power steering JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 628 of 2199

²Continuous Rear Wipe Mode- The internal

circuitry and hardware of the right (wiper) multi-

function switch control sleeve provides one continu-

ous rear wipe switch position.

²Front Washer Mode- The internal circuitry

and hardware of the right (wiper) multi-function

switch control stalk provide front washer system

operation.

²Front Wipe-After-Wash Mode- The internal

circuitry and hardware of the right (wiper) multi-

function switch control stalk provide a wipe-after-

wash mode.

²Front Wiper Mist Mode- The internal cir-

cuitry and hardware of the right (wiper) multi-func-

tion switch control stalk provide a front wiper system

mist mode.

²Intermittent Front Wipe Mode- The internal

circuitry and hardware of the right (wiper) multi-

function switch control knob provide an intermittent

front wipe mode with five delay interval positions,

except on models equipped with the optional auto-

matic wiper system.

²Intermittent Rear Wipe Mode- The internal

circuitry and hardware of the right (wiper) multi-

function switch control ring provide one fixed inter-

val intermittent rear wipe mode switch position.

²Rear Washer Mode- The internal circuitry and

hardware of the right (wiper) multi-function switch

control stalk provide rear washer system operation.

OPERATION

The right (wiper) multi-function switch uses a com-

bination of resistor multiplexed and conventionally

switched outputs to control the many functions and

features it provides. The switch receives battery cur-

rent on a fused ignition switch output (run-acc) cir-

cuit from a fuse in the Junction Block (JB) whenever

the ignition switch is in the On or Accessory posi-

tions, and receives ground from the Body Control

Module (BCM) on a windshield wiper switch return

circuit. The right (wiper) multi-function switch may

be diagnosed using conventional diagnostic tools and

methods.

Following are descriptions of how the right (wiper)

multi-function switch control stalk operates to control

the functions and features it provides:

²Automatic Wipe Mode- On models equipped

with the optional automatic wiper system, the control

knob on the end of the right (wiper) multi-function

switch control stalk is rotated to one of five minor

intermediate detents to select the desired automatic

wipe sensitivity level. The control knob is rotated

rearward (counterclockwise) to reduce the sensitivity

(increase the interval between wipes), or forward

(clockwise) to increase the sensitivity (decrease the

interval between wipes). The right (wiper) multi-function switch provides a resistor multiplexed out-

put to the Body Control Module (BCM) on a

windshield wiper switch mux circuit. The BCM

responds by sending an electronic message to the

Rain Sensor Module (RSM) over the Programmable

Communications Interface (PCI) data bus indicating

the selected sensitivity level, and by operating the

front wiper system based upon electronic wipe com-

mands received from the RSM over the PCI data bus.

²Continuous Front Wipe Modes- The control

knob on the end of the right (wiper) multi-function

switch control stalk is rotated to an intermediate

detent that is one detent rearward (counterclockwise)

from the full forward (clockwise) detent to select the

low speed continuous front wiper mode, or to its full

forward (clockwise) detent to select the high speed

continuous front wiper mode. For the low speed

mode, the multi-function switch provides a resistor

multiplexed output to the Body Control Module

(BCM) on a windshield wiper switch mux circuit, and

the BCM responds by energizing the wiper on/off

relay in the Power Distribution Center (PDC) for the

front low speed continuous wipe mode. For the high

speed mode, the multi-function switch provides the

same resistor multiplexed output to the BCM on the

windshield wiper switch mux circuit as the low speed

mode, but also provides a ground output to the BCM

on a wiper high control circuit. The BCM responds to

these inputs by energizing the wiper on/off relay and

the wiper high/low relay in the PDC for the front

high speed continuous wipe mode.

²Continuous Rear Wipe Mode- The control

ring on the right (wiper) multi-function switch con-

trol stalk is rotated to the most forward (clockwise)

detent to select the continuous rear wiper mode. The

multi-function switch provides a battery current out-

put to the rear wiper motor on a rear wiper motor

control circuit to signal the rear wiper module to

operate the rear wiper motor in the continuous wipe

mode.

²Front Washer Mode- The control stalk of the

right (wiper) multi-function switch is pulled toward

the steering wheel to momentarily activate the front

washer pump/motor in the front washer mode. The

front washer pump will continue to operate in the

front washer mode until the control stalk is released.

The right (wiper) multi-function switch provides a

battery current output on a washer pump motor

switch output circuit to energize the front washer

pump in the front washer mode.

²Front Wiper Mist Mode- The control stalk of

the right (wiper) multi-function switch is pushed

towards the floor to momentarily activate the front

wiper motor in the mist mode. The front wiper motor

will continue to operate in the mist mode until the

control stalk is released. The right (wiper) multi-

WJFRONT WIPERS/WASHERS 8R - 21

RIGHT MULTI-FUNCTION SWITCH (Continued)

Page 629 of 2199

function switch provides a resistor multiplexed out-

put to the Body Control Module (BCM) on a

windshield wiper switch mux circuit, and the BCM

responds by energizing the wiper on/off relay in the

Power Distribution Center (PDC) to operate the front

wiper motor momentarily at low speed to provide the

front wiper mist mode.

²Intermittent Front Wipe Mode- On models

not equipped with the optional automatic wiper sys-

tem, the control knob on the end of the right (wiper)

multi-function switch control stalk is rotated to one

of five minor intermediate detents to select the

desired intermittent front wipe delay interval. The

control knob is rotated rearward (counterclockwise)

to increase the delay, or forward (clockwise) to

decrease the delay. The right (wiper) multi-function

switch provides a resistor multiplexed output to the

Body Control Module (BCM) on a windshield wiper

switch mux circuit. The BCM responds by monitoring

electronic vehicle speed messages received from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus,

then energizing the wiper on/off relay in the Power

Distribution Center (PDC) to operate the front wiper

motor at the proper delay intervals.

