Abs JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 88 of 2199

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer to

Adjustments (Differential Bearing Preload and Gear

Backlash) to determine the proper shim selection.

(1) Position Spreader W-129-B with Adapter Kit

6987B on differential locating holes. Install hold

down clamps and tighten the tool turnbuckle finger-

tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

(3) Spread the housing enough to install the case

in the housing. Measure the distance with the dial

indicator.

CAUTION: Never spread the housing over 0.50 mm

(0.020 in). If housing is over-spread, it could dis-

torted and damaged the housing.

(4) Remove the dial indicator.

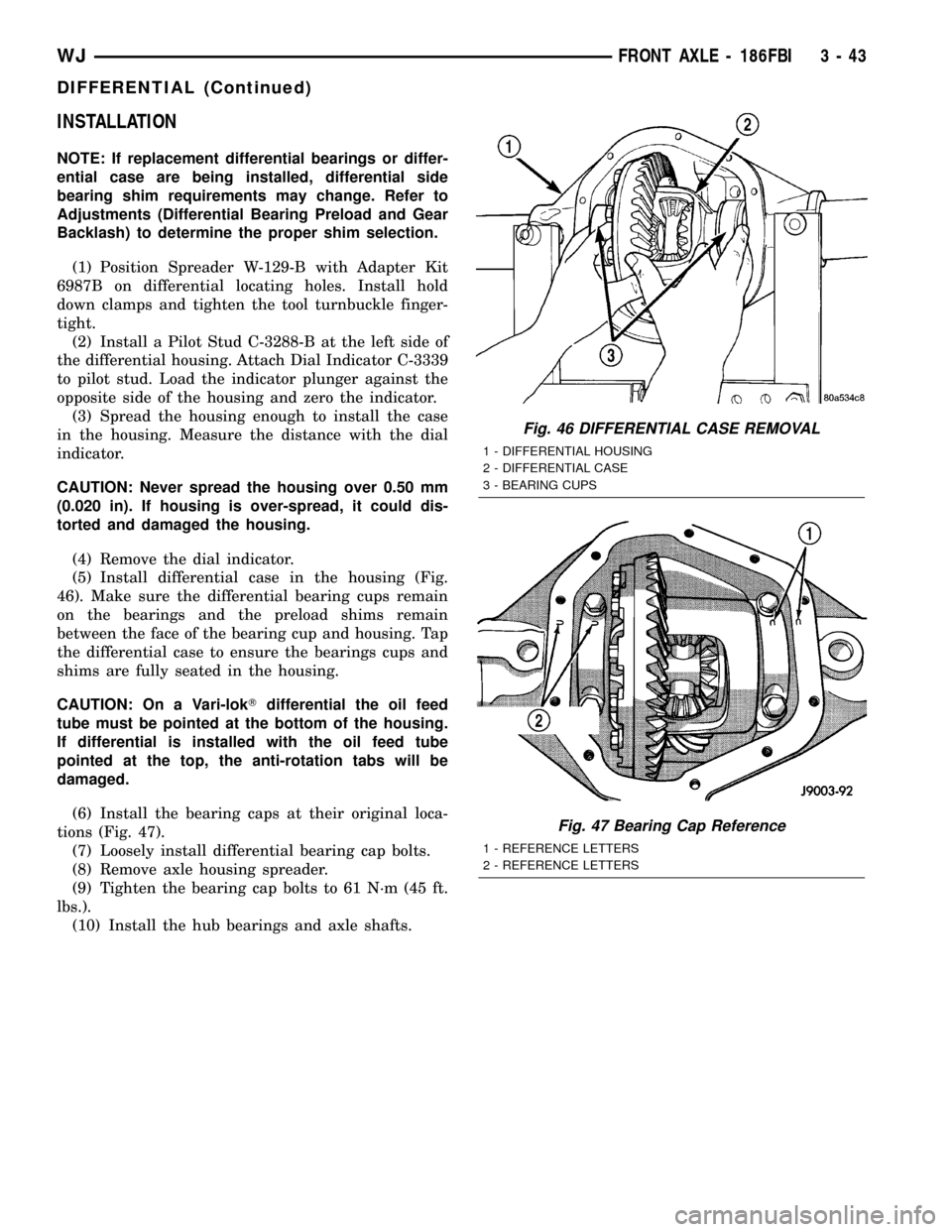

(5) Install differential case in the housing (Fig.

46). Make sure the differential bearing cups remain

on the bearings and the preload shims remain

between the face of the bearing cup and housing. Tap

the differential case to ensure the bearings cups and

shims are fully seated in the housing.

CAUTION: On a Vari-lokTdifferential the oil feed

tube must be pointed at the bottom of the housing.

If differential is installed with the oil feed tube

pointed at the top, the anti-rotation tabs will be

damaged.

(6) Install the bearing caps at their original loca-

tions (Fig. 47).

(7) Loosely install differential bearing cap bolts.

(8) Remove axle housing spreader.

(9) Tighten the bearing cap bolts to 61 N´m (45 ft.

lbs.).

(10) Install the hub bearings and axle shafts.

Fig. 46 DIFFERENTIAL CASE REMOVAL

1 - DIFFERENTIAL HOUSING

2 - DIFFERENTIAL CASE

3 - BEARING CUPS

Fig. 47 Bearing Cap Reference

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

WJFRONT AXLE - 186FBI 3 - 43

DIFFERENTIAL (Continued)

