lock JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1686 of 2199

²pressure adjusting screw and bracket assembly

²throttle lever

²manual lever and shaft seal

²throttle lever shaft seal, washer, and E-clip

²fluid filter and screws

²detent ball and spring

²valve body screws

²governor pressure solenoid

²governor pressure sensor and retaining clip

²park lock rod and E-clip

ASSEMBLY

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the housings resulting in

valve sticking, cross leakage and unsatisfactory

operation. Tighten valve body screws to recom-

mended torque only.

LOWER HOUSING

(1) Lubricate valves, springs, and the housing

valve and plug bores with clean transmission fluid

(Fig. 309).

(2) Install 3-4 timing valve spring and valve in

lower housing.

(3) Install 3-4 quick fill valve in lower housing.

(4) Install 3-4 quick fill valve spring and plug in

housing.

(5) Install timing valve end plate. Tighten end

plate screws to 4 N´m (35 in. lbs.) torque.

3-4 ACCUMULATOR

(1) Lubricate accumulator piston, seals and hous-

ing piston bore with clean transmission fluid (Fig.

310).

(2) Install new seal rings on accumulator piston.

(3) Install piston and spring in housing.

(4) Install end plate on housing.

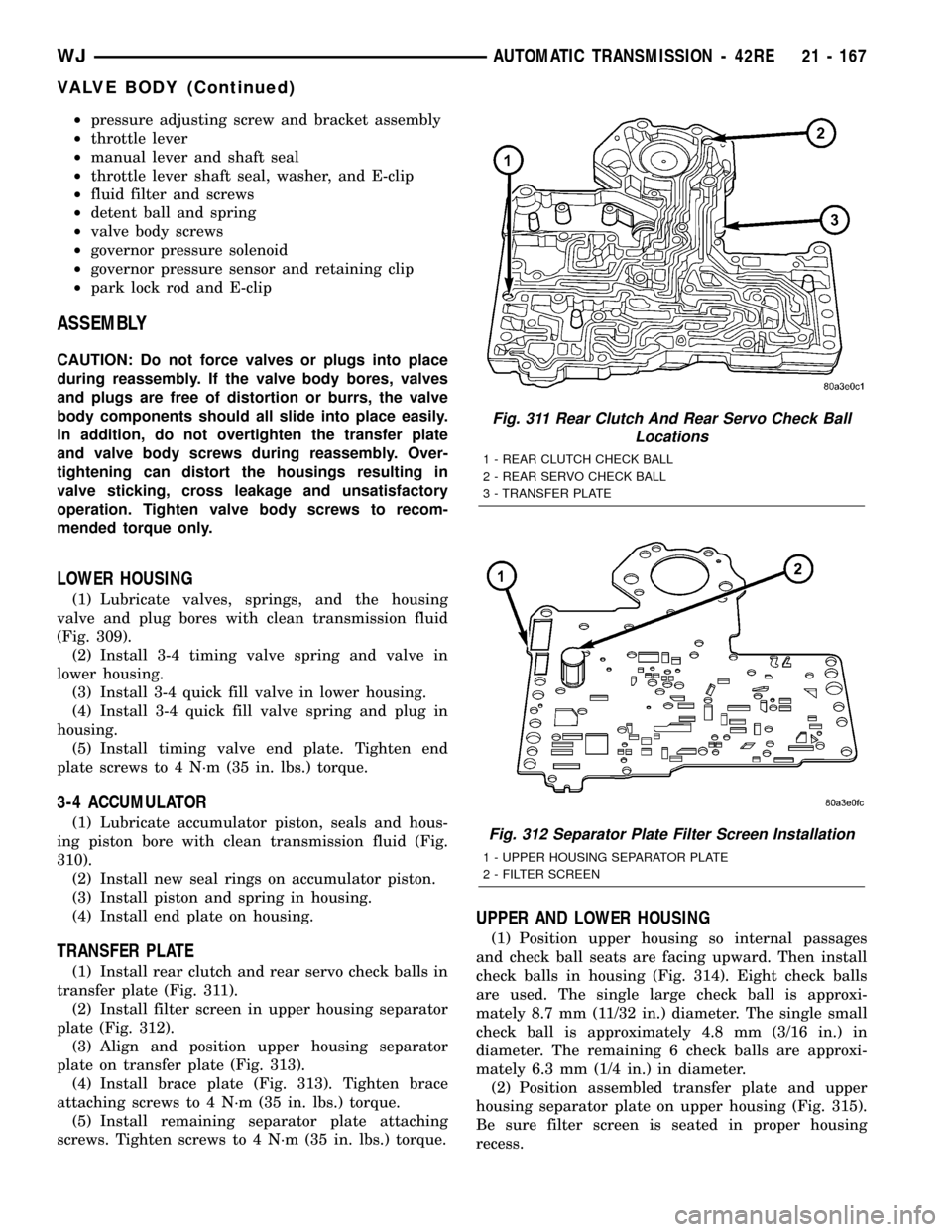

TRANSFER PLATE

(1) Install rear clutch and rear servo check balls in

transfer plate (Fig. 311).

