adjust steering JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 202 of 2199

(2) Remove nut from pedal shaft.

(3) Slide pedal shaft out and remove brake pedal.

(4) Remove pedal bushings (Fig. 54) if they are to

be replaced.

REMOVAL - ADJUSTABLE PEDALS

NOTE: If possible put the pedals in the full forward

position.

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Disconnect the module electrical connector.

(5) Remove the brake light switch.

(6) Disconnect the booster rod clip (Fig. 53).

(7) Disconnect the accelerator cable from the

pedal.

(8) Lock the steering wheel into place.

(9) Remove the lower steering shaft pinch bolt

(Fig. 56).

(10) Separate the lower shaft coupler and push for-

ward (Fig. 56).

(11) Remove the two pedal bracket upper nuts

(Fig. 55).

(12) Remove the brake booster nuts (Fig. 56).

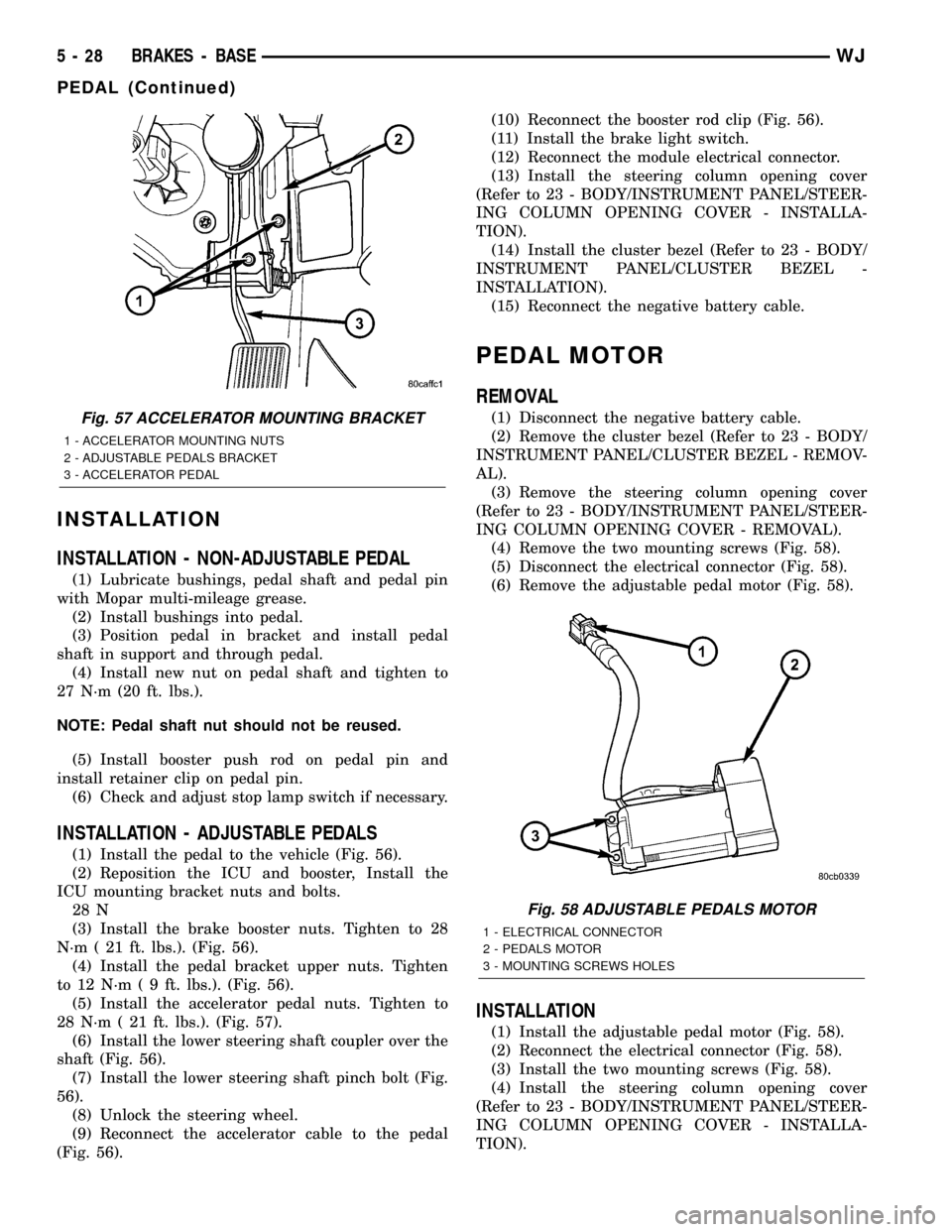

(13) Remove the accelerator pedal nuts (Fig. 57).(14) Remove the ICU mounting bracket nuts and

bolts and move the ICU and booster forward this will

allow enough clearance to remove the adjustable

pedal bracket from over the booster push rod.

(15) Remove the pedal from the vehicle (Fig. 56).

(16) Transfer the module if needed.

