JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1541 of 2199

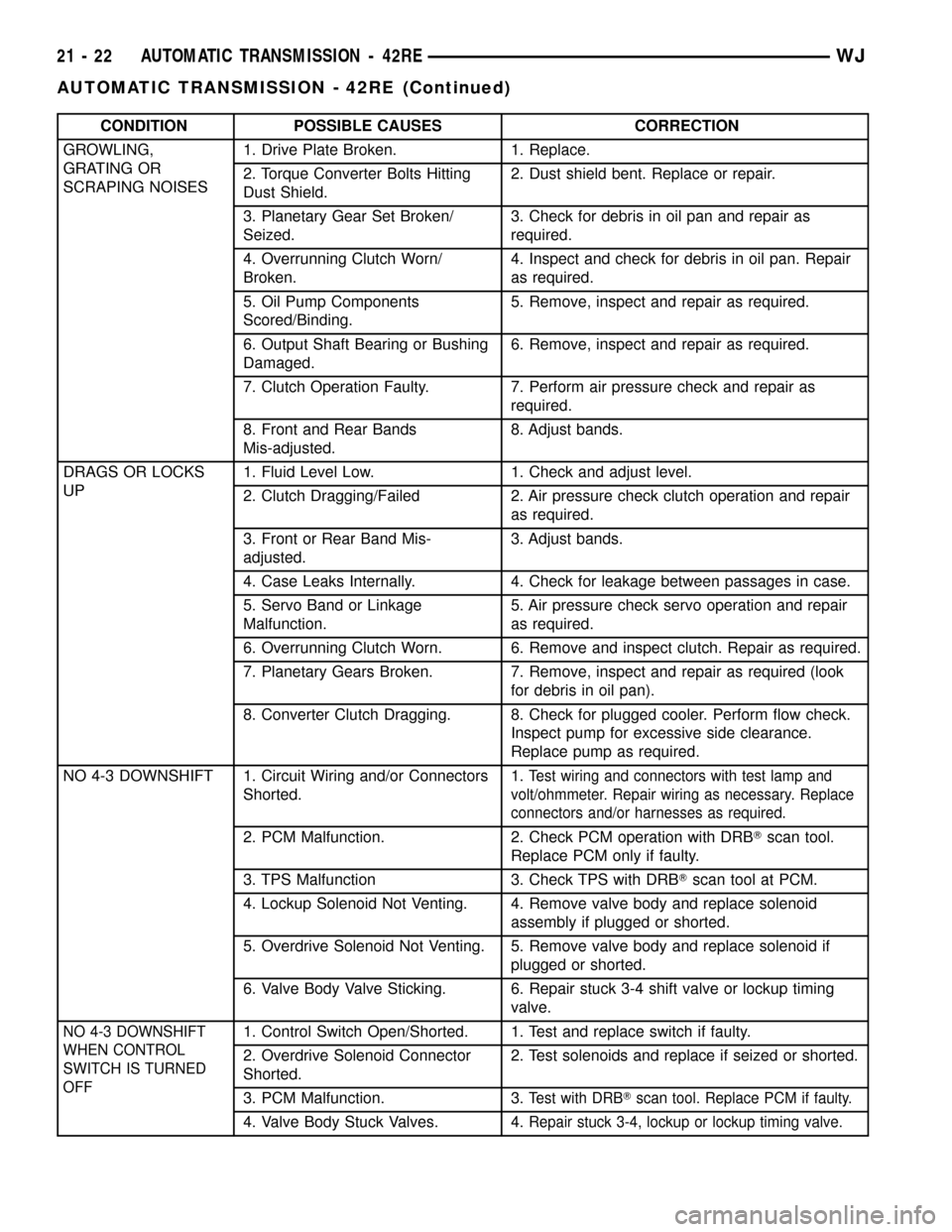

CONDITION POSSIBLE CAUSES CORRECTION

GROWLING,

GRATING OR

SCRAPING NOISES1. Drive Plate Broken. 1. Replace.

2. Torque Converter Bolts Hitting

Dust Shield.2. Dust shield bent. Replace or repair.

3. Planetary Gear Set Broken/

Seized.3. Check for debris in oil pan and repair as

required.

4. Overrunning Clutch Worn/

Broken.4. Inspect and check for debris in oil pan. Repair

as required.

5. Oil Pump Components

Scored/Binding.5. Remove, inspect and repair as required.

6. Output Shaft Bearing or Bushing

Damaged.6. Remove, inspect and repair as required.

7. Clutch Operation Faulty. 7. Perform air pressure check and repair as

required.

8. Front and Rear Bands

Mis-adjusted.8. Adjust bands.

DRAGS OR LOCKS

UP1. Fluid Level Low. 1. Check and adjust level.

2. Clutch Dragging/Failed 2. Air pressure check clutch operation and repair

as required.

3. Front or Rear Band Mis-

adjusted.3. Adjust bands.

4. Case Leaks Internally. 4. Check for leakage between passages in case.

5. Servo Band or Linkage

Malfunction.5. Air pressure check servo operation and repair

as required.

6. Overrunning Clutch Worn. 6. Remove and inspect clutch. Repair as required.

7. Planetary Gears Broken. 7. Remove, inspect and repair as required (look

for debris in oil pan).

8. Converter Clutch Dragging. 8. Check for plugged cooler. Perform flow check.

Inspect pump for excessive side clearance.

Replace pump as required.

NO 4-3 DOWNSHIFT 1. Circuit Wiring and/or Connectors

Shorted.1.

Test wiring and connectors with test lamp and

volt/ohmmeter. Repair wiring as necessary. Replace

connectors and/or harnesses as required.

2. PCM Malfunction. 2. Check PCM operation with DRBTscan tool.

Replace PCM only if faulty.

3. TPS Malfunction 3. Check TPS with DRBTscan tool at PCM.

4. Lockup Solenoid Not Venting. 4. Remove valve body and replace solenoid

assembly if plugged or shorted.

5. Overdrive Solenoid Not Venting. 5. Remove valve body and replace solenoid if

plugged or shorted.

6. Valve Body Valve Sticking. 6. Repair stuck 3-4 shift valve or lockup timing

valve.

NO 4-3 DOWNSHIFT

WHEN CONTROL

SWITCH IS TURNED

OFF1. Control Switch Open/Shorted. 1. Test and replace switch if faulty.

2. Overdrive Solenoid Connector

Shorted.2. Test solenoids and replace if seized or shorted.

3. PCM Malfunction. 3.

Test with DRBTscan tool. Replace PCM if faulty.

