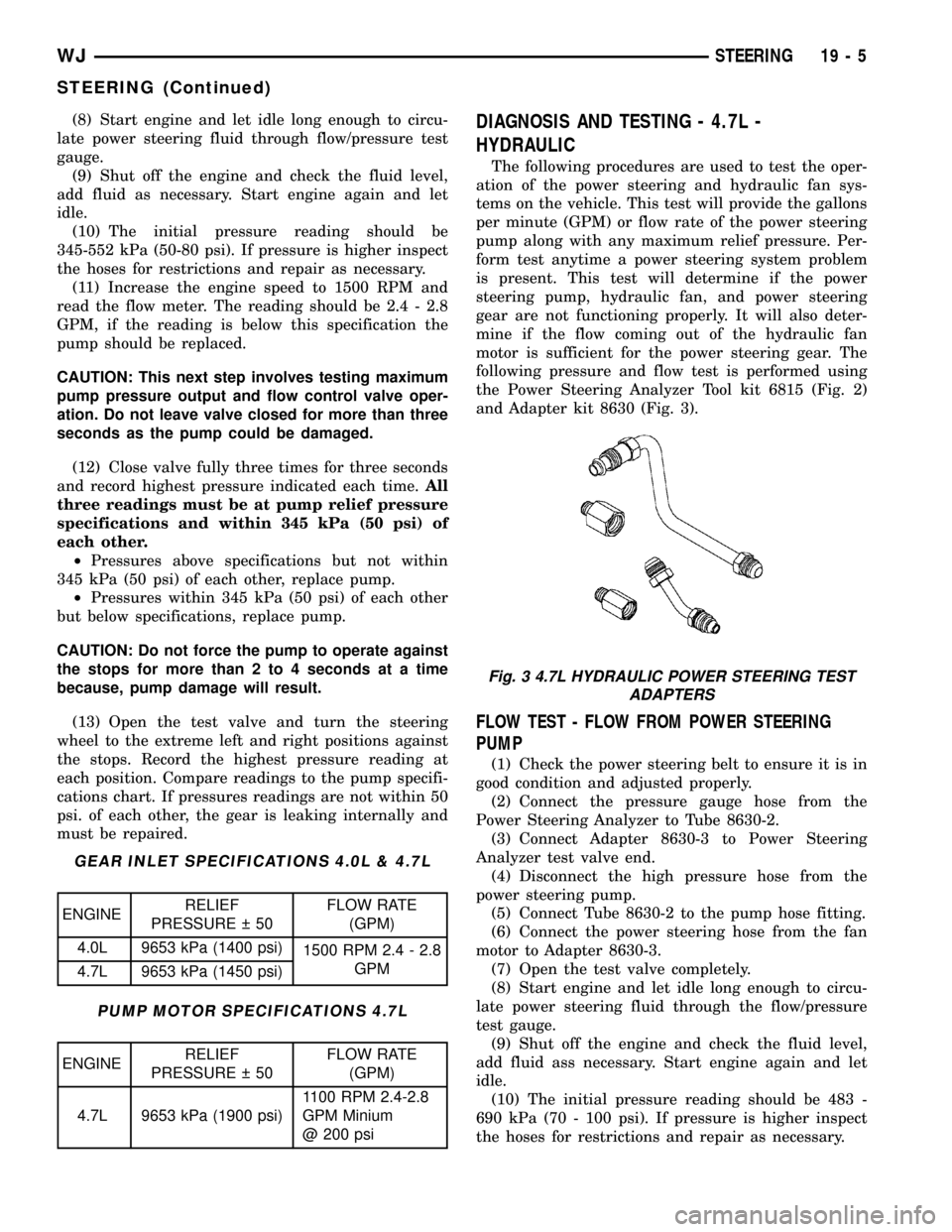

following pressure and flow test is performed using

the Power Steering Analyzer Tool kit 6815 (Fig. 2)

and Adapter kit 8630 (Fig. 3).

FLOW TEST - FLOW FROM POWER STEERING

PUMP

(1) Check the power steering belt to ensure it is in

good condition and adjusted properly.

(2) Connect the pressure gauge hose from the

Power Steering Analyzer to Tube 8630-2.

(3) Connect Adapter 8630-3 to Power Steering

Analyzer test valve end.

(4) Disconnect the high pressure hose from the

power steering pump.

(5) Connect Tube 8630-2 to the pump hose fitting.

(6) Connect the power steering hose from the fan

motor to Adapter 8630-3.

(7) Open the test valve completely.

(8) Start engine and let idle long enough to circu-

late power steering fluid through the flow/pressure

test gauge.

(9) Shut off the engine and check the fluid level,

add fluid ass necessary. Start engine again and let

idle.

(10) The initial pressure reading should be 483 -

690 kPa (70 - 100 psi). If pressure is higher inspect

the hoses for restrictions and repair as necessary.

Fig. 3 4.7L HYDRAULIC POWER STEERING TEST

ADAPTERS

WJSTEERING 19 - 5

STEERING (Continued)

Page 1483 of 2199

(11) Increase the engine speed to 1100 rpm and

read the flow meter. The reading should be 2.6 GPM

minimum, if the reading is below this specification,

the pump should be replaced.

FLOW AND PRESSURE TEST - FLOW FROM

HYDRAULIC FAN MOTOR TO STEERING GEAR

(should be done if necessary after the Pump flow

test)

(1) Connect the pressure gauge hose from the

Power Steering Analyzer to Fitting 8630-1.

(2) Connect Adapter 8630-4 to Power Steering

Analyzer test valve end.

(3) Disconnect the high pressure hose from the

power steering gear.

(4) Connect Fitting 8630-1 to the high pressure

hose.

(5) Connect Adapter 8630-4 to the power steering

gear.

(6) Open the test valve completely.

(7) Start engine and let idle long enough to circu-

late power steering fluid through the flow/pressure

test gauge.

(8) Shut off the engine and check the fluid level,

add fluid ass necessary. Start engine again and let

idle.

(9) The initial pressure reading should be 345-552

kPa (50-80 psi). If pressure is higher inspect the

hoses for restrictions and repair as necessary.(10) Increase the engine speed to 1500 RPM and

read the flow meter. The reading should be 2.4 - 2.8

GPM if the reading is below this specification the fan

should be replaced.

CAUTION: This next step involves testing maximum

fan motor steering relief pressure. Do not leave the

valve closed for more than three seconds.

(11) Close the valve fully three times for three sec-

onds and record highest pressures indicated each

time. All three readings must be at fan motor steer-

ing relief pressures.

(12) Open the test valve and turn the steering

wheel to the extreme left and right positions against

the stops. Record the highest pressure readings at

each position. If pressure readings are not within 50

psi from each other, the gear is leaking internally

and must be repaired.

PUMP MOTOR SPECIFICATIONS 4.7L

ENGINERELIEF

PRESSURE 50FLOW RATE

(GPM)

4.7L 9653 kPa (1900 psi)1100 RPM 2.4-2.8

GPM Minium

@ 200 psi

19 - 6 STEERINGWJ

STEERING (Continued)

Page 1495 of 2199

ADJUSTMENTS

STEERING GEAR

NOTE: Adjusting the steering gear in the vehicle is

not recommended. Remove gear from the vehicle

and drain the fluid. Then mount gear in a vise to

perform adjustments.

