head JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 66 of 2199

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before suspension arms and

track bar fasteners can be tightened. If springs are

not at their normal ride position, ride height and

handling could be affected.

(1) Install the springs and retainer clips. Tighten

the retainer bolts to 21 N´m (16 ft. lbs.).

(2) Support the axle on a lifting device and posi-

tion axle under the vehicle.

(3) Raise the axle and align it with the spring

pads.

(4) Position the upper and lower suspension arms

in the axle brackets. Loosely install bolts and nuts to

hold suspension arms to the axle brackets.

(5) Install vent hose to the axle shaft tube.

(6) Install track bar in the axle bracket and install

the bolt loosely.

(7) Install shock absorbers and tighten the bolts to

23 N´m (17 ft. lbs.).

(8) Install stabilizer bar links to the axle brackets

and tighten the nuts to 95 N´m (70 ft. lbs.).

(9) Install drag link and tie rod to the steering

knuckles.

(10) Install steering damper to the axle bracket

and tighten the nut to 75 N´m (55 ft. lbs.).

(11) Install the brake rotors (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION) and calipers.

(12) Connect the wheel speed sensor wiring har-

ness to the vehicle wiring harness.

(13) Align the previously made marks on the pro-

peller shaft and the yoke/pinion flange.

(14) Install propeller shaft to pinion flange bolts ,

if equipped.

(15) Install propeller shaft to yoke straps and

bolts, if equipped.

(16) Check and fill axle lubricant.

(17) Install the wheel and tire assemblies.

(18) Remove the lifting device from the axle and

lower the vehicle.

(19) Tighten the upper suspension arm nuts to 75

N´m (55 ft. lbs.). Tighten the lower suspension arm

nuts to 115 N´m (85 ft. lbs.).

(20) Tighten the track bar bolt at the axle bracket

to 100 N´m (74 ft. lbs.).

(21) Check the front wheel alignment.

ADJUSTMENTS

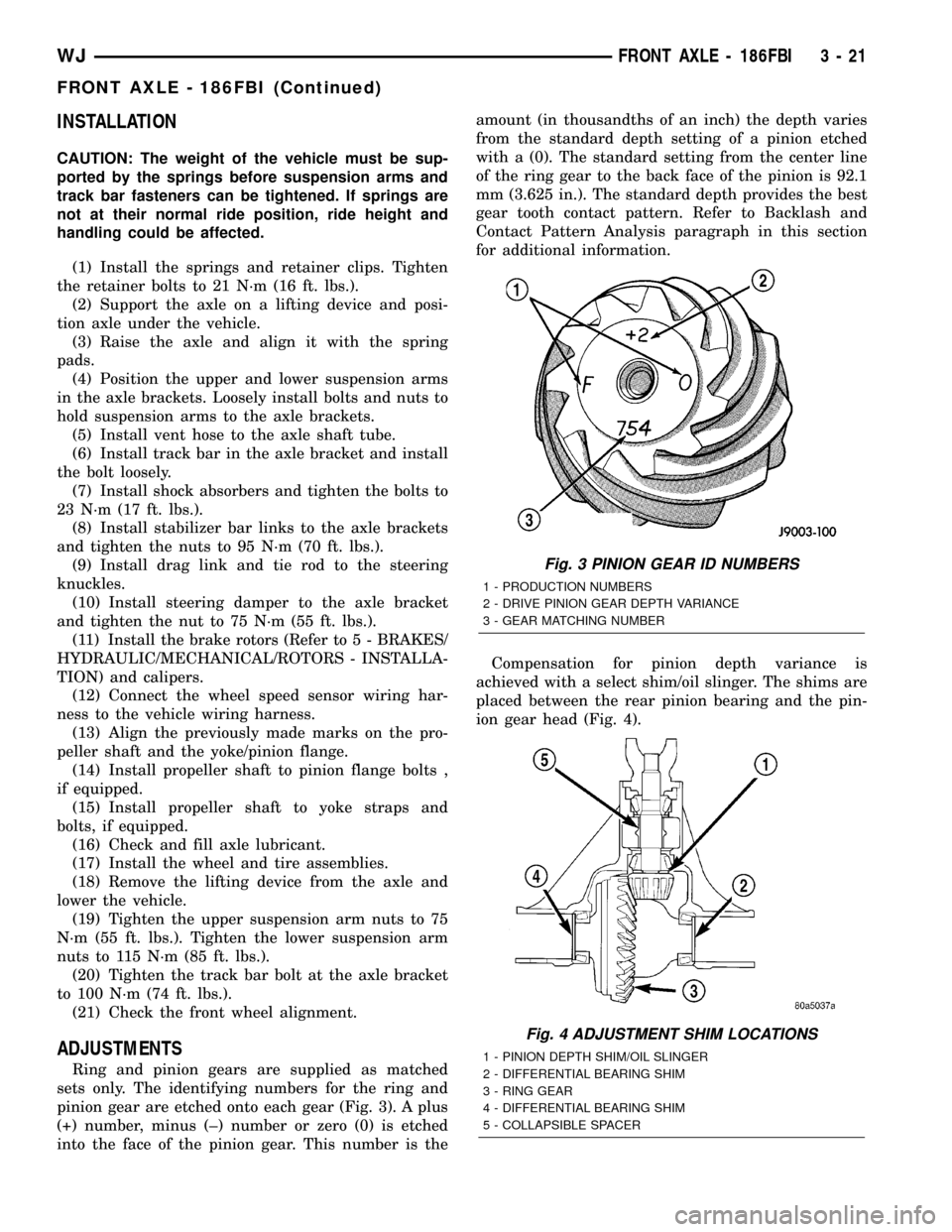

Ring and pinion gears are supplied as matched

sets only. The identifying numbers for the ring and

pinion gear are etched onto each gear (Fig. 3). A plus

(+) number, minus (±) number or zero (0) is etched

into the face of the pinion gear. This number is theamount (in thousandths of an inch) the depth varies

from the standard depth setting of a pinion etched

with a (0). The standard setting from the center line

of the ring gear to the back face of the pinion is 92.1

mm (3.625 in.). The standard depth provides the best

gear tooth contact pattern. Refer to Backlash and

Contact Pattern Analysis paragraph in this section

for additional information.

