window lock JEEP GRAND CHEROKEE 2002 WJ / 2.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1974 of 2199

CONTROL MODULE

REMOVAL

(1) Move the glass panel to the fully closed posi-

tion.

(2) Remove the A-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - REMOVAL)

(3) Remove the sun visors. (Refer to 23 - BODY/

INTERIOR/SUN VISOR - REMOVAL)

(4) Remove the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOVAL)

(5) Lower headliner as necessary to gain access to

the sunroof express module.

(6) Disconnect the express module wire harness

connectors.

(7) Remove express module screw.

(8) Remove express module from the keyway by

sliding module towards the center of the vehicle.

INSTALLATION

(1) Insert sunroof express module in the keyway

located in the sunroof module and slide the module

outward to lock it into position.

(2) Install the sunroof express module screw.

(3) Connect the wire connectors to the sunroof

express module.

(4) Install the headliner into position.

(5) Install the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - INSTALLA-

TION)

(6) Install the sun visors. (Refer to 23 - BODY/IN-

TERIOR/SUN VISOR - INSTALLATION)

(7) Install the A-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - INSTALLATION)

(8) Test sunroof operation, adjust if necessary.

(Refer to 23 - BODY/SUNROOF/GLASS PANEL -

ADJUSTMENTS)

DRIVE MOTOR

REMOVAL

CAUTION: The sunroof system is timed from the

factory so that the motor shuts off automatically

when the sunroof window reaches a certain posi-

tion. Extreme care must be taken when removing

the motor, timing may be thrown off causing possi-

ble damage to the sunroof system. Anytime the

motor is removed from the sunroof assembly the

sunroof glass panel must be in the FULLY CLOSED

POSITION or the unit will be out of timing. The drive

motor cannot be reset to the park position after

being removed.CAUTION: The sunroof motor should only be pow-

ered through the vehicle battery and sunroof wire

harness. Applying power to the sunroof motor leads

will cause failure of the control module.

(1) Move glass panel to the fully closed position.

(2) Remove the A-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - REMOVAL)

(3) Remove the B-pillar upper trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL)

(4) Remove the C-pillar trim. (Refer to 23 - BODY/

INTERIOR/C-PILLAR TRIM - REMOVAL)

(5) Remove the D-pillar trim. (Refer to 23 - BODY/

INTERIOR/D-PILLAR TRIM - REMOVAL)

(6) Remove the sunvisors. (Refer to 23 - BODY/IN-

TERIOR/SUN VISOR - REMOVAL)

(7) Remove the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOVAL)

(8) Disconnect the control switch wire connector.

(9) Remove headliner as necessary to gain access

to sunroof drive motor. Refer to Headliner Removal

and Installation for proper procedures.