OVER-CENTER

(1) Rotate the stub shaft with Socket 8343 from

stop to stop and count the number of turns.

(2) Center the stub shaft by rotating it from the

stop 1/2 of the total amount of turns.

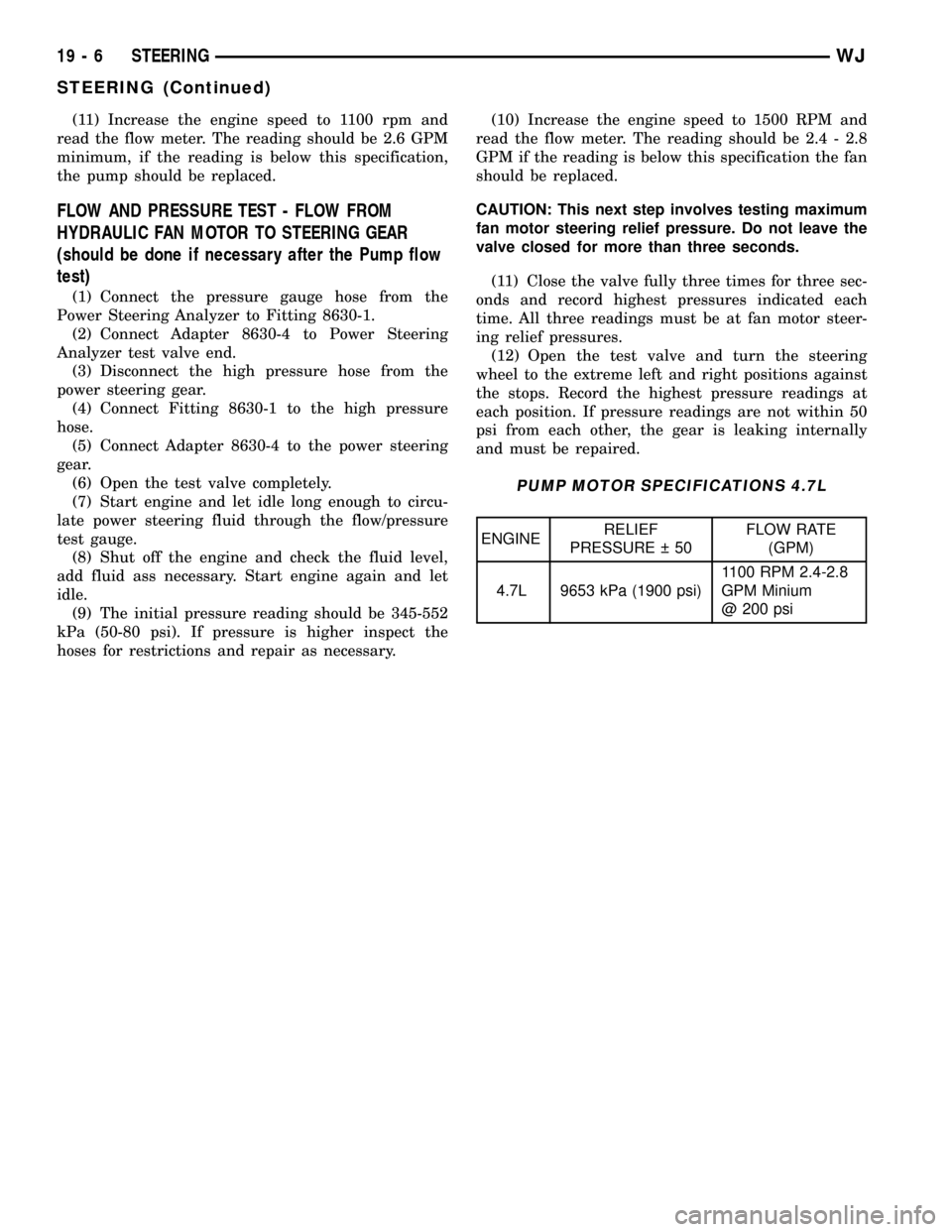

(3) Place torque wrench and Socket 8343 in a ver-

tical position on the stub shaft. Rotate the wrench 45

degrees each side of the center and record the high-

est rotational torque in this range (Fig. 4) . This is

the Over-Center Rotating Torque.

NOTE: The stub shaft must rotate smoothly without

sticking or binding.

(4) Rotate the stub shaft between 90É and 180É to

the left of center and record the left off-center pre-

load. Repeat this to the right of center and record the

right off-center preload. The average of these two

recorded readings is the Preload Rotating Torque.

(5) The Over-Center Rotating Torque should be

0.45-0.80 N´m (4-7 in. lbs.)higherthan the Preload

Rotating Torque.

(6) If an adjustment to the Over-Center Rotating

Torque is necessary, first loosen the adjuster lock

nut. Then turn the pitman shaft adjuster screw back

(COUNTERCLOCKWISE) until fully extended, then

turn back in (CLOCKWISE) one full turn.

(7) Remeasure Over-Center Rotating Torque. If

necessary turn the adjuster screw and repeat mea-

surement until correct Over-Center Rotating Torque

is reached.

NOTE: To increase the Over-Center Rotating Torque

turn the screw CLOCKWISE.(8) Prevent the adjuster screw from turning while

tightening adjuster lock nut. Tighten the adjuster

lock nut to 37-52 N´m (27-38 ft. lbs.).

SPECIFICATIONS

POWER STEERING GEAR

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Steering Gear

TypeRecirculating Ball

Steering Gear

Overall Ratio12.7:1

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Pitman Shaft Overcenter Drag

New Gear (under 400 miles)0.45-0.80

+ Worm Shaft PreloadÐ 4-7

+ Worm Shaft Preload

Pitman Shaft Overcenter Drag

Used Gear (over 400 miles)0.5-0.6

+ Worm Shaft PreloadÐ 4-5

+ Worm Shaft Preload

Fig. 4 Checking Over-center Rotation Torque

1 - CENTER

19 - 18 GEARWJ

GEAR (Continued)

Page 1502 of 2199

INSTALLATION

(1) Lubricate new o-ring and teflon rings with

power steering fluid and install on the rack piston/

valve assembly.

(2) Lubricate the rack piston/valve assembly with

power steering fluid.

(3) Slide the assembly into the gear housing.

(4) Install new stub shaft housing o-rings and

install the housing. Tighten the housing bolts to 62

N´m (46 ft. lbs.).

(5) Install new o-ring on the pitman shaft cover.

(6) Install the pitman shaft into the gear housing.

(7) Install the pitman shaft cover bolts and tighten

to 62 N´m (46 ft. lbs.).

(8) Perform over-center rotation torque adjustment

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS)..

(9) Install the steering gear (Refer to 19 - STEER-

ING/GEAR - INSTALLATION).

