light JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1477 of 2199

INSTALLATION

INSTALLATION - 4.0L

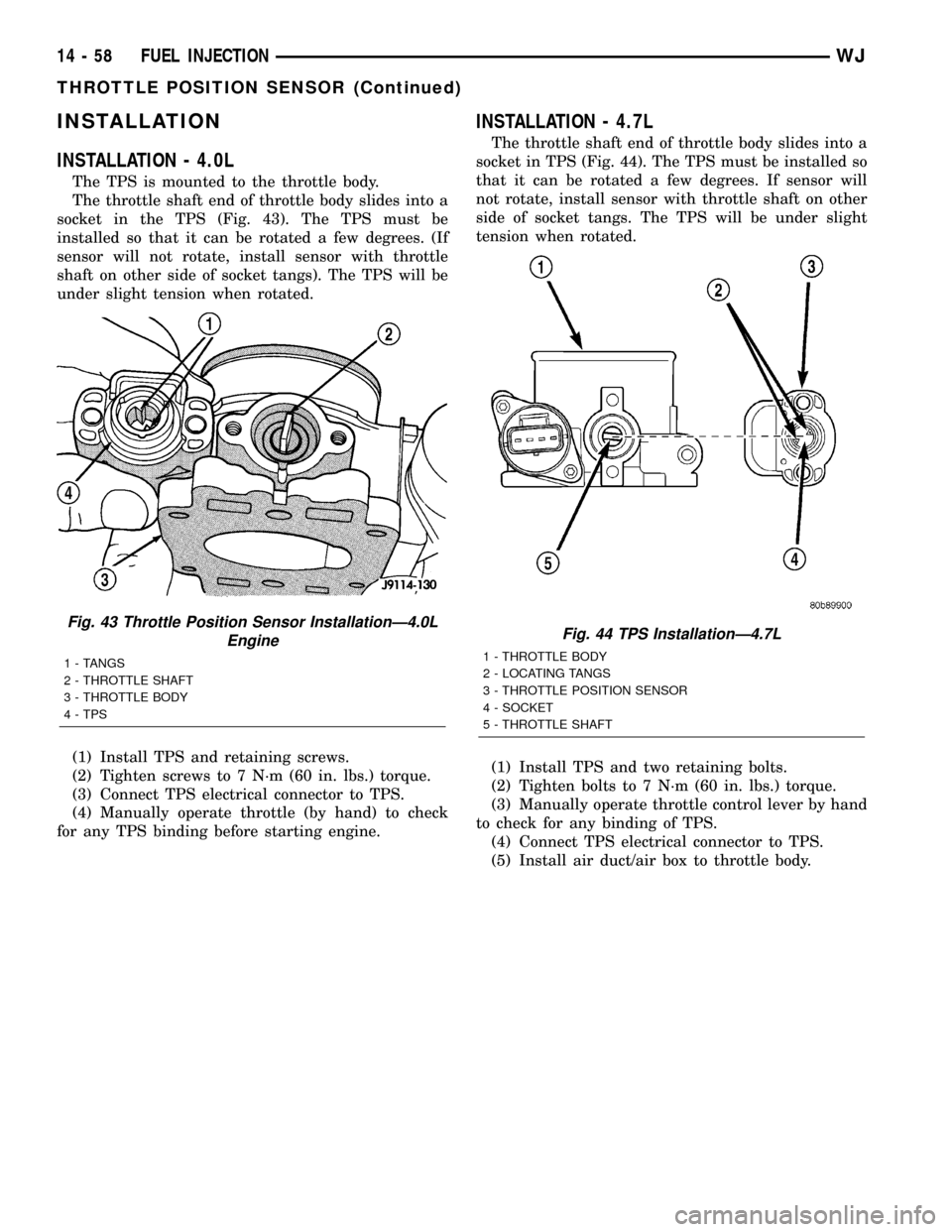

The TPS is mounted to the throttle body.

The throttle shaft end of throttle body slides into a

socket in the TPS (Fig. 43). The TPS must be

installed so that it can be rotated a few degrees. (If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs). The TPS will be

under slight tension when rotated.

(1) Install TPS and retaining screws.

(2) Tighten screws to 7 N´m (60 in. lbs.) torque.

(3) Connect TPS electrical connector to TPS.

(4) Manually operate throttle (by hand) to check

for any TPS binding before starting engine.

INSTALLATION - 4.7L

The throttle shaft end of throttle body slides into a

socket in TPS (Fig. 44). The TPS must be installed so

that it can be rotated a few degrees. If sensor will

not rotate, install sensor with throttle shaft on other

side of socket tangs. The TPS will be under slight

tension when rotated.

(1) Install TPS and two retaining bolts.

(2) Tighten bolts to 7 N´m (60 in. lbs.) torque.

(3) Manually operate throttle control lever by hand

to check for any binding of TPS.

(4) Connect TPS electrical connector to TPS.

(5) Install air duct/air box to throttle body.

Fig. 43 Throttle Position Sensor InstallationÐ4.0L

Engine

1 - TANGS

2 - THROTTLE SHAFT

3 - THROTTLE BODY

4 - TPS

Fig. 44 TPS InstallationÐ4.7L

1 - THROTTLE BODY

2 - LOCATING TANGS

3 - THROTTLE POSITION SENSOR

4 - SOCKET

5 - THROTTLE SHAFT

14 - 58 FUEL INJECTIONWJ

THROTTLE POSITION SENSOR (Continued)

