gear shift JEEP GRAND CHEROKEE 2003 WJ / 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1798 of 2199

(8) Position the accumulator cover onto the valve

body.

(9) Install the screws to hold the accumulator

cover onto the valve body. Tighten the screws to 4.5

N´m (40 in. lbs.).

(10) Install the TRS selector plate onto the valve

body and the manual valve.

(11) Install the solenoid and pressure switch

assembly onto the valve body.

(12) Install the screws to hold the solenoid and

pressure switch assembly onto the valve body.

Tighten the screws to 5.7 N´m (50 in. lbs.). Tighten

the screws adjacent to the arrows cast into the bot-

tom of the transfer plate first.

(13) Position the detent spring onto the valve body.

(14) Install the screw to hold the detent spring

onto the valve body. Tighten the screw to 4.5 N´m (40

in. lbs.).

(15) Install new clutch passage seals onto the

valve body, if necessary

INSTALLATION

(1) Check condition of seals on valve body and the

solenoid and pressure switch assembly. Replace seals

if cut or worn.

(2) Place TRS selector plate in the PARK position.

(3) Place the transmission in the PARK position.

(4) Lubricate seal on the solenoid and pressure

switch assembly connector with petroleum jelly.(5) Position valve body in transmission and align

the manual lever on the valve body to the pin on the

transmission manual shift lever.

(6) Seat valve body in case and install one or two

bolts to hold valve body in place.

(7) Tighten valve body bolts alternately and evenly

to 12 N´m (105 in. lbs.) torque.

(8) Install a new primary oil filter seal in the oil

pump inlet bore. Seat the seal in the bore with the

butt end of a hammer, or other suitable tool.

CAUTION: The primary oil filter seal MUST be fully

installed flush against the oil pump body. DO NOT

install the seal onto the filter neck and attempt to

install the filter and seal as an assembly. Damage to

the transmission will result.

(9) Place replacement filter in position on valve

body and into the oil pump.

(10) Install screw to hold filter to valve body.

Tighten screw to 4.5 N´m (40 in. lbs.) torque.

(11) Connect the solenoid and pressure switch

assembly connector.

(12) Install oil pan. Tighten pan bolts to 12 N´m

(105 in. lbs.) torque.

(13) Lower vehicle and fill transmission with

MopartATF +4, type 9602, fluid.

(14) Check and adjust gearshift cable, if necessary.

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 279

VALVE BODY (Continued)

Page 1799 of 2199

TRANSFER CASE - NV242

TABLE OF CONTENTS

page page

TRANSFER CASE - NV242

DESCRIPTION........................280

OPERATION..........................281

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV242.......................281

REMOVAL............................282

DISASSEMBLY........................282

CLEANING...........................292

INSPECTION.........................293

ASSEMBLY...........................295

INSTALLATION........................307

SPECIFICATIONS

TRANSFER CASE - NV242.............308

SPECIAL TOOLS

TRANSFER CASE - NV242.............308

FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL............................310FRONT OUTPUT SHAFT SEAL

REMOVAL............................310

INSTALLATION........................310

POSITION SENSOR

DESCRIPTION........................311

OPERATION..........................311

REMOVAL............................312

INSTALLATION........................312

REAR RETAINER BUSHING AND SEAL -

NV242HD

REMOVAL............................312

INSTALLATION........................312

SHIFT CABLE

REMOVAL............................313

INSTALLATION........................313

TRANSFER CASE - NV242

DESCRIPTION

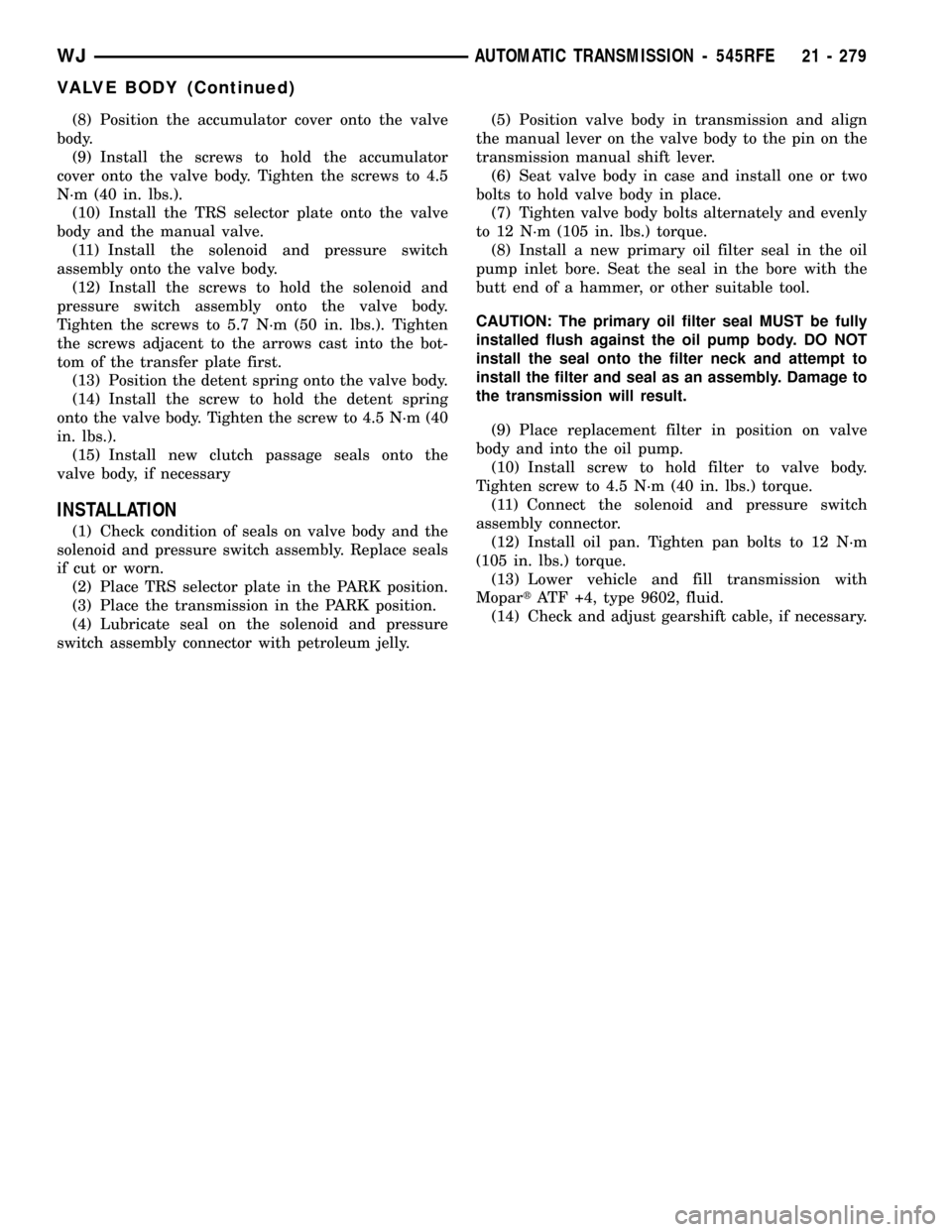

The NV242 is a full transfer case (Fig. 1). It pro-

vides full time 2-wheel, or 4-wheel drive operation.