(10) Fill the power steering pump (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

STUB SHAFT HOUSING

REMOVAL

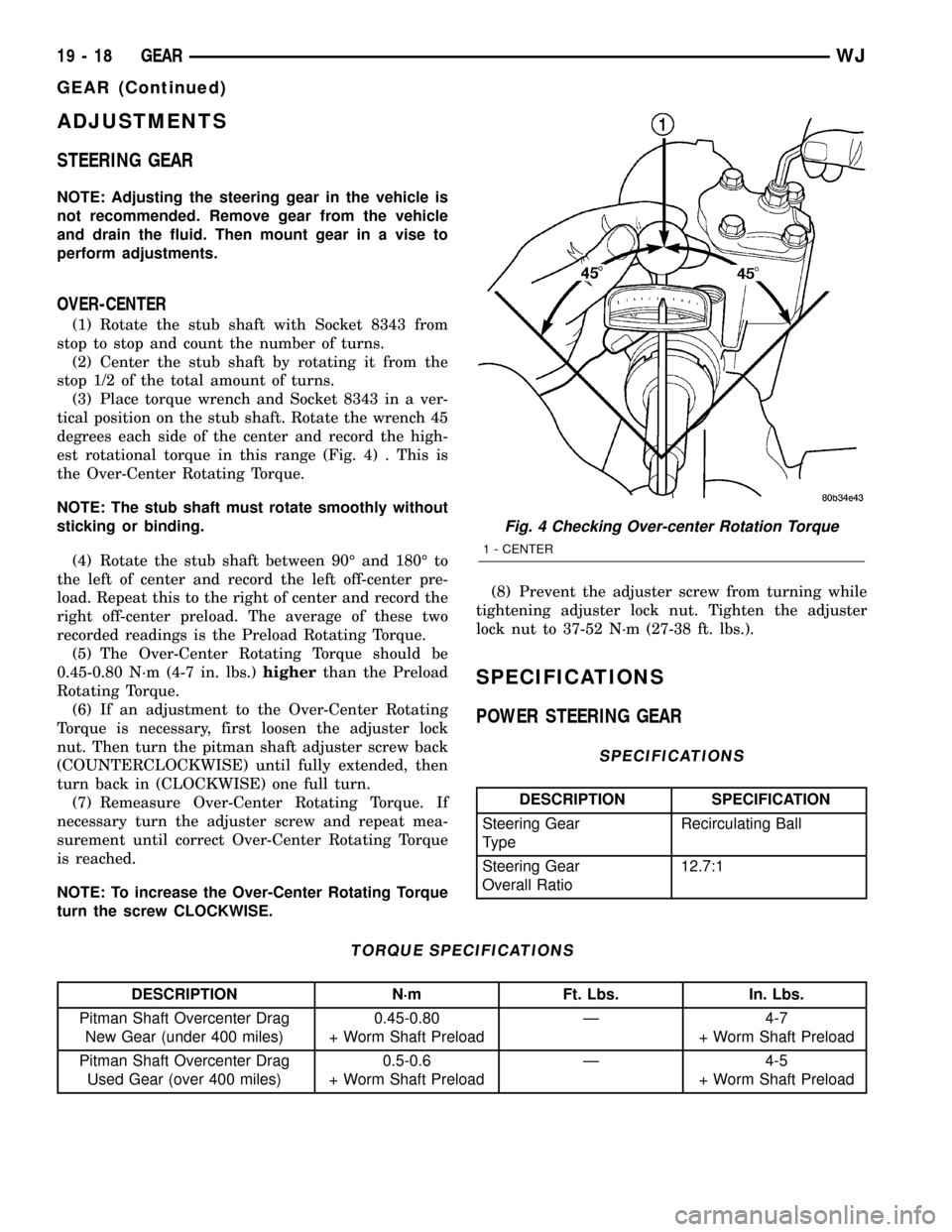

NOTE: If stub shaft housing, seal or bearing is dam-

aged the housing must be replaced.

(1) Remove the steering gear (Refer to 19 -

STEERING/GEAR - REMOVAL).

(2) Remove stub shaft housing bolts (Fig. 19).

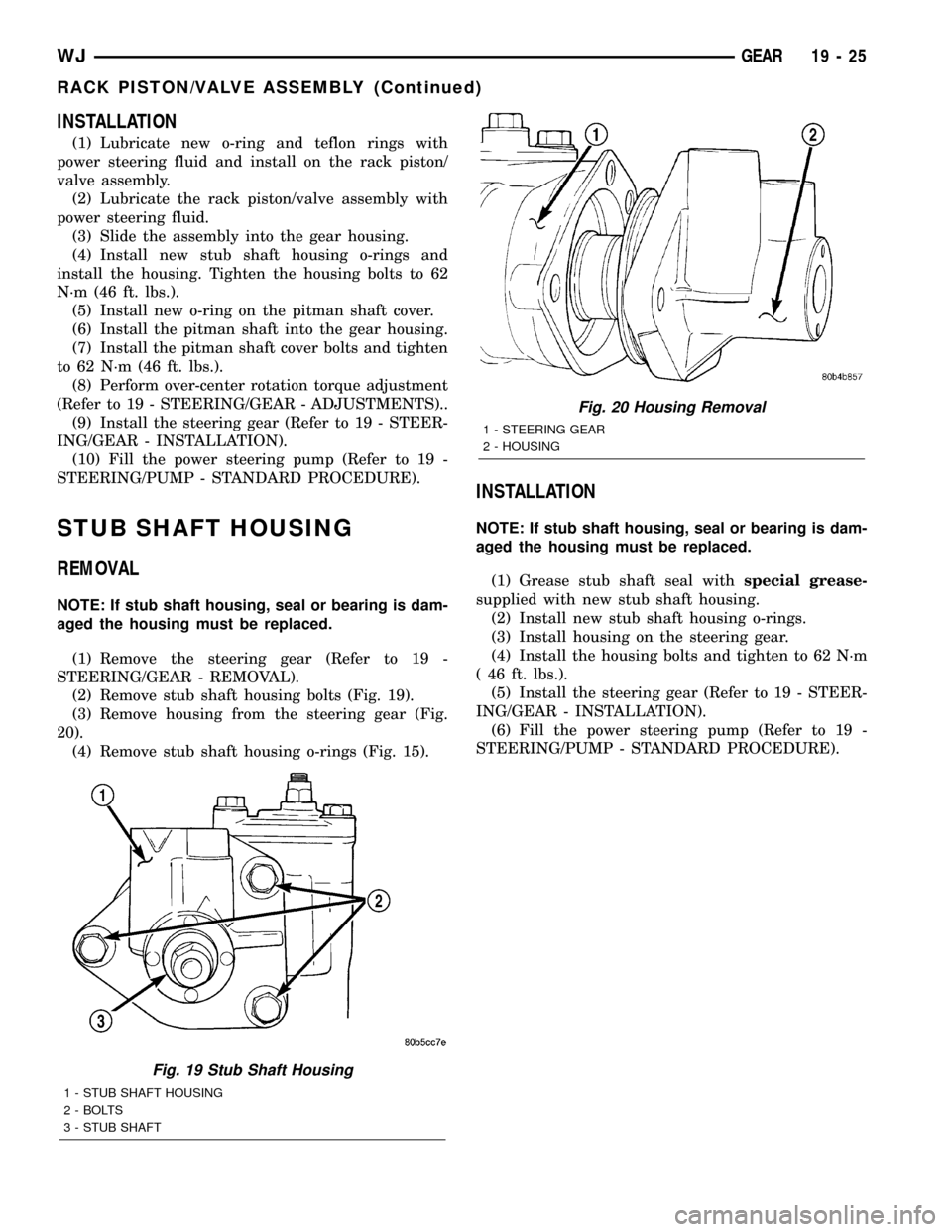

(3) Remove housing from the steering gear (Fig.