Page 1510 of 2199

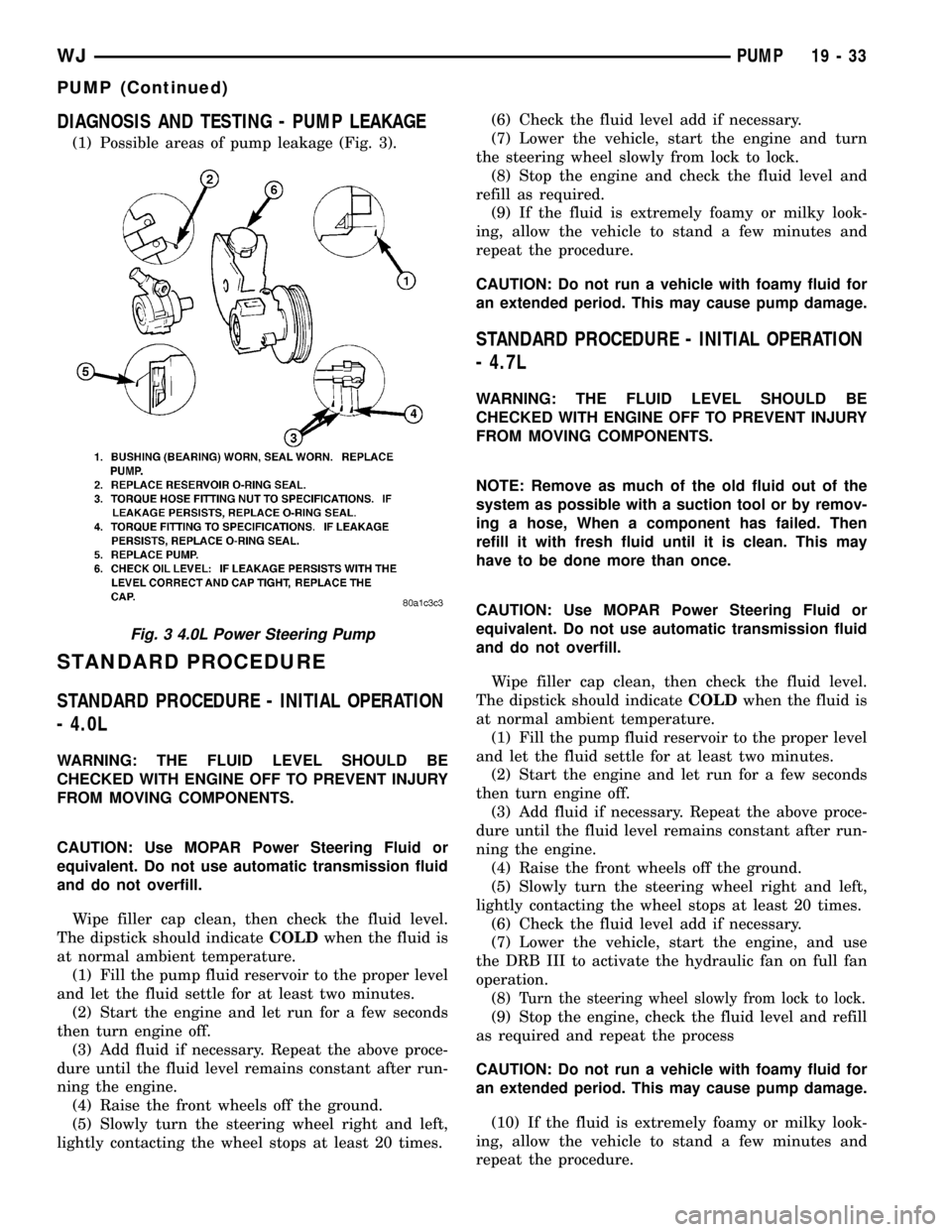

DIAGNOSIS AND TESTING - PUMP LEAKAGE

(1) Possible areas of pump leakage (Fig. 3).

STANDARD PROCEDURE

STANDARD PROCEDURE - INITIAL OPERATION

- 4.0L

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal ambient temperature.

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two minutes.

(2) Start the engine and let run for a few seconds

then turn engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine and turn

the steering wheel slowly from lock to lock.

(8) Stop the engine and check the fluid level and

refill as required.

(9) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

STANDARD PROCEDURE - INITIAL OPERATION

- 4.7L

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

NOTE: Remove as much of the old fluid out of the

system as possible with a suction tool or by remov-

ing a hose, When a component has failed. Then

refill it with fresh fluid until it is clean. This may

have to be done more than once.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal ambient temperature.

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two minutes.

(2) Start the engine and let run for a few seconds

then turn engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.

(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine, and use

the DRB III to activate the hydraulic fan on full fan

operation.

(8)

Turn the steering wheel slowly from lock to lock.

(9) Stop the engine, check the fluid level and refill

as required and repeat the process

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

(10) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

Fig. 3 4.0L Power Steering Pump

WJPUMP 19 - 33

PUMP (Continued)

Page 1547 of 2199

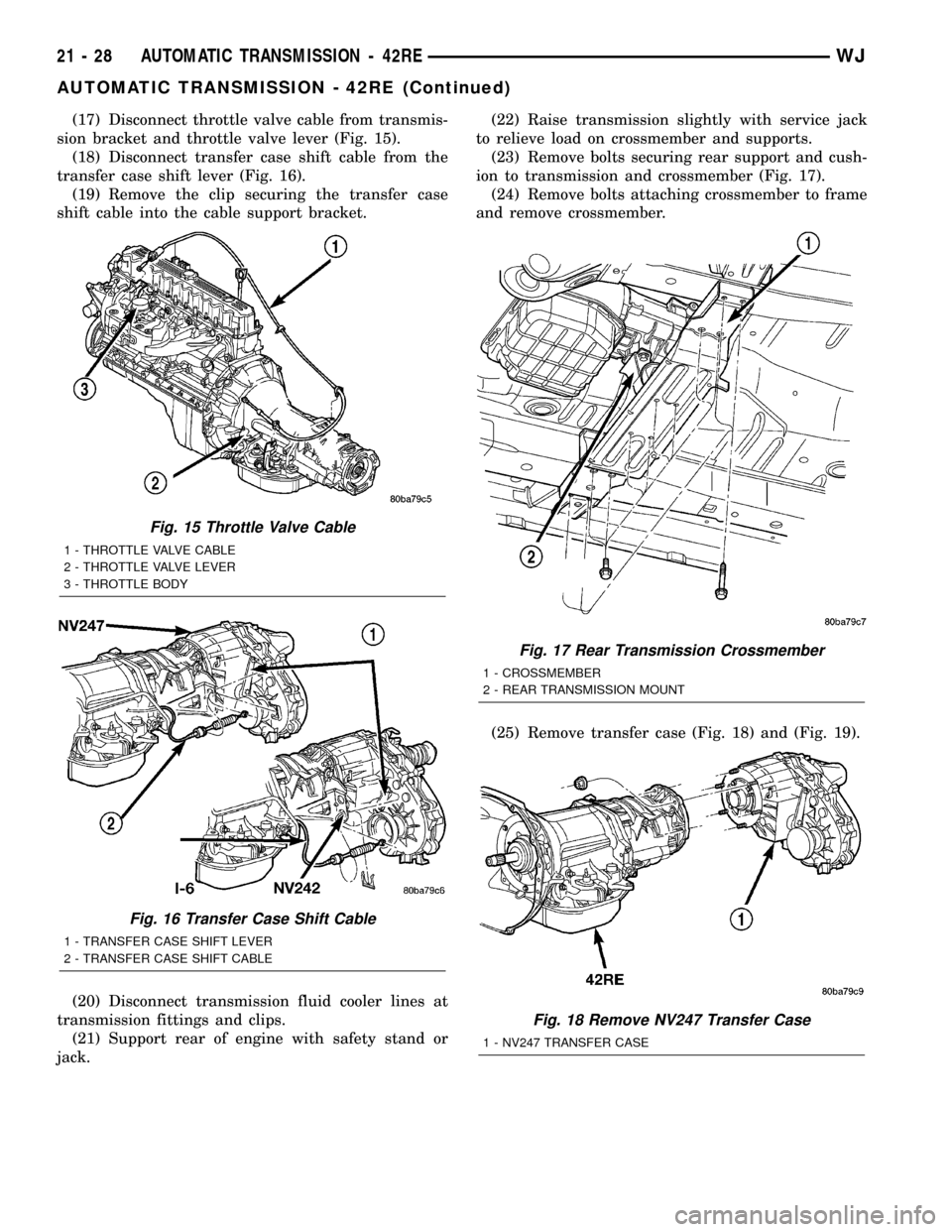

(17) Disconnect throttle valve cable from transmis-

sion bracket and throttle valve lever (Fig. 15).

(18) Disconnect transfer case shift cable from the

transfer case shift lever (Fig. 16).

(19) Remove the clip securing the transfer case

shift cable into the cable support bracket.

(20) Disconnect transmission fluid cooler lines at

transmission fittings and clips.

(21) Support rear of engine with safety stand or

jack.(22) Raise transmission slightly with service jack

to relieve load on crossmember and supports.

(23) Remove bolts securing rear support and cush-

ion to transmission and crossmember (Fig. 17).