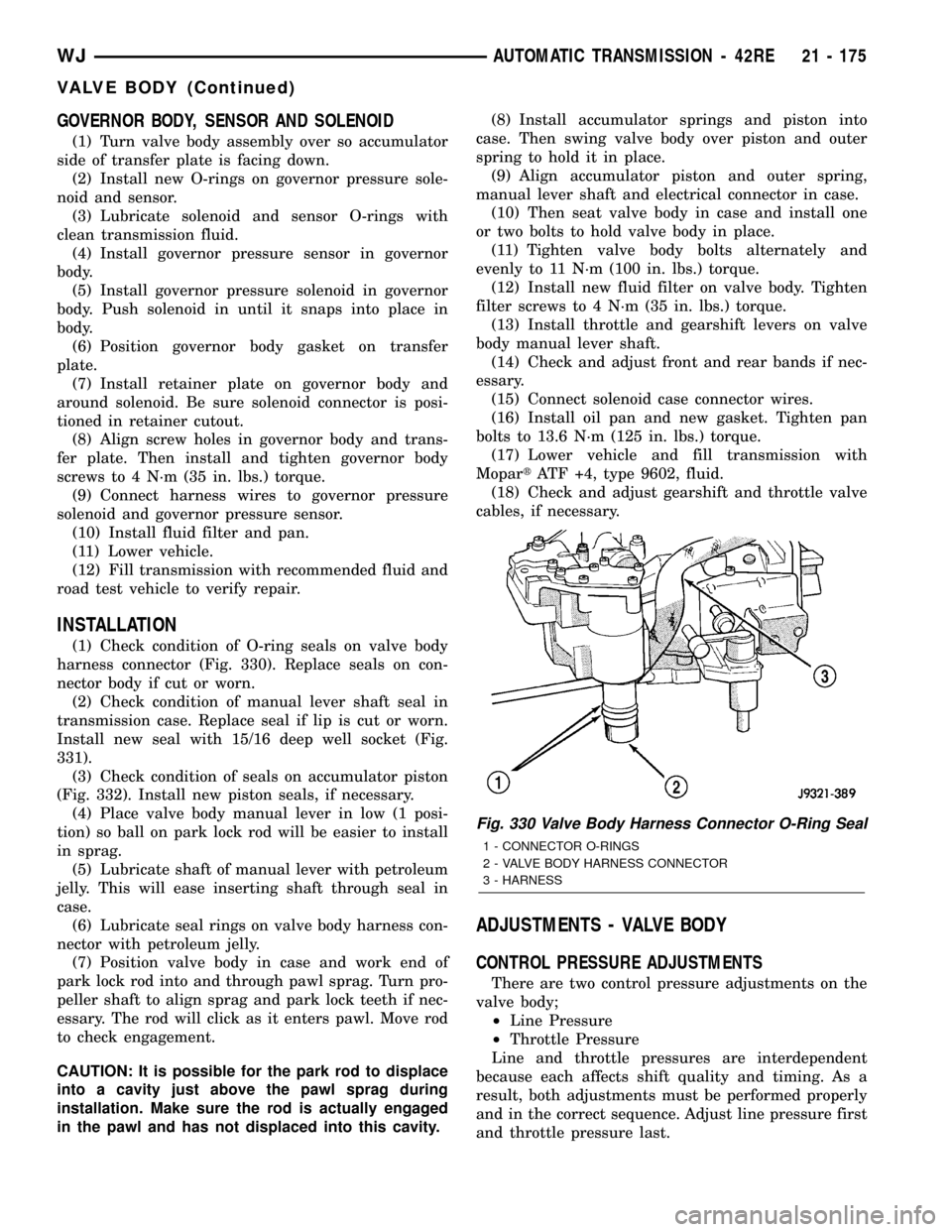

(2) Install filter screen in upper housing separator

plate (Fig. 312).

(3) Align and position upper housing separator

plate on transfer plate (Fig. 313).

(4) Install brace plate (Fig. 313). Tighten brace

attaching screws to 4 N´m (35 in. lbs.) torque.

(5) Install remaining separator plate attaching

screws. Tighten screws to 4 N´m (35 in. lbs.) torque.

UPPER AND LOWER HOUSING

(1) Position upper housing so internal passages

and check ball seats are facing upward. Then install

check balls in housing (Fig. 314). Eight check balls

are used. The single large check ball is approxi-

mately 8.7 mm (11/32 in.) diameter. The single small

check ball is approximately 4.8 mm (3/16 in.) in

diameter. The remaining 6 check balls are approxi-

mately 6.3 mm (1/4 in.) in diameter.

(2) Position assembled transfer plate and upper

housing separator plate on upper housing (Fig. 315).

Be sure filter screen is seated in proper housing

recess.

Fig. 311 Rear Clutch And Rear Servo Check Ball

Locations

1 - REAR CLUTCH CHECK BALL

2 - REAR SERVO CHECK BALL

3 - TRANSFER PLATE

Fig. 312 Separator Plate Filter Screen Installation

1 - UPPER HOUSING SEPARATOR PLATE

2 - FILTER SCREEN

WJAUTOMATIC TRANSMISSION - 42RE 21 - 167

VALVE BODY (Continued)

Page 1694 of 2199

GOVERNOR BODY, SENSOR AND SOLENOID

(1) Turn valve body assembly over so accumulator

side of transfer plate is facing down.

(2) Install new O-rings on governor pressure sole-

noid and sensor.

(3) Lubricate solenoid and sensor O-rings with

clean transmission fluid.

(4) Install governor pressure sensor in governor

body.

(5) Install governor pressure solenoid in governor

body. Push solenoid in until it snaps into place in

body.

(6) Position governor body gasket on transfer

plate.

(7) Install retainer plate on governor body and

around solenoid. Be sure solenoid connector is posi-

tioned in retainer cutout.

(8) Align screw holes in governor body and trans-

fer plate. Then install and tighten governor body

screws to 4 N´m (35 in. lbs.) torque.

(9) Connect harness wires to governor pressure

solenoid and governor pressure sensor.

(10) Install fluid filter and pan.

(11) Lower vehicle.

(12) Fill transmission with recommended fluid and

road test vehicle to verify repair.