20).

(4) Remove stub shaft housing o-rings (Fig. 15).

INSTALLATION

NOTE: If stub shaft housing, seal or bearing is dam-

aged the housing must be replaced.

(1) Grease stub shaft seal withspecial grease-

supplied with new stub shaft housing.

(2) Install new stub shaft housing o-rings.

(3) Install housing on the steering gear.

(4) Install the housing bolts and tighten to 62 N´m

( 46 ft. lbs.).

(5) Install the steering gear (Refer to 19 - STEER-

ING/GEAR - INSTALLATION).

(6) Fill the power steering pump (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

Fig. 19 Stub Shaft Housing

1 - STUB SHAFT HOUSING

2 - BOLTS

3 - STUB SHAFT

Fig. 20 Housing Removal

1 - STEERING GEAR

2 - HOUSING

WJGEAR 19 - 25

RACK PISTON/VALVE ASSEMBLY (Continued)

Page 1508 of 2199

PUMP

TABLE OF CONTENTS

page page

PUMP

DESCRIPTION - 4.0L, 4.7L................32

OPERATION

OPERATION - 4.7L....................32

OPERATION - 4.0L....................32

DIAGNOSIS AND TESTING - PUMP LEAKAGE . 33

STANDARD PROCEDURE

STANDARD PROCEDURE - INITIAL

OPERATION - 4.0L....................33

STANDARD PROCEDURE - INITIAL

OPERATION - 4.7L....................33

REMOVAL

REMOVAL - 4.0L ENGINE...............34

REMOVAL - 4.7L ENGINE...............34

INSTALLATION

INSTALLATION - 4.0L ENGINE...........34

INSTALLATION - 4.7L ENGINE...........34

SPECIFICATIONS

TORQUE CHART......................35

SPECIAL TOOLS

POWER STEERING PUMP..............36

FLUID COOLER

DESCRIPTION.........................36

REMOVAL.............................36

INSTALLATION.........................37

HOSES - 4.0L

DESCRIPTION

DESCRIPTION - PRESSURE LINE........37

DESCRIPTION - RETURN LINE...........37

OPERATION

OPERATION - PRESSURE LINE..........37

OPERATION - RETURN LINE............37

REMOVAL.............................37

INSTALLATION.........................37

HOSES - 4.7L

DESCRIPTION

DESCRIPTION - 1/2º PRESSURE HOSE....38DESCRIPTION - 1/2º RETURN HOSE......38

DESCRIPTION - 3/8º PRESSURE HOSE....38

DESCRIPTION - 3/8º GEAR OUTLET HOSE . 38

DESCRIPTION - 3/8º RETURN HOSE......38

OPERATION

OPERATION - 1/2º PRESSURE HOSE......38

OPERATION - 1/2º RETURN HOSE........38

OPERATION - 3/8º PRESSURE HOSE......39

OPERATION - 3/8º GEAR OUTLET HOSE . . . 39

OPERATION - 3/8ºRETURN HOSE........39

REMOVAL

REMOVAL - 1/29PRESSURE HOSE.......39

REMOVAL - 1/29RETURN HOSE..........39

REMOVAL - 3/89PRESSURE HOSE.......39

REMOVAL - 3/89RETURN HOSE..........39

