Cable JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 178 of 2199

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.

(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, brake lines, master cyl-

inder, and HCU.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals,

cups, hoses, master cylinder, and HCU will also

have to be replaced after flushing. Use clean brake

fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and lever. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only (do not exceed 25 mph) and note grab,

drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper. If leakage is severe, fluid will be evident at

or around the leaking component.Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS system may also be

the problem with no visual fluid leak.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, the most

likely causes are worn linings, rotors, or calipers are

not sliding on the slide pins. The proper course of

action is to inspect and replace all worn component.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However substandard brake hoses can cause

a spongy pedal. The proper course of action is to

bleed the system, and replace substandard quality

brake hoses if suspected.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster, check valve, check

valve seal/grommet or vacuum leak could also cause

a hard pedal or high pedal effort.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness vari-

ation. Other causes are loose wheel bearings or cali-

pers and worn, damaged tires.

NOTE: Some pedal pulsation may be felt during

ABS activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.

Drag is a product of incomplete brake release.

Drag can be minor or severe enough to overheat the

linings, rotors and park brake drums.

Minor drag will usually cause slight surface charring

of the lining. It can also generate hard spots in rotors

and park brake drums from the overheat-cool down pro-

cess. In most cases, the rotors, wheels and tires are

quite warm to the touch after the vehicle is stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors to the

point of replacement. The wheels, tires and brake

components will be extremely hot. In severe cases,

the lining may generate smoke as it chars from over-

heating.

WJBRAKES - BASE 5 - 3

BRAKES - BASE (Continued)

Page 179 of 2199

Common causes of brake drag are:

²Parking brake partially applied.

²Loose/worn wheel bearing.

²Seized caliper.

²Caliper binding.

²Loose caliper mounting.

²Mis-assembled components.

²Damaged brake lines.

If brake drag occurs at the front, rear or all

wheels, the problem may be related to a blocked mas-

ter cylinder return port, faulty power booster (binds-

does not release) or the ABS system.

BRAKE FADE

Brake fade is usually a product of overheating

caused by brake drag. However, brake overheating

and resulting fade can also be caused by riding the

brake pedal, making repeated high deceleration stops

in a short time span, or constant braking on steep

mountain roads. Refer to the Brake Drag information

in this section for causes.

BRAKE PULL

Front brake pull condition could result from:

²Contaminated lining in one caliper

²Seized caliper piston

²Binding caliper

²Loose caliper

²Rusty caliper slide surfaces

²Improper brake shoes

²Damaged rotor

²Wheel alignment.

²Tire pressure.

A worn, damaged wheel bearing or suspension compo-

nent are further causes of pull. A damaged front tire

(bruised, ply separation) can also cause pull.

A common and frequently misdiagnosed pull condi-

tion is where direction of pull changes after a few

stops. The cause is a combination of brake drag fol-

lowed by fade at one of the brake units.

As the dragging brake overheats, efficiency is so

reduced that fade occurs. Since the opposite brake

unit is still functioning normally, its braking effect is

magnified. This causes pull to switch direction in

favor of the normally functioning brake unit.

An additional point when diagnosing a change in

pull condition concerns brake cool down. Remember

that pull will return to the original direction, if the

dragging brake unit is allowed to cool down (and is

not seriously damaged).

REAR BRAKE DRAG OR PULL

Rear drag or pull may be caused by improperly

adjusted park brake shoes or seized parking brake

cables, contaminated lining, bent or binding shoes or

improperly assembled components. This is particu-

larly true when only one rear wheel is involved.However, when both rear wheels are affected, the

master cylinder or ABS system could be at fault.

BRAKES DO NOT HOLD AFTER DRIVING THROUGH DEEP

WATER PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by

driving with the brakes very lightly applied for a

mile or two. However, if the lining is both soaked and

dirt contaminated, cleaning and or replacement will

be necessary.

BRAKE LINING CONTAMINATION

Brake lining contamination is mostly a product of

leaking calipers or worn seals, driving through deep

water puddles, or lining that has become covered with

grease and grit during repair. Contaminated lining

should be replaced to avoid further brake problems.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

NOTE: Propshaft angle can also cause vibration/

shudder.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and

recovers traction. Flat-spotted tires can cause vibra-

tion and generate shudder during brake operation.

Tire damage such as a severe bruise, cut, ply separa-

tion, low air pressure can cause pull and vibration.

BRAKE NOISES

Some brake noise is common on some disc brakes

during the first few stops after a vehicle has been

parked overnight or stored. This is primarily due to

the formation of trace corrosion (light rust) on metal

surfaces. This light corrosion is typically cleared from

the metal surfaces after a few brake applications

causing the noise to subside.

BRAKE SQUEAK/SQUEAL

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or oil.

Glazed linings and rotors with hard spots can also con-

tribute to squeak. Dirt and foreign material embedded

in the brake lining will also cause squeak/squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brake shoes in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors may become so scored that replacement is nec-

essary.

5 - 4 BRAKES - BASEWJ

BRAKES - BASE (Continued)

