Oil plug JEEP GRAND CHEROKEE 2002 WJ / 2.G Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1374 of 2199

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhib-

ited loss of oil pressure, run the engine for about five

minutes before checking oil level. Checking engine oil

level on a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil if level is below the SAFE ZONE on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Remove oil fill cap.

(3) Hoist and support vehicle on safety stands.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase.

(7) Remove oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine. Refer to the WARNING at beginning of this

section.

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

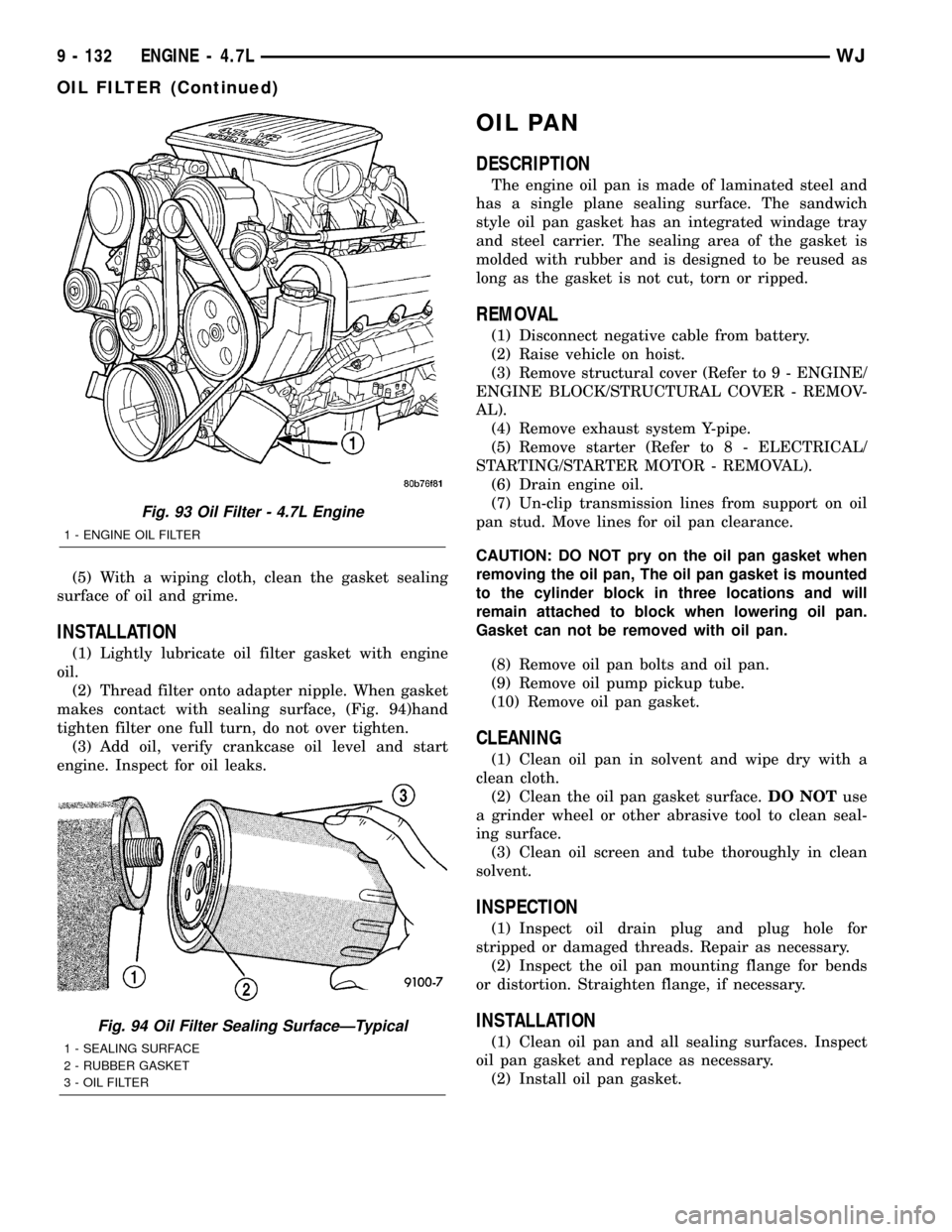

(3) Rotate the oil filter counterclockwise (Fig. 93)to

remove it from the cylinder block oil filter boss.

(4) When filter separates from cylinder block oil

filter boss, tip gasket end upward to minimize oil

spill. Remove filter from vehicle.

NOTE: Make sure filter gasket was removed with fil-

ter.

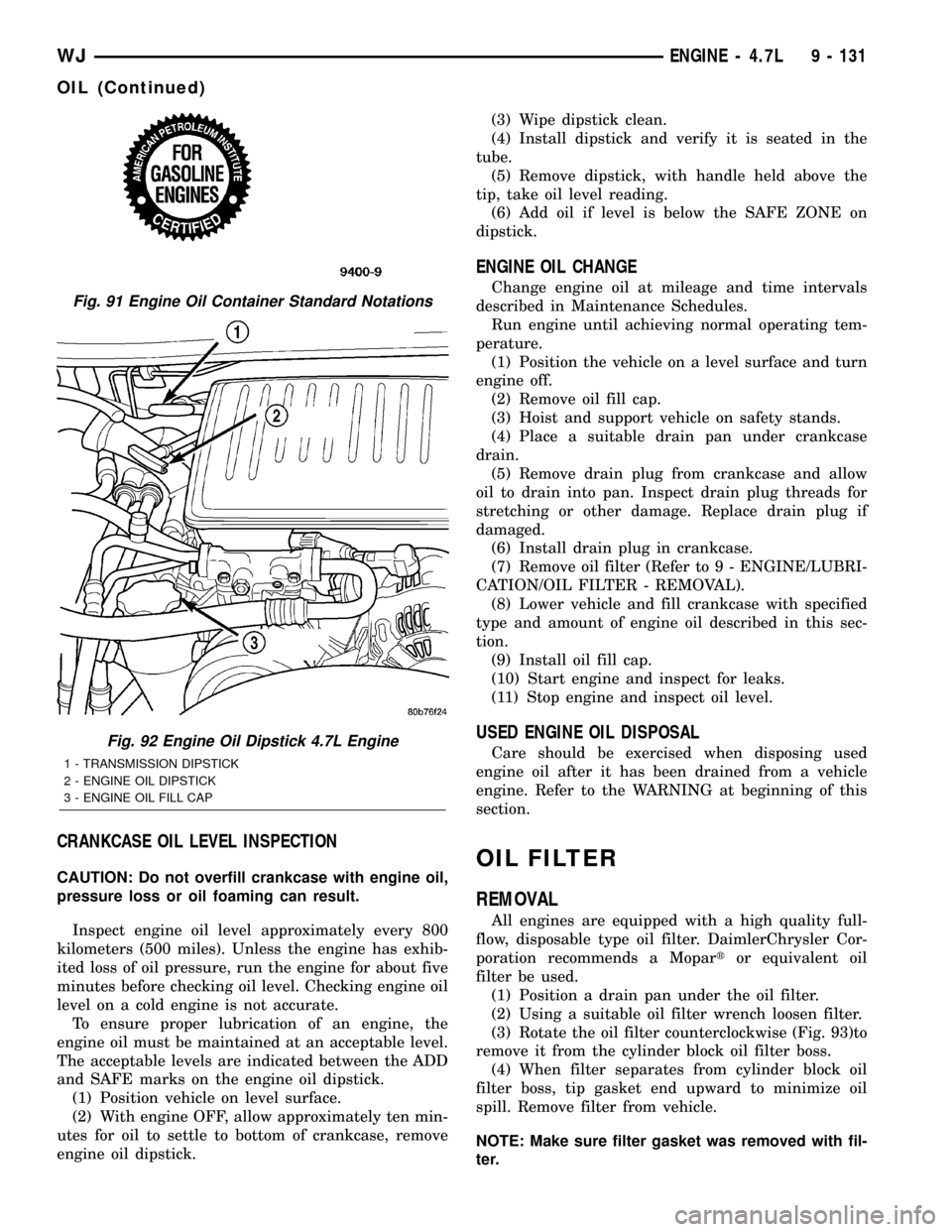

Fig. 91 Engine Oil Container Standard Notations

Fig. 92 Engine Oil Dipstick 4.7L Engine

1 - TRANSMISSION DIPSTICK

2 - ENGINE OIL DIPSTICK

3 - ENGINE OIL FILL CAP

WJENGINE - 4.7L 9 - 131

OIL (Continued)

Page 1375 of 2199

(5) With a wiping cloth, clean the gasket sealing

surface of oil and grime.