(24) Remove bolts attaching crossmember to frame

and remove crossmember.

(25) Remove transfer case (Fig. 18) and (Fig. 19).

Fig. 15 Throttle Valve Cable

1 - THROTTLE VALVE CABLE

2 - THROTTLE VALVE LEVER

3 - THROTTLE BODY

Fig. 16 Transfer Case Shift Cable

1 - TRANSFER CASE SHIFT LEVER

2 - TRANSFER CASE SHIFT CABLE

Fig. 17 Rear Transmission Crossmember

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

Fig. 18 Remove NV247 Transfer Case

1 - NV247 TRANSFER CASE

21 - 28 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1554 of 2199

Petroleum jelly can also be used to hold thrust

washers, thrust plates and gaskets in position during

assembly. However,do notuse chassis grease, bear-

ing grease, white grease, or similar lubricants on any

transmission part. These types of lubricants can

eventually block or restrict fluid passages and inter-

fere with valve operation. Use petroleum jelly only.

Do not force parts into place. The transmission

components and subassemblies are easily installed by

hand when properly aligned.

If a part seems extremely difficult to install, it is

either misaligned or incorrectly assembled. Also ver-

ify that thrust washers, thrust plates and seal rings

are correctly positioned before assembly. These parts

can interfere with proper assembly if mis-positioned.

The planetary geartrain, front/rear clutch assem-

blies and oil pump are all much easier to install

when the transmission case is upright.

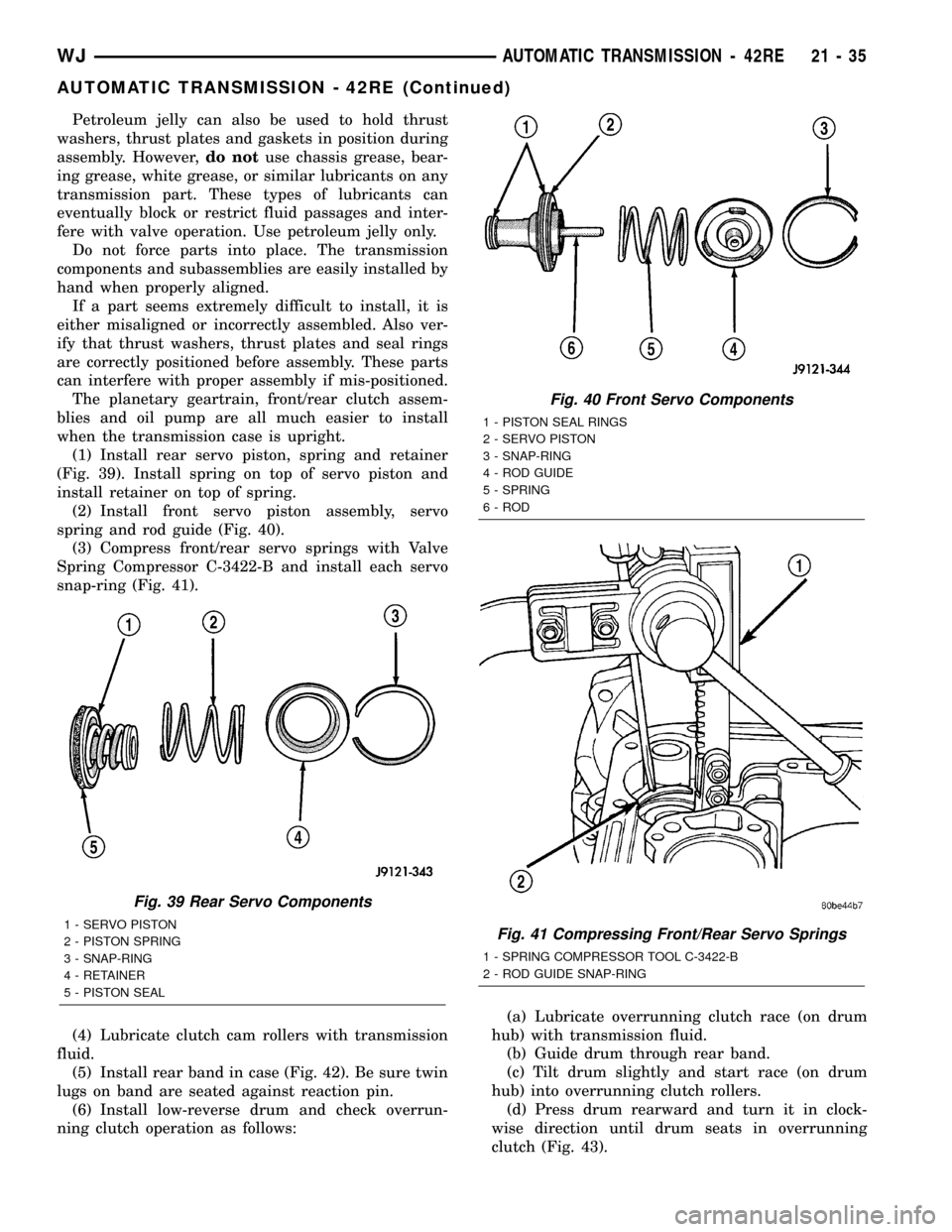

(1) Install rear servo piston, spring and retainer

(Fig. 39). Install spring on top of servo piston and

install retainer on top of spring.

(2) Install front servo piston assembly, servo

spring and rod guide (Fig. 40).

(3) Compress front/rear servo springs with Valve

Spring Compressor C-3422-B and install each servo

snap-ring (Fig. 41).

(4) Lubricate clutch cam rollers with transmission

fluid.

(5) Install rear band in case (Fig. 42). Be sure twin

lugs on band are seated against reaction pin.

(6) Install low-reverse drum and check overrun-

ning clutch operation as follows:(a) Lubricate overrunning clutch race (on drum

hub) with transmission fluid.

(b) Guide drum through rear band.

(c) Tilt drum slightly and start race (on drum

hub) into overrunning clutch rollers.

(d) Press drum rearward and turn it in clock-

wise direction until drum seats in overrunning

clutch (Fig. 43).

Fig. 39 Rear Servo Components

1 - SERVO PISTON

2 - PISTON SPRING

3 - SNAP-RING

4 - RETAINER

5 - PISTON SEAL

Fig. 40 Front Servo Components

1 - PISTON SEAL RINGS

2 - SERVO PISTON

3 - SNAP-RING

4 - ROD GUIDE

5 - SPRING

6 - ROD

Fig. 41 Compressing Front/Rear Servo Springs

1 - SPRING COMPRESSOR TOOL C-3422-B

2 - ROD GUIDE SNAP-RING

WJAUTOMATIC TRANSMISSION - 42RE 21 - 35

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1560 of 2199

(32) Install valve body as follows:

(a) Align and carefully insert park rod into pawl.

Rod will make click noise as it enters pawl. Move

rod slightly to check engagement.

(b) Align and seat valve body on case. Be sure

manual lever shaft and overdrive connector are

fully seated in case. Also be sure valve body wiring

is not pinched or kinked.

(c) Install and start all valve body attaching

bolts by hand. Then tighten bolts evenly, in a diag-

onal pattern to 12 N´m (105 in. lbs.) torque. Do not

overtighten valve body bolts. This could result in

distortion and cross leakage after installation.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into the cavity.

(33) Install new filter on valve body. Tighten filter

screws to 4 N´m (35 in. lbs.).

(34) Adjust front and rear bands.