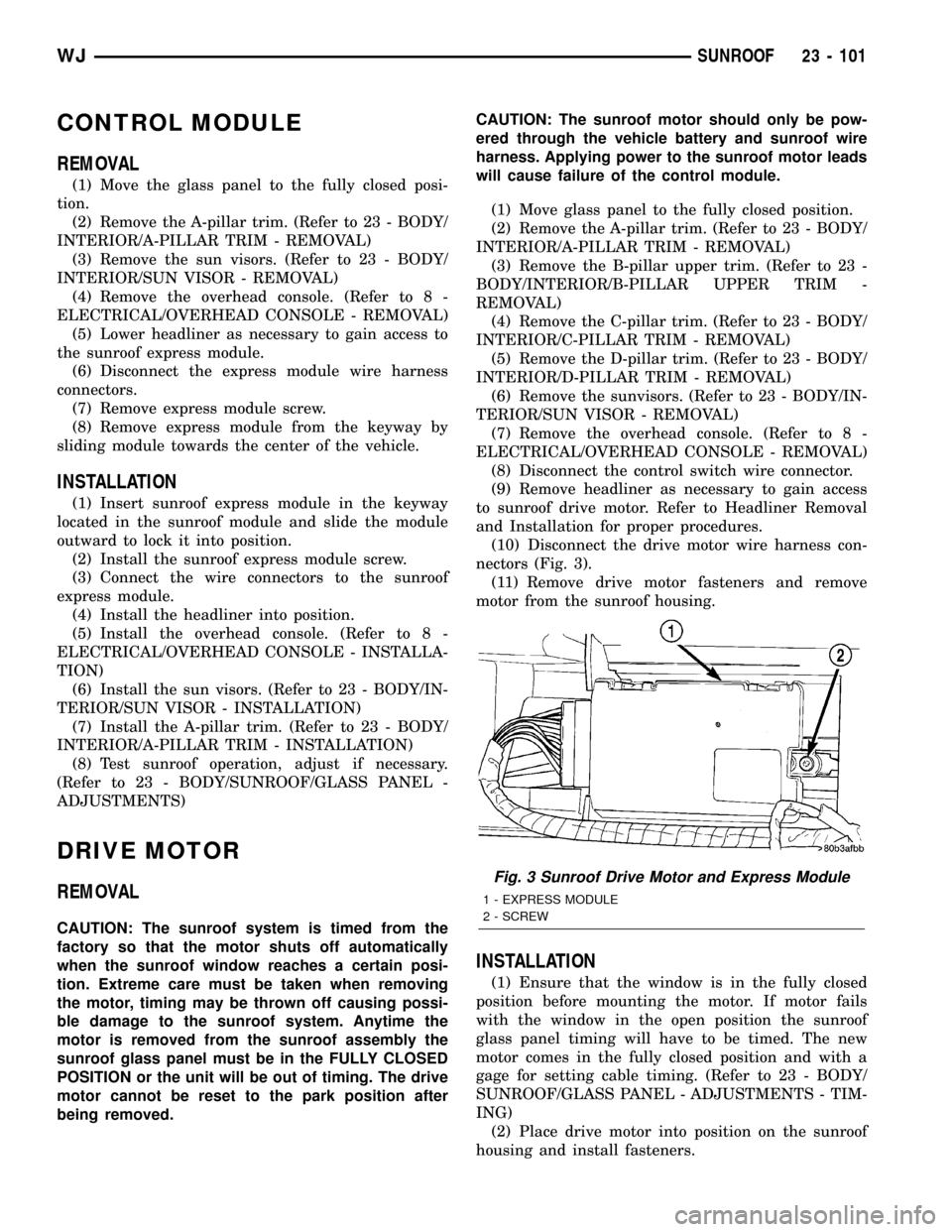

(10) Disconnect the drive motor wire harness con-

nectors (Fig. 3).

(11) Remove drive motor fasteners and remove

motor from the sunroof housing.

INSTALLATION

(1) Ensure that the window is in the fully closed

position before mounting the motor. If motor fails

with the window in the open position the sunroof

glass panel timing will have to be timed. The new

motor comes in the fully closed position and with a

gage for setting cable timing. (Refer to 23 - BODY/

SUNROOF/GLASS PANEL - ADJUSTMENTS - TIM-

ING)

(2) Place drive motor into position on the sunroof

housing and install fasteners.