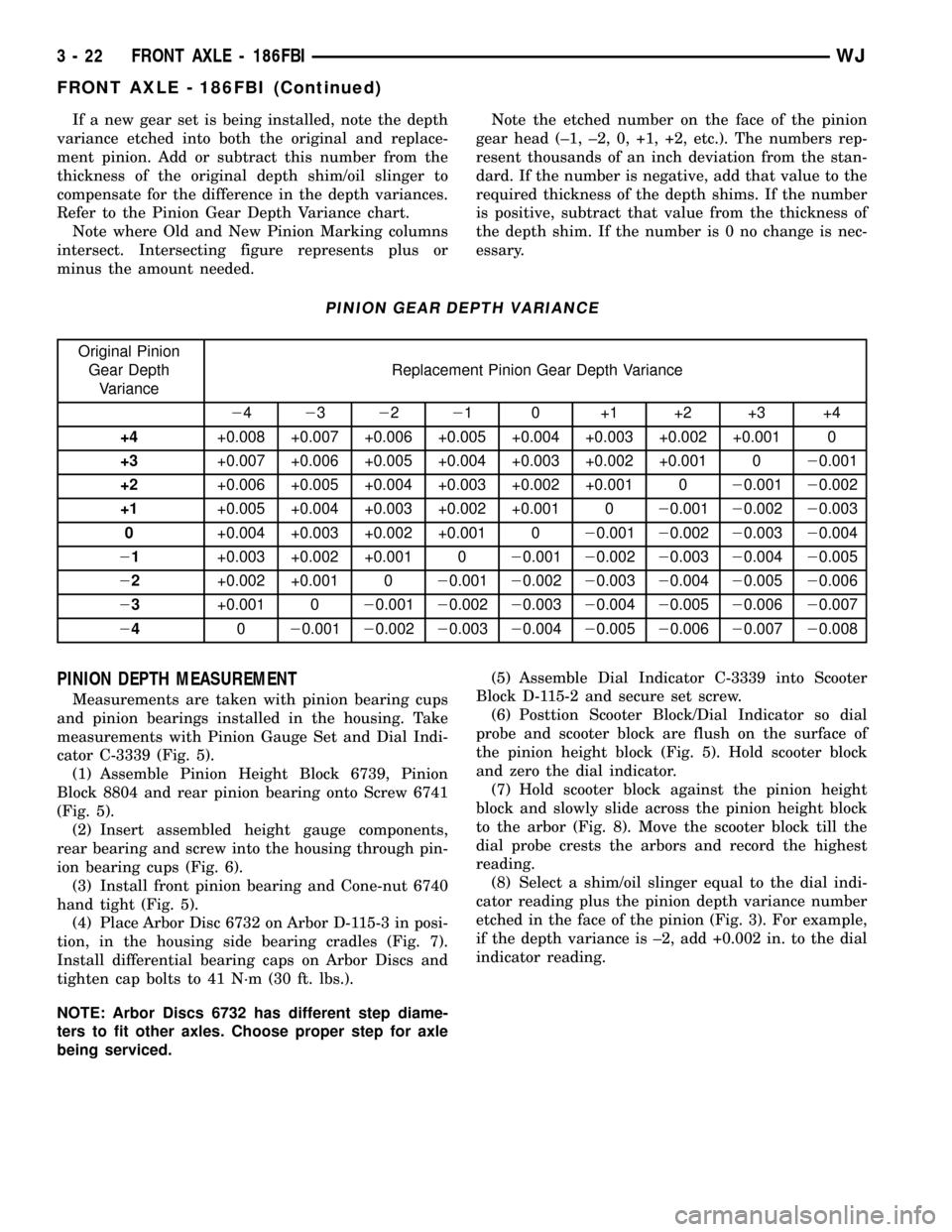

Compensation for pinion depth variance is

achieved with a select shim/oil slinger. The shims are

placed between the rear pinion bearing and the pin-

ion gear head (Fig. 4).

Fig. 3 PINION GEAR ID NUMBERS

1 - PRODUCTION NUMBERS

2 - DRIVE PINION GEAR DEPTH VARIANCE

3 - GEAR MATCHING NUMBER

Fig. 4 ADJUSTMENT SHIM LOCATIONS

1 - PINION DEPTH SHIM/OIL SLINGER

2 - DIFFERENTIAL BEARING SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING SHIM

5 - COLLAPSIBLE SPACER

WJFRONT AXLE - 186FBI 3 - 21

FRONT AXLE - 186FBI (Continued)

Page 67 of 2199

If a new gear set is being installed, note the depth

variance etched into both the original and replace-

ment pinion. Add or subtract this number from the

thickness of the original depth shim/oil slinger to

compensate for the difference in the depth variances.

Refer to the Pinion Gear Depth Variance chart.

Note where Old and New Pinion Marking columns

intersect. Intersecting figure represents plus or

minus the amount needed.Note the etched number on the face of the pinion

gear head (±1, ±2, 0, +1, +2, etc.). The numbers rep-

resent thousands of an inch deviation from the stan-

dard. If the number is negative, add that value to the

required thickness of the depth shims. If the number

is positive, subtract that value from the thickness of

the depth shim. If the number is 0 no change is nec-

essary.

PINION GEAR DEPTH VARIANCE

Original Pinion

Gear Depth

VarianceReplacement Pinion Gear Depth Variance

24232221 0 +1 +2 +3 +4

+4+0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3+0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.001

+2+0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.00120.002

+1+0.005 +0.004 +0.003 +0.002 +0.001 020.00120.00220.003

0+0.004 +0.003 +0.002 +0.001 020.00120.00220.00320.004

21+0.003 +0.002 +0.001 020.00120.00220.00320.00420.005

22+0.002 +0.001 020.00120.00220.00320.00420.00520.006

23+0.001 020.00120.00220.00320.00420.00520.00620.007

24020.00120.00220.00320.00420.00520.00620.00720.008

PINION DEPTH MEASUREMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 5).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8804 and rear pinion bearing onto Screw 6741

(Fig. 5).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 6).

(3) Install front pinion bearing and Cone-nut 6740

hand tight (Fig. 5).

(4) Place Arbor Disc 6732 on Arbor D-115-3 in posi-

tion, in the housing side bearing cradles (Fig. 7).

Install differential bearing caps on Arbor Discs and

tighten cap bolts to 41 N´m (30 ft. lbs.).

NOTE: Arbor Discs 6732 has different step diame-

ters to fit other axles. Choose proper step for axle

being serviced.(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Posttion Scooter Block/Dial Indicator so dial

probe and scooter block are flush on the surface of

the pinion height block (Fig. 5). Hold scooter block

and zero the dial indicator.

(7) Hold scooter block against the pinion height

block and slowly slide across the pinion height block

to the arbor (Fig. 8). Move the scooter block till the

dial probe crests the arbors and record the highest

reading.

(8) Select a shim/oil slinger equal to the dial indi-

cator reading plus the pinion depth variance number

etched in the face of the pinion (Fig. 3). For example,

if the depth variance is ±2, add +0.002 in. to the dial

indicator reading.