(35) Install seal on park/neutral position switch.

Then install and tighten switch to 34 N´m (25 ft.

lbs.).

(36) Install magnet in oil pan. Magnet goes on

small protrusion at corner of pan.

(37) Position new oil pan gasket on case and

install oil pan. Tighten pan bolts to 17 N´m (13 ft.

lbs.).

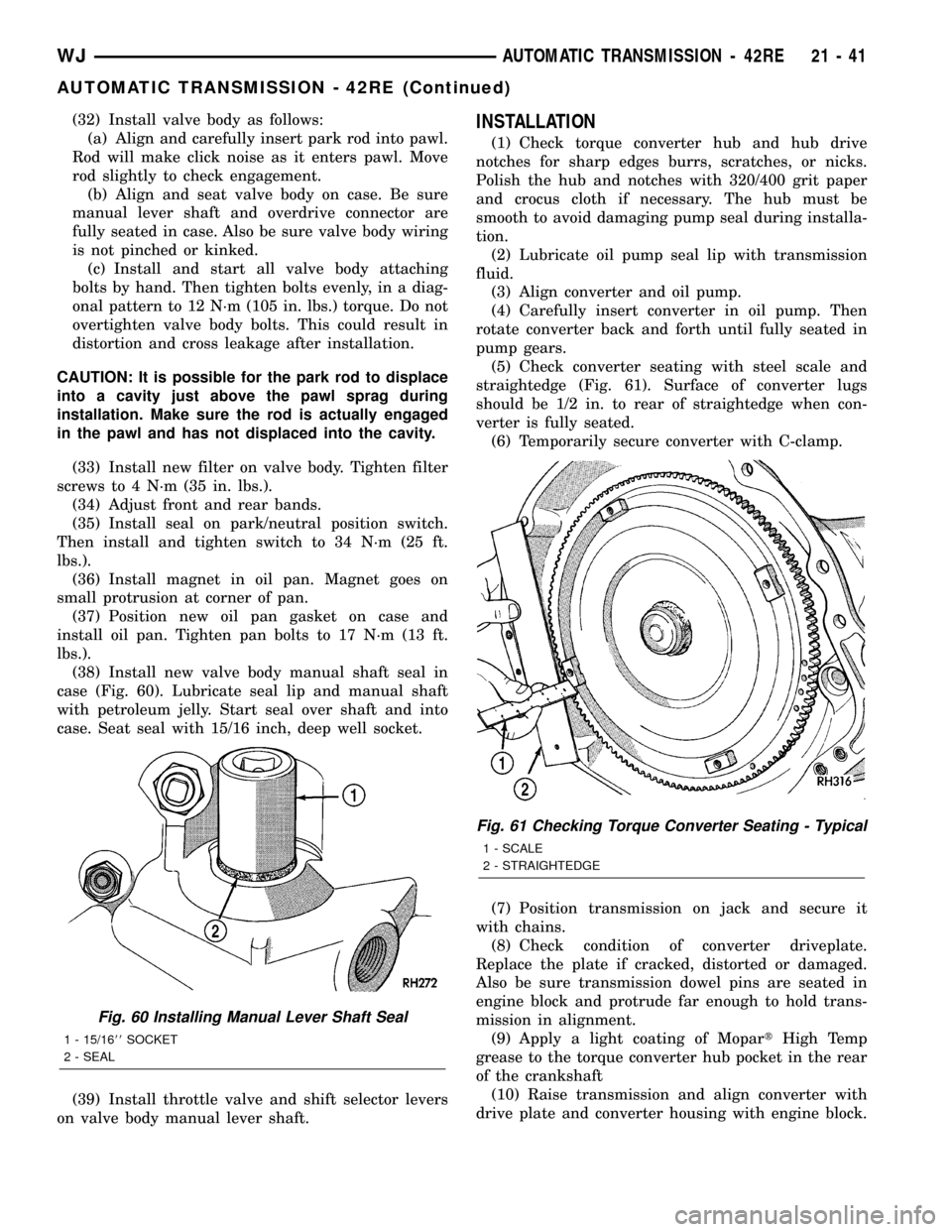

(38) Install new valve body manual shaft seal in

case (Fig. 60). Lubricate seal lip and manual shaft

with petroleum jelly. Start seal over shaft and into

case. Seat seal with 15/16 inch, deep well socket.

(39) Install throttle valve and shift selector levers

on valve body manual lever shaft.INSTALLATION

(1) Check torque converter hub and hub drive

notches for sharp edges burrs, scratches, or nicks.

Polish the hub and notches with 320/400 grit paper

and crocus cloth if necessary. The hub must be

smooth to avoid damaging pump seal during installa-

tion.

(2) Lubricate oil pump seal lip with transmission

fluid.

(3) Align converter and oil pump.