²Intermittent Rear Wipe Mode- The control

ring on the right (wiper) multi-function switch con-

trol stalk is rotated to the center detent to select the

intermittent rear wiper mode. The right (wiper)

multi-function switch provides a battery current out-

put to the rear wiper motor on a rear wiper motor

delay control circuit to signal the rear wiper module

to operate the rear wiper in the intermittent wipe

mode.

²Rear Washer Mode- The right (wiper) multi-

function switch control stalk is pushed forward

toward the instrument panel to a momentary posi-

tions to activate the rear washer pump/motor in the

rear washer mode. The rear washer pump will con-

tinue to operate in the rear washer mode until the

control stalk is released. The right (wiper) multi-

function switch provides battery current on a rear

washer pump motor control circuit to energize the

rear washer pump in the rear washer mode.DIAGNOSIS AND TESTING - RIGHT MULTI-

FUNCTION SWITCH

Be certain to perform the diagnosis for the front

wiper system, front washer system, rear wiper sys-

tem, and/or rear washer system before testing the

right multi-function switch. (Refer to 8 - ELECTRI-

CAL/FRONT WIPERS/WASHERS - DIAGNOSIS

AND TESTING) or (Refer to 8 - ELECTRICAL/REAR

WIPERS/WASHERS - DIAGNOSIS AND TESTING).

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE PASSIVE RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG. SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE PASSIVE RESTRAINT

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right multi-function switch from

the steering column and disconnect the instrument

panel wire harness connector for the switch from the

switch connector receptacle.

(3) Using an ohmmeter, check the right multi-func-

tion switch continuity and resistances at the switch

terminals as shown in the Right Multi-Function

Switch test chart (Fig. 17).

8R - 22 FRONT WIPERS/WASHERSWJ

RIGHT MULTI-FUNCTION SWITCH (Continued)

Page 642 of 2199

stalk is moved to the rear Wash position, the Wash

position circuitry within the switch directs battery

current to the rear washer pump/motor unit, and to

both the rear wiper motor control and rear washer

switch output signal inputs of the rear wiper module

electronic circuitry, which causes the wiper motor to

run at a fixed cycle for as long as the Wash mode is

selected plus about three additional fixed wipe cycles.

The rear wiper module electronic circuitry controls

the switching of battery current to the rear wiper

motor brush, which controls wiper motor operation.

The intermittent wipe and wipe-after-wash features

of the rear wiper and washer system are both pro-

vided by the rear wiper module electronic circuitry.

The rear wiper module electronic circuitry also mon-

itors the liftgate flip-up glass ajar switch and will

park the rear wiper blade off of the glass any time it

senses that the liftgate flip-up glass is ajar, the igni-

tion switch is turned to the Off position, or the right

multi-function switch control sleeve is moved to the

Off position. This feature ensures that the rear wiper

blade will not interfere with or be damaged by the

operation of the liftgate flip-up glass. However, if the

ignition switch is turned to the Off position or the

liftgate flip-up glass is opened while the rear wiper is

operating, the right multi-function switch control

sleeve must be cycled to the Off position and back to

the On or Delay position after the ignition switch is

turned back On or the liftgate flip-up glass is closed

before the rear wiper will operate again.

Refer to the owner's manual in the vehicle glove

box for more information on the features and opera-

tion of the rear wiper and washer system.

DIAGNOSIS AND TESTING - REAR WIPER &

WASHER SYSTEM

WIPER SYSTEM

The diagnosis found here addresses an electrically

inoperative rear wiper system. If the rear wiper

motor operates, but the wiper does not move on the

liftgate glass, replace the faulty rear wiper module. If

the wiper operates, but chatters, lifts, or does not

clear the glass, clean and inspect the wiper system

components as required. (Refer to 8 - ELECTRICAL/

REAR WIPERS/WASHERS - INSPECTION) and

(Refer to 8 - ELECTRICAL/REAR WIPERS/WASH-

ERS - CLEANING). Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds.WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check that the interior lighting switch on the

control stalk of the left multi-function switch is not

in the dome lamp disable position. With all four

doors and the liftgate closed, open the liftgate flip-up

glass. The interior lamps should light. If not, depress

the cargo lamp lens to actuate the cargo lamp defeat

switch and the interior lamps should light. Close all

four doors, the liftgate and the liftgate flip-up glass.

Note whether the interior lamps remain lighted.

They should turn off after about thirty seconds. If

OK, go to Step 2. If not OK, go to Step 9.

(2) Check the fused B(+) fuse (Fuse8-15ampere)

in the Junction Block (JB). If OK, go to Step 3. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(3) Check for battery voltage at the fused B(+) fuse

(Fuse8-15ampere) in the JB. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(4) Check the fused ignition switch output (run-

acc) fuse (Fuse 29 - 10 ampere) in the JB. If OK, go

to Step 5. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(5) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run-acc) fuse (Fuse 29 - 10 ampere) in the

JB. If OK, turn the ignition switch to the Off position

and go to Step 6. If not OK, repair the open fused

ignition switch output (run-acc) circuit between the

JB and the ignition switch as required.

