Speed control JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 411 of 2199

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives the knock sensor voltage signal as an input.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except at

Wide Open Throttle (WOT). The PCM, using short

term memory, can respond quickly to retard timing

when engine knock is detected. Short term memory

is lost any time the ignition key is turned off.

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors.

REMOVAL

4.7L High-Output Engine Only

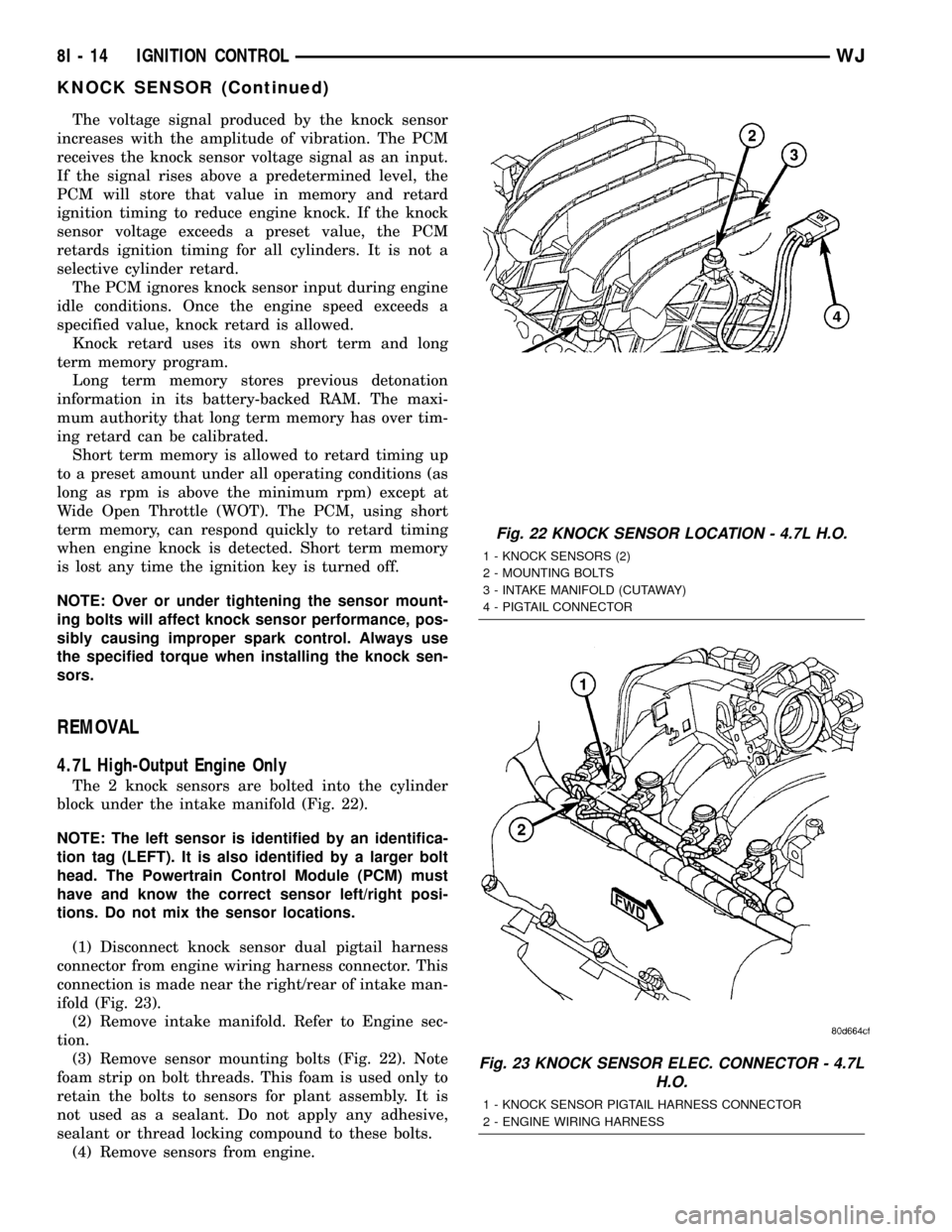

The 2 knock sensors are bolted into the cylinder

block under the intake manifold (Fig. 22).

NOTE: The left sensor is identified by an identifica-

tion tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right posi-

tions. Do not mix the sensor locations.