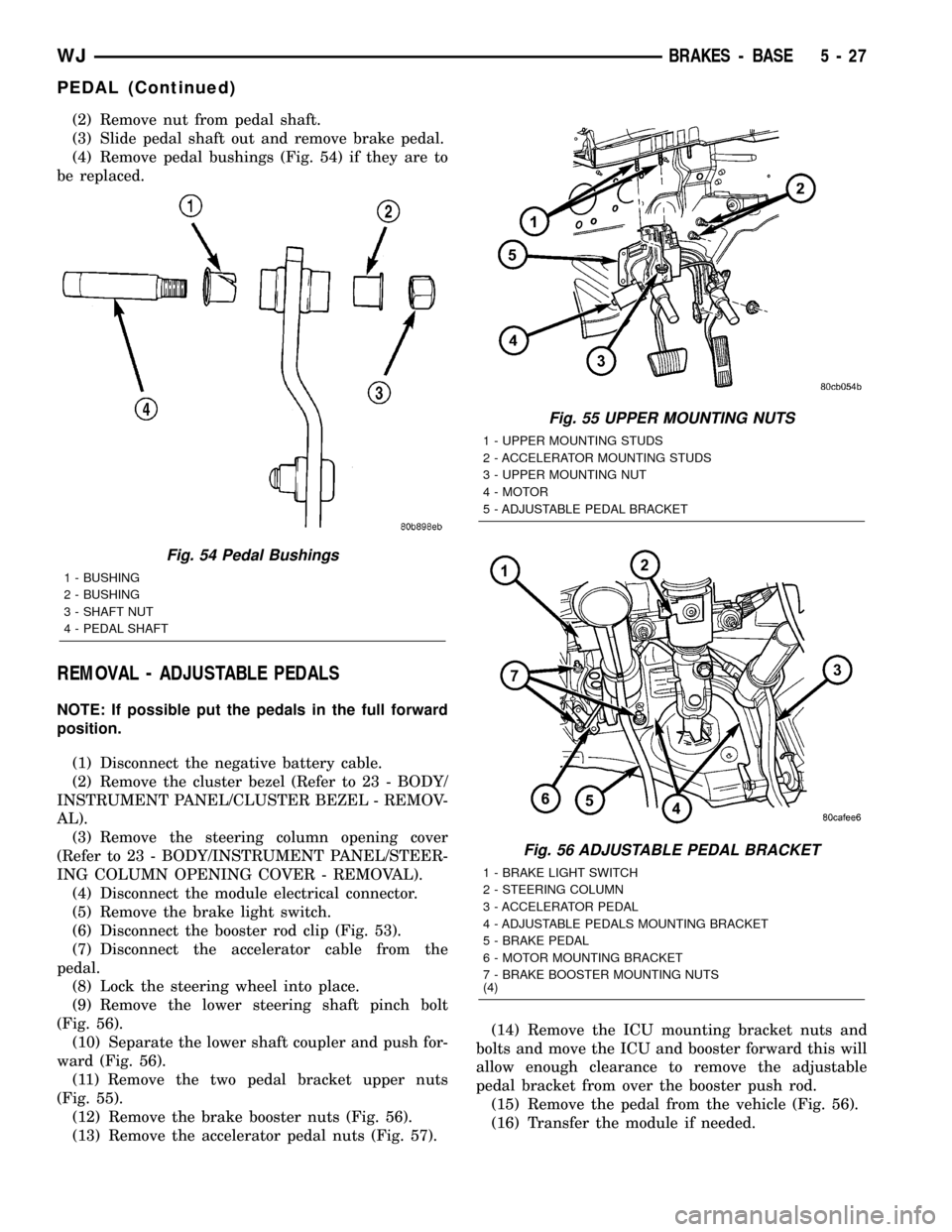

Fig. 54 Pedal Bushings

1 - BUSHING

2 - BUSHING

3 - SHAFT NUT

4 - PEDAL SHAFT

Fig. 55 UPPER MOUNTING NUTS

1 - UPPER MOUNTING STUDS

2 - ACCELERATOR MOUNTING STUDS

3 - UPPER MOUNTING NUT

4 - MOTOR

5 - ADJUSTABLE PEDAL BRACKET

Fig. 56 ADJUSTABLE PEDAL BRACKET

1 - BRAKE LIGHT SWITCH

2 - STEERING COLUMN

3 - ACCELERATOR PEDAL

4 - ADJUSTABLE PEDALS MOUNTING BRACKET

5 - BRAKE PEDAL

6 - MOTOR MOUNTING BRACKET

7 - BRAKE BOOSTER MOUNTING NUTS

(4)

WJBRAKES - BASE 5 - 27

PEDAL (Continued)

Page 203 of 2199

INSTALLATION

INSTALLATION - NON-ADJUSTABLE PEDAL

(1) Lubricate bushings, pedal shaft and pedal pin

with Mopar multi-mileage grease.

(2) Install bushings into pedal.

(3) Position pedal in bracket and install pedal

shaft in support and through pedal.

(4) Install new nut on pedal shaft and tighten to

27 N´m (20 ft. lbs.).

NOTE: Pedal shaft nut should not be reused.

(5) Install booster push rod on pedal pin and

install retainer clip on pedal pin.

(6) Check and adjust stop lamp switch if necessary.

INSTALLATION - ADJUSTABLE PEDALS

(1) Install the pedal to the vehicle (Fig. 56).

(2) Reposition the ICU and booster, Install the

ICU mounting bracket nuts and bolts.

28 N

(3) Install the brake booster nuts. Tighten to 28

N´m ( 21 ft. lbs.). (Fig. 56).

(4) Install the pedal bracket upper nuts. Tighten

to 12 N´m ( 9 ft. lbs.). (Fig. 56).

(5) Install the accelerator pedal nuts. Tighten to

28 N´m ( 21 ft. lbs.). (Fig. 57).

(6) Install the lower steering shaft coupler over the

shaft (Fig. 56).

(7) Install the lower steering shaft pinch bolt (Fig.

56).

(8) Unlock the steering wheel.

(9) Reconnect the accelerator cable to the pedal

(Fig. 56).(10) Reconnect the booster rod clip (Fig. 56).

(11) Install the brake light switch.

(12) Reconnect the module electrical connector.

(13) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(14) Install the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(15) Reconnect the negative battery cable.

PEDAL MOTOR

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Remove the two mounting screws (Fig. 58).

(5) Disconnect the electrical connector (Fig. 58).

(6) Remove the adjustable pedal motor (Fig. 58).

INSTALLATION

(1) Install the adjustable pedal motor (Fig. 58).

(2) Reconnect the electrical connector (Fig. 58).

(3) Install the two mounting screws (Fig. 58).

(4) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

Fig. 57 ACCELERATOR MOUNTING BRACKET

1 - ACCELERATOR MOUNTING NUTS

2 - ADJUSTABLE PEDALS BRACKET

3 - ACCELERATOR PEDAL

Fig. 58 ADJUSTABLE PEDALS MOTOR

1 - ELECTRICAL CONNECTOR

2 - PEDALS MOTOR

3 - MOUNTING SCREWS HOLES

5 - 28 BRAKES - BASEWJ

PEDAL (Continued)

Page 242 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

BELT BROKEN (NOTE: IDENTIFY

AND CORRECT PROBLEM

BEFORE NEW BELT IS

INSTALLED)1. Excessive tension. 1. Replace belt and automatic belt

tensioner.

2. Incorrect belt. 2. Replace belt.

3. Tensile member damaged during

belt installation.3. Replace belt.