Page 101 of 2199

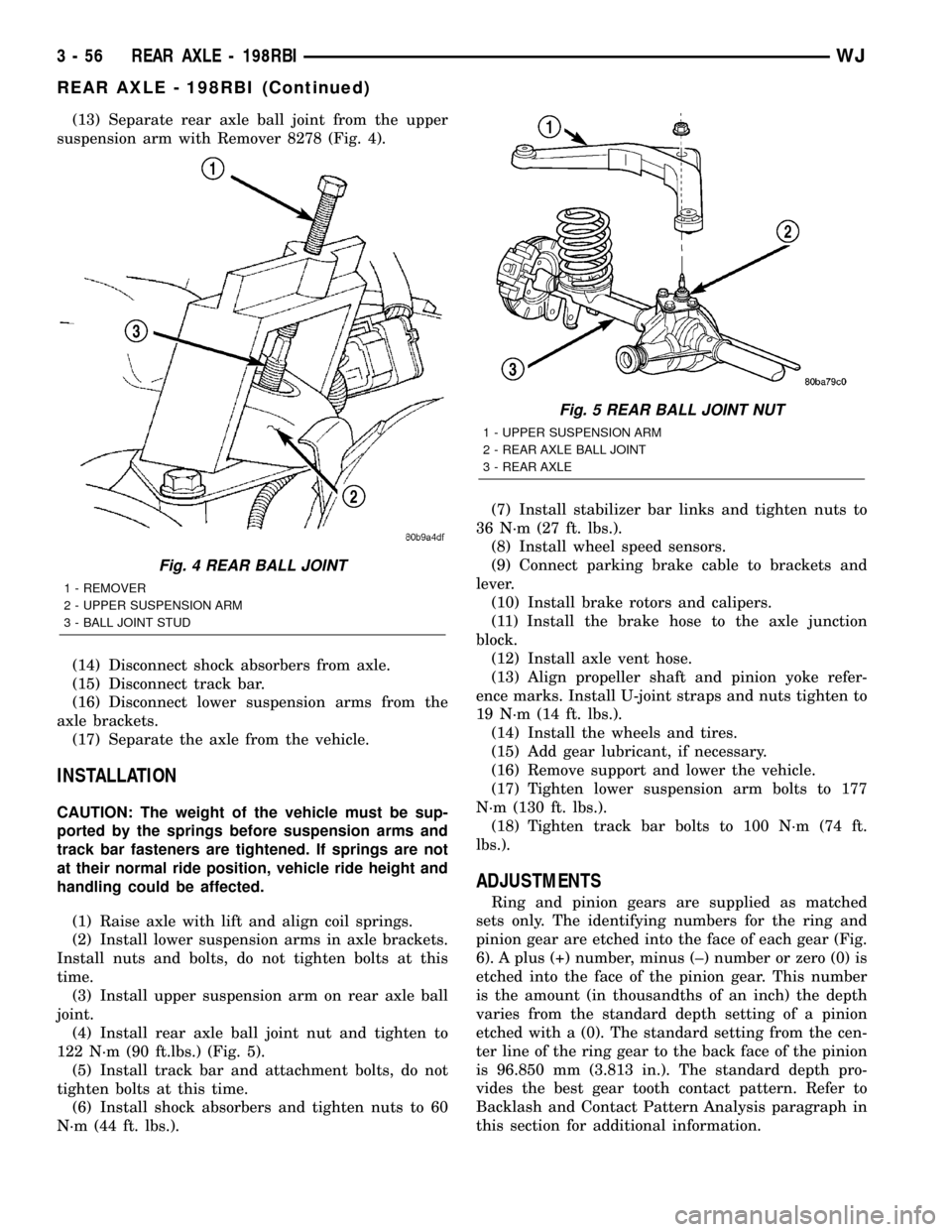

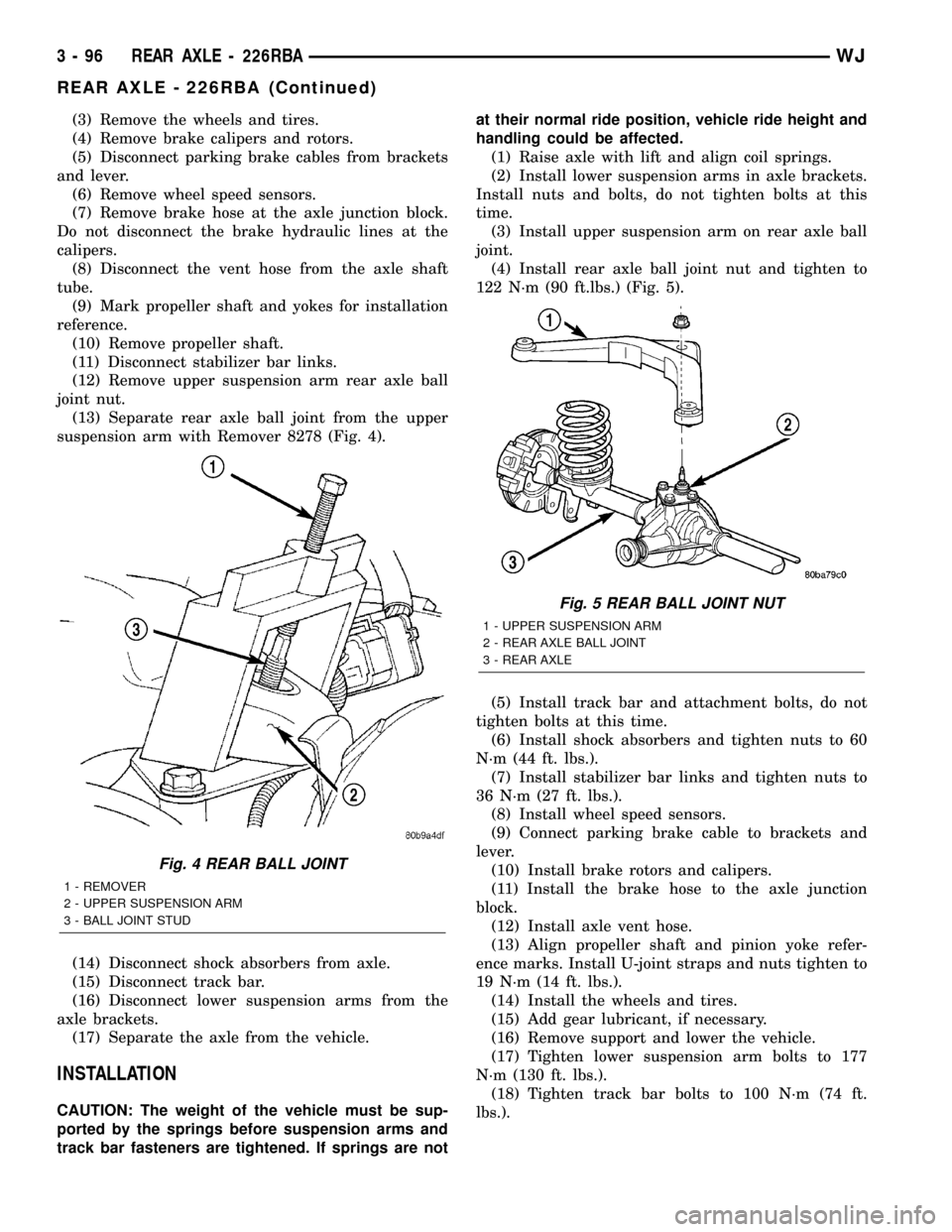

(13) Separate rear axle ball joint from the upper

suspension arm with Remover 8278 (Fig. 4).