4. Valve Body Stuck Valves. 4.Repair stuck 3-4, lockup or lockup timing valve.

21 - 22 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1542 of 2199

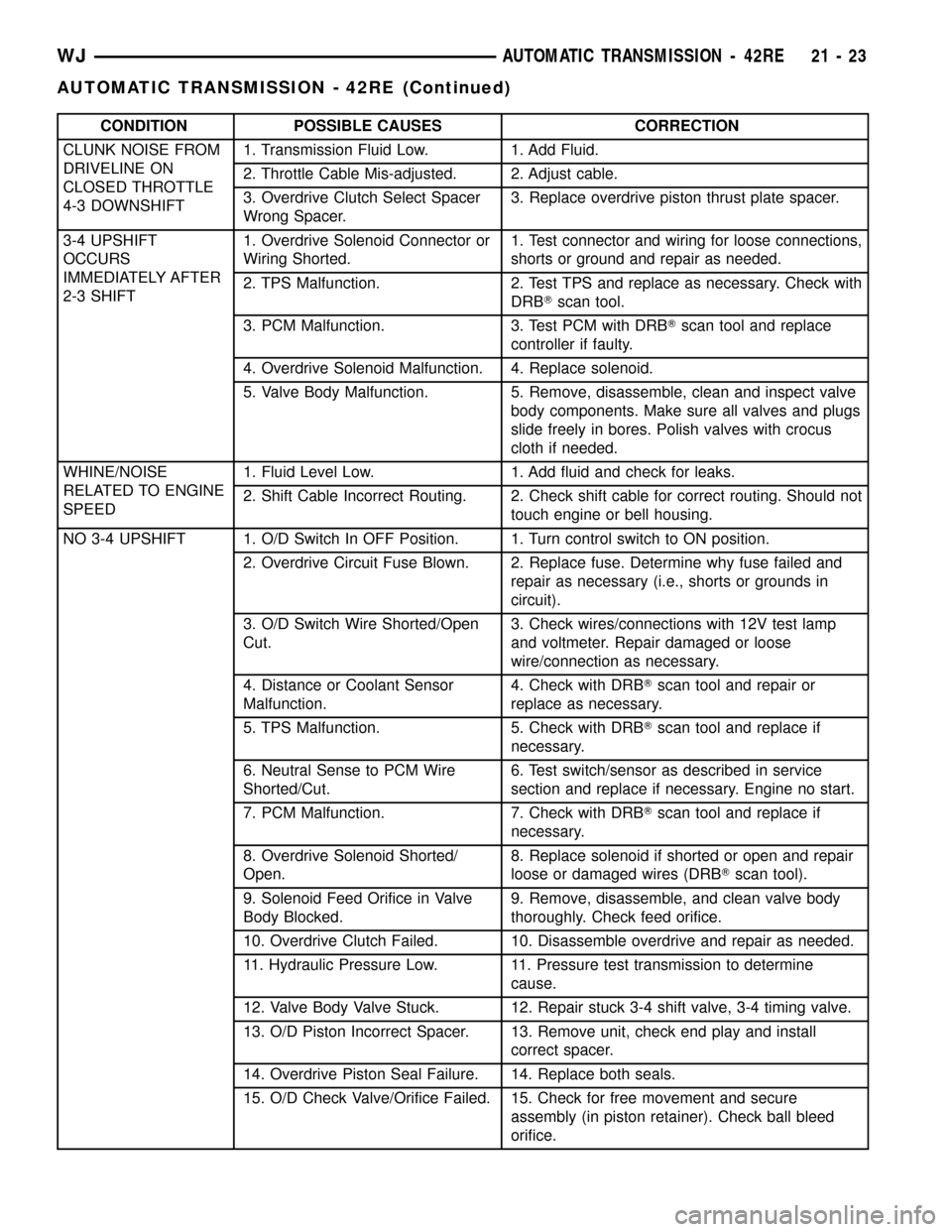

CONDITION POSSIBLE CAUSES CORRECTION

CLUNK NOISE FROM

DRIVELINE ON

CLOSED THROTTLE

4-3 DOWNSHIFT1. Transmission Fluid Low. 1. Add Fluid.

2. Throttle Cable Mis-adjusted. 2. Adjust cable.

3. Overdrive Clutch Select Spacer

Wrong Spacer.3. Replace overdrive piston thrust plate spacer.

3-4 UPSHIFT

OCCURS

IMMEDIATELY AFTER

2-3 SHIFT1. Overdrive Solenoid Connector or

Wiring Shorted.1.

Test connector and wiring for loose connections,

shorts or ground and repair as needed.

2. TPS Malfunction. 2. Test TPS and replace as necessary. Check with

DRBTscan tool.

3. PCM Malfunction. 3. Test PCM with DRBTscan tool and replace

controller if faulty.

4. Overdrive Solenoid Malfunction. 4. Replace solenoid.

5. Valve Body Malfunction. 5. Remove, disassemble, clean and inspect valve

body components. Make sure all valves and plugs

slide freely in bores. Polish valves with crocus

cloth if needed.

WHINE/NOISE

RELATED TO ENGINE

SPEED1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing. Should not

touch engine or bell housing.

NO 3-4 UPSHIFT 1. O/D Switch In OFF Position. 1. Turn control switch to ON position.

2. Overdrive Circuit Fuse Blown. 2. Replace fuse. Determine why fuse failed and

repair as necessary (i.e., shorts or grounds in

circuit).

3. O/D Switch Wire Shorted/Open

Cut.3. Check wires/connections with 12V test lamp

and voltmeter. Repair damaged or loose

wire/connection as necessary.

4. Distance or Coolant Sensor

Malfunction.4. Check with DRBTscan tool and repair or

replace as necessary.

5. TPS Malfunction. 5. Check with DRBTscan tool and replace if

necessary.

6. Neutral Sense to PCM Wire

Shorted/Cut.6. Test switch/sensor as described in service

section and replace if necessary. Engine no start.

7. PCM Malfunction. 7. Check with DRBTscan tool and replace if

necessary.

8. Overdrive Solenoid Shorted/

Open.8. Replace solenoid if shorted or open and repair

loose or damaged wires (DRBTscan tool).

9. Solenoid Feed Orifice in Valve

Body Blocked.9. Remove, disassemble, and clean valve body

thoroughly. Check feed orifice.

10. Overdrive Clutch Failed. 10. Disassemble overdrive and repair as needed.

11. Hydraulic Pressure Low. 11. Pressure test transmission to determine

cause.

12. Valve Body Valve Stuck. 12. Repair stuck 3-4 shift valve, 3-4 timing valve.

13. O/D Piston Incorrect Spacer. 13. Remove unit, check end play and install

correct spacer.

