light JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1880 of 2199

(4) Close flip up glass panel and verify proper

operation.

(5)

Install liftgate trim panel, refer to (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - INSTALLATION).

FLIP-UP GLASS LATCH

STRIKER

REMOVAL

(1) Raise flip up glass panel.

(2) Mark the position of the handle/striker on the

glass panel.

(3) Remove the screws attaching the handle/striker

to the glass.

INSTALLATION

(1) Position the handle/striker on the glass panel

and align the reference marks.

(2) Install the screws attaching the handle/striker

to the glass panel. Tighten the fasteners to 6 N´m (60

in. lbs.).

FLIP-UP GLASS SWITCH

REMOVAL

(1) Remove license plate lamp housing/trim panel

from liftgate, refer to (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/LICENSE PLATE

LAMP UNIT - REMOVAL).

(2) Squeeze the locking tabs inward to release the

switch from the housing.

(3) Disconnect the switch harness connector,

remove the switch from the housing.

INSTALLATION

(1) Install switch harness connector.(2) Position switch in housing, snap switch into

place.

(3) Install license plate lamp housing/trim panel

onto liftgate, refer to (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/LICENSE PLATE

LAMP UNIT - INSTALLATION).

HINGE

REMOVAL

NOTE: It is not necessary to remove the liftgate to

replace one or both hinges. The hinges can be

replaced one at a time.

(1) Open the liftgate. Support the liftgate for ease

of repair.

(2) Remove the liftgate header trim panel.

(3) Mark the hinge location with a grease pencil or

other suitable device.

(4) Remove the hinge screws (Fig. 5).

(5) Remove hinge.

INSTALLATION

NOTE: It is not necessary to remove the liftgate to

replace one or both hinges. The hinges can be

replaced one at a time.

(1) Position the hinge on the roof panel and on the

liftgate. (Use 3MŸ Fast and Firm or equivalent on

the hinge to body mating surfaces as a sealant.

(2) Install and tighten hinge screws at roof panel

to 28N´m (21 ft. lbs.).

(3) Install hinge screws at liftgate. Tighten screws

to 28N´m (21 ft. lbs.).

(4) Install liftgate header trim panel.

(5) Check the liftgate for proper alignment and

operation.

WJDECKLID/HATCH/LIFTGATE/TAILGATE 23 - 7

FLIP-UP GLASS LATCH (Continued)

Page 1881 of 2199

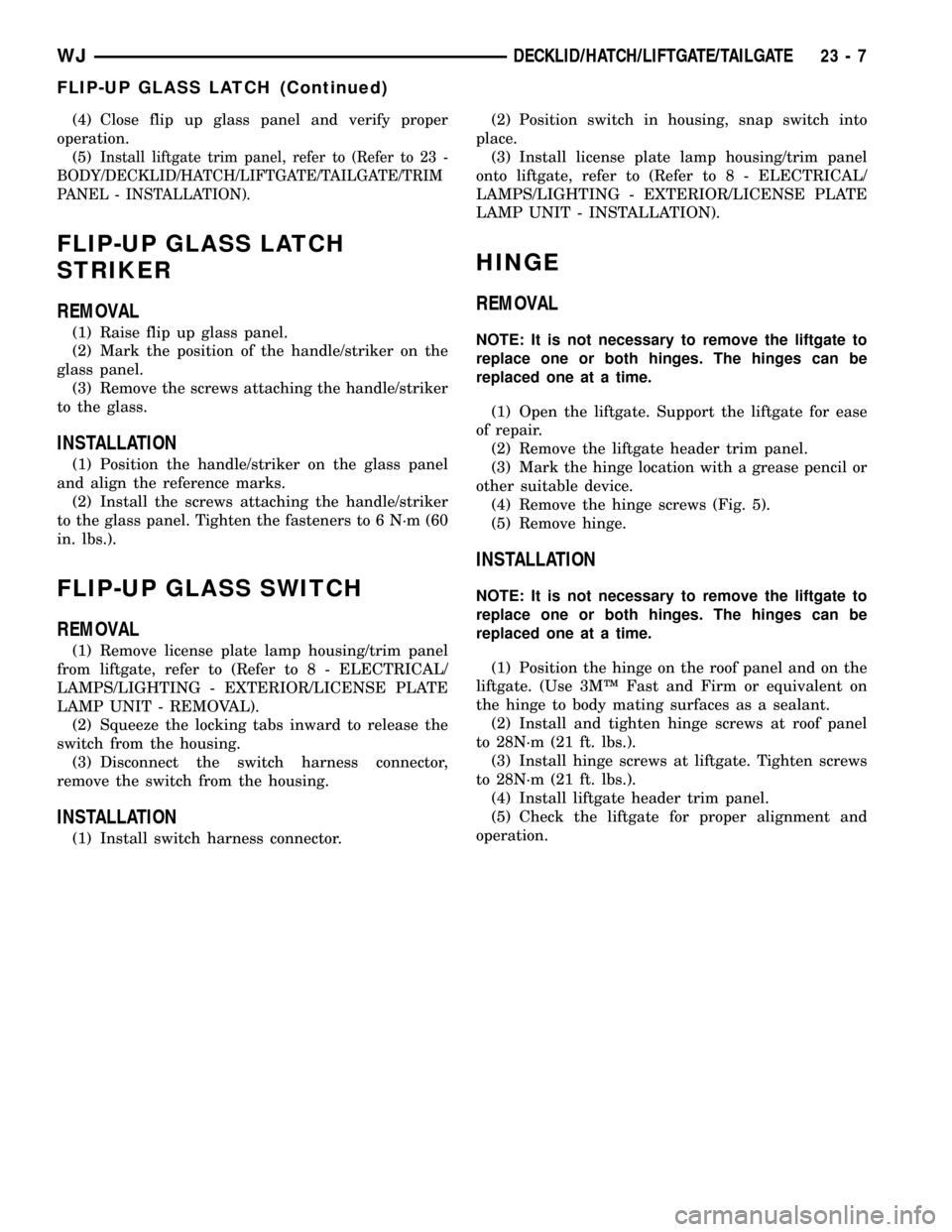

LATCH

REMOVAL

(1) Raise the liftgate.

(2) Remove the liftgate trim panel (Fig. 3).

(3) Disconnect the power connector.

(4)

Disconnect the outside handle link from the latch.

(5) Remove the latch screws and remove latch.

INSTALLATION

(1) Install the latch into the liftgate and tighten

the screws to 7N´m (5 ft. lbs.).

(2)

Connect the outside handle to the liftgate latch.

(3) Plug in the connector for the power.

(4) Install the liftgate trim panel.