(6) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the right multi-function switch from the

switch connector receptacle. Reconnect the battery

negative cable. Turn the ignition switch to the On

position. Check for battery voltage at the fused igni-

tion switch output (run-acc) circuit cavity of the

instrument panel wire harness connector for the

right multi-function switch. If OK, go to Step 7. If

not OK, repair the open fused ignition switch output

WJREAR WIPERS/WASHERS 8R - 35

REAR WIPERS/WASHERS (Continued)

Page 661 of 2199

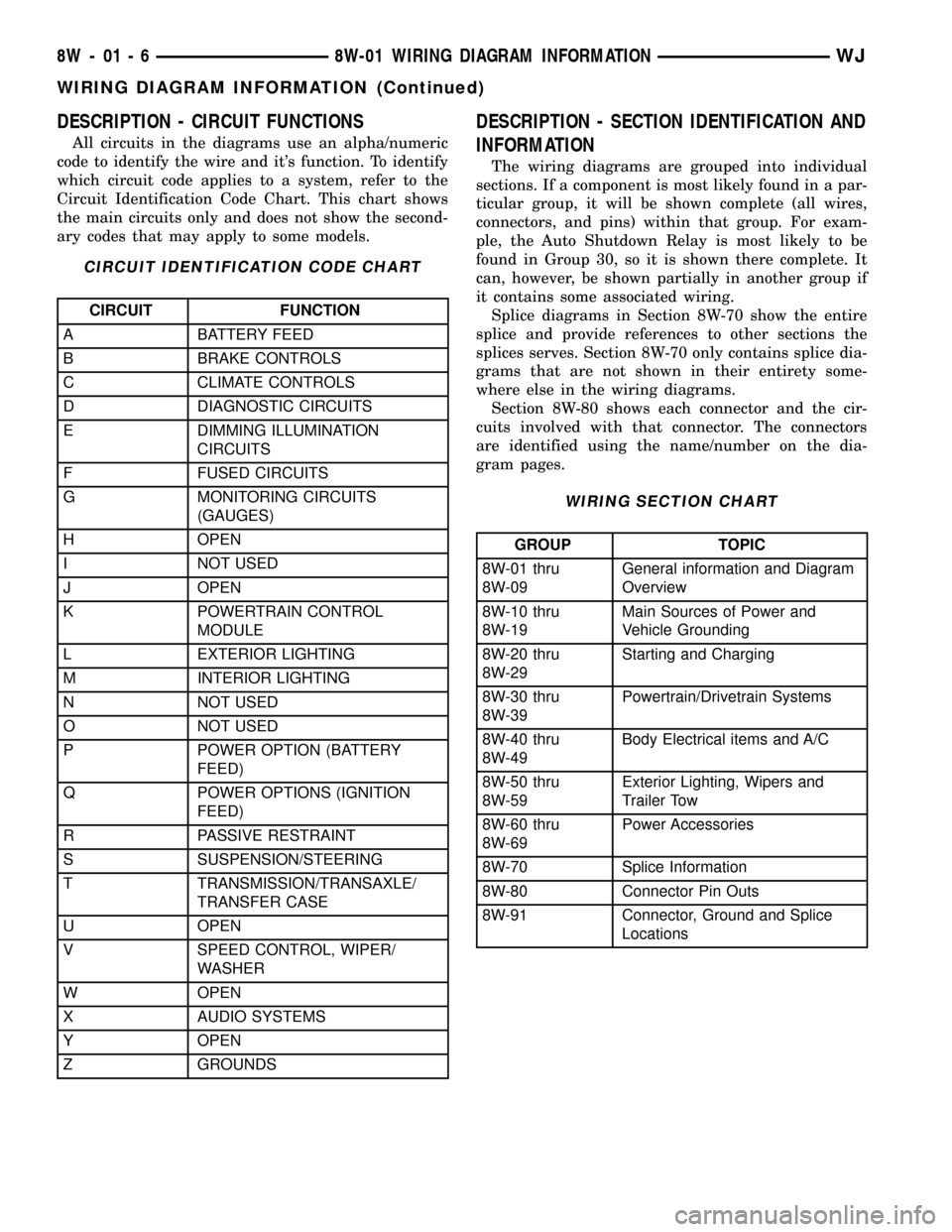

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONWJ

WIRING DIAGRAM INFORMATION (Continued)

Page 1179 of 2199

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Coil On Plug NO. 8 (4.7L) BK Right Side of Engine Near Fuel

