power distribution JEEP GRAND CHEROKEE 2003 WJ / 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1463 of 2199

The PCM determines injector on-time (pulse width)

based on various inputs.

DIAGNOSIS AND TESTING - FUEL INJECTOR

To perform a complete test of the fuel injectors and

their circuitry, use the DRB scan tool and refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the injector only, refer to the following:

Disconnect the fuel injector wire harness connector

from the injector. The injector is equipped with 2

electrical terminals (pins). Place an ohmmeter across

the terminals. Resistance reading should be approxi-

mately 12 ohms 1.2 ohms at 20ÉC (68ÉF).

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL INJECTOR(S), FUEL

SYSTEM PRESSURE MUST BE RELEASED.

To remove one or more fuel injectors, the fuel rail

assembly must be removed from engine.

(1) Perform Fuel System Pressure Release Proce-

dure.

(2) Remove fuel injector rail. Refer to Fuel Injector

Rail Removal/Installation.

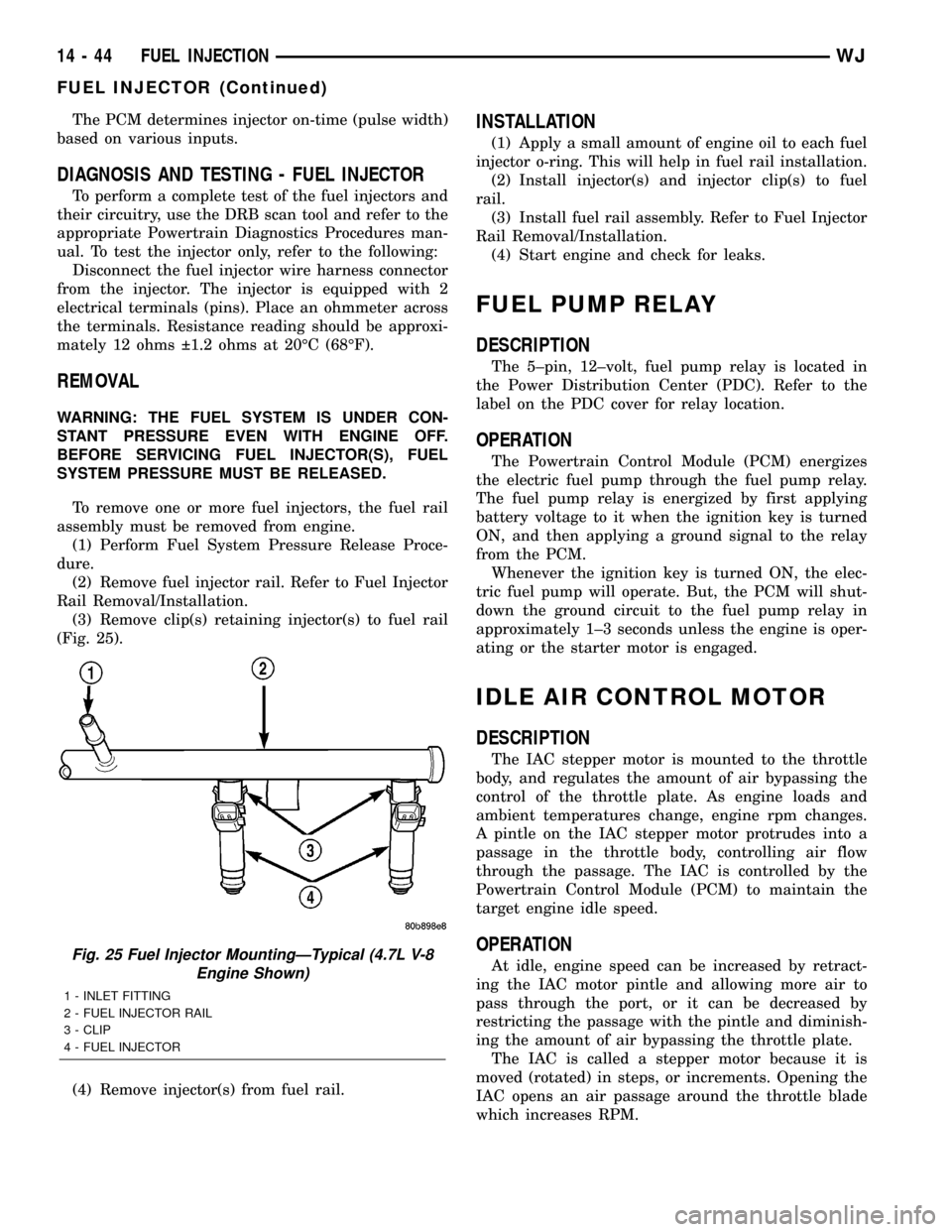

(3) Remove clip(s) retaining injector(s) to fuel rail

(Fig. 25).

(4) Remove injector(s) from fuel rail.

INSTALLATION

(1) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(2) Install injector(s) and injector clip(s) to fuel

rail.

(3) Install fuel rail assembly. Refer to Fuel Injector

Rail Removal/Installation.

(4) Start engine and check for leaks.

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

IDLE AIR CONTROL MOTOR

DESCRIPTION

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into a

passage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.Fig. 25 Fuel Injector MountingÐTypical (4.7L V-8

Engine Shown)

1 - INLET FITTING

2 - FUEL INJECTOR RAIL

3 - CLIP

4 - FUEL INJECTOR

14 - 44 FUEL INJECTIONWJ

FUEL INJECTOR (Continued)