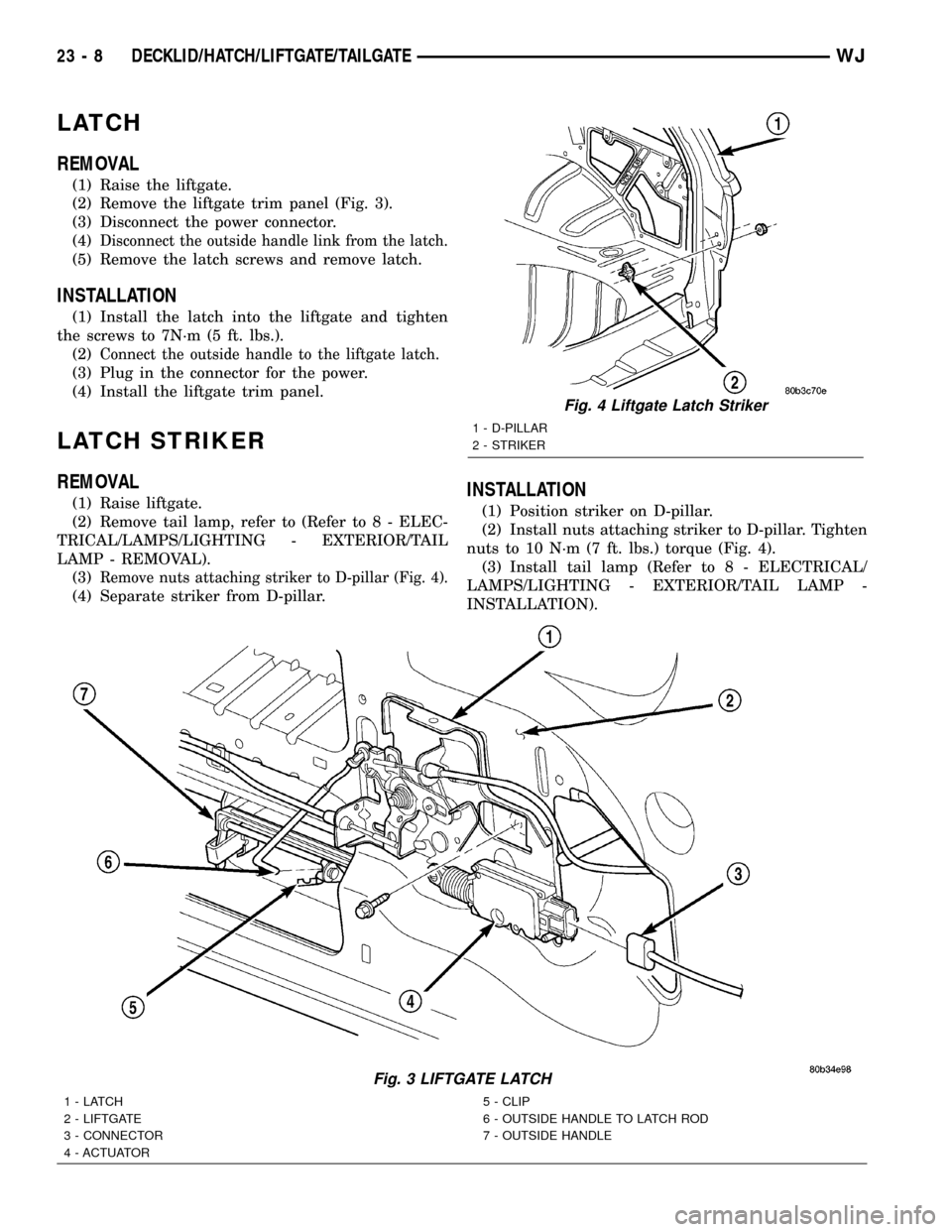

LATCH STRIKER

REMOVAL

(1) Raise liftgate.

(2) Remove tail lamp, refer to (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP - REMOVAL).

(3)

Remove nuts attaching striker to D-pillar (Fig. 4).

(4) Separate striker from D-pillar.

INSTALLATION

(1) Position striker on D-pillar.

(2) Install nuts attaching striker to D-pillar. Tighten

nuts to 10 N´m (7 ft. lbs.) torque (Fig. 4).

(3) Install tail lamp (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/TAIL LAMP -

INSTALLATION).

Fig. 3 LIFTGATE LATCH

1-LATCH

2 - LIFTGATE

3 - CONNECTOR

4 - ACTUATOR5 - CLIP

6 - OUTSIDE HANDLE TO LATCH ROD

7 - OUTSIDE HANDLE

Fig. 4 Liftgate Latch Striker

1 - D-PILLAR

2 - STRIKER

23 - 8 DECKLID/HATCH/LIFTGATE/TAILGATEWJ

Page 1900 of 2199

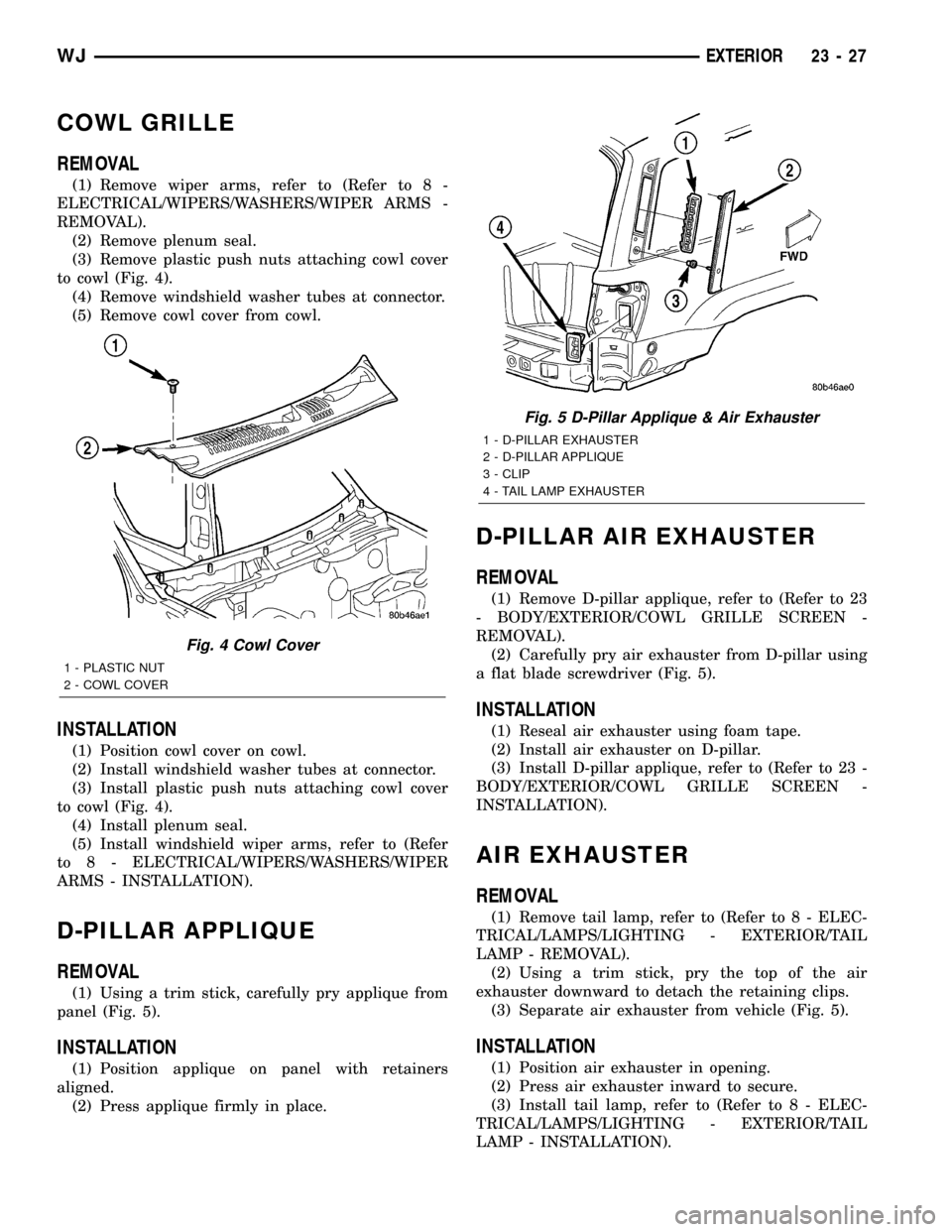

COWL GRILLE

REMOVAL

(1) Remove wiper arms, refer to (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL).