A differential in the transfer case is used to control

torque transfer to the front and rear axles. A low

range gear provides increased low speed torque capa-

bility for off road operation. The low range provides a

2.72:1 reduction ratio.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum retainer

housings bolted to the case halves.

TRANSFER CASE IDENTIFICATION

Two versions of the NV242 are used in the WJ

vehicles, NV242LD and NV242HD. The two transfer

cases can be distinguished from one another by the

rear output shaft retainer. The NV242LD uses a rub-

ber boot to cover the rear output shaft, while the

NV242HD uses a cast aluminum housing. Other than

this difference, the two transfer cases are serviced

the same.

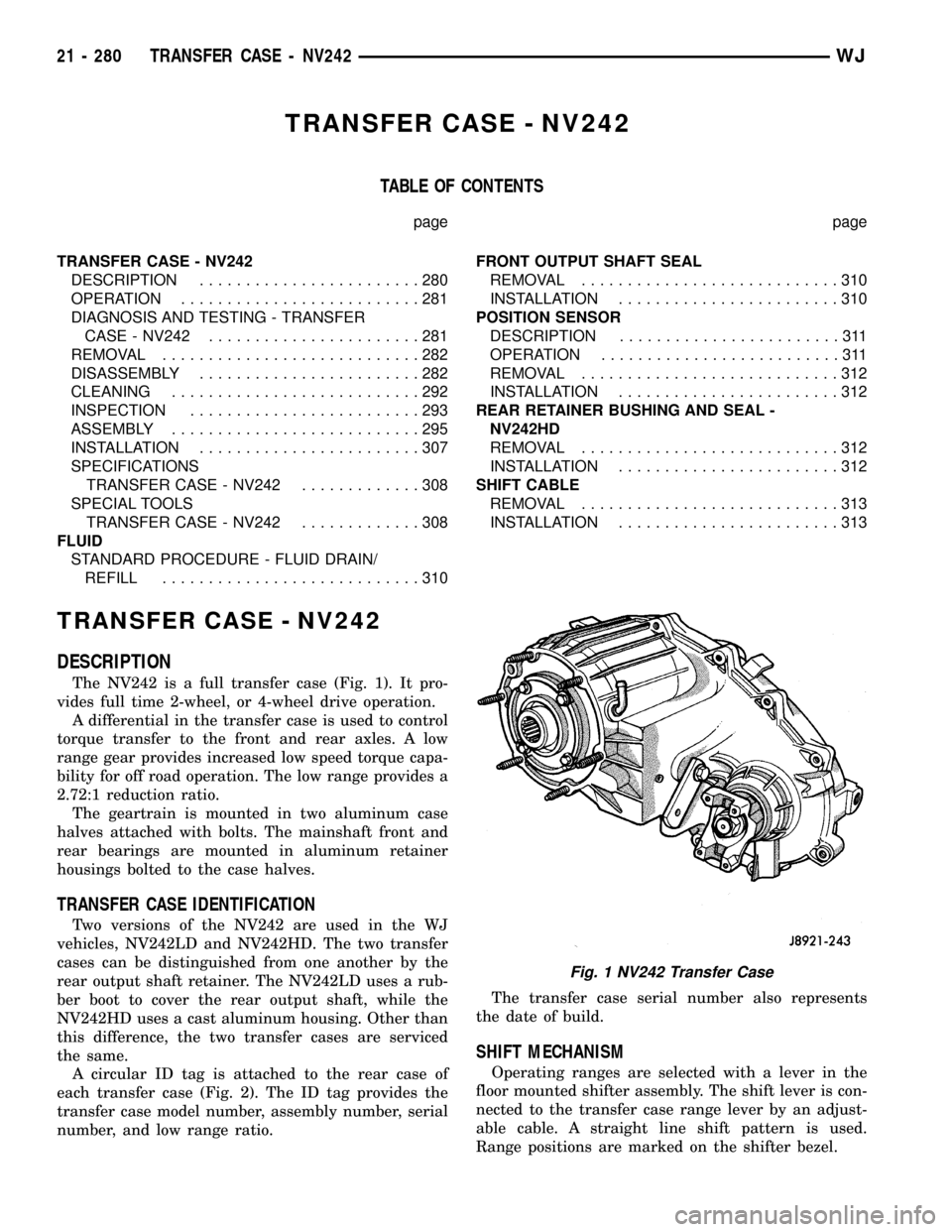

A circular ID tag is attached to the rear case of

each transfer case (Fig. 2). The ID tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.The transfer case serial number also represents

the date of build.

SHIFT MECHANISM

Operating ranges are selected with a lever in the

floor mounted shifter assembly. The shift lever is con-

nected to the transfer case range lever by an adjust-

able cable. A straight line shift pattern is used.

Range positions are marked on the shifter bezel.

Fig. 1 NV242 Transfer Case

21 - 280 TRANSFER CASE - NV242WJ

Page 1800 of 2199

OPERATION

The input gear is splined to the transmission out-

put shaft. It drives the mainshaft through the plan-

etary gear and range hub. The front output shaft is

operated by a drive chain that connects the shaft to a

drive sprocket on the mainshaft. The drive sprocket

is engaged/disengaged by the mode fork, which oper-

ates the mode sleeve and hub. The sleeve and hub

are not equipped with a synchro mechanism for shift-

ing.

OPERATING RANGES

NV242 operating ranges are 2WD (2-wheel drive),

4x4 part-time, 4x4 full time, and 4 Lo.

The 2WD and 4x4 full time ranges can be used at

any time and on any road surface.

The 4x4 part-time and 4 Lo ranges are for off road

use only. The only time these ranges can be used on

hard surface roads, is when the surface is covered

with snow and ice.