REMOVAL - 3/89GEAR OUTLET HOSE.....40

REMOVAL - INLET COOLER HOSE........40

REMOVAL - OUTLET COOLER HOSE......40

INSTALLATION

INSTALLATION - 1/29PRESSURE HOSE....40

INSTALLATION - 1/29RETURN HOSE......40

INSTALLATION - 3/89PRESSURE HOSE....41

INSTALLATION - 3/89RETURN HOSE......41

INSTALLATION - 3/89GEAR OUTLET HOSE . 41

INSTALLATION - INLET COOLER HOSE....41

INSTALLATION - OUTLET COOLER HOSE . . 41

PULLEY

DESCRIPTION

POWER STEERING PUMP PULLEY - 3.1L

DIESEL.............................41

REMOVAL.............................41

INSTALLATION.........................42

RESERVOIR

REMOVAL.............................42

INSTALLATION.........................42

WJPUMP 19 - 31

Page 1509 of 2199

PUMP

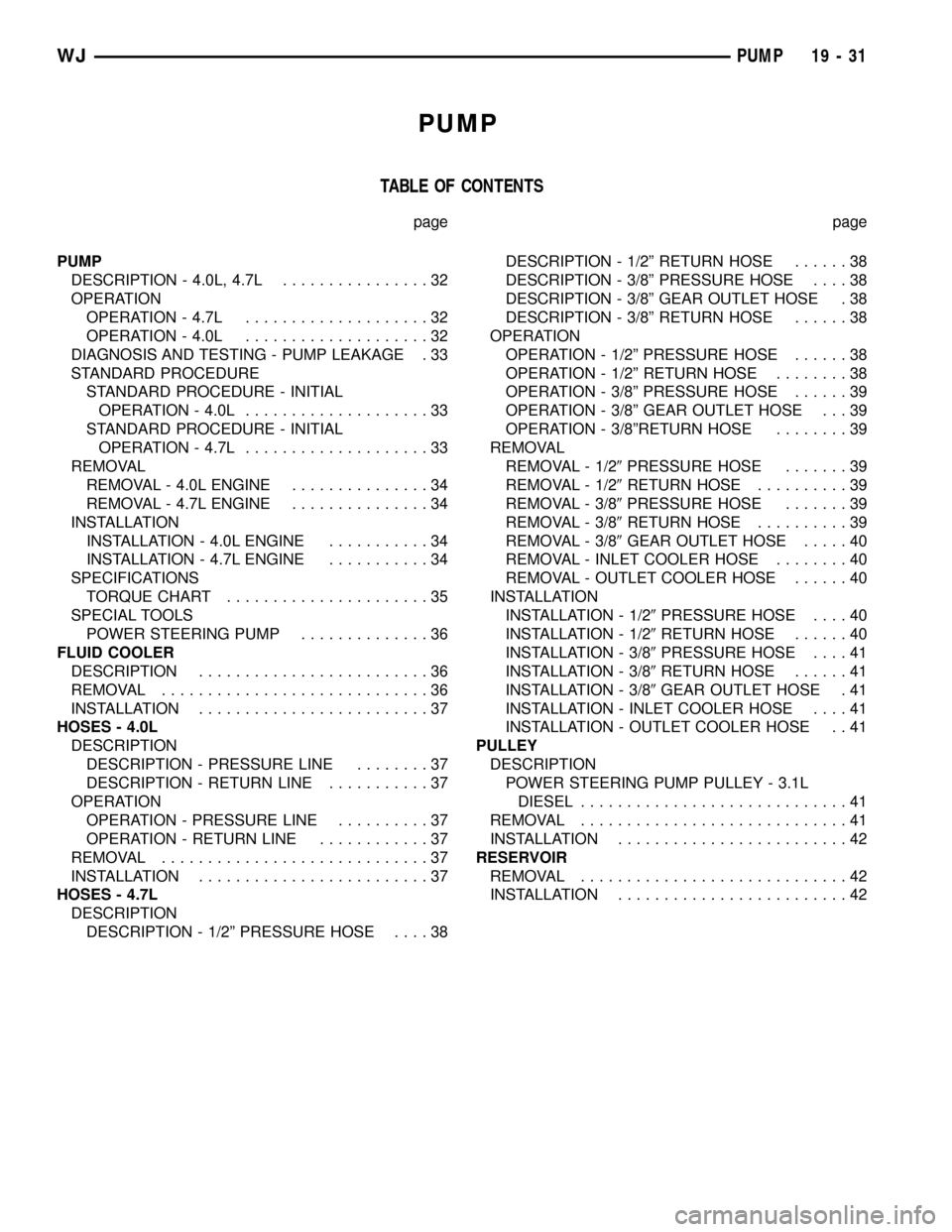

DESCRIPTION - 4.0L, 4.7L

Hydraulic pressure for the power steering system

is provided by a belt driven power steering pump

(Fig. 1) and (Fig. 2). The pump shaft has a

pressed-on drive pulley that is belt driven by the

crankshaft pulley.

OPERATION

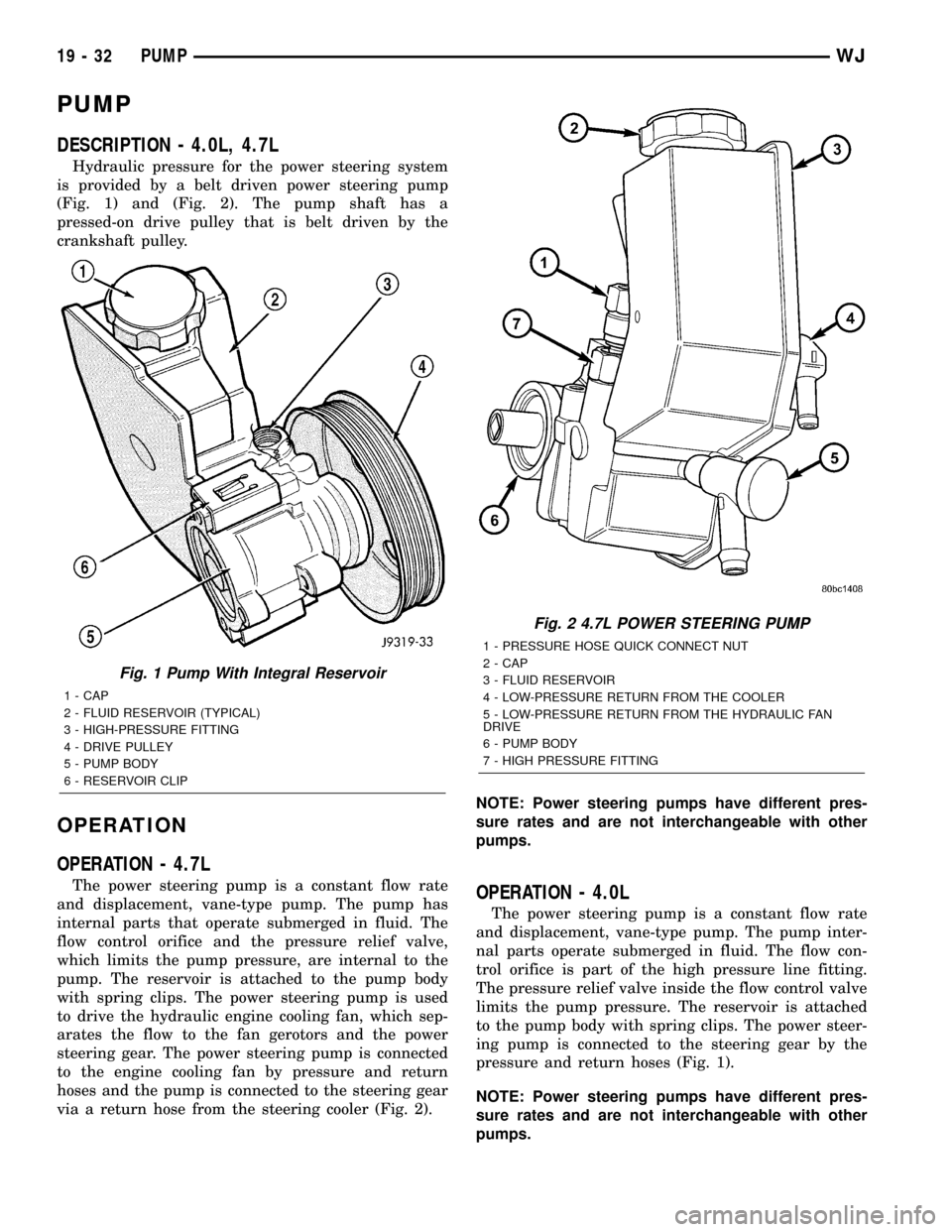

OPERATION - 4.7L

The power steering pump is a constant flow rate

and displacement, vane-type pump. The pump has

internal parts that operate submerged in fluid. The

flow control orifice and the pressure relief valve,

which limits the pump pressure, are internal to the

pump. The reservoir is attached to the pump body

with spring clips. The power steering pump is used

to drive the hydraulic engine cooling fan, which sep-

arates the flow to the fan gerotors and the power

steering gear. The power steering pump is connected

to the engine cooling fan by pressure and return

hoses and the pump is connected to the steering gear

via a return hose from the steering cooler (Fig. 2).NOTE: Power steering pumps have different pres-

sure rates and are not interchangeable with other

pumps.OPERATION - 4.0L

The power steering pump is a constant flow rate

and displacement, vane-type pump. The pump inter-

nal parts operate submerged in fluid. The flow con-

trol orifice is part of the high pressure line fitting.

The pressure relief valve inside the flow control valve

limits the pump pressure. The reservoir is attached

to the pump body with spring clips. The power steer-

ing pump is connected to the steering gear by the

pressure and return hoses (Fig. 1).

NOTE: Power steering pumps have different pres-

sure rates and are not interchangeable with other

pumps.