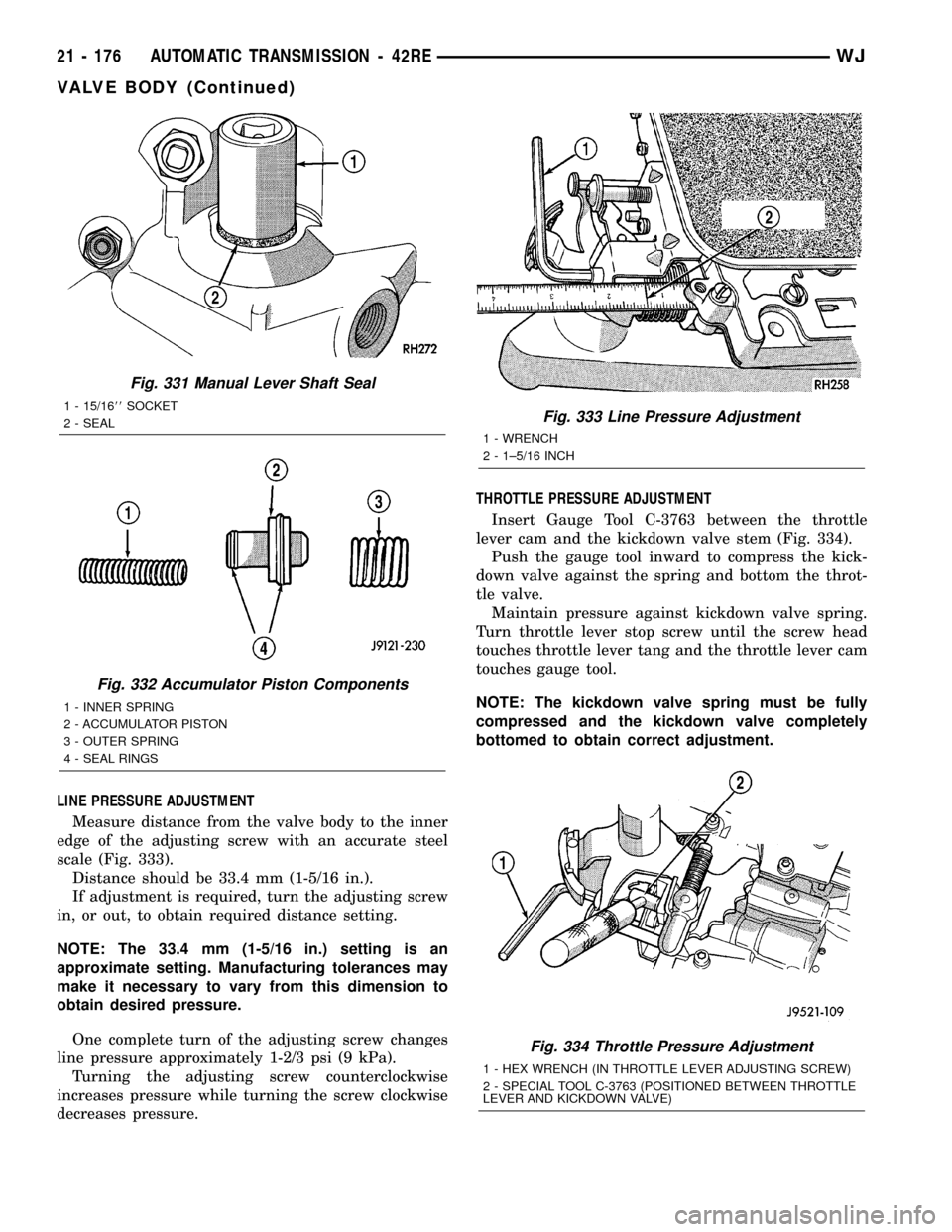

INSTALLATION

(1) Check condition of O-ring seals on valve body

harness connector (Fig. 330). Replace seals on con-

nector body if cut or worn.

(2) Check condition of manual lever shaft seal in

transmission case. Replace seal if lip is cut or worn.

Install new seal with 15/16 deep well socket (Fig.

331).

(3) Check condition of seals on accumulator piston

(Fig. 332). Install new piston seals, if necessary.

(4) Place valve body manual lever in low (1 posi-

tion) so ball on park lock rod will be easier to install

in sprag.

(5) Lubricate shaft of manual lever with petroleum

jelly. This will ease inserting shaft through seal in

case.

(6) Lubricate seal rings on valve body harness con-

nector with petroleum jelly.

(7) Position valve body in case and work end of

park lock rod into and through pawl sprag. Turn pro-

peller shaft to align sprag and park lock teeth if nec-

essary. The rod will click as it enters pawl. Move rod

to check engagement.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.(8) Install accumulator springs and piston into

case. Then swing valve body over piston and outer

spring to hold it in place.

(9) Align accumulator piston and outer spring,

manual lever shaft and electrical connector in case.

(10) Then seat valve body in case and install one

or two bolts to hold valve body in place.

(11) Tighten valve body bolts alternately and

evenly to 11 N´m (100 in. lbs.) torque.

(12) Install new fluid filter on valve body. Tighten

filter screws to 4 N´m (35 in. lbs.) torque.

(13) Install throttle and gearshift levers on valve

body manual lever shaft.

(14) Check and adjust front and rear bands if nec-

essary.

(15) Connect solenoid case connector wires.

(16) Install oil pan and new gasket. Tighten pan

bolts to 13.6 N´m (125 in. lbs.) torque.

(17) Lower vehicle and fill transmission with

MopartATF +4, type 9602, fluid.

(18) Check and adjust gearshift and throttle valve

cables, if necessary.

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

Fig. 330 Valve Body Harness Connector O-Ring Seal

1 - CONNECTOR O-RINGS

2 - VALVE BODY HARNESS CONNECTOR

3 - HARNESS

WJAUTOMATIC TRANSMISSION - 42RE 21 - 175

VALVE BODY (Continued)

Page 1695 of 2199

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 333).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 334).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 331 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

Fig. 332 Accumulator Piston Components

1 - INNER SPRING

2 - ACCUMULATOR PISTON

3 - OUTER SPRING

4 - SEAL RINGS

Fig. 333 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 334 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

21 - 176 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1696 of 2199

AUTOMATIC TRANSMISSION - 545RFE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 545RFE

DESCRIPTION........................178

OPERATION..........................179

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION.....................179

DIAGNOSIS AND TESTING - PRELIMINARY . 180

DIAGNOSIS AND TESTING - ROAD

TESTING...........................180

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST....................181

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION....182

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK................182

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR.....................183

REMOVAL............................183

DISASSEMBLY........................185

CLEANING...........................190

INSPECTION.........................190

ASSEMBLY...........................190

INSTALLATION........................197

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS.............199

SPECIFICATIONS

TRANSMISSION.....................220

SPECIAL TOOLS

RFE TRANSMISSION.................221

4C RETAINER/BULKHEAD

DISASSEMBLY........................224

ASSEMBLY...........................224

ADAPTER HOUSING SEAL

REMOVAL............................225

INSTALLATION........................225

BRAKE TRANSMISSION SHIFT INTERLOCK

MECHANISM

DESCRIPTION........................226

OPERATION..........................226

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK......226

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK...................227

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL.............228

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID.......................228DIAGNOSIS AND TESTING - FLUID

CONTAMINATION....................228

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK............................229

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT...............230

STANDARD PROCEDURE - TRANSMISSION

FILL...............................230

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE.............................231