Page 201 of 2199

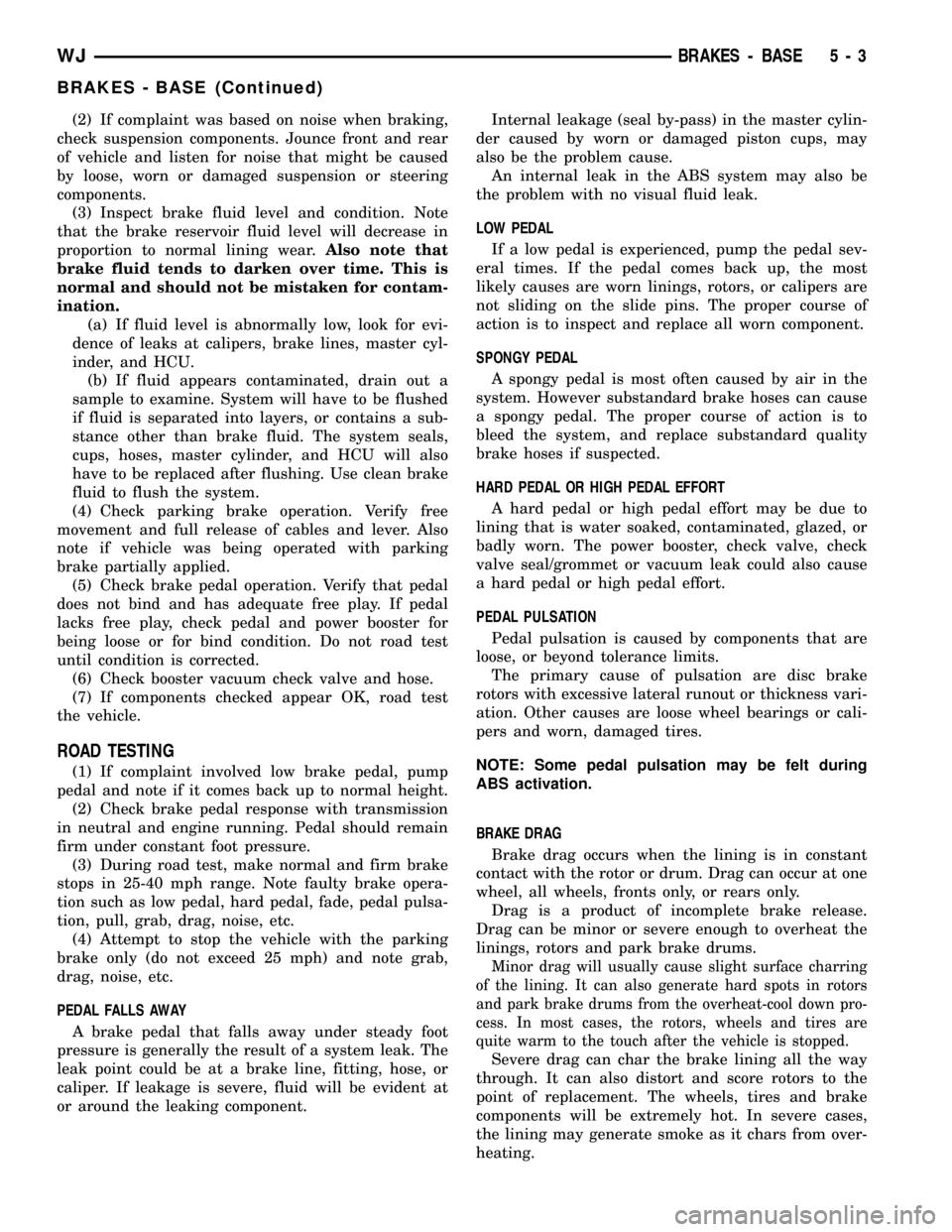

tions also allows the driver to set steering wheel tilt

and seat position to the most comfortable position.

The position of the brake and accelerator pedals can

be adjusted without compromising safety or comfort

in actuating the pedals. Repositioning the pedals

does not change the effort required for actuation.

Change of pedal position is accomplished by means

of a motor driven screw. Operating the adjustable

pedal switch activates the pedal drive motor. The

pedal drive motor turns a screw that changes the

position of the brake and accelerator pedals. The

pedal can be moved rearward (closer to the driver) or

forward (away from driver). The brake pedal is

moved on its drive screw to a position where the

driver feels most comfortable (Fig. 52).

The accelerator pedal is moved at the same time

and the same distance as the brake pedal. The accel-

erator pedal adjustment screw is turned by a flexible

shaft slaved off the brake adjustment screw.

Neither the pedal drive motor nor drive mecha-

nism are subject to the mechanical stress of brake or

accelerator application.

²SYSTEM FEATURES:

²Range of Adjustment: The pedals may be

adjusted up to 3 in. (75 mm)

²Pedal Adjustment Speed: 0.5 in./sec (12.5

mm/sec)

²Pedal Adjustment Inhibitors: Pedal adjust-

ment is inhibited when the vehicle is in reverse or

when cruise control is activated.

²Memory: An optional memory feature is avail-

able. This allows storing of one or two preferred

pedal positions in the Adjustable Pedal Module

(APM). A preferred position can be stored and

recalled using the door-mounted switches. A stored

pedal position can be recalled (but not stored)

using the Remote Keyless Entry (RKE).

²

Adjustable Pedal Feedback Message: The Elec-

tronic Vehicle Information Center (EVIC) will display

a message when the APS is disabled. ie:9Adjustable

Pedal Disabled - Cruise Control Engaged9or9Adjust-

able Pedal Disabled - Vehicle in Reverse9.

²Damage Prevention: Foot pressure or debris

can stall pedal adjustment. In order to avoid dam-

age to system components during pedal adjust-

ment, the APM will monitor pedal position sensor

voltage. If the APM does not detect expected volt-

age change within 1.5 seconds, it will cut power to

the adjustable pedal motor.

OPERATION

The brake pedal is attached to the booster push

rod. When the pedal is depressed, the primary

booster push rod is depressed which moves the

booster secondary rod. The booster secondary rod

depresses the master cylinder piston.

REMOVAL

REMOVAL - NON-ADJUSTABLE PEDAL

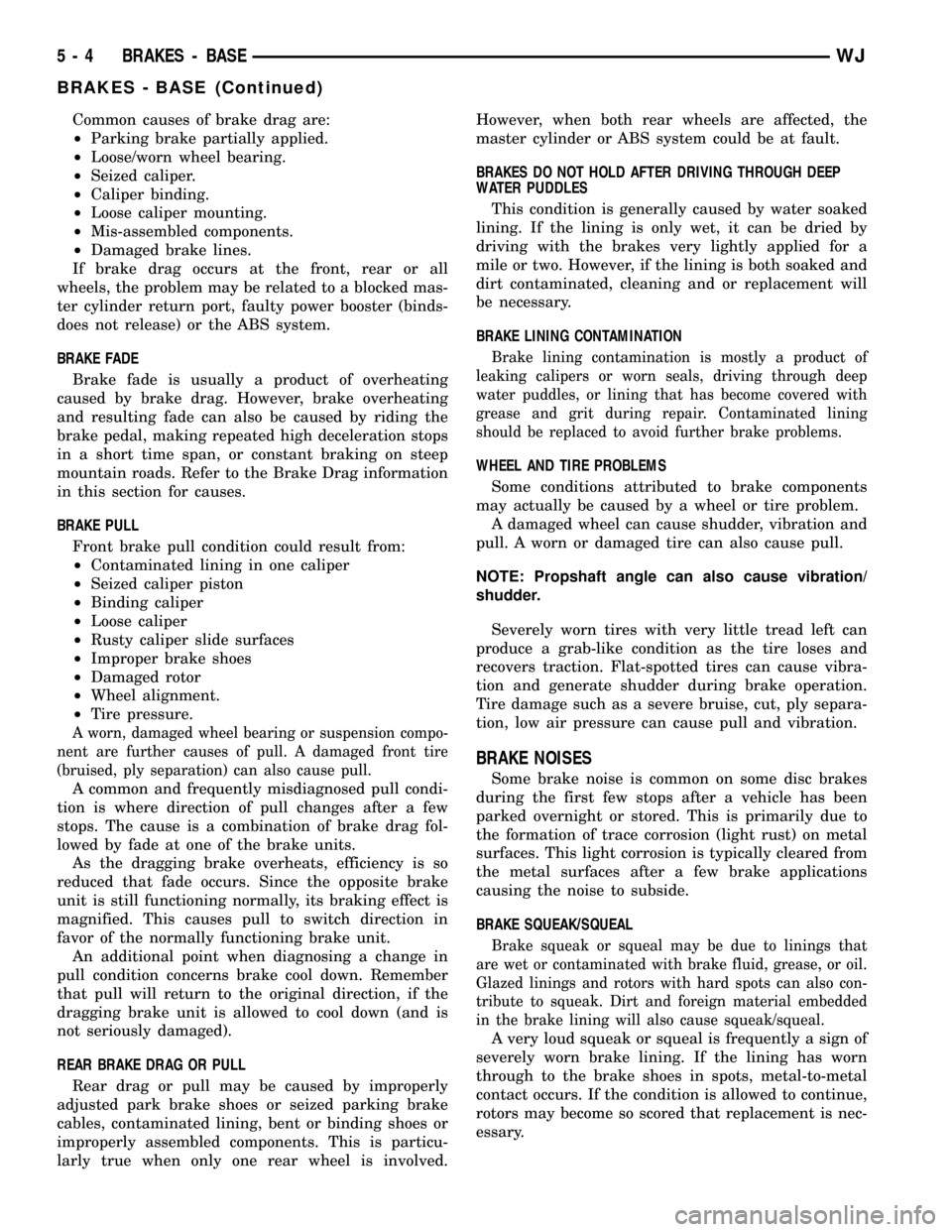

(1) Remove retainer clip that holds booster to

pedal pin (Fig. 53).