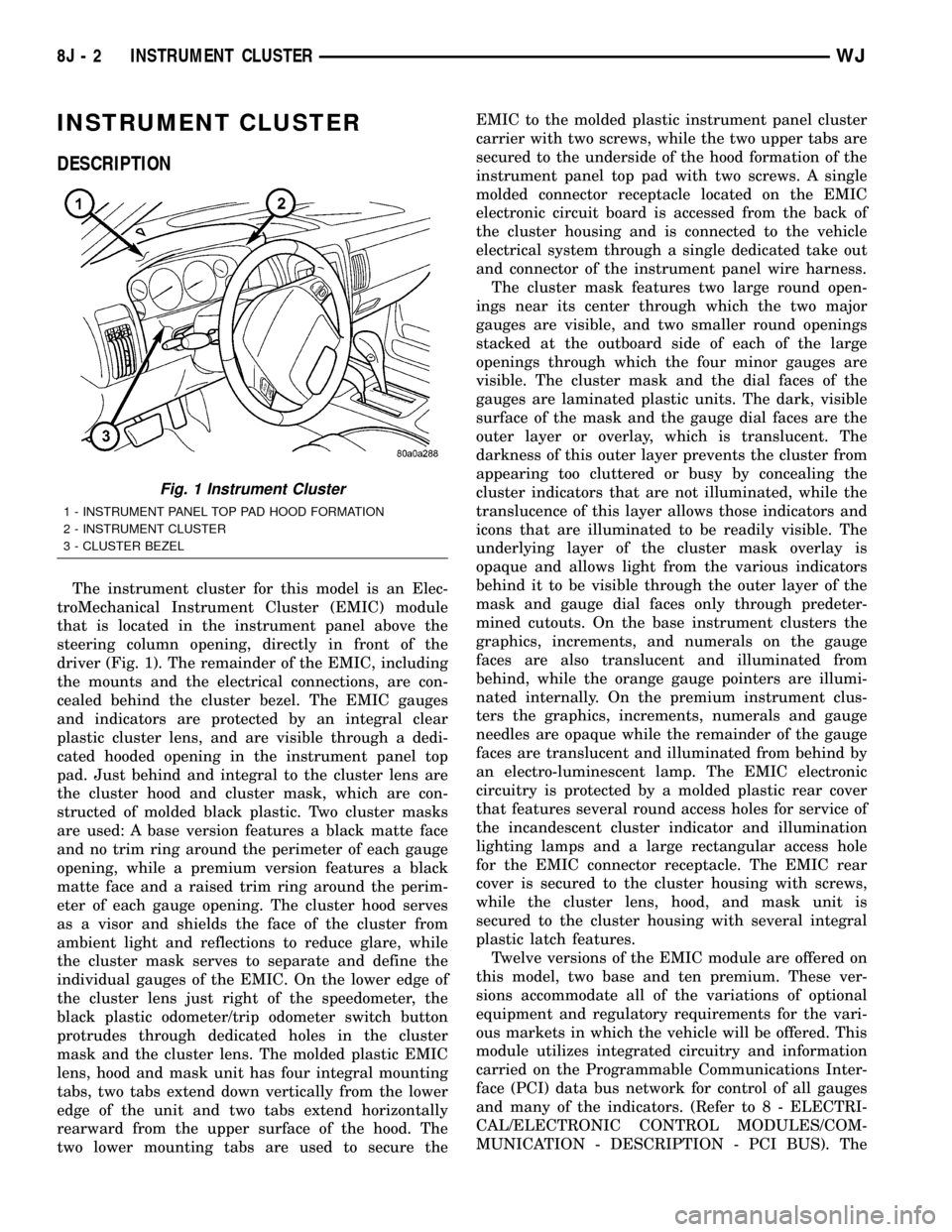

(1) Disconnect knock sensor dual pigtail harness

connector from engine wiring harness connector. This

connection is made near the right/rear of intake man-

ifold (Fig. 23).

(2) Remove intake manifold. Refer to Engine sec-

tion.

(3) Remove sensor mounting bolts (Fig. 22). Note

foam strip on bolt threads. This foam is used only to

retain the bolts to sensors for plant assembly. It is

not used as a sealant. Do not apply any adhesive,

sealant or thread locking compound to these bolts.

(4) Remove sensors from engine.

Fig. 22 KNOCK SENSOR LOCATION - 4.7L H.O.

1 - KNOCK SENSORS (2)

2 - MOUNTING BOLTS

3 - INTAKE MANIFOLD (CUTAWAY)

4 - PIGTAIL CONNECTOR

Fig. 23 KNOCK SENSOR ELEC. CONNECTOR - 4.7L

H.O.

1 - KNOCK SENSOR PIGTAIL HARNESS CONNECTOR

2 - ENGINE WIRING HARNESS

8I - 14 IGNITION CONTROLWJ

KNOCK SENSOR (Continued)