REMOVAL............................231

INSTALLATION........................231

ADJUSTMENTS - GEARSHIFT CABLE......232

HOLDING CLUTCHES

DESCRIPTION........................233

OPERATION..........................234

INPUT CLUTCH ASSEMBLY

DESCRIPTION........................235

OPERATION..........................235

DISASSEMBLY........................237

ASSEMBLY...........................238

INPUT SPEED SENSOR

DESCRIPTION........................244

OPERATION..........................244

REMOVAL............................244

INSTALLATION........................244

LINE PRESSURE (LP) SENSOR

DESCRIPTION........................245

OPERATION..........................245

REMOVAL............................245

INSTALLATION........................245

LOW/REVERSE CLUTCH

DISASSEMBLY........................246

CLEANING...........................247

INSPECTION.........................247

ASSEMBLY...........................247

OIL PUMP

DESCRIPTION........................248

OPERATION..........................248

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................249

DISASSEMBLY........................250

CLEANING...........................252

INSPECTION.........................252

ASSEMBLY...........................253

OIL PUMP FRONT SEAL

REMOVAL............................253

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 177

Page 1697 of 2199

INSTALLATION........................253

OUTPUT SPEED SENSOR

DESCRIPTION........................254

OPERATION..........................254

REMOVAL............................254

INSTALLATION........................254

OVERDRIVE SWITCH

DESCRIPTION........................254

OPERATION..........................254

PARK LOCK CABLE

REMOVAL............................255

INSTALLATION........................255

PISTONS

DESCRIPTION........................256

OPERATION..........................256

PLANETARY GEARTRAIN

DESCRIPTION........................258

OPERATION..........................260

DISASSEMBLY........................260

CLEANING...........................260

INSPECTION.........................260

ASSEMBLY...........................261

SHIFT MECHANISM

DESCRIPTION........................261

OPERATION..........................261

REMOVAL............................261

INSTALLATION........................263

SOLENOID SWITCH VALVE

DESCRIPTION........................263

OPERATION..........................263

SOLENOIDS

DESCRIPTION........................263OPERATION..........................264

TORQUE CONVERTER

DESCRIPTION........................264

OPERATION..........................268

REMOVAL............................269

INSTALLATION........................269

TRANSMISSION CONTROL RELAY

DESCRIPTION........................270

OPERATION..........................270

TRANSMISSION RANGE SENSOR

DESCRIPTION........................270

OPERATION..........................270

TRANSMISSION SOLENOID/TRS ASSEMBLY

DESCRIPTION........................271

OPERATION..........................271

REMOVAL............................272

INSTALLATION........................272

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................272

OPERATION..........................272

VALVE BODY

DESCRIPTION........................273

OPERATION..........................273

REMOVAL............................274

DISASSEMBLY........................275

CLEANING...........................277

INSPECTION.........................277

ASSEMBLY...........................278

INSTALLATION........................279

AUTOMATIC TRANSMISSION -

545RFE

DESCRIPTION

The 545RFE automatic transmission is a sophisti-

cated, multi-range, electronically controlled transmis-

sion which combines optimized gear ratios for

responsive performance, state of the art efficiency

features and low NVH. Other features include driver

adaptive shifting and three planetary gear sets to

provide wide ratio capability with precise ratio steps

for optimum driveability. The three planetary gear

sets also make available a unique alternate second

gear ratio. The primary 2nd gear ratio fits between

1st and 3rd gears for normal through-gear accelera-

tions. The alternate second gear ratio (2prime) allows

smoother 4-2 kickdowns at high speeds to provide

2nd gear passing performance over a wider highway

cruising range. An additional overdrive ratio (0.67:1)

is also provided for greater fuel economy and less

NVH at highway speeds.The hydraulic portion of the transmission consists

of the transmission fluid, fluid passages, hydraulic

valves, and various line pressure control components.

The primary mechanical components of the trans-

mission consist of the following:

²Three multiple disc input clutches

²Three multiple disc holding clutches

²Five hydraulic accumulators

²Three planetary gear sets

²Dual Stage Hydraulic oil pump

²Valve body

²Solenoid pack

The TCM is the ªheartº or ªbrainº of the electronic

control system and relies on information from vari-

ous direct and indirect inputs (sensors, switches, etc.)

to determine driver demand and vehicle operating

conditions. With this information, the TCM can cal-

culate and perform timely and quality shifts through

various output or control devices (solenoid pack,

transmission control relay, etc.).

21 - 178 AUTOMATIC TRANSMISSION - 545RFEWJ

Page 1702 of 2199

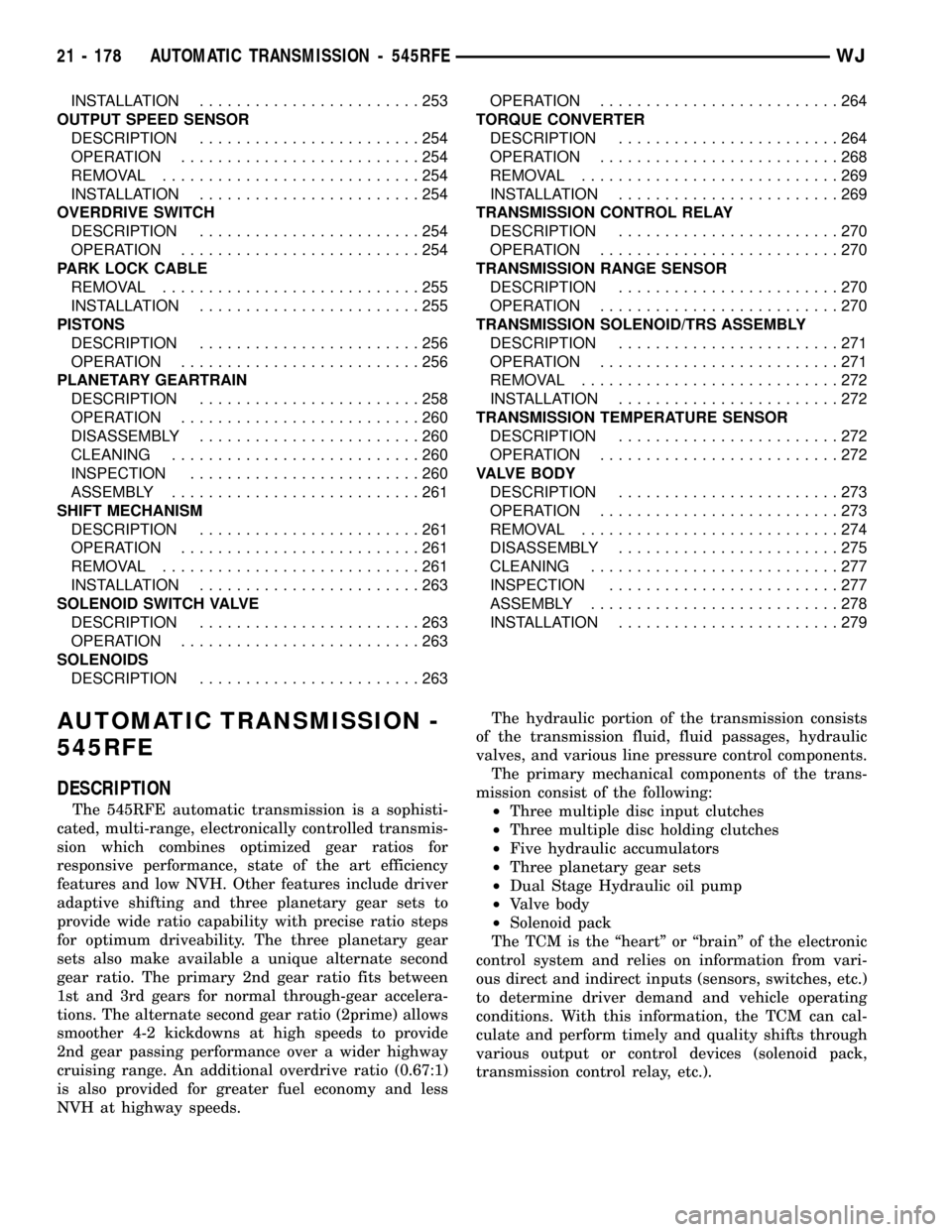

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

(1) Leaks at the weld joint around the outside

diameter weld (Fig. 7).

(2) Leaks at the converter hub weld (Fig. 7).

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

REMOVAL

CAUTION: The transmission and torque converter

must be removed as an assembly to avoid compo-

nent damage. The converter driveplate, converter

hub o-ring, or oil seal can be damaged if the con-

verter is left attached to the driveplate during

removal. Be sure to remove the transmission and

converter as an assembly.

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle

(3) Mark propeller shaft and axle yokes for assem-

bly alignment.