Page 1932 of 2199

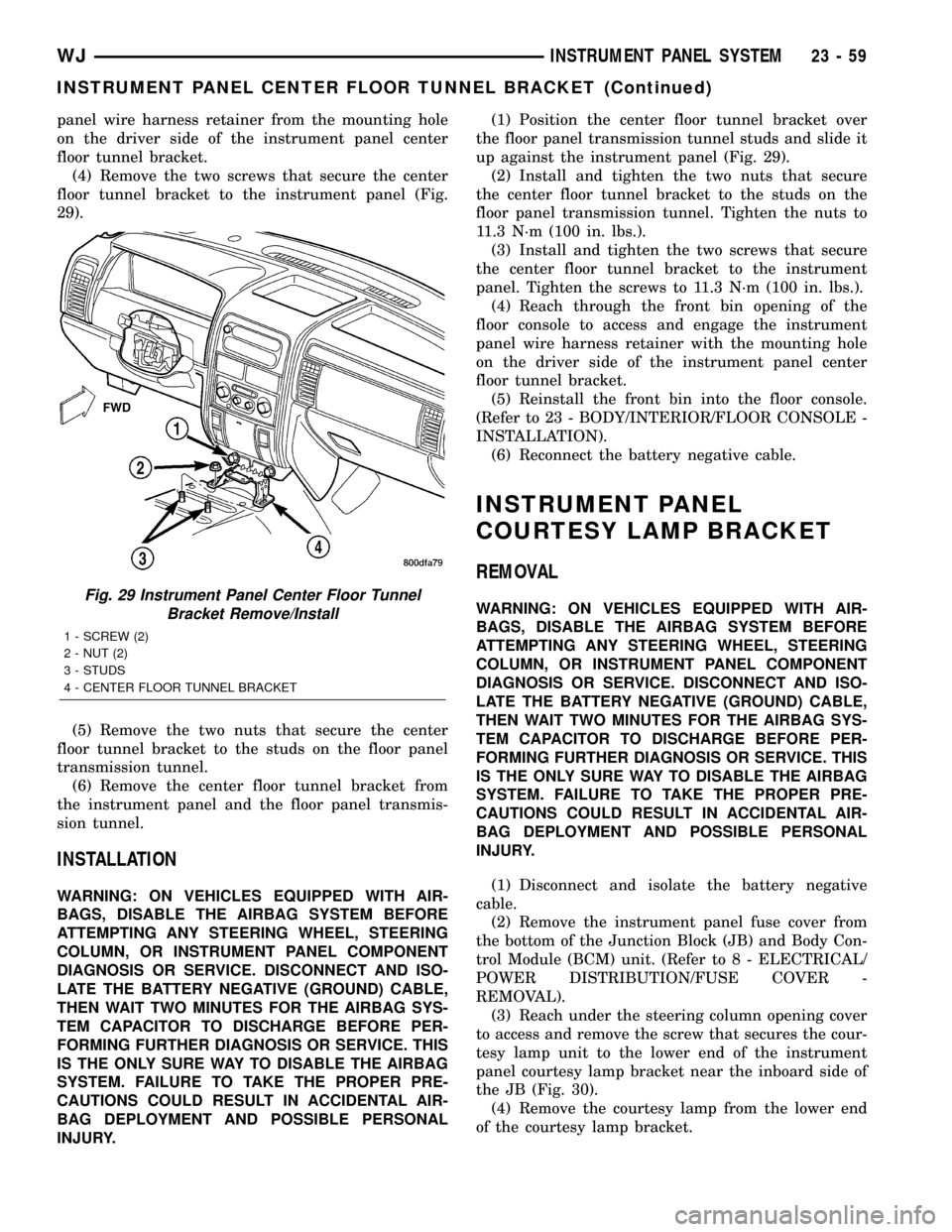

panel wire harness retainer from the mounting hole

on the driver side of the instrument panel center

floor tunnel bracket.

(4) Remove the two screws that secure the center

floor tunnel bracket to the instrument panel (Fig.

29).

(5) Remove the two nuts that secure the center

floor tunnel bracket to the studs on the floor panel

transmission tunnel.

(6) Remove the center floor tunnel bracket from

the instrument panel and the floor panel transmis-

sion tunnel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Position the center floor tunnel bracket over

the floor panel transmission tunnel studs and slide it

up against the instrument panel (Fig. 29).

(2) Install and tighten the two nuts that secure

the center floor tunnel bracket to the studs on the

floor panel transmission tunnel. Tighten the nuts to

11.3 N´m (100 in. lbs.).

(3) Install and tighten the two screws that secure

the center floor tunnel bracket to the instrument

panel. Tighten the screws to 11.3 N´m (100 in. lbs.).

(4) Reach through the front bin opening of the

floor console to access and engage the instrument

panel wire harness retainer with the mounting hole

on the driver side of the instrument panel center

floor tunnel bracket.

(5) Reinstall the front bin into the floor console.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

INSTALLATION).

(6) Reconnect the battery negative cable.

INSTRUMENT PANEL

COURTESY LAMP BRACKET

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel fuse cover from

the bottom of the Junction Block (JB) and Body Con-

trol Module (BCM) unit. (Refer to 8 - ELECTRICAL/

POWER DISTRIBUTION/FUSE COVER -

REMOVAL).

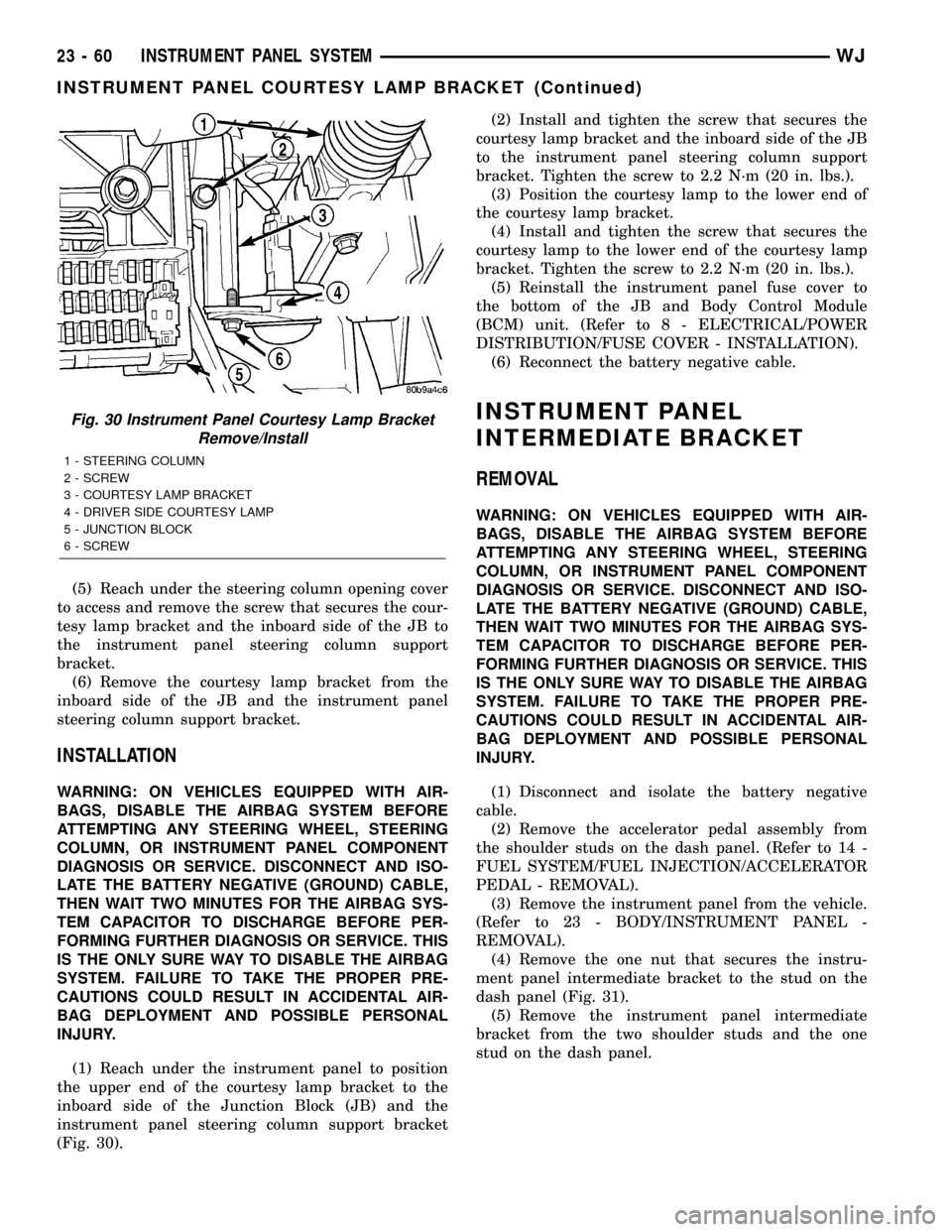

(3) Reach under the steering column opening cover

to access and remove the screw that secures the cour-

tesy lamp unit to the lower end of the instrument

panel courtesy lamp bracket near the inboard side of

the JB (Fig. 30).

