Oil JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1699 of 2199

Diagnosis of these problems should always begin

by checking the easily accessible variables: fluid level

and condition, gearshift cable adjustment. Then per-

form a road test to determine if the problem has been

corrected or if more diagnosis is necessary. If the

problem persists after the preliminary tests and cor-

rections are completed, hydraulic pressure checks

should be performed.

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure for

vehicles that are drivable and an alternate procedure for

disabled vehicles (will not back up or move forward).

VEHICLE IS DRIVABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust gearshift cable if complaint was based

on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

(5) Perform stall test if complaint is based on slug-

gish acceleration. Or, if abnormal throttle opening is

needed to maintain normal speeds with a properly

tuned engine.

(6) Perform hydraulic pressure test if shift prob-

lems were noted during road test.

(7)

Perform air-pressure test to check clutch operation.

VEHICLE IS DISABLED

(1) Check fluid level and condition.

(2)

Check for broken or disconnected gearshift cable.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shaft does not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged driveplate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmis-

sion is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that all diagnostic trou-

ble codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analy-

sis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, overrunning clutch, or line presure problems.

A slipping clutch can often be determined by com-

paring which internal units are applied in the vari-

ous gear ranges. The Clutch Application chart

provides a basis for analyzing road test results.

CLUTCH APPLICATION CHART

SLP UD OD R 2C 4C L/R OVERRUNNING

P±PARKON

R±REVERSEON ON

N-NEUTRALON

D±OVERDRIVE

FIRSTON ON* ON

SECONDON ON

SECOND PRIMEON ON

THIRDON ON

FOURTHON ON

FIFTHON ON

LIMP-INON ON

2±FIRSTON ON* ON

SECONDON ON

LIMP-INON ON

1±LOWON ON ON

*L/R clutch is on only with the output shaft speed below 150 rpm.

21 - 180 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1700 of 2199

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST

An accurate tachometer and pressure test gauges

are required. Test Gauge C-3293-SP has a 300 psi

range and is used at all locations where pressures

exceed 100 psi.

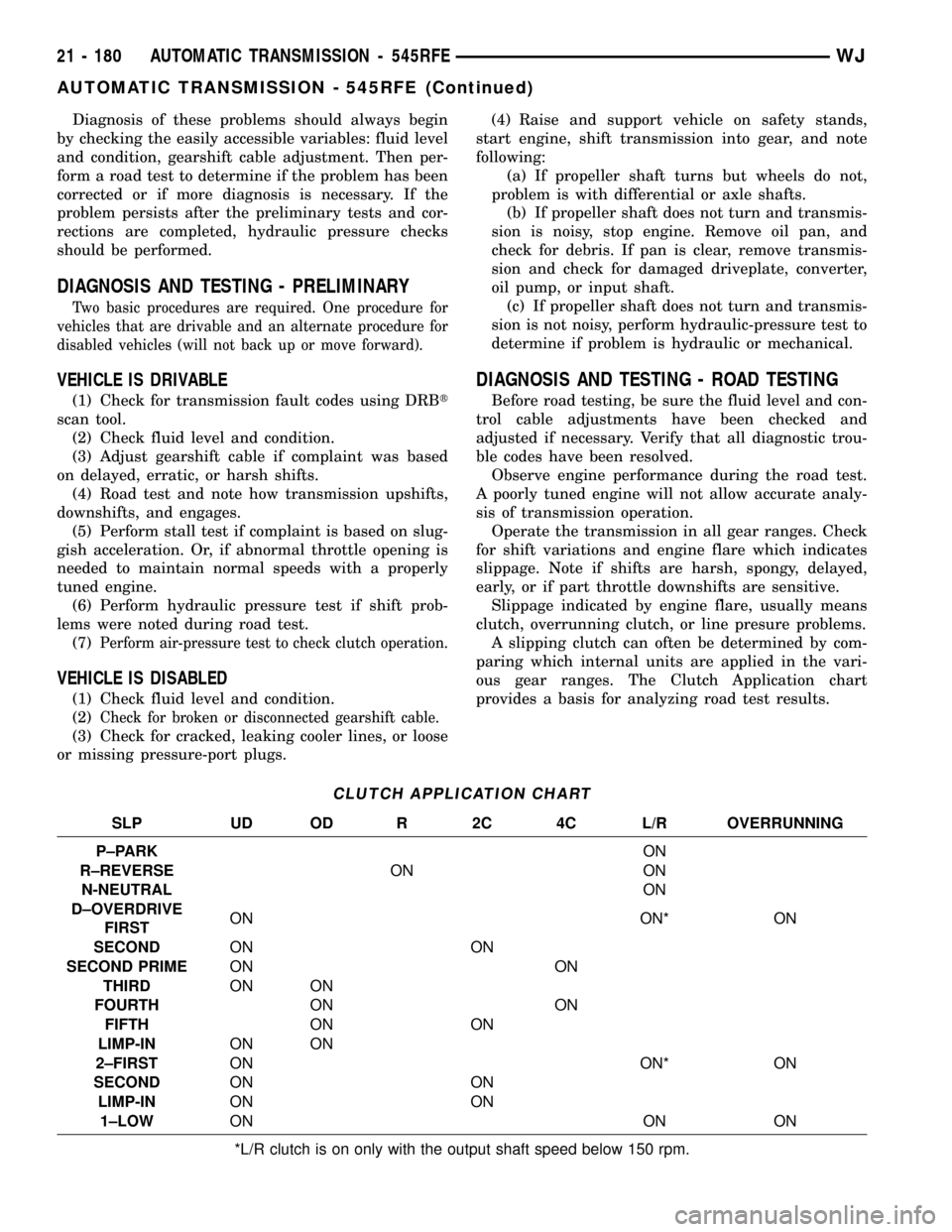

Pressure Test Port Locations

Only two pressure ports are supplied on the trans-

mission case. The torque converter clutch apply and

release ports are located on the right side of the

transmission case (Fig. 2).