4. Severe misalignment. 4. Check and replace.

5. Bracket, pulley, or bearing failure. 5. Replace defective component

and belt.

NOISE (OBJECTIONABLE

SQUEAL, SQUEAK, OR RUMBLE

IS HEARD OR FELT WHILE

DRIVE BELT IS IN OPERATION)1. Belt slippage. 1. Replace belt or automatic belt

tensioner.

2. Bearing noise. 2. Locate and repair.

3. Belt misalignment. 3. Replace belt.

4. Belt-to-pulley mismatch. 4. Install correct belt.

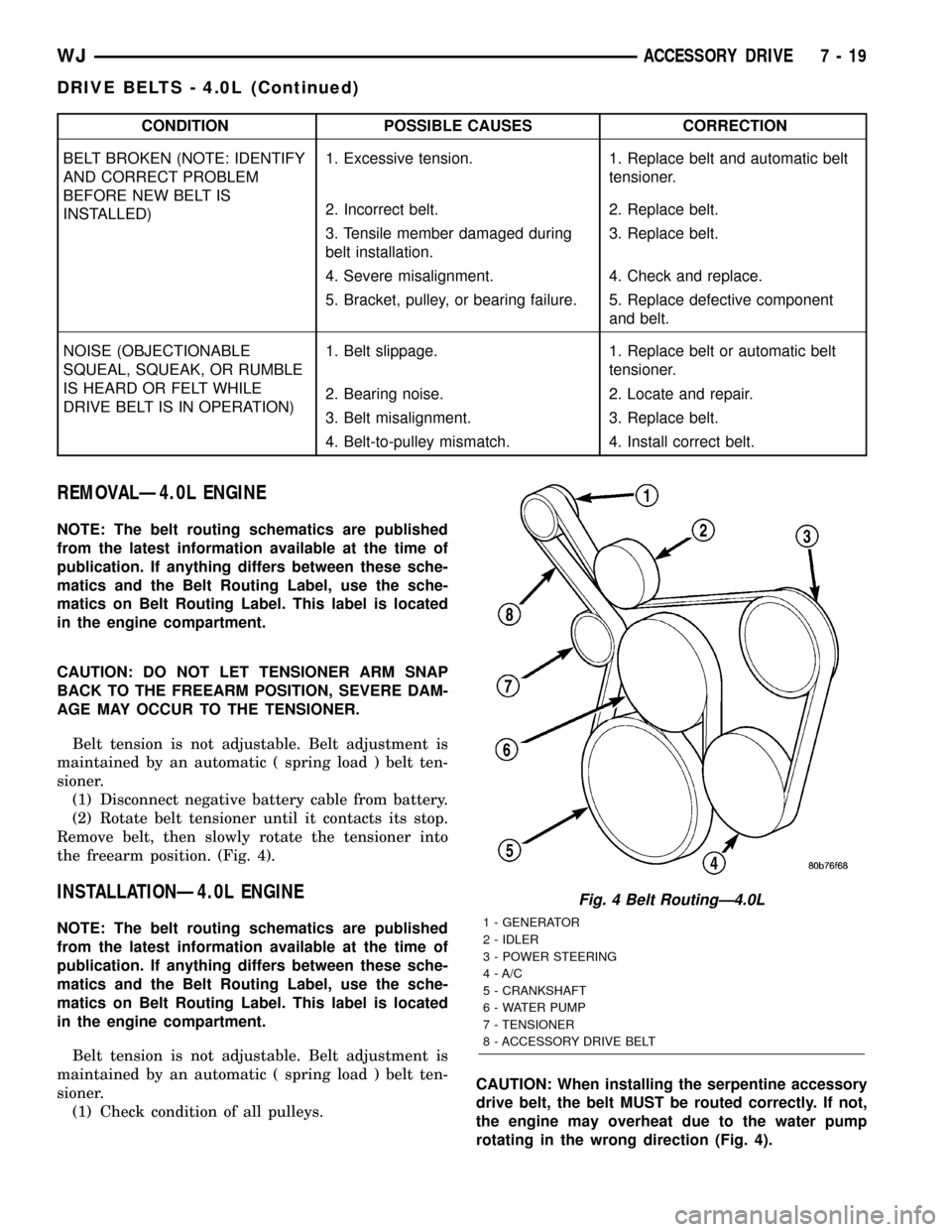

REMOVALÐ4.0L ENGINE

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label. This label is located

in the engine compartment.

CAUTION: DO NOT LET TENSIONER ARM SNAP

BACK TO THE FREEARM POSITION, SEVERE DAM-

AGE MAY OCCUR TO THE TENSIONER.

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic ( spring load ) belt ten-

sioner.

(1) Disconnect negative battery cable from battery.

(2) Rotate belt tensioner until it contacts its stop.

Remove belt, then slowly rotate the tensioner into

the freearm position. (Fig. 4).

INSTALLATIONÐ4.0L ENGINE

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label. This label is located

in the engine compartment.

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic ( spring load ) belt ten-

sioner.

(1) Check condition of all pulleys.CAUTION: When installing the serpentine accessory

drive belt, the belt MUST be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction (Fig. 4).

Fig. 4 Belt RoutingÐ4.0L

1 - GENERATOR

2 - IDLER

3 - POWER STEERING

4 - A/C

5 - CRANKSHAFT

6 - WATER PUMP

7 - TENSIONER

8 - ACCESSORY DRIVE BELT

WJACCESSORY DRIVE 7 - 19

DRIVE BELTS - 4.0L (Continued)

Page 245 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

BELT BROKEN (NOTE: IDENTIFY

AND CORRECT PROBLEM

BEFORE NEW BELT IS

INSTALLED)1. Excessive tension. 1. Replace belt and automatic belt

tensioner.

2. Incorrect belt. 2. Replace belt.

3. Tensile member damaged during

belt installation.3. Replace belt.

4. Severe misalignment. 4. Check and replace.

5. Bracket, pulley, or bearing failure. 5. Replace defective component

and belt.

NOISE (OBJECTIONABLE

SQUEAL, SQUEAK, OR RUMBLE

IS HEARD OR FELT WHILE

DRIVE BELT IS IN OPERATION)1. Belt slippage. 1. Replace belt or automatic belt

tensioner.