Fig. 52 ADJUSTABLE PEDALS ASSEMBLY

1 - HARNESS

2 - ADJUSTABLE PEDAL BRACKET

3 - CABLE

4 - ACCELERATOR PEDAL

5 - BRAKE PEDAL

6 - ADJUSTABLE PEDAL MOTOR

7 - BRAKE LIGHT SWITCH

8 - ADJUSTABLE PEDALS MODULE

Fig. 53 Push Rod Retainer Clip

1 - RETAINER CLIP

2 - PUSH ROD

3 - PEDAL PIN

5 - 26 BRAKES - BASEWJ

PEDAL (Continued)

Page 202 of 2199

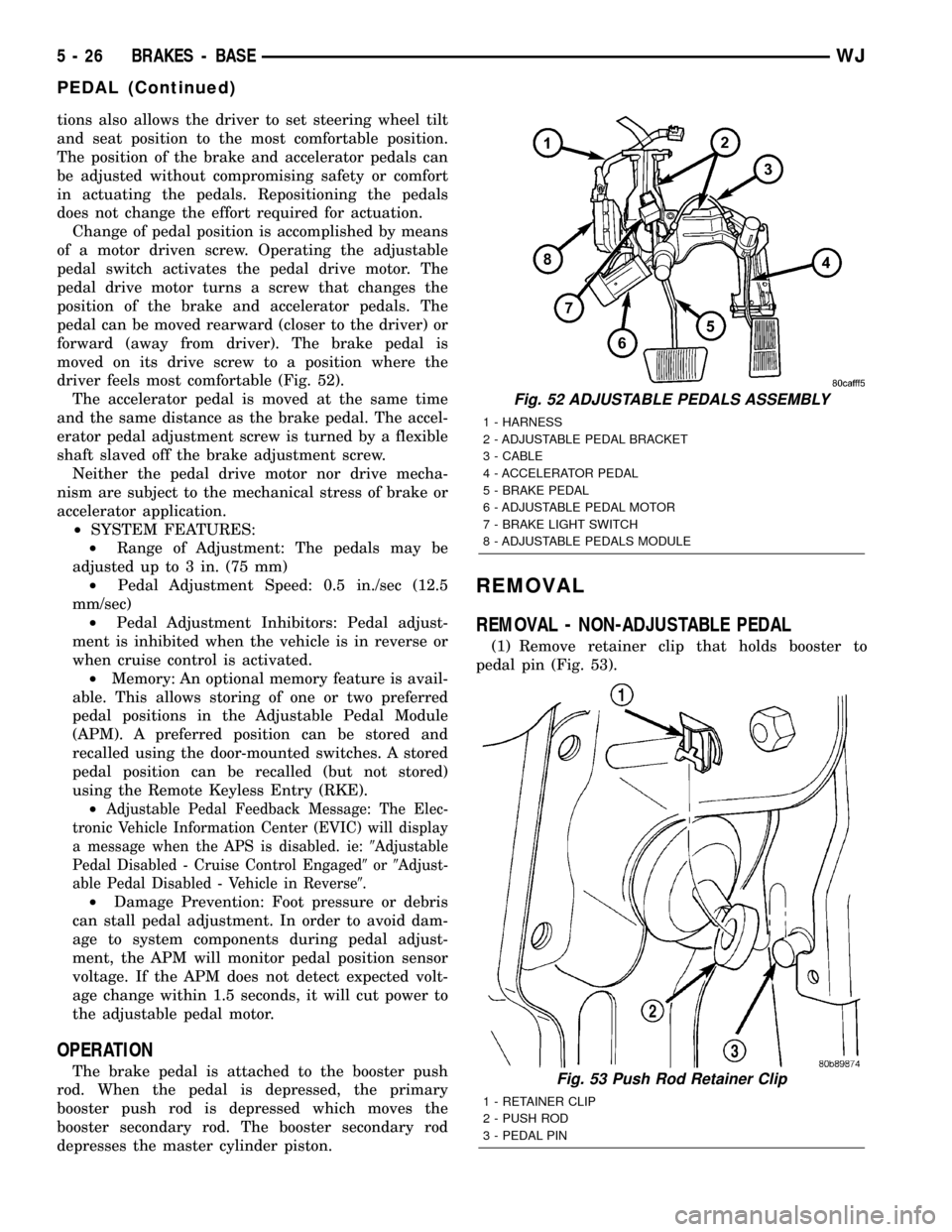

(2) Remove nut from pedal shaft.

(3) Slide pedal shaft out and remove brake pedal.

(4) Remove pedal bushings (Fig. 54) if they are to

be replaced.

REMOVAL - ADJUSTABLE PEDALS

NOTE: If possible put the pedals in the full forward

position.

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Disconnect the module electrical connector.

(5) Remove the brake light switch.

(6) Disconnect the booster rod clip (Fig. 53).

(7) Disconnect the accelerator cable from the

pedal.

(8) Lock the steering wheel into place.