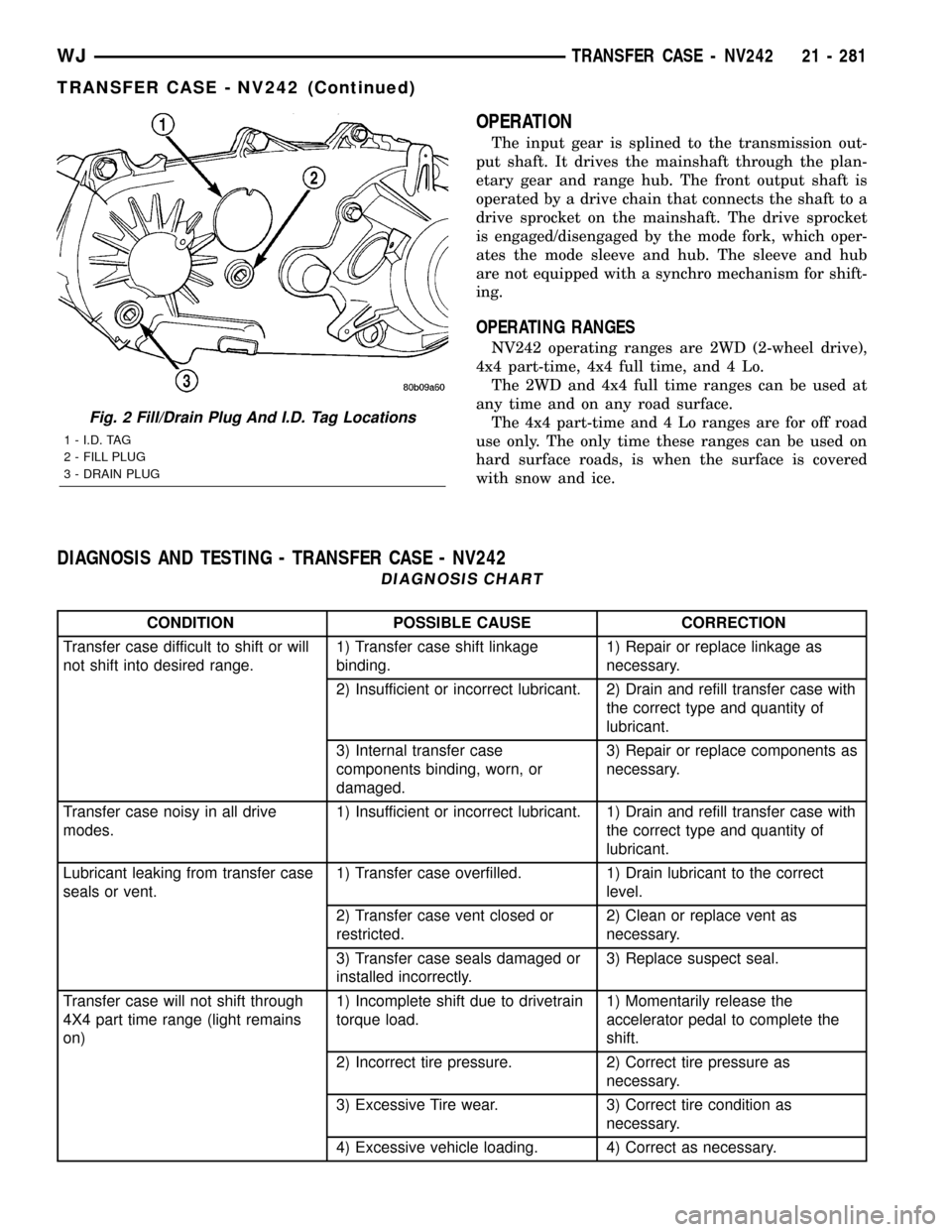

DIAGNOSIS AND TESTING - TRANSFER CASE - NV242

DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

Transfer case difficult to shift or will

not shift into desired range.1) Transfer case shift linkage

binding.1) Repair or replace linkage as

necessary.

2) Insufficient or incorrect lubricant. 2) Drain and refill transfer case with

the correct type and quantity of

lubricant.

3) Internal transfer case

components binding, worn, or

damaged.3) Repair or replace components as

necessary.

Transfer case noisy in all drive

modes.1) Insufficient or incorrect lubricant. 1) Drain and refill transfer case with

the correct type and quantity of

lubricant.

Lubricant leaking from transfer case

seals or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Transfer case vent closed or

restricted.2) Clean or replace vent as

necessary.

3) Transfer case seals damaged or

installed incorrectly.3) Replace suspect seal.

Transfer case will not shift through

4X4 part time range (light remains

on)1) Incomplete shift due to drivetrain

torque load.1) Momentarily release the

accelerator pedal to complete the

shift.

2) Incorrect tire pressure. 2) Correct tire pressure as

necessary.

3) Excessive Tire wear. 3) Correct tire condition as

necessary.

4) Excessive vehicle loading. 4) Correct as necessary.

Fig. 2 Fill/Drain Plug And I.D. Tag Locations

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

WJTRANSFER CASE - NV242 21 - 281

TRANSFER CASE - NV242 (Continued)