2. Bearing noise. 2. Locate and repair.

3. Belt misalignment. 3. Replace belt.

4. Belt-to-pulley mismatch. 4. Install correct belt.

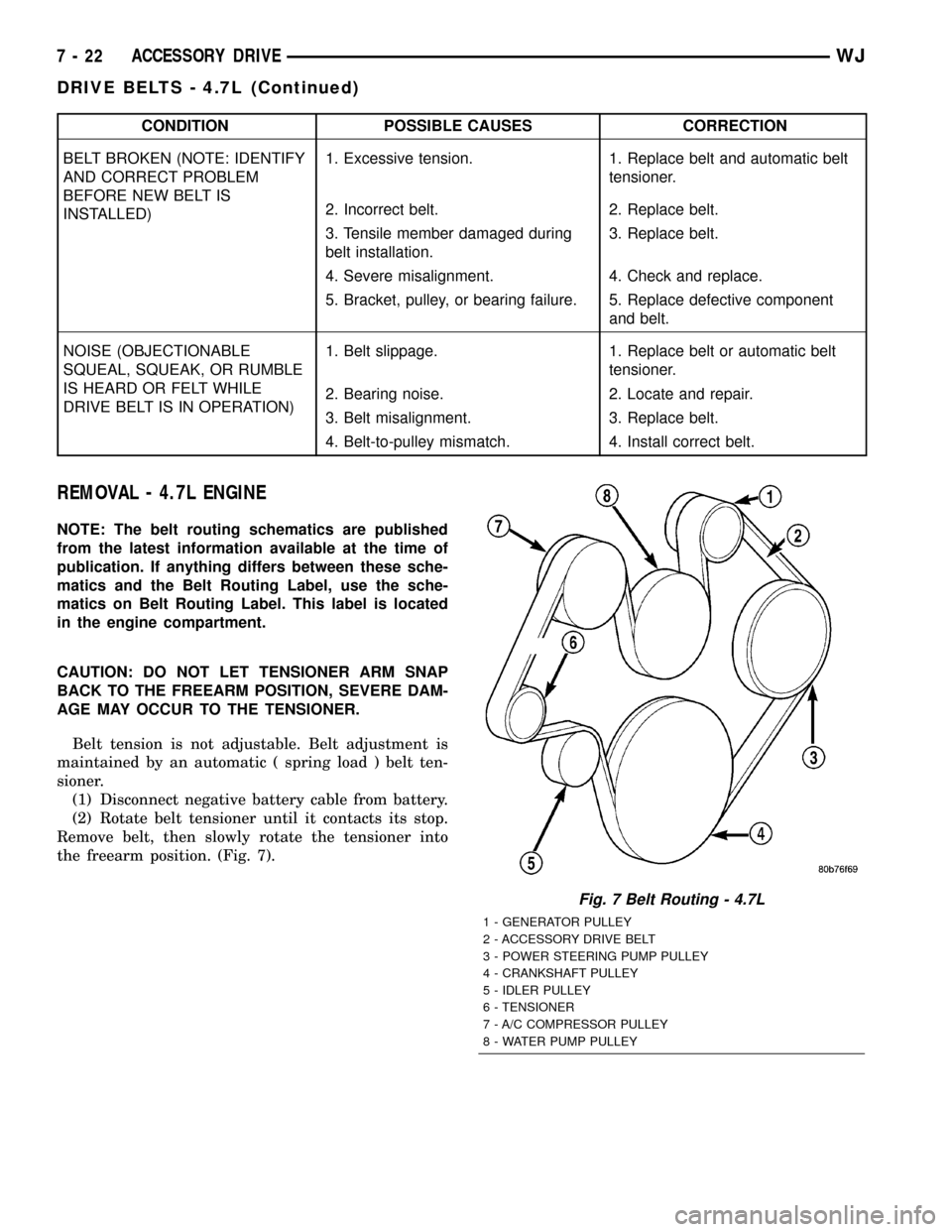

REMOVAL - 4.7L ENGINE

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label. This label is located

in the engine compartment.

CAUTION: DO NOT LET TENSIONER ARM SNAP

BACK TO THE FREEARM POSITION, SEVERE DAM-

AGE MAY OCCUR TO THE TENSIONER.

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic ( spring load ) belt ten-

sioner.

(1) Disconnect negative battery cable from battery.

(2) Rotate belt tensioner until it contacts its stop.

Remove belt, then slowly rotate the tensioner into

the freearm position. (Fig. 7).

Fig. 7 Belt Routing - 4.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

7 - 22 ACCESSORY DRIVEWJ

DRIVE BELTS - 4.7L (Continued)

Page 282 of 2199

OPERATION

The audio system components are designed to pro-

vide audio entertainment and information through

the reception, tuning and amplification of locally

broadcast radio signals in both the Amplitude Modu-

lating (AM) and Frequency Modulating (FM) com-

mercial frequency ranges. Electromagnetic radio

signals that are broadcast from a radio station

induce electrical modulations into the audio system

antenna mast. The antenna body and cable conduct

these weak signals from the antenna mast to the

radio. The radio then tunes and amplifies these weak

radio frequency signals into stronger electrical audio

signals that are required in order to operate the

audio system speakers. The speakers convert these

electrical signals into air movement, which repro-

duces the sounds being broadcast by the radio sta-

tion.

Some audio systems also offer the user the option

of selecting from and listening to prerecorded audio

cassette tapes, audio compact discs, or both. Regard-

less of the media type, the audio system components

provide the user with the ability to electronically

amplify and adjust the audio signals being repro-

duced by the speakers within the vehicle to suit the

preferences of the vehicle occupants.

The audio system components operate on battery

current received through a fuse in the Junction Block

(JB) on a fused ignition switch output (run-acc) cir-

cuit so that the system will only operate when the

ignition switch is in the On or Accessory positions.