Page 417 of 2199

INSTRUMENT CLUSTER

DESCRIPTION

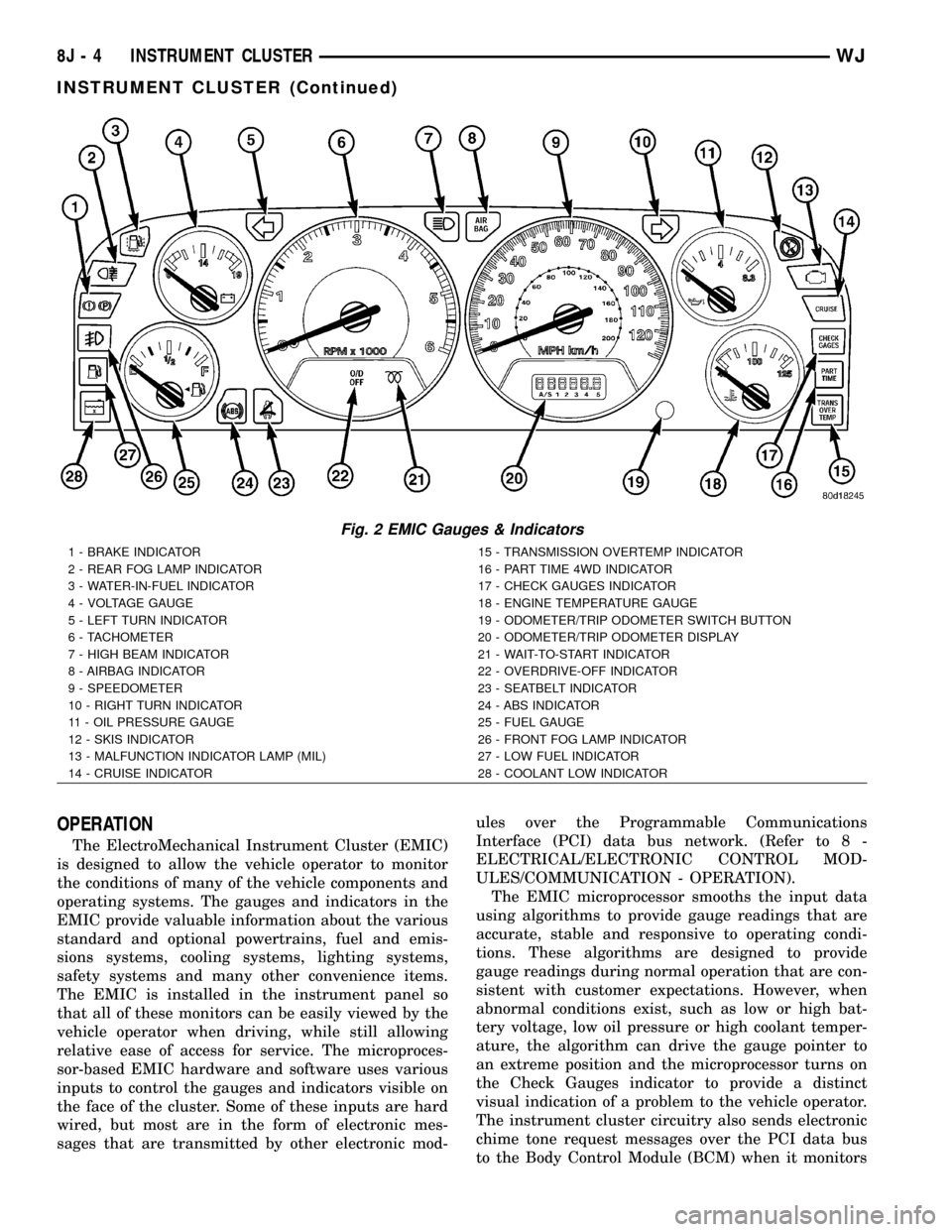

The instrument cluster for this model is an Elec-

troMechanical Instrument Cluster (EMIC) module

that is located in the instrument panel above the

steering column opening, directly in front of the

driver (Fig. 1). The remainder of the EMIC, including

the mounts and the electrical connections, are con-

cealed behind the cluster bezel. The EMIC gauges

and indicators are protected by an integral clear

plastic cluster lens, and are visible through a dedi-

cated hooded opening in the instrument panel top

pad. Just behind and integral to the cluster lens are

the cluster hood and cluster mask, which are con-

structed of molded black plastic. Two cluster masks

are used: A base version features a black matte face

and no trim ring around the perimeter of each gauge

opening, while a premium version features a black

matte face and a raised trim ring around the perim-

eter of each gauge opening. The cluster hood serves

as a visor and shields the face of the cluster from

ambient light and reflections to reduce glare, while

the cluster mask serves to separate and define the

individual gauges of the EMIC. On the lower edge of

the cluster lens just right of the speedometer, the

black plastic odometer/trip odometer switch button

protrudes through dedicated holes in the cluster

mask and the cluster lens. The molded plastic EMIC

lens, hood and mask unit has four integral mounting

tabs, two tabs extend down vertically from the lower

edge of the unit and two tabs extend horizontally

rearward from the upper surface of the hood. The

two lower mounting tabs are used to secure theEMIC to the molded plastic instrument panel cluster

carrier with two screws, while the two upper tabs are

secured to the underside of the hood formation of the

instrument panel top pad with two screws. A single

molded connector receptacle located on the EMIC

electronic circuit board is accessed from the back of

the cluster housing and is connected to the vehicle

electrical system through a single dedicated take out

and connector of the instrument panel wire harness.

The cluster mask features two large round open-

ings near its center through which the two major

gauges are visible, and two smaller round openings

stacked at the outboard side of each of the large

openings through which the four minor gauges are

visible. The cluster mask and the dial faces of the

gauges are laminated plastic units. The dark, visible

surface of the mask and the gauge dial faces are the

outer layer or overlay, which is translucent. The

darkness of this outer layer prevents the cluster from

appearing too cluttered or busy by concealing the

cluster indicators that are not illuminated, while the

translucence of this layer allows those indicators and

icons that are illuminated to be readily visible. The

underlying layer of the cluster mask overlay is

opaque and allows light from the various indicators

behind it to be visible through the outer layer of the

mask and gauge dial faces only through predeter-

mined cutouts. On the base instrument clusters the

graphics, increments, and numerals on the gauge

faces are also translucent and illuminated from

behind, while the orange gauge pointers are illumi-

nated internally. On the premium instrument clus-

ters the graphics, increments, numerals and gauge

needles are opaque while the remainder of the gauge

faces are translucent and illuminated from behind by

an electro-luminescent lamp. The EMIC electronic

circuitry is protected by a molded plastic rear cover

that features several round access holes for service of

the incandescent cluster indicator and illumination

lighting lamps and a large rectangular access hole

for the EMIC connector receptacle. The EMIC rear

cover is secured to the cluster housing with screws,

while the cluster lens, hood, and mask unit is

secured to the cluster housing with several integral

plastic latch features.

Twelve versions of the EMIC module are offered on

this model, two base and ten premium. These ver-

sions accommodate all of the variations of optional

equipment and regulatory requirements for the vari-

ous markets in which the vehicle will be offered. This

module utilizes integrated circuitry and information

carried on the Programmable Communications Inter-

face (PCI) data bus network for control of all gauges

and many of the indicators. (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/COM-

MUNICATION - DESCRIPTION - PCI BUS). The

Fig. 1 Instrument Cluster

1 - INSTRUMENT PANEL TOP PAD HOOD FORMATION

2 - INSTRUMENT CLUSTER

3 - CLUSTER BEZEL

8J - 2 INSTRUMENT CLUSTERWJ

Page 419 of 2199

OPERATION

The ElectroMechanical Instrument Cluster (EMIC)

is designed to allow the vehicle operator to monitor

the conditions of many of the vehicle components and

operating systems. The gauges and indicators in the

EMIC provide valuable information about the various

standard and optional powertrains, fuel and emis-

sions systems, cooling systems, lighting systems,

safety systems and many other convenience items.

The EMIC is installed in the instrument panel so

that all of these monitors can be easily viewed by the

vehicle operator when driving, while still allowing

relative ease of access for service. The microproces-

sor-based EMIC hardware and software uses various

inputs to control the gauges and indicators visible on

the face of the cluster. Some of these inputs are hard

wired, but most are in the form of electronic mes-

sages that are transmitted by other electronic mod-ules over the Programmable Communications

Interface (PCI) data bus network. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/COMMUNICATION - OPERATION).

The EMIC microprocessor smooths the input data

using algorithms to provide gauge readings that are

accurate, stable and responsive to operating condi-

tions. These algorithms are designed to provide

gauge readings during normal operation that are con-

sistent with customer expectations. However, when

abnormal conditions exist, such as low or high bat-

tery voltage, low oil pressure or high coolant temper-

ature, the algorithm can drive the gauge pointer to

an extreme position and the microprocessor turns on

the Check Gauges indicator to provide a distinct

visual indication of a problem to the vehicle operator.