Fig. 3 Sunroof Drive Motor and Express Module

1 - EXPRESS MODULE

2 - SCREW

WJSUNROOF 23 - 101

Page 2094 of 2199

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

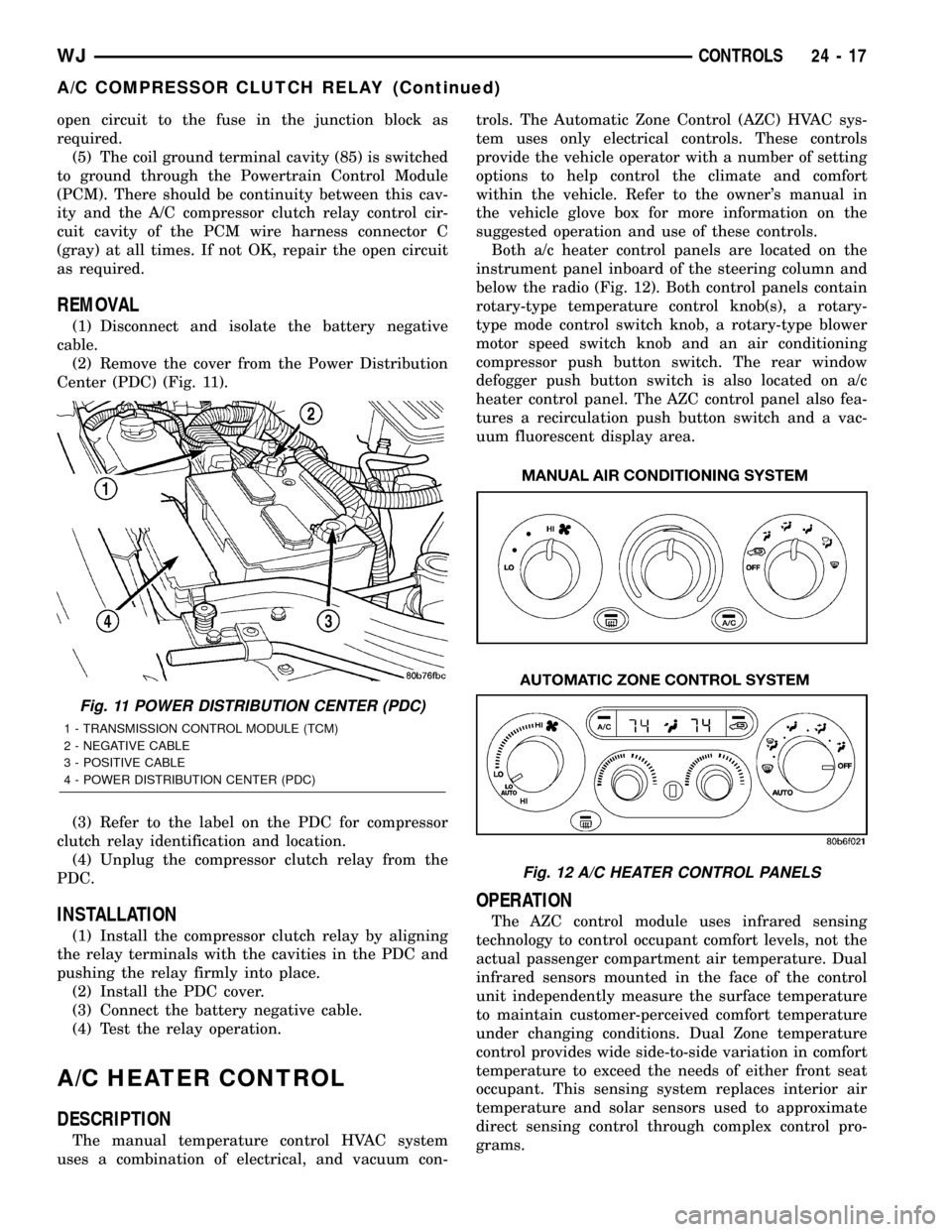

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 11).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

The manual temperature control HVAC system

uses a combination of electrical, and vacuum con-trols. The Automatic Zone Control (AZC) HVAC sys-

tem uses only electrical controls. These controls

provide the vehicle operator with a number of setting

options to help control the climate and comfort

within the vehicle. Refer to the owner's manual in

the vehicle glove box for more information on the

suggested operation and use of these controls.