(9) Remove the lower steering shaft pinch bolt

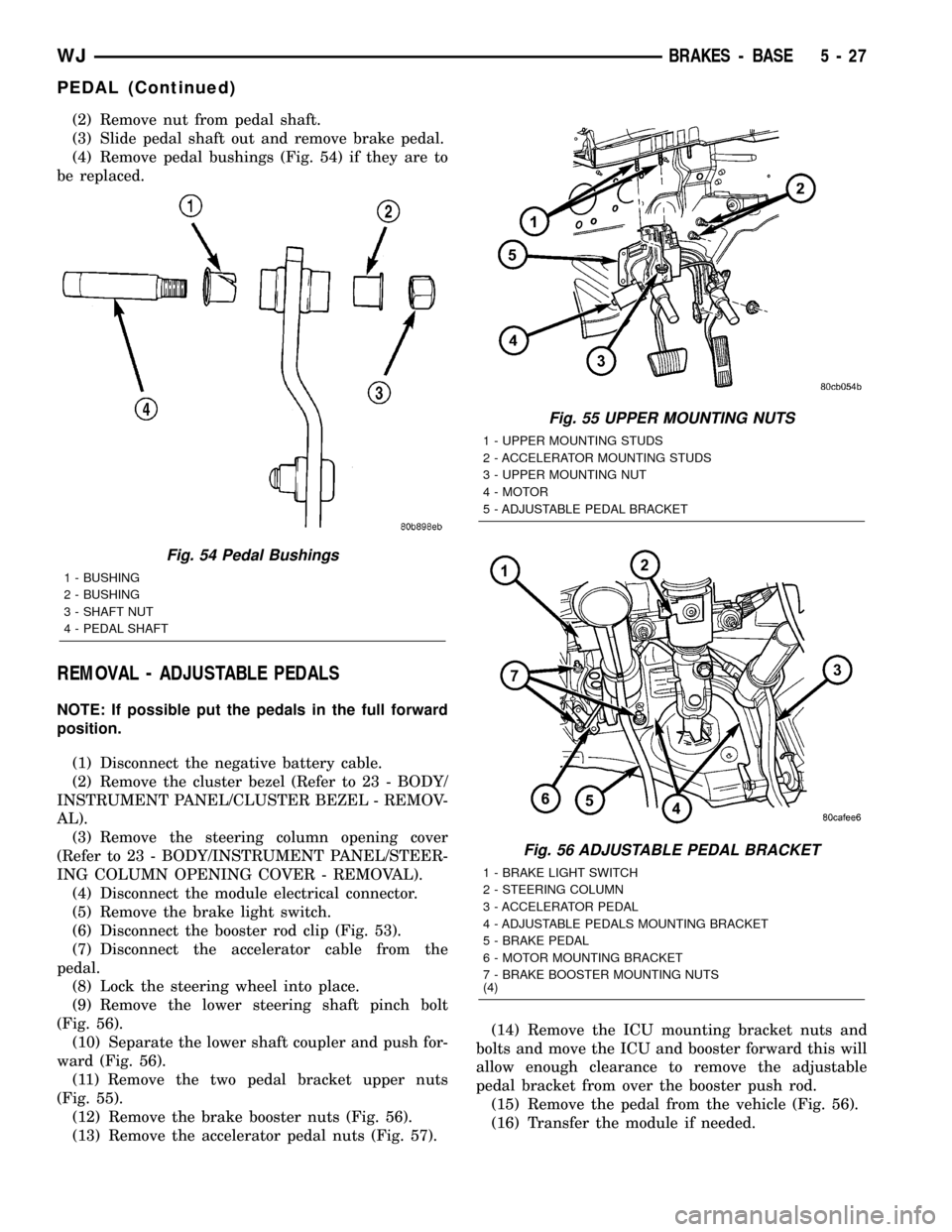

(Fig. 56).

(10) Separate the lower shaft coupler and push for-

ward (Fig. 56).

(11) Remove the two pedal bracket upper nuts

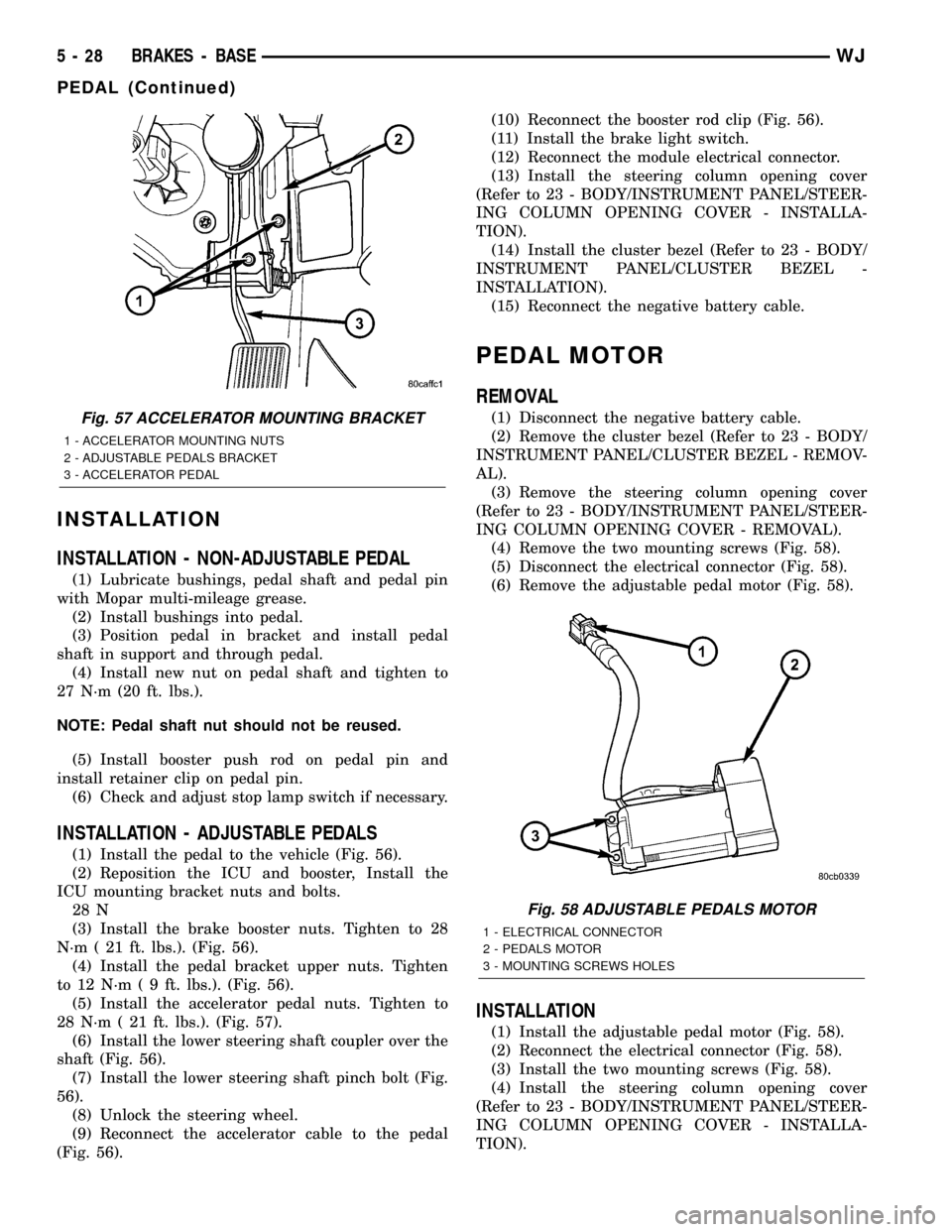

(Fig. 55).

(12) Remove the brake booster nuts (Fig. 56).

(13) Remove the accelerator pedal nuts (Fig. 57).(14) Remove the ICU mounting bracket nuts and

bolts and move the ICU and booster forward this will

allow enough clearance to remove the adjustable

pedal bracket from over the booster push rod.

(15) Remove the pedal from the vehicle (Fig. 56).

(16) Transfer the module if needed.

Fig. 54 Pedal Bushings

1 - BUSHING

2 - BUSHING

3 - SHAFT NUT

4 - PEDAL SHAFT

Fig. 55 UPPER MOUNTING NUTS

1 - UPPER MOUNTING STUDS

2 - ACCELERATOR MOUNTING STUDS

3 - UPPER MOUNTING NUT

4 - MOTOR

5 - ADJUSTABLE PEDAL BRACKET

Fig. 56 ADJUSTABLE PEDAL BRACKET

1 - BRAKE LIGHT SWITCH

2 - STEERING COLUMN

3 - ACCELERATOR PEDAL

4 - ADJUSTABLE PEDALS MOUNTING BRACKET

5 - BRAKE PEDAL

6 - MOTOR MOUNTING BRACKET

7 - BRAKE BOOSTER MOUNTING NUTS

(4)

WJBRAKES - BASE 5 - 27

PEDAL (Continued)

Page 203 of 2199

INSTALLATION

INSTALLATION - NON-ADJUSTABLE PEDAL

(1) Lubricate bushings, pedal shaft and pedal pin

with Mopar multi-mileage grease.

(2) Install bushings into pedal.

(3) Position pedal in bracket and install pedal

shaft in support and through pedal.

(4) Install new nut on pedal shaft and tighten to

27 N´m (20 ft. lbs.).

NOTE: Pedal shaft nut should not be reused.

(5) Install booster push rod on pedal pin and

install retainer clip on pedal pin.

(6) Check and adjust stop lamp switch if necessary.

INSTALLATION - ADJUSTABLE PEDALS

(1) Install the pedal to the vehicle (Fig. 56).

(2) Reposition the ICU and booster, Install the

ICU mounting bracket nuts and bolts.

28 N

(3) Install the brake booster nuts. Tighten to 28

N´m ( 21 ft. lbs.). (Fig. 56).

(4) Install the pedal bracket upper nuts. Tighten

to 12 N´m ( 9 ft. lbs.). (Fig. 56).