Fig. 1 Pump With Integral Reservoir

1 - CAP

2 - FLUID RESERVOIR (TYPICAL)

3 - HIGH-PRESSURE FITTING

4 - DRIVE PULLEY

5 - PUMP BODY

6 - RESERVOIR CLIP

Fig. 2 4.7L POWER STEERING PUMP

1 - PRESSURE HOSE QUICK CONNECT NUT

2 - CAP

3 - FLUID RESERVOIR

4 - LOW-PRESSURE RETURN FROM THE COOLER

5 - LOW-PRESSURE RETURN FROM THE HYDRAULIC FAN

DRIVE

6 - PUMP BODY

7 - HIGH PRESSURE FITTING

19 - 32 PUMPWJ

Page 1510 of 2199

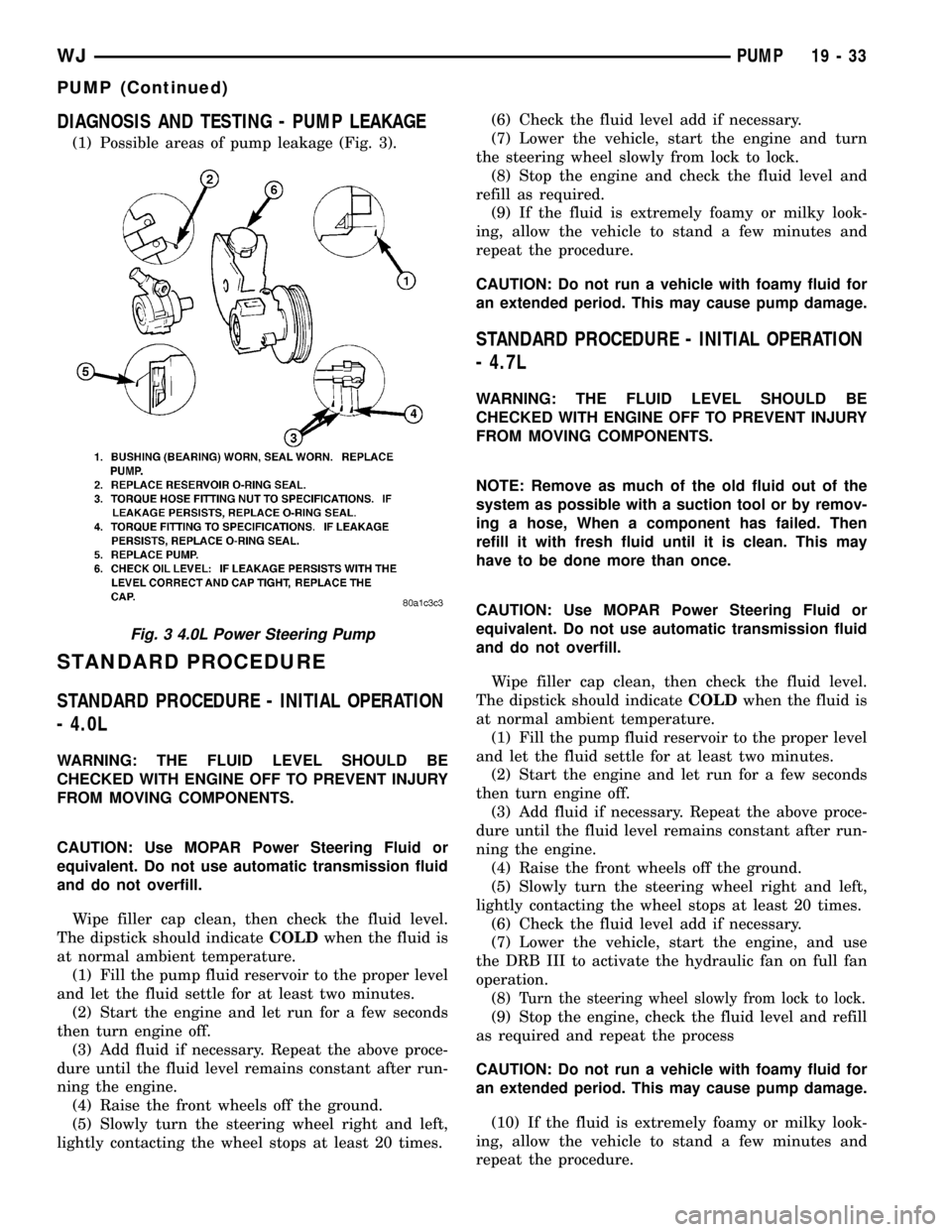

DIAGNOSIS AND TESTING - PUMP LEAKAGE

(1) Possible areas of pump leakage (Fig. 3).

STANDARD PROCEDURE

STANDARD PROCEDURE - INITIAL OPERATION

- 4.0L

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal ambient temperature.

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two minutes.

(2) Start the engine and let run for a few seconds

then turn engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine and turn

the steering wheel slowly from lock to lock.

(8) Stop the engine and check the fluid level and

refill as required.

(9) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

STANDARD PROCEDURE - INITIAL OPERATION

- 4.7L

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

NOTE: Remove as much of the old fluid out of the

system as possible with a suction tool or by remov-

ing a hose, When a component has failed. Then

refill it with fresh fluid until it is clean. This may

have to be done more than once.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal ambient temperature.

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two minutes.

(2) Start the engine and let run for a few seconds

then turn engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.

(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine, and use

the DRB III to activate the hydraulic fan on full fan

operation.

(8)

Turn the steering wheel slowly from lock to lock.

(9) Stop the engine, check the fluid level and refill

as required and repeat the process

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

(10) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

Fig. 3 4.0L Power Steering Pump

WJPUMP 19 - 33

PUMP (Continued)

Page 1511 of 2199

(11) While the vehicle is in park, use the DRB III

to activate the hydraulic fan to full fan operation and

briefly rev the engine up to 3000 rpm to fully engage

the hydraulic fan.

(12) Check the fluid level add if necessary.

REMOVAL

REMOVAL - 4.0L ENGINE

(1) Remove serpentine drive belt,(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove pressure and return hoses from pump

and drain the pump.

(3)

Loosen the pump bracket bolt at the engine block.