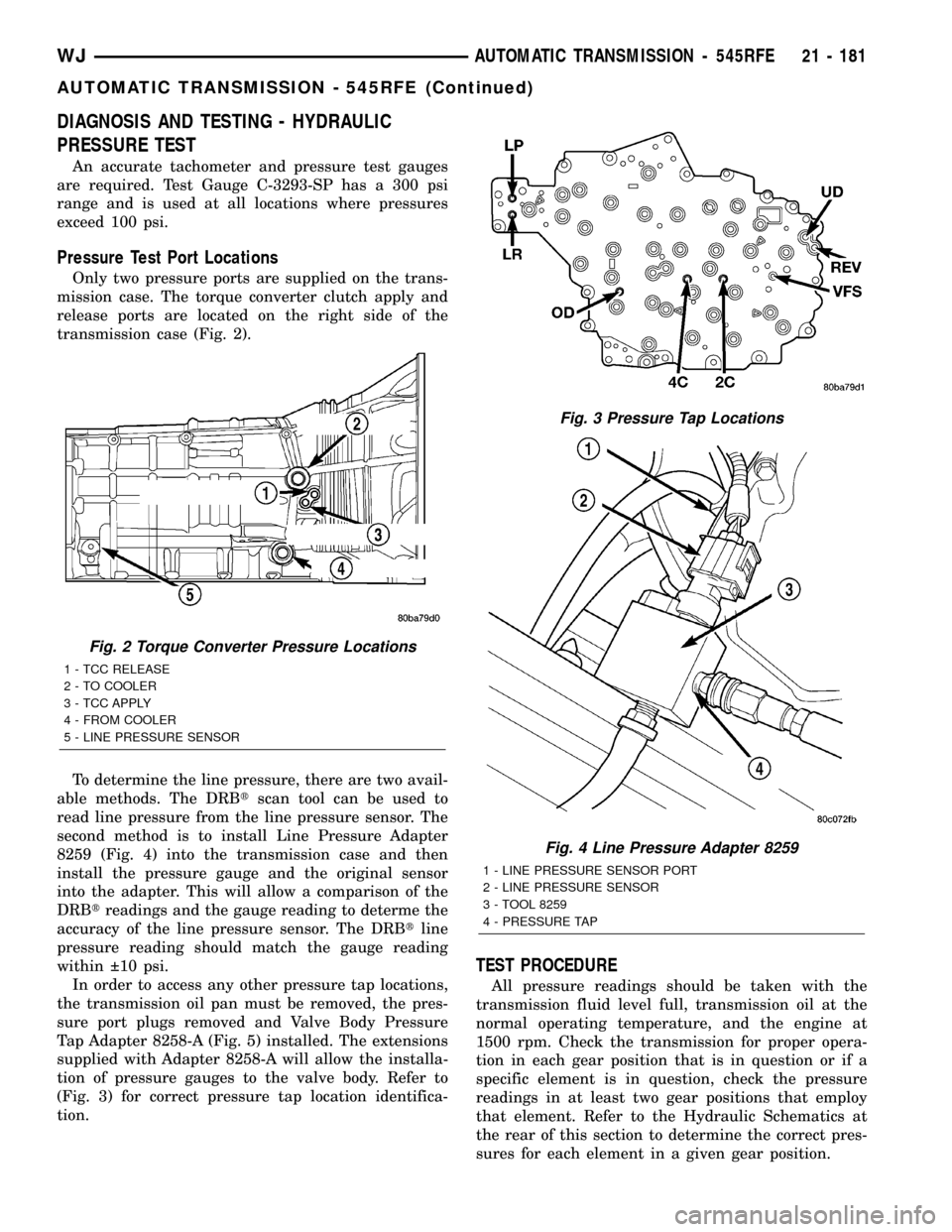

To determine the line pressure, there are two avail-

able methods. The DRBtscan tool can be used to

read line pressure from the line pressure sensor. The

second method is to install Line Pressure Adapter

8259 (Fig. 4) into the transmission case and then

install the pressure gauge and the original sensor

into the adapter. This will allow a comparison of the

DRBtreadings and the gauge reading to determe the

accuracy of the line pressure sensor. The DRBtline

pressure reading should match the gauge reading

within 10 psi.

In order to access any other pressure tap locations,

the transmission oil pan must be removed, the pres-

sure port plugs removed and Valve Body Pressure

Tap Adapter 8258-A (Fig. 5) installed. The extensions

supplied with Adapter 8258-A will allow the installa-

tion of pressure gauges to the valve body. Refer to

(Fig. 3) for correct pressure tap location identifica-

tion.

TEST PROCEDURE

All pressure readings should be taken with the

transmission fluid level full, transmission oil at the

normal operating temperature, and the engine at

1500 rpm. Check the transmission for proper opera-

tion in each gear position that is in question or if a

specific element is in question, check the pressure

readings in at least two gear positions that employ

that element. Refer to the Hydraulic Schematics at

the rear of this section to determine the correct pres-

sures for each element in a given gear position.

Fig. 2 Torque Converter Pressure Locations

1 - TCC RELEASE

2 - TO COOLER

3 - TCC APPLY

4 - FROM COOLER

5 - LINE PRESSURE SENSOR

Fig. 3 Pressure Tap Locations

Fig. 4 Line Pressure Adapter 8259

1 - LINE PRESSURE SENSOR PORT

2 - LINE PRESSURE SENSOR

3 - TOOL 8259

4 - PRESSURE TAP

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 181

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1701 of 2199

NOTE: The 545RFE utilizes closed loop control of

pump line pressure. The pressure readings may

therefore vary greatly but should always follow line

pressure.

Some common pressures that can be measured to

evaluate pump and clutch performance are the

upshift/downshift pressures and the garage shift

pressures. The upshift/downshift pressure for all

shifts except the 4-5 shift is 120 psi. The upshift

pressure for the 4-5 shift is 130 psi. The garage shift

pressure when performing a N-R shift is 220 psi. The

garage shift pressure for the R-N and N-1 shifts is

120 psi.