(5) Install the accelerator pedal nuts. Tighten to

28 N´m ( 21 ft. lbs.). (Fig. 57).

(6) Install the lower steering shaft coupler over the

shaft (Fig. 56).

(7) Install the lower steering shaft pinch bolt (Fig.

56).

(8) Unlock the steering wheel.

(9) Reconnect the accelerator cable to the pedal

(Fig. 56).(10) Reconnect the booster rod clip (Fig. 56).

(11) Install the brake light switch.

(12) Reconnect the module electrical connector.

(13) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(14) Install the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(15) Reconnect the negative battery cable.

PEDAL MOTOR

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

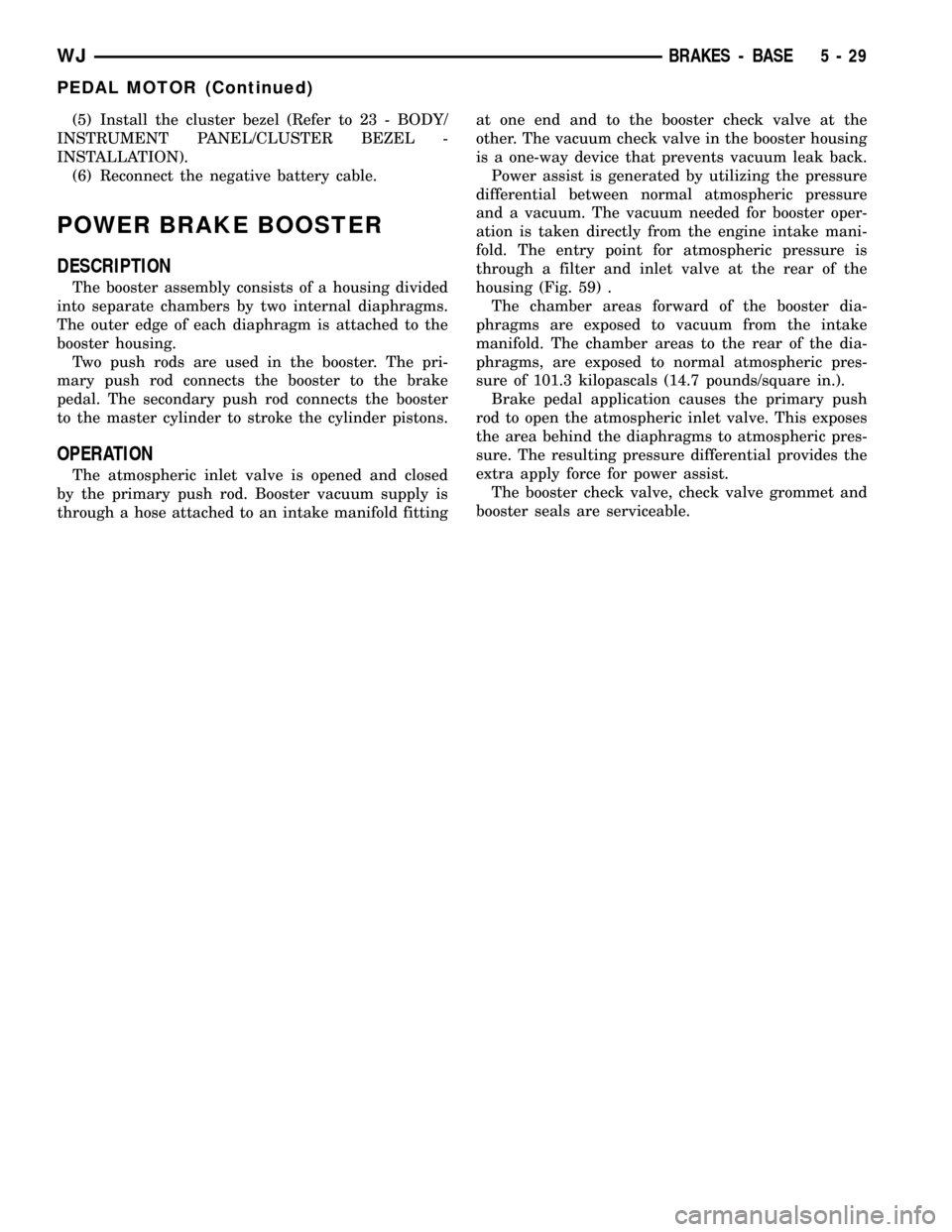

(4) Remove the two mounting screws (Fig. 58).

(5) Disconnect the electrical connector (Fig. 58).

(6) Remove the adjustable pedal motor (Fig. 58).

INSTALLATION

(1) Install the adjustable pedal motor (Fig. 58).

(2) Reconnect the electrical connector (Fig. 58).

(3) Install the two mounting screws (Fig. 58).

(4) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

Fig. 57 ACCELERATOR MOUNTING BRACKET

1 - ACCELERATOR MOUNTING NUTS

2 - ADJUSTABLE PEDALS BRACKET

3 - ACCELERATOR PEDAL

Fig. 58 ADJUSTABLE PEDALS MOTOR

1 - ELECTRICAL CONNECTOR

2 - PEDALS MOTOR

3 - MOUNTING SCREWS HOLES

5 - 28 BRAKES - BASEWJ

PEDAL (Continued)

Page 204 of 2199

(5) Install the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(6) Reconnect the negative battery cable.

POWER BRAKE BOOSTER

DESCRIPTION

The booster assembly consists of a housing divided

into separate chambers by two internal diaphragms.

The outer edge of each diaphragm is attached to the

booster housing.

Two push rods are used in the booster. The pri-

mary push rod connects the booster to the brake

pedal. The secondary push rod connects the booster

to the master cylinder to stroke the cylinder pistons.

OPERATION

The atmospheric inlet valve is opened and closed

by the primary push rod. Booster vacuum supply is

through a hose attached to an intake manifold fittingat one end and to the booster check valve at the

other. The vacuum check valve in the booster housing

is a one-way device that prevents vacuum leak back.

Power assist is generated by utilizing the pressure

differential between normal atmospheric pressure

and a vacuum. The vacuum needed for booster oper-

ation is taken directly from the engine intake mani-

fold. The entry point for atmospheric pressure is

through a filter and inlet valve at the rear of the

housing (Fig. 59) .

The chamber areas forward of the booster dia-

phragms are exposed to vacuum from the intake

manifold. The chamber areas to the rear of the dia-

phragms, are exposed to normal atmospheric pres-

sure of 101.3 kilopascals (14.7 pounds/square in.).

Brake pedal application causes the primary push

rod to open the atmospheric inlet valve. This exposes

the area behind the diaphragms to atmospheric pres-

sure. The resulting pressure differential provides the

extra apply force for power assist.

The booster check valve, check valve grommet and

booster seals are serviceable.