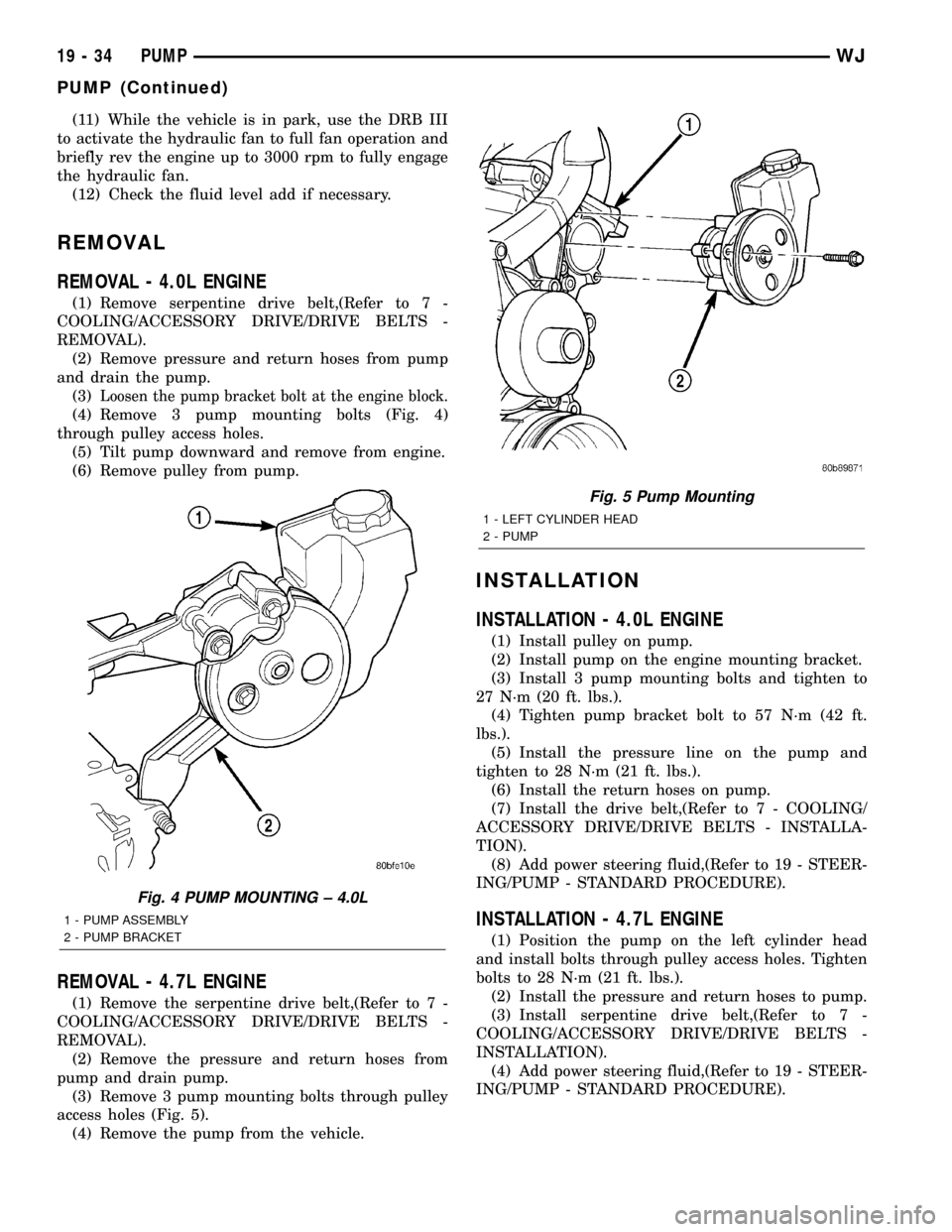

(4) Remove 3 pump mounting bolts (Fig. 4)

through pulley access holes.

(5) Tilt pump downward and remove from engine.

(6) Remove pulley from pump.

REMOVAL - 4.7L ENGINE

(1) Remove the serpentine drive belt,(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove the pressure and return hoses from

pump and drain pump.

(3) Remove 3 pump mounting bolts through pulley

access holes (Fig. 5).

(4) Remove the pump from the vehicle.

INSTALLATION

INSTALLATION - 4.0L ENGINE

(1) Install pulley on pump.

(2) Install pump on the engine mounting bracket.

(3) Install 3 pump mounting bolts and tighten to

27 N´m (20 ft. lbs.).

(4) Tighten pump bracket bolt to 57 N´m (42 ft.

lbs.).

(5) Install the pressure line on the pump and

tighten to 28 N´m (21 ft. lbs.).

(6) Install the return hoses on pump.

(7) Install the drive belt,(Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(8) Add power steering fluid,(Refer to 19 - STEER-

ING/PUMP - STANDARD PROCEDURE).

INSTALLATION - 4.7L ENGINE

(1) Position the pump on the left cylinder head

and install bolts through pulley access holes. Tighten

bolts to 28 N´m (21 ft. lbs.).

(2) Install the pressure and return hoses to pump.

(3) Install serpentine drive belt,(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(4) Add power steering fluid,(Refer to 19 - STEER-

ING/PUMP - STANDARD PROCEDURE).

Fig. 4 PUMP MOUNTING ± 4.0L

1 - PUMP ASSEMBLY

2 - PUMP BRACKET

Fig. 5 Pump Mounting

1 - LEFT CYLINDER HEAD

2 - PUMP

19 - 34 PUMPWJ

PUMP (Continued)

Page 1513 of 2199

SPECIAL TOOLS

POWER STEERING PUMP

FLUID COOLER

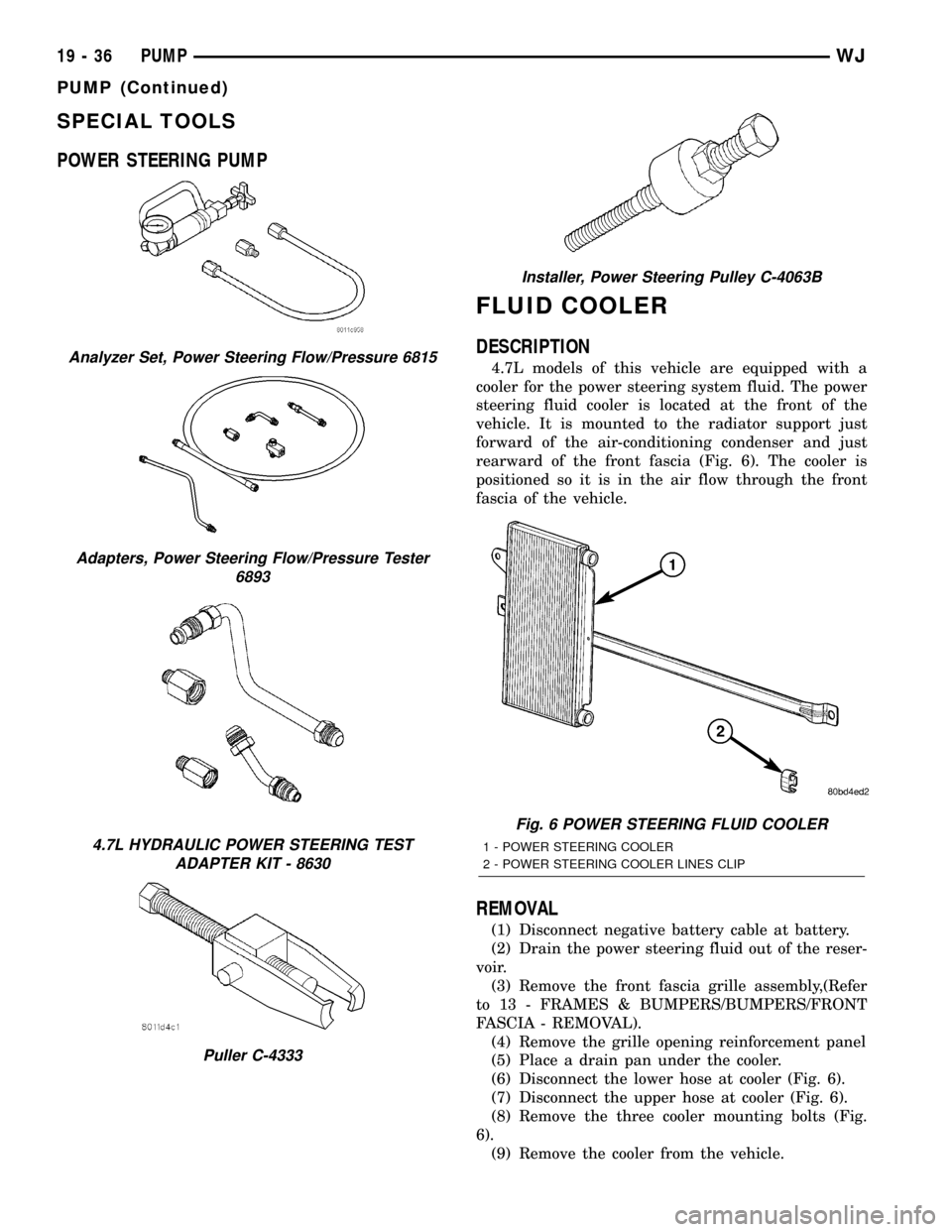

DESCRIPTION

4.7L models of this vehicle are equipped with a

cooler for the power steering system fluid. The power

steering fluid cooler is located at the front of the

vehicle. It is mounted to the radiator support just

forward of the air-conditioning condenser and just

rearward of the front fascia (Fig. 6). The cooler is

positioned so it is in the air flow through the front

fascia of the vehicle.