The instrument cluster circuitry also sends electronic

chime tone request messages over the PCI data bus

to the Body Control Module (BCM) when it monitors

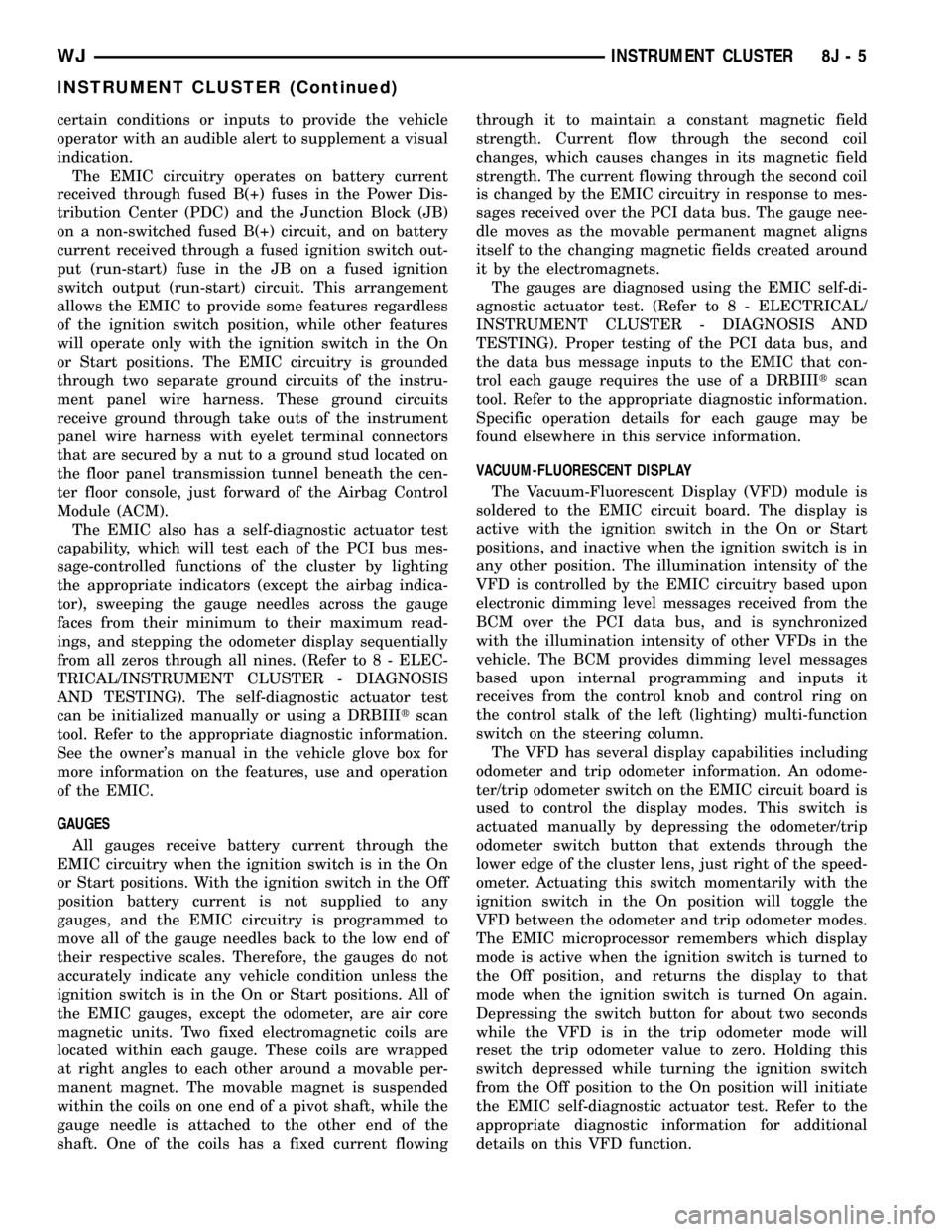

Fig. 2 EMIC Gauges & Indicators

1 - BRAKE INDICATOR 15 - TRANSMISSION OVERTEMP INDICATOR

2 - REAR FOG LAMP INDICATOR 16 - PART TIME 4WD INDICATOR

3 - WATER-IN-FUEL INDICATOR 17 - CHECK GAUGES INDICATOR

4 - VOLTAGE GAUGE 18 - ENGINE TEMPERATURE GAUGE

5 - LEFT TURN INDICATOR 19 - ODOMETER/TRIP ODOMETER SWITCH BUTTON

6 - TACHOMETER 20 - ODOMETER/TRIP ODOMETER DISPLAY

7 - HIGH BEAM INDICATOR 21 - WAIT-TO-START INDICATOR

8 - AIRBAG INDICATOR 22 - OVERDRIVE-OFF INDICATOR

9 - SPEEDOMETER 23 - SEATBELT INDICATOR

10 - RIGHT TURN INDICATOR 24 - ABS INDICATOR

11 - OIL PRESSURE GAUGE 25 - FUEL GAUGE

12 - SKIS INDICATOR 26 - FRONT FOG LAMP INDICATOR

13 - MALFUNCTION INDICATOR LAMP (MIL) 27 - LOW FUEL INDICATOR

14 - CRUISE INDICATOR 28 - COOLANT LOW INDICATOR

8J - 4 INSTRUMENT CLUSTERWJ

INSTRUMENT CLUSTER (Continued)

Page 420 of 2199

certain conditions or inputs to provide the vehicle

operator with an audible alert to supplement a visual

indication.

The EMIC circuitry operates on battery current

received through fused B(+) fuses in the Power Dis-

tribution Center (PDC) and the Junction Block (JB)

on a non-switched fused B(+) circuit, and on battery

current received through a fused ignition switch out-

put (run-start) fuse in the JB on a fused ignition

switch output (run-start) circuit. This arrangement

allows the EMIC to provide some features regardless

of the ignition switch position, while other features

will operate only with the ignition switch in the On

or Start positions. The EMIC circuitry is grounded

through two separate ground circuits of the instru-

ment panel wire harness. These ground circuits

receive ground through take outs of the instrument

panel wire harness with eyelet terminal connectors

that are secured by a nut to a ground stud located on

the floor panel transmission tunnel beneath the cen-

ter floor console, just forward of the Airbag Control

Module (ACM).

The EMIC also has a self-diagnostic actuator test

capability, which will test each of the PCI bus mes-

sage-controlled functions of the cluster by lighting

the appropriate indicators (except the airbag indica-

tor), sweeping the gauge needles across the gauge

faces from their minimum to their maximum read-

ings, and stepping the odometer display sequentially

from all zeros through all nines. (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). The self-diagnostic actuator test

can be initialized manually or using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EMIC.