(4) Remove the rear propeller shaft

(5) Remove the front propeller shaft.

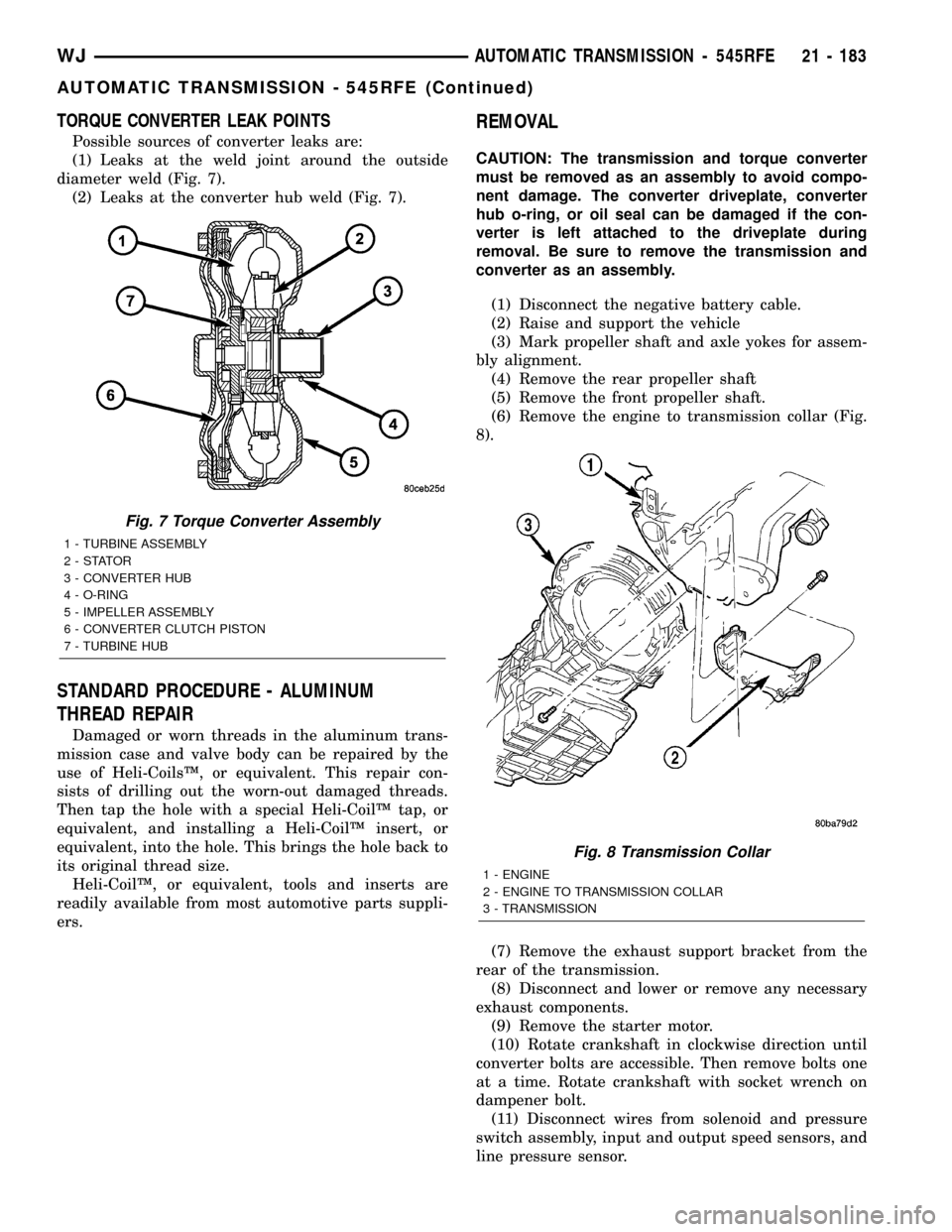

(6) Remove the engine to transmission collar (Fig.

8).

(7) Remove the exhaust support bracket from the

rear of the transmission.

(8) Disconnect and lower or remove any necessary

exhaust components.

(9) Remove the starter motor.

(10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(11) Disconnect wires from solenoid and pressure

switch assembly, input and output speed sensors, and

line pressure sensor.