(4) Remove the courtesy lamp from the lower end

of the courtesy lamp bracket.Fig. 29 Instrument Panel Center Floor Tunnel

Bracket Remove/Install

1 - SCREW (2)

2 - NUT (2)

3 - STUDS

4 - CENTER FLOOR TUNNEL BRACKET

WJINSTRUMENT PANEL SYSTEM 23 - 59

INSTRUMENT PANEL CENTER FLOOR TUNNEL BRACKET (Continued)

Page 1933 of 2199

(5) Reach under the steering column opening cover

to access and remove the screw that secures the cour-

tesy lamp bracket and the inboard side of the JB to

the instrument panel steering column support

bracket.

(6) Remove the courtesy lamp bracket from the

inboard side of the JB and the instrument panel

steering column support bracket.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Reach under the instrument panel to position

the upper end of the courtesy lamp bracket to the

inboard side of the Junction Block (JB) and the

instrument panel steering column support bracket

(Fig. 30).(2) Install and tighten the screw that secures the

courtesy lamp bracket and the inboard side of the JB

to the instrument panel steering column support

bracket. Tighten the screw to 2.2 N´m (20 in. lbs.).

(3) Position the courtesy lamp to the lower end of

the courtesy lamp bracket.

(4) Install and tighten the screw that secures the

courtesy lamp to the lower end of the courtesy lamp

bracket. Tighten the screw to 2.2 N´m (20 in. lbs.).

(5) Reinstall the instrument panel fuse cover to

the bottom of the JB and Body Control Module

(BCM) unit. (Refer to 8 - ELECTRICAL/POWER

DISTRIBUTION/FUSE COVER - INSTALLATION).

(6) Reconnect the battery negative cable.

INSTRUMENT PANEL

INTERMEDIATE BRACKET

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the accelerator pedal assembly from

the shoulder studs on the dash panel. (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/ACCELERATOR

PEDAL - REMOVAL).

(3) Remove the instrument panel from the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL -

REMOVAL).

(4) Remove the one nut that secures the instru-

ment panel intermediate bracket to the stud on the

dash panel (Fig. 31).

(5) Remove the instrument panel intermediate

bracket from the two shoulder studs and the one

stud on the dash panel.

Fig. 30 Instrument Panel Courtesy Lamp Bracket

Remove/Install

1 - STEERING COLUMN

2 - SCREW

3 - COURTESY LAMP BRACKET

4 - DRIVER SIDE COURTESY LAMP

5 - JUNCTION BLOCK

6 - SCREW

23 - 60 INSTRUMENT PANEL SYSTEMWJ

INSTRUMENT PANEL COURTESY LAMP BRACKET (Continued)

Page 1937 of 2199

INSTRUMENT PANEL

STEERING COLUMN SUPPORT

BRACKET

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instru-

ment panel. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - REMOVAL).

(3) Remove the instrument panel plenum bracket

from the steering column support bracket. (Refer to

23 - BODY/INSTRUMENT PANEL/IP PLENUM

BRACKET - REMOVAL).

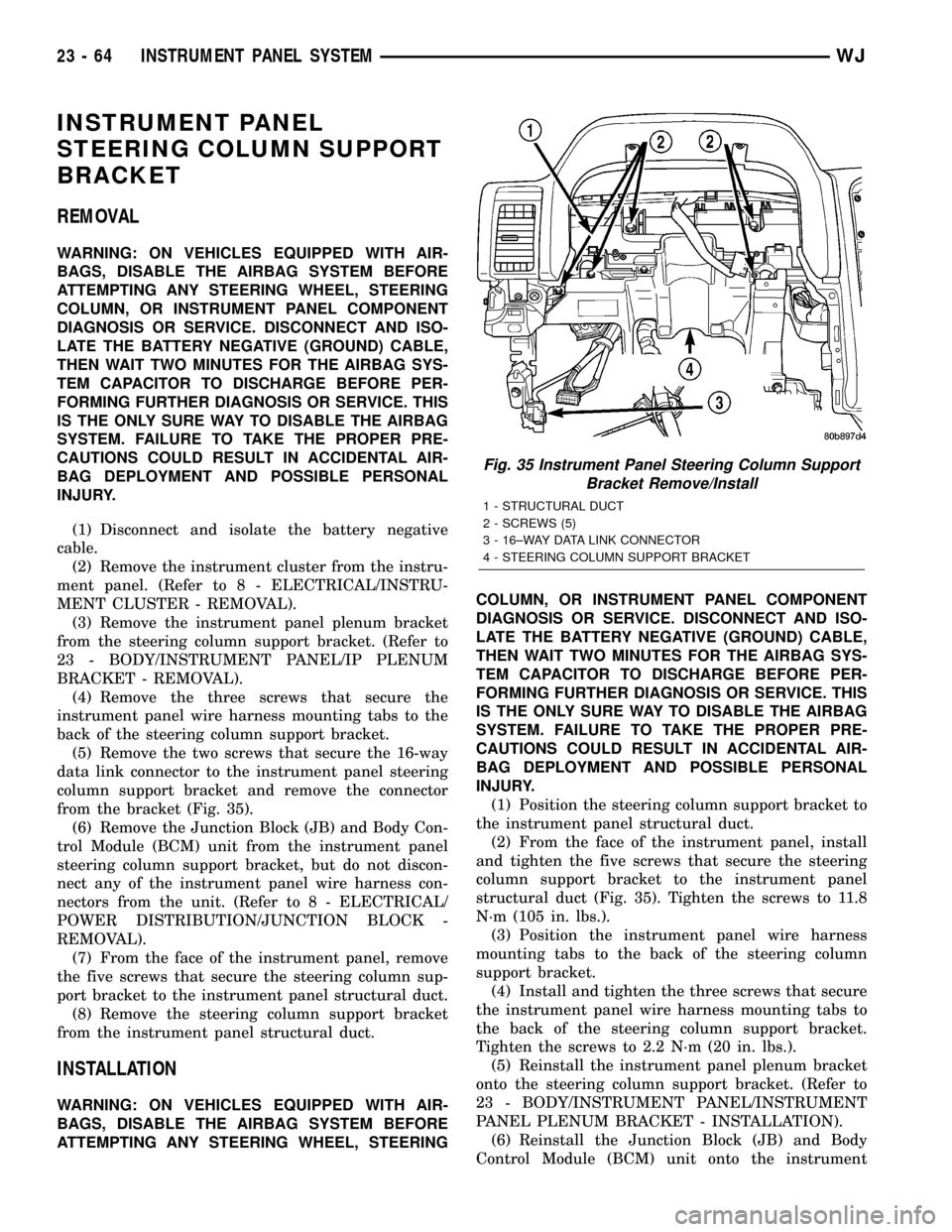

(4) Remove the three screws that secure the

instrument panel wire harness mounting tabs to the

back of the steering column support bracket.