(4) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

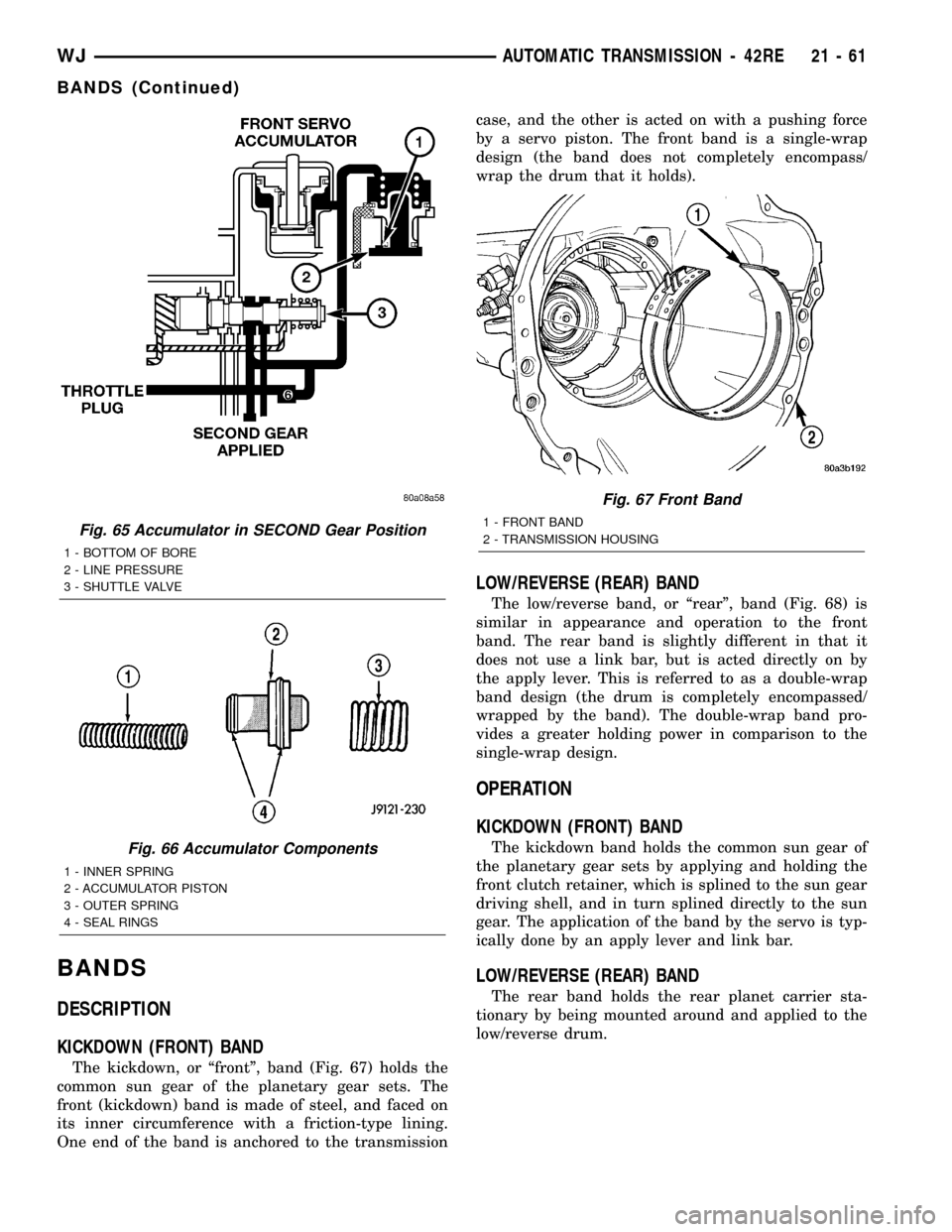

(5) Check converter seating with steel scale and

straightedge (Fig. 61). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(6) Temporarily secure converter with C-clamp.

(7) Position transmission on jack and secure it

with chains.

(8) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated in

engine block and protrude far enough to hold trans-

mission in alignment.

(9) Apply a light coating of MopartHigh Temp

grease to the torque converter hub pocket in the rear

of the crankshaft

(10) Raise transmission and align converter with

drive plate and converter housing with engine block.

Fig. 60 Installing Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

Fig. 61 Checking Torque Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

WJAUTOMATIC TRANSMISSION - 42RE 21 - 41

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1580 of 2199

BANDS

DESCRIPTION

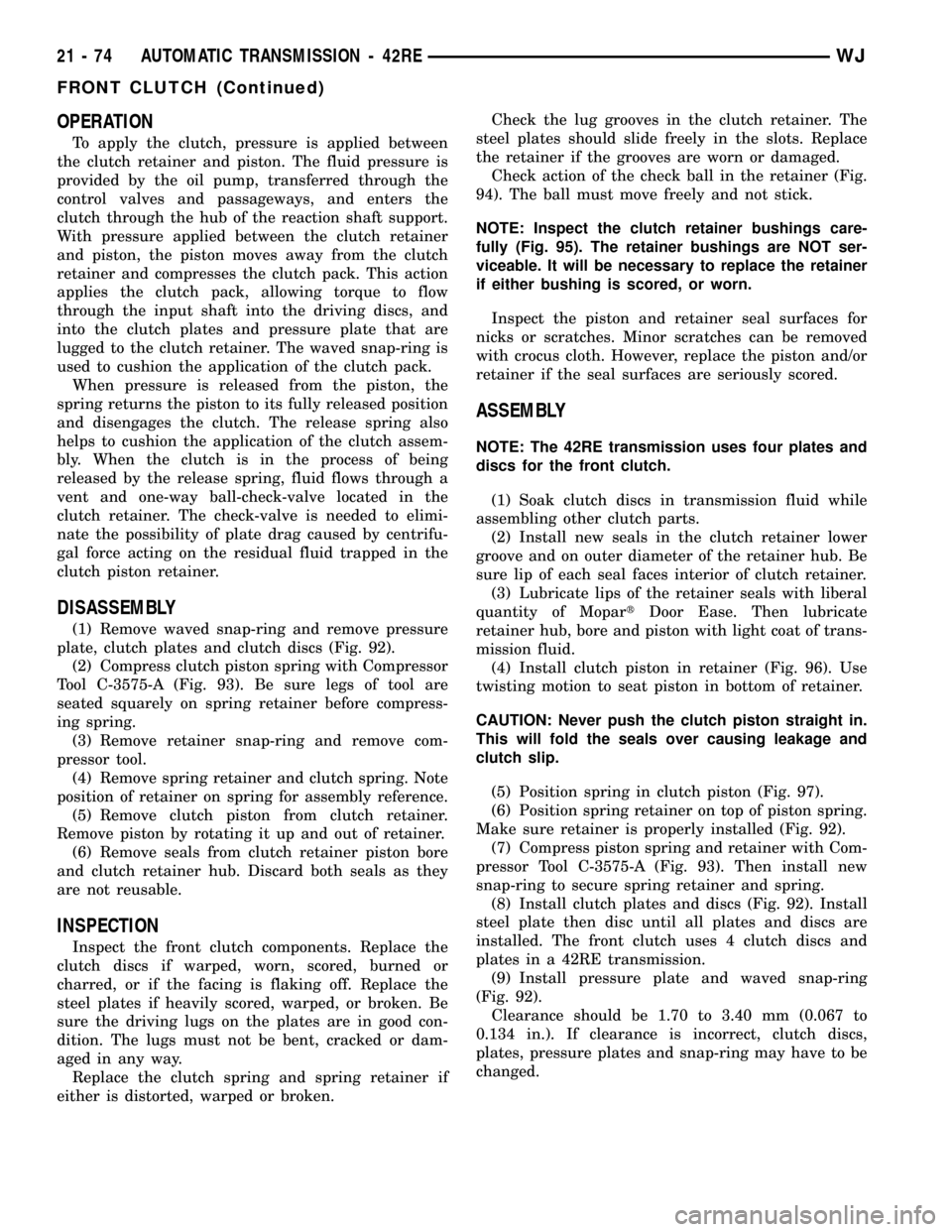

KICKDOWN (FRONT) BAND

The kickdown, or ªfrontº, band (Fig. 67) holds the

common sun gear of the planetary gear sets. The

front (kickdown) band is made of steel, and faced on

its inner circumference with a friction-type lining.

One end of the band is anchored to the transmissioncase, and the other is acted on with a pushing force

by a servo piston. The front band is a single-wrap

design (the band does not completely encompass/

wrap the drum that it holds).

LOW/REVERSE (REAR) BAND

The low/reverse band, or ªrearº, band (Fig. 68) is

similar in appearance and operation to the front

band. The rear band is slightly different in that it

does not use a link bar, but is acted directly on by

the apply lever. This is referred to as a double-wrap

band design (the drum is completely encompassed/

wrapped by the band). The double-wrap band pro-

vides a greater holding power in comparison to the

single-wrap design.

OPERATION

KICKDOWN (FRONT) BAND

The kickdown band holds the common sun gear of

the planetary gear sets by applying and holding the

front clutch retainer, which is splined to the sun gear

driving shell, and in turn splined directly to the sun

gear. The application of the band by the servo is typ-

ically done by an apply lever and link bar.

LOW/REVERSE (REAR) BAND

The rear band holds the rear planet carrier sta-

tionary by being mounted around and applied to the

low/reverse drum.

Fig. 65 Accumulator in SECOND Gear Position

1 - BOTTOM OF BORE

2 - LINE PRESSURE

3 - SHUTTLE VALVE

Fig. 66 Accumulator Components

1 - INNER SPRING

2 - ACCUMULATOR PISTON

3 - OUTER SPRING

4 - SEAL RINGS

Fig. 67 Front Band

1 - FRONT BAND

2 - TRANSMISSION HOUSING

WJAUTOMATIC TRANSMISSION - 42RE 21 - 61

BANDS (Continued)

Page 1593 of 2199

OPERATION

To apply the clutch, pressure is applied between

the clutch retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through the hub of the reaction shaft support.