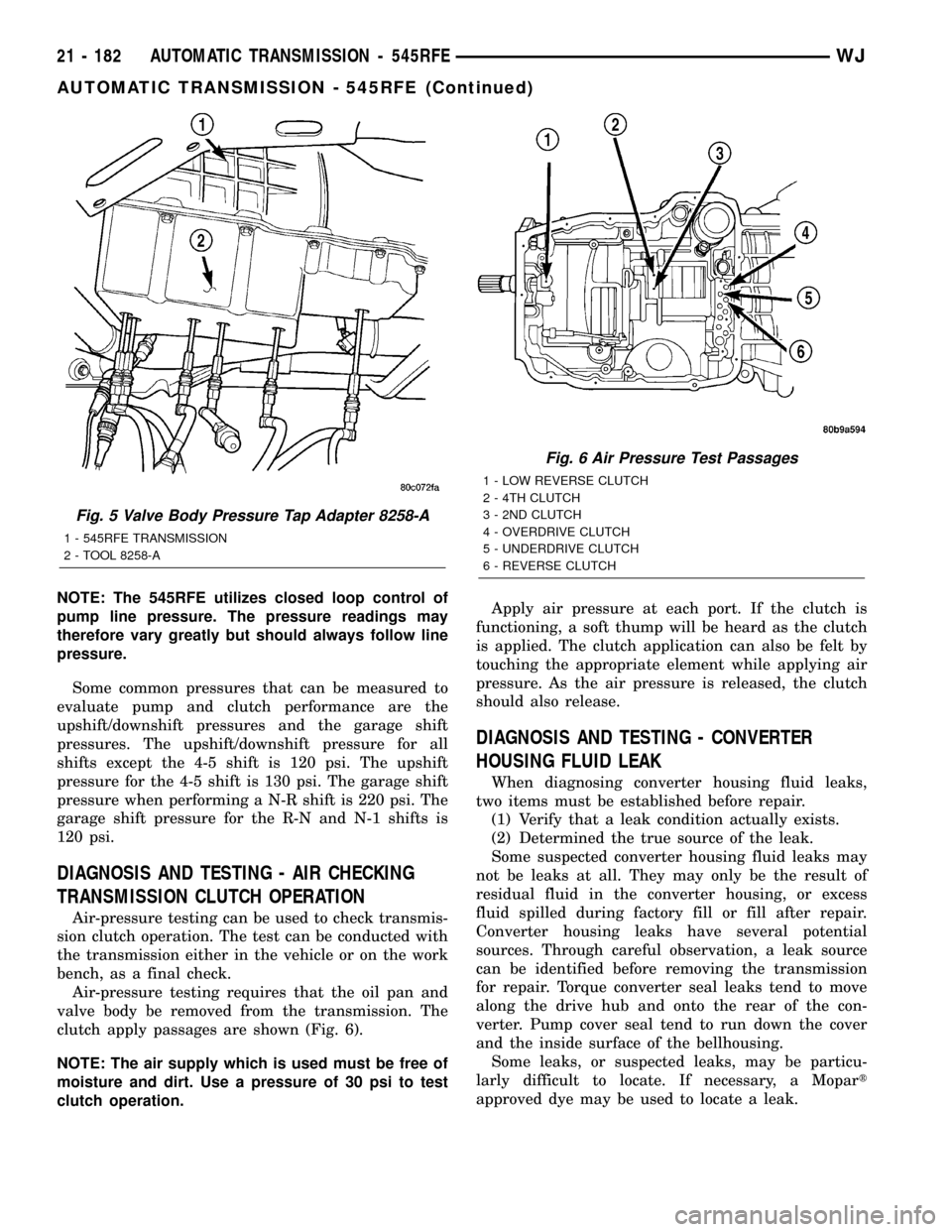

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION

Air-pressure testing can be used to check transmis-

sion clutch operation. The test can be conducted with

the transmission either in the vehicle or on the work

bench, as a final check.

Air-pressure testing requires that the oil pan and

valve body be removed from the transmission. The

clutch apply passages are shown (Fig. 6).

NOTE: The air supply which is used must be free of

moisture and dirt. Use a pressure of 30 psi to test

clutch operation.Apply air pressure at each port. If the clutch is

functioning, a soft thump will be heard as the clutch

is applied. The clutch application can also be felt by

touching the appropriate element while applying air

pressure. As the air pressure is released, the clutch

should also release.

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK

When diagnosing converter housing fluid leaks,

two items must be established before repair.

(1) Verify that a leak condition actually exists.

(2) Determined the true source of the leak.

Some suspected converter housing fluid leaks may

not be leaks at all. They may only be the result of

residual fluid in the converter housing, or excess

fluid spilled during factory fill or fill after repair.

Converter housing leaks have several potential

sources. Through careful observation, a leak source

can be identified before removing the transmission

for repair. Torque converter seal leaks tend to move

along the drive hub and onto the rear of the con-

verter. Pump cover seal tend to run down the cover

and the inside surface of the bellhousing.

Some leaks, or suspected leaks, may be particu-

larly difficult to locate. If necessary, a Mopart

approved dye may be used to locate a leak.

Fig. 5 Valve Body Pressure Tap Adapter 8258-A

1 - 545RFE TRANSMISSION

2 - TOOL 8258-A

Fig. 6 Air Pressure Test Passages

1 - LOW REVERSE CLUTCH

2 - 4TH CLUTCH

3 - 2ND CLUTCH

4 - OVERDRIVE CLUTCH

5 - UNDERDRIVE CLUTCH

6 - REVERSE CLUTCH

21 - 182 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1702 of 2199

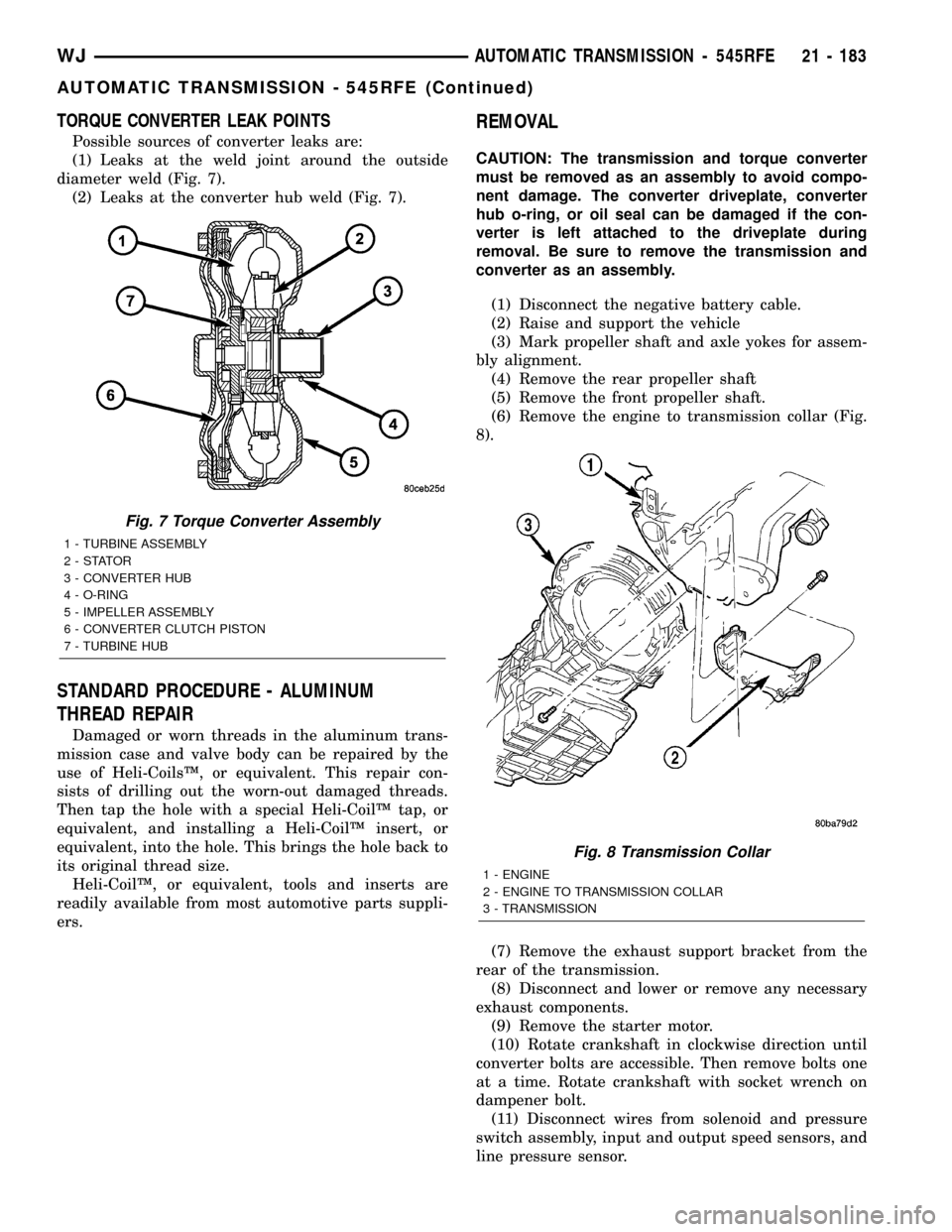

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

(1) Leaks at the weld joint around the outside

diameter weld (Fig. 7).