On vehicles that are equipped with the optional

remote radio switches, the BCM receives hard wired

resistor multiplexed inputs from the remote radio

switches. The programming in the BCM allows it to

process those inputs and send the proper messages to

the radio receiver over the PCI data bus to control

the radio volume up or down, station seek up or

down, preset station advance, and mode advance

functions.On vehicles equipped with the optional memory

system, when the DDM receives a Driver 1 or Driver

2 memory recall input from the memory switch on

the driver side front door trim panel or a memory

recall message from the Remote Keyless Entry (RKE)

receiver in the PDM, the DDM sends a memory

recall message back to the radio receiver over the

PCI data bus to recall the radio station presets and

last station listened to information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of each of the available audio systems.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WJAUDIO 8A - 3

AUDIO (Continued)

Page 299 of 2199

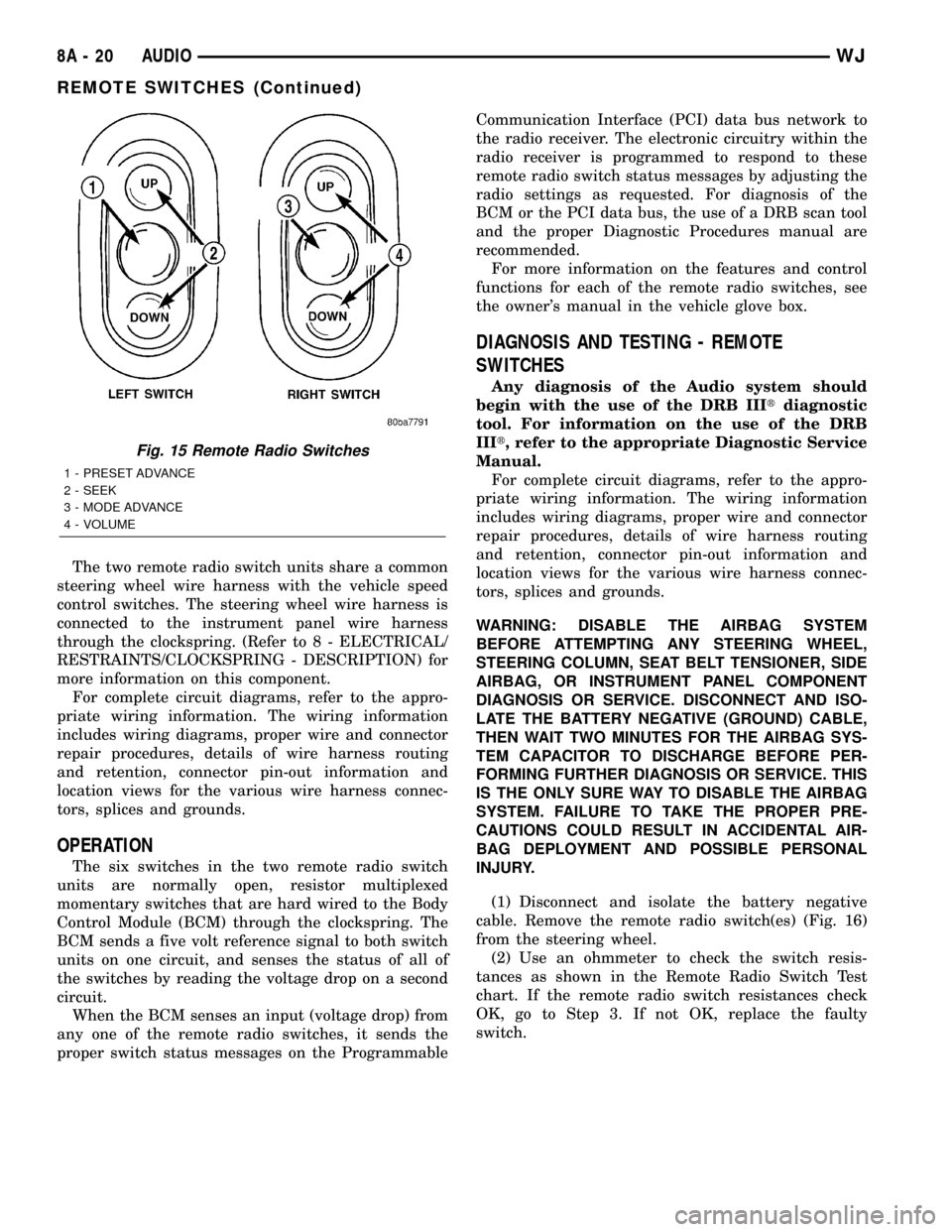

The two remote radio switch units share a common

steering wheel wire harness with the vehicle speed

control switches. The steering wheel wire harness is

connected to the instrument panel wire harness

through the clockspring. (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - DESCRIPTION) for

more information on this component.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

OPERATION

The six switches in the two remote radio switch

units are normally open, resistor multiplexed

momentary switches that are hard wired to the Body

Control Module (BCM) through the clockspring. The

BCM sends a five volt reference signal to both switch

units on one circuit, and senses the status of all of

the switches by reading the voltage drop on a second

circuit.

When the BCM senses an input (voltage drop) from

any one of the remote radio switches, it sends the

proper switch status messages on the ProgrammableCommunication Interface (PCI) data bus network to

the radio receiver. The electronic circuitry within the

radio receiver is programmed to respond to these

remote radio switch status messages by adjusting the

radio settings as requested. For diagnosis of the

BCM or the PCI data bus, the use of a DRB scan tool

and the proper Diagnostic Procedures manual are

recommended.

For more information on the features and control

functions for each of the remote radio switches, see

the owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the remote radio switch(es) (Fig. 16)

from the steering wheel.

(2) Use an ohmmeter to check the switch resis-

tances as shown in the Remote Radio Switch Test

chart. If the remote radio switch resistances check

OK, go to Step 3. If not OK, replace the faulty

switch.

Fig. 15 Remote Radio Switches

1 - PRESET ADVANCE

2 - SEEK

3 - MODE ADVANCE

4 - VOLUME

8A - 20 AUDIOWJ

REMOTE SWITCHES (Continued)

Page 302 of 2199

DIAGNOSIS AND TESTING - SPEAKER

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) Turn the ignition switch to the On position.

Turn the radio receiver on. Adjust the balance and

fader controls to check the performance of each indi-

vidual speaker. Note the speaker locations that are

not performing correctly. Go to Step 2.

(2) Turn the radio receiver off. Turn the ignition

switch to the Off position. Disconnect and isolate the

battery negative cable. Remove the radio receiver

from the instrument panel. If the vehicle is equipped

with the Infinity speaker package, also disconnect

the wire harness connectors at the power amplifier.