WJBRAKES - BASE 5 - 29

PEDAL MOTOR (Continued)

Page 209 of 2199

INSTALLATION

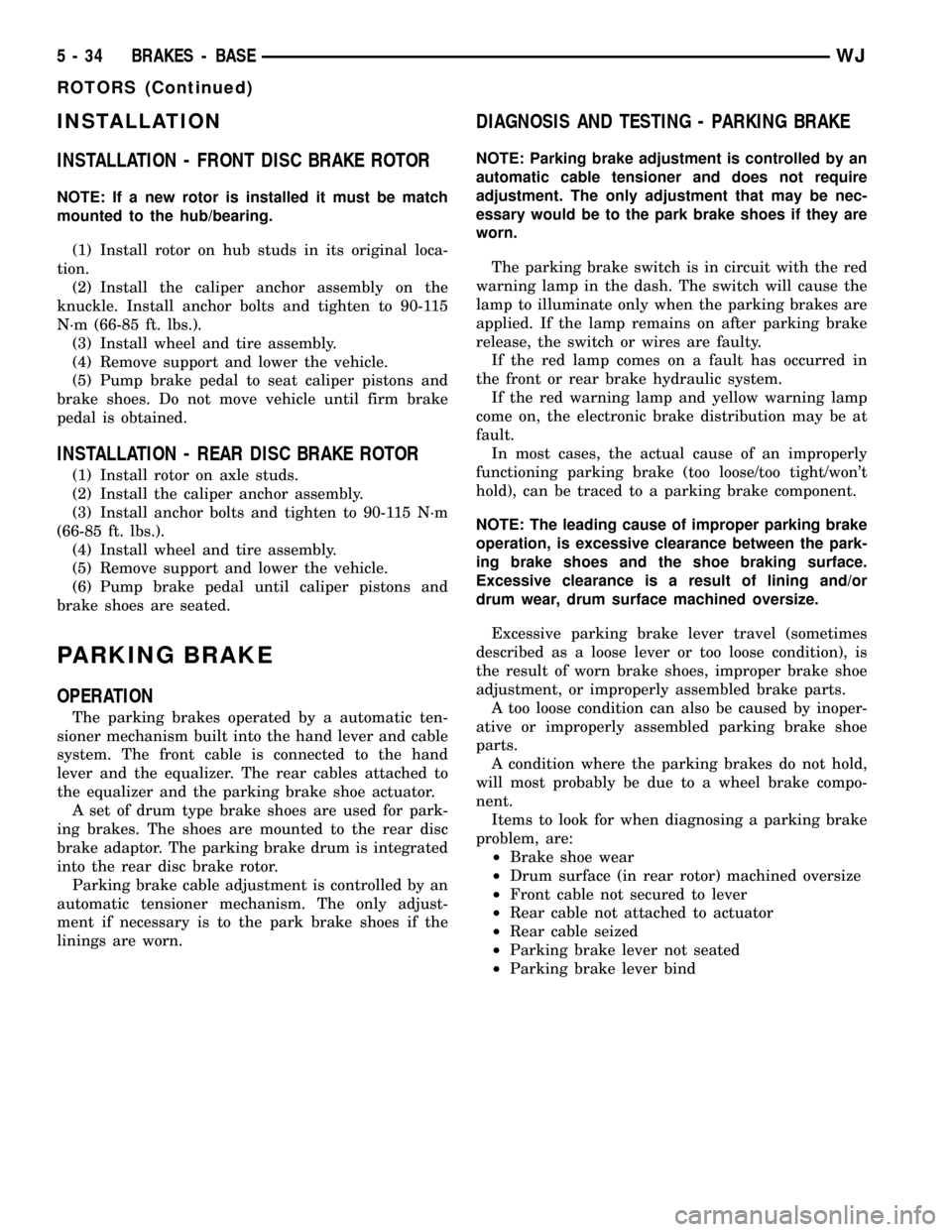

INSTALLATION - FRONT DISC BRAKE ROTOR

NOTE: If a new rotor is installed it must be match

mounted to the hub/bearing.

(1) Install rotor on hub studs in its original loca-

tion.

(2) Install the caliper anchor assembly on the

knuckle. Install anchor bolts and tighten to 90-115

N´m (66-85 ft. lbs.).

(3) Install wheel and tire assembly.

(4) Remove support and lower the vehicle.

(5) Pump brake pedal to seat caliper pistons and

brake shoes. Do not move vehicle until firm brake

pedal is obtained.

INSTALLATION - REAR DISC BRAKE ROTOR

(1) Install rotor on axle studs.

(2) Install the caliper anchor assembly.

(3) Install anchor bolts and tighten to 90-115 N´m

(66-85 ft. lbs.).

(4) Install wheel and tire assembly.

(5) Remove support and lower the vehicle.

(6) Pump brake pedal until caliper pistons and

brake shoes are seated.

PARKING BRAKE

OPERATION

The parking brakes operated by a automatic ten-

sioner mechanism built into the hand lever and cable

system. The front cable is connected to the hand

lever and the equalizer. The rear cables attached to

the equalizer and the parking brake shoe actuator.

A set of drum type brake shoes are used for park-

ing brakes. The shoes are mounted to the rear disc

brake adaptor. The parking brake drum is integrated

into the rear disc brake rotor.

Parking brake cable adjustment is controlled by an

automatic tensioner mechanism. The only adjust-

ment if necessary is to the park brake shoes if the

linings are worn.

DIAGNOSIS AND TESTING - PARKING BRAKE

NOTE: Parking brake adjustment is controlled by an

automatic cable tensioner and does not require

adjustment. The only adjustment that may be nec-

essary would be to the park brake shoes if they are

worn.

The parking brake switch is in circuit with the red

warning lamp in the dash. The switch will cause the

lamp to illuminate only when the parking brakes are

applied. If the lamp remains on after parking brake

release, the switch or wires are faulty.

If the red lamp comes on a fault has occurred in

the front or rear brake hydraulic system.

If the red warning lamp and yellow warning lamp

come on, the electronic brake distribution may be at

fault.

In most cases, the actual cause of an improperly

functioning parking brake (too loose/too tight/won't

hold), can be traced to a parking brake component.

NOTE: The leading cause of improper parking brake

operation, is excessive clearance between the park-

ing brake shoes and the shoe braking surface.

Excessive clearance is a result of lining and/or

drum wear, drum surface machined oversize.

Excessive parking brake lever travel (sometimes

described as a loose lever or too loose condition), is

the result of worn brake shoes, improper brake shoe

adjustment, or improperly assembled brake parts.

A too loose condition can also be caused by inoper-

ative or improperly assembled parking brake shoe

parts.

A condition where the parking brakes do not hold,

will most probably be due to a wheel brake compo-

nent.

Items to look for when diagnosing a parking brake

problem, are:

²Brake shoe wear

²Drum surface (in rear rotor) machined oversize

²Front cable not secured to lever

²Rear cable not attached to actuator

²Rear cable seized

²Parking brake lever not seated

²Parking brake lever bind

5 - 34 BRAKES - BASEWJ

ROTORS (Continued)