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 94)hand

tighten filter one full turn, do not over tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

OIL PAN

DESCRIPTION

The engine oil pan is made of laminated steel and

has a single plane sealing surface. The sandwich

style oil pan gasket has an integrated windage tray

and steel carrier. The sealing area of the gasket is

molded with rubber and is designed to be reused as

long as the gasket is not cut, torn or ripped.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Remove structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - REMOV-

AL).

(4) Remove exhaust system Y-pipe.

(5) Remove starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

(6) Drain engine oil.

(7) Un-clip transmission lines from support on oil

pan stud. Move lines for oil pan clearance.

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when lowering oil pan.

Gasket can not be removed with oil pan.

(8) Remove oil pan bolts and oil pan.

(9) Remove oil pump pickup tube.

(10) Remove oil pan gasket.

CLEANING

(1) Clean oil pan in solvent and wipe dry with a

clean cloth.

(2) Clean the oil pan gasket surface.DO NOTuse

a grinder wheel or other abrasive tool to clean seal-

ing surface.

(3) Clean oil screen and tube thoroughly in clean

solvent.

INSPECTION

(1) Inspect oil drain plug and plug hole for

stripped or damaged threads. Repair as necessary.

(2) Inspect the oil pan mounting flange for bends

or distortion. Straighten flange, if necessary.

INSTALLATION

(1) Clean oil pan and all sealing surfaces. Inspect

oil pan gasket and replace as necessary.

(2) Install oil pan gasket.

Fig. 93 Oil Filter - 4.7L Engine

1 - ENGINE OIL FILTER

Fig. 94 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

9 - 132 ENGINE - 4.7LWJ

OIL FILTER (Continued)

Page 1377 of 2199

OIL PUMP

REMOVAL

(1) Remove the oil pan and pick-up tube (Refer to

9 - ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(2) Remove the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(3) Remove the timing chains and tensioners

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

(4) Remove the four bolts, primary timing chain

tensioner and the oil pump.

DISASSEMBLY

(1) Remove oil pump cover screws and lift off cover

plate.

(2) Remove pump inner and outer rotors.

NOTE: Once the oil pressure relief valve, cup plug,

and pin are removed, the pump assembly must be

replaced.

(3) If it is necessary to remove the pressure relief

valve, drive the roll pin from pump housing and

remove cup plug, spring and valve.

CLEANING

(1) Wash all parts in a suitable solvent.

INSPECTION

CAUTION: Oil pump pressure relief valve and

spring should not be removed from the oil pump. If

these components are disassembled and or

removed from the pump the entire oil pump assem-

bly must be replaced.

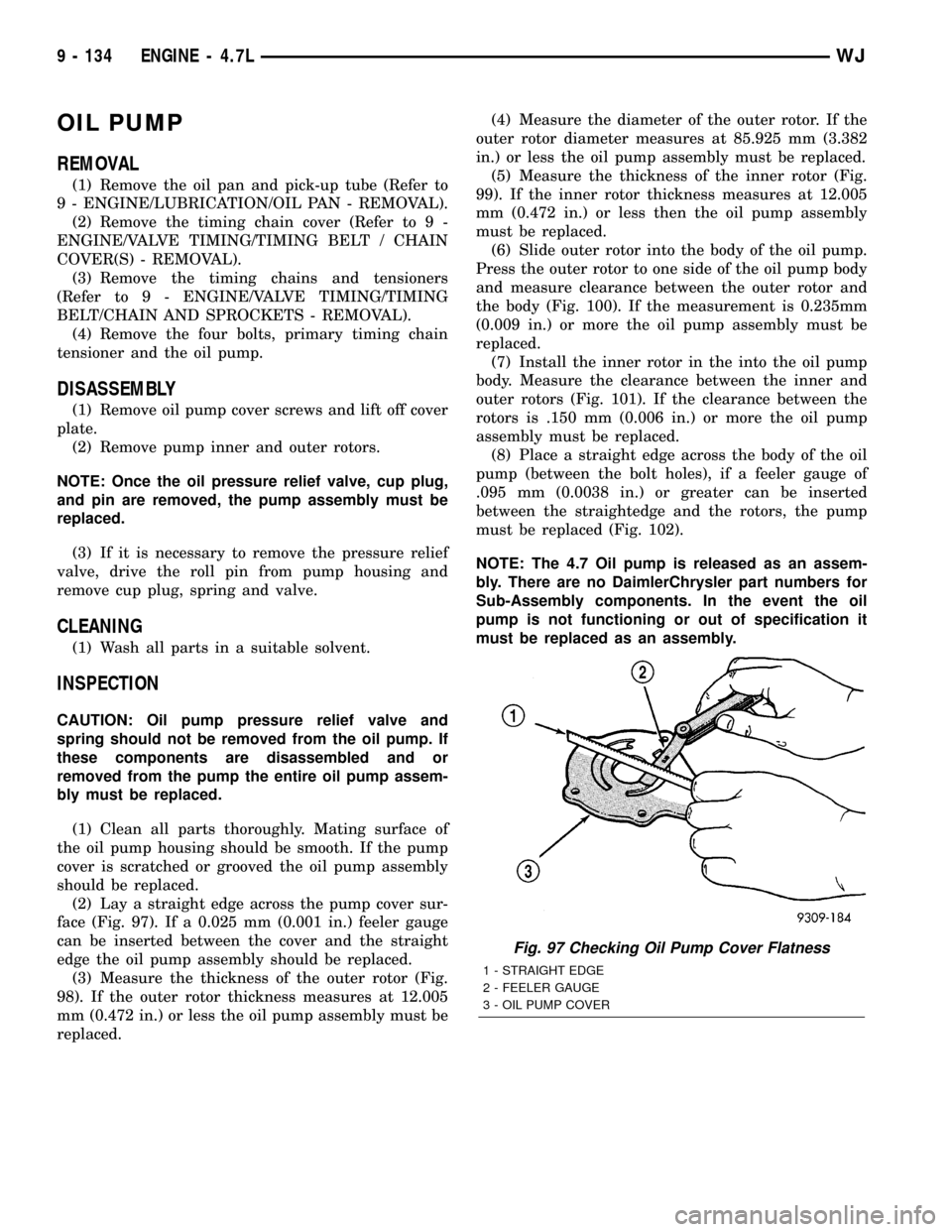

(1) Clean all parts thoroughly. Mating surface of

the oil pump housing should be smooth. If the pump

cover is scratched or grooved the oil pump assembly

should be replaced.

(2) Lay a straight edge across the pump cover sur-

face (Fig. 97). If a 0.025 mm (0.001 in.) feeler gauge

can be inserted between the cover and the straight

edge the oil pump assembly should be replaced.

(3) Measure the thickness of the outer rotor (Fig.