(5) Remove the two screws that secure the 16-way

data link connector to the instrument panel steering

column support bracket and remove the connector

from the bracket (Fig. 35).

(6) Remove the Junction Block (JB) and Body Con-

trol Module (BCM) unit from the instrument panel

steering column support bracket, but do not discon-

nect any of the instrument panel wire harness con-

nectors from the unit. (Refer to 8 - ELECTRICAL/

POWER DISTRIBUTION/JUNCTION BLOCK -

REMOVAL).

(7) From the face of the instrument panel, remove

the five screws that secure the steering column sup-

port bracket to the instrument panel structural duct.

(8) Remove the steering column support bracket

from the instrument panel structural duct.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERINGCOLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the steering column support bracket to

the instrument panel structural duct.

(2) From the face of the instrument panel, install

and tighten the five screws that secure the steering

column support bracket to the instrument panel

structural duct (Fig. 35). Tighten the screws to 11.8

N´m (105 in. lbs.).

(3) Position the instrument panel wire harness

mounting tabs to the back of the steering column

support bracket.

(4) Install and tighten the three screws that secure

the instrument panel wire harness mounting tabs to

the back of the steering column support bracket.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(5) Reinstall the instrument panel plenum bracket

onto the steering column support bracket. (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL PLENUM BRACKET - INSTALLATION).

(6) Reinstall the Junction Block (JB) and Body

Control Module (BCM) unit onto the instrument

Fig. 35 Instrument Panel Steering Column Support

Bracket Remove/Install

1 - STRUCTURAL DUCT

2 - SCREWS (5)

3 - 16±WAY DATA LINK CONNECTOR

4 - STEERING COLUMN SUPPORT BRACKET

23 - 64 INSTRUMENT PANEL SYSTEMWJ

Page 1938 of 2199

panel steering column support bracket. (Refer to 8 -

ELECTRICAL/POWER DISTRIBUTION/JUNCTION

BLOCK - INSTALLATION).

(7) Position the 16-way data link connector to the

instrument panel steering column support bracket.

(8) Install and tighten the two screws that secure

the 16-way data link connector to the instrument

panel steering column support bracket. Tighten the

screws to 2.2 N´m (20 in. lbs.).

(9) Reinstall the instrument cluster onto the

instrument panel. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - INSTALLATION).

(10) Reconnect the battery negative cable.

INSTRUMENT PANEL TRIM

BEZEL - DRIVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

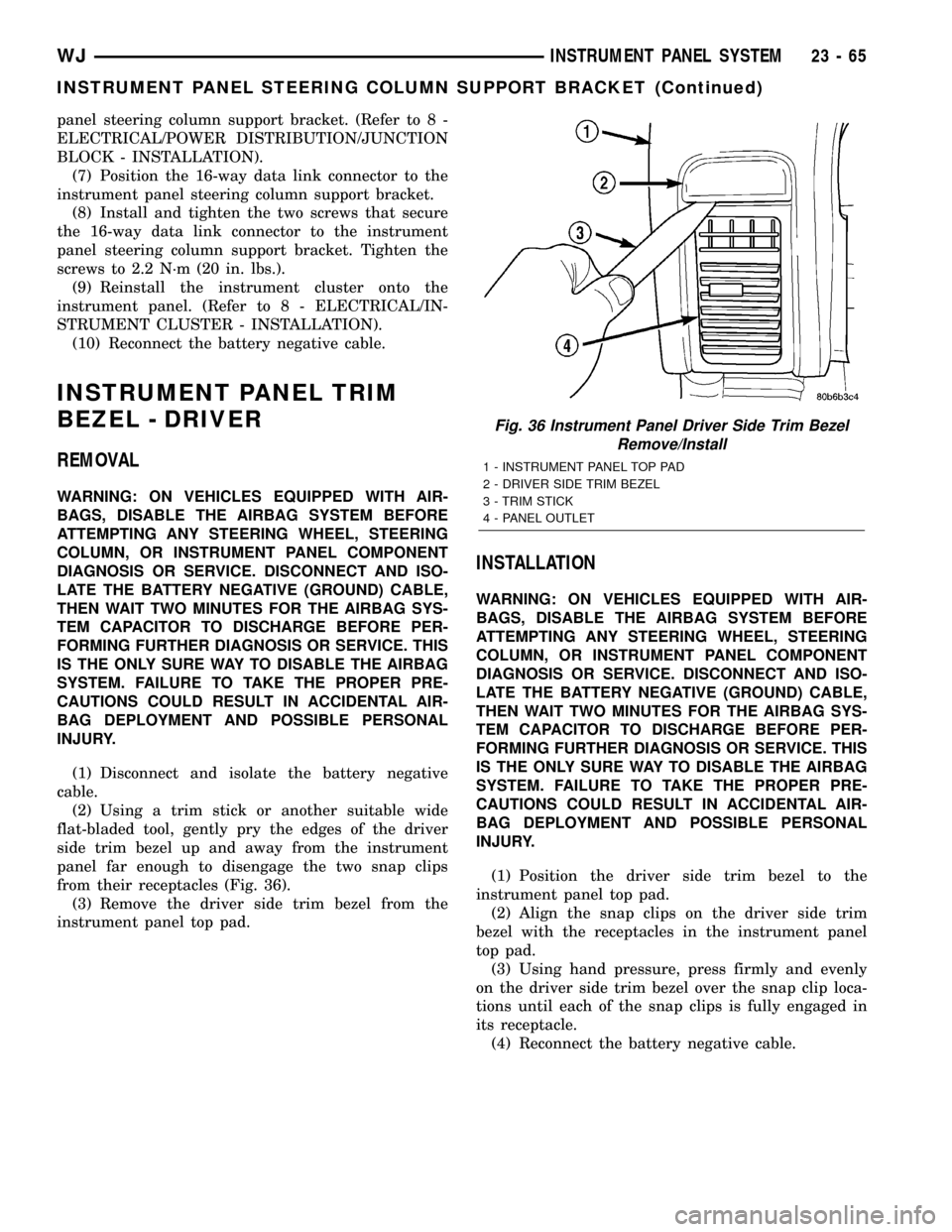

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the edges of the driver

side trim bezel up and away from the instrument

panel far enough to disengage the two snap clips

from their receptacles (Fig. 36).