Injector No.814, 15

Coil Rail (4.0L) BK Right Rear of Engine 10, 11

Compact Disc Changer BK Near Radio N/S

Compact Disc Changer BK Right Rear Quarter Panel 37

Controller Antilock Brake BK Left Front Engine Compartment 3, 4

Coolant Level Sensor LT GY Right Rear of Engine 5

Crankcase Heater (Diesel) BK Near T/O for G105 8

Crankshaft Position Sensor

(Diesel)BK Rear of Engine Near Transmission

Bell HousingN/S

Crankshaft Position Sensor

(Gas)BK Rear of Engine Near Transmission

Bell Housing10, 11, 14, 15, 17

Data Link Connector BK Under Lower Driver's Side of

Instrument Panel20, 21, 22

Diagnostic Junction Port BK At Steering Column 23

Driver Airbag Squib 1 BK In Steering Wheel N/S

Driver Airbag Squib 2 BK In Steering Wheel N/S

Driver Blend Door Motor/

Actuator (AZC)BK On HVAC Housing N/S

Driver Cylinder Lock Switch GY In Driver Door 24, 25

Driver Door Lock Motor/Ajar

SwitchBK In Driver Door 24, 25

Driver Door Module - C1 WT In Driver Door 24, 25

Driver Door Module - C2 BK In Driver Door N/S

Driver Door Module - C3 BK In Driver Door N/S

Driver Front Door Courtesy

LampBK In Driver Door N/S

Driver Front Power Window

MotorBK In Driver Door 24, 25

Driver Heated Seat Back

(Premium I/III)GN At Driver Seat N/S

Driver Heated Seat Cushion

(Premium I/III)BK At Driver Seat N/S

Driver Heated Seat Switch WT Center of Instrument Panel 19 20, 21

Driver Lumbar Motor

(Midline/Premium)BK At Driver Seat N/S

Driver Lumbar Switch

(Midline/Premium)WT At Driver Seat N/S

Driver Power Mirror BK At Driver Door N/S

Driver Power Seat Front Riser

MotorRD At Driver Seat N/S

Driver Power Seat Front Riser

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Horizontal

MotorBK At Driver Seat N/S

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1230 of 2199

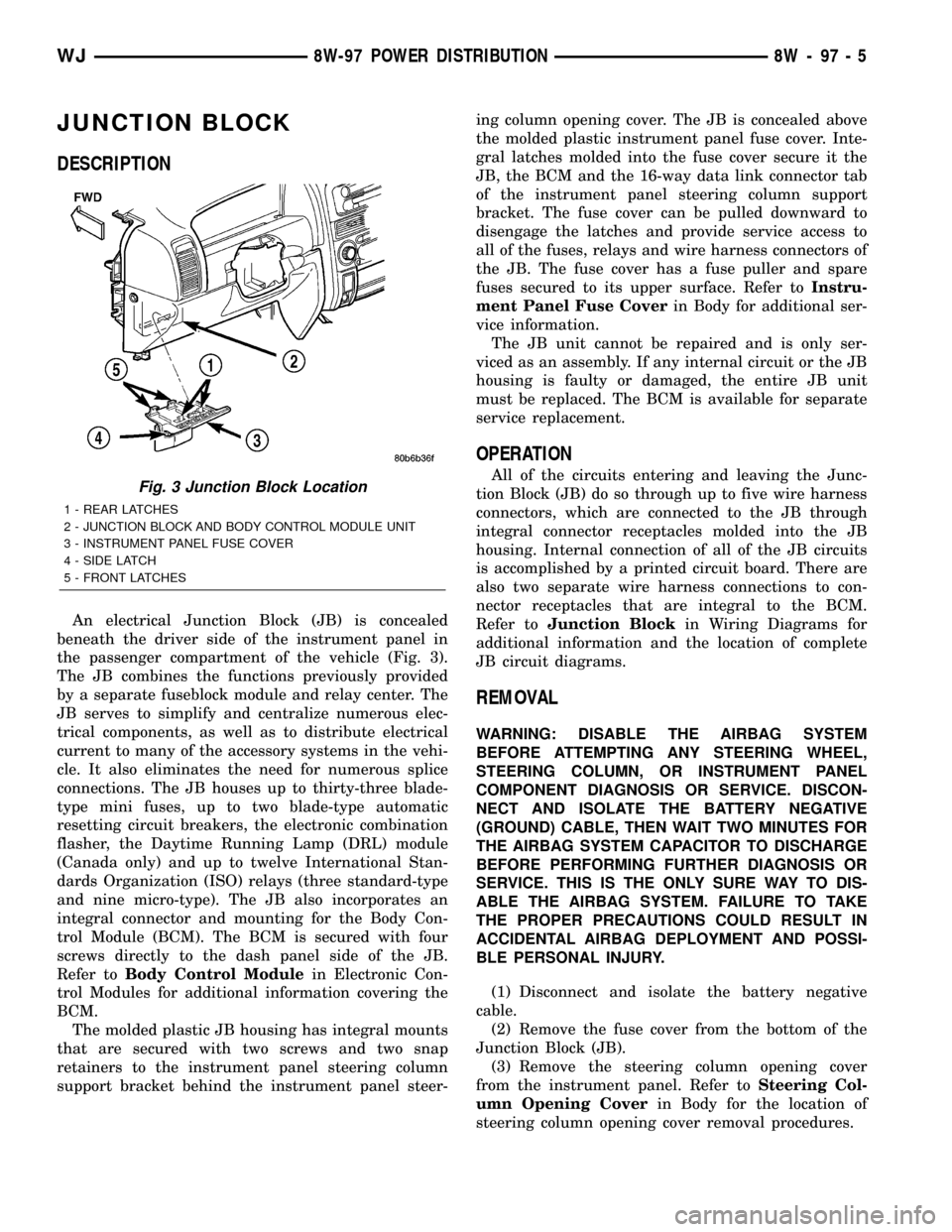

JUNCTION BLOCK

DESCRIPTION

An electrical Junction Block (JB) is concealed

beneath the driver side of the instrument panel in

the passenger compartment of the vehicle (Fig. 3).

The JB combines the functions previously provided

by a separate fuseblock module and relay center. The

JB serves to simplify and centralize numerous elec-

trical components, as well as to distribute electrical

current to many of the accessory systems in the vehi-

cle. It also eliminates the need for numerous splice

connections. The JB houses up to thirty-three blade-

type mini fuses, up to two blade-type automatic

resetting circuit breakers, the electronic combination

flasher, the Daytime Running Lamp (DRL) module

(Canada only) and up to twelve International Stan-

dards Organization (ISO) relays (three standard-type

and nine micro-type). The JB also incorporates an

integral connector and mounting for the Body Con-

trol Module (BCM). The BCM is secured with four

screws directly to the dash panel side of the JB.

Refer toBody Control Modulein Electronic Con-

trol Modules for additional information covering the

BCM.

The molded plastic JB housing has integral mounts

that are secured with two screws and two snap

retainers to the instrument panel steering column

support bracket behind the instrument panel steer-ing column opening cover. The JB is concealed above

the molded plastic instrument panel fuse cover. Inte-

gral latches molded into the fuse cover secure it the

JB, the BCM and the 16-way data link connector tab

of the instrument panel steering column support

bracket. The fuse cover can be pulled downward to

disengage the latches and provide service access to

all of the fuses, relays and wire harness connectors of

the JB. The fuse cover has a fuse puller and spare

fuses secured to its upper surface. Refer toInstru-

ment Panel Fuse Coverin Body for additional ser-

vice information.

The JB unit cannot be repaired and is only ser-

viced as an assembly. If any internal circuit or the JB

housing is faulty or damaged, the entire JB unit

must be replaced. The BCM is available for separate

service replacement.

OPERATION

All of the circuits entering and leaving the Junc-

tion Block (JB) do so through up to five wire harness

connectors, which are connected to the JB through

integral connector receptacles molded into the JB

housing. Internal connection of all of the JB circuits

is accomplished by a printed circuit board. There are

also two separate wire harness connections to con-

nector receptacles that are integral to the BCM.