(2) Leaks at the converter hub weld (Fig. 7).

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

REMOVAL

CAUTION: The transmission and torque converter

must be removed as an assembly to avoid compo-

nent damage. The converter driveplate, converter

hub o-ring, or oil seal can be damaged if the con-

verter is left attached to the driveplate during

removal. Be sure to remove the transmission and

converter as an assembly.

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle

(3) Mark propeller shaft and axle yokes for assem-

bly alignment.

(4) Remove the rear propeller shaft

(5) Remove the front propeller shaft.

(6) Remove the engine to transmission collar (Fig.

8).

(7) Remove the exhaust support bracket from the

rear of the transmission.

(8) Disconnect and lower or remove any necessary

exhaust components.

(9) Remove the starter motor.

(10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(11) Disconnect wires from solenoid and pressure

switch assembly, input and output speed sensors, and

line pressure sensor.

Fig. 7 Torque Converter Assembly

1 - TURBINE ASSEMBLY

2-STATOR

3 - CONVERTER HUB

4 - O-RING

5 - IMPELLER ASSEMBLY

6 - CONVERTER CLUTCH PISTON

7 - TURBINE HUB

Fig. 8 Transmission Collar

1 - ENGINE

2 - ENGINE TO TRANSMISSION COLLAR

3 - TRANSMISSION

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 183

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1705 of 2199

NOTE: When measuring the input shaft end-play,

two(stops(will be felt. When the input shaft is

pushed inward and the dial indicator zeroed, the

first(stop(felt when the input shaft is pulled out-

ward is the movement of the input shaft in the input

clutch housing hub. This value should not be

included in the end-play measured value and there-

fore must be recorded and subtracted from the dial

indicator reading.

(9) Remove the bolts holding the transmission

extension/adapter housing to the transmission case.

(10) Remove the extension/adapter housing from

the transmission case.

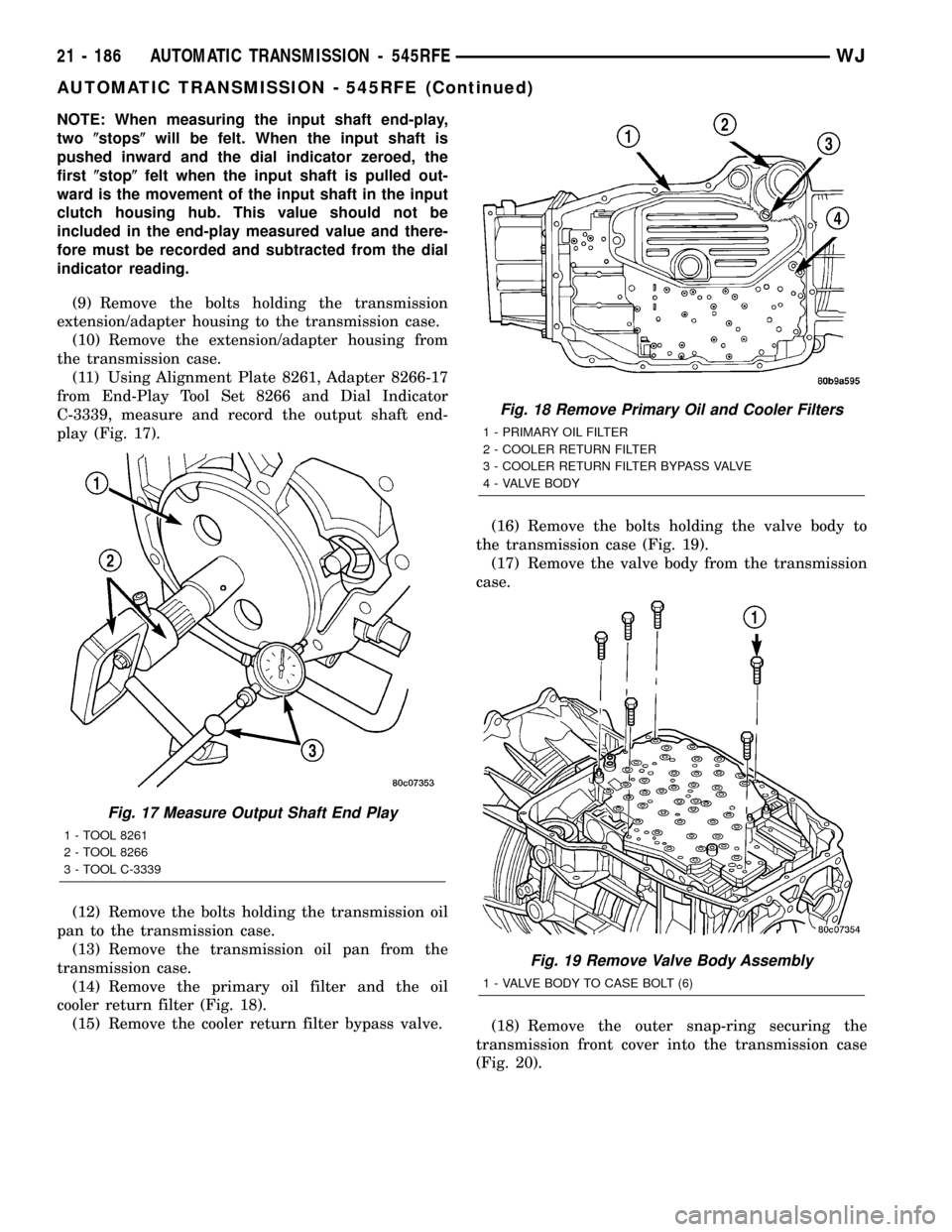

(11) Using Alignment Plate 8261, Adapter 8266-17

from End-Play Tool Set 8266 and Dial Indicator

C-3339, measure and record the output shaft end-

play (Fig. 17).

(12) Remove the bolts holding the transmission oil

pan to the transmission case.

(13) Remove the transmission oil pan from the

transmission case.