Fig. 7 Torque Converter Assembly

1 - TURBINE ASSEMBLY

2-STATOR

3 - CONVERTER HUB

4 - O-RING

5 - IMPELLER ASSEMBLY

6 - CONVERTER CLUTCH PISTON

7 - TURBINE HUB

Fig. 8 Transmission Collar

1 - ENGINE

2 - ENGINE TO TRANSMISSION COLLAR

3 - TRANSMISSION

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 183

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1703 of 2199

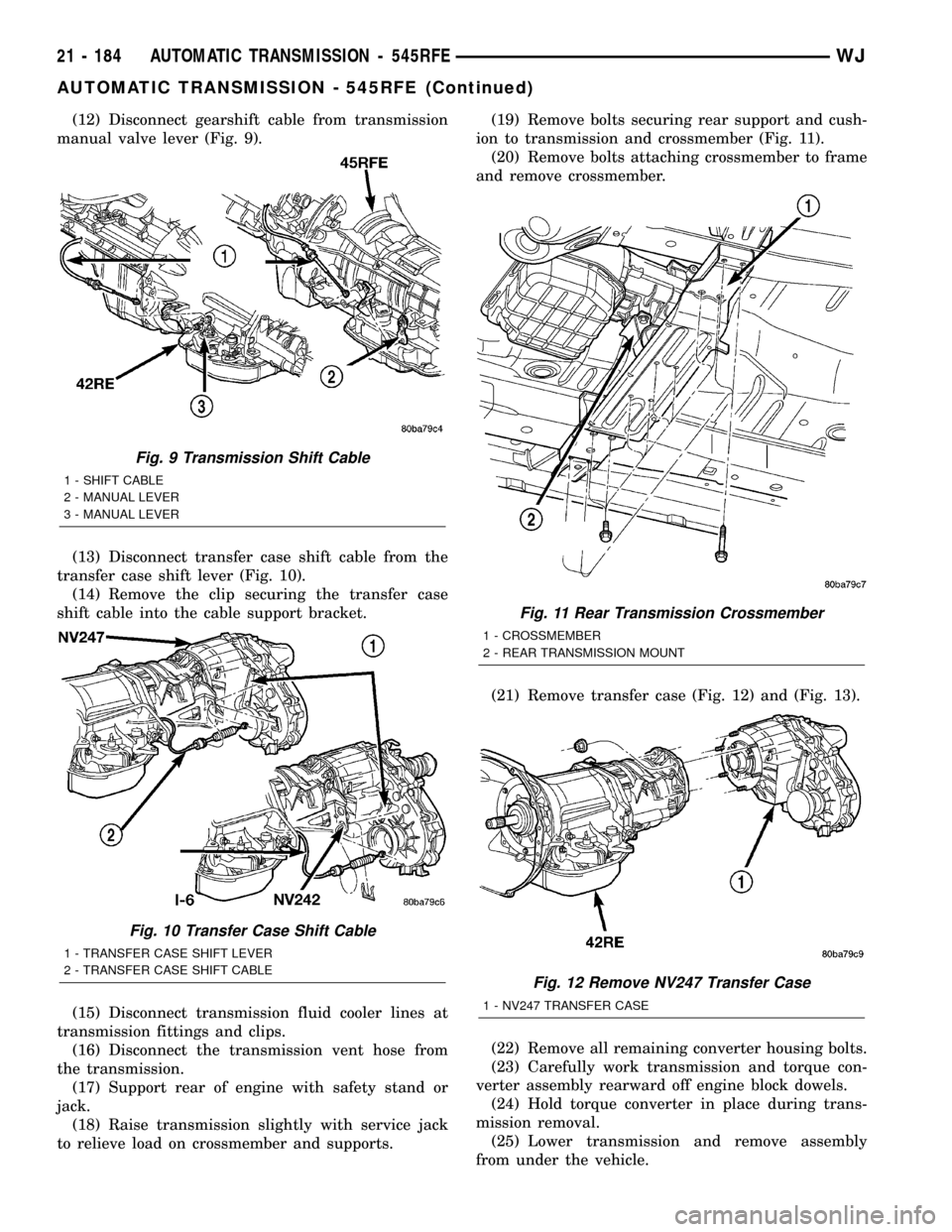

(12) Disconnect gearshift cable from transmission

manual valve lever (Fig. 9).

(13) Disconnect transfer case shift cable from the

transfer case shift lever (Fig. 10).

(14) Remove the clip securing the transfer case

shift cable into the cable support bracket.

(15) Disconnect transmission fluid cooler lines at

transmission fittings and clips.

(16) Disconnect the transmission vent hose from

the transmission.

(17) Support rear of engine with safety stand or

jack.

(18) Raise transmission slightly with service jack

to relieve load on crossmember and supports.(19) Remove bolts securing rear support and cush-

ion to transmission and crossmember (Fig. 11).

(20) Remove bolts attaching crossmember to frame

and remove crossmember.

(21) Remove transfer case (Fig. 12) and (Fig. 13).

(22) Remove all remaining converter housing bolts.

(23) Carefully work transmission and torque con-

verter assembly rearward off engine block dowels.

(24) Hold torque converter in place during trans-

mission removal.

(25) Lower transmission and remove assembly

from under the vehicle.

Fig. 9 Transmission Shift Cable

1 - SHIFT CABLE

2 - MANUAL LEVER

3 - MANUAL LEVER

Fig. 10 Transfer Case Shift Cable

1 - TRANSFER CASE SHIFT LEVER

2 - TRANSFER CASE SHIFT CABLE

Fig. 11 Rear Transmission Crossmember

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

Fig. 12 Remove NV247 Transfer Case

1 - NV247 TRANSFER CASE

21 - 184 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1709 of 2199

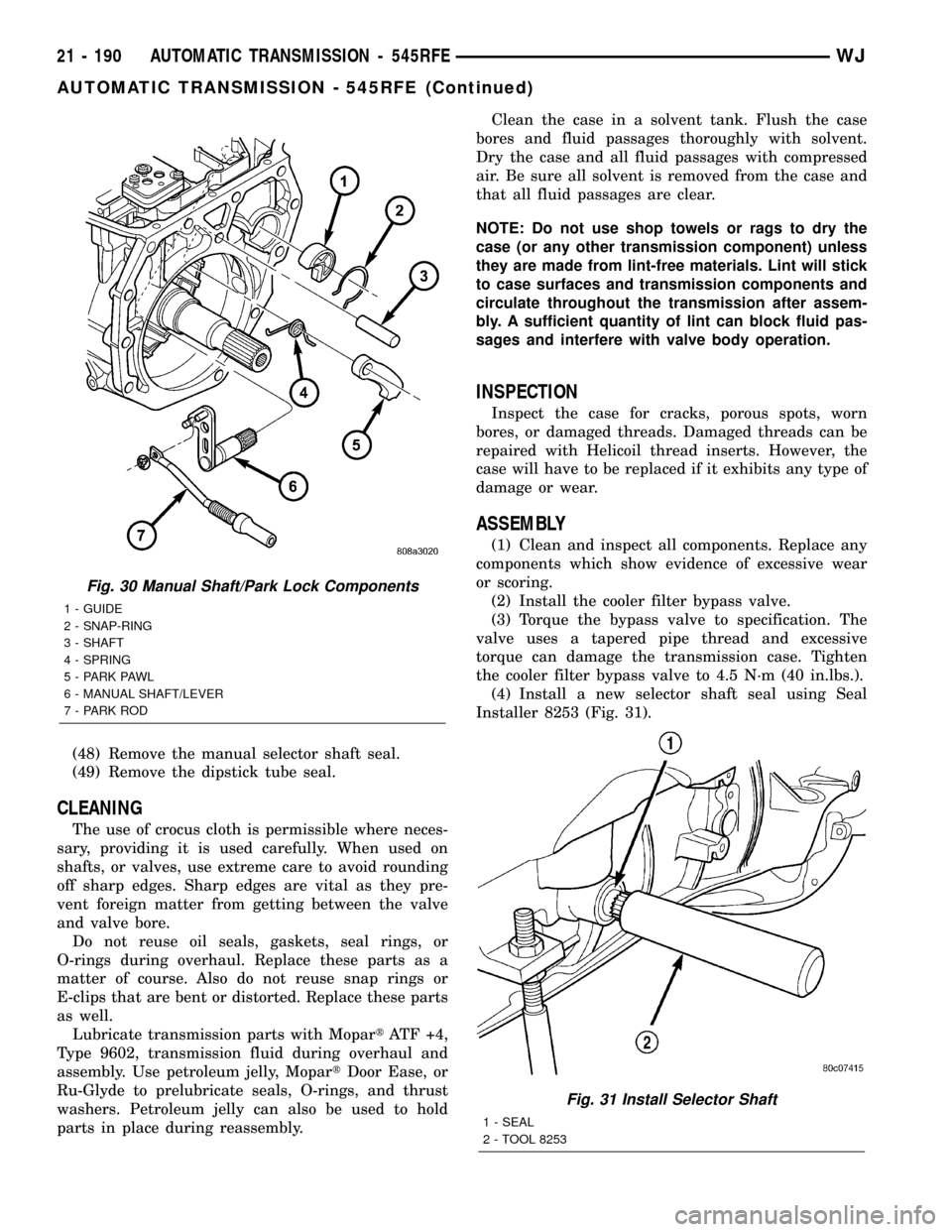

(48) Remove the manual selector shaft seal.

(49) Remove the dipstick tube seal.