14. Overdrive Piston Seal Failure. 14. Replace both seals.

15. O/D Check Valve/Orifice Failed. 15. Check for free movement and secure

assembly (in piston retainer). Check ball bleed

orifice.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 23

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1543 of 2199

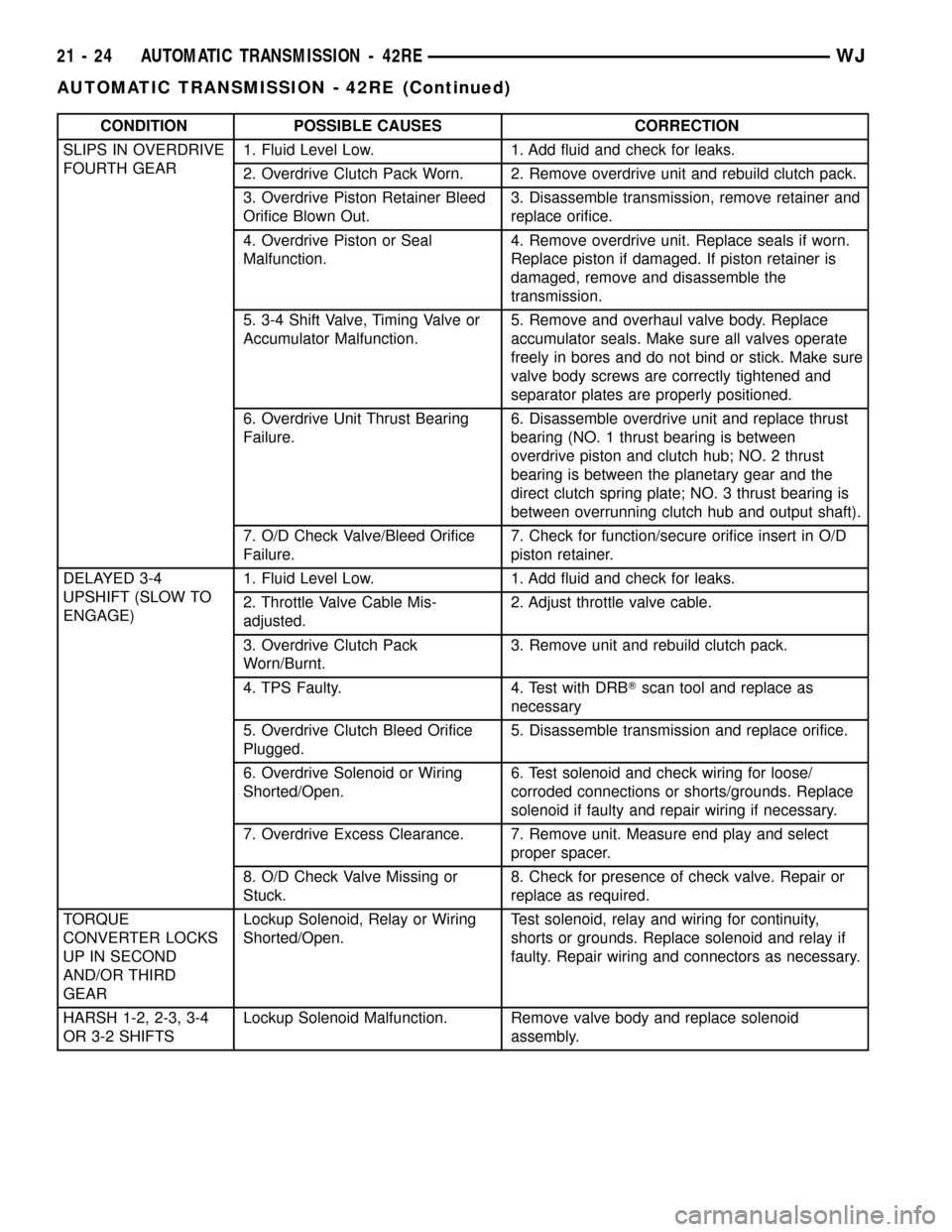

CONDITION POSSIBLE CAUSES CORRECTION

SLIPS IN OVERDRIVE

FOURTH GEAR1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Overdrive Clutch Pack Worn. 2. Remove overdrive unit and rebuild clutch pack.

3. Overdrive Piston Retainer Bleed

Orifice Blown Out.3. Disassemble transmission, remove retainer and

replace orifice.

4. Overdrive Piston or Seal

Malfunction.4. Remove overdrive unit. Replace seals if worn.

Replace piston if damaged. If piston retainer is

damaged, remove and disassemble the

transmission.

5. 3-4 Shift Valve, Timing Valve or

Accumulator Malfunction.5. Remove and overhaul valve body. Replace

accumulator seals. Make sure all valves operate

freely in bores and do not bind or stick. Make sure

valve body screws are correctly tightened and

separator plates are properly positioned.

6. Overdrive Unit Thrust Bearing

Failure.6. Disassemble overdrive unit and replace thrust

bearing (NO. 1 thrust bearing is between

overdrive piston and clutch hub; NO. 2 thrust

bearing is between the planetary gear and the

direct clutch spring plate; NO. 3 thrust bearing is

between overrunning clutch hub and output shaft).

7. O/D Check Valve/Bleed Orifice

Failure.7. Check for function/secure orifice insert in O/D

piston retainer.

DELAYED 3-4

UPSHIFT (SLOW TO

ENGAGE)1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Throttle Valve Cable Mis-

adjusted.2. Adjust throttle valve cable.

3. Overdrive Clutch Pack

Worn/Burnt.3. Remove unit and rebuild clutch pack.

4. TPS Faulty. 4. Test with DRBTscan tool and replace as

necessary

5. Overdrive Clutch Bleed Orifice

Plugged.5. Disassemble transmission and replace orifice.

6. Overdrive Solenoid or Wiring

Shorted/Open.6. Test solenoid and check wiring for loose/

corroded connections or shorts/grounds. Replace

solenoid if faulty and repair wiring if necessary.

7. Overdrive Excess Clearance. 7. Remove unit. Measure end play and select

proper spacer.

8. O/D Check Valve Missing or

Stuck.8. Check for presence of check valve. Repair or

replace as required.

TORQUE

CONVERTER LOCKS

UP IN SECOND

AND/OR THIRD

GEARLockup Solenoid, Relay or Wiring

Shorted/Open.Test solenoid, relay and wiring for continuity,

shorts or grounds. Replace solenoid and relay if

faulty. Repair wiring and connectors as necessary.

HARSH 1-2, 2-3, 3-4

OR 3-2 SHIFTSLockup Solenoid Malfunction. Remove valve body and replace solenoid

assembly.