GAUGES

All gauges receive battery current through the

EMIC circuitry when the ignition switch is in the On

or Start positions. With the ignition switch in the Off

position battery current is not supplied to any

gauges, and the EMIC circuitry is programmed to

move all of the gauge needles back to the low end of

their respective scales. Therefore, the gauges do not

accurately indicate any vehicle condition unless the

ignition switch is in the On or Start positions. All of

the EMIC gauges, except the odometer, are air core

magnetic units. Two fixed electromagnetic coils are

located within each gauge. These coils are wrapped

at right angles to each other around a movable per-

manent magnet. The movable magnet is suspended

within the coils on one end of a pivot shaft, while the

gauge needle is attached to the other end of the

shaft. One of the coils has a fixed current flowingthrough it to maintain a constant magnetic field

strength. Current flow through the second coil

changes, which causes changes in its magnetic field

strength. The current flowing through the second coil

is changed by the EMIC circuitry in response to mes-

sages received over the PCI data bus. The gauge nee-

dle moves as the movable permanent magnet aligns

itself to the changing magnetic fields created around

it by the electromagnets.

The gauges are diagnosed using the EMIC self-di-

agnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus, and

the data bus message inputs to the EMIC that con-

trol each gauge requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

Specific operation details for each gauge may be

found elsewhere in this service information.

VACUUM-FLUORESCENT DISPLAY

The Vacuum-Fluorescent Display (VFD) module is

soldered to the EMIC circuit board. The display is

active with the ignition switch in the On or Start

positions, and inactive when the ignition switch is in

any other position. The illumination intensity of the

VFD is controlled by the EMIC circuitry based upon

electronic dimming level messages received from the

BCM over the PCI data bus, and is synchronized

with the illumination intensity of other VFDs in the

vehicle. The BCM provides dimming level messages

based upon internal programming and inputs it

receives from the control knob and control ring on

the control stalk of the left (lighting) multi-function

switch on the steering column.

The VFD has several display capabilities including

odometer and trip odometer information. An odome-

ter/trip odometer switch on the EMIC circuit board is

used to control the display modes. This switch is

actuated manually by depressing the odometer/trip

odometer switch button that extends through the

lower edge of the cluster lens, just right of the speed-

ometer. Actuating this switch momentarily with the

ignition switch in the On position will toggle the

VFD between the odometer and trip odometer modes.

The EMIC microprocessor remembers which display

mode is active when the ignition switch is turned to

the Off position, and returns the display to that

mode when the ignition switch is turned On again.

Depressing the switch button for about two seconds

while the VFD is in the trip odometer mode will

reset the trip odometer value to zero. Holding this

switch depressed while turning the ignition switch

from the Off position to the On position will initiate

the EMIC self-diagnostic actuator test. Refer to the

appropriate diagnostic information for additional

details on this VFD function.

WJINSTRUMENT CLUSTER 8J - 5

INSTRUMENT CLUSTER (Continued)

Page 422 of 2199

an input from the auto headlamp light sensor to

determine the ambient light levels. If the BCM

decides that the exterior lighting is turned on in the

daylight, it overrides the selected panel dimmer

switch signal by sending a message over the PCI

data bus to illuminate all vacuum fluorescent dis-

plays at full brightness for improved visibility in day-

time light levels. The automatic parade mode has no

effect on the incandescent bulb illumination intensity.

The hard wired cluster illumination circuits

between the left (lighting) multi-function switch and

the BCM may be diagnosed using conventional diag-

nostic tools and methods. The electro-luminescent

lamp is diagnosed using the EMIC self-diagnostic

actuator test. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING).

However, proper testing of the EMIC and the elec-

tronic dimming level messages sent by the BCM over

the PCI data bus requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

CHIME SERVICE

The EMIC is programmed to request chime service

from the Body Control Module (BCM) when certain

indicators are illuminated. The EMIC chime request

for illumination of the low fuel indicator is a cus-

tomer programmable feature. When the programmed

conditions are met, the EMIC generates an electronic

chime request message and sends it over the PCI

data bus to the BCM. Upon receiving the proper

chime request, the BCM activates an integral chime

tone generator to provide the audible chime tone to

the vehicle operator. (Refer to 8 - ELECTRICAL/

CHIME WARNING SYSTEM - OPERATION). Proper

testing of the PCI data bus and the electronic chime

request message outputs from the EMIC requires the

use of a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER

If all of the instrument cluster gauges and/or indi-

cators are inoperative, refer to PRELIMINARY

DIAGNOSIS . If an individual gauge or Programma-

ble Communications Interface (PCI) data bus mes-

sage-controlled indicator is inoperative, refer to

ACTUATOR TEST . If an individual hard wired indi-

cator is inoperative, refer to the diagnosis and testing

information for that specific indicator. If the base

instrument cluster incandescent illumination lighting

is inoperative, refer to CLUSTER ILLUMINATION

DIAGNOSIS . If the premium instrument cluster

electro-luminescent illumination lighting is inopera-

tive, refer to ACTUATOR TEST . Refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connectorrepair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

NOTE: Occasionally, a condition may be encoun-

tered where the gauge pointer for the speedometer

or the tachometer becomes caught on the wrong

side of the pointer stop. To correct this condition,

the technician should use a DRBIIITscan tool and

the appropriate diagnostic information to perform

the instrument cluster self-diagnostic actuator test

procedure. When performed, the actuator test pro-

cedure will automatically return the pointer to the

correct side of the pointer stop.

PRELIMINARY DIAGNOSIS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: ON VEHICLES EQUIPPED WITH THE

PREMIUM INSTRUMENT CLUSTER, THE CLUSTER

CIRCUITRY PROVIDES AN ALTERNATING CURRENT

TO SUPPLY POWER TO THE ELECTRO-LUMINES-

CENT ILLUMINATION LAMP THROUGH A PIGTAIL

WIRE AND CONNECTOR THAT IS ACCESSIBLE AT

THE BACK OF THE CLUSTER HOUSING. USE

PROPER PRECAUTIONS WHEN HANDLING THIS

UNIT DURING DIAGNOSIS OR SERVICE TO AVOID

ELECTRICAL SHOCK AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused B(+) fuse (Fuse 17 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 17 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

WJINSTRUMENT CLUSTER 8J - 7

INSTRUMENT CLUSTER (Continued)

Page 424 of 2199

(3) While still holding the odometer/trip odometer

switch button depressed, turn the ignition switch to

the On position, but do not start the engine.