(3) Remove the driver side trim bezel from the

instrument panel top pad.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the driver side trim bezel to the

instrument panel top pad.

(2) Align the snap clips on the driver side trim

bezel with the receptacles in the instrument panel

top pad.

(3) Using hand pressure, press firmly and evenly

on the driver side trim bezel over the snap clip loca-

tions until each of the snap clips is fully engaged in

its receptacle.

(4) Reconnect the battery negative cable.

Fig. 36 Instrument Panel Driver Side Trim Bezel

Remove/Install

1 - INSTRUMENT PANEL TOP PAD

2 - DRIVER SIDE TRIM BEZEL

3 - TRIM STICK

4 - PANEL OUTLET

WJINSTRUMENT PANEL SYSTEM 23 - 65

INSTRUMENT PANEL STEERING COLUMN SUPPORT BRACKET (Continued)

Page 1969 of 2199

SUNROOF

TABLE OF CONTENTS

page page

SUNROOF

DESCRIPTION.........................96

DIAGNOSIS AND TESTING - SUNROOF......96

DRAIN TUBE

REMOVAL............................100

INSTALLATION........................100

CONTROL MODULE

REMOVAL............................101

INSTALLATION........................101

DRIVE MOTOR

REMOVAL............................101

INSTALLATION........................101

WIND DEFLECTOR

REMOVAL............................102INSTALLATION........................102

GLASS PANEL

REMOVAL............................102

INSTALLATION........................103

ADJUSTMENTS

ADJUSTMENTS - FIT.................103

ADJUSTMENT - TIMING...............103

SUNSHADE

REMOVAL............................103

INSTALLATION........................103

HOUSING ASSEMBLY

REMOVAL............................104

INSTALLATION........................104

SUNROOF

DESCRIPTION

WARNING: Keep fingers and other body parts out

of sunroof opening at all times.

The sunroof features a power sliding glass panel

and a sunshade which can be manually positioned

anywhere along its travel, rearward of glass panel

front edge.

The sunroof is electrically operated from a switch

located on the mini overhead console. To operate the

sunroof the ignition switch must be in the On/Run

position. The sunroof has both manual and Express

Open modes of operation when opening. To open the

sunroof in the Express Open mode, the switch is

pressed rearward for less than1 second.This causes

the sunroof glass to automatically retract and stop at

a position slightly forward of full open that reduces

low speed wind buffeting. The sunroof can also be

opened manually by pressing and holding the switch

rearward. Once the switch is held reward for more

than1 second,the glass will retract in the manual

mode. Releasing the switch at any time during travel

will cause the sunroof to stop at the current position.

To close the sunroof from an open position, the

switch must be pushed forward and held until the

sunroof glass comes to a complete stop. Releasing the

switch at any time in this mode will cause the sun-

roof to stop at the current position.

To vent the sunroof from the closed position, the

switch is pushed forward and held. Releasing theswitch at any time during travel will cause the sun-

roof to stop at the current vent position. To reach the

fully vented position, continue to hold the switch for-

ward until vent motion stops. To close the sunroof

from the vent position, push and hold the switch

rearward until the glass comes to a complete stop.

DIAGNOSIS AND TESTING - SUNROOF

CAUTION: The sunroof motor is only to be powered

through the vehicle battery and vehicle wire har-

ness. Applying power to the sunroof motor leads

will cause failure of the sunroof control unit.

Before beginning sunroof diagnostics verify that all

other power accessories are in proper operating con-

dition. Refer to Sunroof Diagnostic Chart for possible

causes. If not, a common electrical problem may

exist. Refer to Group 8W, Wiring Diagrams, of this

publication for circuit, splice and component descrip-

tions. Check the condition of the circuit protection

(20 amp high current fuse (battery feed) located in

the Power Distribution Center (PDC). Check the

cover of the PDC for location of the fuse. Check for

correct operation of the sunroof delay relay. Inspect

all wiring connector pins for proper engagement and

continuity. Check for battery voltage at battery and

ignition pins of the power sunroof express module

wiring connector. Refer to Group 8W, Wiring Dia-

grams, for circuit information. The controller will not

operate at less than 10 volts. Check the ground at

the sunroof express module.