(14) Disconnect shock absorbers from axle.

(15) Disconnect track bar.

(16) Disconnect lower suspension arms from the

axle brackets.

(17) Separate the axle from the vehicle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before suspension arms and

track bar fasteners are tightened. If springs are not

at their normal ride position, vehicle ride height and

handling could be affected.

(1) Raise axle with lift and align coil springs.

(2) Install lower suspension arms in axle brackets.

Install nuts and bolts, do not tighten bolts at this

time.

(3) Install upper suspension arm on rear axle ball

joint.

(4) Install rear axle ball joint nut and tighten to

122 N´m (90 ft.lbs.) (Fig. 5).

(5) Install track bar and attachment bolts, do not

tighten bolts at this time.

(6) Install shock absorbers and tighten nuts to 60

N´m (44 ft. lbs.).(7) Install stabilizer bar links and tighten nuts to

36 N´m (27 ft. lbs.).

(8) Install wheel speed sensors.

(9) Connect parking brake cable to brackets and

lever.

(10) Install brake rotors and calipers.

(11) Install the brake hose to the axle junction

block.

(12) Install axle vent hose.

(13) Align propeller shaft and pinion yoke refer-

ence marks. Install U-joint straps and nuts tighten to

19 N´m (14 ft. lbs.).

(14) Install the wheels and tires.

(15) Add gear lubricant, if necessary.

(16) Remove support and lower the vehicle.

(17) Tighten lower suspension arm bolts to 177

N´m (130 ft. lbs.).

(18) Tighten track bar bolts to 100 N´m (74 ft.

lbs.).

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets only. The identifying numbers for the ring and

pinion gear are etched into the face of each gear (Fig.

6). A plus (+) number, minus (±) number or zero (0) is

etched into the face of the pinion gear. This number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

etched with a (0). The standard setting from the cen-

ter line of the ring gear to the back face of the pinion

is 96.850 mm (3.813 in.). The standard depth pro-

vides the best gear tooth contact pattern. Refer to

Backlash and Contact Pattern Analysis paragraph in

this section for additional information.

Fig. 4 REAR BALL JOINT

1 - REMOVER

2 - UPPER SUSPENSION ARM

3 - BALL JOINT STUD

Fig. 5 REAR BALL JOINT NUT

1 - UPPER SUSPENSION ARM

2 - REAR AXLE BALL JOINT

3 - REAR AXLE

3 - 56 REAR AXLE - 198RBIWJ

REAR AXLE - 198RBI (Continued)