Page 1809 of 2199

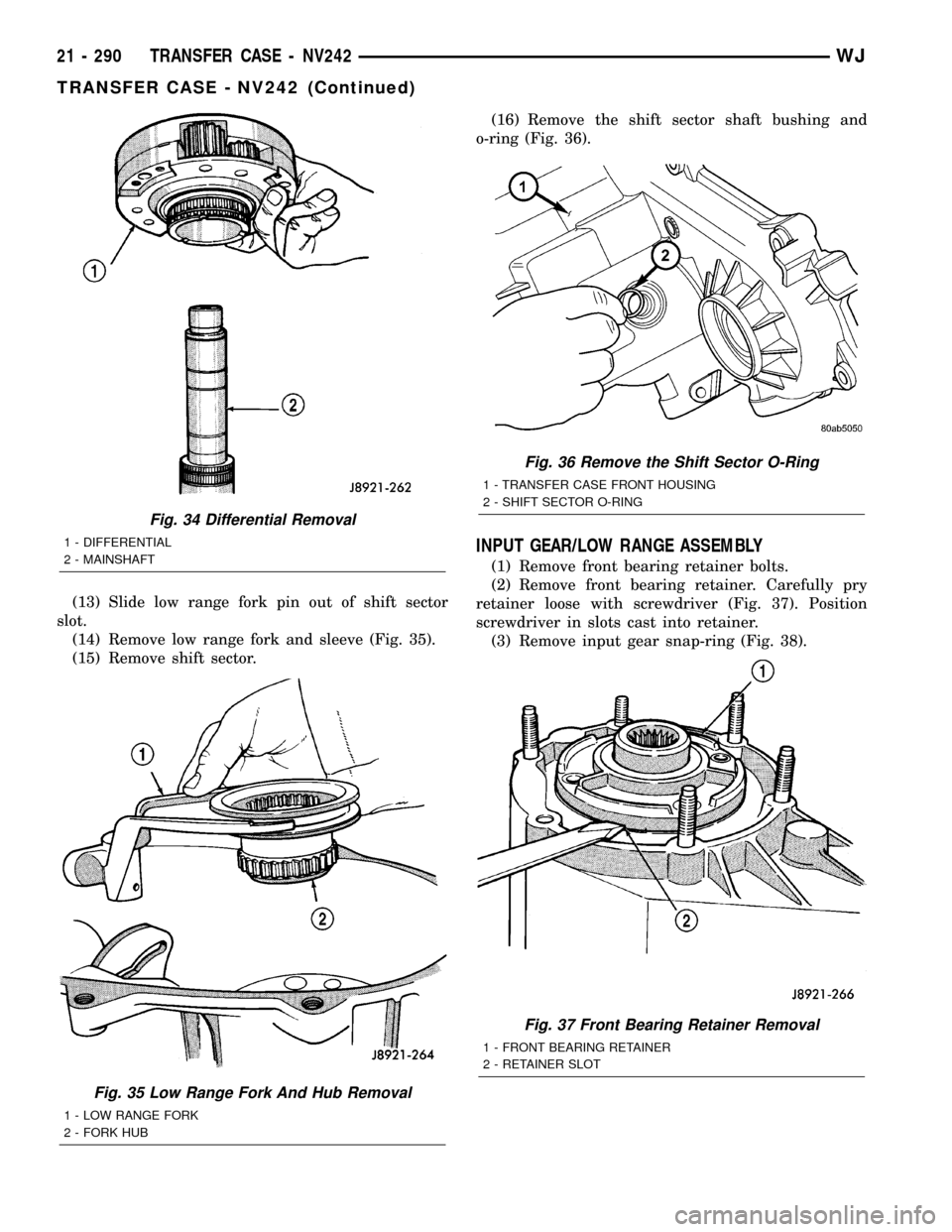

(13) Slide low range fork pin out of shift sector

slot.

(14) Remove low range fork and sleeve (Fig. 35).

(15) Remove shift sector.(16) Remove the shift sector shaft bushing and

o-ring (Fig. 36).

INPUT GEAR/LOW RANGE ASSEMBLY

(1) Remove front bearing retainer bolts.

(2) Remove front bearing retainer. Carefully pry

retainer loose with screwdriver (Fig. 37). Position

screwdriver in slots cast into retainer.

(3) Remove input gear snap-ring (Fig. 38).

Fig. 34 Differential Removal

1 - DIFFERENTIAL

2 - MAINSHAFT

Fig. 35 Low Range Fork And Hub Removal

1 - LOW RANGE FORK

2 - FORK HUB

Fig. 36 Remove the Shift Sector O-Ring

1 - TRANSFER CASE FRONT HOUSING

2 - SHIFT SECTOR O-RING

Fig. 37 Front Bearing Retainer Removal

1 - FRONT BEARING RETAINER

2 - RETAINER SLOT

21 - 290 TRANSFER CASE - NV242WJ

TRANSFER CASE - NV242 (Continued)

Page 1819 of 2199

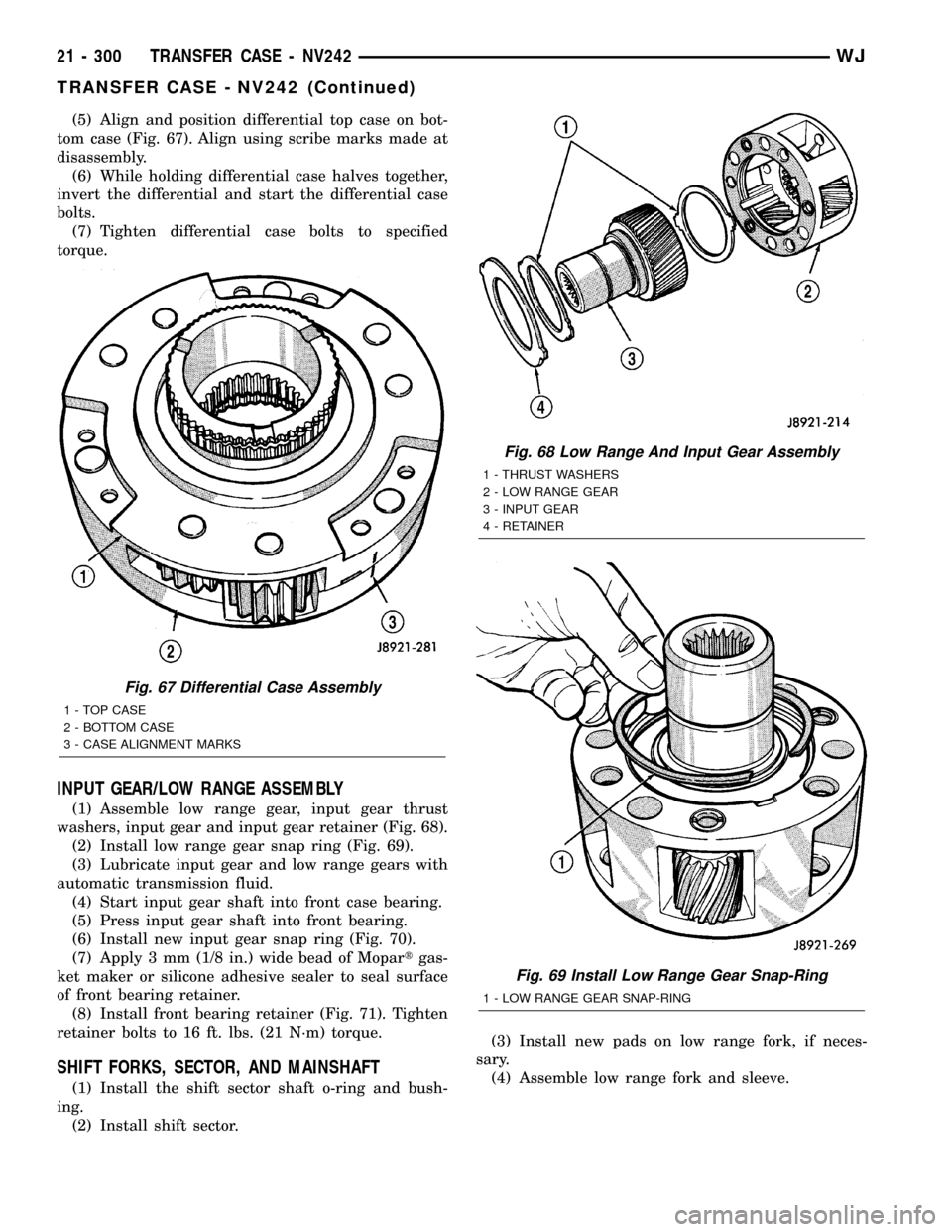

(5) Align and position differential top case on bot-

tom case (Fig. 67). Align using scribe marks made at

disassembly.

(6) While holding differential case halves together,

invert the differential and start the differential case

bolts.

(7) Tighten differential case bolts to specified

torque.