Before beginning diagnosis for wind noise or water

leaks, verify that the problem was not caused by

23 - 96 SUNROOFWJ

Page 2081 of 2199

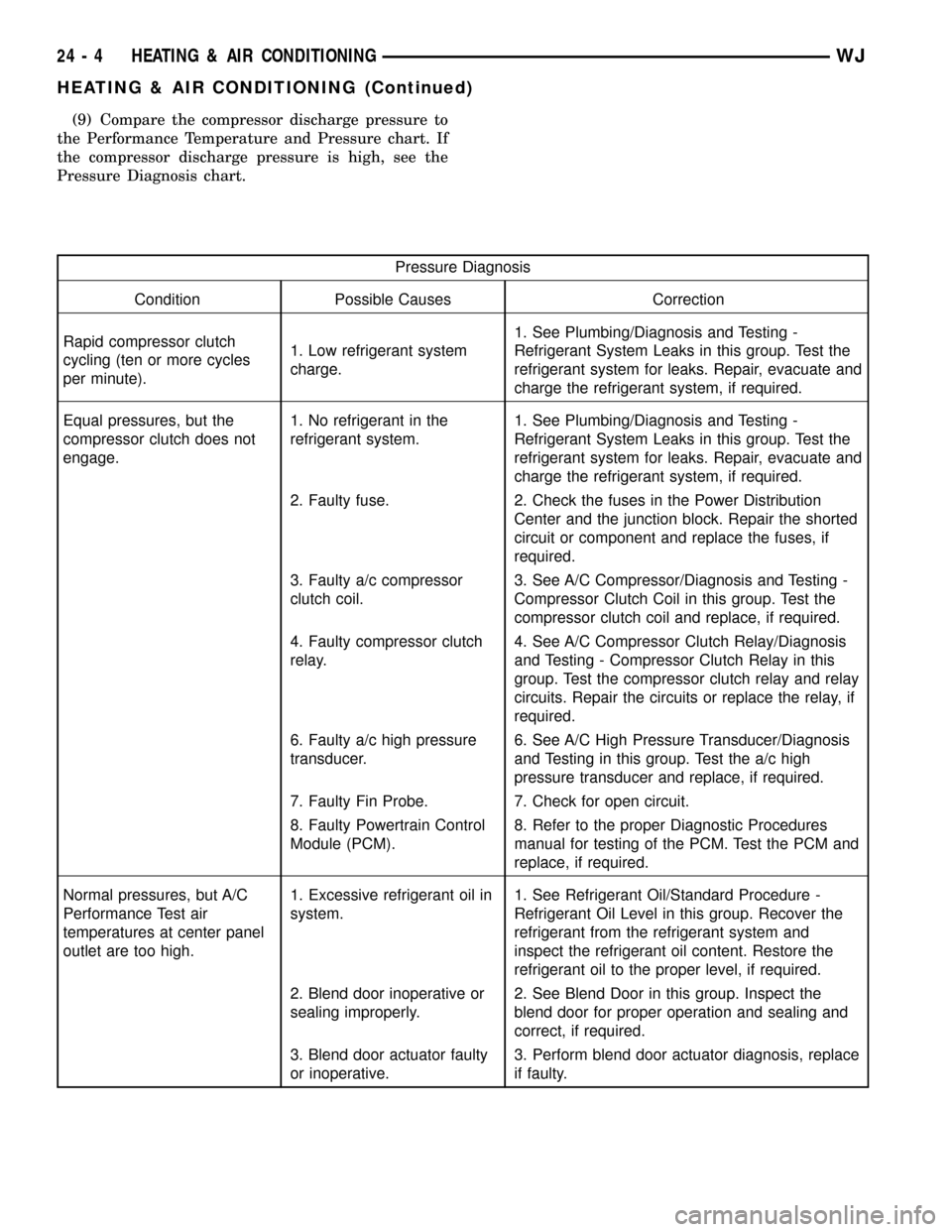

(9) Compare the compressor discharge pressure to

the Performance Temperature and Pressure chart. If

the compressor discharge pressure is high, see the

Pressure Diagnosis chart.

Pressure Diagnosis

Condition Possible Causes Correction

Rapid compressor clutch

cycling (ten or more cycles

per minute).1. Low refrigerant system

charge.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

Equal pressures, but the

compressor clutch does not

engage.1. No refrigerant in the

refrigerant system.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

2. Faulty fuse. 2. Check the fuses in the Power Distribution

Center and the junction block. Repair the shorted

circuit or component and replace the fuses, if

required.

3. Faulty a/c compressor

clutch coil.3. See A/C Compressor/Diagnosis and Testing -

Compressor Clutch Coil in this group. Test the

compressor clutch coil and replace, if required.

4. Faulty compressor clutch

relay.4. See A/C Compressor Clutch Relay/Diagnosis

and Testing - Compressor Clutch Relay in this

group. Test the compressor clutch relay and relay

circuits. Repair the circuits or replace the relay, if

required.

6. Faulty a/c high pressure

transducer.6. See A/C High Pressure Transducer/Diagnosis

and Testing in this group. Test the a/c high

pressure transducer and replace, if required.

7. Faulty Fin Probe. 7. Check for open circuit.

8. Faulty Powertrain Control

Module (PCM).8. Refer to the proper Diagnostic Procedures

manual for testing of the PCM. Test the PCM and

replace, if required.

Normal pressures, but A/C

Performance Test air

temperatures at center panel

outlet are too high.1. Excessive refrigerant oil in

system.1. See Refrigerant Oil/Standard Procedure -

Refrigerant Oil Level in this group. Recover the

refrigerant from the refrigerant system and

inspect the refrigerant oil content. Restore the

refrigerant oil to the proper level, if required.

2. Blend door inoperative or

sealing improperly.2. See Blend Door in this group. Inspect the

blend door for proper operation and sealing and

correct, if required.

3. Blend door actuator faulty

or inoperative.3. Perform blend door actuator diagnosis, replace

if faulty.

24 - 4 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2093 of 2199

gap should be between 0.35 to 0.65 millimeter (0.014

to 0.026 inch). If the proper air gap is not obtained,

add or subtract shims as needed until the desired air

gap is obtained.

(9) Install the compressor shaft bolt. Tighten the

bolt to 13 N´m (115 in. lbs.).

NOTE: The shims may compress after tightening

the shaft bolt. Check the air gap in four or more

places to verify the air gap is still correct. Spin the

pulley before performing a final check of the air

gap.

(10) To complete the installation, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION)