Refer toJunction Blockin Wiring Diagrams for

additional information and the location of complete

JB circuit diagrams.

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse cover from the bottom of the

Junction Block (JB).

(3) Remove the steering column opening cover

from the instrument panel. Refer toSteering Col-

umn Opening Coverin Body for the location of

steering column opening cover removal procedures.

Fig. 3 Junction Block Location

1 - REAR LATCHES

2 - JUNCTION BLOCK AND BODY CONTROL MODULE UNIT

3 - INSTRUMENT PANEL FUSE COVER

4 - SIDE LATCH

5 - FRONT LATCHES

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 5

Page 1231 of 2199

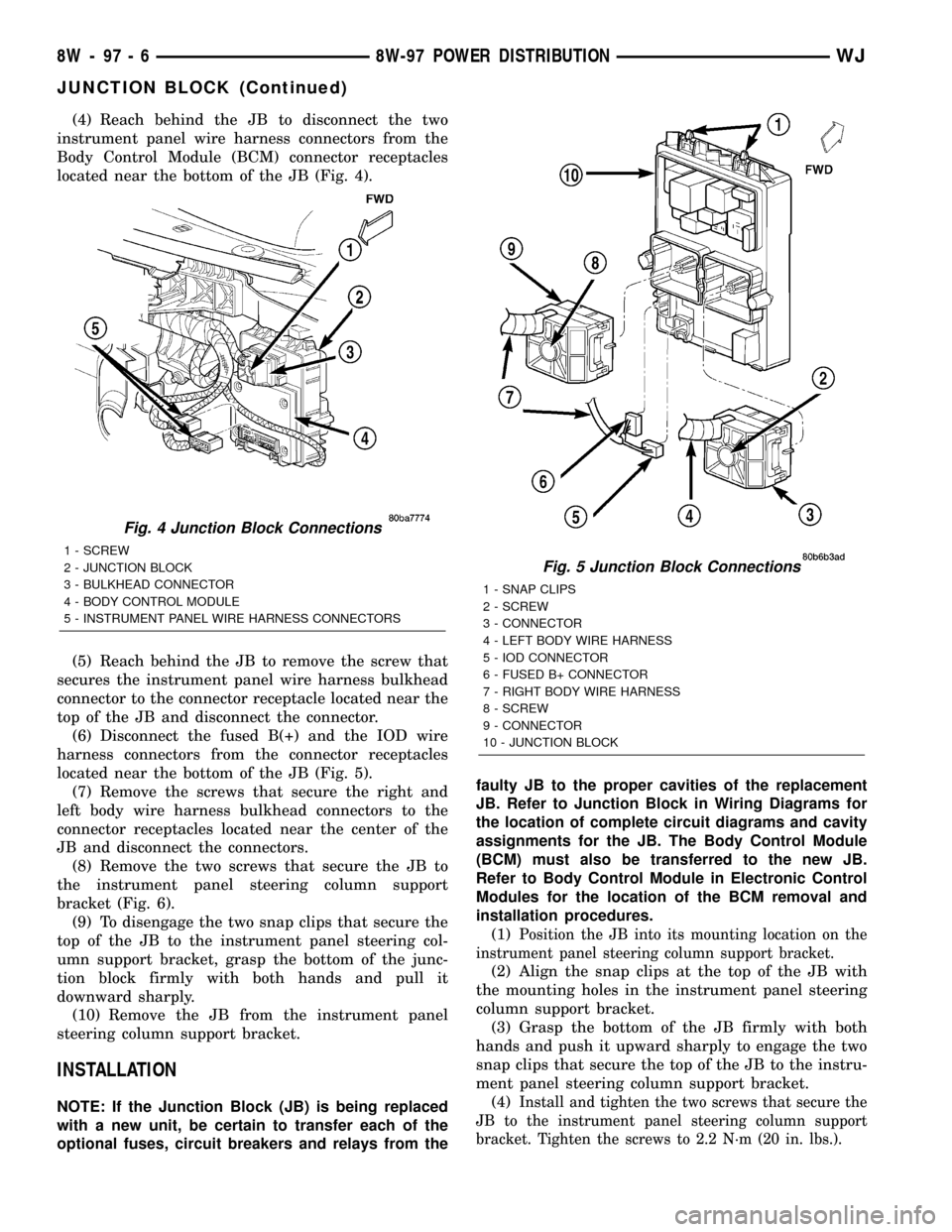

(4) Reach behind the JB to disconnect the two

instrument panel wire harness connectors from the

Body Control Module (BCM) connector receptacles

located near the bottom of the JB (Fig. 4).

(5) Reach behind the JB to remove the screw that

secures the instrument panel wire harness bulkhead

connector to the connector receptacle located near the

top of the JB and disconnect the connector.

(6) Disconnect the fused B(+) and the IOD wire

harness connectors from the connector receptacles

located near the bottom of the JB (Fig. 5).

(7) Remove the screws that secure the right and

left body wire harness bulkhead connectors to the

connector receptacles located near the center of the

JB and disconnect the connectors.