(4) Release the odometer/trip odometer switch but-

ton.

(5) The instrument cluster will automatically

begin the actuator test sequence, as follows:

(a) The cluster will turn on, then off again each

of the PCI data bus message controlled indicators

(except Airbag) to confirm the functionality of the

indicator and the cluster control circuitry:

(b) The cluster will sweep the needles for each of

the gauges from minimum to maximum and back

to minimum to confirm the functionality of the

gauge and the cluster control circuitry:

(c) Only on models with a premium version of

the cluster, the cluster will illuminate the electro-

luminescent lamp and turn it off again to confirm

the functionality of the lamp and the cluster con-

trol circuitry.

(d) The cluster will sequentially step the odome-

ter/trip odometer VFD display from all zeros

(000000) through all nines (999999) to confirm the

functionality of all VFD segments and their control

circuitry, then display the software version number,

followed by ªDONEº.

(6) The actuator test is now completed. The instru-

ment cluster will automatically exit the self-diagnos-

tic mode and return to normal operation at the

completion of the test, if the ignition switch is turned

to the Off position during the test, or if a vehicle

speed message indicating that the vehicle is moving

is received from the PCM over the PCI data bus dur-

ing the test.

(7) Go back to Step 1 to repeat the test, if

required.

CLUSTER ILLUMINATION DIAGNOSIS

On models equipped with a base version of the

instrument cluster, the EMIC has several incandes-

cent illumination lamps that are illuminated when-

ever the exterior lighting is turned On. If the

problem being diagnosed is a single inoperative illu-

mination lamp, be certain that the bulb and bulb

holder unit are properly installed in the instrument

cluster electronic circuit board. If no installation

problems are found replace the faulty bulb and bulb

holder unit. If all of the cluster illumination lamps

are inoperative, the most reliable, efficient, and accu-

rate means to diagnose the cluster illumination func-tion of the instrument cluster requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: ON VEHICLES EQUIPPED WITH THE

PREMIUM INSTRUMENT CLUSTER, THE CLUSTER

CIRCUITRY PROVIDES AN ALTERNATING CURRENT

TO SUPPLY POWER TO THE ELECTRO-LUMINES-

CENT ILLUMINATION LAMP THROUGH A PIGTAIL

WIRE AND CONNECTOR THAT IS ACCESSIBLE AT

THE BACK OF THE CLUSTER HOUSING. USE

PROPER PRECAUTIONS WHEN HANDLING THIS

UNIT DURING DIAGNOSIS OR SERVICE TO AVOID

ELECTRICAL SHOCK AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(3) Remove the two screws that secure the upper

mounting tabs of the instrument cluster to the

underside of the instrument cluster hood formation of

the instrument panel top pad.

(4) Remove the two screws that secure the lower

mounting tabs of the instrument cluster to the

instrument panel structural duct.

WJINSTRUMENT CLUSTER 8J - 9

INSTRUMENT CLUSTER (Continued)

Page 429 of 2199

tor will be turned on for the duration of the test to

confirm the functionality of the bulb and the cluster

control circuitry.

²ABS Diagnostic Test- The ABS indicator is

blinked on and off based upon lamp-on and lamp-off

messages from the CAB during the performance of

the ABS diagnostic tests.

The CAB continually monitors the ABS circuits

and sensors to decide whether the system is in good

operating condition. The CAB then sends the proper

ABS indicator lamp-on or lamp-off messages to the

instrument cluster. If the ABS indicator fails to light

during the bulb test, replace the bulb with a known

good unit. If the CAB sends an ABS indicator

lamp-on message after the bulb test, it indicates that

the CAB has detected a system malfunction and/or

that the ABS system has become inoperative. The

CAB will store a Diagnostic Trouble Code (DTC) for

any malfunction it detects. Each time the ABS indi-

cator fails to illuminate due to an open or short in

the cluster ABS indicator circuit or bulb, the cluster

sends a message notifying the CAB of the condition,

then the instrument cluster and the CAB will each

store a DTC. For proper diagnosis of the anti-lock

brake system, the CAB, the PCI data bus, or the

electronic message inputs to the instrument cluster

that control the ABS indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

AIRBAG INDICATOR

DESCRIPTION

An airbag indicator is standard equipment on all

instrument clusters. However, the instrument cluster

is programmed to automatically enable this indicator

only on vehicles equipped with the airbag system,

which is not available in some markets. The airbag

indicator is located on the upper edge of the instru-

ment cluster, between the speedometer and the

tachometer. The airbag indicator consists of the

words ªAIR BAGº imprinted on a red lens. The lens

is located behind a cutout in the opaque layer of the

instrument cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. The ªAIR BAGº

text appears silhouetted against a red field through

the translucent outer layer of the overlay when the

indicator is illuminated from behind by a Light Emit-

ting Diode (LED), which is soldered onto the instru-

ment cluster electronic circuit board. The airbag

indicator lens is serviced as a unit with the instru-

ment cluster lens, hood and mask unit.

OPERATION

The airbag indicator gives an indication to the

vehicle operator when the airbag system is faulty or

inoperative. The airbag indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Airbag Control

Module (ACM) over the Programmable Communica-

tions Interface (PCI) data bus. The airbag indicator

Light Emitting Diode (LED) is completely controlled

by the instrument cluster logic circuit, and that logic

will only allow this indicator to operate when the

instrument cluster receives a battery current input

on the fused ignition switch output (run-start) cir-

cuit. Therefore, the indicator will always be off when

the ignition switch is in any position except On or

Start. The LED only illuminates when it is switched

to ground by the instrument cluster transistor. The

instrument cluster will turn on the airbag indicator

for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the ACM sends an elec-

tronic airbag indicator lamp-on message to the clus-

ter which will illuminate the airbag indicator for

about six seconds as a bulb test. The entire six sec-

ond bulb test is a function of the ACM.