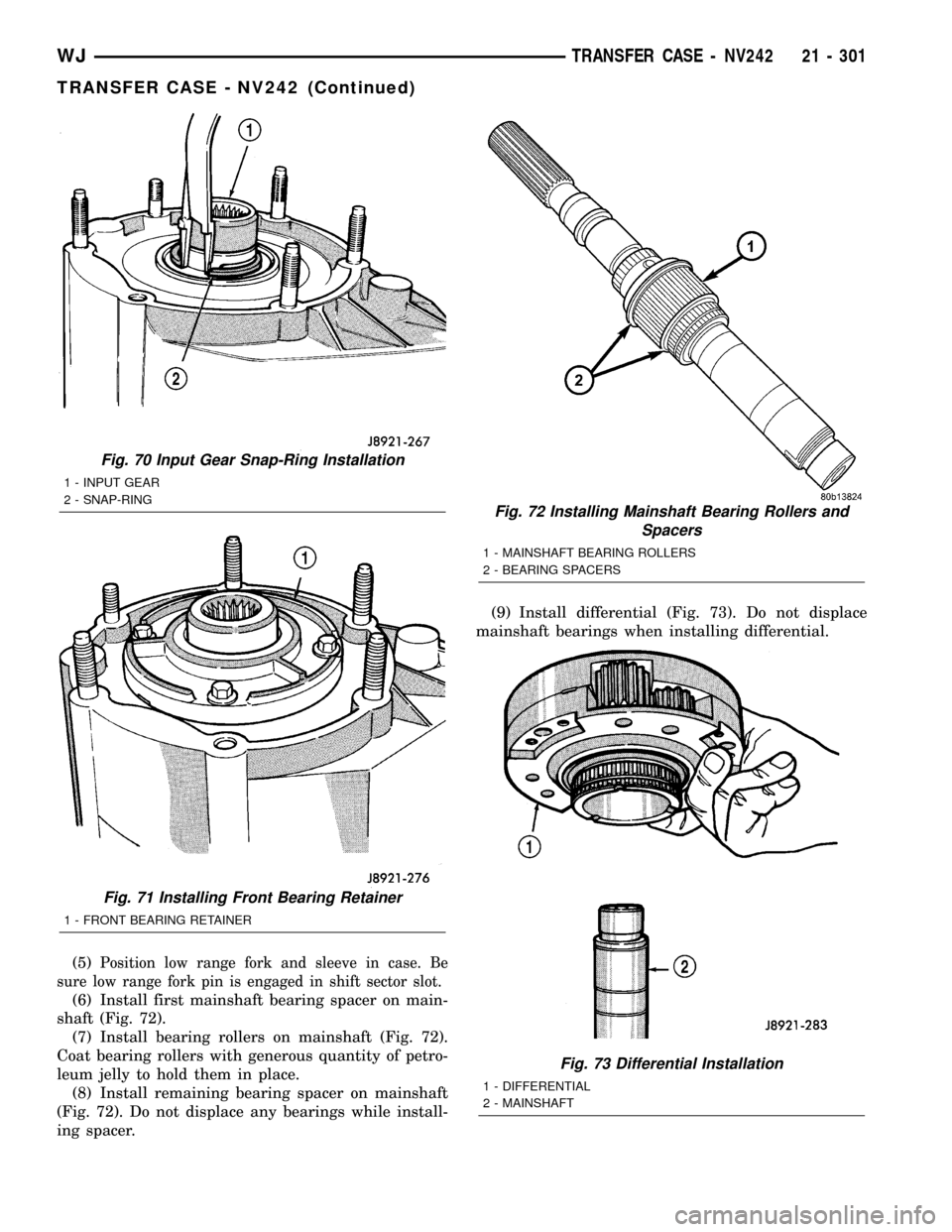

INPUT GEAR/LOW RANGE ASSEMBLY

(1) Assemble low range gear, input gear thrust

washers, input gear and input gear retainer (Fig. 68).

(2) Install low range gear snap ring (Fig. 69).

(3) Lubricate input gear and low range gears with

automatic transmission fluid.

(4) Start input gear shaft into front case bearing.

(5) Press input gear shaft into front bearing.

(6) Install new input gear snap ring (Fig. 70).

(7) Apply 3 mm (1/8 in.) wide bead of Mopartgas-

ket maker or silicone adhesive sealer to seal surface

of front bearing retainer.

(8) Install front bearing retainer (Fig. 71). Tighten

retainer bolts to 16 ft. lbs. (21 N´m) torque.

SHIFT FORKS, SECTOR, AND MAINSHAFT

(1) Install the shift sector shaft o-ring and bush-

ing.

(2) Install shift sector.(3) Install new pads on low range fork, if neces-

sary.

(4) Assemble low range fork and sleeve.

Fig. 67 Differential Case Assembly

1 - TOP CASE

2 - BOTTOM CASE

3 - CASE ALIGNMENT MARKS

Fig. 68 Low Range And Input Gear Assembly

1 - THRUST WASHERS

2 - LOW RANGE GEAR

3 - INPUT GEAR

4 - RETAINER

Fig. 69 Install Low Range Gear Snap-Ring

1 - LOW RANGE GEAR SNAP-RING

21 - 300 TRANSFER CASE - NV242WJ

TRANSFER CASE - NV242 (Continued)

Page 1820 of 2199

(5)Position low range fork and sleeve in case. Be

sure low range fork pin is engaged in shift sector slot.