With pressure applied between the clutch retainer

and piston, the piston moves away from the clutch

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and

into the clutch plates and pressure plate that are

lugged to the clutch retainer. The waved snap-ring is

used to cushion the application of the clutch pack.

When pressure is released from the piston, the

spring returns the piston to its fully released position

and disengages the clutch. The release spring also

helps to cushion the application of the clutch assem-

bly. When the clutch is in the process of being

released by the release spring, fluid flows through a

vent and one-way ball-check-valve located in the

clutch retainer. The check-valve is needed to elimi-

nate the possibility of plate drag caused by centrifu-

gal force acting on the residual fluid trapped in the

clutch piston retainer.

DISASSEMBLY

(1) Remove waved snap-ring and remove pressure

plate, clutch plates and clutch discs (Fig. 92).

(2) Compress clutch piston spring with Compressor

Tool C-3575-A (Fig. 93). Be sure legs of tool are

seated squarely on spring retainer before compress-

ing spring.

(3) Remove retainer snap-ring and remove com-

pressor tool.

(4) Remove spring retainer and clutch spring. Note

position of retainer on spring for assembly reference.

(5) Remove clutch piston from clutch retainer.

Remove piston by rotating it up and out of retainer.

(6) Remove seals from clutch retainer piston bore

and clutch retainer hub. Discard both seals as they

are not reusable.

INSPECTION

Inspect the front clutch components. Replace the

clutch discs if warped, worn, scored, burned or

charred, or if the facing is flaking off. Replace the

steel plates if heavily scored, warped, or broken. Be

sure the driving lugs on the plates are in good con-

dition. The lugs must not be bent, cracked or dam-

aged in any way.

Replace the clutch spring and spring retainer if

either is distorted, warped or broken.Check the lug grooves in the clutch retainer. The

steel plates should slide freely in the slots. Replace

the retainer if the grooves are worn or damaged.

Check action of the check ball in the retainer (Fig.

94). The ball must move freely and not stick.

NOTE: Inspect the clutch retainer bushings care-

fully (Fig. 95). The retainer bushings are NOT ser-

viceable. It will be necessary to replace the retainer

if either bushing is scored, or worn.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

ASSEMBLY

NOTE: The 42RE transmission uses four plates and

discs for the front clutch.

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seals in the clutch retainer lower

groove and on outer diameter of the retainer hub. Be

sure lip of each seal faces interior of clutch retainer.

(3) Lubricate lips of the retainer seals with liberal

quantity of MopartDoor Ease. Then lubricate

retainer hub, bore and piston with light coat of trans-

mission fluid.

(4) Install clutch piston in retainer (Fig. 96). Use

twisting motion to seat piston in bottom of retainer.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip.

(5) Position spring in clutch piston (Fig. 97).

(6) Position spring retainer on top of piston spring.

Make sure retainer is properly installed (Fig. 92).

(7) Compress piston spring and retainer with Com-

pressor Tool C-3575-A (Fig. 93). Then install new

snap-ring to secure spring retainer and spring.

(8) Install clutch plates and discs (Fig. 92). Install

steel plate then disc until all plates and discs are

installed. The front clutch uses 4 clutch discs and

plates in a 42RE transmission.

(9) Install pressure plate and waved snap-ring

(Fig. 92).

Clearance should be 1.70 to 3.40 mm (0.067 to

0.134 in.). If clearance is incorrect, clutch discs,

plates, pressure plates and snap-ring may have to be

changed.

21 - 74 AUTOMATIC TRANSMISSION - 42REWJ

FRONT CLUTCH (Continued)

Page 1602 of 2199

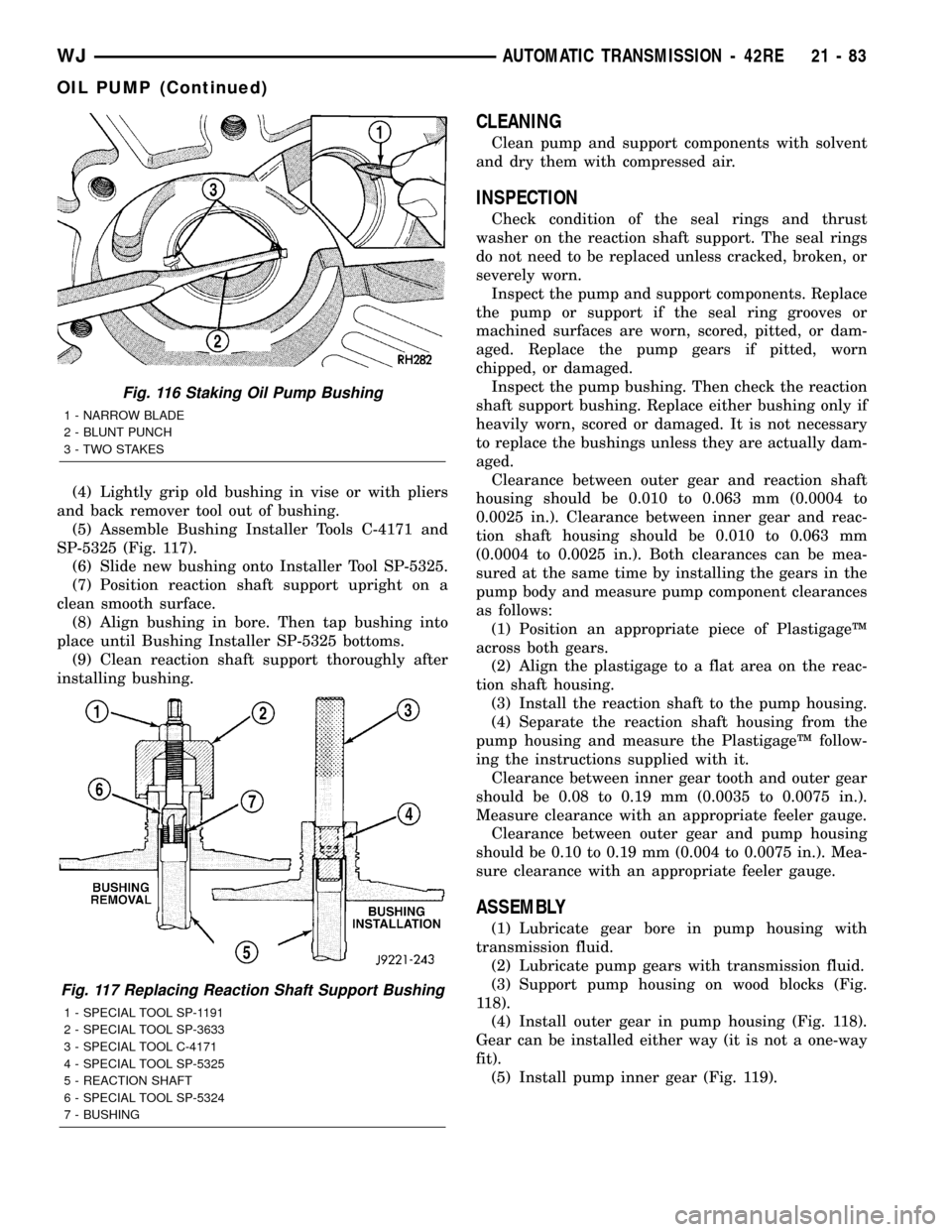

(4) Lightly grip old bushing in vise or with pliers

and back remover tool out of bushing.