3 - 22 FRONT AXLE - 186FBIWJ

FRONT AXLE - 186FBI (Continued)

Page 70 of 2199

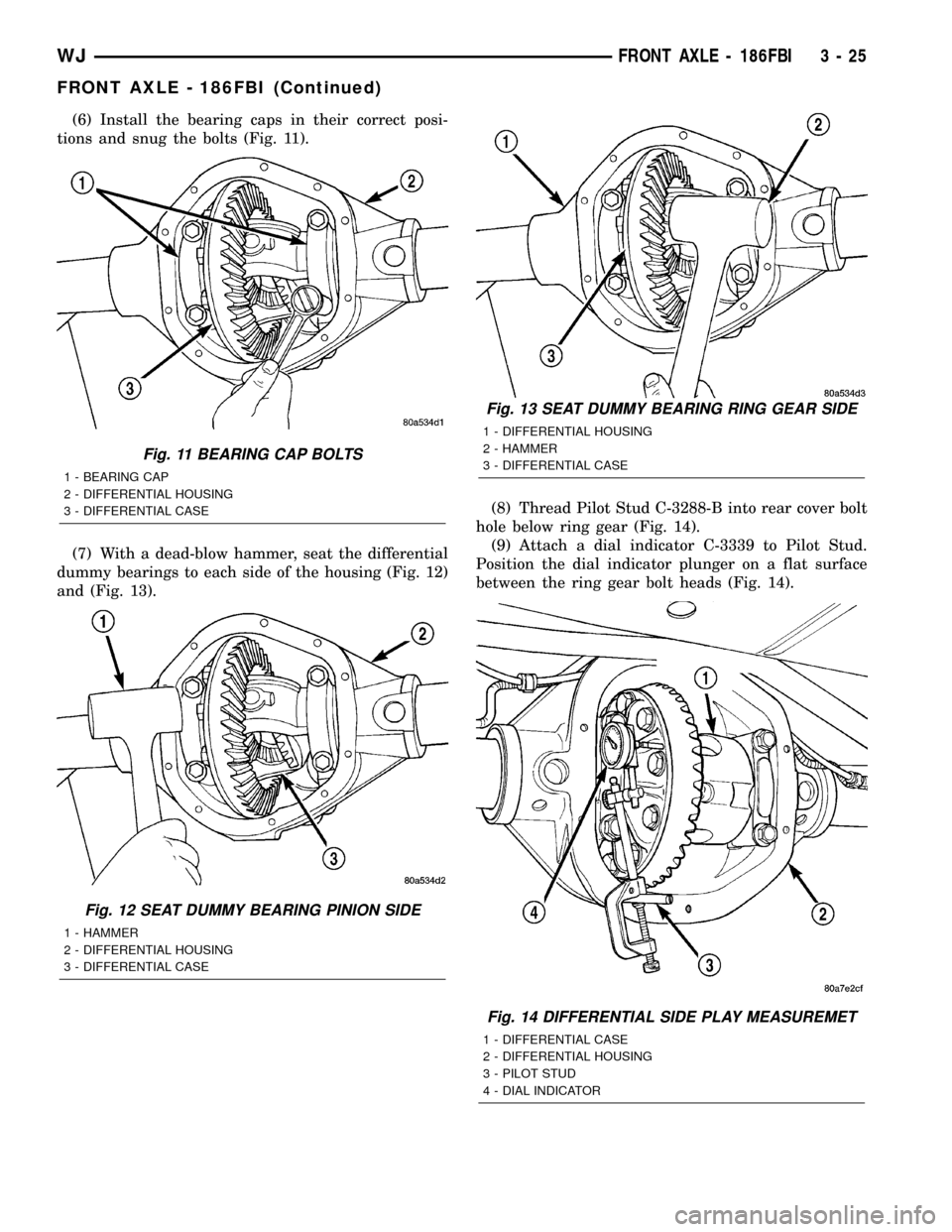

(6) Install the bearing caps in their correct posi-

tions and snug the bolts (Fig. 11).

(7) With a dead-blow hammer, seat the differential

dummy bearings to each side of the housing (Fig. 12)

and (Fig. 13).(8) Thread Pilot Stud C-3288-B into rear cover bolt

hole below ring gear (Fig. 14).

(9) Attach a dial indicator C-3339 to Pilot Stud.

Position the dial indicator plunger on a flat surface

between the ring gear bolt heads (Fig. 14).

Fig. 11 BEARING CAP BOLTS

1 - BEARING CAP

2 - DIFFERENTIAL HOUSING

3 - DIFFERENTIAL CASE

Fig. 12 SEAT DUMMY BEARING PINION SIDE

1 - HAMMER

2 - DIFFERENTIAL HOUSING

3 - DIFFERENTIAL CASE

Fig. 13 SEAT DUMMY BEARING RING GEAR SIDE

1 - DIFFERENTIAL HOUSING

2 - HAMMER

3 - DIFFERENTIAL CASE

Fig. 14 DIFFERENTIAL SIDE PLAY MEASUREMET

1 - DIFFERENTIAL CASE

2 - DIFFERENTIAL HOUSING

3 - PILOT STUD

4 - DIAL INDICATOR

WJFRONT AXLE - 186FBI 3 - 25

FRONT AXLE - 186FBI (Continued)

Page 71 of 2199

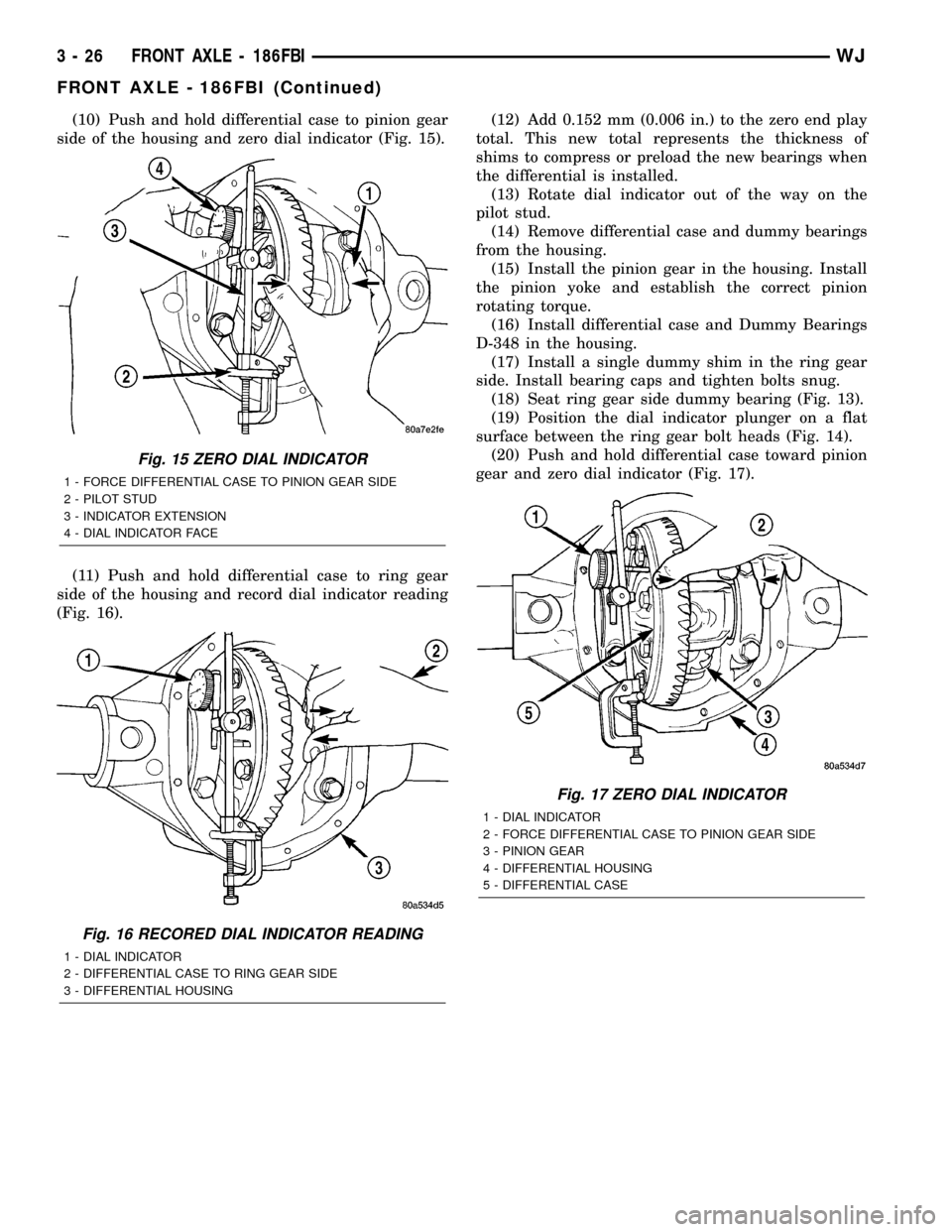

(10) Push and hold differential case to pinion gear

side of the housing and zero dial indicator (Fig. 15).