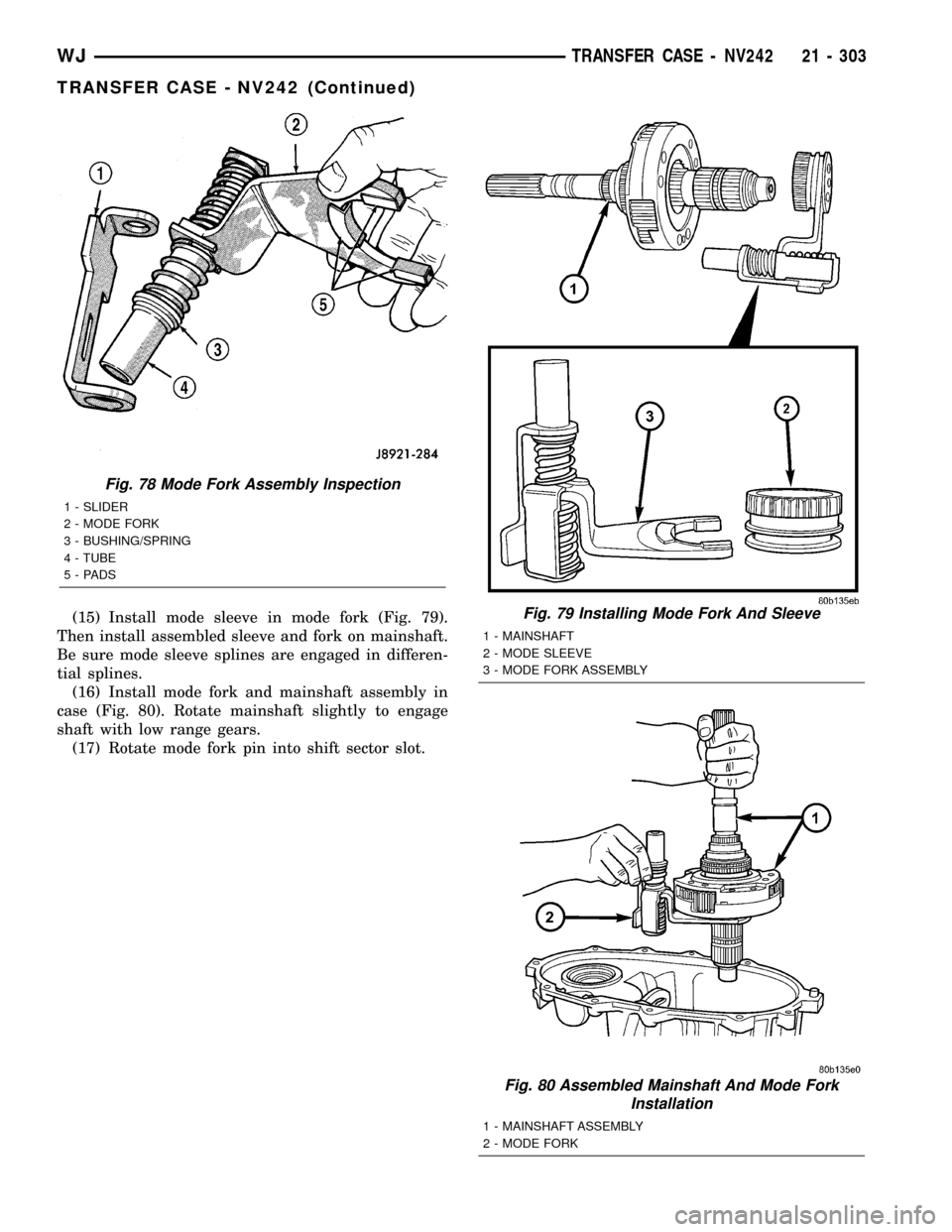

(6) Install first mainshaft bearing spacer on main-

shaft (Fig. 72).

(7) Install bearing rollers on mainshaft (Fig. 72).

Coat bearing rollers with generous quantity of petro-

leum jelly to hold them in place.

(8) Install remaining bearing spacer on mainshaft

(Fig. 72). Do not displace any bearings while install-

ing spacer.(9) Install differential (Fig. 73). Do not displace

mainshaft bearings when installing differential.

Fig. 70 Input Gear Snap-Ring Installation

1 - INPUT GEAR

2 - SNAP-RING

Fig. 71 Installing Front Bearing Retainer

1 - FRONT BEARING RETAINER

Fig. 72 Installing Mainshaft Bearing Rollers and

Spacers

1 - MAINSHAFT BEARING ROLLERS

2 - BEARING SPACERS

Fig. 73 Differential Installation

1 - DIFFERENTIAL

2 - MAINSHAFT

WJTRANSFER CASE - NV242 21 - 301

TRANSFER CASE - NV242 (Continued)

Page 1822 of 2199

(15) Install mode sleeve in mode fork (Fig. 79).

Then install assembled sleeve and fork on mainshaft.

Be sure mode sleeve splines are engaged in differen-

tial splines.

(16) Install mode fork and mainshaft assembly in

case (Fig. 80). Rotate mainshaft slightly to engage

shaft with low range gears.

(17) Rotate mode fork pin into shift sector slot.Fig. 79 Installing Mode Fork And Sleeve

1 - MAINSHAFT

2 - MODE SLEEVE

3 - MODE FORK ASSEMBLY

Fig. 80 Assembled Mainshaft And Mode Fork

Installation

1 - MAINSHAFT ASSEMBLY

2 - MODE FORK

Fig. 78 Mode Fork Assembly Inspection

1 - SLIDER

2 - MODE FORK

3 - BUSHING/SPRING

4 - TUBE

5-PADS

WJTRANSFER CASE - NV242 21 - 303

TRANSFER CASE - NV242 (Continued)

Page 1834 of 2199

TRANSFER CASE - NV247

TABLE OF CONTENTS

page page

TRANSFER CASE - NV247

DESCRIPTION........................315

OPERATION..........................316

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV247.......................316

REMOVAL............................317

DISASSEMBLY........................317

CLEANING...........................324

INSPECTION.........................324

ASSEMBLY...........................326

INSTALLATION........................335

SPECIFICATIONS

TRANSFER CASE - NV247.............336

SPECIAL TOOLS

TRANSFER CASE - NV247.............337FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL............................338