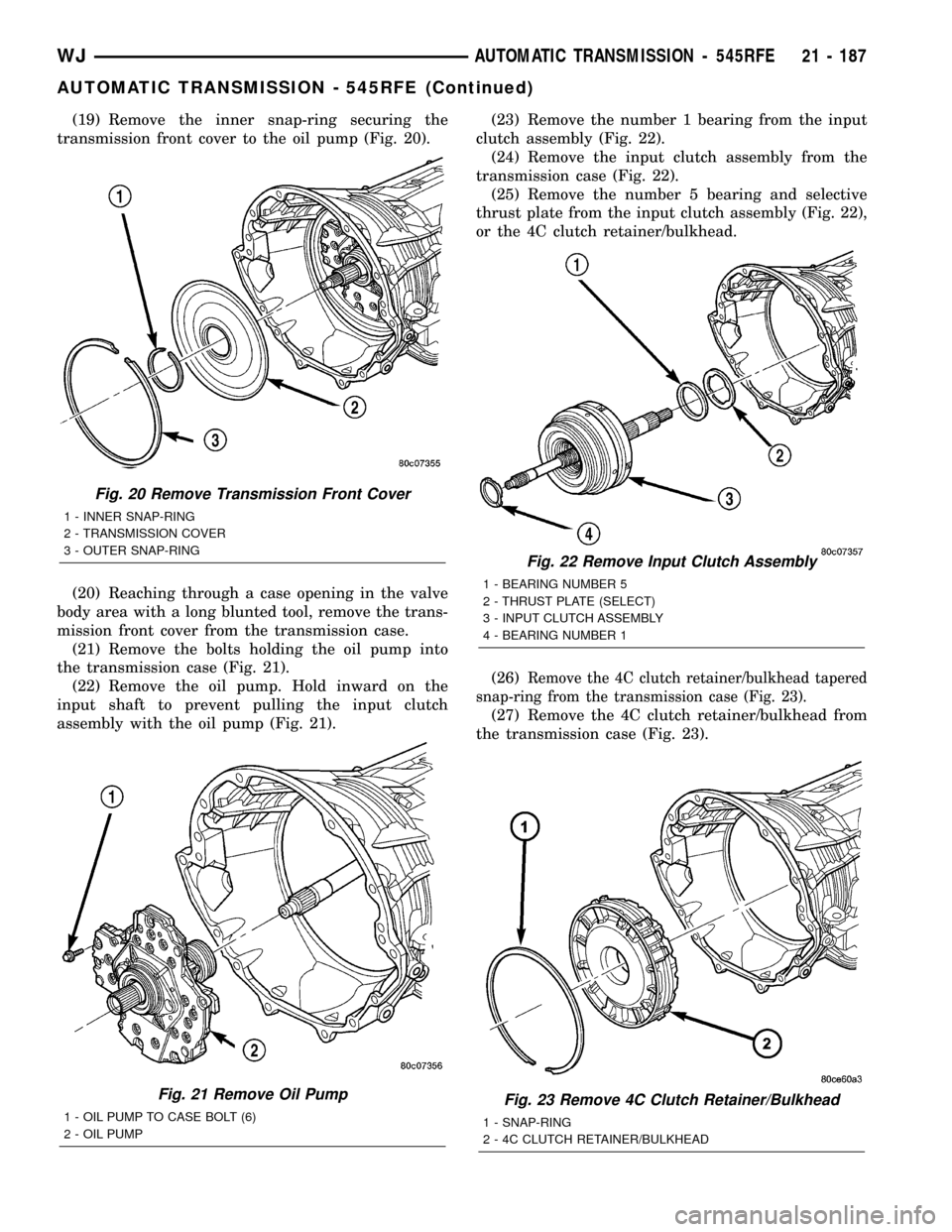

(14) Remove the primary oil filter and the oil

cooler return filter (Fig. 18).

(15) Remove the cooler return filter bypass valve.(16) Remove the bolts holding the valve body to

the transmission case (Fig. 19).

(17) Remove the valve body from the transmission

case.

(18) Remove the outer snap-ring securing the

transmission front cover into the transmission case

(Fig. 20).

Fig. 17 Measure Output Shaft End Play

1 - TOOL 8261

2 - TOOL 8266

3 - TOOL C-3339

Fig. 18 Remove Primary Oil and Cooler Filters

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

Fig. 19 Remove Valve Body Assembly

1 - VALVE BODY TO CASE BOLT (6)

21 - 186 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1706 of 2199

(19) Remove the inner snap-ring securing the

transmission front cover to the oil pump (Fig. 20).

(20) Reaching through a case opening in the valve

body area with a long blunted tool, remove the trans-

mission front cover from the transmission case.

(21) Remove the bolts holding the oil pump into

the transmission case (Fig. 21).

(22) Remove the oil pump. Hold inward on the

input shaft to prevent pulling the input clutch

assembly with the oil pump (Fig. 21).(23) Remove the number 1 bearing from the input

clutch assembly (Fig. 22).

(24) Remove the input clutch assembly from the

transmission case (Fig. 22).

(25) Remove the number 5 bearing and selective

thrust plate from the input clutch assembly (Fig. 22),

or the 4C clutch retainer/bulkhead.

(26)

Remove the 4C clutch retainer/bulkhead tapered

snap-ring from the transmission case (Fig. 23).

(27) Remove the 4C clutch retainer/bulkhead from

the transmission case (Fig. 23).

Fig. 20 Remove Transmission Front Cover

1 - INNER SNAP-RING

2 - TRANSMISSION COVER

3 - OUTER SNAP-RING

Fig. 21 Remove Oil Pump

1 - OIL PUMP TO CASE BOLT (6)

2 - OIL PUMP

Fig. 22 Remove Input Clutch Assembly

1 - BEARING NUMBER 5

2 - THRUST PLATE (SELECT)

3 - INPUT CLUTCH ASSEMBLY

4 - BEARING NUMBER 1

Fig. 23 Remove 4C Clutch Retainer/Bulkhead

1 - SNAP-RING

2 - 4C CLUTCH RETAINER/BULKHEAD

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 187

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1709 of 2199

(48) Remove the manual selector shaft seal.

(49) Remove the dipstick tube seal.

CLEANING

The use of crocus cloth is permissible where neces-

sary, providing it is used carefully. When used on

shafts, or valves, use extreme care to avoid rounding

off sharp edges. Sharp edges are vital as they pre-

vent foreign matter from getting between the valve

and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or

E-clips that are bent or distorted. Replace these parts

as well.

Lubricate transmission parts with MopartATF +4,

Type 9602, transmission fluid during overhaul and

assembly. Use petroleum jelly, MopartDoor Ease, or

Ru-Glyde to prelubricate seals, O-rings, and thrust

washers. Petroleum jelly can also be used to hold

parts in place during reassembly.Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Dry the case and all fluid passages with compressed

air. Be sure all solvent is removed from the case and

that all fluid passages are clear.

NOTE: Do not use shop towels or rags to dry the

case (or any other transmission component) unless

they are made from lint-free materials. Lint will stick

to case surfaces and transmission components and

circulate throughout the transmission after assem-

bly. A sufficient quantity of lint can block fluid pas-

sages and interfere with valve body operation.

INSPECTION

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

ASSEMBLY

(1) Clean and inspect all components. Replace any

components which show evidence of excessive wear

or scoring.

(2) Install the cooler filter bypass valve.

(3) Torque the bypass valve to specification. The

valve uses a tapered pipe thread and excessive

torque can damage the transmission case. Tighten

the cooler filter bypass valve to 4.5 N´m (40 in.lbs.).

(4) Install a new selector shaft seal using Seal

Installer 8253 (Fig. 31).