Page 122 of 2199

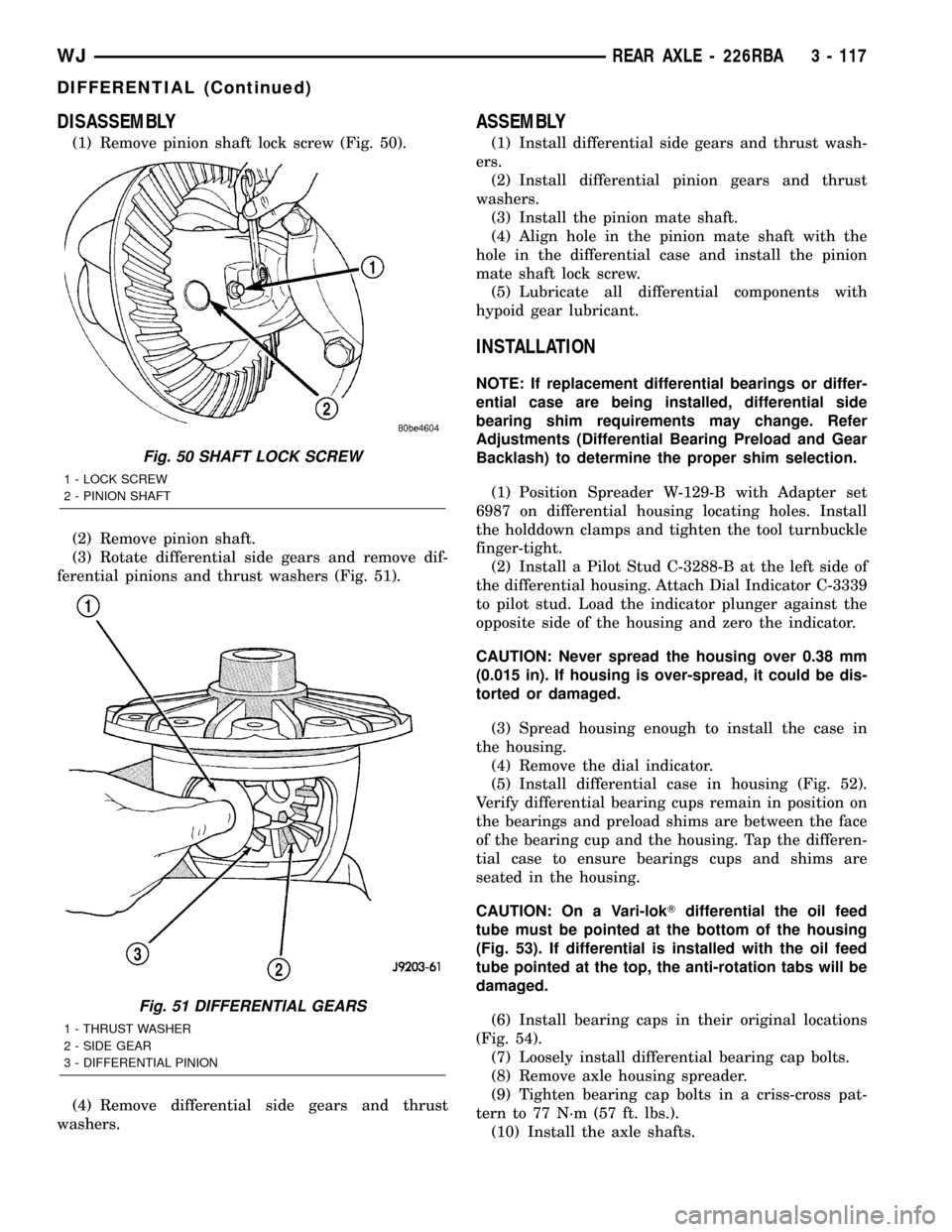

DISASSEMBLY

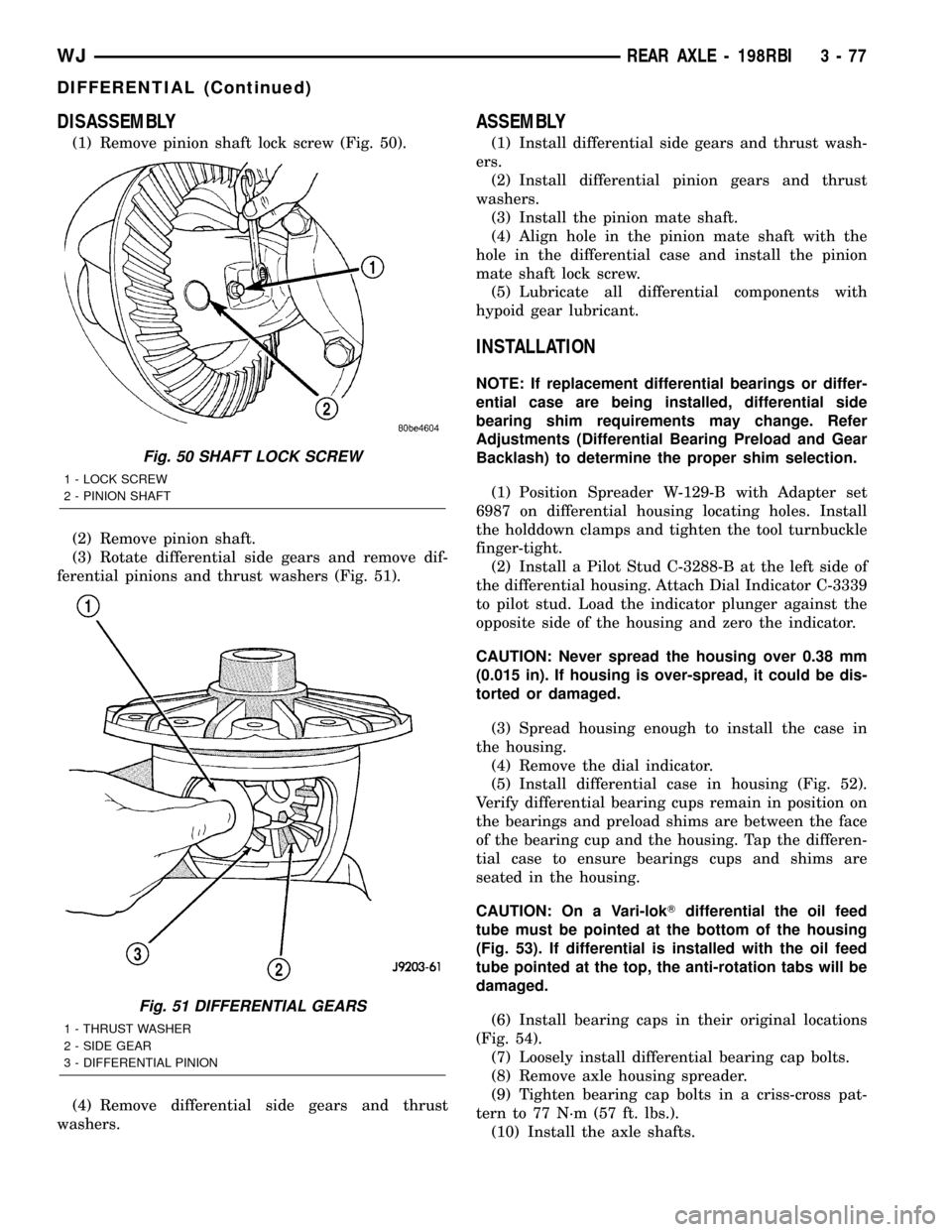

(1) Remove pinion shaft lock screw (Fig. 50).

(2) Remove pinion shaft.

(3) Rotate differential side gears and remove dif-

ferential pinions and thrust washers (Fig. 51).

(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install differential pinion gears and thrust

washers.

(3) Install the pinion mate shaft.

(4) Align hole in the pinion mate shaft with the

hole in the differential case and install the pinion

mate shaft lock screw.

(5) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer

Adjustments (Differential Bearing Preload and Gear

Backlash) to determine the proper shim selection.

(1) Position Spreader W-129-B with Adapter set

6987 on differential housing locating holes. Install

the holddown clamps and tighten the tool turnbuckle

finger-tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

CAUTION: Never spread the housing over 0.38 mm

(0.015 in). If housing is over-spread, it could be dis-

torted or damaged.

(3) Spread housing enough to install the case in

the housing.

(4) Remove the dial indicator.

(5) Install differential case in housing (Fig. 52).

Verify differential bearing cups remain in position on

the bearings and preload shims are between the face

of the bearing cup and the housing. Tap the differen-

tial case to ensure bearings cups and shims are

seated in the housing.

CAUTION: On a Vari-lokTdifferential the oil feed

tube must be pointed at the bottom of the housing

(Fig. 53). If differential is installed with the oil feed

tube pointed at the top, the anti-rotation tabs will be

damaged.

(6) Install bearing caps in their original locations

(Fig. 54).

(7) Loosely install differential bearing cap bolts.

(8) Remove axle housing spreader.

(9) Tighten bearing cap bolts in a criss-cross pat-

tern to 77 N´m (57 ft. lbs.).

(10) Install the axle shafts.

Fig. 50 SHAFT LOCK SCREW

1 - LOCK SCREW

2 - PINION SHAFT

Fig. 51 DIFFERENTIAL GEARS

1 - THRUST WASHER

2 - SIDE GEAR

3 - DIFFERENTIAL PINION

WJREAR AXLE - 198RBI 3 - 77

DIFFERENTIAL (Continued)