A/C COMPRESSOR CLUTCH

RELAY

DESCRIPTION

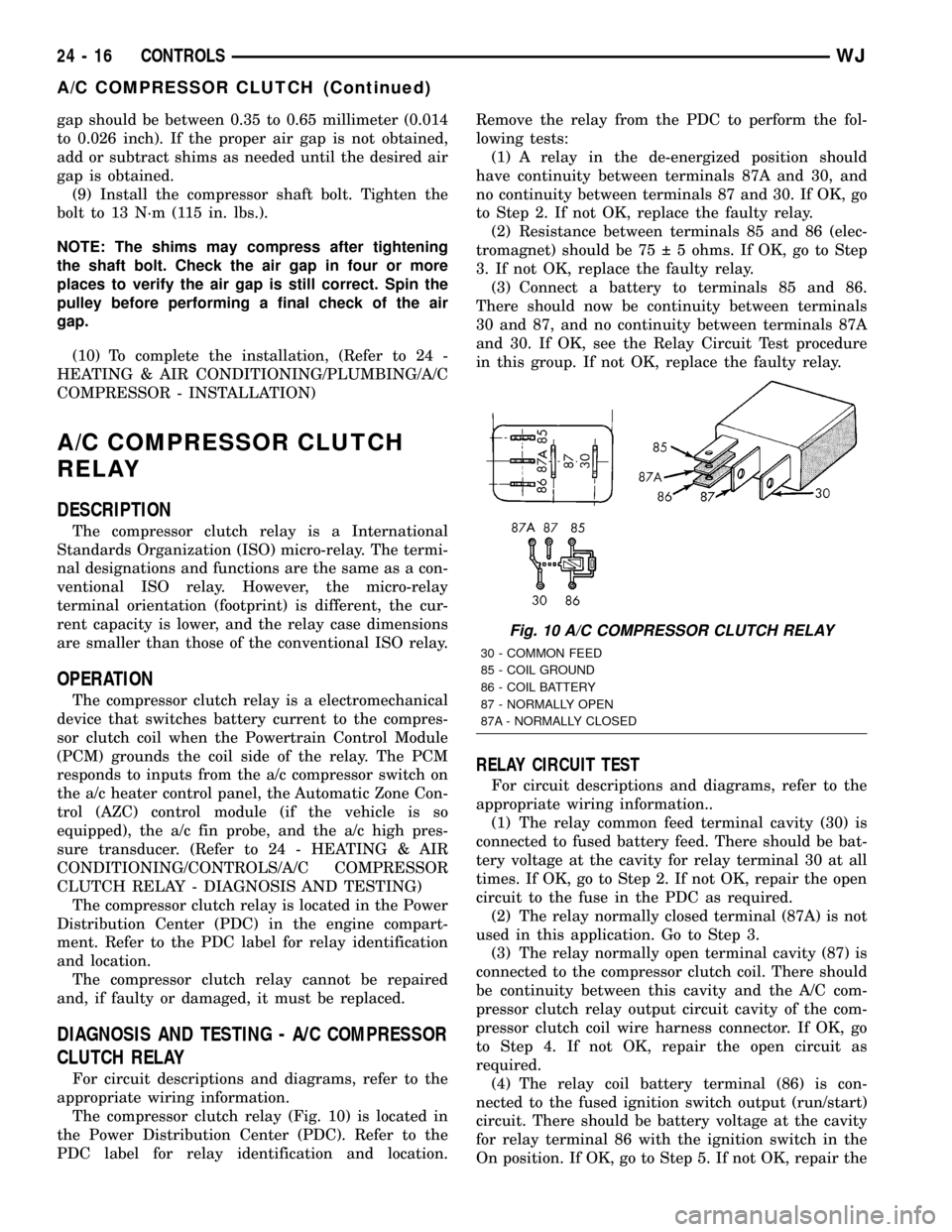

The compressor clutch relay is a International

Standards Organization (ISO) micro-relay. The termi-

nal designations and functions are the same as a con-

ventional ISO relay. However, the micro-relay

terminal orientation (footprint) is different, the cur-

rent capacity is lower, and the relay case dimensions

are smaller than those of the conventional ISO relay.

OPERATION

The compressor clutch relay is a electromechanical

device that switches battery current to the compres-

sor clutch coil when the Powertrain Control Module

(PCM) grounds the coil side of the relay. The PCM

responds to inputs from the a/c compressor switch on

the a/c heater control panel, the Automatic Zone Con-

trol (AZC) control module (if the vehicle is so

equipped), the a/c fin probe, and the a/c high pres-

sure transducer. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH RELAY - DIAGNOSIS AND TESTING)

The compressor clutch relay is located in the Power

Distribution Center (PDC) in the engine compart-

ment. Refer to the PDC label for relay identification

and location.

The compressor clutch relay cannot be repaired

and, if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

CLUTCH RELAY

For circuit descriptions and diagrams, refer to the

appropriate wiring information.

The compressor clutch relay (Fig. 10) is located in

the Power Distribution Center (PDC). Refer to the

PDC label for relay identification and location.Remove the relay from the PDC to perform the fol-

lowing tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see the Relay Circuit Test procedure

in this group. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

For circuit descriptions and diagrams, refer to the

appropriate wiring information..

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed. There should be bat-

tery voltage at the cavity for relay terminal 30 at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is not

used in this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the compressor clutch coil. There should

be continuity between this cavity and the A/C com-

pressor clutch relay output circuit cavity of the com-

pressor clutch coil wire harness connector. If OK, go

to Step 4. If not OK, repair the open circuit as

required.

(4) The relay coil battery terminal (86) is con-

nected to the fused ignition switch output (run/start)

circuit. There should be battery voltage at the cavity

for relay terminal 86 with the ignition switch in the

On position. If OK, go to Step 5. If not OK, repair the

Fig. 10 A/C COMPRESSOR CLUTCH RELAY

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

24 - 16 CONTROLSWJ

A/C COMPRESSOR CLUTCH (Continued)

Page 2094 of 2199

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

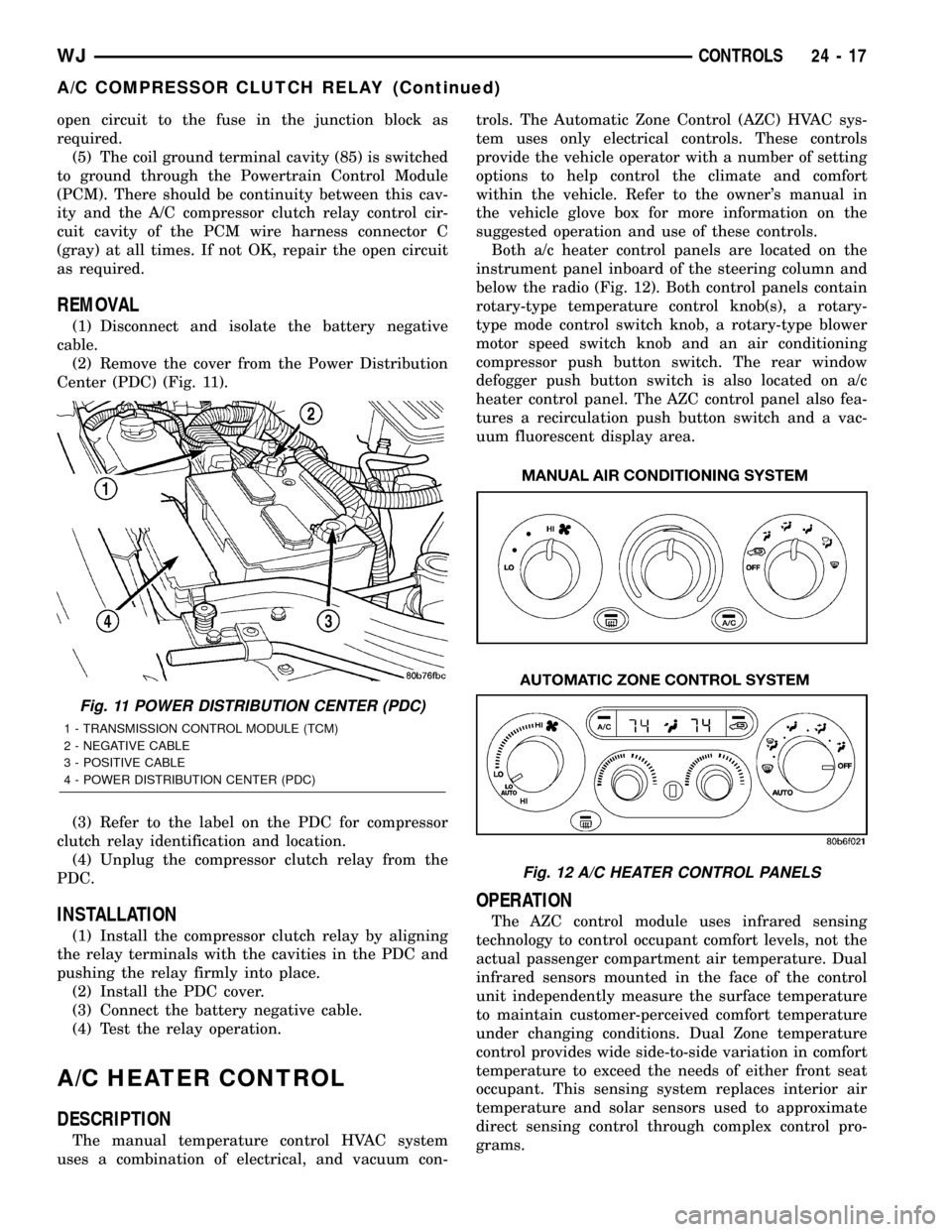

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 11).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