CLEANING

The use of crocus cloth is permissible where neces-

sary, providing it is used carefully. When used on

shafts, or valves, use extreme care to avoid rounding

off sharp edges. Sharp edges are vital as they pre-

vent foreign matter from getting between the valve

and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or

E-clips that are bent or distorted. Replace these parts

as well.

Lubricate transmission parts with MopartATF +4,

Type 9602, transmission fluid during overhaul and

assembly. Use petroleum jelly, MopartDoor Ease, or

Ru-Glyde to prelubricate seals, O-rings, and thrust

washers. Petroleum jelly can also be used to hold

parts in place during reassembly.Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Dry the case and all fluid passages with compressed

air. Be sure all solvent is removed from the case and

that all fluid passages are clear.

NOTE: Do not use shop towels or rags to dry the

case (or any other transmission component) unless

they are made from lint-free materials. Lint will stick

to case surfaces and transmission components and

circulate throughout the transmission after assem-

bly. A sufficient quantity of lint can block fluid pas-

sages and interfere with valve body operation.

INSPECTION

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

ASSEMBLY

(1) Clean and inspect all components. Replace any

components which show evidence of excessive wear

or scoring.

(2) Install the cooler filter bypass valve.

(3) Torque the bypass valve to specification. The

valve uses a tapered pipe thread and excessive

torque can damage the transmission case. Tighten

the cooler filter bypass valve to 4.5 N´m (40 in.lbs.).

(4) Install a new selector shaft seal using Seal

Installer 8253 (Fig. 31).

Fig. 30 Manual Shaft/Park Lock Components

1 - GUIDE

2 - SNAP-RING

3 - SHAFT

4 - SPRING

5 - PARK PAWL

6 - MANUAL SHAFT/LEVER

7 - PARK ROD

Fig. 31 Install Selector Shaft

1 - SEAL

2 - TOOL 8253

21 - 190 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1710 of 2199

(5) Install the manual selector shaft and retaining

screw. Tighten the manual selector shaft retaining

screw to 28 N´m (250 in.lbs.).

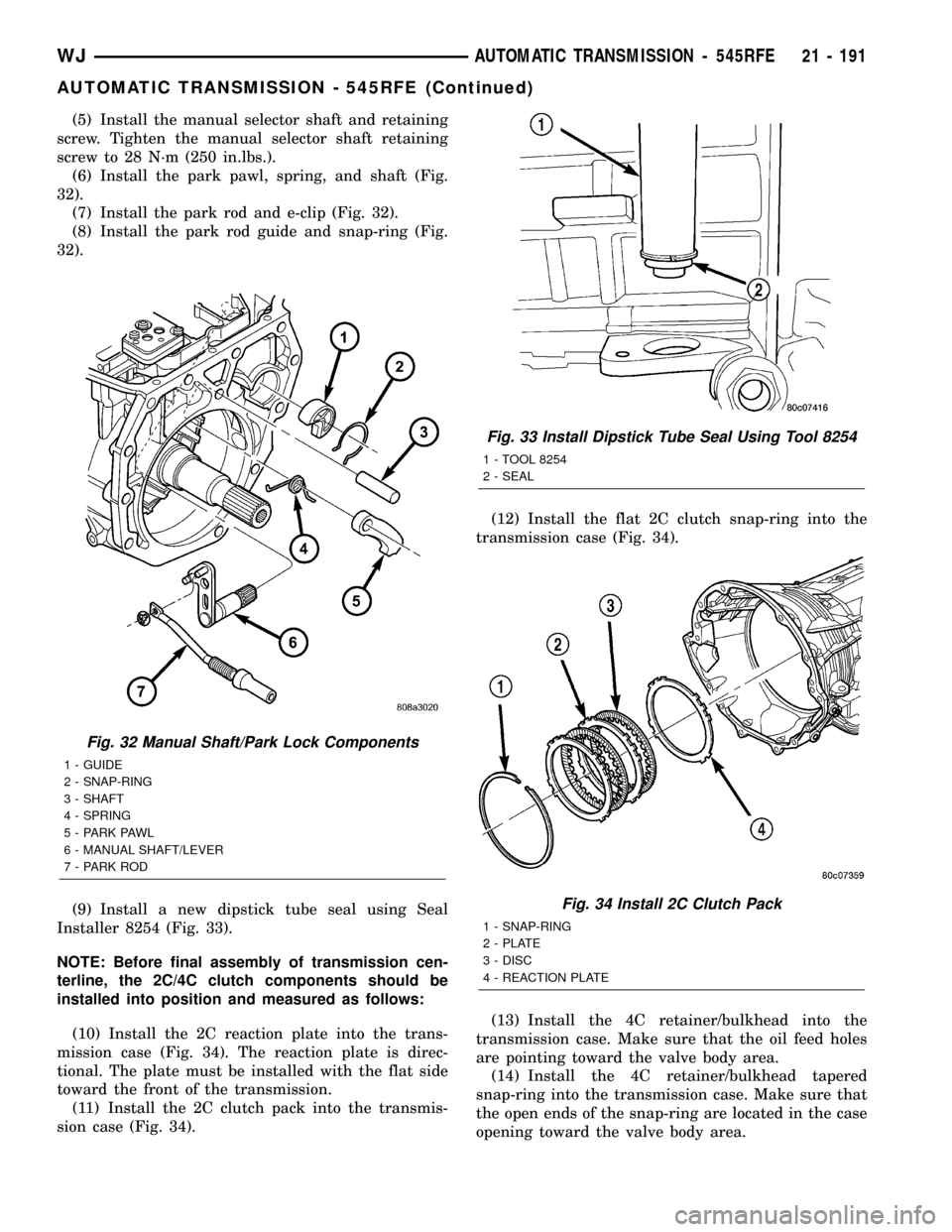

(6) Install the park pawl, spring, and shaft (Fig.

32).

(7) Install the park rod and e-clip (Fig. 32).

(8) Install the park rod guide and snap-ring (Fig.

32).

(9) Install a new dipstick tube seal using Seal

Installer 8254 (Fig. 33).

NOTE: Before final assembly of transmission cen-

terline, the 2C/4C clutch components should be

installed into position and measured as follows:

(10) Install the 2C reaction plate into the trans-

mission case (Fig. 34). The reaction plate is direc-

tional. The plate must be installed with the flat side

toward the front of the transmission.

(11) Install the 2C clutch pack into the transmis-

sion case (Fig. 34).(12) Install the flat 2C clutch snap-ring into the

transmission case (Fig. 34).

(13) Install the 4C retainer/bulkhead into the

transmission case. Make sure that the oil feed holes

are pointing toward the valve body area.

(14) Install the 4C retainer/bulkhead tapered

snap-ring into the transmission case. Make sure that

the open ends of the snap-ring are located in the case

opening toward the valve body area.