Page 134 of 2199

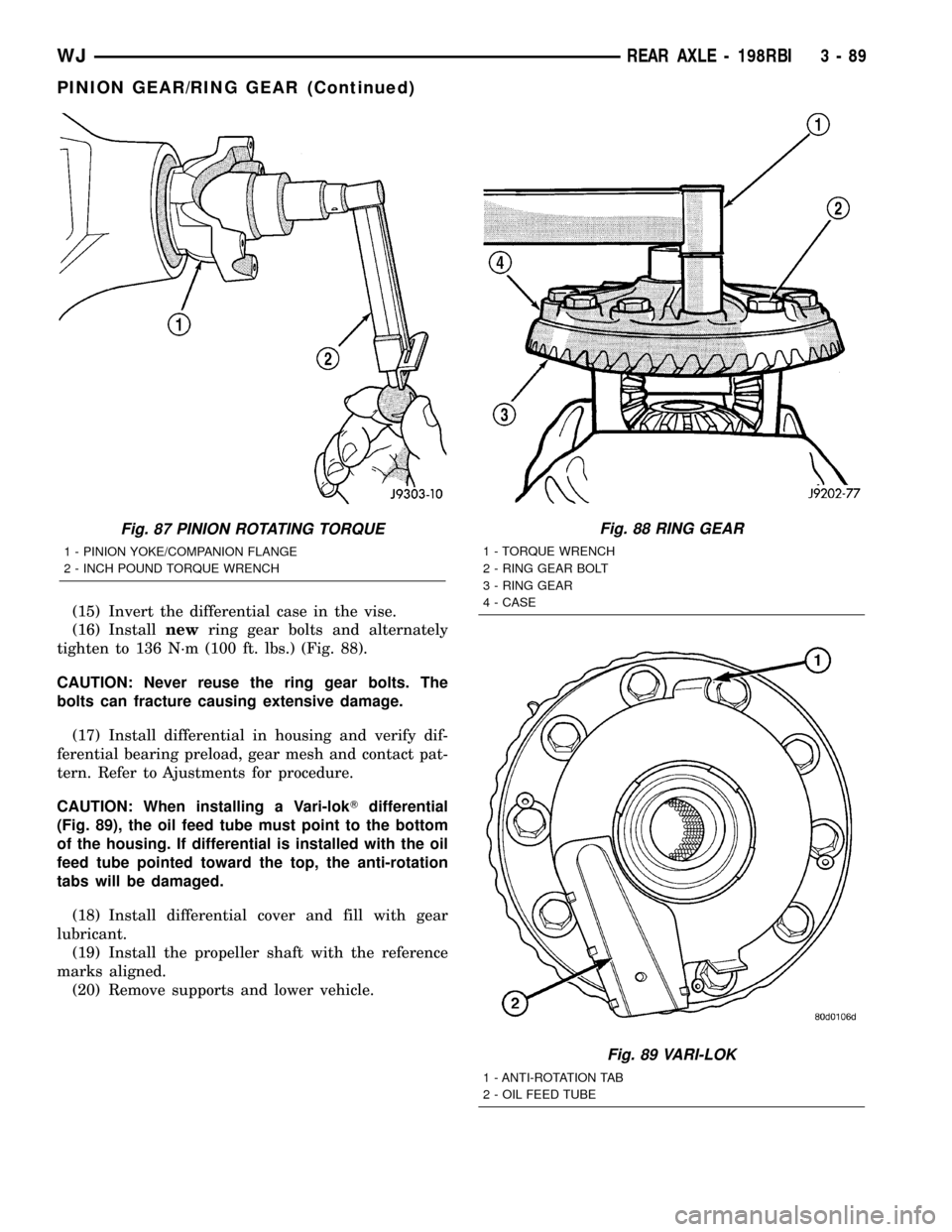

(15) Invert the differential case in the vise.

(16) Installnewring gear bolts and alternately

tighten to 136 N´m (100 ft. lbs.) (Fig. 88).

CAUTION: Never reuse the ring gear bolts. The

bolts can fracture causing extensive damage.

(17) Install differential in housing and verify dif-

ferential bearing preload, gear mesh and contact pat-

tern. Refer to Ajustments for procedure.

CAUTION: When installing a Vari-lokTdifferential

(Fig. 89), the oil feed tube must point to the bottom

of the housing. If differential is installed with the oil

feed tube pointed toward the top, the anti-rotation

tabs will be damaged.

(18) Install differential cover and fill with gear

lubricant.

(19) Install the propeller shaft with the reference

marks aligned.

(20) Remove supports and lower vehicle.

Fig. 87 PINION ROTATING TORQUE

1 - PINION YOKE/COMPANION FLANGE

2 - INCH POUND TORQUE WRENCH

Fig. 88 RING GEAR

1 - TORQUE WRENCH

2 - RING GEAR BOLT

3 - RING GEAR

4 - CASE

Fig. 89 VARI-LOK

1 - ANTI-ROTATION TAB

2 - OIL FEED TUBE

WJREAR AXLE - 198RBI 3 - 89

PINION GEAR/RING GEAR (Continued)

Page 141 of 2199

(3) Remove the wheels and tires.

(4) Remove brake calipers and rotors.

(5) Disconnect parking brake cables from brackets

and lever.

(6) Remove wheel speed sensors.

(7) Remove brake hose at the axle junction block.

Do not disconnect the brake hydraulic lines at the

calipers.

(8) Disconnect the vent hose from the axle shaft

tube.

(9) Mark propeller shaft and yokes for installation

reference.

(10) Remove propeller shaft.

(11) Disconnect stabilizer bar links.

(12) Remove upper suspension arm rear axle ball

joint nut.

(13) Separate rear axle ball joint from the upper

suspension arm with Remover 8278 (Fig. 4).

(14) Disconnect shock absorbers from axle.

(15) Disconnect track bar.

(16) Disconnect lower suspension arms from the

axle brackets.

(17) Separate the axle from the vehicle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before suspension arms and

track bar fasteners are tightened. If springs are notat their normal ride position, vehicle ride height and

handling could be affected.

(1) Raise axle with lift and align coil springs.

(2) Install lower suspension arms in axle brackets.

Install nuts and bolts, do not tighten bolts at this

time.

(3) Install upper suspension arm on rear axle ball

joint.

(4) Install rear axle ball joint nut and tighten to

122 N´m (90 ft.lbs.) (Fig. 5).

(5) Install track bar and attachment bolts, do not

tighten bolts at this time.

(6) Install shock absorbers and tighten nuts to 60

N´m (44 ft. lbs.).

(7) Install stabilizer bar links and tighten nuts to

36 N´m (27 ft. lbs.).

(8) Install wheel speed sensors.

(9) Connect parking brake cable to brackets and

lever.

(10) Install brake rotors and calipers.

(11) Install the brake hose to the axle junction

block.

(12) Install axle vent hose.

(13) Align propeller shaft and pinion yoke refer-

ence marks. Install U-joint straps and nuts tighten to

19 N´m (14 ft. lbs.).

(14) Install the wheels and tires.

(15) Add gear lubricant, if necessary.

(16) Remove support and lower the vehicle.

(17) Tighten lower suspension arm bolts to 177

N´m (130 ft. lbs.).

(18) Tighten track bar bolts to 100 N´m (74 ft.

lbs.).