21 - 24 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1544 of 2199

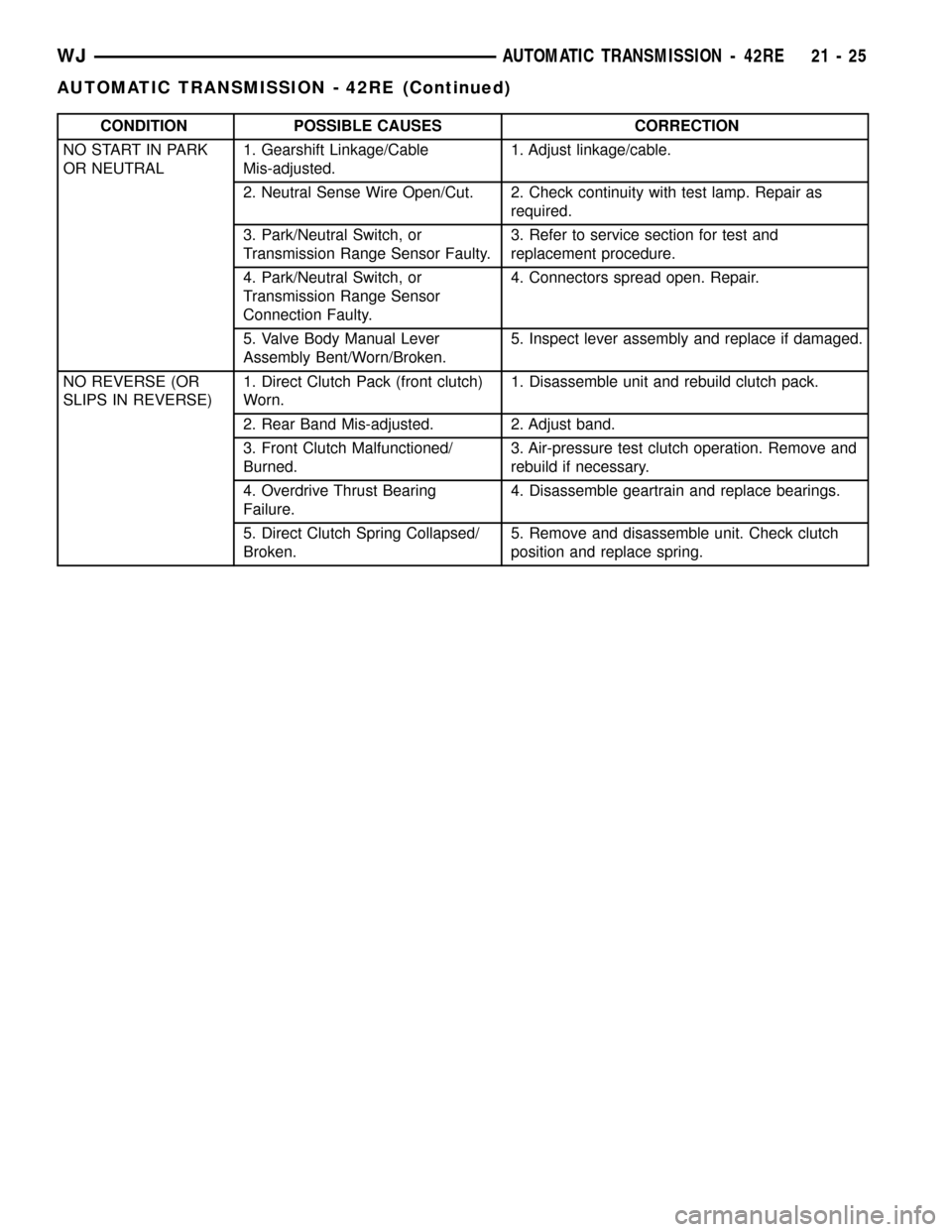

CONDITION POSSIBLE CAUSES CORRECTION

NO START IN PARK

OR NEUTRAL1. Gearshift Linkage/Cable

Mis-adjusted.1. Adjust linkage/cable.

2. Neutral Sense Wire Open/Cut. 2. Check continuity with test lamp. Repair as

required.

3. Park/Neutral Switch, or

Transmission Range Sensor Faulty.3. Refer to service section for test and

replacement procedure.

4. Park/Neutral Switch, or

Transmission Range Sensor

Connection Faulty.4. Connectors spread open. Repair.

5. Valve Body Manual Lever

Assembly Bent/Worn/Broken.5. Inspect lever assembly and replace if damaged.

NO REVERSE (OR

SLIPS IN REVERSE)1. Direct Clutch Pack (front clutch)

Worn.1. Disassemble unit and rebuild clutch pack.

2. Rear Band Mis-adjusted. 2. Adjust band.

3. Front Clutch Malfunctioned/

Burned.3. Air-pressure test clutch operation. Remove and

rebuild if necessary.

4. Overdrive Thrust Bearing

Failure.4. Disassemble geartrain and replace bearings.

5. Direct Clutch Spring Collapsed/

Broken.5. Remove and disassemble unit. Check clutch

position and replace spring.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 25

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1545 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS. 1. Fluid Lines and Fittings

Loose/Leaks/Damaged.1. Tighten fittings. If leaks persist, replace fittings

and lines if necessary.

2. Fill Tube (where tube enters

case) Leaks/Damaged.2. Replace tube seal. Inspect tube for cracks in fill

tube.

3. Pressure Port Plug Loose

Loose/Damaged.3. Tighten to correct torque. Replace plug or

reseal if leak persists.

4. Pan Gasket Leaks. 4. Tighten pan screws (150 in. lbs.). If leaks

persist, replace gasket.

5. Valve Body Manual Lever Shaft

Seal Leaks/Worn.5. Replace shaft seal.

6. Rear Bearing Access Plate

Leaks.6. Replace gasket. Tighten screws.

7. Gasket Damaged or Bolts are

Loose.7. Replace bolts or gasket or tighten both.

8. Adapter/Extension Gasket

Damaged Leaks/Damaged.8. Replace gasket.

9. Park/Neutral Switch, or

Transmission Range Sensor

Leaks/Damaged.9. Replace switch and gasket.

10. Converter Housing Area Leaks. 10. Check for leaks at seal caused by worn seal

or burr on converter hub (cutting seal), worn

bushing, missing oil return, oil in front pump

housing or hole plugged. Check for leaks past

O-ring seal on pump or past pump-to-case bolts;

pump housing porous, oil coming out vent due to

overfill or leak past front band shaft access plug.

11. Pump Seal Leaks/Worn/

Damaged.11. Replace seal.

12. Torque Converter Weld

Leak/Cracked Hub.12. Replace converter.

13. Case Porosity Leaks. 13. Replace case.

NOISY OPERATION

IN FOURTH GEAR

ONLY1. Overdrive Clutch Discs, Plates

or Snap Rings Damaged.1. Remove unit and rebuild clutch pack.

2. Overdrive Piston or Planetary

Thrust Bearing Damaged.2. Remove and disassemble unit. Replace either

thrust bearing if damaged.

3. Output Shaft Bearings

Scored/Damaged.3. Remove and disassemble unit. Replace either

bearing if damaged.

4. Planetary Gears Worn/Chipped. 4. Remove and overhaul overdrive unit.

5. Overdrive Unit Overrunning

Clutch Rollers Worn/Scored.5. Remove and overhaul overdrive unit.

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, orequivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

21 - 26 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1546 of 2199

REMOVAL

The overdrive unit can be removed and serviced

separately. It is not necessary to remove the entire

transmission assembly to perform overdrive unit

repairs.

If only the overdrive unit requires service, refer to

Overdrive Removal for proper procedures.

CAUTION: The transmission and torque converter

must be removed as an assembly to avoid compo-

nent damage. The converter driveplate, pump bush-

ing, or oil seal can be damaged if the converter is

left attached to the driveplate during removal. Be

sure to remove the transmission and converter as

an assembly.

(1) Disconnect battery negative cable.

(2) Disconnect and lower or remove necessary

exhaust components.

(3) Disconnect fluid cooler lines at transmission.

(4) Remove starter motor. (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

(5) Disconnect and remove crankshaft position sen-

sor. (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/CRANKSHAFT POSITION SENSOR -

REMOVAL) Retain sensor attaching bolts.

CAUTION: The crankshaft position sensor will be

damaged if the transmission is removed, or

installed, while the sensor is still bolted to the

engine block, or transmission (4.0L only). To avoid

damage, be sure to remove the sensor before

removing the transmission.