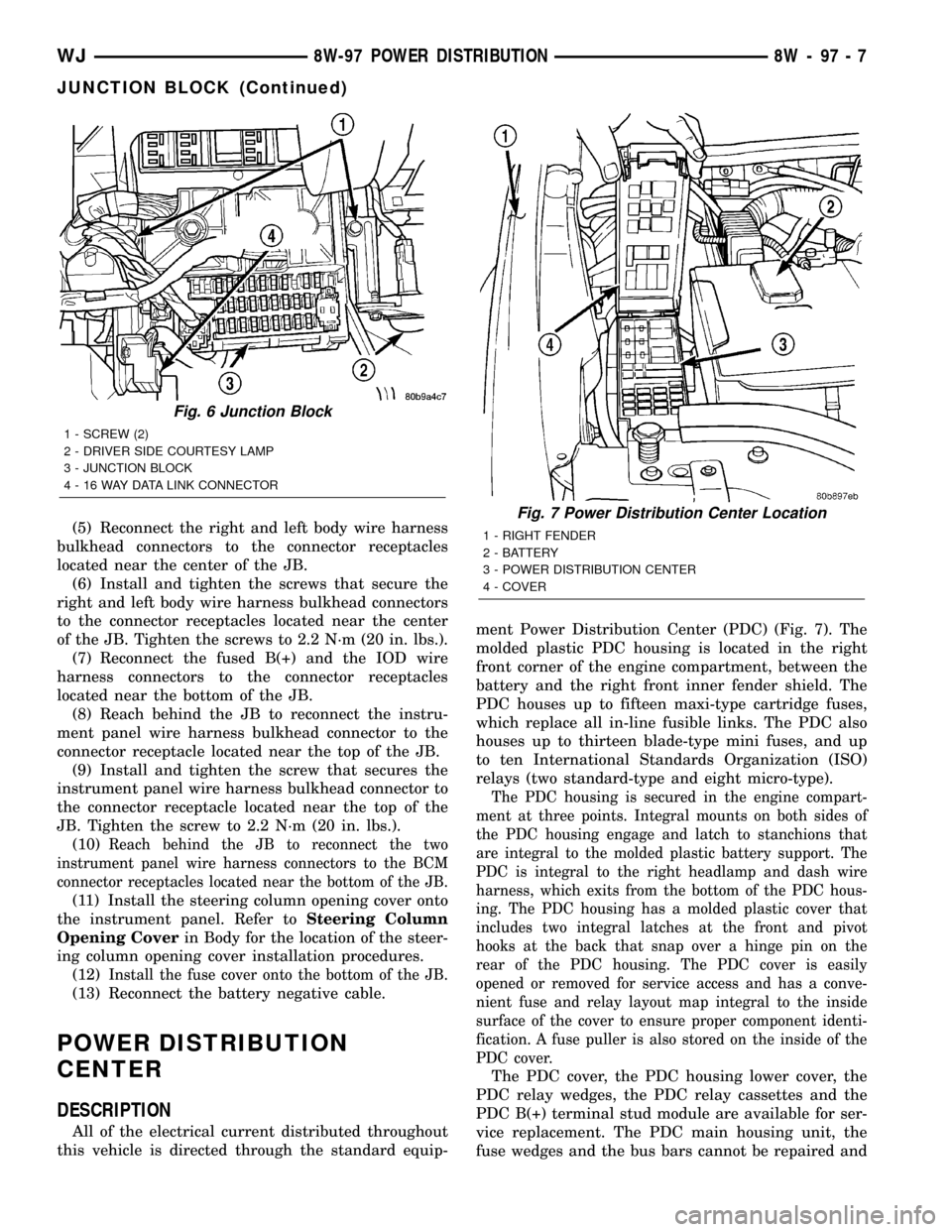

(8) Remove the two screws that secure the JB to

the instrument panel steering column support

bracket (Fig. 6).

(9) To disengage the two snap clips that secure the

top of the JB to the instrument panel steering col-

umn support bracket, grasp the bottom of the junc-

tion block firmly with both hands and pull it

downward sharply.

(10) Remove the JB from the instrument panel

steering column support bracket.

INSTALLATION

NOTE: If the Junction Block (JB) is being replaced

with a new unit, be certain to transfer each of the

optional fuses, circuit breakers and relays from thefaulty JB to the proper cavities of the replacement

JB. Refer to Junction Block in Wiring Diagrams for

the location of complete circuit diagrams and cavity

assignments for the JB. The Body Control Module

(BCM) must also be transferred to the new JB.

Refer to Body Control Module in Electronic Control

Modules for the location of the BCM removal and

installation procedures.

(1)

Position the JB into its mounting location on the

instrument panel steering column support bracket.

(2) Align the snap clips at the top of the JB with

the mounting holes in the instrument panel steering

column support bracket.

(3) Grasp the bottom of the JB firmly with both

hands and push it upward sharply to engage the two

snap clips that secure the top of the JB to the instru-

ment panel steering column support bracket.

(4)

Install and tighten the two screws that secure the

JB to the instrument panel steering column support

bracket. Tighten the screws to 2.2 N´m (20 in. lbs.).

Fig. 4 Junction Block Connections

1 - SCREW

2 - JUNCTION BLOCK

3 - BULKHEAD CONNECTOR

4 - BODY CONTROL MODULE

5 - INSTRUMENT PANEL WIRE HARNESS CONNECTORS

Fig. 5 Junction Block Connections

1 - SNAP CLIPS

2 - SCREW

3 - CONNECTOR

4 - LEFT BODY WIRE HARNESS

5 - IOD CONNECTOR

6 - FUSED B+ CONNECTOR

7 - RIGHT BODY WIRE HARNESS

8 - SCREW

9 - CONNECTOR

10 - JUNCTION BLOCK

8W - 97 - 6 8W-97 POWER DISTRIBUTIONWJ

JUNCTION BLOCK (Continued)

Page 1232 of 2199

(5) Reconnect the right and left body wire harness

bulkhead connectors to the connector receptacles

located near the center of the JB.

(6) Install and tighten the screws that secure the

right and left body wire harness bulkhead connectors

to the connector receptacles located near the center

of the JB. Tighten the screws to 2.2 N´m (20 in. lbs.).

(7) Reconnect the fused B(+) and the IOD wire

harness connectors to the connector receptacles

located near the bottom of the JB.

(8) Reach behind the JB to reconnect the instru-

ment panel wire harness bulkhead connector to the

connector receptacle located near the top of the JB.

(9) Install and tighten the screw that secures the

instrument panel wire harness bulkhead connector to

the connector receptacle located near the top of the

JB. Tighten the screw to 2.2 N´m (20 in. lbs.).