98). If the outer rotor thickness measures at 12.005

mm (0.472 in.) or less the oil pump assembly must be

replaced.(4) Measure the diameter of the outer rotor. If the

outer rotor diameter measures at 85.925 mm (3.382

in.) or less the oil pump assembly must be replaced.

(5) Measure the thickness of the inner rotor (Fig.

99). If the inner rotor thickness measures at 12.005

mm (0.472 in.) or less then the oil pump assembly

must be replaced.

(6) Slide outer rotor into the body of the oil pump.

Press the outer rotor to one side of the oil pump body

and measure clearance between the outer rotor and

the body (Fig. 100). If the measurement is 0.235mm

(0.009 in.) or more the oil pump assembly must be

replaced.

(7) Install the inner rotor in the into the oil pump

body. Measure the clearance between the inner and

outer rotors (Fig. 101). If the clearance between the

rotors is .150 mm (0.006 in.) or more the oil pump

assembly must be replaced.

(8) Place a straight edge across the body of the oil

pump (between the bolt holes), if a feeler gauge of

.095 mm (0.0038 in.) or greater can be inserted

between the straightedge and the rotors, the pump

must be replaced (Fig. 102).

NOTE: The 4.7 Oil pump is released as an assem-

bly. There are no DaimlerChrysler part numbers for

Sub-Assembly components. In the event the oil

pump is not functioning or out of specification it

must be replaced as an assembly.

Fig. 97 Checking Oil Pump Cover Flatness

1 - STRAIGHT EDGE

2 - FEELER GAUGE

3 - OIL PUMP COVER

9 - 134 ENGINE - 4.7LWJ

Page 1390 of 2199

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove right and left cylinder head covers

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(4) Remove radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL).

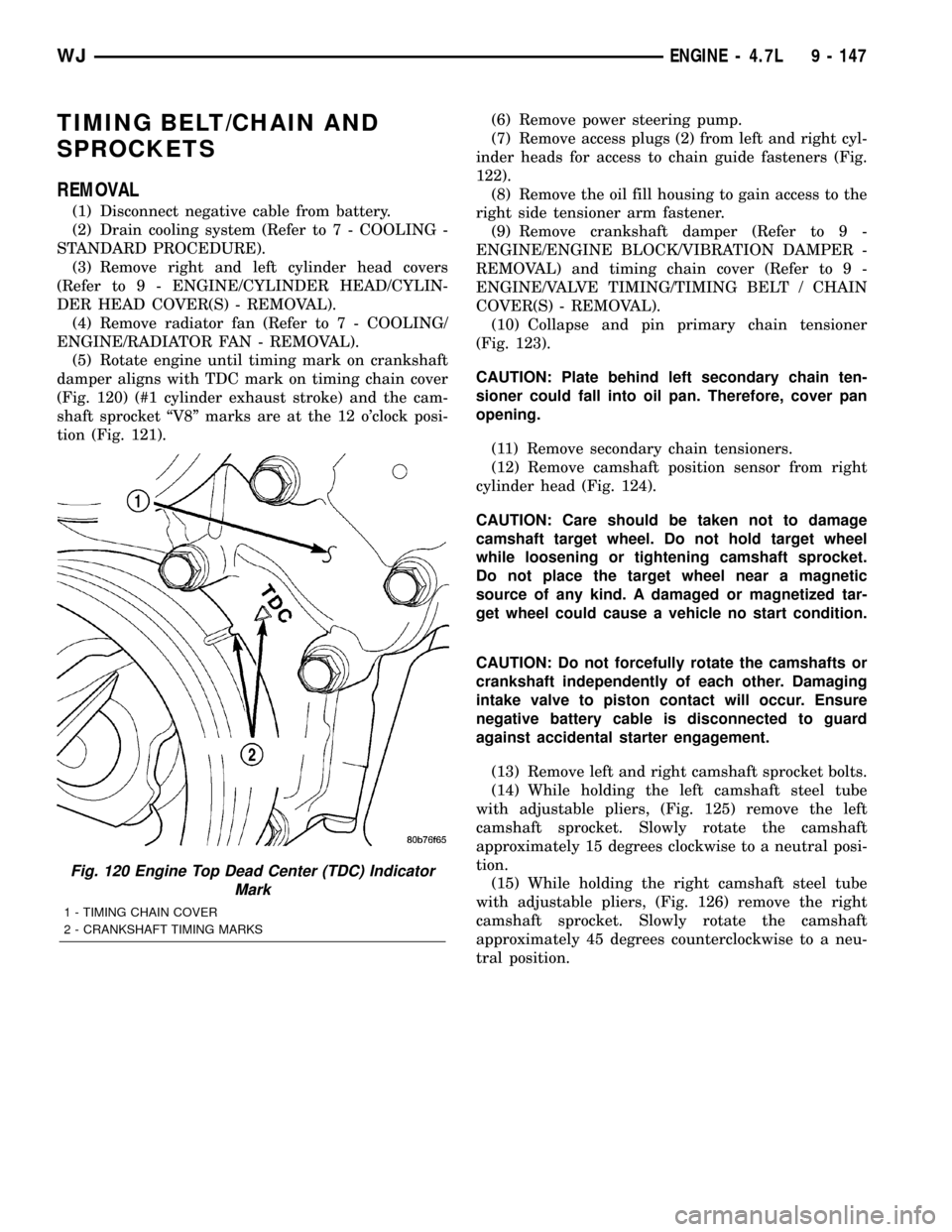

(5) Rotate engine until timing mark on crankshaft

damper aligns with TDC mark on timing chain cover

(Fig. 120) (#1 cylinder exhaust stroke) and the cam-

shaft sprocket ªV8º marks are at the 12 o'clock posi-

tion (Fig. 121).(6) Remove power steering pump.

(7) Remove access plugs (2) from left and right cyl-

inder heads for access to chain guide fasteners (Fig.

122).

(8) Remove the oil fill housing to gain access to the

right side tensioner arm fastener.

(9) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(10) Collapse and pin primary chain tensioner

(Fig. 123).

CAUTION: Plate behind left secondary chain ten-

sioner could fall into oil pan. Therefore, cover pan

opening.

(11) Remove secondary chain tensioners.

(12) Remove camshaft position sensor from right

cylinder head (Fig. 124).

CAUTION: Care should be taken not to damage

camshaft target wheel. Do not hold target wheel

while loosening or tightening camshaft sprocket.

Do not place the target wheel near a magnetic

source of any kind. A damaged or magnetized tar-

get wheel could cause a vehicle no start condition.

CAUTION: Do not forcefully rotate the camshafts or

crankshaft independently of each other. Damaging

intake valve to piston contact will occur. Ensure

negative battery cable is disconnected to guard

against accidental starter engagement.

(13) Remove left and right camshaft sprocket bolts.

(14) While holding the left camshaft steel tube

with adjustable pliers, (Fig. 125) remove the left

camshaft sprocket. Slowly rotate the camshaft

approximately 15 degrees clockwise to a neutral posi-

tion.

(15) While holding the right camshaft steel tube

with adjustable pliers, (Fig. 126) remove the right

camshaft sprocket. Slowly rotate the camshaft

approximately 45 degrees counterclockwise to a neu-

tral position.

Fig. 120 Engine Top Dead Center (TDC) Indicator

Mark

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

WJENGINE - 4.7L 9 - 147

Page 1396 of 2199

(22) Install timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION) and crankshaft

damper (Refer to 9 - ENGINE/ENGINE BLOCK/VI-

BRATION DAMPER - INSTALLATION).

(23) Install cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

NOTE: Before installing threaded plug in right cylin-

der head, the plug must be coated with sealant to

prevent leaks.