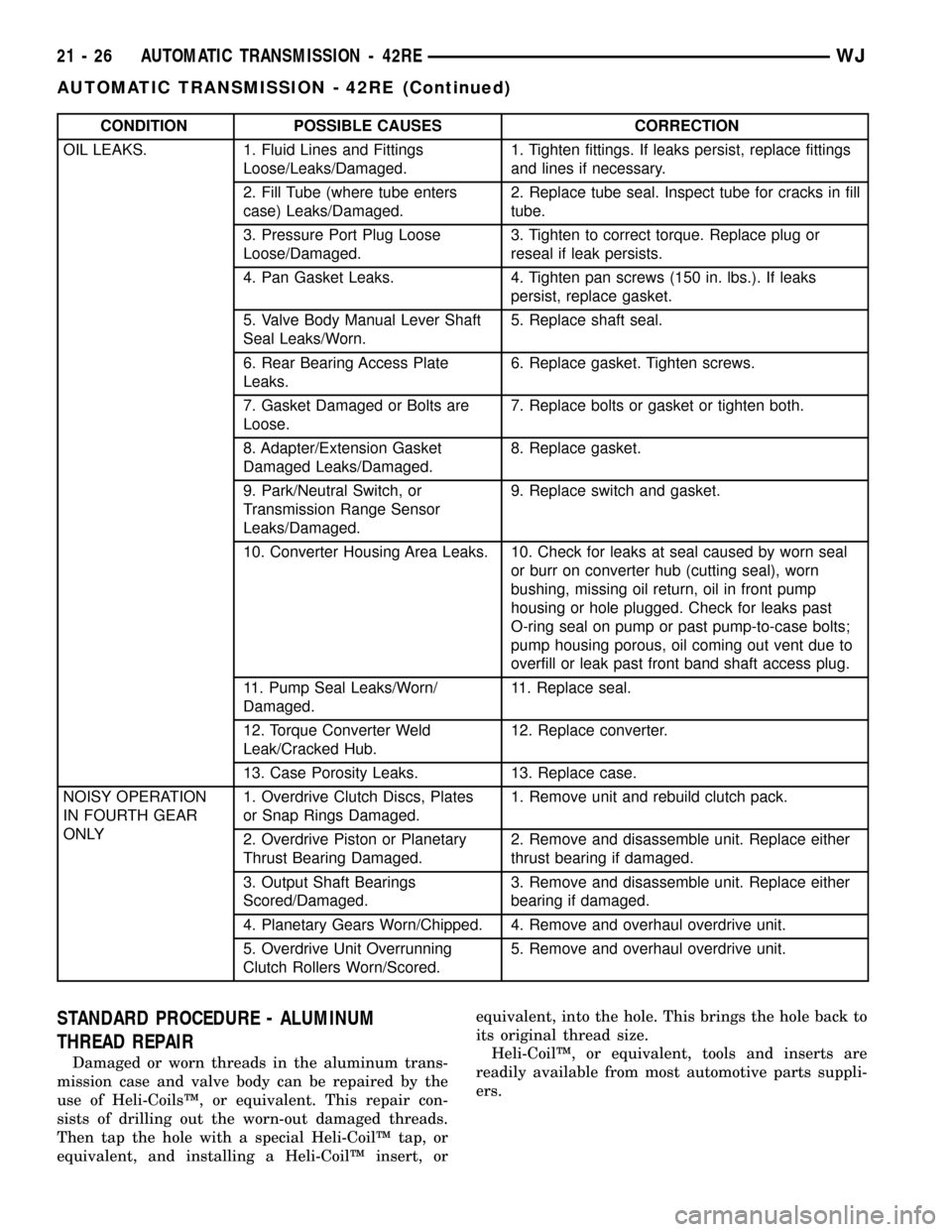

(6) Remove the bolts holding the bell housing

brace to the transmission.

(7) Remove nut holding the bell housing brace to

the engine to transmission bending brace.

(8) Remove the bell housing brace from the trans-

mission (Fig. 13).

(9) Remove the bolt holding the torque converter

cover to the transmission.

(10) Remove the torque converter cover from the

transmission.

(11) If transmission is being removed for overhaul,

remove transmission oil pan, drain fluid and reinstall

pan.

(12) Remove fill tube bracket bolts and pull tube

out of transmission. Retain fill tube seal. On4x4

models, it will also be necessary to remove bolt

attaching transfer case vent tube to converter hous-

ing.

(13) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.(14) Mark propeller shaft and axle yokes for

assembly alignment. Then disconnect and remove

propeller shaft. On4x4models, remove both propel-

ler shafts.

(15) Disconnect wires from park/neutral position

switch and transmission solenoid.

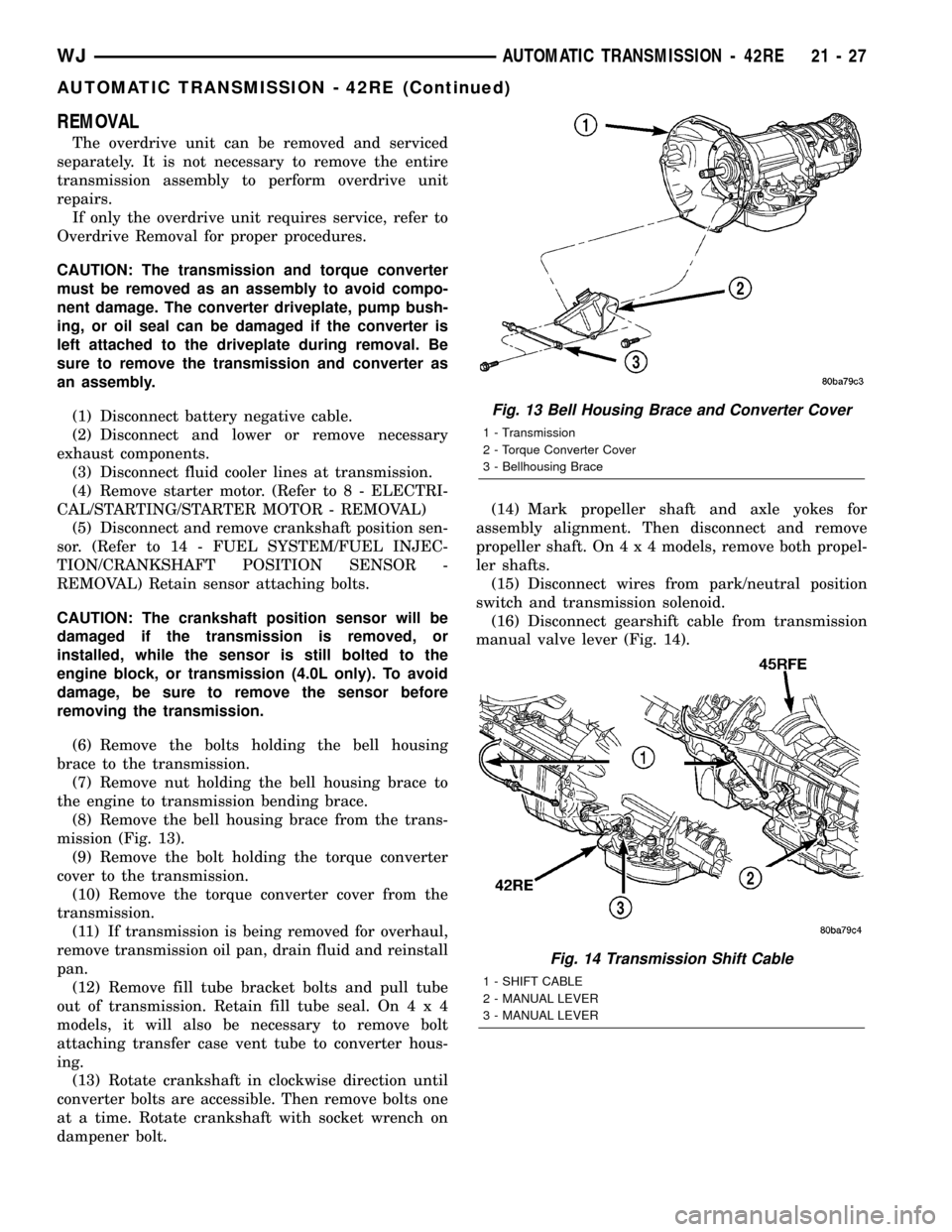

(16) Disconnect gearshift cable from transmission

manual valve lever (Fig. 14).