FRONT OUTPUT SHAFT SEAL

REMOVAL............................338

INSTALLATION........................338

REAR RETAINER BUSHING AND SEAL

REMOVAL............................339

INSTALLATION........................339

SHIFT CABLE

REMOVAL............................340

INSTALLATION........................340

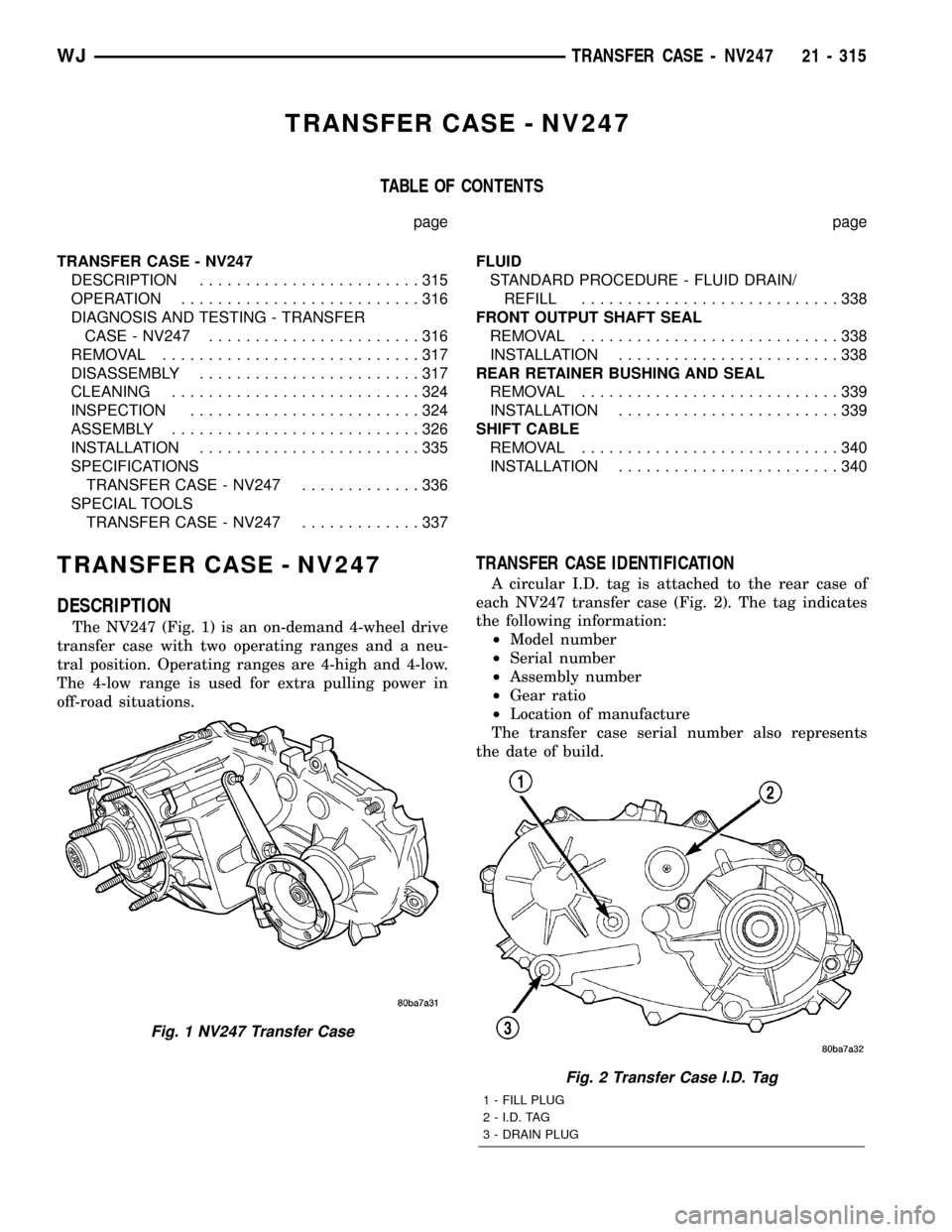

TRANSFER CASE - NV247

DESCRIPTION

The NV247 (Fig. 1) is an on-demand 4-wheel drive

transfer case with two operating ranges and a neu-

tral position. Operating ranges are 4-high and 4-low.

The 4-low range is used for extra pulling power in

off-road situations.

TRANSFER CASE IDENTIFICATION

A circular I.D. tag is attached to the rear case of

each NV247 transfer case (Fig. 2). The tag indicates

the following information:

²Model number

²Serial number

²Assembly number

²Gear ratio

²Location of manufacture

The transfer case serial number also represents

the date of build.

Fig. 1 NV247 Transfer Case

Fig. 2 Transfer Case I.D. Tag

1 - FILL PLUG

2 - I.D. TAG

3 - DRAIN PLUG

WJTRANSFER CASE - NV247 21 - 315

Page 1836 of 2199

CONDITION POSSIBLE CAUSE CORRECTION

NOISY INÐOR JUMPS OUT OF

4WD LOW RANGE1. Transfer case not completely

engaged in 4WD LOW (possibly

from shift to 4L while rolling)1. Stop vehicle, shift transfer case

to neutral, then shift back to 4WD

LOW

2. Shift linkage loose, binding, or is

misadjusted2. Tighten, lubricate, or repair

linkage as necessary. Adjust linkage

if necessary

3. Range fork cracked, inserts

worn, or fork is binding on shift rail3. Disassemble unit and repair as

necessary

4. Annulus gear or lockplate worn

or damaged4. Disassemble unit and repair as

necessary

LUBRICANT LEAKING FROM

OUTPUT SHAFT SEALS OR FROM

VENT1. Transfer case over filled 1. Drain to correct level

2. Vent closed or restricted 2. Clear or replace vent if necessary

3. Output shaft seals damaged or

installed correctly3. Replace seals. Be sure seal lip

faces interior of case when installed.

Also be sure yoke seal surfaces are

not scored or nicked. Remove

scores and nicks with fine

sandpaper or replace yoke(s) if

necessary.

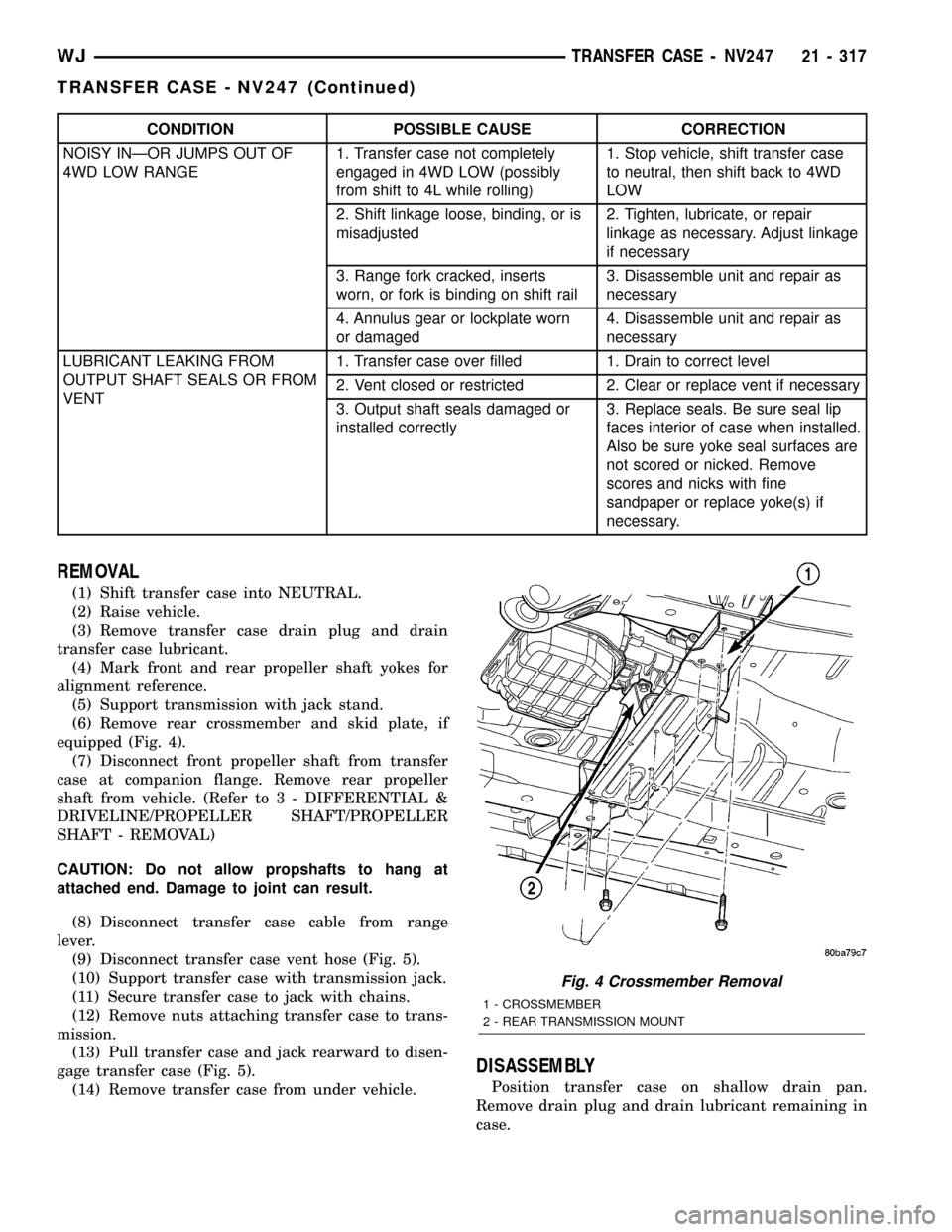

REMOVAL

(1) Shift transfer case into NEUTRAL.