(2) Remove plenum seal.

(3) Remove plastic push nuts attaching cowl cover

to cowl (Fig. 4).

(4) Remove windshield washer tubes at connector.

(5) Remove cowl cover from cowl.

INSTALLATION

(1) Position cowl cover on cowl.

(2) Install windshield washer tubes at connector.

(3) Install plastic push nuts attaching cowl cover

to cowl (Fig. 4).

(4) Install plenum seal.

(5) Install windshield wiper arms, refer to (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS/WIPER

ARMS - INSTALLATION).

D-PILLAR APPLIQUE

REMOVAL

(1) Using a trim stick, carefully pry applique from

panel (Fig. 5).

INSTALLATION

(1) Position applique on panel with retainers

aligned.

(2) Press applique firmly in place.

D-PILLAR AIR EXHAUSTER

REMOVAL

(1) Remove D-pillar applique, refer to (Refer to 23

- BODY/EXTERIOR/COWL GRILLE SCREEN -

REMOVAL).

(2) Carefully pry air exhauster from D-pillar using

a flat blade screwdriver (Fig. 5).

INSTALLATION

(1) Reseal air exhauster using foam tape.

(2) Install air exhauster on D-pillar.

(3) Install D-pillar applique, refer to (Refer to 23 -

BODY/EXTERIOR/COWL GRILLE SCREEN -

INSTALLATION).

AIR EXHAUSTER

REMOVAL

(1) Remove tail lamp, refer to (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP - REMOVAL).

(2) Using a trim stick, pry the top of the air

exhauster downward to detach the retaining clips.

(3) Separate air exhauster from vehicle (Fig. 5).

INSTALLATION

(1) Position air exhauster in opening.

(2) Press air exhauster inward to secure.

(3) Install tail lamp, refer to (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP - INSTALLATION).

Fig. 4 Cowl Cover

1 - PLASTIC NUT

2 - COWL COVER

Fig. 5 D-Pillar Applique & Air Exhauster

1 - D-PILLAR EXHAUSTER

2 - D-PILLAR APPLIQUE

3 - CLIP

4 - TAIL LAMP EXHAUSTER

WJEXTERIOR 23 - 27

Page 1904 of 2199

(4) Remove the screws attaching the supports to

the roof panel.

(5) Separate the supports from the roof panel.

NOTE: If a crossbar needs to be serviced, the for-

ward or rearward supports will have to be removed.

INSTALLATION

(1) Position the supports on the roof panel and

install the screw. Be sure that the gasket is properly

seated.

(2) Position the luggage rack on the supports.

(3) Install the screws attaching the side rails to

the supports.

(4) Position the supports covers on the supports

and press into place.

SIDE VIEW MIRROR GLASS

REMOVAL

(1) With damaged mirror still on vehicle, position

mirror glass down and centered.

(2) Position a wide leverage device between the

bottom edge of the glass and the mirror shell.

(3) Firmly apply pressure in an upward direction

until glass assembly disengages from adapter plate.

(4) Disconnect the heater wire terminal, if

equipped, or the EC plug, if equipped.

INSTALLATION

(1) Connect the heater wire terminal or the EC

plug, if equipped.

(2) Position the replacement glass in the mirror

shell and align the four snap tabs with the four cav-

ities in the shell.

(3) Apply firm pressure inward until the replace-

ment glass assembly engages with the adapter plate.

Correct assembly will result in a firm click. Glass

assembly should exhibit even gaps to the shell when

complete.

(4) Pull lightly on corners of glass assembly to

ensure all four snaps are engaged and there is no

free play.

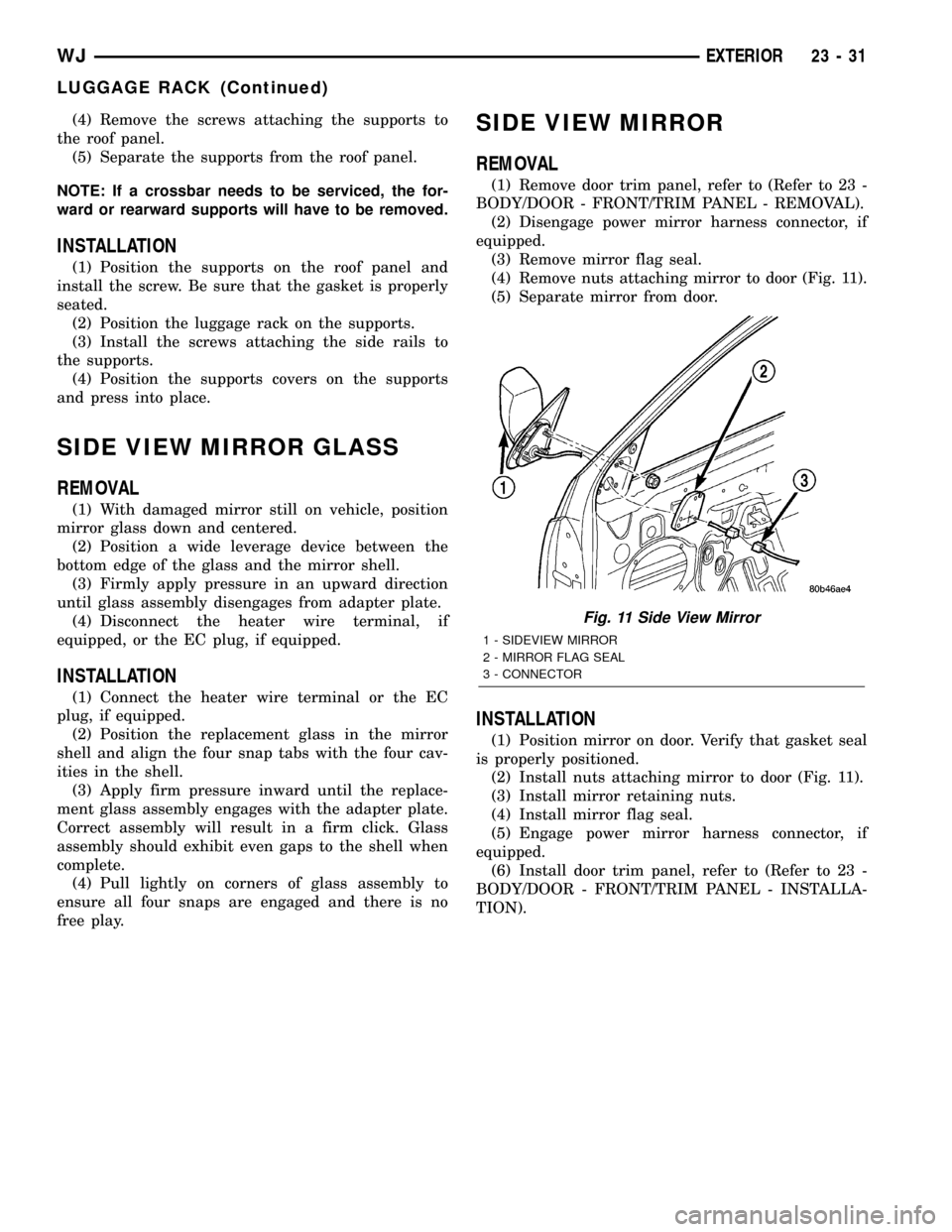

SIDE VIEW MIRROR

REMOVAL

(1) Remove door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(2) Disengage power mirror harness connector, if

equipped.

(3) Remove mirror flag seal.

(4) Remove nuts attaching mirror to door (Fig. 11).