Fig. 13 Bell Housing Brace and Converter Cover

1 - Transmission

2 - Torque Converter Cover

3 - Bellhousing Brace

Fig. 14 Transmission Shift Cable

1 - SHIFT CABLE

2 - MANUAL LEVER

3 - MANUAL LEVER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 27

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1547 of 2199

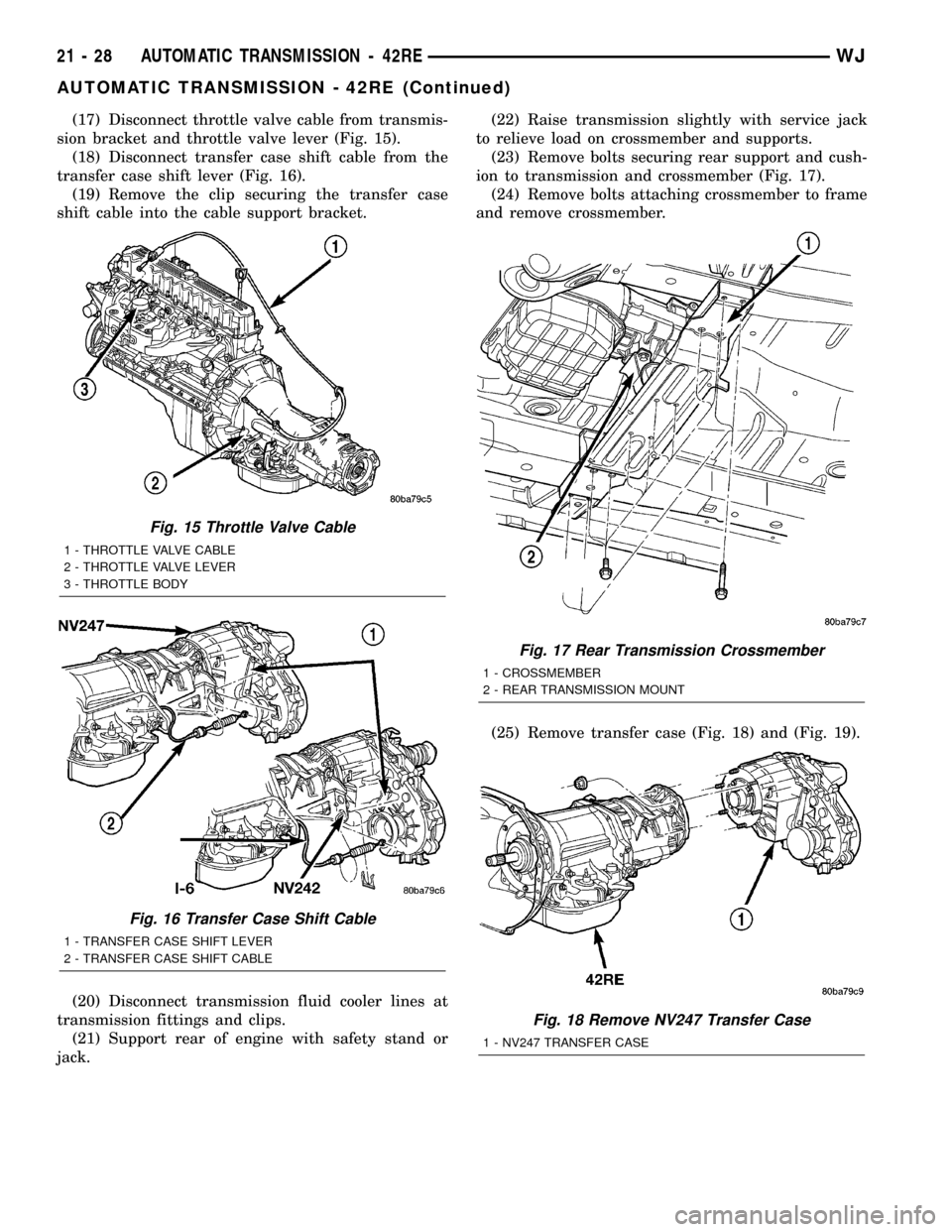

(17) Disconnect throttle valve cable from transmis-

sion bracket and throttle valve lever (Fig. 15).

(18) Disconnect transfer case shift cable from the

transfer case shift lever (Fig. 16).

(19) Remove the clip securing the transfer case

shift cable into the cable support bracket.

(20) Disconnect transmission fluid cooler lines at

transmission fittings and clips.

(21) Support rear of engine with safety stand or

jack.(22) Raise transmission slightly with service jack

to relieve load on crossmember and supports.

(23) Remove bolts securing rear support and cush-

ion to transmission and crossmember (Fig. 17).

(24) Remove bolts attaching crossmember to frame

and remove crossmember.

(25) Remove transfer case (Fig. 18) and (Fig. 19).

Fig. 15 Throttle Valve Cable

1 - THROTTLE VALVE CABLE

2 - THROTTLE VALVE LEVER

3 - THROTTLE BODY

Fig. 16 Transfer Case Shift Cable

1 - TRANSFER CASE SHIFT LEVER

2 - TRANSFER CASE SHIFT CABLE

Fig. 17 Rear Transmission Crossmember

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

Fig. 18 Remove NV247 Transfer Case

1 - NV247 TRANSFER CASE

21 - 28 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1548 of 2199

(26) Remove bolts holding the upper transmission

bending braces to the torque converter housing and

the overdrive unit (Fig. 20).

(27) Remove all remaining converter housing bolts.

(28) Carefully work transmission and torque con-

verter assembly rearward off engine block dowels.

(29) Hold torque converter in place during trans-

mission removal.

(30) Lower transmission and remove assembly

from under the vehicle.

(31) To remove torque converter, carefully slide

torque converter out of the transmission.