²Airbag Indicator Lamp-On Message- Each

time the cluster receives an airbag indicator lamp-on

message from the ACM, the airbag indicator will be

illuminated. The indicator remains illuminated for

about twelve seconds or until the cluster receives an

airbag indicator lamp-off message from the ACM,

whichever is longer.

²Communication Error- If the cluster receives

no airbag indicator lamp-on or lamp-off messages for

six consecutive seconds, the airbag indicator is illu-

minated. The indicator remains illuminated until the

cluster receives a single valid airbag indicator lamp-

off message from the ACM.

²Actuator Test- Each time the cluster is put

through the actuator test, the airbag indicator will be

turned on, then off again during the bulb check por-

tion of the test to confirm the functionality of the

LED and the cluster control circuitry. The actuator

test illumination of the airbag indicator is also a

function of the ACM.

The ACM continually monitors the airbag system

circuits and sensors to decide whether the system is

in good operating condition. The ACM then sends the

proper airbag indicator lamp-on or lamp-off messages

to the instrument cluster. If the ACM sends an air-

bag indicator lamp-on message after the bulb test, it

indicates that the ACM has detected a system mal-

function. Such a malfunction could mean that the

airbags may not deploy when required, or may

deploy when not required. The ACM will store a

8J - 14 INSTRUMENT CLUSTERWJ

ABS INDICATOR (Continued)

Page 431 of 2199

For further diagnosis of the brake indicator or the

instrument cluster circuitry that controls the indica-

tor, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). The park

brake switch input to the instrument cluster can be

diagnosed using conventional diagnostic tools and

methods. For proper diagnosis of the brake fluid level

switch input to the CAB, the anti-lock brake system,

the CAB, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the

brake indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

DIAGNOSIS AND TESTING - BRAKE INDICATOR

The diagnosis found here addresses an inoperative

park brake indicator condition. If there are problems

with several indicators in the instrument cluster,

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). If the brake

indicator stays on with the ignition switch in the On

position and the park brake released, or comes on

while driving, (Refer to 5 - BRAKES - DIAGNOSIS

AND TESTING). If no brake system problem is

found, the following procedures will help to locate a

shorted or open circuit, or a faulty park brake switch

input. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

INDICATOR ILLUMINATES DURING BULB TEST, BUT DOES

NOT WHEN PARK BRAKE APPLIED

(1) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the park brake switch from the switch

terminal. Apply the parking brake. Check for conti-nuity between the park brake switch terminal and a

good ground. There should be continuity. If OK, go to

Step 2. If not OK, replace the faulty park brake

switch.

(2) Disconnect the instrument panel wire harness

connector for the instrument cluster from the cluster

connector receptacle. Check for continuity between

the red brake warning indicator driver circuit cavi-

ties of the instrument panel wire harness connector

for the park brake switch and the instrument panel

wire harness connector for the instrument cluster.

There should be continuity. If not OK, repair the

open red brake warning indicator driver circuit

between the park brake switch and the instrument

cluster as required.

INDICATOR REMAINS ILLUMINATED - BRAKE SYSTEM

CHECKS OK

(1) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the park brake switch from the park

brake switch terminal. Check for continuity between

the terminal of the park brake switch and a good

ground. There should be no continuity with the park

brake released, and continuity with the park brake

applied. If OK, go to Step 2. If not OK, replace the

faulty park brake switch.

(2) Disconnect the instrument panel wire harness

connector for the instrument cluster from the cluster

connector receptacle. Check for continuity between

the red brake warning indicator driver circuit cavity

of the instrument panel wire harness connector for

the park brake switch and a good ground. There

should be no continuity. If not OK, repair the shorted

red brake warning indicator driver circuit between

the park brake switch and the instrument cluster as

required.

CHECK GAUGES INDICATOR

DESCRIPTION

A check gauges indicator is standard equipment on

all instrument clusters. The check gauges indicator is

located on the right edge of the instrument cluster, to

the right of the speedometer. The check gauges indi-

cator consists of the words ªCHECK GAGESº

imprinted on a red lens. The lens is located behind a

cutout in the opaque layer of the instrument cluster

overlay. The dark outer layer of the overlay prevents

the indicator from being clearly visible when it is not

illuminated. The ªCHECK GAGESº text appears sil-

houetted against a red field through the translucent

outer layer of the overlay when the indicator is illu-

minated from behind by a Light Emitting Diode

(LED), which is soldered onto the instrument cluster

electronic circuit board. The check gauges indicator

8J - 16 INSTRUMENT CLUSTERWJ

BRAKE/PARK BRAKE INDICATOR (Continued)

Page 432 of 2199

lens is serviced as a unit with the instrument cluster

lens, hood and mask unit.

OPERATION

The check gauges indicator gives an indication to

the vehicle operator when certain instrument cluster

gauge readings reflect a condition requiring immedi-

ate attention. This indicator is controlled by a tran-

sistor on the instrument cluster circuit board based

upon cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) over the Programmable Communica-

tions Interface (PCI) data bus. The check gauges

indicator Light Emitting Diode (LED) is completely

controlled by the instrument cluster logic circuit, and

that logic will only allow this indicator to operate

when the instrument cluster receives a battery cur-

rent input on the fused ignition switch output (run-

start) circuit. Therefore, the indicator will always be

off when the ignition switch is in any position except

On or Start. The LED only illuminates when it is

provided a path to ground by the instrument cluster

transistor. The instrument cluster will turn on the

check gauges indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the check gauges indicator

is illuminated for about three seconds as a bulb test.

²Engine Temperature High/Critical Message

- Each time the cluster receives a message from the

PCM indicating the engine coolant temperature is

high or critical [above about 127É C (261É F) for gas-

oline engines except Gulf Coast Country (GCC), 129É

C (264É F) for GCC gasoline engines, and 118É C

(244É F) for diesel engines], the check gauges indica-

tor is illuminated. The indicator remains illuminated

until the cluster receives a message indicating the

engine coolant temperature is not high or critical

[about 125É C (255É F) or below for all gasoline

engines, or 115É C (239É F) for all diesel engines].