Check both the speaker feed (+) circuit and return (±)

circuit cavities for the inoperative speaker location(s)

at the radio receiver wire harness connectors for con-

tinuity to ground. In each case, there should be no

continuity. If OK, go to Step 3. If not OK, repair the

shorted speaker feed (+) and/or return (±) circuit(s) to

the speaker as required.

(3) If the vehicle is equipped with the Infinity

speaker package, go to Step 6. If the vehicle is

equipped with the standard speaker system, check

the resistance between the speaker feed (+) circuit

and return (±) circuit cavities of the radio receiverwire harness connectors for the inoperative speaker

location(s). The meter should read between 2 and 3

ohms (speaker resistance). If OK, go to Step 4. If not

OK, go to Step 5.

(4) Install a known good radio receiver. Connect

the battery negative cable. Turn the ignition switch

to the On position. Turn on the radio receiver and

test the speaker operation. If OK, replace the faulty

radio receiver. If not OK, turn the radio receiver off,

turn the ignition switch to the Off position, discon-

nect and isolate the battery negative cable, remove

the test radio receiver, and go to Step 5.

(5) Disconnect the wire harness connector at the

inoperative speaker. Check for continuity between

the speaker feed (+) circuit cavities of the radio

receiver wire harness connector and the speaker wire

harness connector. Repeat the check between the

speaker return (±) circuit cavities of the radio

receiver wire harness connector and the speaker wire

harness connector. In each case, there should be con-

tinuity. If OK, replace the faulty speaker. If not OK,

repair the open speaker feed (+) and/or return (±) cir-

cuit(s) as required.

(6) For each inoperative speaker location, check for

continuity between the speaker feed (+) circuit cavi-

ties of the radio receiver wire harness connectors and

the power amplifier wire harness connectors. Repeat

the check for each inoperative speaker location

between the speaker return (±) circuit cavities of the

radio receiver wire harness connectors and the power

amplifier wire harness connectors. In each case,

there should be continuity. If OK, go to Step 7. If not

OK, repair the open speaker feed (+) and/or return

(±) circuit(s) as required.

(7) Check for continuity between the two ground

circuit cavities of the power amplifier wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 8. If not OK, repair the open

ground circuit(s) to ground as required.

(8) Check the fused B(+) fuse for the power ampli-

fier in the junction block. If OK, go to Step 9. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(9) Install the radio receiver. Connect the battery

negative cable. Check for battery voltage at the fused

B(+) fuse for the power amplifier in the junction

block. If OK, go to Step 10. If not OK, repair the

open fused B(+) circuit to the Power Distribution

Center (PDC) fuse as required.

(10) Check for battery voltage at the two fused

B(+) circuit cavities of the power amplifier wire har-

ness connector. If OK, go to Step 11. If not OK, repair

the open fused B(+) circuit(s) to the power amplifier

fuse in the junction block as required.

(11) Turn the ignition switch to the On position.

Turn the radio receiver on. Check for battery voltage

WJAUDIO 8A - 23

SPEAKER (Continued)

Page 311 of 2199

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

(5) Select ENTER to update PCM VIN.

NOTE: If three attempts are made to enter secure

access mode using an incorrect PIN, secured

access mode will be locked out for one hour. To

exit this lockout mode, turn the ignition switch to

the ON position for one hour, then enter the correct

PIN. (Ensure all accessories are turned off. Also

monitor the battery state and connect a battery

charger if necessary).

(6) Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

(7) Press Page Back to get to the Select System

menu and select ENGINE, MISCELLANEOUS, and

SRI MEMORY CHECK.

(8) The DRBIIItwill ask, ªIs odometer reading

between XX and XX?º Select the YES or NO button

on the DRBIIIt. If NO is selected, the DRBIIItwill

read, ªEnter Odometer Reading (From I.P. odome-

ter)º. Enter the odometer reading from the instru-

ment cluster and press ENTER.

PROGRAMMING THE SKIM

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Program the vehicle four-digit PIN into SKIM.

(5) Select COUNTRY CODE and enter the correct

country.

NOTE: Be sure to enter the correct country code. If

the incorrect country code is programmed into

SKIM, it cannot be changed and the SKIM must be

replaced.

(6) Select YES to update VIN (the SKIM will learn

the VIN from the PCM).

(7) Press ENTER to transfer the secret key (the

PCM will send the secret key to the SKIM).

(8) Program ignition keys to the SKIM.

NOTE: If the PCM and the SKIM are replaced at the

same time, all vehicle ignition keys will need to be

replaced and programmed to the new SKIM.

PROGRAMMING IGNITION KEYS TO THE SKIM

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PROGRAM IGNITION KEY'S.

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

NOTE: A maximum of eight keys can be learned to

each SKIM. Once a key is learned to a SKIM it (the

key) cannot be transferred to another vehicle.

(5) Obtain ignition keys to be programmed from

the customer (8 keys maximum).

(6) Using the DRBIIIt, erase all ignition keys by

selecting MISCELLANEOUS, and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all of the ignition keys.

If ignition key programming is unsuccessful, the

DRBIIItwill display one of the following messages:

²Programming Not Attempted- The DRBIIIt

attempts to read the programmed key status and

there are no keys programmed into SKIM memory.

²Programming Key Failed (Possible Used

Key From Wrong Vehicle)- SKIM is unable to pro-

gram an ignition key transponder due to one of the

following:

²The ignition key transponder is faulty.

²The ignition key transponder is or has been

already programmed to another vehicle.

²8 Keys Already Learned, Programming Not

Done- The SKIM transponder ID memory is full.

²Learned Key In Ignition- The ID for the igni-

tion key transponder currently in the ignition lock

cylinder is already programmed in SKIM memory.