(10)

Reach behind the JB to reconnect the two

instrument panel wire harness connectors to the BCM

connector receptacles located near the bottom of the JB.

(11) Install the steering column opening cover onto

the instrument panel. Refer toSteering Column

Opening Coverin Body for the location of the steer-

ing column opening cover installation procedures.

(12)

Install the fuse cover onto the bottom of the JB.

(13) Reconnect the battery negative cable.

POWER DISTRIBUTION

CENTER

DESCRIPTION

All of the electrical current distributed throughout

this vehicle is directed through the standard equip-ment Power Distribution Center (PDC) (Fig. 7). The

molded plastic PDC housing is located in the right

front corner of the engine compartment, between the

battery and the right front inner fender shield. The

PDC houses up to fifteen maxi-type cartridge fuses,

which replace all in-line fusible links. The PDC also

houses up to thirteen blade-type mini fuses, and up

to ten International Standards Organization (ISO)

relays (two standard-type and eight micro-type).

The PDC housing is secured in the engine compart-

ment at three points. Integral mounts on both sides of

the PDC housing engage and latch to stanchions that

are integral to the molded plastic battery support. The

PDC is integral to the right headlamp and dash wire

harness, which exits from the bottom of the PDC hous-

ing. The PDC housing has a molded plastic cover that

includes two integral latches at the front and pivot

hooks at the back that snap over a hinge pin on the

rear of the PDC housing. The PDC cover is easily

opened or removed for service access and has a conve-

nient fuse and relay layout map integral to the inside

surface of the cover to ensure proper component identi-

fication. A fuse puller is also stored on the inside of the

PDC cover.

The PDC cover, the PDC housing lower cover, the

PDC relay wedges, the PDC relay cassettes and the

PDC B(+) terminal stud module are available for ser-

vice replacement. The PDC main housing unit, the

fuse wedges and the bus bars cannot be repaired and

Fig. 6 Junction Block

1 - SCREW (2)

2 - DRIVER SIDE COURTESY LAMP

3 - JUNCTION BLOCK

4 - 16 WAY DATA LINK CONNECTOR

Fig. 7 Power Distribution Center Location

1 - RIGHT FENDER

2 - BATTERY

3 - POWER DISTRIBUTION CENTER

4 - COVER

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 7

JUNCTION BLOCK (Continued)

Page 1237 of 2199

PDC LOWER COVER INSTALLATION

(1) Align the PDC housing lower cover on the bot-

tom of the PDC.

(2) Evenly press the lower cover into place until

latches are fully engaged.

(3) Where the right headlamp and dash harness

enters the PDC, tape the harness securely to the

trough formation on the PDC lower cover.

(4) Install the PDC in its mounting location on the

battery support.

(5) Install the battery wire harness over the two

PDC B+ terminal studs. Torque the nuts to 11.3 N´m

(100 in. lbs.).

(6) Install the battery. Refer to Battery System for

the procedure.

(7) Install the PDC cover.

INSTALLATION

The Power Distribution Center (PDC) main hous-

ing unit, the PDC fuse wedges and the PDC bus bars

cannot be repaired and are only serviced as a unit

with the right headlamp and dash wire harness. If

the PDC main housing unit, the fuse wedges or the

bus bars are faulty or damaged, the entire PDC and

right headlamp and dash wire harness unit must be

replaced.

(1) Position the PDC and the right headlamp and

dash wire harness unit in the engine compartment.

(2) Engage the PDC housing mounts with the

stanchions of the battery support and push the unit

downward until the mount latches fully engage the

mounting tabs on the stanchions.

(3) Install the two-holed eyelet of the battery wire

harness PDC take outs onto the two PDC B(+) termi-

nal studs.

(4) Install and tighten the nuts that secure the

eyelet of the battery wire harness PDC take outs to

the B(+) terminal studs. Tighten the nuts to 11.3

N´m (100 in. lbs.).

(5) Engage each of the retainers that secure the

right headlamp and dash wire harness to the vehicle

body and chassis components. Refer toConnector

Locationsin Wiring Diagrams for the location of

more information on the right headlamp and dash

wire harness retainer locations.

(6) Install all of the fasteners that secure each of

the right headlamp and dash wire harness ground

eyelets to the vehicle body and chassis components.

Refer toConnector Locationsin Wiring Diagrams

for the location of more information on the ground

eyelet locations.

(7) Reconnect each of the right headlamp and dash

wire harness connectors. Refer toConnector Loca-

tionsin Wiring Diagrams for the location of more

information on the right headlamp and dash wire

harness connector locations. For connectors securedwith screws, tighten the screws to 4.3 N´m (38 in.

lbs.).

(8) Reconnect the battery negative cable.

POWER OUTLET

DESCRIPTION - FRONT POWER OUTLET

An accessory power outlet is standard equipment

on this model. The power outlet is installed in the

instrument panel center lower bezel, which is located

near the bottom of the instrument panel center stack

area, below the heater and air conditioner controls.

The power outlet base is secured by a snap fit within

the center lower bezel. A hinged door with an over-

center spring flips closed to conceal and protect the

power outlet base when the power outlet is not being

used, and flips open below the center lower bezel

while the power outlet is in use.

The power outlet receptacle unit and the power

outlet door are each available for service replace-

ment.

OPERATION - FRONT POWER OUTLET

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet receives battery voltage from a fuse

in the junction block at all times.

While the power outlet is very similar to a cigar

lighter base unit, it does not include the two small

spring-clip retainers inside the bottom of the recepta-

cle shell that are used to secure the cigar lighter

heating element to the insulated contact.

DIAGNOSIS AND TESTING - POWER OUTLET

For complete circuit diagrams, refer toHorn/Ci-

gar Lighter/Power Outletin Wiring Diagrams.