(2) Raise vehicle.

(3) Remove transfer case drain plug and drain

transfer case lubricant.

(4) Mark front and rear propeller shaft yokes for

alignment reference.

(5) Support transmission with jack stand.

(6) Remove rear crossmember and skid plate, if

equipped (Fig. 4).

(7) Disconnect front propeller shaft from transfer

case at companion flange. Remove rear propeller

shaft from vehicle. (Refer to 3 - DIFFERENTIAL &

DRIVELINE/PROPELLER SHAFT/PROPELLER

SHAFT - REMOVAL)

CAUTION: Do not allow propshafts to hang at

attached end. Damage to joint can result.

(8) Disconnect transfer case cable from range

lever.

(9) Disconnect transfer case vent hose (Fig. 5).

(10) Support transfer case with transmission jack.

(11) Secure transfer case to jack with chains.

(12) Remove nuts attaching transfer case to trans-

mission.

(13) Pull transfer case and jack rearward to disen-

gage transfer case (Fig. 5).

(14) Remove transfer case from under vehicle.

DISASSEMBLY

Position transfer case on shallow drain pan.

Remove drain plug and drain lubricant remaining in

case.

Fig. 4 Crossmember Removal

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

WJTRANSFER CASE - NV247 21 - 317

TRANSFER CASE - NV247 (Continued)

Page 1840 of 2199

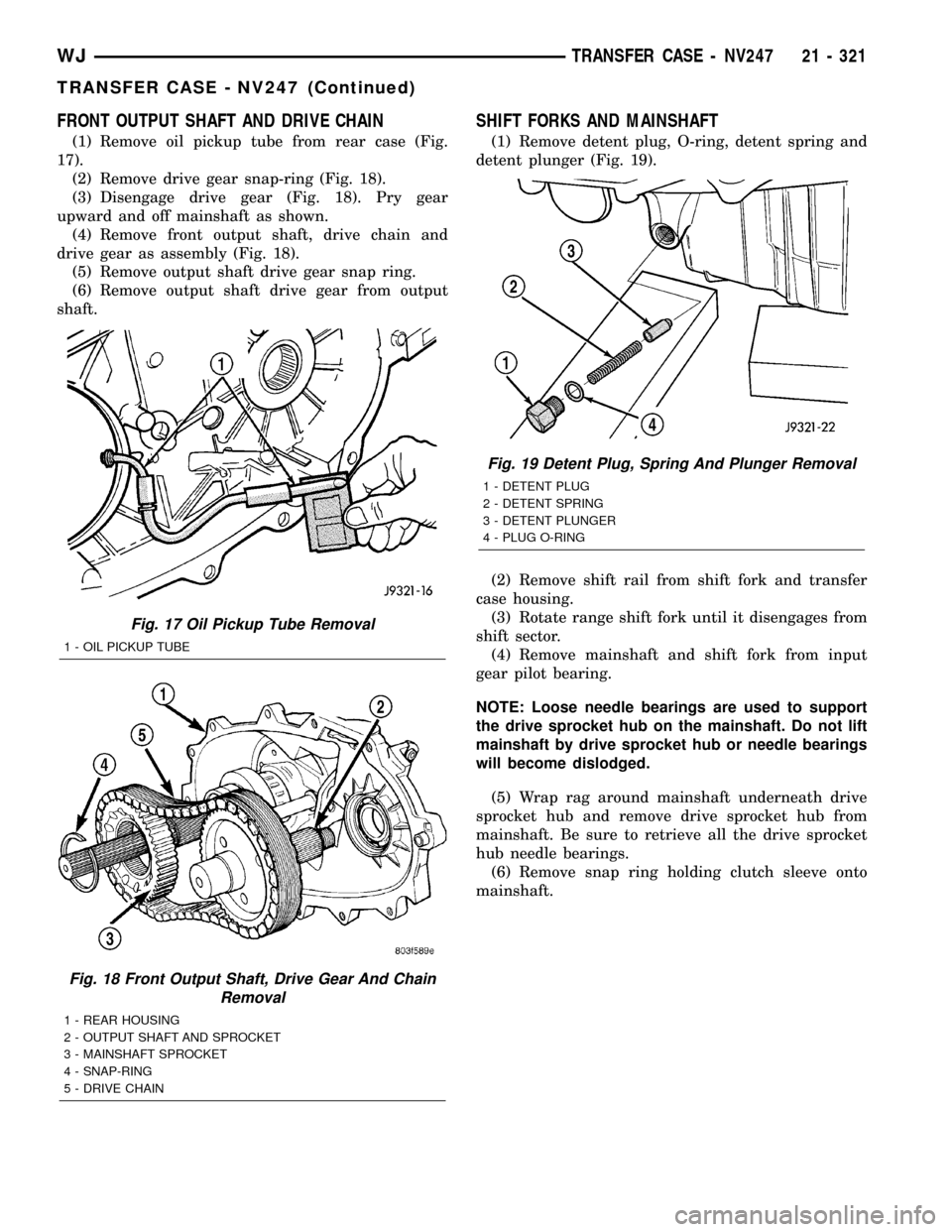

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Remove oil pickup tube from rear case (Fig.

17).

(2) Remove drive gear snap-ring (Fig. 18).

(3) Disengage drive gear (Fig. 18). Pry gear

upward and off mainshaft as shown.

(4) Remove front output shaft, drive chain and

drive gear as assembly (Fig. 18).

(5) Remove output shaft drive gear snap ring.

(6) Remove output shaft drive gear from output

shaft.

SHIFT FORKS AND MAINSHAFT

(1) Remove detent plug, O-ring, detent spring and

detent plunger (Fig. 19).

(2) Remove shift rail from shift fork and transfer

case housing.

(3) Rotate range shift fork until it disengages from

shift sector.

(4) Remove mainshaft and shift fork from input

gear pilot bearing.

NOTE: Loose needle bearings are used to support

the drive sprocket hub on the mainshaft. Do not lift

mainshaft by drive sprocket hub or needle bearings

will become dislodged.

(5) Wrap rag around mainshaft underneath drive

sprocket hub and remove drive sprocket hub from

mainshaft. Be sure to retrieve all the drive sprocket

hub needle bearings.

(6) Remove snap ring holding clutch sleeve onto

mainshaft.

Fig. 17 Oil Pickup Tube Removal

1 - OIL PICKUP TUBE

Fig. 18 Front Output Shaft, Drive Gear And Chain

Removal

1 - REAR HOUSING

2 - OUTPUT SHAFT AND SPROCKET

3 - MAINSHAFT SPROCKET

4 - SNAP-RING

5 - DRIVE CHAIN

Fig. 19 Detent Plug, Spring And Plunger Removal

1 - DETENT PLUG

2 - DETENT SPRING

3 - DETENT PLUNGER

4 - PLUG O-RING

WJTRANSFER CASE - NV247 21 - 321

TRANSFER CASE - NV247 (Continued)