(5) Separate mirror from door.

INSTALLATION

(1) Position mirror on door. Verify that gasket seal

is properly positioned.

(2) Install nuts attaching mirror to door (Fig. 11).

(3) Install mirror retaining nuts.

(4) Install mirror flag seal.

(5) Engage power mirror harness connector, if

equipped.

(6) Install door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - INSTALLA-

TION).

Fig. 11 Side View Mirror

1 - SIDEVIEW MIRROR

2 - MIRROR FLAG SEAL

3 - CONNECTOR

WJEXTERIOR 23 - 31

LUGGAGE RACK (Continued)

Page 1920 of 2199

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Roll the glove box down from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - STANDARD PROCEDURE - GLOVE

BOX ROLL DOWN).

NOTE: Be certain to use care not to damage or

remove the glove box hinge bumpers on the lower

instrument panel glove box opening reinforcement

when removing the glove box from the instrument

panel.

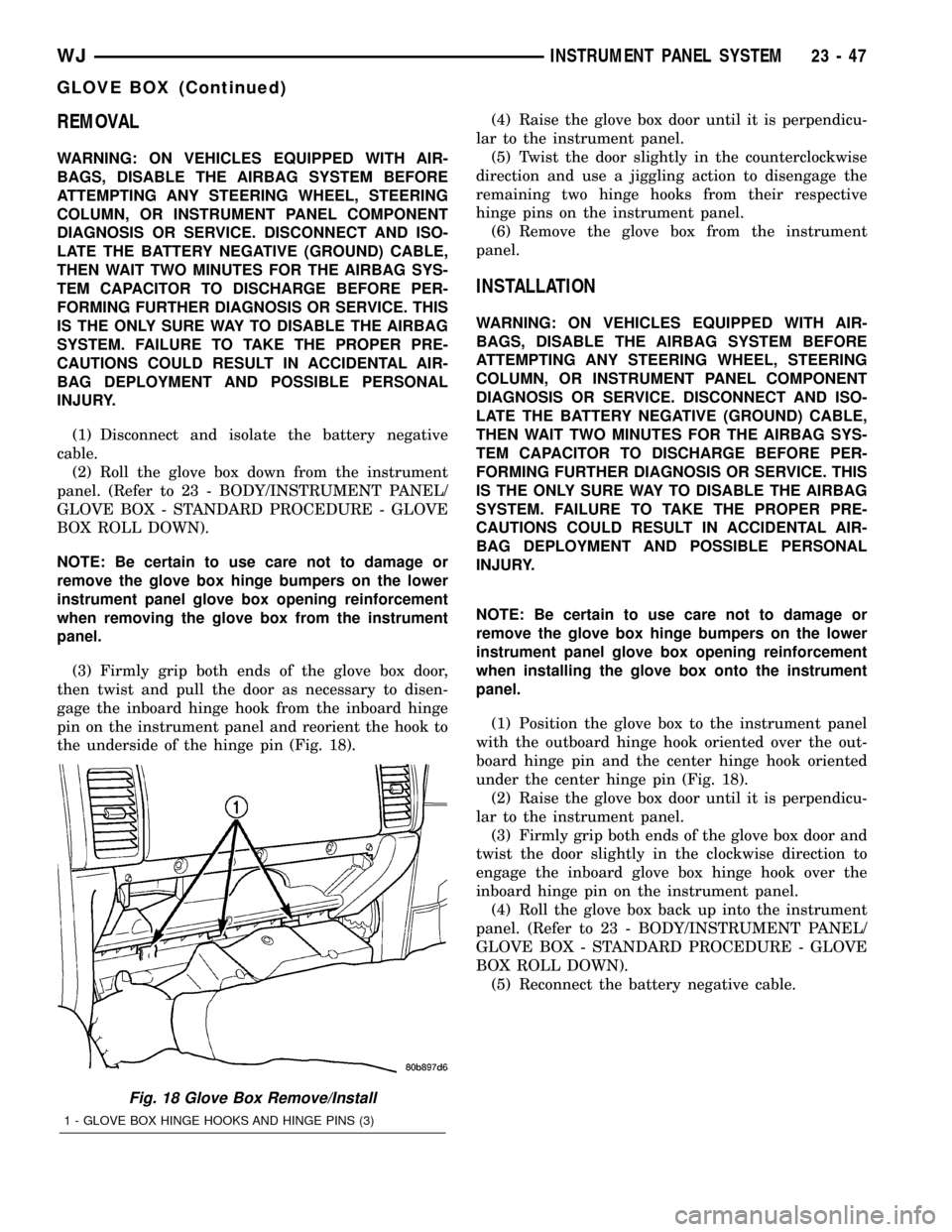

(3) Firmly grip both ends of the glove box door,

then twist and pull the door as necessary to disen-

gage the inboard hinge hook from the inboard hinge

pin on the instrument panel and reorient the hook to

the underside of the hinge pin (Fig. 18).(4) Raise the glove box door until it is perpendicu-

lar to the instrument panel.

(5) Twist the door slightly in the counterclockwise

direction and use a jiggling action to disengage the

remaining two hinge hooks from their respective

hinge pins on the instrument panel.

(6) Remove the glove box from the instrument

panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: Be certain to use care not to damage or

remove the glove box hinge bumpers on the lower

instrument panel glove box opening reinforcement

when installing the glove box onto the instrument

panel.

(1) Position the glove box to the instrument panel

with the outboard hinge hook oriented over the out-

board hinge pin and the center hinge hook oriented

under the center hinge pin (Fig. 18).

(2) Raise the glove box door until it is perpendicu-

lar to the instrument panel.

(3) Firmly grip both ends of the glove box door and

twist the door slightly in the clockwise direction to

engage the inboard glove box hinge hook over the

inboard hinge pin on the instrument panel.

(4) Roll the glove box back up into the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - STANDARD PROCEDURE - GLOVE

BOX ROLL DOWN).

(5) Reconnect the battery negative cable.

Fig. 18 Glove Box Remove/Install

1 - GLOVE BOX HINGE HOOKS AND HINGE PINS (3)

WJINSTRUMENT PANEL SYSTEM 23 - 47

GLOVE BOX (Continued)

Page 1924 of 2199

INSTRUMENT PANEL

STUCTURAL DUCT

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE AIRBAG SYSTEM BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO MIN-

UTES FOR THE AIRBAG SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1)Disconnect and isolate the battery negative cable.

(2) Remove the instrument panel from the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL -

REMOVAL).

(3) Place the instrument panel on a suitable work

surface. Be certain to take the proper precautions to

protect the instrument panel from any possible cos-

metic damage.

(4)

Remove all of the individual components that

remain secured to the instrument panel structural duct

as described elsewhere in this service information.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Reinstall all of the individual components that

were removed from the instrument panel structural

duct as described elsewhere in this service informa-

tion.

(2) Reinstall the instrument panel into the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL -

INSTALLATION).

(3) Reconnect the battery negative cable.