(11) Push and hold differential case to ring gear

side of the housing and record dial indicator reading

(Fig. 16).(12) Add 0.152 mm (0.006 in.) to the zero end play

total. This new total represents the thickness of

shims to compress or preload the new bearings when

the differential is installed.

(13) Rotate dial indicator out of the way on the

pilot stud.

(14) Remove differential case and dummy bearings

from the housing.

(15) Install the pinion gear in the housing. Install

the pinion yoke and establish the correct pinion

rotating torque.

(16) Install differential case and Dummy Bearings

D-348 in the housing.

(17) Install a single dummy shim in the ring gear

side. Install bearing caps and tighten bolts snug.

(18) Seat ring gear side dummy bearing (Fig. 13).

(19) Position the dial indicator plunger on a flat

surface between the ring gear bolt heads (Fig. 14).

(20) Push and hold differential case toward pinion

gear and zero dial indicator (Fig. 17).

Fig. 15 ZERO DIAL INDICATOR

1 - FORCE DIFFERENTIAL CASE TO PINION GEAR SIDE

2 - PILOT STUD

3 - INDICATOR EXTENSION

4 - DIAL INDICATOR FACE

Fig. 16 RECORED DIAL INDICATOR READING

1 - DIAL INDICATOR

2 - DIFFERENTIAL CASE TO RING GEAR SIDE

3 - DIFFERENTIAL HOUSING

Fig. 17 ZERO DIAL INDICATOR

1 - DIAL INDICATOR

2 - FORCE DIFFERENTIAL CASE TO PINION GEAR SIDE

3 - PINION GEAR

4 - DIFFERENTIAL HOUSING

5 - DIFFERENTIAL CASE

3 - 26 FRONT AXLE - 186FBIWJ

FRONT AXLE - 186FBI (Continued)

Page 91 of 2199

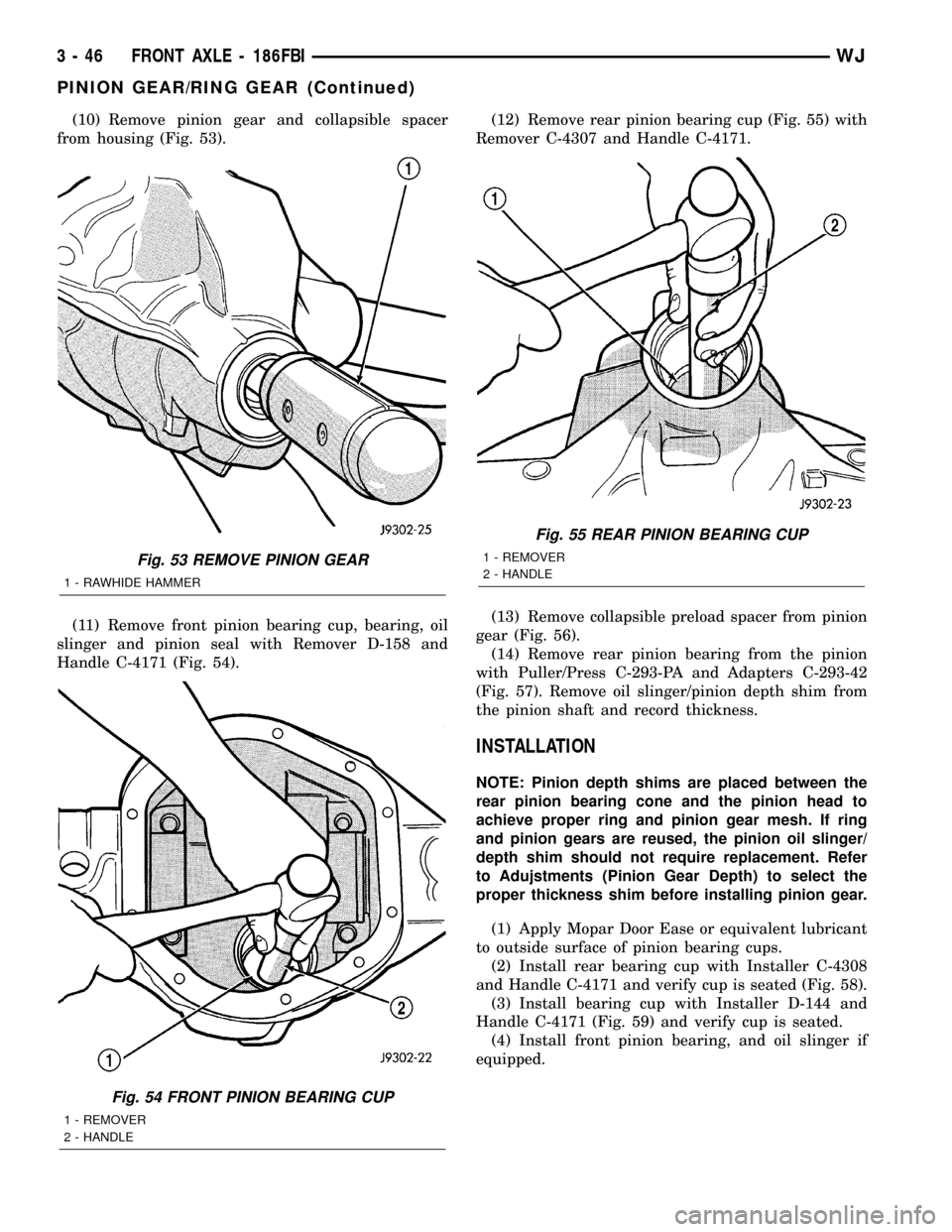

(10) Remove pinion gear and collapsible spacer

from housing (Fig. 53).