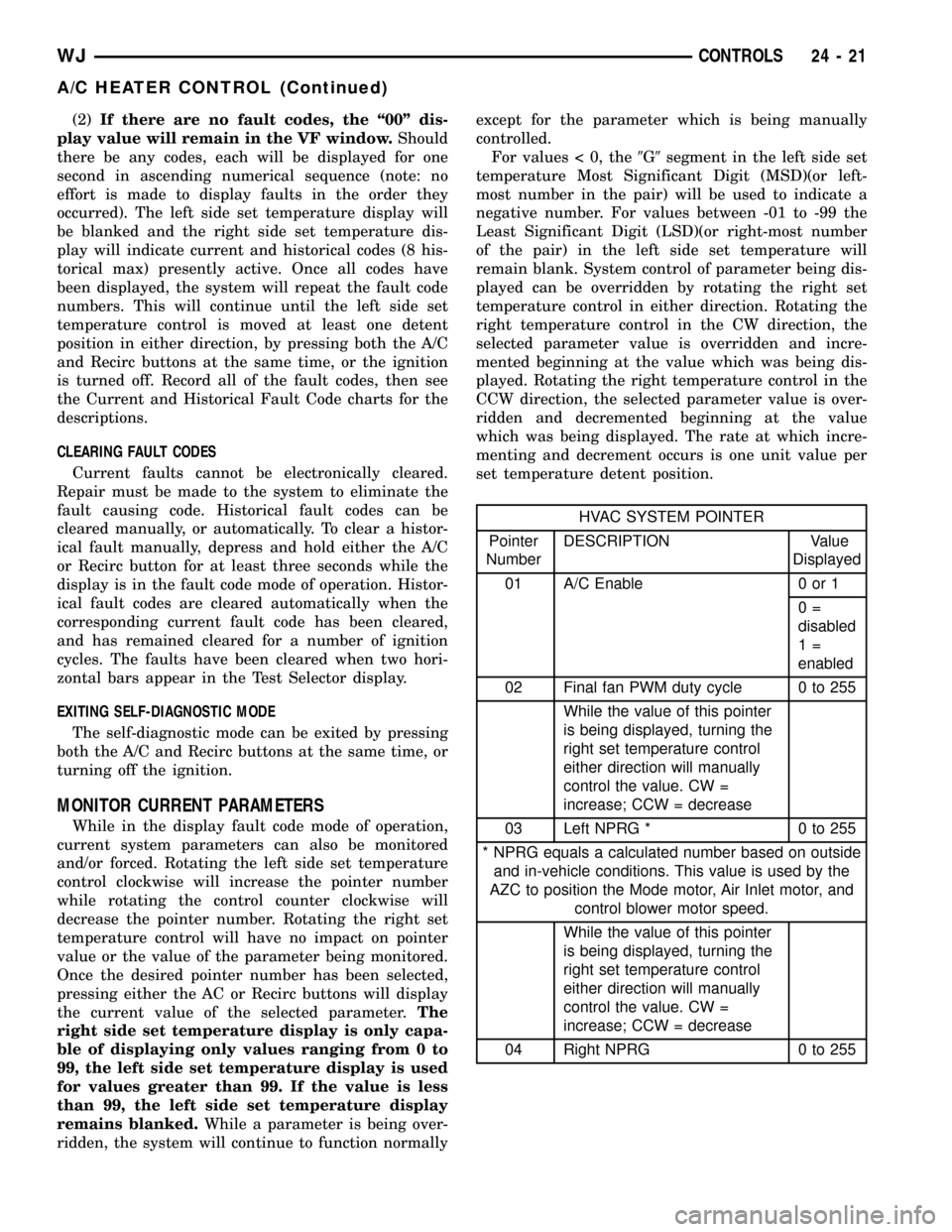

Both a/c heater control panels are located on the

instrument panel inboard of the steering column and

below the radio (Fig. 12). Both control panels contain

rotary-type temperature control knob(s), a rotary-

type mode control switch knob, a rotary-type blower

motor speed switch knob and an air conditioning

compressor push button switch. The rear window

defogger push button switch is also located on a/c

heater control panel. The AZC control panel also fea-

tures a recirculation push button switch and a vac-

uum fluorescent display area.