Fig. 32 Manual Shaft/Park Lock Components

1 - GUIDE

2 - SNAP-RING

3 - SHAFT

4 - SPRING

5 - PARK PAWL

6 - MANUAL SHAFT/LEVER

7 - PARK ROD

Fig. 33 Install Dipstick Tube Seal Using Tool 8254

1 - TOOL 8254

2 - SEAL

Fig. 34 Install 2C Clutch Pack

1 - SNAP-RING

2 - PLATE

3 - DISC

4 - REACTION PLATE

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 191

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1717 of 2199

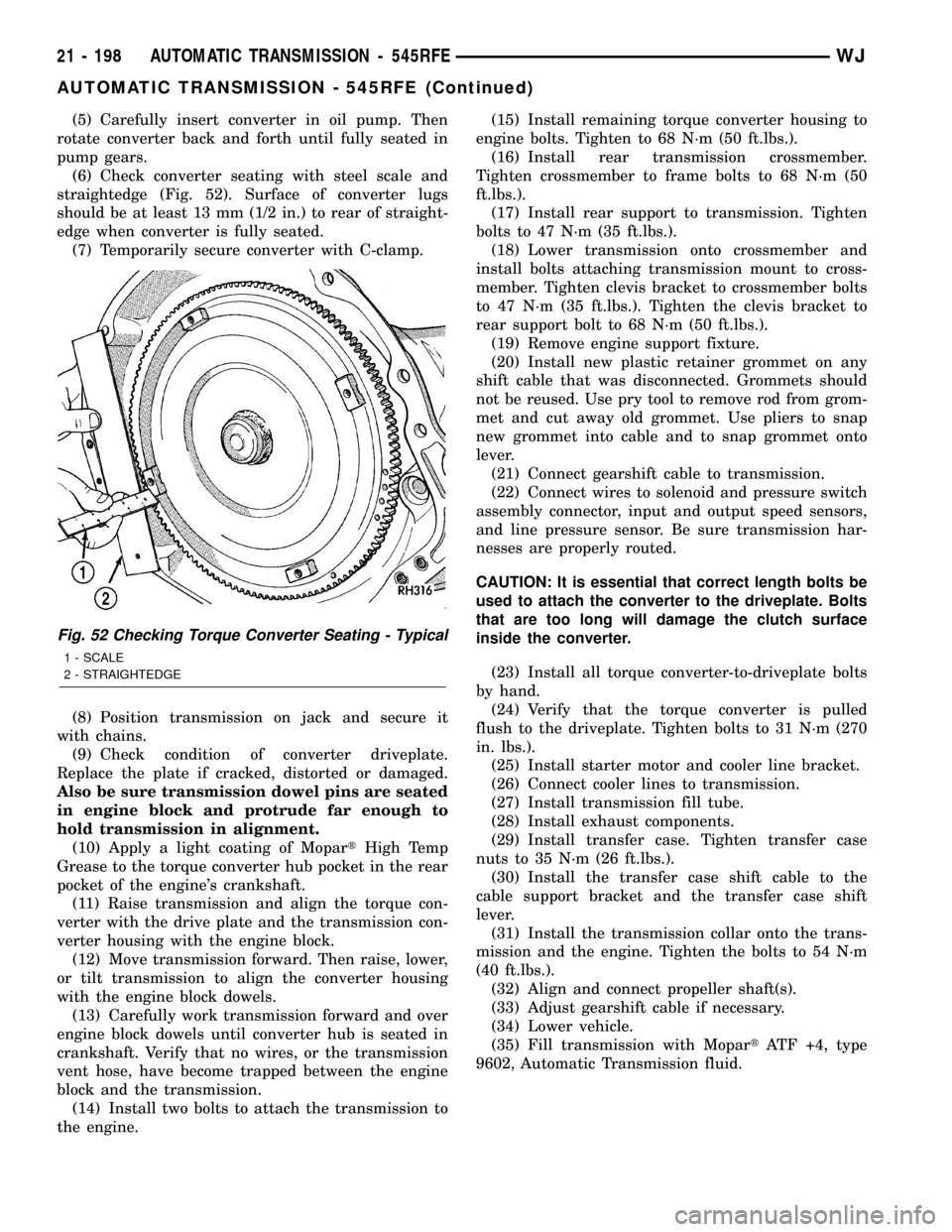

(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

(6) Check converter seating with steel scale and

straightedge (Fig. 52). Surface of converter lugs

should be at least 13 mm (1/2 in.) to rear of straight-

edge when converter is fully seated.

(7) Temporarily secure converter with C-clamp.

(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Apply a light coating of MopartHigh Temp

Grease to the torque converter hub pocket in the rear

pocket of the engine's crankshaft.

(11) Raise transmission and align the torque con-

verter with the drive plate and the transmission con-

verter housing with the engine block.

(12) Move transmission forward. Then raise, lower,

or tilt transmission to align the converter housing

with the engine block dowels.

(13) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft. Verify that no wires, or the transmission

vent hose, have become trapped between the engine

block and the transmission.

(14) Install two bolts to attach the transmission to

the engine.(15) Install remaining torque converter housing to

engine bolts. Tighten to 68 N´m (50 ft.lbs.).

(16) Install rear transmission crossmember.

Tighten crossmember to frame bolts to 68 N´m (50

ft.lbs.).

(17) Install rear support to transmission. Tighten

bolts to 47 N´m (35 ft.lbs.).

(18) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member. Tighten clevis bracket to crossmember bolts

to 47 N´m (35 ft.lbs.). Tighten the clevis bracket to

rear support bolt to 68 N´m (50 ft.lbs.).

(19) Remove engine support fixture.

(20) Install new plastic retainer grommet on any

shift cable that was disconnected. Grommets should

not be reused. Use pry tool to remove rod from grom-

met and cut away old grommet. Use pliers to snap

new grommet into cable and to snap grommet onto

lever.

(21) Connect gearshift cable to transmission.

(22) Connect wires to solenoid and pressure switch

assembly connector, input and output speed sensors,

and line pressure sensor. Be sure transmission har-

nesses are properly routed.

CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.

(23) Install all torque converter-to-driveplate bolts

by hand.

(24) Verify that the torque converter is pulled

flush to the driveplate. Tighten bolts to 31 N´m (270

in. lbs.).

(25) Install starter motor and cooler line bracket.

(26) Connect cooler lines to transmission.

(27) Install transmission fill tube.

(28) Install exhaust components.

(29) Install transfer case. Tighten transfer case

nuts to 35 N´m (26 ft.lbs.).

(30) Install the transfer case shift cable to the

cable support bracket and the transfer case shift

lever.

(31) Install the transmission collar onto the trans-

mission and the engine. Tighten the bolts to 54 N´m

(40 ft.lbs.).

(32) Align and connect propeller shaft(s).

(33) Adjust gearshift cable if necessary.

(34) Lower vehicle.

(35) Fill transmission with MopartATF +4, type

9602, Automatic Transmission fluid.

Fig. 52 Checking Torque Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

21 - 198 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)