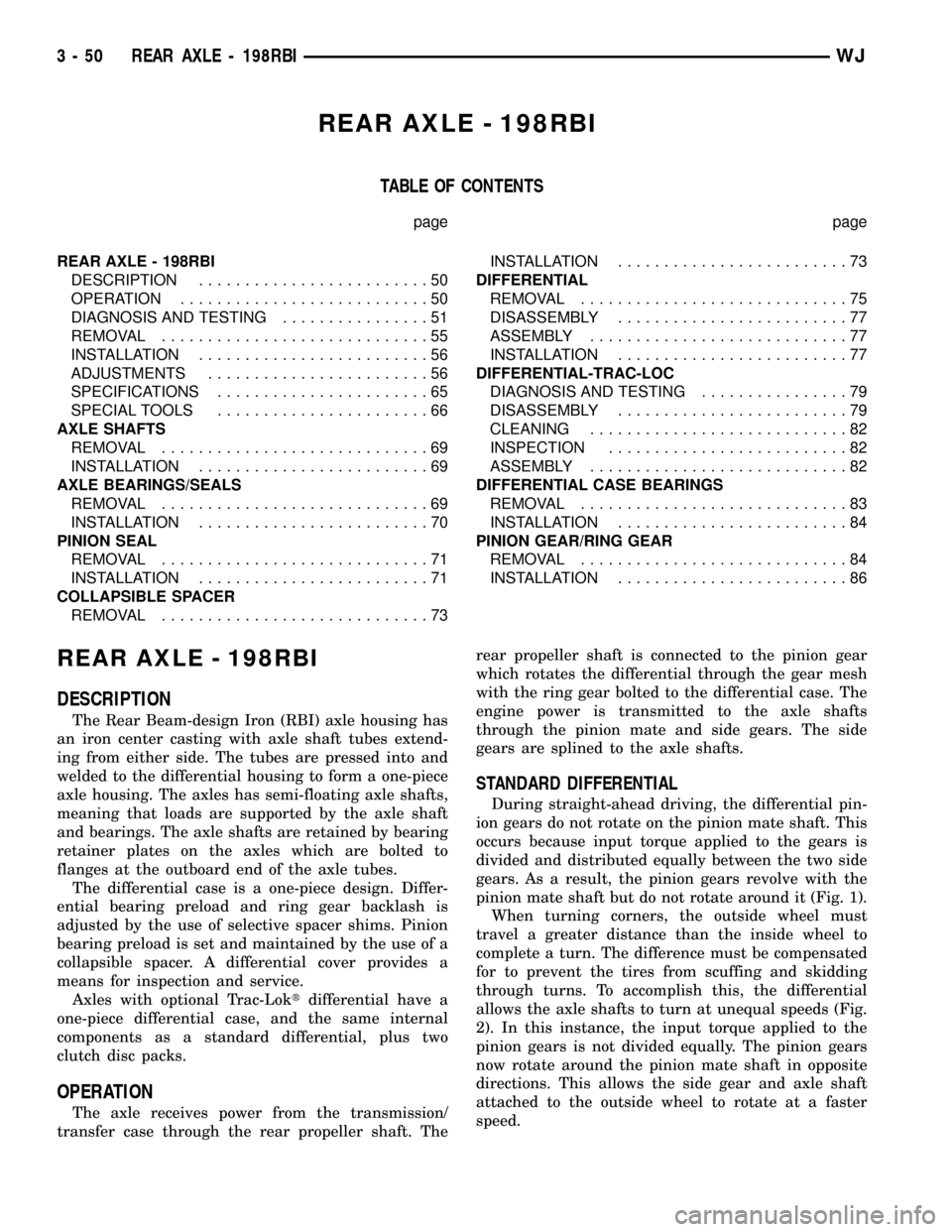

(11) Remove front pinion bearing cup, bearing, oil

slinger and pinion seal with Remover D-158 and

Handle C-4171 (Fig. 54).(12) Remove rear pinion bearing cup (Fig. 55) with

Remover C-4307 and Handle C-4171.

(13) Remove collapsible preload spacer from pinion

gear (Fig. 56).

(14) Remove rear pinion bearing from the pinion

with Puller/Press C-293-PA and Adapters C-293-42

(Fig. 57). Remove oil slinger/pinion depth shim from

the pinion shaft and record thickness.

INSTALLATION

NOTE: Pinion depth shims are placed between the

rear pinion bearing cone and the pinion head to

achieve proper ring and pinion gear mesh. If ring

and pinion gears are reused, the pinion oil slinger/

depth shim should not require replacement. Refer

to Adujstments (Pinion Gear Depth) to select the

proper thickness shim before installing pinion gear.

(1) Apply Mopar Door Ease or equivalent lubricant

to outside surface of pinion bearing cups.

(2) Install rear bearing cup with Installer C-4308

and Handle C-4171 and verify cup is seated (Fig. 58).

(3) Install bearing cup with Installer D-144 and

Handle C-4171 (Fig. 59) and verify cup is seated.

(4) Install front pinion bearing, and oil slinger if

equipped.

Fig. 53 REMOVE PINION GEAR

1 - RAWHIDE HAMMER

Fig. 54 FRONT PINION BEARING CUP

1 - REMOVER

2 - HANDLE

Fig. 55 REAR PINION BEARING CUP

1 - REMOVER

2 - HANDLE

3 - 46 FRONT AXLE - 186FBIWJ

PINION GEAR/RING GEAR (Continued)

Page 95 of 2199

REAR AXLE - 198RBI

TABLE OF CONTENTS

page page

REAR AXLE - 198RBI

DESCRIPTION.........................50

OPERATION...........................50

DIAGNOSIS AND TESTING................51

REMOVAL.............................55

INSTALLATION.........................56

ADJUSTMENTS........................56

SPECIFICATIONS.......................65

SPECIAL TOOLS.......................66

AXLE SHAFTS

REMOVAL.............................69

INSTALLATION.........................69

AXLE BEARINGS/SEALS

REMOVAL.............................69

INSTALLATION.........................70

PINION SEAL

REMOVAL.............................71

INSTALLATION.........................71

COLLAPSIBLE SPACER

REMOVAL.............................73INSTALLATION.........................73

DIFFERENTIAL

REMOVAL.............................75

DISASSEMBLY.........................77

ASSEMBLY............................77

INSTALLATION.........................77

DIFFERENTIAL-TRAC-LOC

DIAGNOSIS AND TESTING................79

DISASSEMBLY.........................79

CLEANING............................82

INSPECTION..........................82

ASSEMBLY............................82

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................83

INSTALLATION.........................84

PINION GEAR/RING GEAR

REMOVAL.............................84

INSTALLATION.........................86

REAR AXLE - 198RBI

DESCRIPTION

The Rear Beam-design Iron (RBI) axle housing has

an iron center casting with axle shaft tubes extend-

ing from either side. The tubes are pressed into and

welded to the differential housing to form a one-piece

axle housing. The axles has semi-floating axle shafts,

meaning that loads are supported by the axle shaft

and bearings. The axle shafts are retained by bearing

retainer plates on the axles which are bolted to

flanges at the outboard end of the axle tubes.

The differential case is a one-piece design. Differ-

ential bearing preload and ring gear backlash is

adjusted by the use of selective spacer shims. Pinion

bearing preload is set and maintained by the use of a

collapsible spacer. A differential cover provides a

means for inspection and service.

Axles with optional Trac-Loktdifferential have a

one-piece differential case, and the same internal

components as a standard differential, plus two

clutch disc packs.

OPERATION

The axle receives power from the transmission/

transfer case through the rear propeller shaft. Therear propeller shaft is connected to the pinion gear

which rotates the differential through the gear mesh

with the ring gear bolted to the differential case. The

engine power is transmitted to the axle shafts

through the pinion mate and side gears. The side

gears are splined to the axle shafts.