(5) Assemble Bushing Installer Tools C-4171 and

SP-5325 (Fig. 117).

(6) Slide new bushing onto Installer Tool SP-5325.

(7) Position reaction shaft support upright on a

clean smooth surface.

(8) Align bushing in bore. Then tap bushing into

place until Bushing Installer SP-5325 bottoms.

(9) Clean reaction shaft support thoroughly after

installing bushing.

CLEANING

Clean pump and support components with solvent

and dry them with compressed air.

INSPECTION

Check condition of the seal rings and thrust

washer on the reaction shaft support. The seal rings

do not need to be replaced unless cracked, broken, or

severely worn.

Inspect the pump and support components. Replace

the pump or support if the seal ring grooves or

machined surfaces are worn, scored, pitted, or dam-

aged. Replace the pump gears if pitted, worn

chipped, or damaged.

Inspect the pump bushing. Then check the reaction

shaft support bushing. Replace either bushing only if

heavily worn, scored or damaged. It is not necessary

to replace the bushings unless they are actually dam-

aged.

Clearance between outer gear and reaction shaft

housing should be 0.010 to 0.063 mm (0.0004 to

0.0025 in.). Clearance between inner gear and reac-

tion shaft housing should be 0.010 to 0.063 mm

(0.0004 to 0.0025 in.). Both clearances can be mea-

sured at the same time by installing the gears in the

pump body and measure pump component clearances

as follows:

(1) Position an appropriate piece of PlastigageŸ

across both gears.

(2) Align the plastigage to a flat area on the reac-

tion shaft housing.

(3) Install the reaction shaft to the pump housing.

(4) Separate the reaction shaft housing from the

pump housing and measure the PlastigageŸ follow-

ing the instructions supplied with it.

Clearance between inner gear tooth and outer gear

should be 0.08 to 0.19 mm (0.0035 to 0.0075 in.).

Measure clearance with an appropriate feeler gauge.

Clearance between outer gear and pump housing

should be 0.10 to 0.19 mm (0.004 to 0.0075 in.). Mea-

sure clearance with an appropriate feeler gauge.

ASSEMBLY

(1) Lubricate gear bore in pump housing with

transmission fluid.

(2) Lubricate pump gears with transmission fluid.

(3) Support pump housing on wood blocks (Fig.

118).

(4) Install outer gear in pump housing (Fig. 118).

Gear can be installed either way (it is not a one-way

fit).

(5) Install pump inner gear (Fig. 119).

Fig. 116 Staking Oil Pump Bushing

1 - NARROW BLADE

2 - BLUNT PUNCH

3 - TWO STAKES

Fig. 117 Replacing Reaction Shaft Support Bushing

1 - SPECIAL TOOL SP-1191

2 - SPECIAL TOOL SP-3633

3 - SPECIAL TOOL C-4171

4 - SPECIAL TOOL SP-5325

5 - REACTION SHAFT

6 - SPECIAL TOOL SP-5324

7 - BUSHING

WJAUTOMATIC TRANSMISSION - 42RE 21 - 83

OIL PUMP (Continued)

Page 1605 of 2199

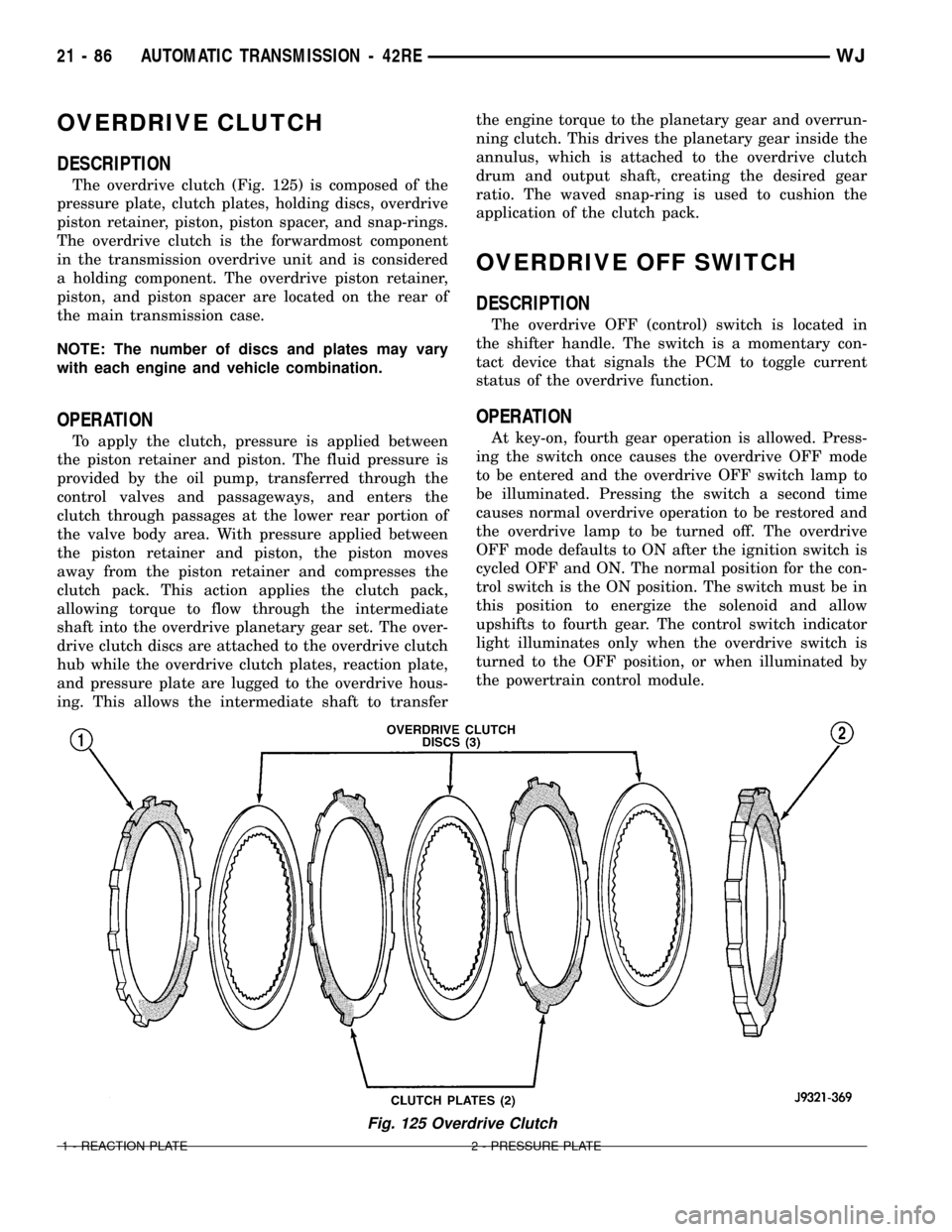

OVERDRIVE CLUTCH

DESCRIPTION

The overdrive clutch (Fig. 125) is composed of the

pressure plate, clutch plates, holding discs, overdrive

piston retainer, piston, piston spacer, and snap-rings.