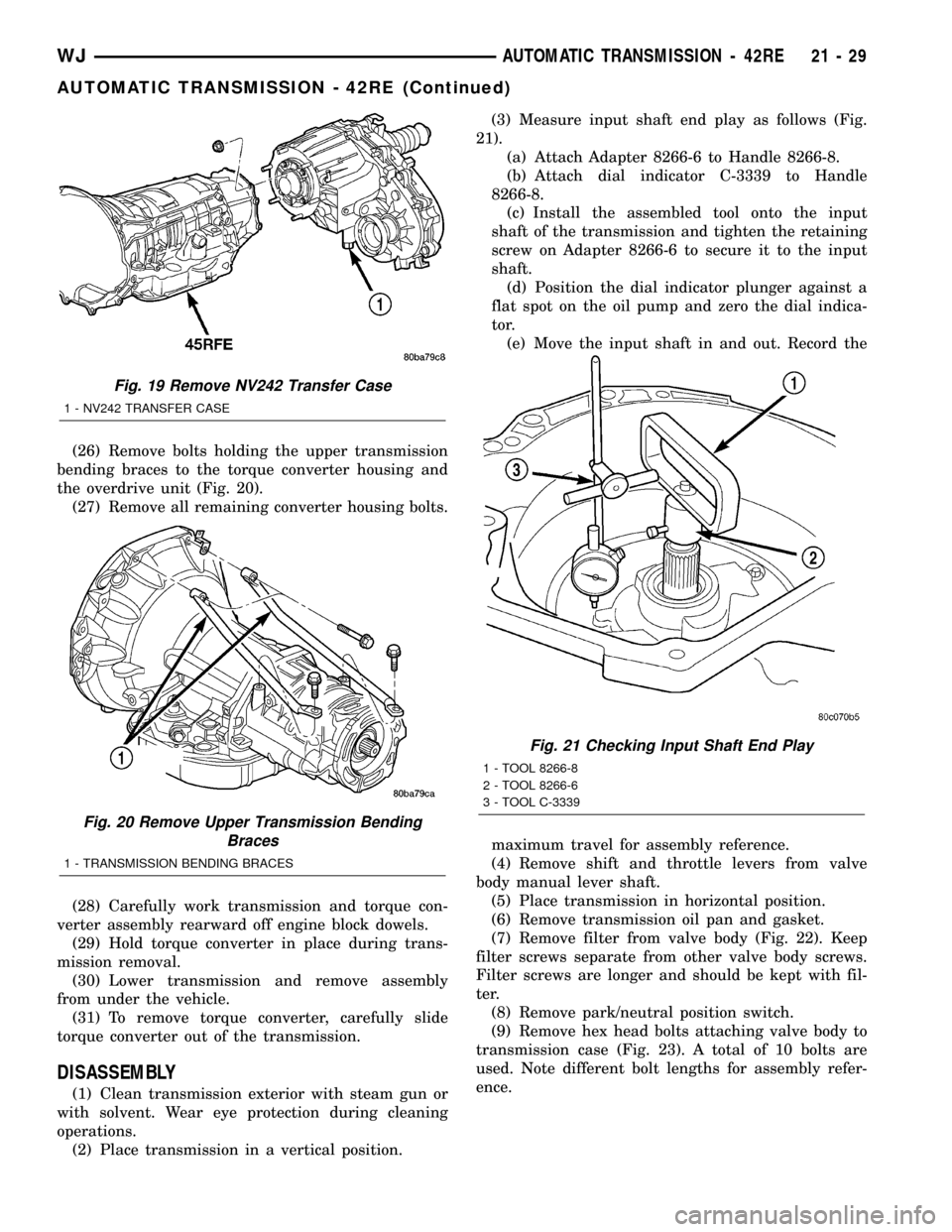

DISASSEMBLY

(1) Clean transmission exterior with steam gun or

with solvent. Wear eye protection during cleaning

operations.

(2) Place transmission in a vertical position.(3) Measure input shaft end play as follows (Fig.

21).

(a) Attach Adapter 8266-6 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-6 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move the input shaft in and out. Record the

maximum travel for assembly reference.

(4) Remove shift and throttle levers from valve

body manual lever shaft.

(5) Place transmission in horizontal position.

(6) Remove transmission oil pan and gasket.

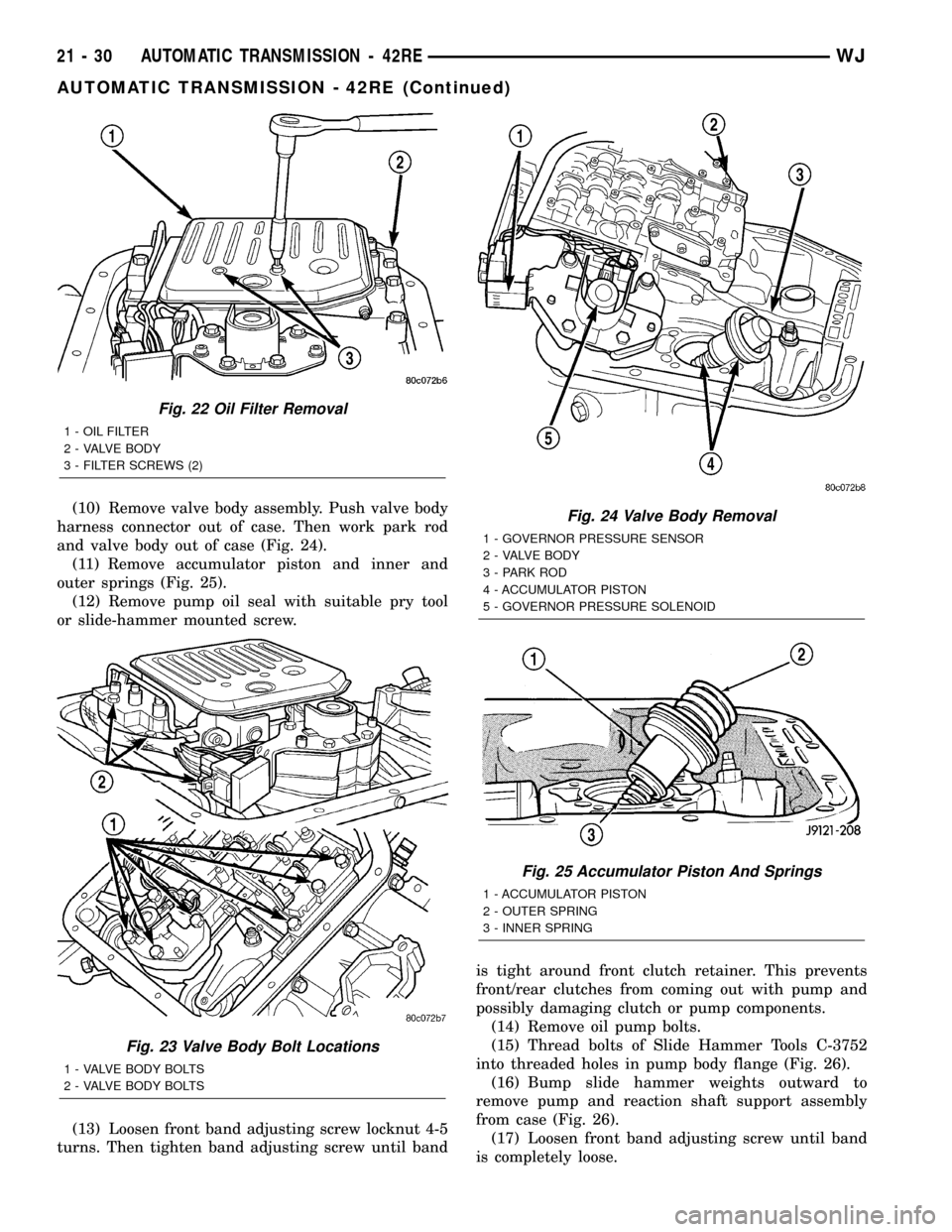

(7) Remove filter from valve body (Fig. 22). Keep

filter screws separate from other valve body screws.