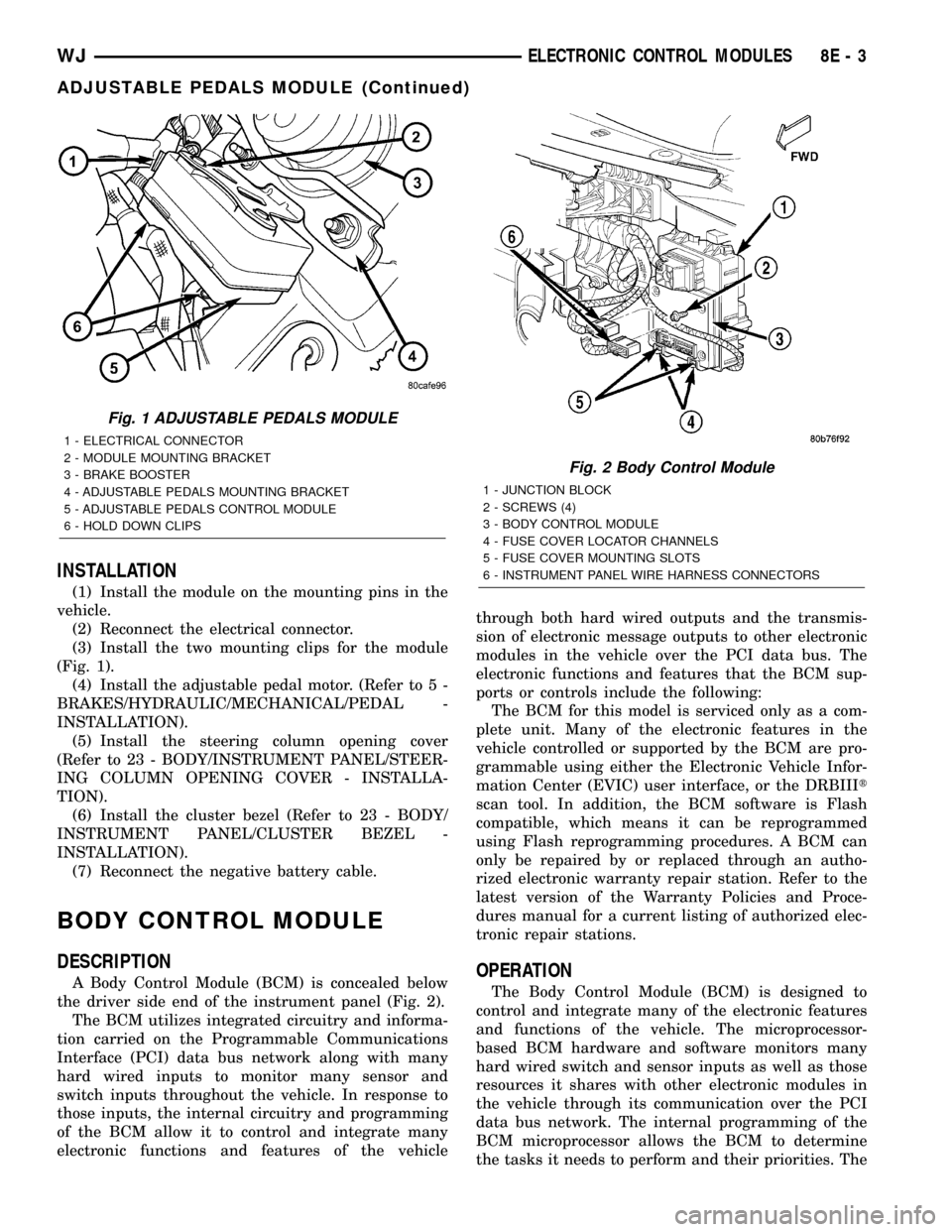

ADJUSTABLE PEDALS

MODULE

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Remove the adjustable pedal motor for accessi-

bility. (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/PEDAL - REMOVAL).

(5) Remove the two mounting clips from the mod-

ule (Fig. 1).

(6) Disconnect the electrical connector.

(7) Remove the adjustable pedal module.

8E - 2 ELECTRONIC CONTROL MODULESWJ

ELECTRONIC CONTROL MODULES (Continued)

Page 312 of 2199

INSTALLATION

(1) Install the module on the mounting pins in the

vehicle.

(2) Reconnect the electrical connector.

(3) Install the two mounting clips for the module

(Fig. 1).

(4) Install the adjustable pedal motor. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/PEDAL -

INSTALLATION).

(5) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(6) Install the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(7) Reconnect the negative battery cable.