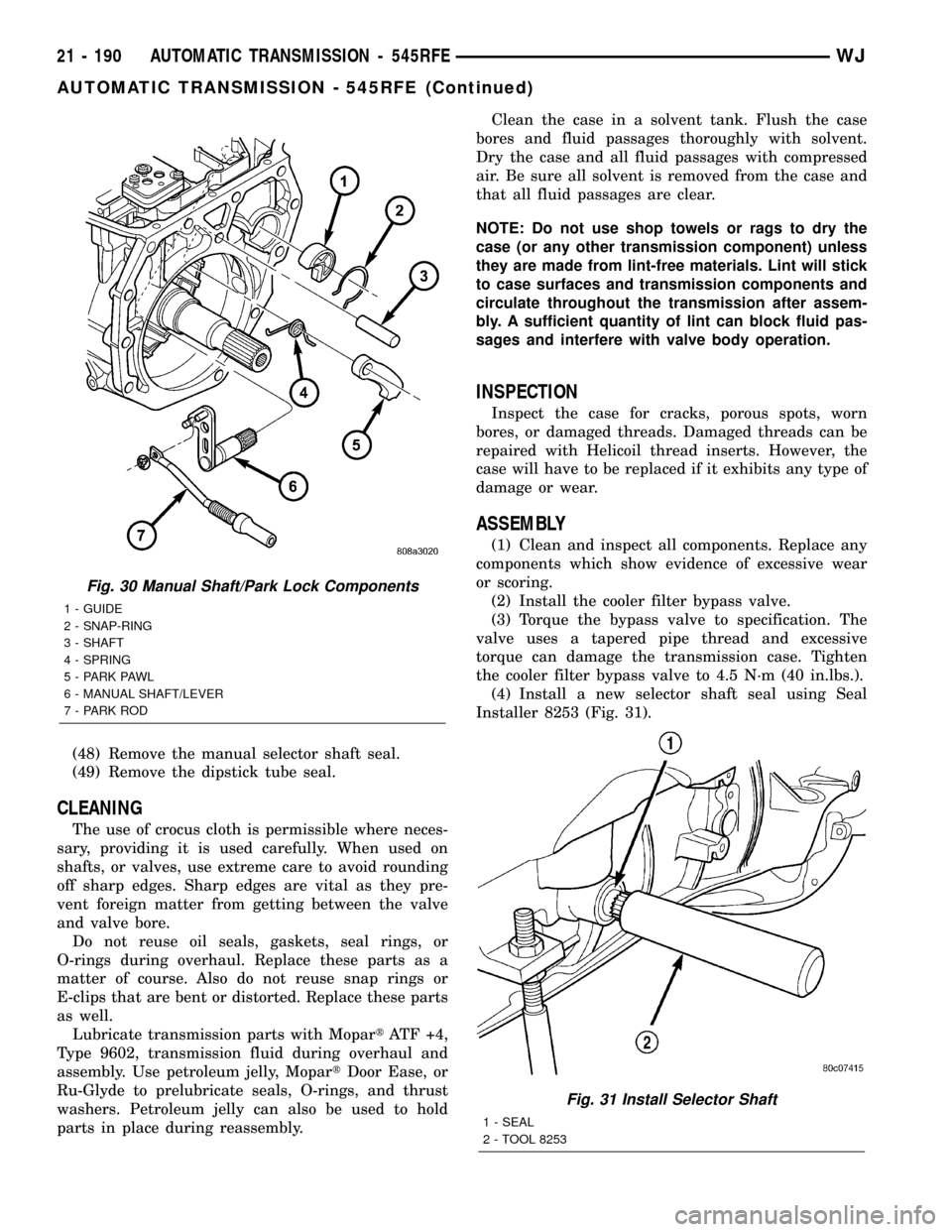

Fig. 30 Manual Shaft/Park Lock Components

1 - GUIDE

2 - SNAP-RING

3 - SHAFT

4 - SPRING

5 - PARK PAWL

6 - MANUAL SHAFT/LEVER

7 - PARK ROD

Fig. 31 Install Selector Shaft

1 - SEAL

2 - TOOL 8253

21 - 190 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1710 of 2199

(5) Install the manual selector shaft and retaining

screw. Tighten the manual selector shaft retaining

screw to 28 N´m (250 in.lbs.).

(6) Install the park pawl, spring, and shaft (Fig.

32).

(7) Install the park rod and e-clip (Fig. 32).

(8) Install the park rod guide and snap-ring (Fig.

32).

(9) Install a new dipstick tube seal using Seal

Installer 8254 (Fig. 33).

NOTE: Before final assembly of transmission cen-

terline, the 2C/4C clutch components should be

installed into position and measured as follows:

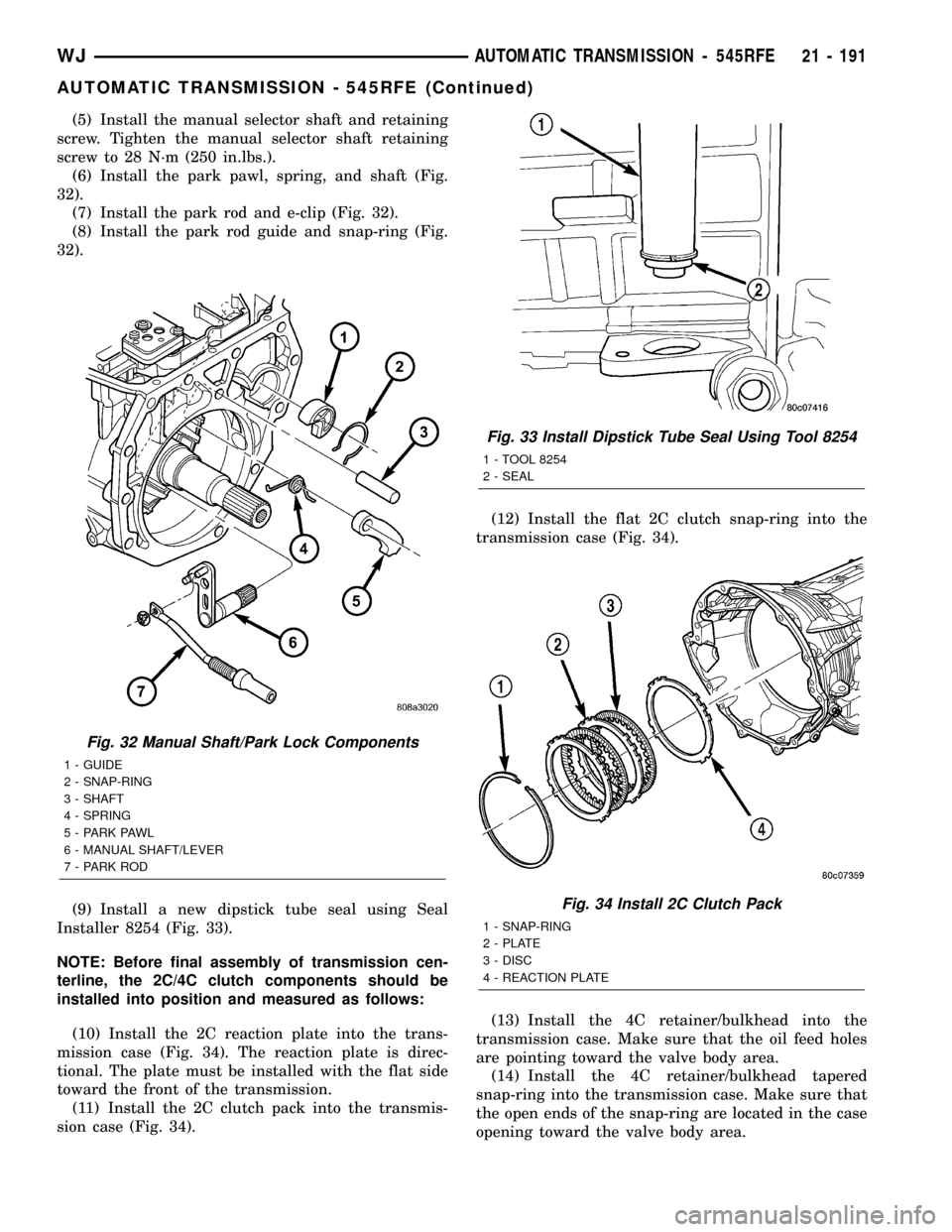

(10) Install the 2C reaction plate into the trans-

mission case (Fig. 34). The reaction plate is direc-

tional. The plate must be installed with the flat side

toward the front of the transmission.

(11) Install the 2C clutch pack into the transmis-

sion case (Fig. 34).(12) Install the flat 2C clutch snap-ring into the

transmission case (Fig. 34).

(13) Install the 4C retainer/bulkhead into the

transmission case. Make sure that the oil feed holes

are pointing toward the valve body area.

(14) Install the 4C retainer/bulkhead tapered

snap-ring into the transmission case. Make sure that

the open ends of the snap-ring are located in the case

opening toward the valve body area.

Fig. 32 Manual Shaft/Park Lock Components

1 - GUIDE

2 - SNAP-RING

3 - SHAFT

4 - SPRING

5 - PARK PAWL

6 - MANUAL SHAFT/LEVER

7 - PARK ROD

Fig. 33 Install Dipstick Tube Seal Using Tool 8254

1 - TOOL 8254

2 - SEAL

Fig. 34 Install 2C Clutch Pack

1 - SNAP-RING

2 - PLATE

3 - DISC

4 - REACTION PLATE

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 191

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1711 of 2199

(15) Using a feeler gauge through the opening in

the rear of the transmission case, measure the 2C

clutch pack clearance between the 2C reaction plate

and the transmission case at four different points.

The average of these measurements is the 2C clutch

pack clearance. The correct clutch clearance is 0.455-

1.335 mm (0.018-0.053 in.). The reaction plate is not

selective. If the clutch pack clearance is not within

specification, the reaction plate, all the friction discs,

and steels must be replaced.

(16) Remove the 4C retainer/bulkhead and all of

the 2C clutch components from the transmission

case.

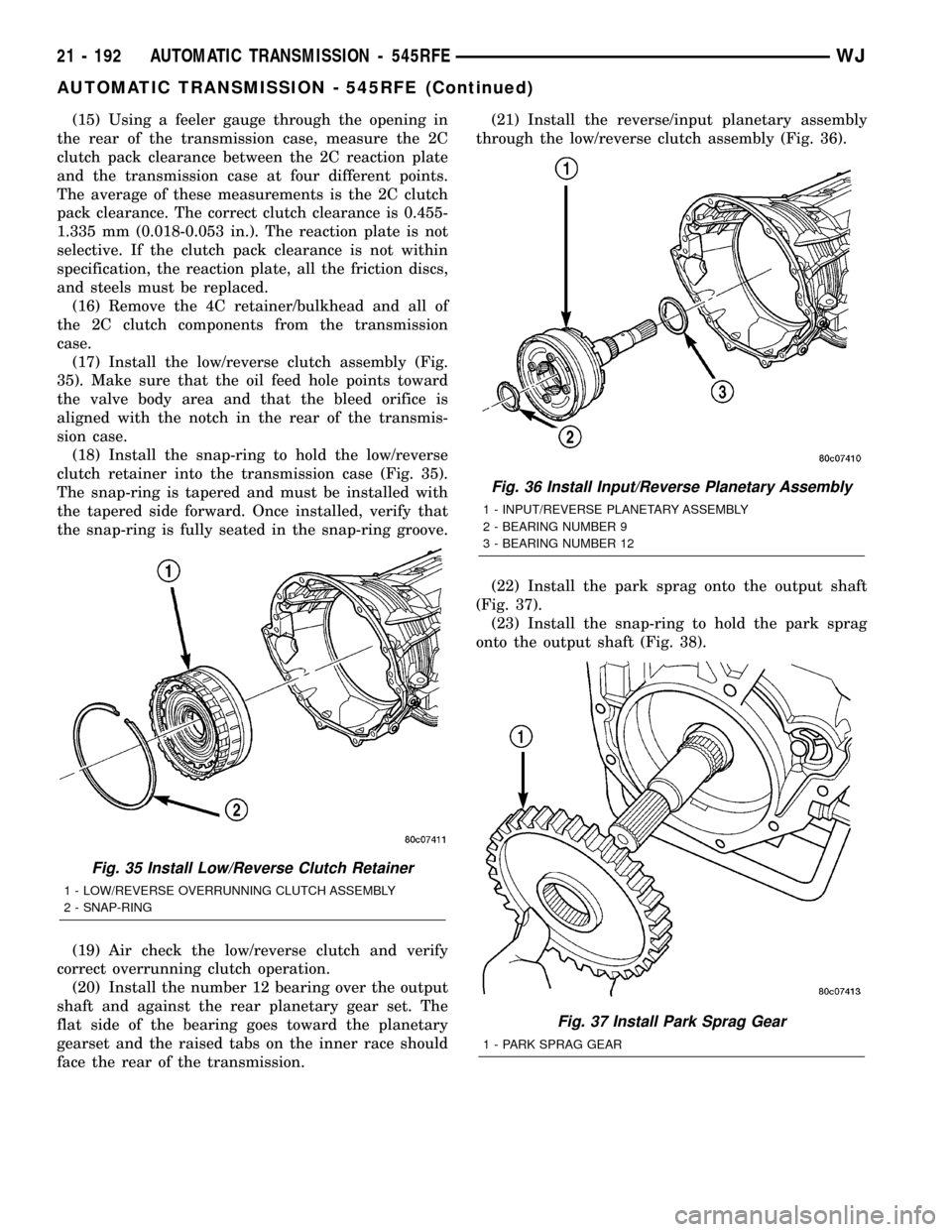

(17) Install the low/reverse clutch assembly (Fig.

35). Make sure that the oil feed hole points toward

the valve body area and that the bleed orifice is

aligned with the notch in the rear of the transmis-

sion case.

(18) Install the snap-ring to hold the low/reverse

clutch retainer into the transmission case (Fig. 35).