(24) Coat the large threaded access plug with

MopartThread Sealant with Teflon, then install

into the right cylinder head and tighten to 81 N´m

(60 ft. lbs.) (Fig. 122).

(25) Install the oil fill housing.

(26) Install access plug in left cylinder head (Fig.

122).

(27) Install power steering pump.

(28) Install radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(29) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(30) Connect negative cable to battery.

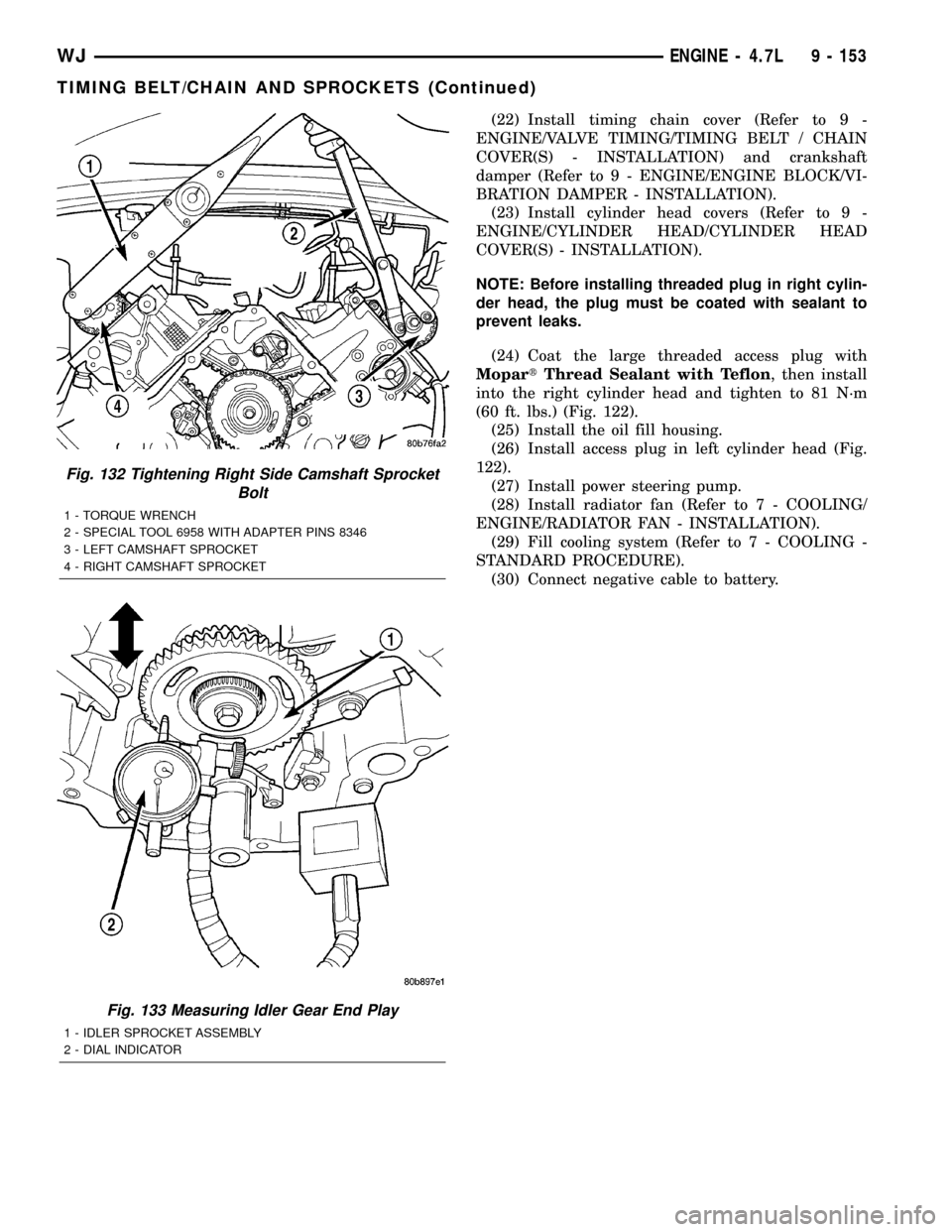

Fig. 132 Tightening Right Side Camshaft Sprocket

Bolt

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKET

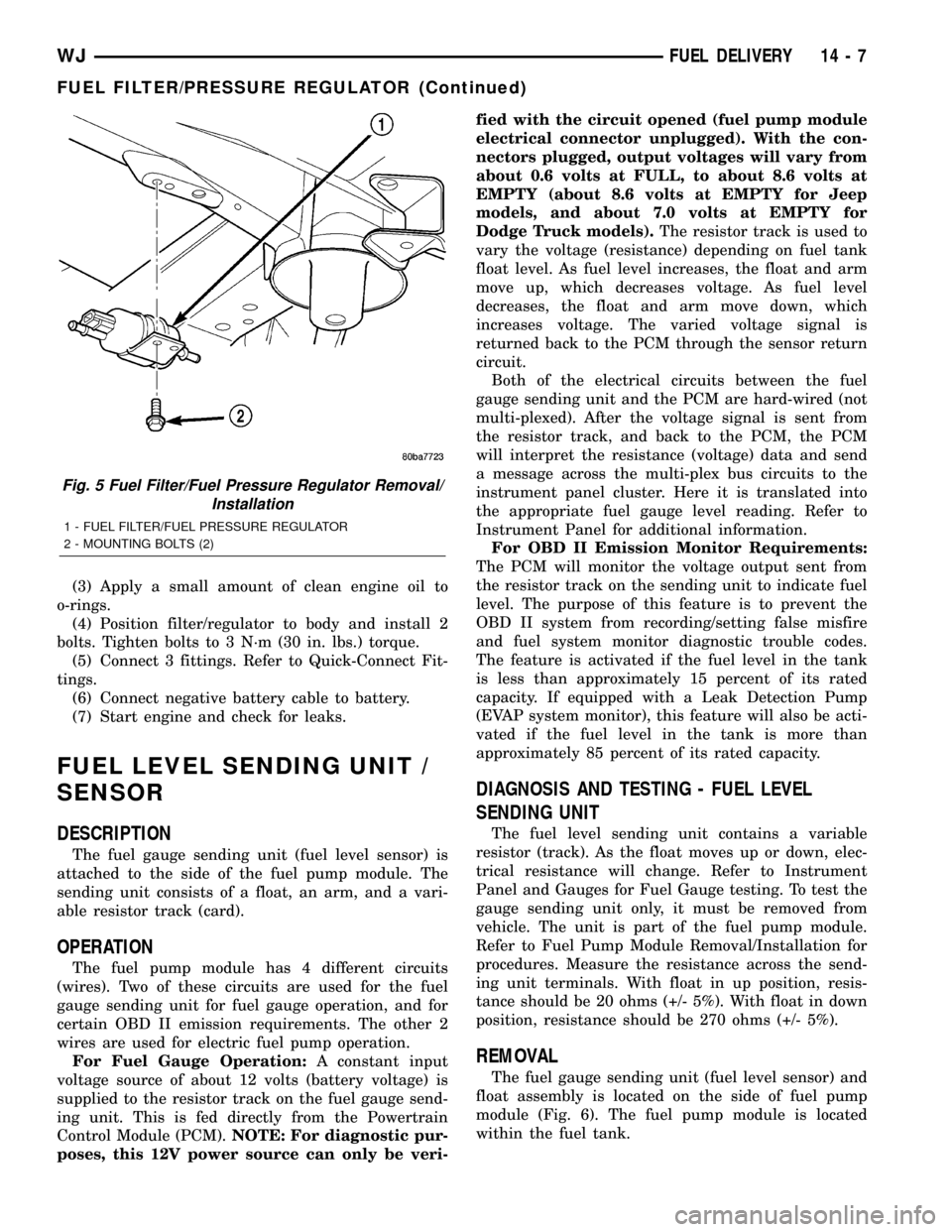

Fig. 133 Measuring Idler Gear End Play

1 - IDLER SPROCKET ASSEMBLY

2 - DIAL INDICATOR

WJENGINE - 4.7L 9 - 153

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1426 of 2199

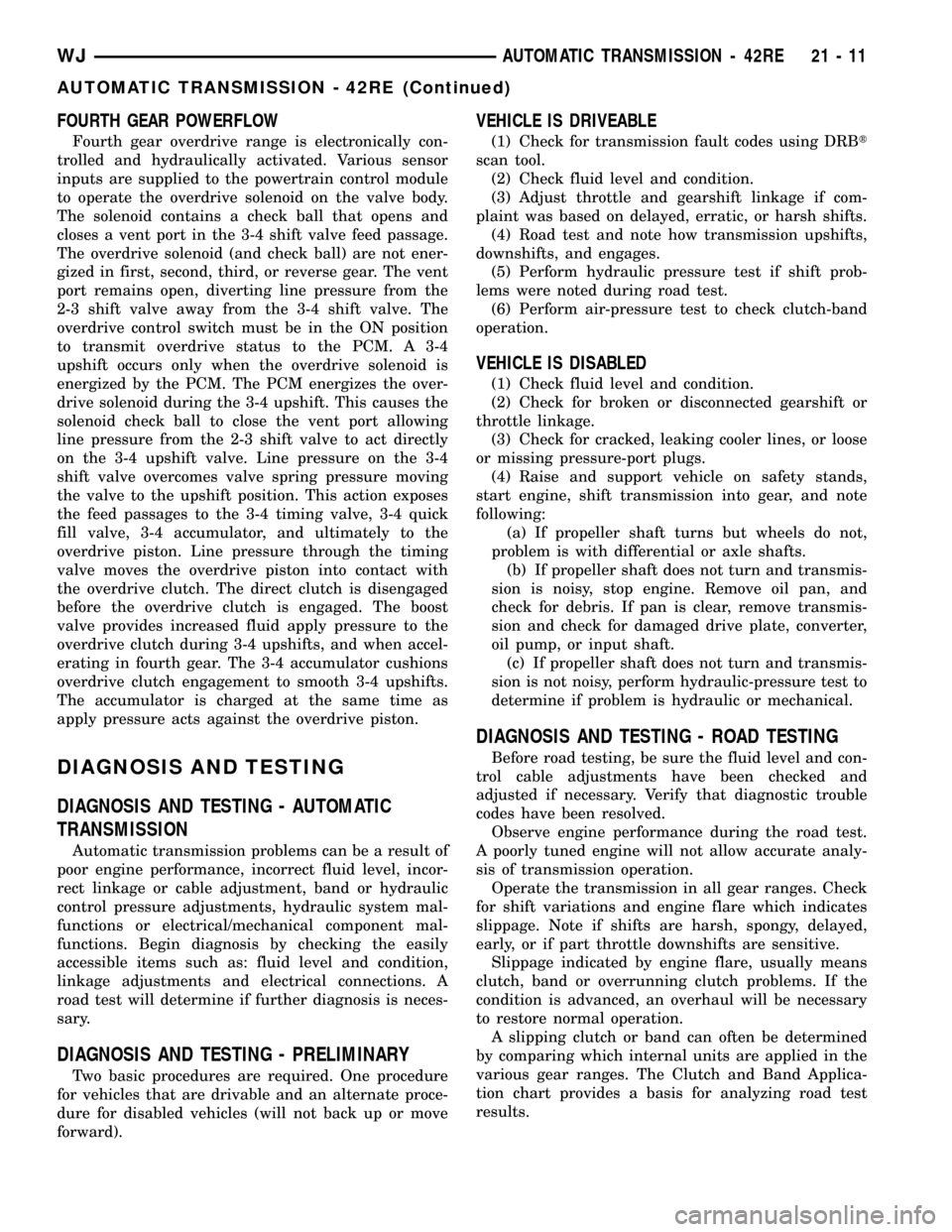

(3) Apply a small amount of clean engine oil to

o-rings.

(4) Position filter/regulator to body and install 2

bolts. Tighten bolts to 3 N´m (30 in. lbs.) torque.

(5) Connect 3 fittings. Refer to Quick-Connect Fit-

tings.

(6) Connect negative battery cable to battery.

(7) Start engine and check for leaks.

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel pump module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel pump module has 4 different circuits

(wires). Two of these circuits are used for the fuel

gauge sending unit for fuel gauge operation, and for

certain OBD II emission requirements. The other 2

wires are used for electric fuel pump operation.

For Fuel Gauge Operation:A constant input

voltage source of about 12 volts (battery voltage) is

supplied to the resistor track on the fuel gauge send-

ing unit. This is fed directly from the Powertrain

Control Module (PCM).NOTE: For diagnostic pur-

poses, this 12V power source can only be veri-fied with the circuit opened (fuel pump module

electrical connector unplugged). With the con-

nectors plugged, output voltages will vary from

about 0.6 volts at FULL, to about 8.6 volts at

EMPTY (about 8.6 volts at EMPTY for Jeep

models, and about 7.0 volts at EMPTY for

Dodge Truck models).The resistor track is used to

vary the voltage (resistance) depending on fuel tank

float level. As fuel level increases, the float and arm

move up, which decreases voltage. As fuel level