OPERATION

The AZC control module uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

Fig. 11 POWER DISTRIBUTION CENTER (PDC)

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - NEGATIVE CABLE

3 - POSITIVE CABLE

4 - POWER DISTRIBUTION CENTER (PDC)

Fig. 12 A/C HEATER CONTROL PANELS

WJCONTROLS 24 - 17

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2098 of 2199

(2)If there are no fault codes, the ª00º dis-

play value will remain in the VF window.Should

there be any codes, each will be displayed for one

second in ascending numerical sequence (note: no

effort is made to display faults in the order they

occurred). The left side set temperature display will

be blanked and the right side set temperature dis-

play will indicate current and historical codes (8 his-

torical max) presently active. Once all codes have

been displayed, the system will repeat the fault code

numbers. This will continue until the left side set

temperature control is moved at least one detent

position in either direction, by pressing both the A/C

and Recirc buttons at the same time, or the ignition

is turned off. Record all of the fault codes, then see

the Current and Historical Fault Code charts for the

descriptions.

CLEARING FAULT CODES

Current faults cannot be electronically cleared.

Repair must be made to the system to eliminate the

fault causing code. Historical fault codes can be

cleared manually, or automatically. To clear a histor-

ical fault manually, depress and hold either the A/C

or Recirc button for at least three seconds while the

display is in the fault code mode of operation. Histor-

ical fault codes are cleared automatically when the

corresponding current fault code has been cleared,

and has remained cleared for a number of ignition

cycles. The faults have been cleared when two hori-

zontal bars appear in the Test Selector display.

EXITING SELF-DIAGNOSTIC MODE

The self-diagnostic mode can be exited by pressing

both the A/C and Recirc buttons at the same time, or

turning off the ignition.

MONITOR CURRENT PARAMETERS

While in the display fault code mode of operation,

current system parameters can also be monitored

and/or forced. Rotating the left side set temperature

control clockwise will increase the pointer number

while rotating the control counter clockwise will

decrease the pointer number. Rotating the right set

temperature control will have no impact on pointer

value or the value of the parameter being monitored.

Once the desired pointer number has been selected,

pressing either the AC or Recirc buttons will display

the current value of the selected parameter.The

right side set temperature display is only capa-

ble of displaying only values ranging from 0 to

99, the left side set temperature display is used

for values greater than 99. If the value is less

than 99, the left side set temperature display

remains blanked.While a parameter is being over-

ridden, the system will continue to function normallyexcept for the parameter which is being manually

controlled.

For values < 0, the9G9segment in the left side set

temperature Most Significant Digit (MSD)(or left-

most number in the pair) will be used to indicate a

negative number. For values between -01 to -99 the

Least Significant Digit (LSD)(or right-most number

of the pair) in the left side set temperature will

remain blank. System control of parameter being dis-

played can be overridden by rotating the right set

temperature control in either direction. Rotating the

right temperature control in the CW direction, the

selected parameter value is overridden and incre-

mented beginning at the value which was being dis-

played. Rotating the right temperature control in the

CCW direction, the selected parameter value is over-

ridden and decremented beginning at the value

which was being displayed. The rate at which incre-

menting and decrement occurs is one unit value per

set temperature detent position.

HVAC SYSTEM POINTER

Pointer

NumberDESCRIPTION Value

Displayed

01 A/C Enable 0 or 1

0=

disabled

1=

enabled

02 Final fan PWM duty cycle 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

03 Left NPRG * 0 to 255

* NPRG equals a calculated number based on outside

and in-vehicle conditions. This value is used by the

AZC to position the Mode motor, Air Inlet motor, and

control blower motor speed.

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

04 Right NPRG 0 to 255

WJCONTROLS 24 - 21

A/C HEATER CONTROL (Continued)