Page 210 of 2199

CABLES

REMOVAL

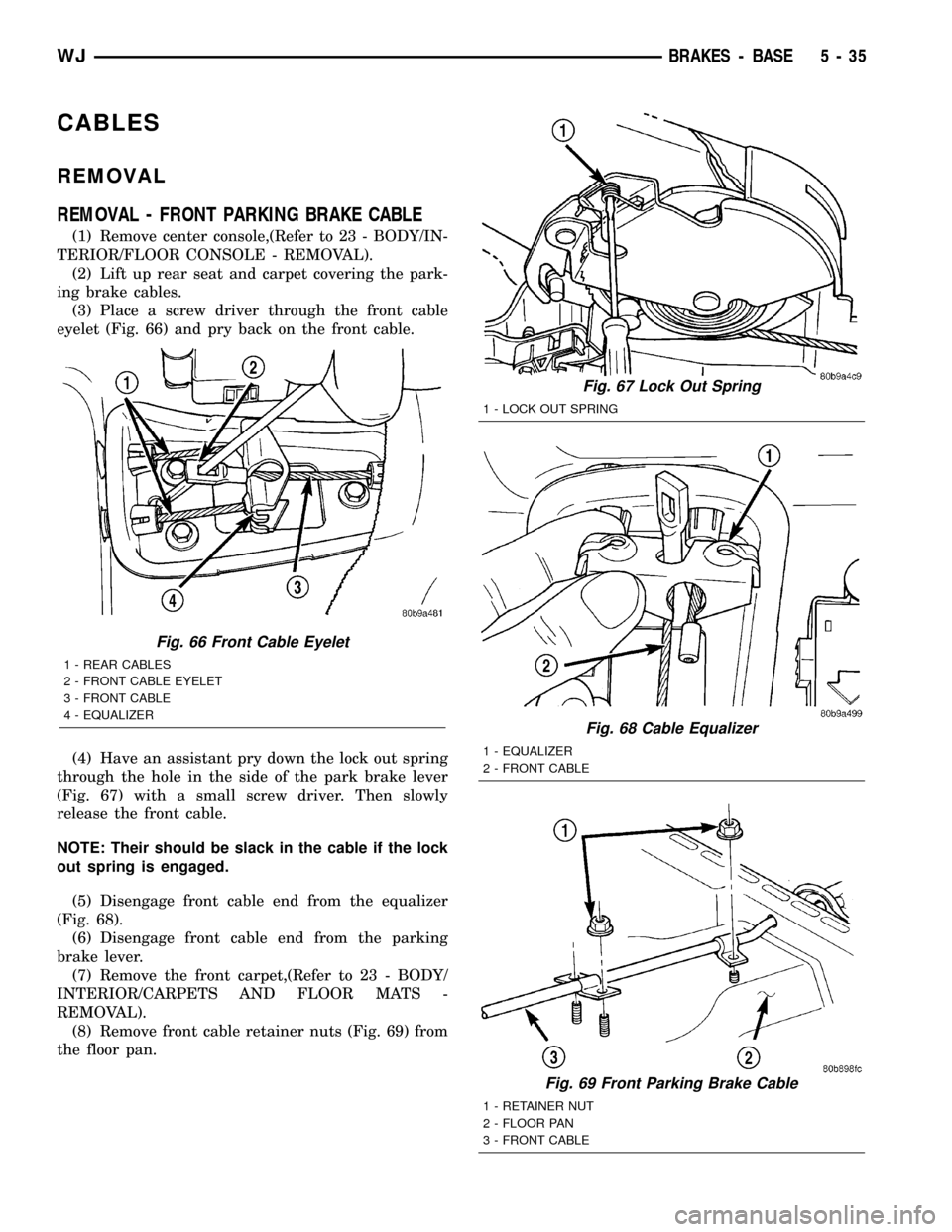

REMOVAL - FRONT PARKING BRAKE CABLE

(1) Remove center console,(Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - REMOVAL).

(2) Lift up rear seat and carpet covering the park-

ing brake cables.

(3) Place a screw driver through the front cable

eyelet (Fig. 66) and pry back on the front cable.

(4) Have an assistant pry down the lock out spring

through the hole in the side of the park brake lever

(Fig. 67) with a small screw driver. Then slowly

release the front cable.

NOTE: Their should be slack in the cable if the lock

out spring is engaged.

(5) Disengage front cable end from the equalizer

(Fig. 68).

(6) Disengage front cable end from the parking

brake lever.

(7) Remove the front carpet,(Refer to 23 - BODY/

INTERIOR/CARPETS AND FLOOR MATS -

REMOVAL).

(8) Remove front cable retainer nuts (Fig. 69) from

the floor pan.

Fig. 66 Front Cable Eyelet

1 - REAR CABLES

2 - FRONT CABLE EYELET

3 - FRONT CABLE

4 - EQUALIZER

Fig. 67 Lock Out Spring

1 - LOCK OUT SPRING

Fig. 68 Cable Equalizer

1 - EQUALIZER

2 - FRONT CABLE

Fig. 69 Front Parking Brake Cable

1 - RETAINER NUT

2 - FLOOR PAN

3 - FRONT CABLE

WJBRAKES - BASE 5 - 35

Page 211 of 2199

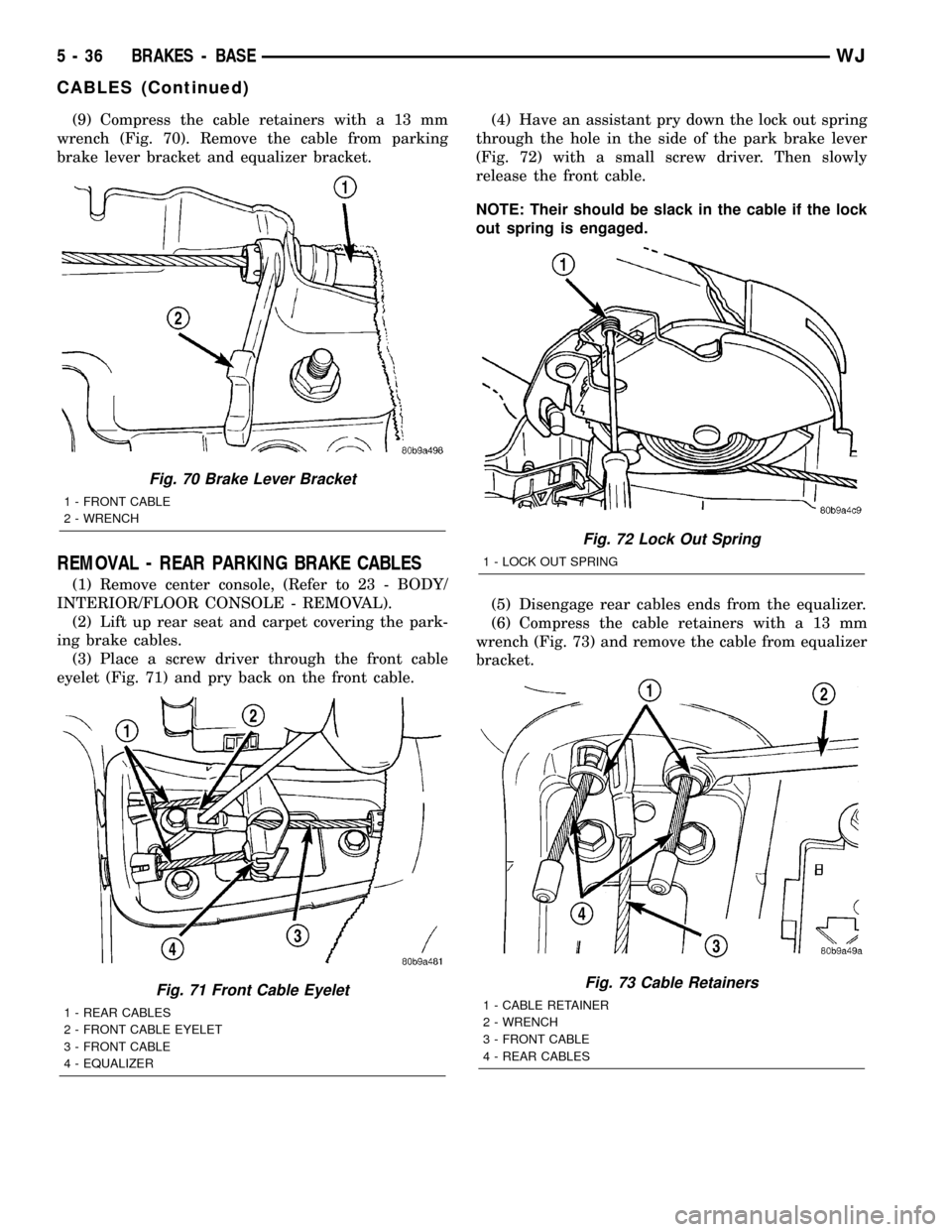

(9) Compress the cable retainers with a 13 mm

wrench (Fig. 70). Remove the cable from parking

brake lever bracket and equalizer bracket.