Filter screws are longer and should be kept with fil-

ter.

(8) Remove park/neutral position switch.

(9) Remove hex head bolts attaching valve body to

transmission case (Fig. 23). A total of 10 bolts are

used. Note different bolt lengths for assembly refer-

ence.

Fig. 19 Remove NV242 Transfer Case

1 - NV242 TRANSFER CASE

Fig. 20 Remove Upper Transmission Bending

Braces

1 - TRANSMISSION BENDING BRACES

Fig. 21 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-6

3 - TOOL C-3339

WJAUTOMATIC TRANSMISSION - 42RE 21 - 29

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1549 of 2199

(10) Remove valve body assembly. Push valve body

harness connector out of case. Then work park rod

and valve body out of case (Fig. 24).

(11) Remove accumulator piston and inner and

outer springs (Fig. 25).

(12) Remove pump oil seal with suitable pry tool

or slide-hammer mounted screw.

(13) Loosen front band adjusting screw locknut 4-5

turns. Then tighten band adjusting screw until bandis tight around front clutch retainer. This prevents

front/rear clutches from coming out with pump and

possibly damaging clutch or pump components.

(14) Remove oil pump bolts.

(15) Thread bolts of Slide Hammer Tools C-3752

into threaded holes in pump body flange (Fig. 26).

(16) Bump slide hammer weights outward to

remove pump and reaction shaft support assembly

from case (Fig. 26).

(17) Loosen front band adjusting screw until band

is completely loose.

Fig. 22 Oil Filter Removal

1 - OIL FILTER

2 - VALVE BODY

3 - FILTER SCREWS (2)

Fig. 23 Valve Body Bolt Locations

1 - VALVE BODY BOLTS

2 - VALVE BODY BOLTS

Fig. 24 Valve Body Removal

1 - GOVERNOR PRESSURE SENSOR

2 - VALVE BODY

3 - PARK ROD

4 - ACCUMULATOR PISTON

5 - GOVERNOR PRESSURE SOLENOID

Fig. 25 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

21 - 30 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1550 of 2199

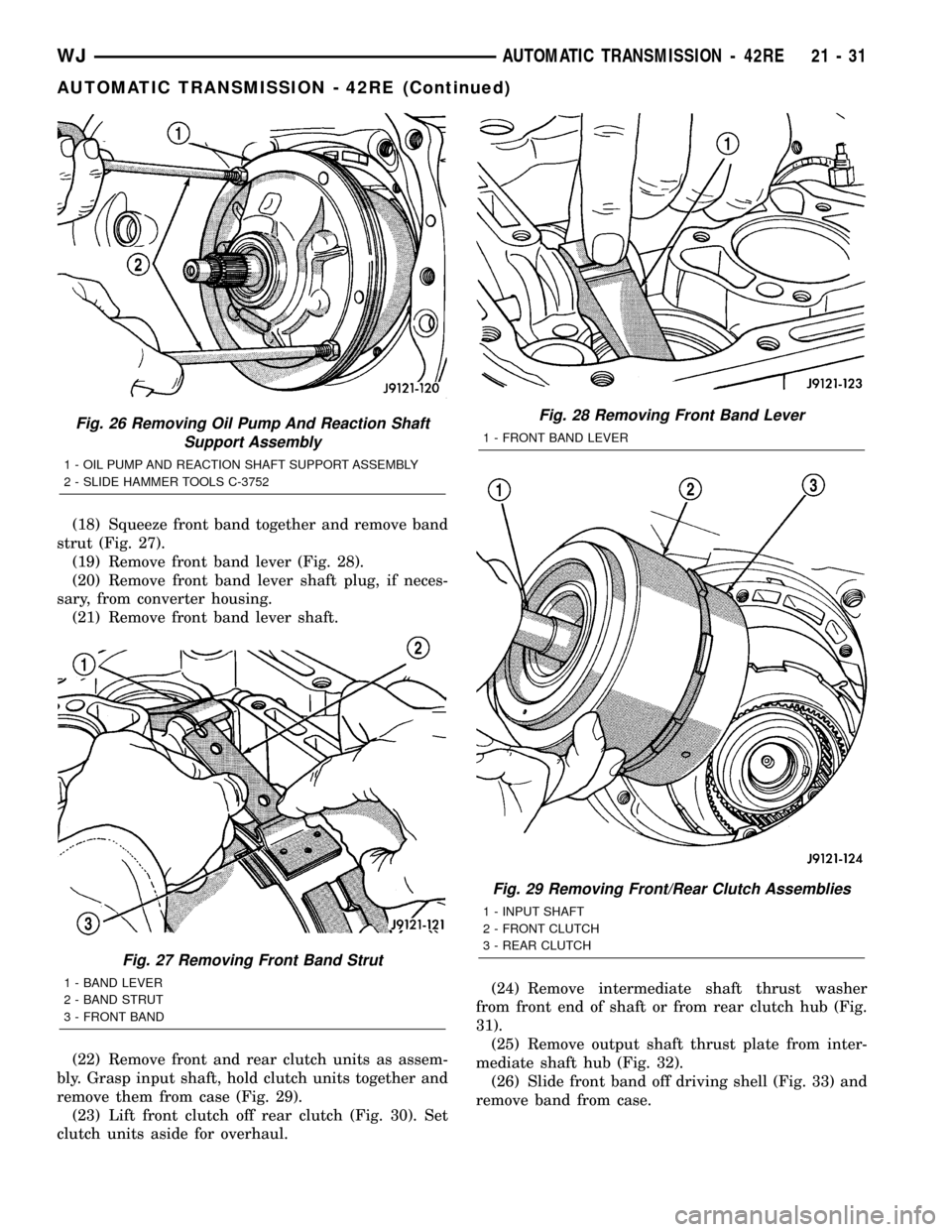

(18) Squeeze front band together and remove band

strut (Fig. 27).

(19) Remove front band lever (Fig. 28).

(20) Remove front band lever shaft plug, if neces-

sary, from converter housing.

(21) Remove front band lever shaft.

(22) Remove front and rear clutch units as assem-

bly. Grasp input shaft, hold clutch units together and

remove them from case (Fig. 29).

(23) Lift front clutch off rear clutch (Fig. 30). Set

clutch units aside for overhaul.(24) Remove intermediate shaft thrust washer

from front end of shaft or from rear clutch hub (Fig.

31).

(25) Remove output shaft thrust plate from inter-

mediate shaft hub (Fig. 32).

(26) Slide front band off driving shell (Fig. 33) and

remove band from case.

Fig. 26 Removing Oil Pump And Reaction Shaft

Support Assembly

1 - OIL PUMP AND REACTION SHAFT SUPPORT ASSEMBLY

2 - SLIDE HAMMER TOOLS C-3752

Fig. 27 Removing Front Band Strut

1 - BAND LEVER

2 - BAND STRUT

3 - FRONT BAND

Fig. 28 Removing Front Band Lever

1 - FRONT BAND LEVER

Fig. 29 Removing Front/Rear Clutch Assemblies

1 - INPUT SHAFT

2 - FRONT CLUTCH

3 - REAR CLUTCH

WJAUTOMATIC TRANSMISSION - 42RE 21 - 31

AUTOMATIC TRANSMISSION - 42RE (Continued)