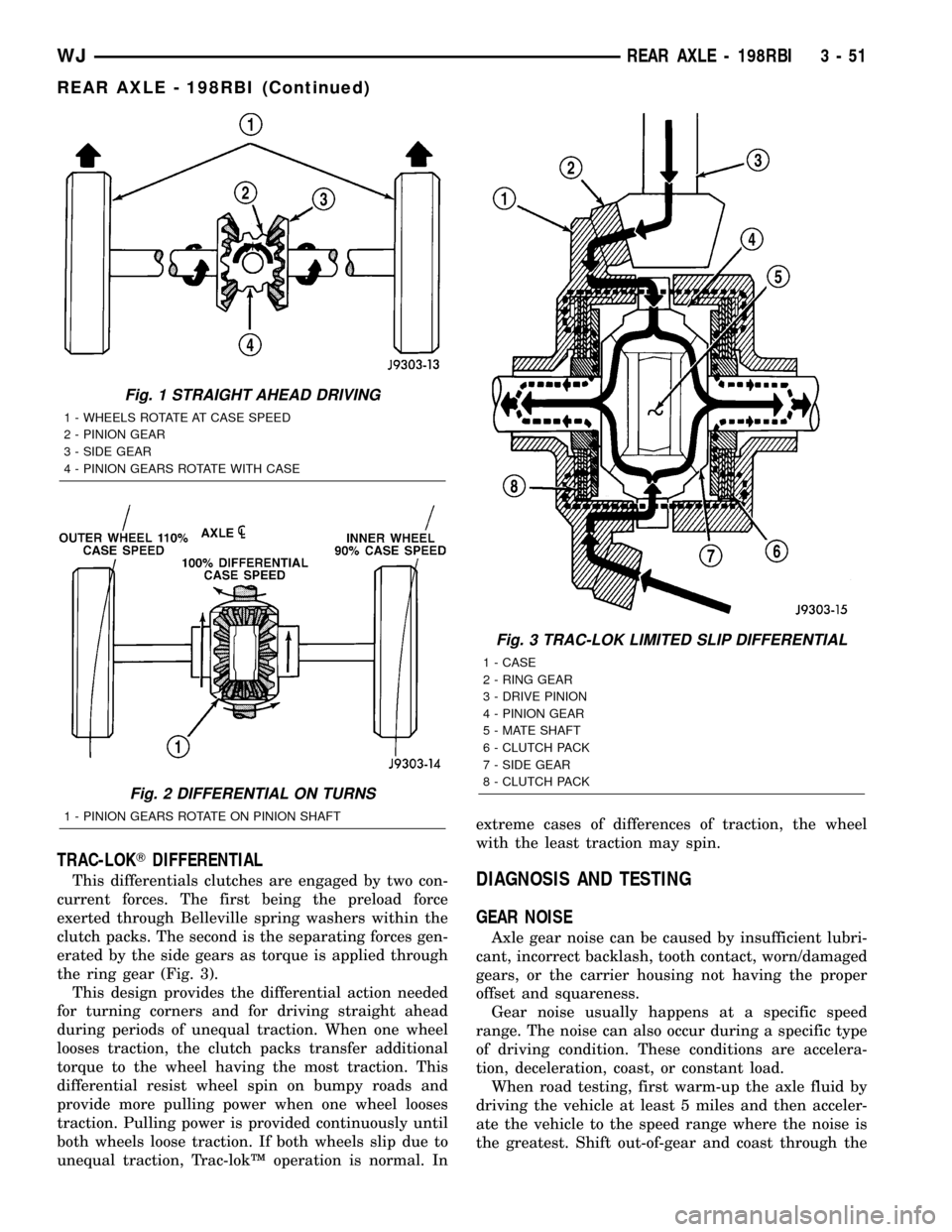

STANDARD DIFFERENTIAL

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig. 1).

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. The difference must be compensated

for to prevent the tires from scuffing and skidding

through turns. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

2). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

3 - 50 REAR AXLE - 198RBIWJ

Page 96 of 2199

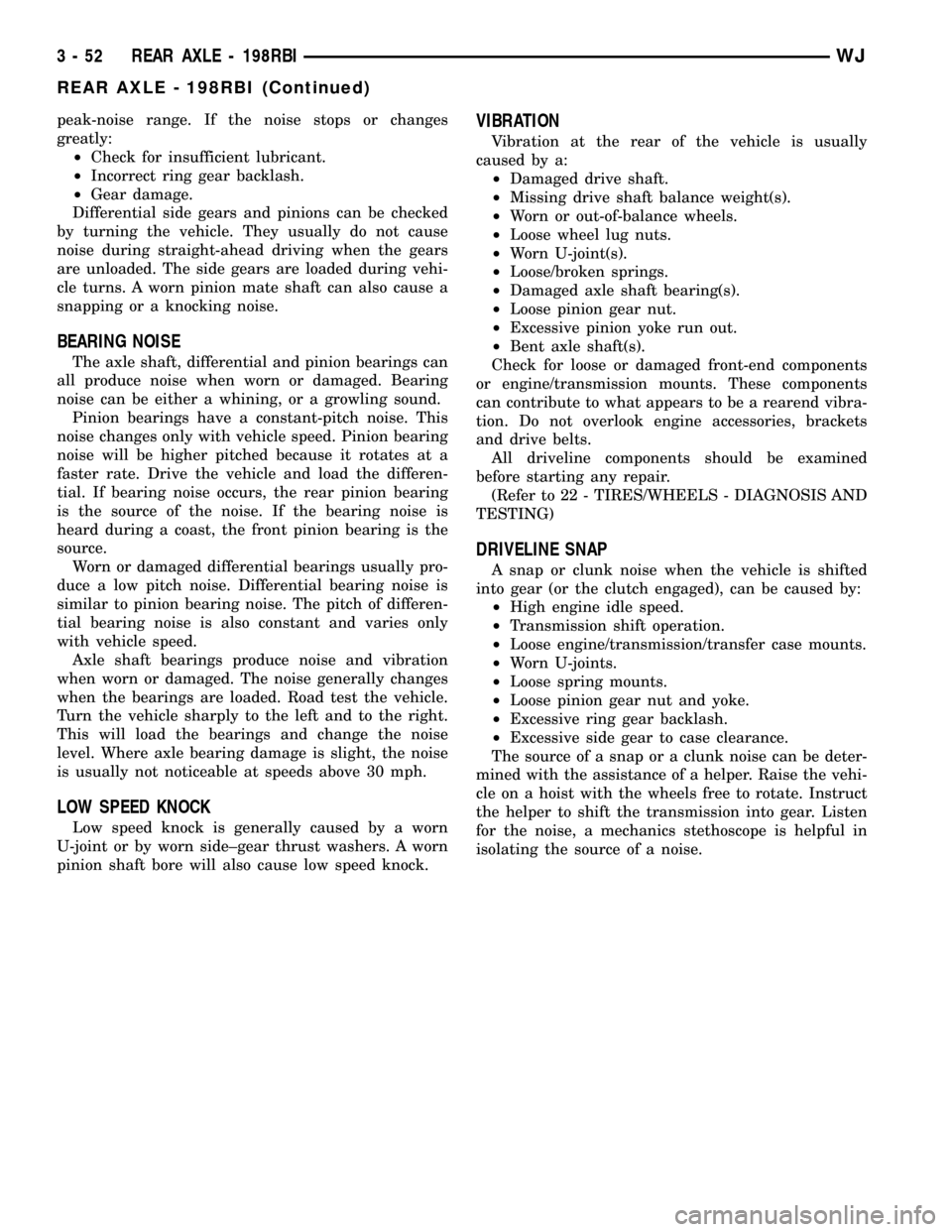

TRAC-LOKTDIFFERENTIAL

This differentials clutches are engaged by two con-

current forces. The first being the preload force

exerted through Belleville spring washers within the

clutch packs. The second is the separating forces gen-

erated by the side gears as torque is applied through

the ring gear (Fig. 3).