WARNING: REFER TO RESTRAINTS BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the Power Dis-

tribution Center (PDC) fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

8W - 97 - 12 8W-97 POWER DISTRIBUTIONWJ

POWER DISTRIBUTION CENTER (Continued)

Page 1239 of 2199

The cigar lighter relay cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING - POWER OUTLET

RELAY

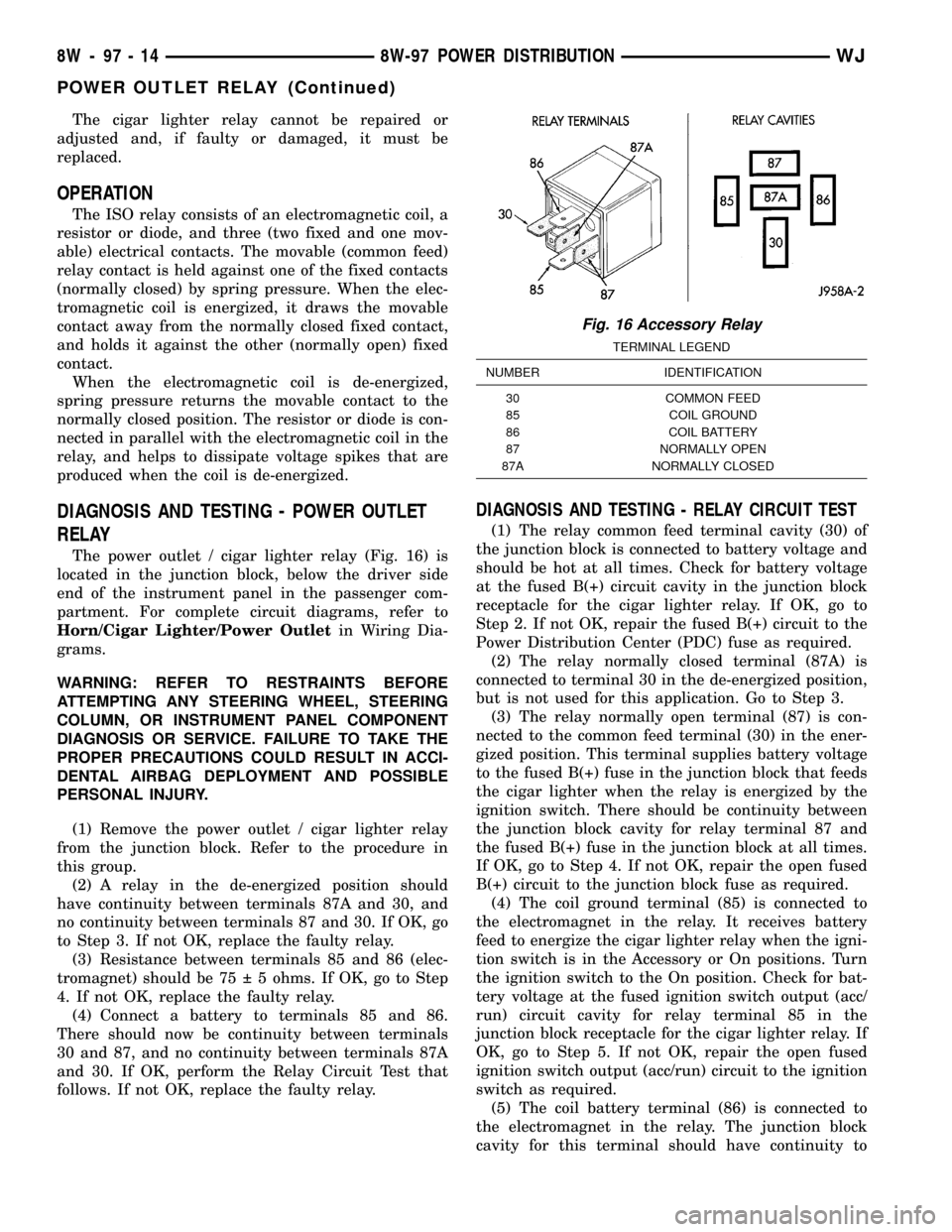

The power outlet / cigar lighter relay (Fig. 16) is

located in the junction block, below the driver side

end of the instrument panel in the passenger com-

partment. For complete circuit diagrams, refer to

Horn/Cigar Lighter/Power Outletin Wiring Dia-

grams.

WARNING: REFER TO RESTRAINTS BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the power outlet / cigar lighter relay

from the junction block. Refer to the procedure in

this group.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

DIAGNOSIS AND TESTING - RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) of

the junction block is connected to battery voltage and

should be hot at all times. Check for battery voltage

at the fused B(+) circuit cavity in the junction block

receptacle for the cigar lighter relay. If OK, go to

Step 2. If not OK, repair the fused B(+) circuit to the

Power Distribution Center (PDC) fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the fused B(+) fuse in the junction block that feeds

the cigar lighter when the relay is energized by the

ignition switch. There should be continuity between

the junction block cavity for relay terminal 87 and

the fused B(+) fuse in the junction block at all times.

If OK, go to Step 4. If not OK, repair the open fused

B(+) circuit to the junction block fuse as required.

(4) The coil ground terminal (85) is connected to

the electromagnet in the relay. It receives battery

feed to energize the cigar lighter relay when the igni-

tion switch is in the Accessory or On positions. Turn

the ignition switch to the On position. Check for bat-

tery voltage at the fused ignition switch output (acc/

run) circuit cavity for relay terminal 85 in the

junction block receptacle for the cigar lighter relay. If

OK, go to Step 5. If not OK, repair the open fused

ignition switch output (acc/run) circuit to the ignition

switch as required.

(5) The coil battery terminal (86) is connected to

the electromagnet in the relay. The junction block

cavity for this terminal should have continuity to

Fig. 16 Accessory Relay

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8W - 97 - 14 8W-97 POWER DISTRIBUTIONWJ

POWER OUTLET RELAY (Continued)