INSTRUMENT PANEL TOP

COVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

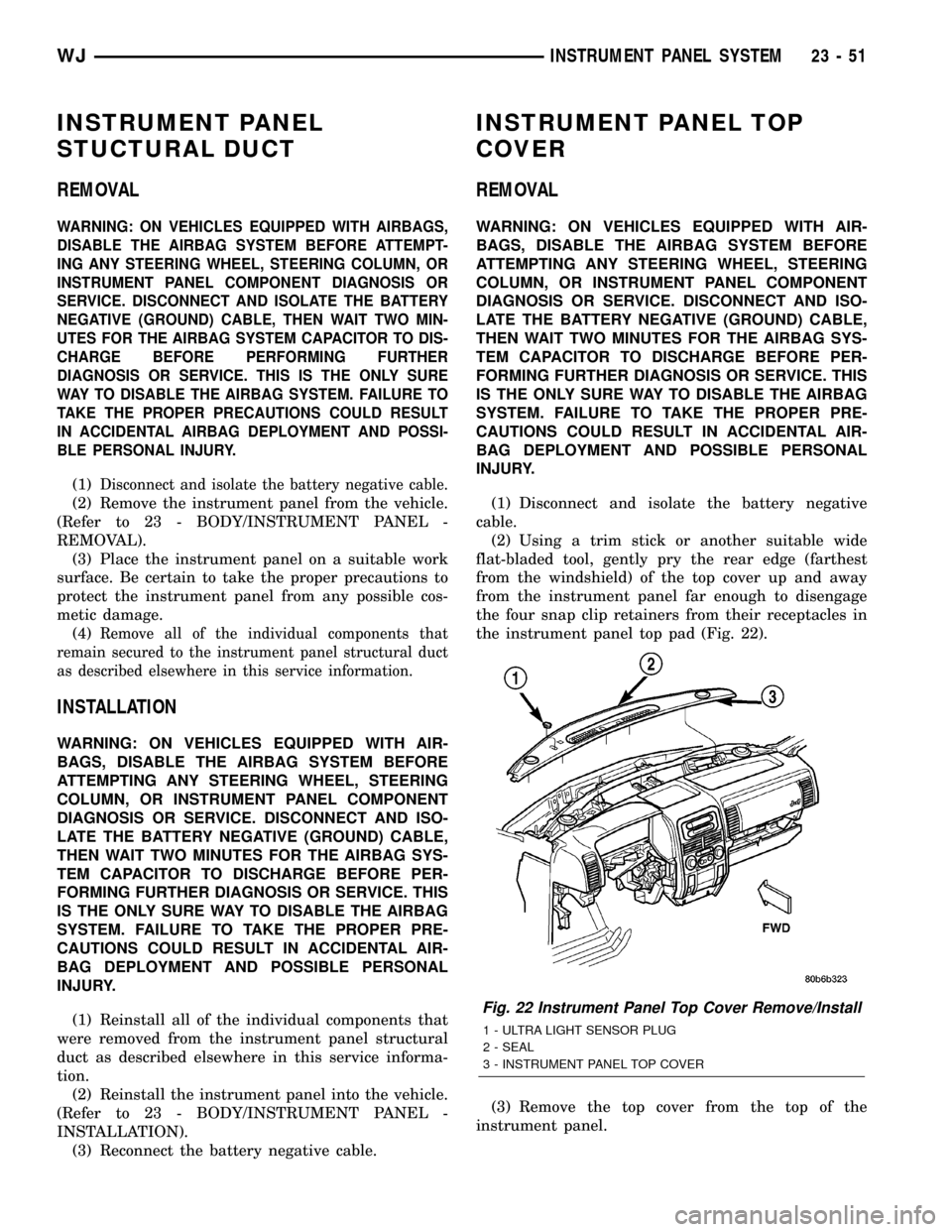

(1) Disconnect and isolate the battery negative

cable.

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the rear edge (farthest

from the windshield) of the top cover up and away

from the instrument panel far enough to disengage

the four snap clip retainers from their receptacles in

the instrument panel top pad (Fig. 22).

(3) Remove the top cover from the top of the

instrument panel.

Fig. 22 Instrument Panel Top Cover Remove/Install

1 - ULTRA LIGHT SENSOR PLUG

2 - SEAL

3 - INSTRUMENT PANEL TOP COVER

WJINSTRUMENT PANEL SYSTEM 23 - 51

Page 1925 of 2199

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) If the vehicle is not equipped with the optional

automatic headlamps light sensor/vehicle theft secu-

rity system indicator, be certain that the hole plug is

installed in the clearance hole located to the out-

board side of the driver side defroster outlet in the

instrument panel top cover (Fig. 22).

(2) Before installing the top cover onto the top of

the instrument panel, be certain that the rubber top

cover seal is properly positioned on the forward edge

of the top cover panel.

(3) Position the top cover onto the top of the

instrument panel.

(4) Align the four snap clips on the top cover with

the snap clip receptacles in the instrument panel top

pad.

(5) Press firmly downward on the top cover over

each of the four snap clip locations until each of the

snap clips is fully seated in their receptacles in the

instrument panel top pad.

(6) Reconnect the battery negative cable.

INSTRUMENT PANEL TOP PAD

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

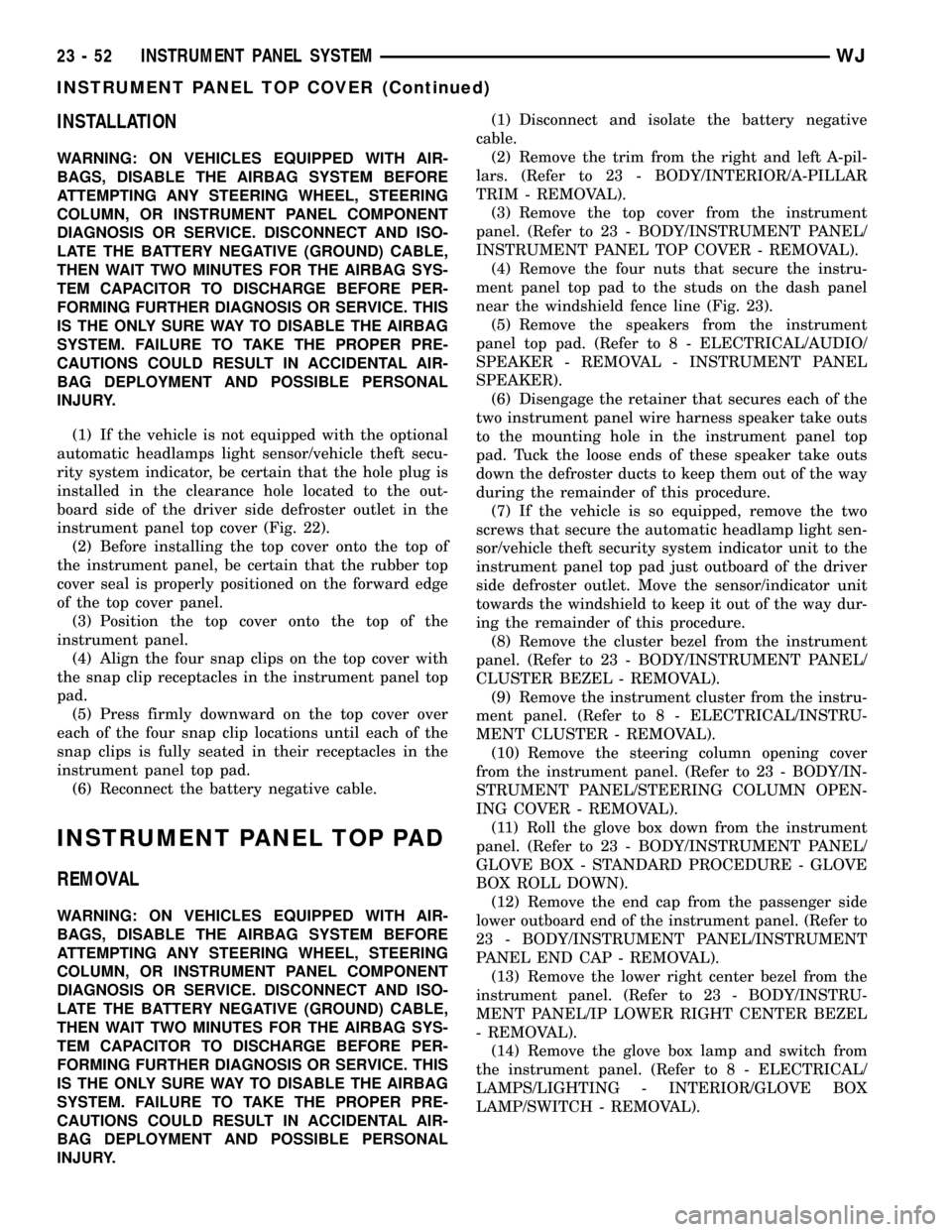

INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim from the right and left A-pil-

lars. (Refer to 23 - BODY/INTERIOR/A-PILLAR

TRIM - REMOVAL).