Fig. 4 REAR BALL JOINT

1 - REMOVER

2 - UPPER SUSPENSION ARM

3 - BALL JOINT STUD

Fig. 5 REAR BALL JOINT NUT

1 - UPPER SUSPENSION ARM

2 - REAR AXLE BALL JOINT

3 - REAR AXLE

3 - 96 REAR AXLE - 226RBAWJ

REAR AXLE - 226RBA (Continued)

Page 162 of 2199

DISASSEMBLY

(1) Remove pinion shaft lock screw (Fig. 50).

(2) Remove pinion shaft.

(3) Rotate differential side gears and remove dif-

ferential pinions and thrust washers (Fig. 51).

(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install differential pinion gears and thrust

washers.

(3) Install the pinion mate shaft.

(4) Align hole in the pinion mate shaft with the

hole in the differential case and install the pinion

mate shaft lock screw.

(5) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer

Adjustments (Differential Bearing Preload and Gear

Backlash) to determine the proper shim selection.

(1) Position Spreader W-129-B with Adapter set

6987 on differential housing locating holes. Install

the holddown clamps and tighten the tool turnbuckle

finger-tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

CAUTION: Never spread the housing over 0.38 mm

(0.015 in). If housing is over-spread, it could be dis-

torted or damaged.

(3) Spread housing enough to install the case in

the housing.

(4) Remove the dial indicator.

(5) Install differential case in housing (Fig. 52).

Verify differential bearing cups remain in position on

the bearings and preload shims are between the face

of the bearing cup and the housing. Tap the differen-

tial case to ensure bearings cups and shims are

seated in the housing.

CAUTION: On a Vari-lokTdifferential the oil feed

tube must be pointed at the bottom of the housing

(Fig. 53). If differential is installed with the oil feed

tube pointed at the top, the anti-rotation tabs will be

damaged.

(6) Install bearing caps in their original locations

(Fig. 54).

(7) Loosely install differential bearing cap bolts.

(8) Remove axle housing spreader.

(9) Tighten bearing cap bolts in a criss-cross pat-

tern to 77 N´m (57 ft. lbs.).

(10) Install the axle shafts.

Fig. 50 SHAFT LOCK SCREW

1 - LOCK SCREW

2 - PINION SHAFT

Fig. 51 DIFFERENTIAL GEARS

1 - THRUST WASHER

2 - SIDE GEAR

3 - DIFFERENTIAL PINION

WJREAR AXLE - 226RBA 3 - 117

DIFFERENTIAL (Continued)

Page 174 of 2199

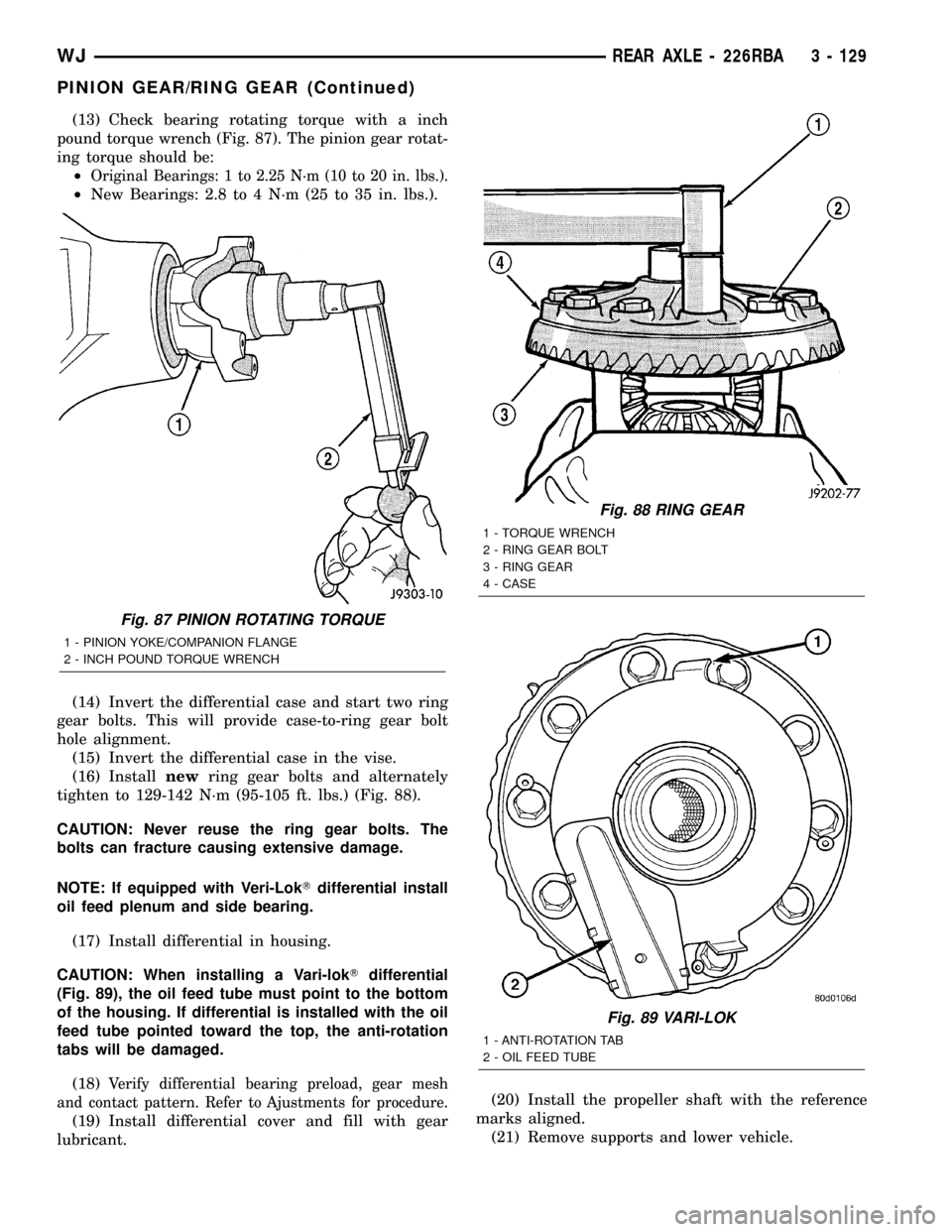

(13) Check bearing rotating torque with a inch

pound torque wrench (Fig. 87). The pinion gear rotat-

ing torque should be:

²

Original Bearings: 1 to 2.25 N´m (10 to 20 in. lbs.).

²New Bearings: 2.8 to 4 N´m (25 to 35 in. lbs.).