decreases, the float and arm move down, which

increases voltage. The varied voltage signal is

returned back to the PCM through the sensor return

circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the PCM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the PCM, the PCM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

For OBD II Emission Monitor Requirements:

The PCM will monitor the voltage output sent from

the resistor track on the sending unit to indicate fuel

level. The purpose of this feature is to prevent the

OBD II system from recording/setting false misfire

and fuel system monitor diagnostic trouble codes.

The feature is activated if the fuel level in the tank

is less than approximately 15 percent of its rated

capacity. If equipped with a Leak Detection Pump

(EVAP system monitor), this feature will also be acti-

vated if the fuel level in the tank is more than

approximately 85 percent of its rated capacity.

DIAGNOSIS AND TESTING - FUEL LEVEL

SENDING UNIT

The fuel level sending unit contains a variable

resistor (track). As the float moves up or down, elec-

trical resistance will change. Refer to Instrument

Panel and Gauges for Fuel Gauge testing. To test the

gauge sending unit only, it must be removed from

vehicle. The unit is part of the fuel pump module.

Refer to Fuel Pump Module Removal/Installation for

procedures. Measure the resistance across the send-

ing unit terminals. With float in up position, resis-

tance should be 20 ohms (+/- 5%). With float in down

position, resistance should be 270 ohms (+/- 5%).

REMOVAL

The fuel gauge sending unit (fuel level sensor) and

float assembly is located on the side of fuel pump

module (Fig. 6). The fuel pump module is located

within the fuel tank.

Fig. 5 Fuel Filter/Fuel Pressure Regulator Removal/

Installation

1 - FUEL FILTER/FUEL PRESSURE REGULATOR

2 - MOUNTING BOLTS (2)

WJFUEL DELIVERY 14 - 7

FUEL FILTER/PRESSURE REGULATOR (Continued)

Page 1530 of 2199

FOURTH GEAR POWERFLOW

Fourth gear overdrive range is electronically con-

trolled and hydraulically activated. Various sensor

inputs are supplied to the powertrain control module

to operate the overdrive solenoid on the valve body.

The solenoid contains a check ball that opens and

closes a vent port in the 3-4 shift valve feed passage.