The overdrive clutch is the forwardmost component

in the transmission overdrive unit and is considered

a holding component. The overdrive piston retainer,

piston, and piston spacer are located on the rear of

the main transmission case.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between

the piston retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through passages at the lower rear portion of

the valve body area. With pressure applied between

the piston retainer and piston, the piston moves

away from the piston retainer and compresses the

clutch pack. This action applies the clutch pack,

allowing torque to flow through the intermediate

shaft into the overdrive planetary gear set. The over-

drive clutch discs are attached to the overdrive clutch

hub while the overdrive clutch plates, reaction plate,

and pressure plate are lugged to the overdrive hous-

ing. This allows the intermediate shaft to transferthe engine torque to the planetary gear and overrun-

ning clutch. This drives the planetary gear inside the

annulus, which is attached to the overdrive clutch

drum and output shaft, creating the desired gear

ratio. The waved snap-ring is used to cushion the

application of the clutch pack.

OVERDRIVE OFF SWITCH

DESCRIPTION

The overdrive OFF (control) switch is located in

the shifter handle. The switch is a momentary con-

tact device that signals the PCM to toggle current

status of the overdrive function.

OPERATION

At key-on, fourth gear operation is allowed. Press-

ing the switch once causes the overdrive OFF mode

to be entered and the overdrive OFF switch lamp to

be illuminated. Pressing the switch a second time

causes normal overdrive operation to be restored and

the overdrive lamp to be turned off. The overdrive

OFF mode defaults to ON after the ignition switch is

cycled OFF and ON. The normal position for the con-

trol switch is the ON position. The switch must be in

this position to energize the solenoid and allow

upshifts to fourth gear. The control switch indicator

light illuminates only when the overdrive switch is

turned to the OFF position, or when illuminated by

the powertrain control module.

Fig. 125 Overdrive Clutch

1 - REACTION PLATE 2 - PRESSURE PLATE

21 - 86 AUTOMATIC TRANSMISSION - 42REWJ

Page 1617 of 2199

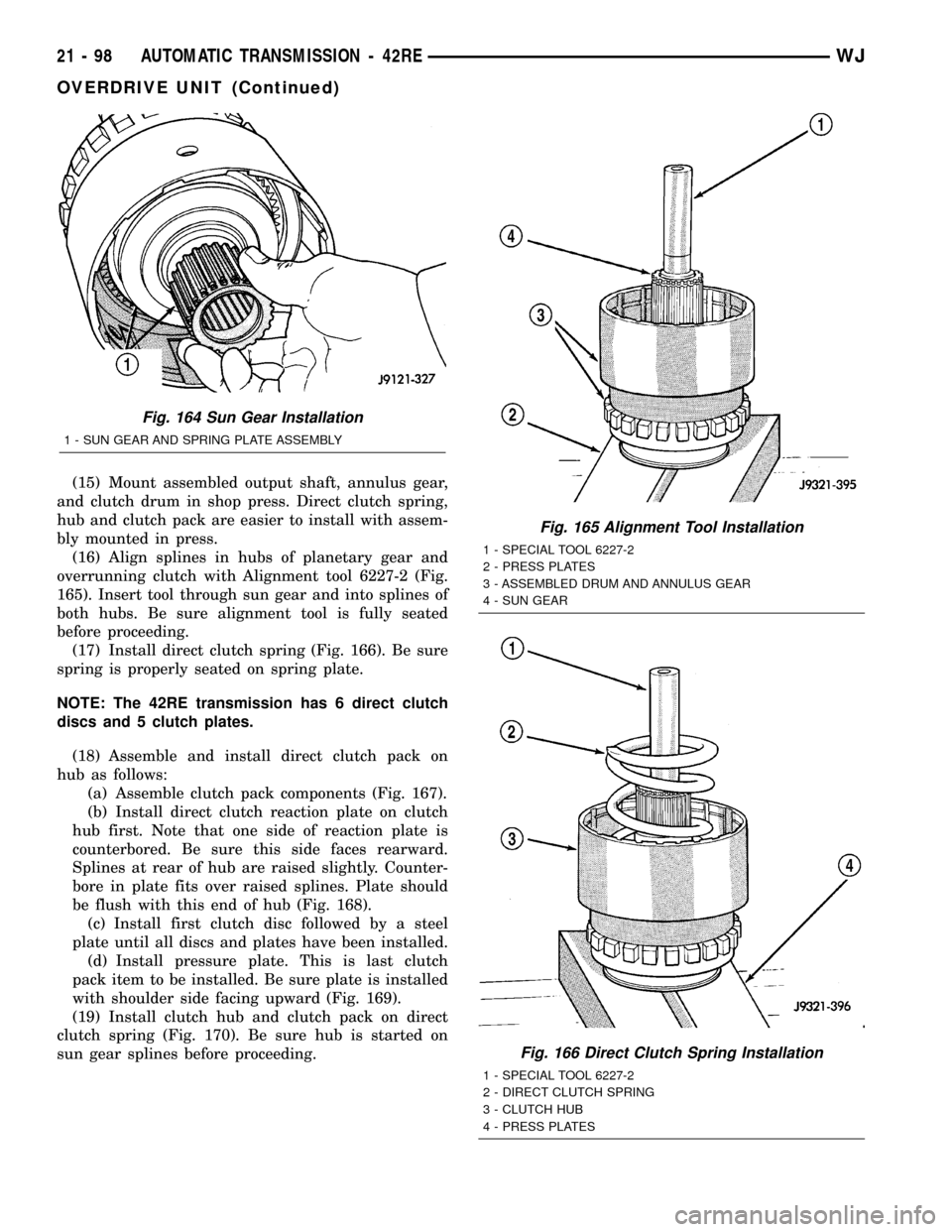

(15) Mount assembled output shaft, annulus gear,

and clutch drum in shop press. Direct clutch spring,

hub and clutch pack are easier to install with assem-

bly mounted in press.

(16) Align splines in hubs of planetary gear and

overrunning clutch with Alignment tool 6227-2 (Fig.

165). Insert tool through sun gear and into splines of

both hubs. Be sure alignment tool is fully seated

before proceeding.

(17) Install direct clutch spring (Fig. 166). Be sure

spring is properly seated on spring plate.

NOTE: The 42RE transmission has 6 direct clutch

discs and 5 clutch plates.

(18) Assemble and install direct clutch pack on

hub as follows:

(a) Assemble clutch pack components (Fig. 167).

(b) Install direct clutch reaction plate on clutch

hub first. Note that one side of reaction plate is

counterbored. Be sure this side faces rearward.

Splines at rear of hub are raised slightly. Counter-

bore in plate fits over raised splines. Plate should

be flush with this end of hub (Fig. 168).

(c) Install first clutch disc followed by a steel

plate until all discs and plates have been installed.

(d) Install pressure plate. This is last clutch

pack item to be installed. Be sure plate is installed

with shoulder side facing upward (Fig. 169).

(19) Install clutch hub and clutch pack on direct

clutch spring (Fig. 170). Be sure hub is started on

sun gear splines before proceeding.

Fig. 164 Sun Gear Installation

1 - SUN GEAR AND SPRING PLATE ASSEMBLY

Fig. 165 Alignment Tool Installation

1 - SPECIAL TOOL 6227-2

2 - PRESS PLATES

3 - ASSEMBLED DRUM AND ANNULUS GEAR

4 - SUN GEAR

Fig. 166 Direct Clutch Spring Installation

1 - SPECIAL TOOL 6227-2

2 - DIRECT CLUTCH SPRING

3 - CLUTCH HUB

4 - PRESS PLATES

21 - 98 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)