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Drain the power steering fluid out of the reser-

voir.

(3) Remove the front fascia grille assembly,(Refer

to 13 - FRAMES & BUMPERS/BUMPERS/FRONT

FASCIA - REMOVAL).

(4) Remove the grille opening reinforcement panel

(5) Place a drain pan under the cooler.

(6) Disconnect the lower hose at cooler (Fig. 6).

(7) Disconnect the upper hose at cooler (Fig. 6).

(8) Remove the three cooler mounting bolts (Fig.

6).

(9) Remove the cooler from the vehicle.

Analyzer Set, Power Steering Flow/Pressure 6815

Adapters, Power Steering Flow/Pressure Tester

6893

4.7L HYDRAULIC POWER STEERING TEST

ADAPTER KIT - 8630

Puller C-4333

Installer, Power Steering Pulley C-4063B

Fig. 6 POWER STEERING FLUID COOLER

1 - POWER STEERING COOLER

2 - POWER STEERING COOLER LINES CLIP

19 - 36 PUMPWJ

PUMP (Continued)

Page 1514 of 2199

INSTALLATION

(1) Position and install the power steering cooler

to the vehicle.

(2) Install the three mounting bracket bolts (Fig.

6).

(3) Reconnect the upper hose at cooler (Fig. 6).

(4) Reconnect the lower hose at cooler (Fig. 6).

(5) Connect negative battery cable to battery.

(6) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

(7) Start engine and check for leaks.

(8) Install the grille opening reinforcement panel

(9) Install the front fascia grille,(Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT FASCIA

- INSTALLATION).

HOSES - 4.0L

DESCRIPTION

DESCRIPTION - PRESSURE LINE

The hose consists of two metal ends and rubber

center section that contains a tuning cable. The

pump end uses a quick connect fitting. Lubircation

must be used on the quick connect nut and o-ring

when installing.

DESCRIPTION - RETURN LINE

Power steering return line is a hose which is

clamped at the pump and the gear.

OPERATION

OPERATION - PRESSURE LINE

Power steering pressure line, is used to transfer

high pressure power steering fluid, from the power

steering pump to the power steering gear on the

4.0L. The 4.7L power steering pressure line, is used

to transfer high pressure power steering fluid, from

the power steering pump to the engine cooling fan

and the steering gear.

OPERATION - RETURN LINE

Power steering return line, is used to transfer low

pressure power steering fluid, from the power steer-

ing gear to the power steering pump.

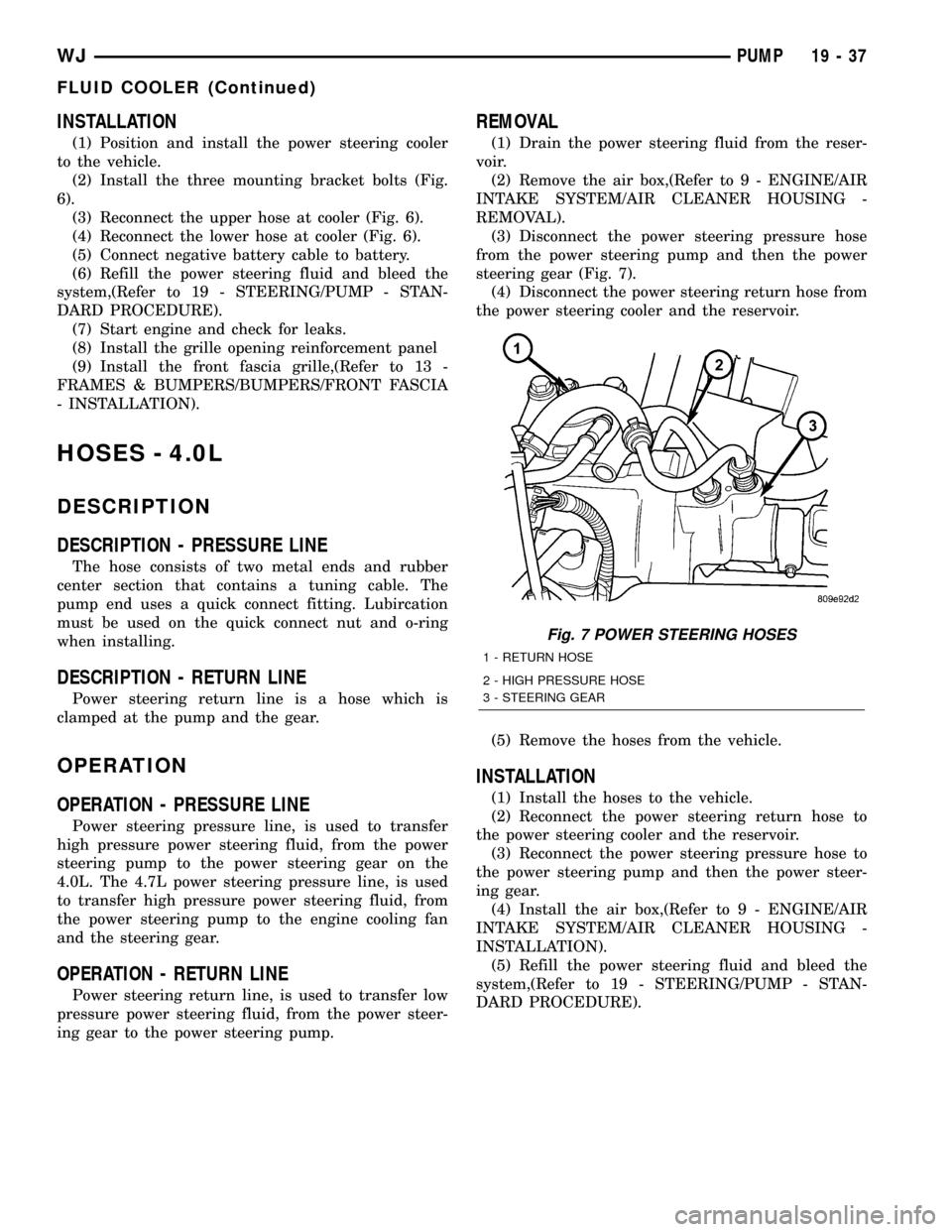

REMOVAL

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Disconnect the power steering pressure hose

from the power steering pump and then the power

steering gear (Fig. 7).

(4) Disconnect the power steering return hose from

the power steering cooler and the reservoir.

(5) Remove the hoses from the vehicle.

INSTALLATION

(1) Install the hoses to the vehicle.

(2) Reconnect the power steering return hose to

the power steering cooler and the reservoir.

(3) Reconnect the power steering pressure hose to

the power steering pump and then the power steer-

ing gear.

(4) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(5) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

Fig. 7 POWER STEERING HOSES

1 - RETURN HOSE

2 - HIGH PRESSURE HOSE

3 - STEERING GEAR

WJPUMP 19 - 37

FLUID COOLER (Continued)