The overdrive solenoid (and check ball) are not ener-

gized in first, second, third, or reverse gear. The vent

port remains open, diverting line pressure from the

2-3 shift valve away from the 3-4 shift valve. The

overdrive control switch must be in the ON position

to transmit overdrive status to the PCM. A 3-4

upshift occurs only when the overdrive solenoid is

energized by the PCM. The PCM energizes the over-

drive solenoid during the 3-4 upshift. This causes the

solenoid check ball to close the vent port allowing

line pressure from the 2-3 shift valve to act directly

on the 3-4 upshift valve. Line pressure on the 3-4

shift valve overcomes valve spring pressure moving

the valve to the upshift position. This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick

fill valve, 3-4 accumulator, and ultimately to the

overdrive piston. Line pressure through the timing

valve moves the overdrive piston into contact with

the overdrive clutch. The direct clutch is disengaged

before the overdrive clutch is engaged. The boost

valve provides increased fluid apply pressure to the

overdrive clutch during 3-4 upshifts, and when accel-

erating in fourth gear. The 3-4 accumulator cushions

overdrive clutch engagement to smooth 3-4 upshifts.

The accumulator is charged at the same time as

apply pressure acts against the overdrive piston.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

Automatic transmission problems can be a result of

poor engine performance, incorrect fluid level, incor-

rect linkage or cable adjustment, band or hydraulic

control pressure adjustments, hydraulic system mal-

functions or electrical/mechanical component mal-

functions. Begin diagnosis by checking the easily

accessible items such as: fluid level and condition,

linkage adjustments and electrical connections. A

road test will determine if further diagnosis is neces-

sary.

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure

for vehicles that are drivable and an alternate proce-

dure for disabled vehicles (will not back up or move

forward).

VEHICLE IS DRIVEABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust throttle and gearshift linkage if com-

plaint was based on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

(5) Perform hydraulic pressure test if shift prob-

lems were noted during road test.

(6) Perform air-pressure test to check clutch-band

operation.

VEHICLE IS DISABLED

(1) Check fluid level and condition.

(2) Check for broken or disconnected gearshift or

throttle linkage.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.

(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shaft does not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged drive plate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmis-

sion is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that diagnostic trouble

codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analy-

sis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, band or overrunning clutch problems. If the

condition is advanced, an overhaul will be necessary

to restore normal operation.

A slipping clutch or band can often be determined

by comparing which internal units are applied in the

various gear ranges. The Clutch and Band Applica-

tion chart provides a basis for analyzing road test

results.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 11

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1533 of 2199

Test Four - Transmission In Reverse

NOTE: This test checks pump output, pressure reg-

ulation and the front clutch and rear servo circuits.

Use 300 psi Test Gauge C-3293-SP for this test.

(1) Leave vehicle on hoist and leave gauge C-3292

in place at accumulator port.

(2) Move 300 psi Gauge C-3293-SP back to rear

servo port.

(3) Have helper start and run engine at 1600 rpm

for test.

(4) Move transmission shift lever four detents

rearward from full forward position. This is Reverse

range.

(5) Move transmission throttle lever fully forward

then fully rearward and note reading at Gauge

C-3293-SP.

(6) Pressure should be 145 - 175 psi (1000-1207

kPa) with throttle lever forward and increase to 230 -

280 psi (1586-1931 kPa) as lever is gradually moved

rearward.

Test Five - Governor Pressure

NOTE: This test checks governor operation by mea-

suring governor pressure response to changes in

vehicle speed. It is usually not necessary to check

governor operation unless shift speeds are incor-

rect or if the transmission will not downshift. The

test should be performed on the road or on a hoist

that will allow the rear wheels to rotate freely.

(1) Move 100 psi Test Gauge C-3292 to governor

pressure port.

(2) Move transmission shift lever two detents rear-

ward from full forward position. This is D range.

(3) Have helper start and run engine at curb idle

speed. Then firmly apply service brakes so wheels

will not rotate.

(4) Note governor pressure:

²Governor pressure should be no more than 20.6

kPa (3 psi) at curb idle speed and wheels not rotat-

ing.

²If pressure exceeds 20.6 kPa (3 psi), a fault

exists in governor pressure control system.

(5) Release brakes, slowly increase engine speed,

and observe speedometer and pressure test gauge (do

not exceed 30 mph on speedometer). Governor pres-

sure should increase in proportion to vehicle speed.

Or approximately 6.89 kPa (1 psi) for every 1 mph.

(6) Governor pressure rise should be smooth and

drop back to no more than 20.6 kPa (3 psi), after

engine returns to curb idle and brakes are applied to

prevent wheels from rotating.

(7) Compare results of pressure test with analysis

chart.Test Six - Transmission In Overdrive Fourth Gear

NOTE: This test checks line pressure at the over-

drive clutch in fourth gear range. Use 300 psi Test

Gauge C-3293-SP for this test. The test should be

performed on the road or on a chassis dyno.

(1) Remove tachometer; it is not needed for this

test.

(2) Move 300 psi Gauge to overdrive clutch pres-

sure test port. Then remove other gauge and reinstall

test port plug.

(3) Lower vehicle.

(4) Turn OD switch on.

(5) Secure test gauge so it can be viewed from

drivers seat.

(6) Start engine and shift into D range.

(7) Increase vehicle speed gradually until 3-4 shift

occurs and note gauge pressure.

(8) Pressure should be 469-496 kPa (68-72 psi)

with closed throttle and increase to 620-827 kPa (90-

120 psi) at 1/2 to 3/4 throttle. Note that pressure can

increase to around 896 kPa (130 psi) at full throttle.

(9) Return to shop or move vehicle off chassis

dyno.