This design provides the differential action needed

for turning corners and for driving straight ahead

during periods of unequal traction. When one wheel

looses traction, the clutch packs transfer additional

torque to the wheel having the most traction. This

differential resist wheel spin on bumpy roads and

provide more pulling power when one wheel looses

traction. Pulling power is provided continuously until

both wheels loose traction. If both wheels slip due to

unequal traction, Trac-lokŸ operation is normal. Inextreme cases of differences of traction, the wheel

with the least traction may spin.DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, tooth contact, worn/damaged

gears, or the carrier housing not having the proper

offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

Fig. 1 STRAIGHT AHEAD DRIVING

1 - WHEELS ROTATE AT CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

Fig. 2 DIFFERENTIAL ON TURNS

1 - PINION GEARS ROTATE ON PINION SHAFT

Fig. 3 TRAC-LOK LIMITED SLIP DIFFERENTIAL

1 - CASE

2 - RING GEAR

3 - DRIVE PINION

4 - PINION GEAR

5 - MATE SHAFT

6 - CLUTCH PACK

7 - SIDE GEAR

8 - CLUTCH PACK

WJREAR AXLE - 198RBI 3 - 51

REAR AXLE - 198RBI (Continued)

Page 97 of 2199

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion mate shaft can also cause a

snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side±gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.

All driveline components should be examined

before starting any repair.

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING)

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

3 - 52 REAR AXLE - 198RBIWJ

REAR AXLE - 198RBI (Continued)

Page 102 of 2199

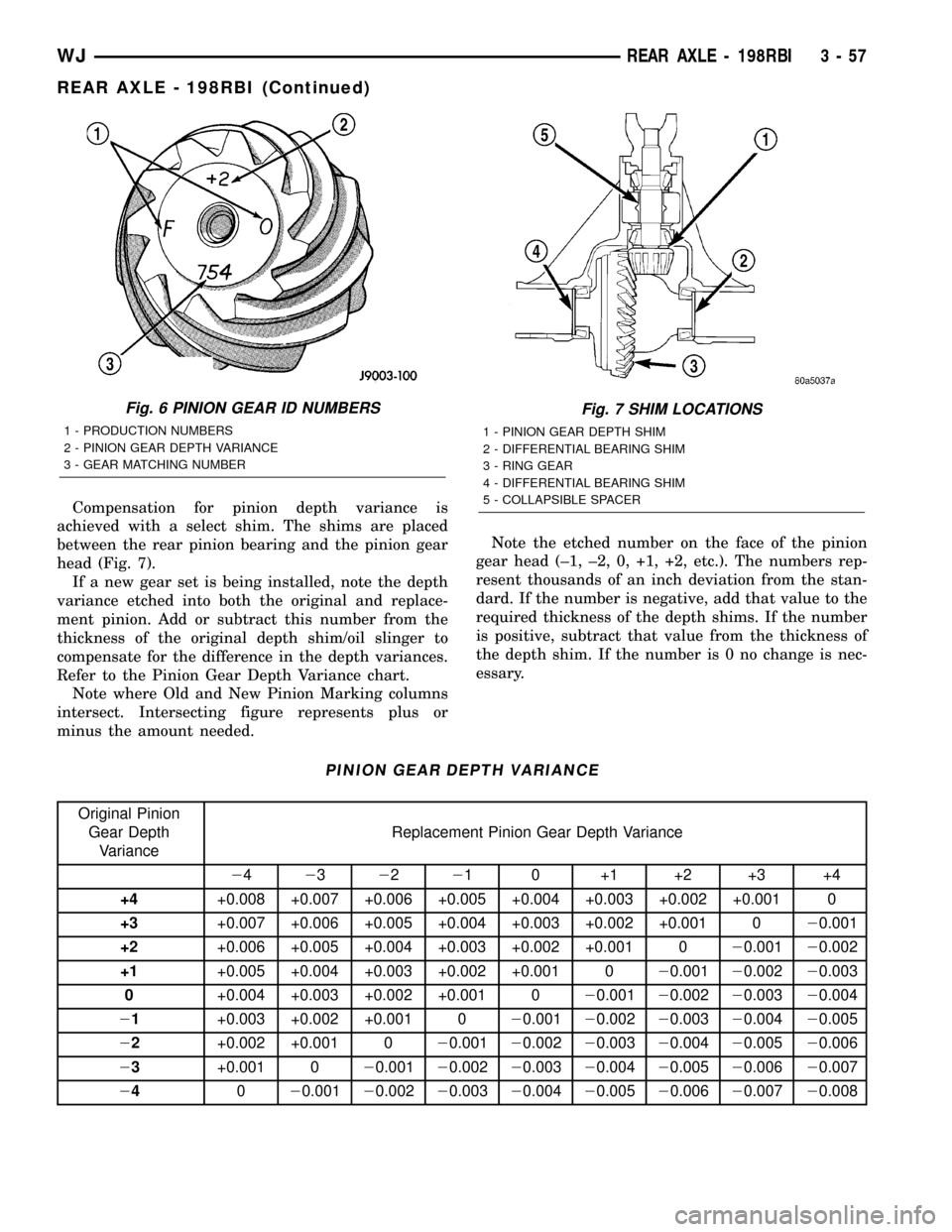

Compensation for pinion depth variance is

achieved with a select shim. The shims are placed

between the rear pinion bearing and the pinion gear

head (Fig. 7).

If a new gear set is being installed, note the depth

variance etched into both the original and replace-

ment pinion. Add or subtract this number from the

thickness of the original depth shim/oil slinger to

compensate for the difference in the depth variances.

Refer to the Pinion Gear Depth Variance chart.

Note where Old and New Pinion Marking columns

intersect. Intersecting figure represents plus or

minus the amount needed.Note the etched number on the face of the pinion

gear head (±1, ±2, 0, +1, +2, etc.). The numbers rep-

resent thousands of an inch deviation from the stan-

dard. If the number is negative, add that value to the

required thickness of the depth shims. If the number

is positive, subtract that value from the thickness of

the depth shim. If the number is 0 no change is nec-

essary.