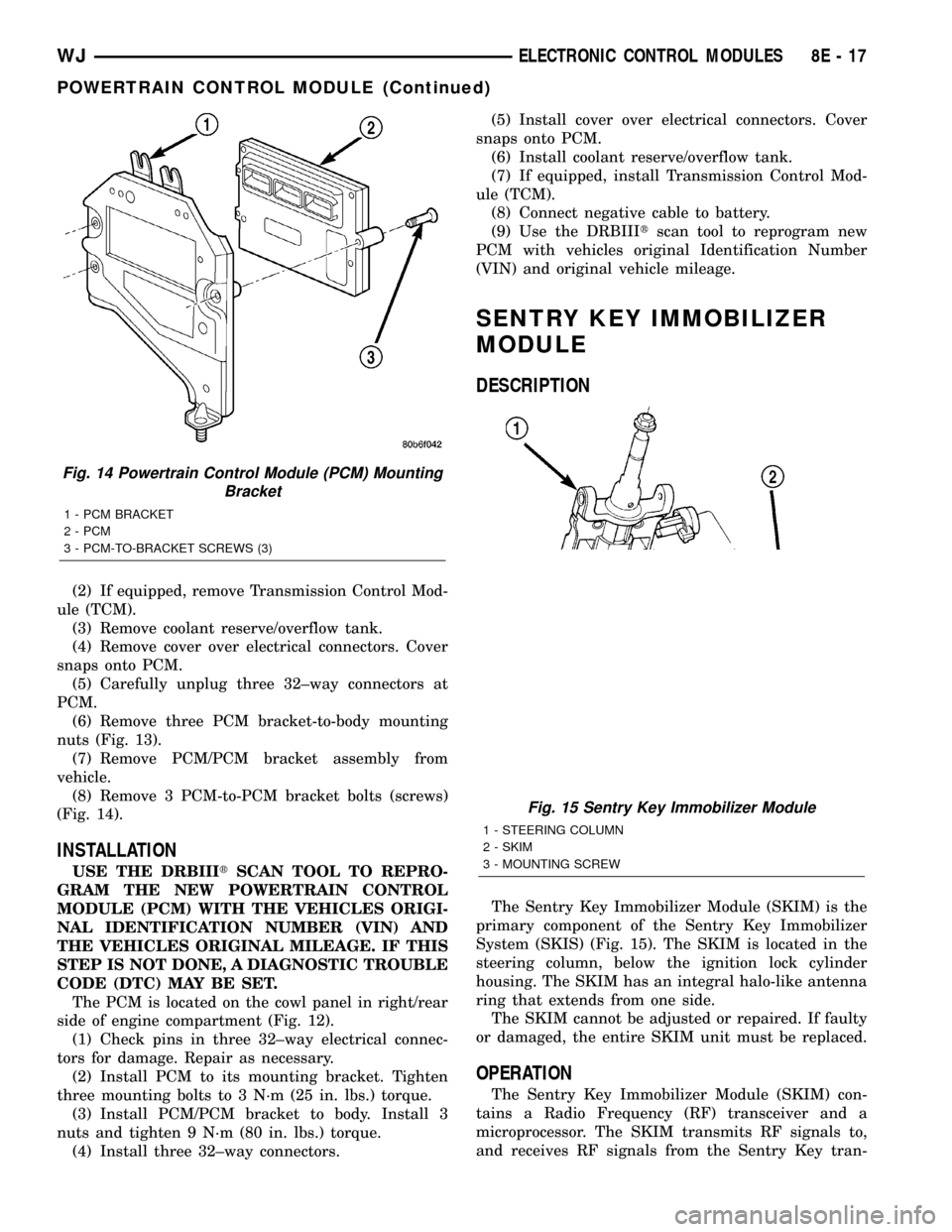

BODY CONTROL MODULE

DESCRIPTION

A Body Control Module (BCM) is concealed below

the driver side end of the instrument panel (Fig. 2).

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehiclethrough both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus. The

electronic functions and features that the BCM sup-

ports or controls include the following:

The BCM for this model is serviced only as a com-

plete unit. Many of the electronic features in the

vehicle controlled or supported by the BCM are pro-

grammable using either the Electronic Vehicle Infor-

mation Center (EVIC) user interface, or the DRBIIIt

scan tool. In addition, the BCM software is Flash

compatible, which means it can be reprogrammed

using Flash reprogramming procedures. A BCM can

only be repaired by or replaced through an autho-

rized electronic warranty repair station. Refer to the

latest version of the Warranty Policies and Proce-

dures manual for a current listing of authorized elec-

tronic repair stations.OPERATION

The Body Control Module (BCM) is designed to

control and integrate many of the electronic features

and functions of the vehicle. The microprocessor-

based BCM hardware and software monitors many

hard wired switch and sensor inputs as well as those

resources it shares with other electronic modules in

the vehicle through its communication over the PCI

data bus network. The internal programming of the

BCM microprocessor allows the BCM to determine

the tasks it needs to perform and their priorities. The

Fig. 1 ADJUSTABLE PEDALS MODULE

1 - ELECTRICAL CONNECTOR

2 - MODULE MOUNTING BRACKET

3 - BRAKE BOOSTER

4 - ADJUSTABLE PEDALS MOUNTING BRACKET

5 - ADJUSTABLE PEDALS CONTROL MODULE

6 - HOLD DOWN CLIPS

Fig. 2 Body Control Module

1 - JUNCTION BLOCK

2 - SCREWS (4)

3 - BODY CONTROL MODULE

4 - FUSE COVER LOCATOR CHANNELS

5 - FUSE COVER MOUNTING SLOTS

6 - INSTRUMENT PANEL WIRE HARNESS CONNECTORS

WJELECTRONIC CONTROL MODULES 8E - 3

ADJUSTABLE PEDALS MODULE (Continued)

Page 326 of 2199

(2) If equipped, remove Transmission Control Mod-

ule (TCM).

(3) Remove coolant reserve/overflow tank.

(4) Remove cover over electrical connectors. Cover

snaps onto PCM.

(5) Carefully unplug three 32±way connectors at

PCM.

(6) Remove three PCM bracket-to-body mounting

nuts (Fig. 13).

(7) Remove PCM/PCM bracket assembly from

vehicle.

(8) Remove 3 PCM-to-PCM bracket bolts (screws)

(Fig. 14).

INSTALLATION

USE THE DRBIIItSCAN TOOL TO REPRO-

GRAM THE NEW POWERTRAIN CONTROL

MODULE (PCM) WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE VEHICLES ORIGINAL MILEAGE. IF THIS

STEP IS NOT DONE, A DIAGNOSTIC TROUBLE

CODE (DTC) MAY BE SET.

The PCM is located on the cowl panel in right/rear

side of engine compartment (Fig. 12).

(1) Check pins in three 32±way electrical connec-

tors for damage. Repair as necessary.

(2) Install PCM to its mounting bracket. Tighten

three mounting bolts to 3 N´m (25 in. lbs.) torque.

(3) Install PCM/PCM bracket to body. Install 3

nuts and tighten 9 N´m (80 in. lbs.) torque.

(4) Install three 32±way connectors.(5) Install cover over electrical connectors. Cover

snaps onto PCM.

(6) Install coolant reserve/overflow tank.

(7) If equipped, install Transmission Control Mod-

ule (TCM).

(8) Connect negative cable to battery.

(9) Use the DRBIIItscan tool to reprogram new

PCM with vehicles original Identification Number

(VIN) and original vehicle mileage.

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) is the

primary component of the Sentry Key Immobilizer

System (SKIS) (Fig. 15). The SKIM is located in the

steering column, below the ignition lock cylinder

housing. The SKIM has an integral halo-like antenna

ring that extends from one side.

The SKIM cannot be adjusted or repaired. If faulty

or damaged, the entire SKIM unit must be replaced.

OPERATION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a

microprocessor. The SKIM transmits RF signals to,

and receives RF signals from the Sentry Key tran-

Fig. 14 Powertrain Control Module (PCM) Mounting

Bracket

1 - PCM BRACKET

2 - PCM

3 - PCM-TO-BRACKET SCREWS (3)

Fig. 15 Sentry Key Immobilizer Module

1 - STEERING COLUMN

2 - SKIM

3 - MOUNTING SCREW

WJELECTRONIC CONTROL MODULES 8E - 17

POWERTRAIN CONTROL MODULE (Continued)