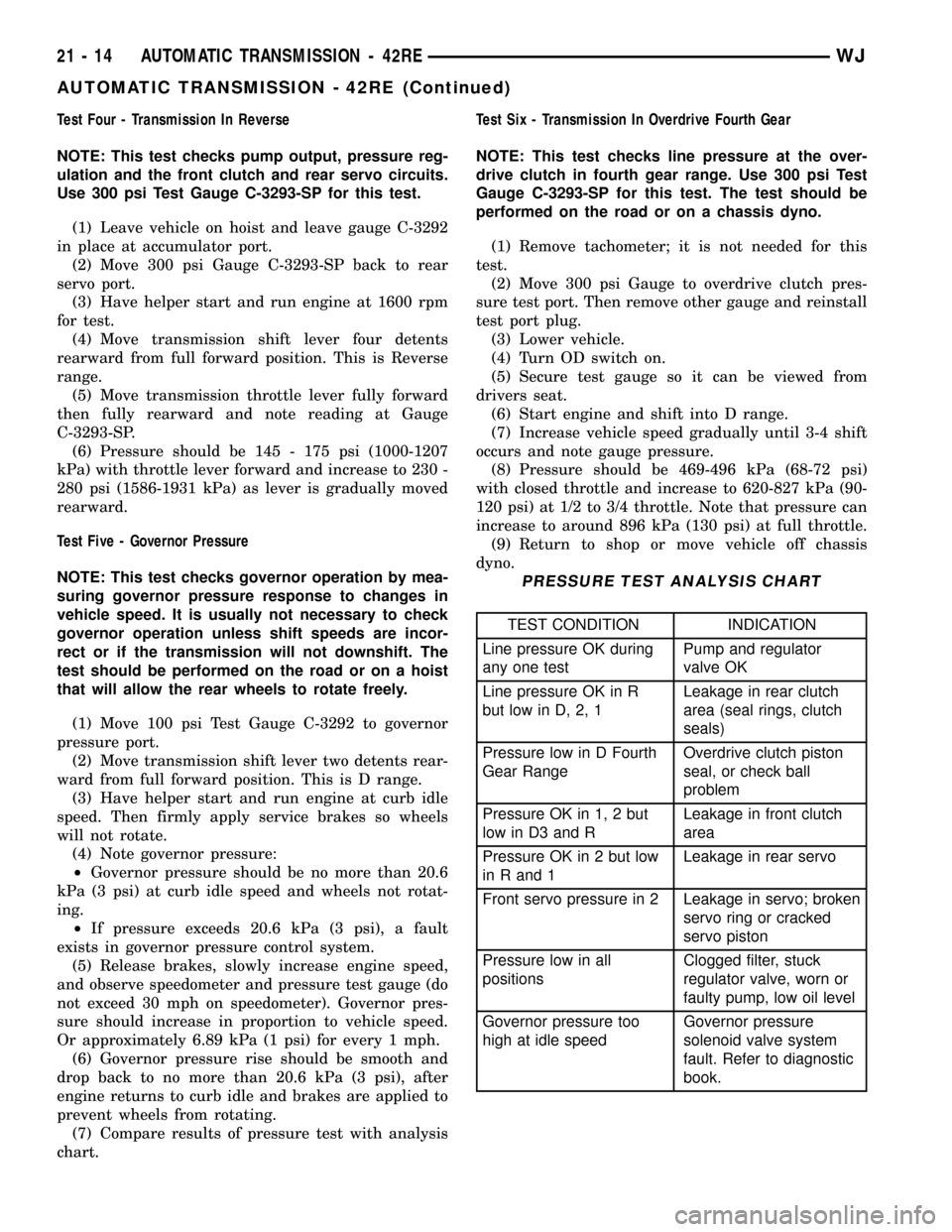

PRESSURE TEST ANALYSIS CHART

TEST CONDITION INDICATION

Line pressure OK during

any one testPump and regulator

valve OK

Line pressure OK in R

but low in D, 2, 1Leakage in rear clutch

area (seal rings, clutch

seals)

Pressure low in D Fourth

Gear RangeOverdrive clutch piston

seal, or check ball

problem

Pressure OK in 1, 2 but

low in D3 and RLeakage in front clutch

area

Pressure OK in 2 but low

in R and 1Leakage in rear servo

Front servo pressure in 2 Leakage in servo; broken

servo ring or cracked

servo piston

Pressure low in all

positionsClogged filter, stuck

regulator valve, worn or

faulty pump, low oil level

Governor pressure too

high at idle speedGovernor pressure

solenoid valve system

fault. Refer to diagnostic

book.

21 - 14 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1534 of 2199

TEST CONDITION INDICATION

Governor pressure low at

all mph figuresFaulty governor pressure

solenoid, transmission

control module, or

governor pressure

sensor

Lubrication pressure low

at all throttle positionsClogged fluid cooler or

lines, seal rings leaking,

worn pump bushings,

pump, clutch retainer, or

clogged filter.

Line pressure high Output shaft plugged,

sticky regulator valve

Line pressure low Sticky regulator valve,

clogged filter, worn pump

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH AND BAND

OPERATION

Air-pressure testing can be used to check transmis-

sion front/rear clutch and band operation. The test

can be conducted with the transmission either in the

vehicle or on the work bench, as a final check, after

overhaul.

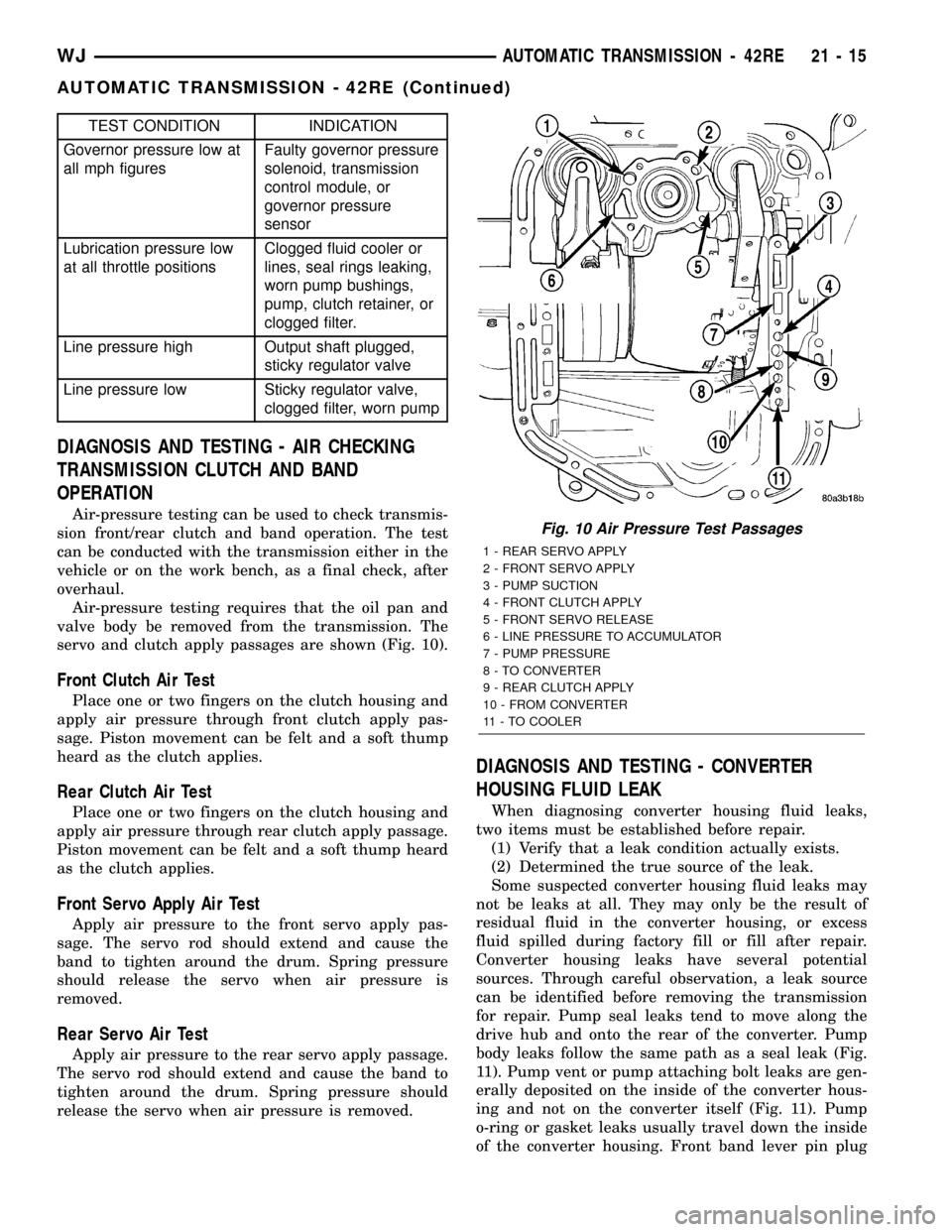

Air-pressure testing requires that the oil pan and

valve body be removed from the transmission. The

servo and clutch apply passages are shown (Fig. 10).

Front Clutch Air Test

Place one or two fingers on the clutch housing and

apply air pressure through front clutch apply pas-

sage. Piston movement can be felt and a soft thump

heard as the clutch applies.

Rear Clutch Air Test

Place one or two fingers on the clutch housing and

apply air pressure through rear clutch apply passage.

Piston movement can be felt and a soft thump heard

as the clutch applies.

Front Servo Apply Air Test

Apply air pressure to the front servo apply pas-

sage. The servo rod should extend and cause the

band to tighten around the drum. Spring pressure

should release the servo when air pressure is

removed.

Rear Servo Air Test

Apply air pressure to the rear servo apply passage.