(3) Remove the top cover from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - REMOVAL).

(4) Remove the four nuts that secure the instru-

ment panel top pad to the studs on the dash panel

near the windshield fence line (Fig. 23).

(5) Remove the speakers from the instrument

panel top pad. (Refer to 8 - ELECTRICAL/AUDIO/

SPEAKER - REMOVAL - INSTRUMENT PANEL

SPEAKER).

(6) Disengage the retainer that secures each of the

two instrument panel wire harness speaker take outs

to the mounting hole in the instrument panel top

pad. Tuck the loose ends of these speaker take outs

down the defroster ducts to keep them out of the way

during the remainder of this procedure.

(7) If the vehicle is so equipped, remove the two

screws that secure the automatic headlamp light sen-

sor/vehicle theft security system indicator unit to the

instrument panel top pad just outboard of the driver

side defroster outlet. Move the sensor/indicator unit

towards the windshield to keep it out of the way dur-

ing the remainder of this procedure.

(8) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(9) Remove the instrument cluster from the instru-

ment panel. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - REMOVAL).

(10) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(11) Roll the glove box down from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - STANDARD PROCEDURE - GLOVE

BOX ROLL DOWN).

(12) Remove the end cap from the passenger side

lower outboard end of the instrument panel. (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL END CAP - REMOVAL).

(13) Remove the lower right center bezel from the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP LOWER RIGHT CENTER BEZEL

- REMOVAL).

(14) Remove the glove box lamp and switch from

the instrument panel. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR/GLOVE BOX

LAMP/SWITCH - REMOVAL).

23 - 52 INSTRUMENT PANEL SYSTEMWJ

INSTRUMENT PANEL TOP COVER (Continued)

Page 1928 of 2199

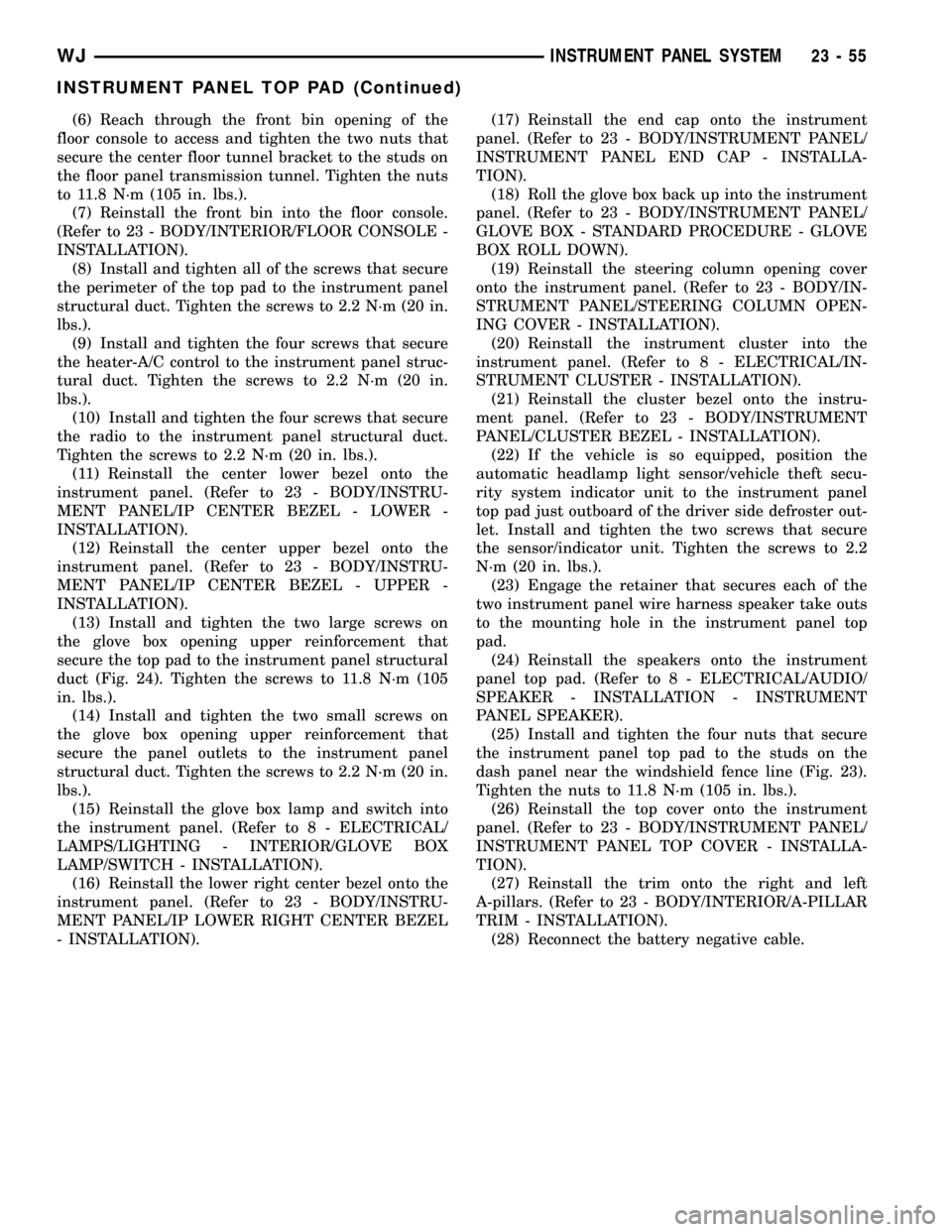

(6) Reach through the front bin opening of the

floor console to access and tighten the two nuts that

secure the center floor tunnel bracket to the studs on

the floor panel transmission tunnel. Tighten the nuts

to 11.8 N´m (105 in. lbs.).

(7) Reinstall the front bin into the floor console.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

INSTALLATION).

(8) Install and tighten all of the screws that secure

the perimeter of the top pad to the instrument panel

structural duct. Tighten the screws to 2.2 N´m (20 in.

lbs.).

(9) Install and tighten the four screws that secure

the heater-A/C control to the instrument panel struc-

tural duct. Tighten the screws to 2.2 N´m (20 in.

lbs.).

(10) Install and tighten the four screws that secure

the radio to the instrument panel structural duct.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(11) Reinstall the center lower bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP CENTER BEZEL - LOWER -

INSTALLATION).

(12) Reinstall the center upper bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP CENTER BEZEL - UPPER -

INSTALLATION).

(13) Install and tighten the two large screws on

the glove box opening upper reinforcement that

secure the top pad to the instrument panel structural

duct (Fig. 24). Tighten the screws to 11.8 N´m (105

in. lbs.).