PINION GEAR DEPTH VARIANCE

Original Pinion

Gear Depth

VarianceReplacement Pinion Gear Depth Variance

24232221 0 +1 +2 +3 +4

+4+0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3+0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.001

+2+0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.00120.002

+1+0.005 +0.004 +0.003 +0.002 +0.001 020.00120.00220.003

0+0.004 +0.003 +0.002 +0.001 020.00120.00220.00320.004

21+0.003 +0.002 +0.001 020.00120.00220.00320.00420.005

22+0.002 +0.001 020.00120.00220.00320.00420.00520.006

23+0.001 020.00120.00220.00320.00420.00520.00620.007

24020.00120.00220.00320.00420.00520.00620.00720.008

Fig. 6 PINION GEAR ID NUMBERS

1 - PRODUCTION NUMBERS

2 - PINION GEAR DEPTH VARIANCE

3 - GEAR MATCHING NUMBER

Fig. 7 SHIM LOCATIONS

1 - PINION GEAR DEPTH SHIM

2 - DIFFERENTIAL BEARING SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING SHIM

5 - COLLAPSIBLE SPACER

WJREAR AXLE - 198RBI 3 - 57

REAR AXLE - 198RBI (Continued)

Page 106 of 2199

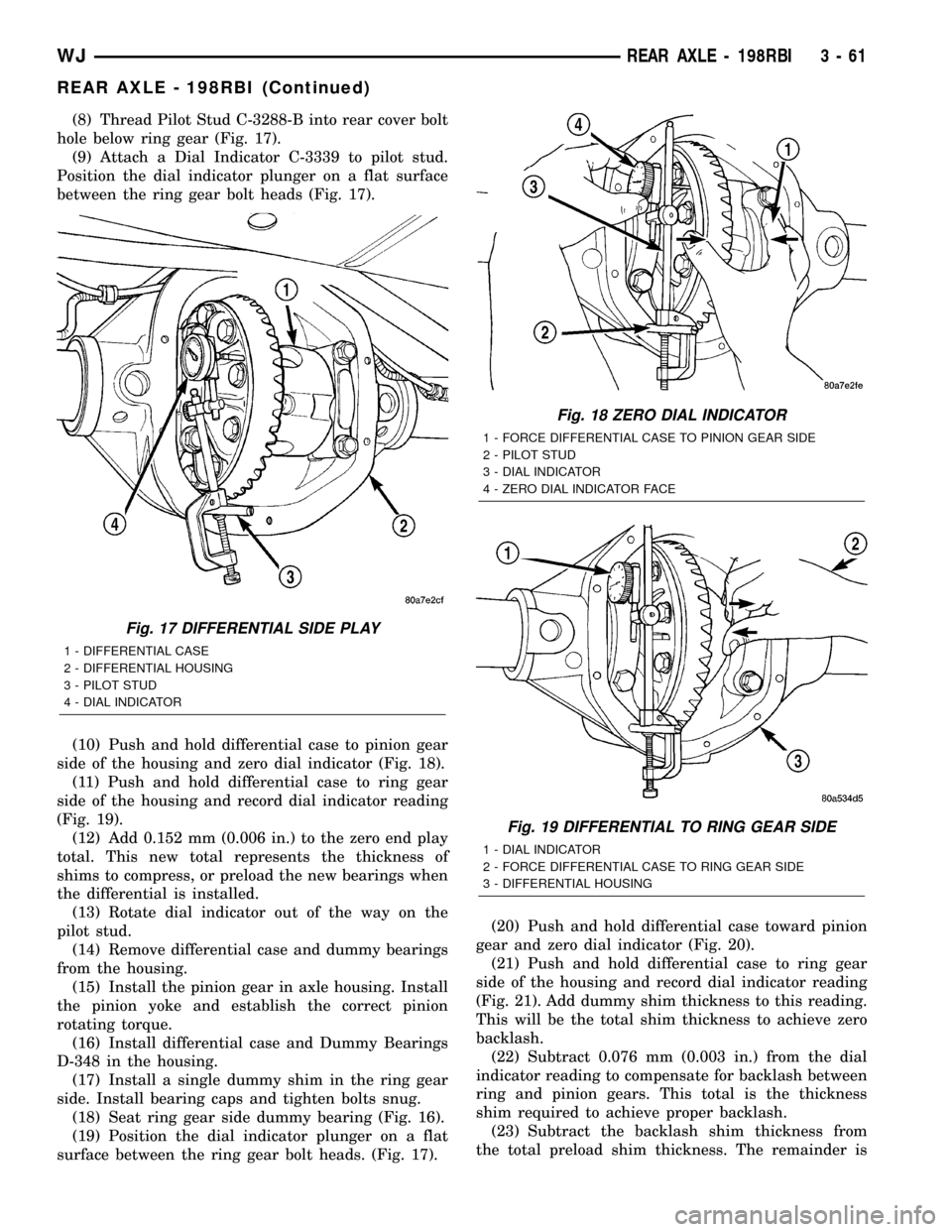

(8) Thread Pilot Stud C-3288-B into rear cover bolt

hole below ring gear (Fig. 17).

(9) Attach a Dial Indicator C-3339 to pilot stud.

Position the dial indicator plunger on a flat surface

between the ring gear bolt heads (Fig. 17).

(10) Push and hold differential case to pinion gear

side of the housing and zero dial indicator (Fig. 18).

(11) Push and hold differential case to ring gear

side of the housing and record dial indicator reading

(Fig. 19).

(12) Add 0.152 mm (0.006 in.) to the zero end play

total. This new total represents the thickness of

shims to compress, or preload the new bearings when

the differential is installed.

(13) Rotate dial indicator out of the way on the

pilot stud.

(14) Remove differential case and dummy bearings

from the housing.

(15) Install the pinion gear in axle housing. Install

the pinion yoke and establish the correct pinion

rotating torque.

(16) Install differential case and Dummy Bearings

D-348 in the housing.

(17) Install a single dummy shim in the ring gear

side. Install bearing caps and tighten bolts snug.

(18) Seat ring gear side dummy bearing (Fig. 16).

(19) Position the dial indicator plunger on a flat

surface between the ring gear bolt heads. (Fig. 17).(20) Push and hold differential case toward pinion

gear and zero dial indicator (Fig. 20).

(21) Push and hold differential case to ring gear

side of the housing and record dial indicator reading

(Fig. 21). Add dummy shim thickness to this reading.

This will be the total shim thickness to achieve zero

backlash.

(22) Subtract 0.076 mm (0.003 in.) from the dial

indicator reading to compensate for backlash between

ring and pinion gears. This total is the thickness

shim required to achieve proper backlash.

(23) Subtract the backlash shim thickness from

the total preload shim thickness. The remainder is

Fig. 17 DIFFERENTIAL SIDE PLAY

1 - DIFFERENTIAL CASE

2 - DIFFERENTIAL HOUSING

3 - PILOT STUD

4 - DIAL INDICATOR

Fig. 18 ZERO DIAL INDICATOR

1 - FORCE DIFFERENTIAL CASE TO PINION GEAR SIDE

2 - PILOT STUD

3 - DIAL INDICATOR

4 - ZERO DIAL INDICATOR FACE

Fig. 19 DIFFERENTIAL TO RING GEAR SIDE

1 - DIAL INDICATOR

2 - FORCE DIFFERENTIAL CASE TO RING GEAR SIDE

3 - DIFFERENTIAL HOUSING

WJREAR AXLE - 198RBI 3 - 61

REAR AXLE - 198RBI (Continued)