The servo rod should extend and cause the band to

tighten around the drum. Spring pressure should

release the servo when air pressure is removed.

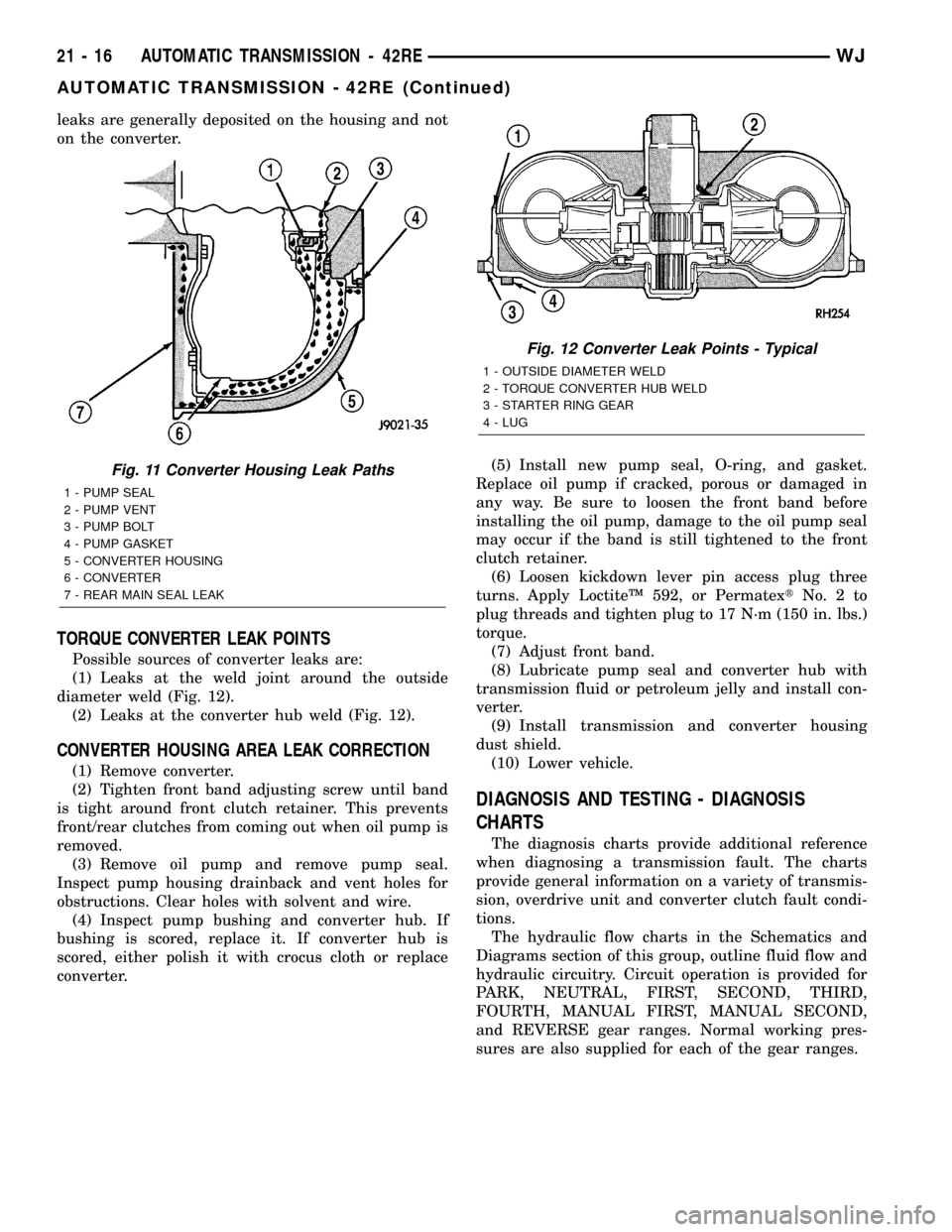

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK

When diagnosing converter housing fluid leaks,

two items must be established before repair.

(1) Verify that a leak condition actually exists.

(2) Determined the true source of the leak.

Some suspected converter housing fluid leaks may

not be leaks at all. They may only be the result of

residual fluid in the converter housing, or excess

fluid spilled during factory fill or fill after repair.

Converter housing leaks have several potential

sources. Through careful observation, a leak source

can be identified before removing the transmission

for repair. Pump seal leaks tend to move along the

drive hub and onto the rear of the converter. Pump

body leaks follow the same path as a seal leak (Fig.

11). Pump vent or pump attaching bolt leaks are gen-

erally deposited on the inside of the converter hous-

ing and not on the converter itself (Fig. 11). Pump

o-ring or gasket leaks usually travel down the inside

of the converter housing. Front band lever pin plug

Fig. 10 Air Pressure Test Passages

1 - REAR SERVO APPLY

2 - FRONT SERVO APPLY

3 - PUMP SUCTION

4 - FRONT CLUTCH APPLY

5 - FRONT SERVO RELEASE

6 - LINE PRESSURE TO ACCUMULATOR

7 - PUMP PRESSURE

8 - TO CONVERTER

9 - REAR CLUTCH APPLY

10 - FROM CONVERTER

11 - TO COOLER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 15

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1535 of 2199

leaks are generally deposited on the housing and not

on the converter.

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

(1) Leaks at the weld joint around the outside

diameter weld (Fig. 12).

(2) Leaks at the converter hub weld (Fig. 12).

CONVERTER HOUSING AREA LEAK CORRECTION

(1) Remove converter.

(2) Tighten front band adjusting screw until band

is tight around front clutch retainer. This prevents

front/rear clutches from coming out when oil pump is

removed.

(3) Remove oil pump and remove pump seal.

Inspect pump housing drainback and vent holes for

obstructions. Clear holes with solvent and wire.

(4) Inspect pump bushing and converter hub. If

bushing is scored, replace it. If converter hub is

scored, either polish it with crocus cloth or replace

converter.(5) Install new pump seal, O-ring, and gasket.

Replace oil pump if cracked, porous or damaged in

any way. Be sure to loosen the front band before

installing the oil pump, damage to the oil pump seal

may occur if the band is still tightened to the front

clutch retainer.

(6) Loosen kickdown lever pin access plug three

turns. Apply LoctiteŸ 592, or PermatextNo.2to

plug threads and tighten plug to 17 N´m (150 in. lbs.)

torque.

(7) Adjust front band.

(8) Lubricate pump seal and converter hub with

transmission fluid or petroleum jelly and install con-

verter.

(9) Install transmission and converter housing

dust shield.

(10) Lower vehicle.

DIAGNOSIS AND TESTING - DIAGNOSIS

CHARTS

The diagnosis charts provide additional reference

when diagnosing a transmission fault. The charts

provide general information on a variety of transmis-

sion, overdrive unit and converter clutch fault condi-

tions.

The hydraulic flow charts in the Schematics and

Diagrams section of this group, outline fluid flow and

hydraulic circuitry. Circuit operation is provided for

PARK, NEUTRAL, FIRST, SECOND, THIRD,

FOURTH, MANUAL FIRST, MANUAL SECOND,

and REVERSE gear ranges. Normal working pres-

sures are also supplied for each of the gear ranges.

Fig. 11 Converter Housing Leak Paths

1 - PUMP SEAL

2 - PUMP VENT

3 - PUMP BOLT

4 - PUMP GASKET

5 - CONVERTER HOUSING

6 - CONVERTER

7 - REAR MAIN SEAL LEAK

Fig. 12 Converter Leak Points - Typical

1 - OUTSIDE DIAMETER WELD

2 - TORQUE CONVERTER HUB WELD

3 - STARTER RING GEAR

4 - LUG

21 - 16 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)