²Engine Oil Pressure Low Message- Each

time the cluster receives a message from the PCM

indicating the engine oil pressure is about 0.28

kg/cm or lower (about 4 psi or lower), the check

gauges indicator is illuminated. The indicator

remains illuminated until the cluster receives a mes-

sage from the PCM indicating that the engine oil

pressure is about 0.56 kg/cm or higher (about 8 psi

or higher). The cluster will only turn the indicator on

in response to an engine oil pressure low message if

the ignition switch is in the On position and the

engine speed is 300 rpm or greater.

²System Voltage Low Message- Each time the

cluster receives a message from the PCM indicating

a low system voltage condition (system voltage is

about eleven volts or lower), the check gauges indica-

tor is illuminated. The indicator remains illuminateduntil the cluster receives a message from the PCM

indicating there is no low system voltage condition

(system voltage is above about eleven volts, but lower

than about sixteen volts).

²System Voltage High Message- Each time

the cluster receives a message from the PCM indicat-

ing a high system voltage condition (system voltage

is about sixteen volts or higher), the check gauges

indicator is illuminated. The indicator remains illu-

minated until the cluster receives a message from

the PCM indicating there is no high system voltage

condition (system voltage is below about sixteen

volts, but higher than about eleven volts).

²Actuator Test- Each time the cluster is put

through the actuator test, the check gauges indicator

will be turned on for the duration of the test to con-

firm the functionality of the LED and the cluster con-

trol circuitry.

The PCM continually monitors the engine temper-

ature, oil pressure, and electrical system voltage,

then sends the proper messages to the instrument

cluster. For further diagnosis of the check gauges

indicator or the instrument cluster circuitry that con-

trols the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the PCM, the PCI

data bus, or the electronic message inputs to the

instrument cluster that control the check gauges

indicator, a DRBIIItscan tool is required. Refer to

the appropriate diagnostic information.

COOLANT LOW INDICATOR

DESCRIPTION

A coolant low indicator is only found in the instru-

ment clusters of vehicles equipped with an optional

diesel engine. The coolant low indicator should not be

confused with the coolant level low indication pro-

vided by the Electronic Vehicle Information Center

(EVIC) of vehicles equipped with a gasoline engine,

although they do perform the same function. The

coolant low indicator is located in the lower left cor-

ner of the instrument cluster, to the left of the

tachometer. The coolant low indicator consists of an

International Control and Display Symbol icon for

ªLow Coolantº imprinted on an amber lens. The lens

is located behind a cutout in the opaque layer of the

instrument cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. The icon appears

silhouetted against an amber field through the trans-

lucent outer layer of the overlay when the indicator

is illuminated from behind by a replaceable incandes-

cent bulb and bulb holder unit located on the instru-

ment cluster electronic circuit board. When the

WJINSTRUMENT CLUSTER 8J - 17

CHECK GAUGES INDICATOR (Continued)

Page 433 of 2199

exterior lighting is turned On, the illumination inten-

sity of the coolant low indicator is dimmable, which

is adjusted using the panel lamps dimmer control

ring on the control stalk of the left multi-function

switch. The coolant low indicator lens is serviced as a

unit with the instrument cluster lens, hood and mask

unit.

OPERATION

The coolant low indicator gives an indication to the

vehicle operator when the diesel engine coolant level

is low. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon clus-

ter programming and electronic messages received by

the cluster from the Body Control Module (BCM)

over the Programmable Communications Interface

(PCI) data bus. The coolant low indicator bulb is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the indicator will

always be off when the ignition switch is in any posi-

tion except On or Start. The bulb only illuminates

when it is provided a path to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the coolant low indicator for the following

reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the coolant low indicator is

illuminated for about three seconds as a bulb test.

²Coolant Low Indicator Lamp-On Message-

Each time the cluster receives a coolant low indicator

lamp-on message from the BCM indicating the

engine coolant is below the minimum level in the

coolant reservoir, the coolant low indicator will be

illuminated. The indicator remains illuminated until

the cluster receives a coolant low indicator lamp-off

message from the BCM indicating that the engine

coolant level is above the minimum level.

²Actuator Test- Each time the cluster is put

through the actuator test, the coolant low indicator

will be turned on for the duration of the test to con-

firm the functionality of the bulb and the cluster con-

trol circuitry.

The BCM continually monitors the input from the

coolant level switch, then sends the proper coolant

low indicator lamp-on and lamp-off messages to the

instrument cluster. If the coolant low indicator fails

to light during the bulb test, replace the bulb with a

known good unit. For further diagnosis of the coolant

low indicator or the instrument cluster circuitry that

controls the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the coolant level

switch, the BCM, the PCI data bus, or the electronicmessage inputs to the instrument cluster that control

the coolant low indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

CRUISE INDICATOR

DESCRIPTION

A cruise indicator is standard equipment on all

instrument clusters, but is only functional on vehi-

cles equipped with the optional speed control system.

The cruise indicator is located on the right edge of

the instrument cluster, to the right of the speedome-

ter. The cruise indicator consists of the word

ªCRUISEº imprinted on a blue/green lens. The lens is

located behind a cutout in the opaque layer of the

instrument cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. The ªCRUISEº text

appears silhouetted against a blue/green field

through the translucent outer layer of the overlay

when the indicator is illuminated from behind by a

replaceable bulb and bulb holder unit located on the

instrument cluster electronic circuit board. When the

exterior lighting is turned On, the illumination inten-

sity of the cruise indicator is dimmable, which is

adjusted using the panel lamps dimmer control ring

on the control stalk of the left multi-function switch.

The cruise indicator lens is serviced as a unit with

the instrument cluster lens, hood and mask unit.

OPERATION

The cruise indicator gives an indication to the vehi-

cle operator when the speed control system is turned

On, regardless of whether the speed control is

engaged. This indicator is controlled by a transistor

on the instrument cluster electronic circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Powertrain

Control Module (PCM) over the Programmable Com-

munications Interface (PCI) data bus. The cruise

indicator bulb is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the indicator will always be off when the ignition

switch is in any position except On or Start. The bulb

only illuminates when it is provided a path to ground

by the instrument cluster transistor. The instrument

cluster will turn on the cruise indicator for the fol-

lowing reasons:

²Cruise Indicator Lamp-On Message- Each

time the cluster receives a cruise indicator lamp-on

message from the PCM indicating the speed control

8J - 18 INSTRUMENT CLUSTERWJ

COOLANT LOW INDICATOR (Continued)