REMOVAL - REAR PARKING BRAKE CABLES

(1) Remove center console, (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - REMOVAL).

(2) Lift up rear seat and carpet covering the park-

ing brake cables.

(3) Place a screw driver through the front cable

eyelet (Fig. 71) and pry back on the front cable.(4) Have an assistant pry down the lock out spring

through the hole in the side of the park brake lever

(Fig. 72) with a small screw driver. Then slowly

release the front cable.

NOTE: Their should be slack in the cable if the lock

out spring is engaged.

(5) Disengage rear cables ends from the equalizer.

(6) Compress the cable retainers with a 13 mm

wrench (Fig. 73) and remove the cable from equalizer

bracket.

Fig. 70 Brake Lever Bracket

1 - FRONT CABLE

2 - WRENCH

Fig. 71 Front Cable Eyelet

1 - REAR CABLES

2 - FRONT CABLE EYELET

3 - FRONT CABLE

4 - EQUALIZER

Fig. 72 Lock Out Spring

1 - LOCK OUT SPRING

Fig. 73 Cable Retainers

1 - CABLE RETAINER

2 - WRENCH

3 - FRONT CABLE

4 - REAR CABLES

5 - 36 BRAKES - BASEWJ

CABLES (Continued)

Page 212 of 2199

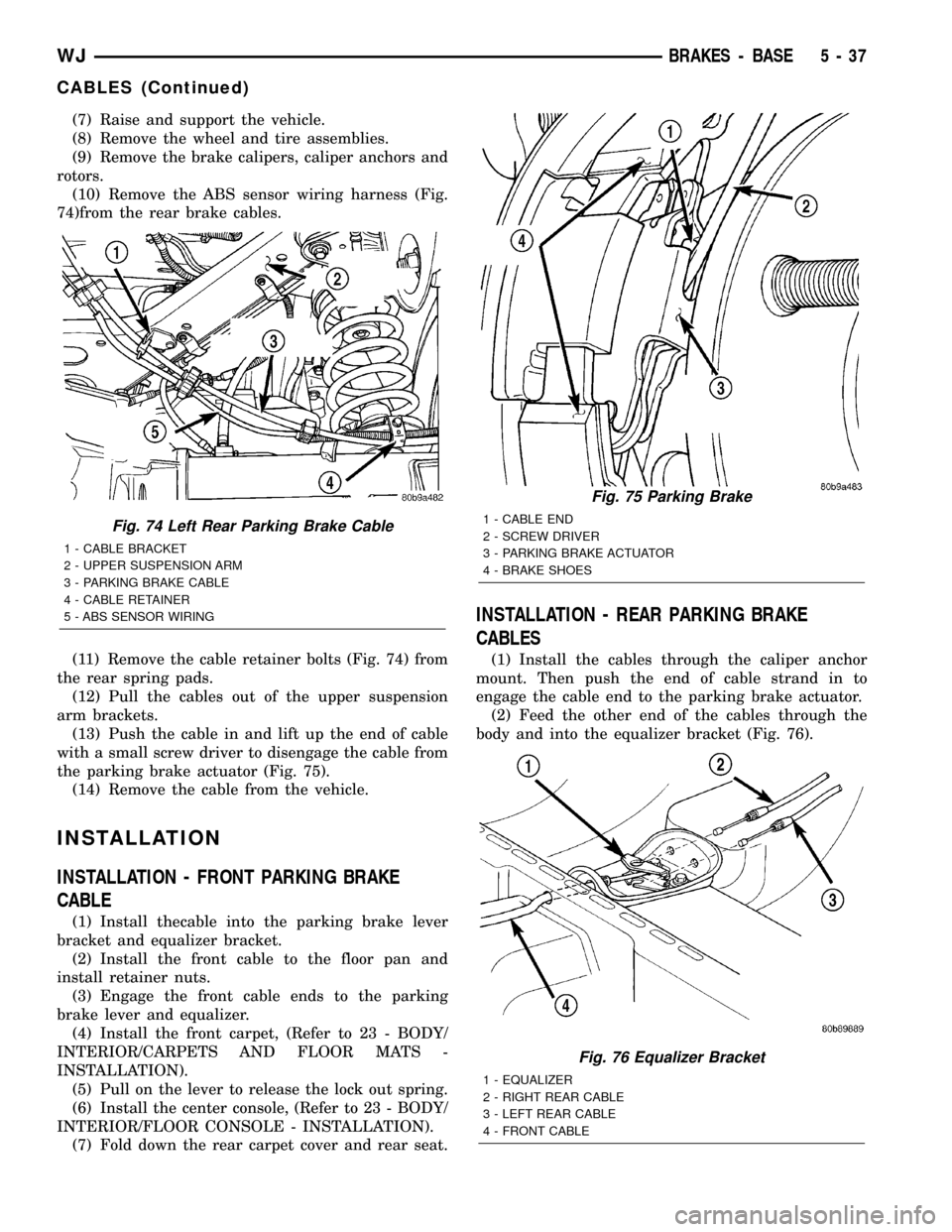

(7) Raise and support the vehicle.

(8) Remove the wheel and tire assemblies.

(9) Remove the brake calipers, caliper anchors and

rotors.

(10) Remove the ABS sensor wiring harness (Fig.

74)from the rear brake cables.

(11) Remove the cable retainer bolts (Fig. 74) from

the rear spring pads.

(12) Pull the cables out of the upper suspension

arm brackets.

(13) Push the cable in and lift up the end of cable

with a small screw driver to disengage the cable from

the parking brake actuator (Fig. 75).

(14) Remove the cable from the vehicle.

INSTALLATION

INSTALLATION - FRONT PARKING BRAKE

CABLE

(1) Install thecable into the parking brake lever

bracket and equalizer bracket.

(2) Install the front cable to the floor pan and

install retainer nuts.

(3) Engage the front cable ends to the parking

brake lever and equalizer.

(4) Install the front carpet, (Refer to 23 - BODY/

INTERIOR/CARPETS AND FLOOR MATS -

INSTALLATION).

(5) Pull on the lever to release the lock out spring.

(6) Install the center console, (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - INSTALLATION).

(7) Fold down the rear carpet cover and rear seat.

INSTALLATION - REAR PARKING BRAKE

CABLES

(1) Install the cables through the caliper anchor

mount. Then push the end of cable strand in to

engage the cable end to the parking brake actuator.

(2) Feed the other end of the cables through the

body and into the equalizer bracket (Fig. 76).

Fig. 74 Left Rear Parking Brake Cable

1 - CABLE BRACKET

2 - UPPER SUSPENSION ARM

3 - PARKING BRAKE CABLE

4 - CABLE RETAINER

5 - ABS SENSOR WIRING

Fig. 75 Parking Brake

1 - CABLE END

2 - SCREW DRIVER

3 - PARKING BRAKE ACTUATOR

4 - BRAKE SHOES

Fig. 76 Equalizer Bracket

1 - EQUALIZER

2 - RIGHT REAR CABLE

3 - LEFT REAR CABLE

4 - FRONT CABLE

WJBRAKES - BASE 5 - 37

CABLES (Continued)