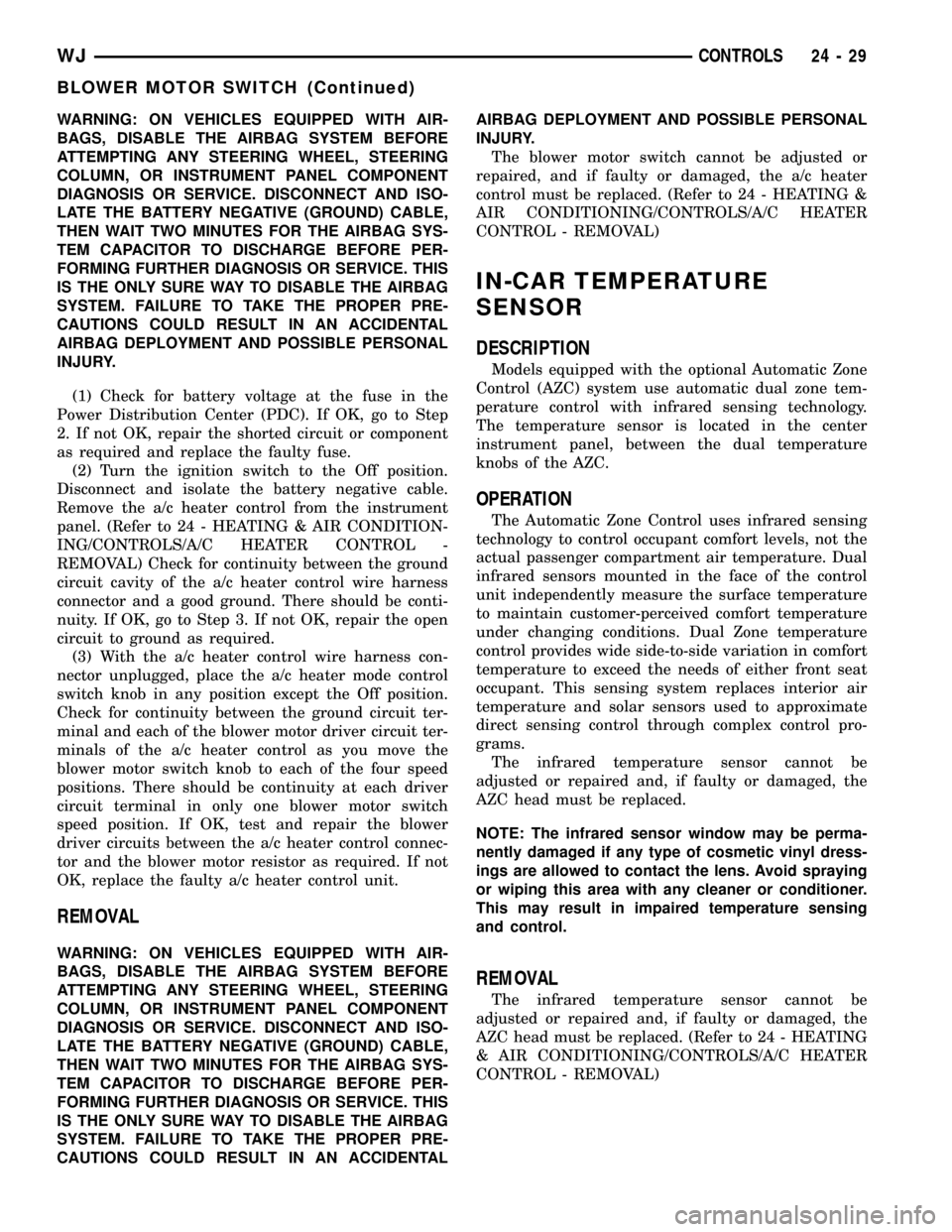

A/C HEATER CONTROL

DESCRIPTION

The manual temperature control HVAC system

uses a combination of electrical, and vacuum con-trols. The Automatic Zone Control (AZC) HVAC sys-

tem uses only electrical controls. These controls

provide the vehicle operator with a number of setting

options to help control the climate and comfort

within the vehicle. Refer to the owner's manual in

the vehicle glove box for more information on the

suggested operation and use of these controls.

Both a/c heater control panels are located on the

instrument panel inboard of the steering column and

below the radio (Fig. 12). Both control panels contain

rotary-type temperature control knob(s), a rotary-

type mode control switch knob, a rotary-type blower

motor speed switch knob and an air conditioning

compressor push button switch. The rear window

defogger push button switch is also located on a/c

heater control panel. The AZC control panel also fea-

tures a recirculation push button switch and a vac-

uum fluorescent display area.

OPERATION

The AZC control module uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

Fig. 11 POWER DISTRIBUTION CENTER (PDC)

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - NEGATIVE CABLE

3 - POSITIVE CABLE

4 - POWER DISTRIBUTION CENTER (PDC)

Fig. 12 A/C HEATER CONTROL PANELS

WJCONTROLS 24 - 17

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2106 of 2199

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check for battery voltage at the fuse in the

Power Distribution Center (PDC). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the a/c heater control from the instrument

panel. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS/A/C HEATER CONTROL -

REMOVAL) Check for continuity between the ground

circuit cavity of the a/c heater control wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 3. If not OK, repair the open

circuit to ground as required.

(3) With the a/c heater control wire harness con-

nector unplugged, place the a/c heater mode control

switch knob in any position except the Off position.

Check for continuity between the ground circuit ter-

minal and each of the blower motor driver circuit ter-

minals of the a/c heater control as you move the

blower motor switch knob to each of the four speed

positions. There should be continuity at each driver

circuit terminal in only one blower motor switch

speed position. If OK, test and repair the blower

driver circuits between the a/c heater control connec-

tor and the blower motor resistor as required. If not

OK, replace the faulty a/c heater control unit.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTALAIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The blower motor switch cannot be adjusted or

repaired, and if faulty or damaged, the a/c heater

control must be replaced. (Refer to 24 - HEATING &

AIR CONDITIONING/CONTROLS/A/C HEATER

CONTROL - REMOVAL)

IN-CAR TEMPERATURE

SENSOR

DESCRIPTION

Models equipped with the optional Automatic Zone

Control (AZC) system use automatic dual zone tem-

perature control with infrared sensing technology.

The temperature sensor is located in the center

instrument panel, between the dual temperature

knobs of the AZC.

OPERATION

The Automatic Zone Control uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

The infrared temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, the

AZC head must be replaced.

NOTE: The infrared sensor window may be perma-

nently damaged if any type of cosmetic vinyl dress-

ings are allowed to contact the lens. Avoid spraying

or wiping this area with any cleaner or conditioner.

This may result in impaired temperature sensing

and control.

REMOVAL

The infrared temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, the

AZC head must be replaced. (Refer to 24 - HEATING

& AIR CONDITIONING/CONTROLS/A/C HEATER

CONTROL - REMOVAL)

WJCONTROLS 24 - 29

BLOWER MOTOR SWITCH (Continued)