(14) Invert the differential case and start two ring

gear bolts. This will provide case-to-ring gear bolt

hole alignment.

(15) Invert the differential case in the vise.

(16) Installnewring gear bolts and alternately

tighten to 129-142 N´m (95-105 ft. lbs.) (Fig. 88).

CAUTION: Never reuse the ring gear bolts. The

bolts can fracture causing extensive damage.

NOTE: If equipped with Veri-LokTdifferential install

oil feed plenum and side bearing.

(17) Install differential in housing.

CAUTION: When installing a Vari-lokTdifferential

(Fig. 89), the oil feed tube must point to the bottom

of the housing. If differential is installed with the oil

feed tube pointed toward the top, the anti-rotation

tabs will be damaged.

(18)

Verify differential bearing preload, gear mesh

and contact pattern. Refer to Ajustments for procedure.

(19) Install differential cover and fill with gear

lubricant.(20) Install the propeller shaft with the reference

marks aligned.

(21) Remove supports and lower vehicle.

Fig. 87 PINION ROTATING TORQUE

1 - PINION YOKE/COMPANION FLANGE

2 - INCH POUND TORQUE WRENCH

Fig. 88 RING GEAR

1 - TORQUE WRENCH

2 - RING GEAR BOLT

3 - RING GEAR

4 - CASE

Fig. 89 VARI-LOK

1 - ANTI-ROTATION TAB

2 - OIL FEED TUBE

WJREAR AXLE - 226RBA 3 - 129

PINION GEAR/RING GEAR (Continued)

Page 176 of 2199

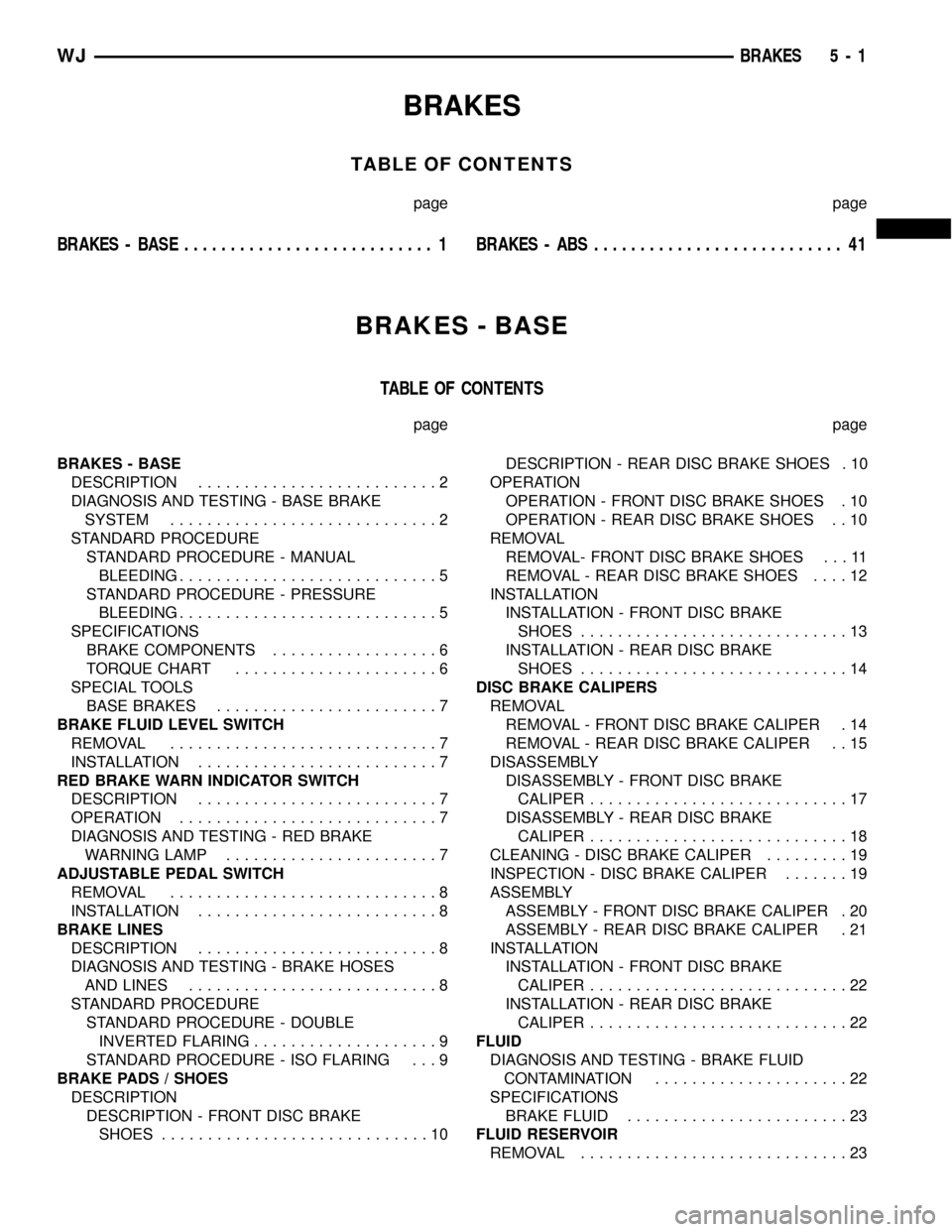

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE........................... 1BRAKES - ABS........................... 41

BRAKES - BASE

TABLE OF CONTENTS

page page

BRAKES - BASE

DESCRIPTION..........................2

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM.............................2