The snap-ring is tapered and must be installed with

the tapered side forward. Once installed, verify that

the snap-ring is fully seated in the snap-ring groove.

(19) Air check the low/reverse clutch and verify

correct overrunning clutch operation.

(20) Install the number 12 bearing over the output

shaft and against the rear planetary gear set. The

flat side of the bearing goes toward the planetary

gearset and the raised tabs on the inner race should

face the rear of the transmission.(21) Install the reverse/input planetary assembly

through the low/reverse clutch assembly (Fig. 36).

(22) Install the park sprag onto the output shaft

(Fig. 37).

(23) Install the snap-ring to hold the park sprag

onto the output shaft (Fig. 38).

Fig. 35 Install Low/Reverse Clutch Retainer

1 - LOW/REVERSE OVERRUNNING CLUTCH ASSEMBLY

2 - SNAP-RING

Fig. 36 Install Input/Reverse Planetary Assembly

1 - INPUT/REVERSE PLANETARY ASSEMBLY

2 - BEARING NUMBER 9

3 - BEARING NUMBER 12

Fig. 37 Install Park Sprag Gear

1 - PARK SPRAG GEAR

21 - 192 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1712 of 2199

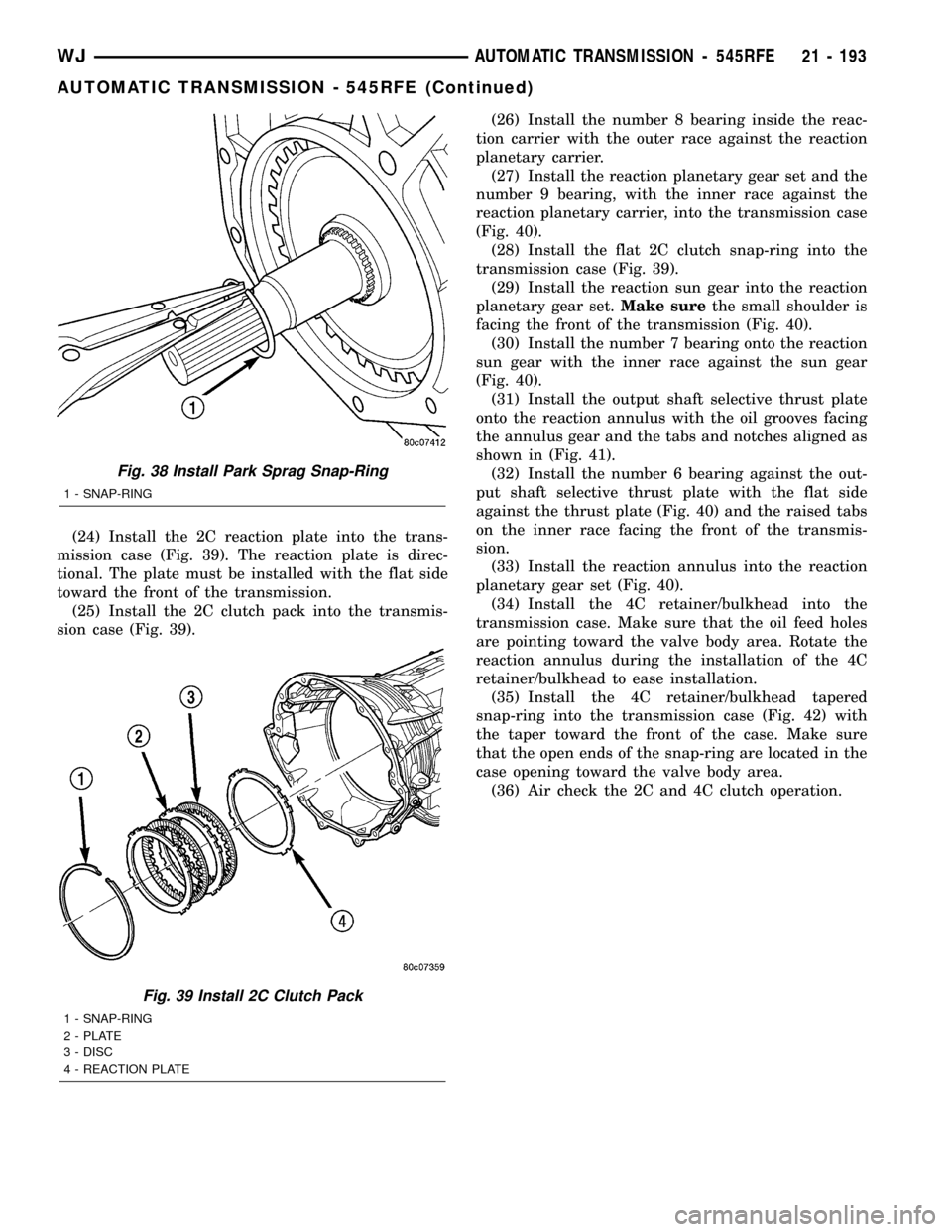

(24) Install the 2C reaction plate into the trans-

mission case (Fig. 39). The reaction plate is direc-

tional. The plate must be installed with the flat side

toward the front of the transmission.

(25) Install the 2C clutch pack into the transmis-

sion case (Fig. 39).(26) Install the number 8 bearing inside the reac-

tion carrier with the outer race against the reaction

planetary carrier.

(27) Install the reaction planetary gear set and the

number 9 bearing, with the inner race against the

reaction planetary carrier, into the transmission case

(Fig. 40).

(28) Install the flat 2C clutch snap-ring into the

transmission case (Fig. 39).

(29) Install the reaction sun gear into the reaction

planetary gear set.Make surethe small shoulder is

facing the front of the transmission (Fig. 40).

(30) Install the number 7 bearing onto the reaction

sun gear with the inner race against the sun gear

(Fig. 40).

(31) Install the output shaft selective thrust plate

onto the reaction annulus with the oil grooves facing

the annulus gear and the tabs and notches aligned as

shown in (Fig. 41).

(32) Install the number 6 bearing against the out-

put shaft selective thrust plate with the flat side

against the thrust plate (Fig. 40) and the raised tabs

on the inner race facing the front of the transmis-

sion.

(33) Install the reaction annulus into the reaction

planetary gear set (Fig. 40).

(34) Install the 4C retainer/bulkhead into the

transmission case. Make sure that the oil feed holes

are pointing toward the valve body area. Rotate the

reaction annulus during the installation of the 4C

retainer/bulkhead to ease installation.

(35) Install the 4C retainer/bulkhead tapered

snap-ring into the transmission case (Fig. 42) with

the taper toward the front of the case. Make sure

that the open ends of the snap-ring are located in the

case opening toward the valve body area.

(36) Air check the 2C and 4C clutch operation.

Fig. 38 Install Park Sprag Snap-Ring

1 - SNAP-RING

Fig. 39 Install 2C Clutch Pack

1 - SNAP-RING

2 - PLATE

3 - DISC

4 - REACTION PLATE

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 193

AUTOMATIC TRANSMISSION - 545RFE (Continued)