(14) Install and tighten the two small screws on

the glove box opening upper reinforcement that

secure the panel outlets to the instrument panel

structural duct. Tighten the screws to 2.2 N´m (20 in.

lbs.).

(15) Reinstall the glove box lamp and switch into

the instrument panel. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR/GLOVE BOX

LAMP/SWITCH - INSTALLATION).

(16) Reinstall the lower right center bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP LOWER RIGHT CENTER BEZEL

- INSTALLATION).(17) Reinstall the end cap onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL END CAP - INSTALLA-

TION).

(18) Roll the glove box back up into the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - STANDARD PROCEDURE - GLOVE

BOX ROLL DOWN).

(19) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(20) Reinstall the instrument cluster into the

instrument panel. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - INSTALLATION).

(21) Reinstall the cluster bezel onto the instru-

ment panel. (Refer to 23 - BODY/INSTRUMENT

PANEL/CLUSTER BEZEL - INSTALLATION).

(22) If the vehicle is so equipped, position the

automatic headlamp light sensor/vehicle theft secu-

rity system indicator unit to the instrument panel

top pad just outboard of the driver side defroster out-

let. Install and tighten the two screws that secure

the sensor/indicator unit. Tighten the screws to 2.2

N´m (20 in. lbs.).

(23) Engage the retainer that secures each of the

two instrument panel wire harness speaker take outs

to the mounting hole in the instrument panel top

pad.

(24) Reinstall the speakers onto the instrument

panel top pad. (Refer to 8 - ELECTRICAL/AUDIO/

SPEAKER - INSTALLATION - INSTRUMENT

PANEL SPEAKER).

(25) Install and tighten the four nuts that secure

the instrument panel top pad to the studs on the

dash panel near the windshield fence line (Fig. 23).

Tighten the nuts to 11.8 N´m (105 in. lbs.).

(26) Reinstall the top cover onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - INSTALLA-

TION).

(27) Reinstall the trim onto the right and left

A-pillars. (Refer to 23 - BODY/INTERIOR/A-PILLAR

TRIM - INSTALLATION).

(28) Reconnect the battery negative cable.

WJINSTRUMENT PANEL SYSTEM 23 - 55

INSTRUMENT PANEL TOP PAD (Continued)

Page 1930 of 2199

INSTRUMENT PANEL CENTER

BEZEL - LOWER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE AIRBAG SYSTEM BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO MIN-

UTES FOR THE AIRBAG SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

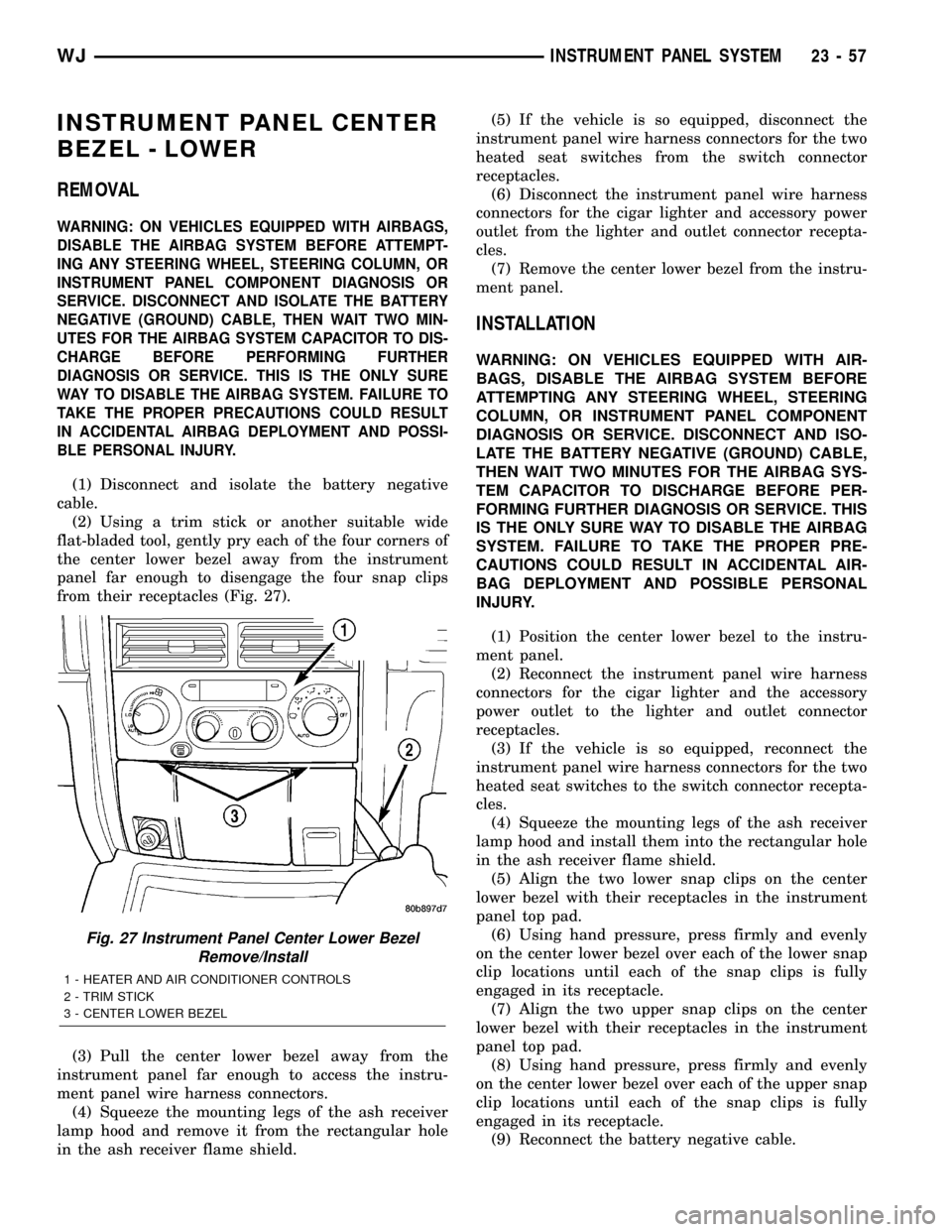

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry each of the four corners of

the center lower bezel away from the instrument

panel far enough to disengage the four snap clips

from their receptacles (Fig. 27).

(3) Pull the center lower bezel away from the

instrument panel far enough to access the instru-

ment panel wire harness connectors.

(4) Squeeze the mounting legs of the ash receiver

lamp hood and remove it from the rectangular hole

in the ash receiver flame shield.(5) If the vehicle is so equipped, disconnect the

instrument panel wire harness connectors for the two

heated seat switches from the switch connector

receptacles.

(6) Disconnect the instrument panel wire harness

connectors for the cigar lighter and accessory power

outlet from the lighter and outlet connector recepta-

cles.

(7) Remove the center lower bezel from the instru-

ment panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the center lower bezel to the instru-

ment panel.

(2) Reconnect the instrument panel wire harness

connectors for the cigar lighter and the accessory

power outlet to the lighter and outlet connector

receptacles.

(3) If the vehicle is so equipped, reconnect the

instrument panel wire harness connectors for the two

heated seat switches to the switch connector recepta-

cles.

(4) Squeeze the mounting legs of the ash receiver

lamp hood and install them into the rectangular hole

in the ash receiver flame shield.

(5) Align the two lower snap clips on the center

lower bezel with their receptacles in the instrument

panel top pad.

(6) Using hand pressure, press firmly and evenly

on the center lower bezel over each of the lower snap

clip locations until each of the snap clips is fully

engaged in its receptacle.

(7) Align the two upper snap clips on the center

lower bezel with their receptacles in the instrument

panel top pad.