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL

BLEEDING............................5

STANDARD PROCEDURE - PRESSURE

BLEEDING............................5

SPECIFICATIONS

BRAKE COMPONENTS..................6

TORQUE CHART......................6

SPECIAL TOOLS

BASE BRAKES........................7

BRAKE FLUID LEVEL SWITCH

REMOVAL.............................7

INSTALLATION..........................7

RED BRAKE WARN INDICATOR SWITCH

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - RED BRAKE

WARNING LAMP.......................7

ADJUSTABLE PEDAL SWITCH

REMOVAL.............................8

INSTALLATION..........................8

BRAKE LINES

DESCRIPTION..........................8

DIAGNOSIS AND TESTING - BRAKE HOSES

AND LINES...........................8

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE

INVERTED FLARING....................9

STANDARD PROCEDURE - ISO FLARING . . . 9

BRAKE PADS / SHOES

DESCRIPTION

DESCRIPTION - FRONT DISC BRAKE

SHOES.............................10DESCRIPTION - REAR DISC BRAKE SHOES . 10

OPERATION

OPERATION - FRONT DISC BRAKE SHOES . 10

OPERATION - REAR DISC BRAKE SHOES . . 10

REMOVAL

REMOVAL- FRONT DISC BRAKE SHOES . . . 11

REMOVAL - REAR DISC BRAKE SHOES....12

INSTALLATION

INSTALLATION - FRONT DISC BRAKE

SHOES.............................13

INSTALLATION - REAR DISC BRAKE

SHOES.............................14

DISC BRAKE CALIPERS

REMOVAL

REMOVAL - FRONT DISC BRAKE CALIPER . 14

REMOVAL - REAR DISC BRAKE CALIPER . . 15

DISASSEMBLY

DISASSEMBLY - FRONT DISC BRAKE

CALIPER............................17

DISASSEMBLY - REAR DISC BRAKE

CALIPER............................18

CLEANING - DISC BRAKE CALIPER.........19

INSPECTION - DISC BRAKE CALIPER.......19

ASSEMBLY

ASSEMBLY - FRONT DISC BRAKE CALIPER . 20

ASSEMBLY - REAR DISC BRAKE CALIPER . 21

INSTALLATION

INSTALLATION - FRONT DISC BRAKE

CALIPER............................22

INSTALLATION - REAR DISC BRAKE

CALIPER............................22

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION.....................22

SPECIFICATIONS

BRAKE FLUID........................23

FLUID RESERVOIR

REMOVAL.............................23

WJBRAKES 5 - 1

Page 177 of 2199

INSTALLATION.........................23

MASTER CYLINDER

DESCRIPTION.........................23

OPERATION...........................24

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER...........24

STANDARD PROCEDURE - MASTER

CYLINDER BLEEDING PROCEDURE......25

REMOVAL.............................25

INSTALLATION.........................25

PEDAL

DESCRIPTION

DESCRIPTION - STANDARD PEDAL.......25

DESCRIPTION - ADJUSTABLE PEDALS....25

OPERATION...........................26

REMOVAL

REMOVAL - NON-ADJUSTABLE PEDAL....26

REMOVAL - ADJUSTABLE PEDALS........27

INSTALLATION

INSTALLATION - NON-ADJUSTABLE PEDAL . 28

INSTALLATION - ADJUSTABLE PEDALS....28

PEDAL MOTOR

REMOVAL.............................28

INSTALLATION.........................28

POWER BRAKE BOOSTER

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................31

INSTALLATION.........................31

ROTORS

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FRONT DISC

BRAKE ROTOR.......................31DIAGNOSIS AND TESTING - REAR DISC

BRAKE ROTOR.......................32

STANDARD PROCEDURE - DISC ROTOR

MACHINING..........................33

REMOVAL

REMOVAL - FRONT DISC BRAKE ROTOR . . 33

REMOVAL - REAR DISC BRAKE ROTOR . . . 33

INSTALLATION

INSTALLATION - FRONT DISC BRAKE

ROTOR .............................34

INSTALLATION - REAR DISC BRAKE

ROTOR .............................34

PARKING BRAKE

OPERATION...........................34

DIAGNOSIS AND TESTING - PARKING BRAKE . 34

CABLES

REMOVAL

REMOVAL - FRONT PARKING BRAKE

CABLE..............................35

REMOVAL - REAR PARKING BRAKE

CABLES............................36

INSTALLATION

INSTALLATION - FRONT PARKING BRAKE

CABLE..............................37

INSTALLATION - REAR PARKING BRAKE

CABLES............................37

LEVER

REMOVAL.............................38

INSTALLATION.........................39

SHOES

REMOVAL.............................39

INSTALLATION.........................39

ADJUSTMENTS - PARKING BRAKE SHOE....40

BRAKES - BASE

DESCRIPTION

Dual piston disc brake calipers are used on the

front. Single piston disc brake calipers are used on

the rear. Ventilated disc brake rotors are used on the

front and solid rotors are used on the rear.

Power brake assist is supplied by a vacuum oper-

ated, dual diaphragm power brake booster. The mas-

ter cylinder used for all applications has an

aluminum body and nylon reservoir with single filler

cap. A fluid level indicator is mounted to the side of

the reservoir.

The braking force of the rear wheels is controlled

by electronic brake distribution (EBD). The EBD

functions like a rear proportioning valve. The EBD

system uses the ABS system to control the slip of the

rear wheels in partial braking range. The braking

force of the rear wheels is controlled electronically by

using the inlet and outlet valves located in the HCU.

Factory installed brake linings on all models con-

sists of organic base material combined with metallic

particles.

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

Base brake components consist of the brake shoes,

calipers, rear park brake drums/rotors, front brake

rotors, brake lines, master cylinder, booster, HCU

and parking brake shoes.

Brake diagnosis involves determining if the prob-

lem is related to a mechanical, hydraulic, electrical

or vacuum operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.

5 - 2 BRAKES - BASEWJ

Page 178 of 2199

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.

(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, brake lines, master cyl-

inder, and HCU.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals,

cups, hoses, master cylinder, and HCU will also

have to be replaced after flushing. Use clean brake

fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and lever. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only (do not exceed 25 mph) and note grab,

drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper. If leakage is severe, fluid will be evident at

or around the leaking component.Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS system may also be

the problem with no visual fluid leak.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, the most

likely causes are worn linings, rotors, or calipers are

not sliding on the slide pins. The proper course of

action is to inspect and replace all worn component.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However substandard brake hoses can cause

a spongy pedal. The proper course of action is to

bleed the system, and replace substandard quality

brake hoses if suspected.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster, check valve, check

valve seal/grommet or vacuum leak could also cause

a hard pedal or high pedal effort.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness vari-

ation. Other causes are loose wheel bearings or cali-

pers and worn, damaged tires.

NOTE: Some pedal pulsation may be felt during

ABS activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.

Drag is a product of incomplete brake release.

Drag can be minor or severe enough to overheat the

linings, rotors and park brake drums.

Minor drag will usually cause slight surface charring

of the lining. It can also generate hard spots in rotors

and park brake drums from the overheat-cool down pro-

cess. In most cases, the rotors, wheels and tires are

quite warm to the touch after the vehicle is stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors to the

point of replacement. The wheels, tires and brake

components will be extremely hot. In severe cases,

the lining may generate smoke as it chars from over-

heating.

WJBRAKES - BASE 5 - 3

BRAKES - BASE (Continued)