(8) Using hand pressure, press firmly and evenly

on the center lower bezel over each of the upper snap

clip locations until each of the snap clips is fully

engaged in its receptacle.

(9) Reconnect the battery negative cable.

Fig. 27 Instrument Panel Center Lower Bezel

Remove/Install

1 - HEATER AND AIR CONDITIONER CONTROLS

2 - TRIM STICK

3 - CENTER LOWER BEZEL

WJINSTRUMENT PANEL SYSTEM 23 - 57

Page 1953 of 2199

INSTALLATION

(1) Position the bin hooks high in the slots on the

quarter trim panel.

(2) Push downward until the bin snaps into place.

(3) Install the hinge screws.

REAR VIEW MIRROR

REMOVAL

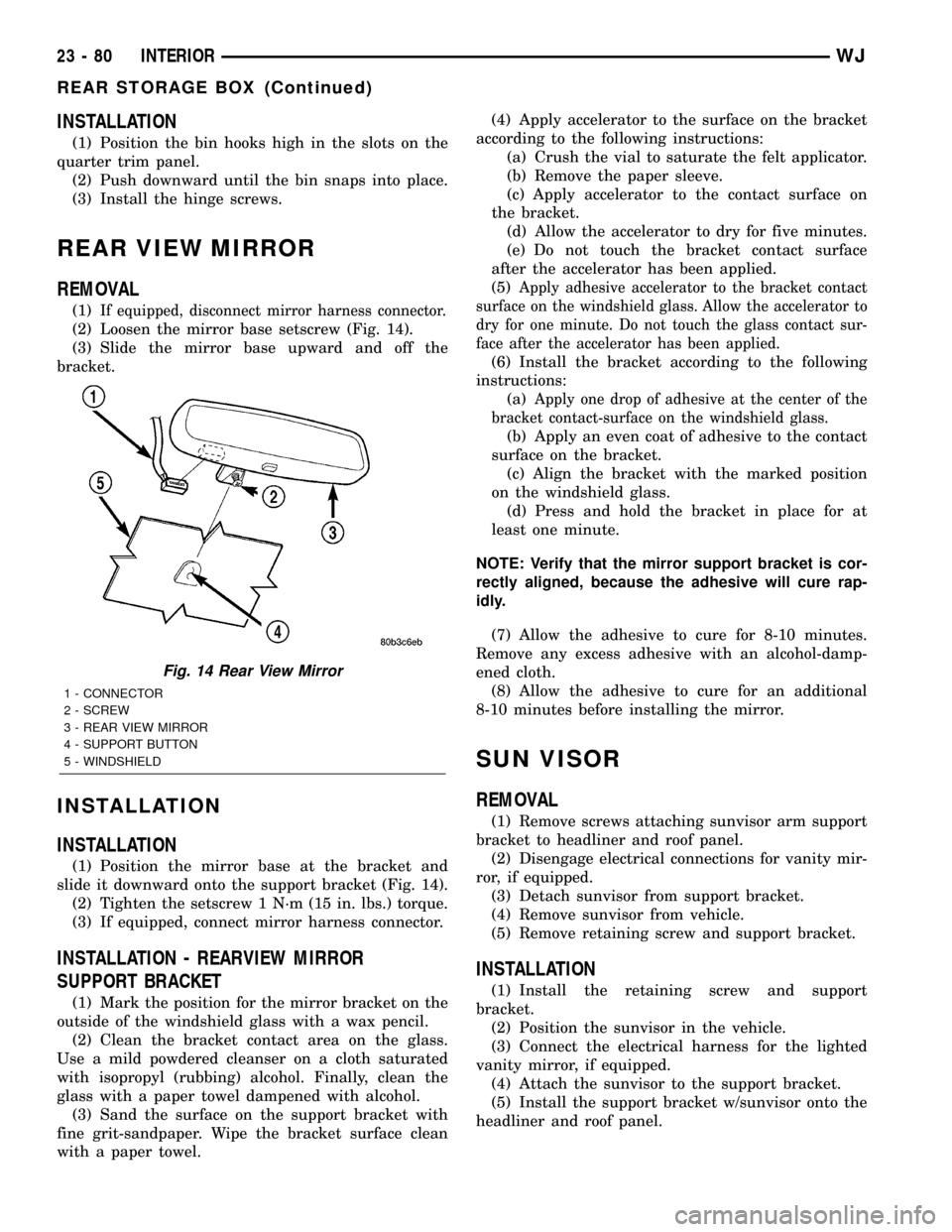

(1)If equipped, disconnect mirror harness connector.

(2) Loosen the mirror base setscrew (Fig. 14).

(3) Slide the mirror base upward and off the

bracket.

INSTALLATION

INSTALLATION

(1) Position the mirror base at the bracket and

slide it downward onto the support bracket (Fig. 14).

(2) Tighten the setscrew 1 N´m (15 in. lbs.) torque.

(3) If equipped, connect mirror harness connector.

INSTALLATION - REARVIEW MIRROR

SUPPORT BRACKET

(1) Mark the position for the mirror bracket on the

outside of the windshield glass with a wax pencil.

(2) Clean the bracket contact area on the glass.

Use a mild powdered cleanser on a cloth saturated

with isopropyl (rubbing) alcohol. Finally, clean the

glass with a paper towel dampened with alcohol.

(3) Sand the surface on the support bracket with

fine grit-sandpaper. Wipe the bracket surface clean

with a paper towel.(4) Apply accelerator to the surface on the bracket

according to the following instructions:

(a) Crush the vial to saturate the felt applicator.

(b) Remove the paper sleeve.

(c) Apply accelerator to the contact surface on

the bracket.

(d) Allow the accelerator to dry for five minutes.

(e) Do not touch the bracket contact surface

after the accelerator has been applied.

(5)

Apply adhesive accelerator to the bracket contact

surface on the windshield glass. Allow the accelerator to

dry for one minute. Do not touch the glass contact sur-

face after the accelerator has been applied.

(6) Install the bracket according to the following

instructions:

(a)

Apply one drop of adhesive at the center of the

bracket contact-surface on the windshield glass.

(b) Apply an even coat of adhesive to the contact

surface on the bracket.

(c) Align the bracket with the marked position

on the windshield glass.

(d) Press and hold the bracket in place for at

least one minute.

NOTE: Verify that the mirror support bracket is cor-

rectly aligned, because the adhesive will cure rap-

idly.

(7) Allow the adhesive to cure for 8-10 minutes.

Remove any excess adhesive with an alcohol-damp-

ened cloth.

(8) Allow the adhesive to cure for an additional

8-10 minutes before installing the mirror.

SUN VISOR

REMOVAL

(1) Remove screws attaching sunvisor arm support

bracket to headliner and roof panel.

(2) Disengage electrical connections for vanity mir-

ror, if equipped.

(3) Detach sunvisor from support bracket.

(4) Remove sunvisor from vehicle.

(5) Remove retaining screw and support bracket.

INSTALLATION

(1) Install the retaining screw and support

bracket.

(2) Position the sunvisor in the vehicle.

(3) Connect the electrical harness for the lighted

vanity mirror, if equipped.

(4) Attach the sunvisor to the support bracket.

(5) Install the support bracket w/sunvisor onto the

headliner and roof panel.

Fig. 14 Rear View Mirror

1 - CONNECTOR

2 - SCREW

3 - REAR VIEW MIRROR

4 - SUPPORT BUTTON

5 - WINDSHIELD

23 - 80 INTERIORWJ

REAR STORAGE BOX (Continued)