Prop JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1312 of 2199

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

(1) Check the coolant level and fill as required. DO

NOT install the radiator cap.

(2) Start and operate the engine until it attains

normal operating temperature, then turn the engine

OFF.

(3) Remove the spark plugs.

(4) Remove the oil filler cap.

(5) Remove the air cleaner.(6) Calibrate the tester according to the manufac-

turer's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

(7) Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

Set piston of cylinder to be tested at TDC compres-

sion,While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to CYLINDER COMBUSTION PRESSURE

LEAKAGE DIAGNOSIS CHART .

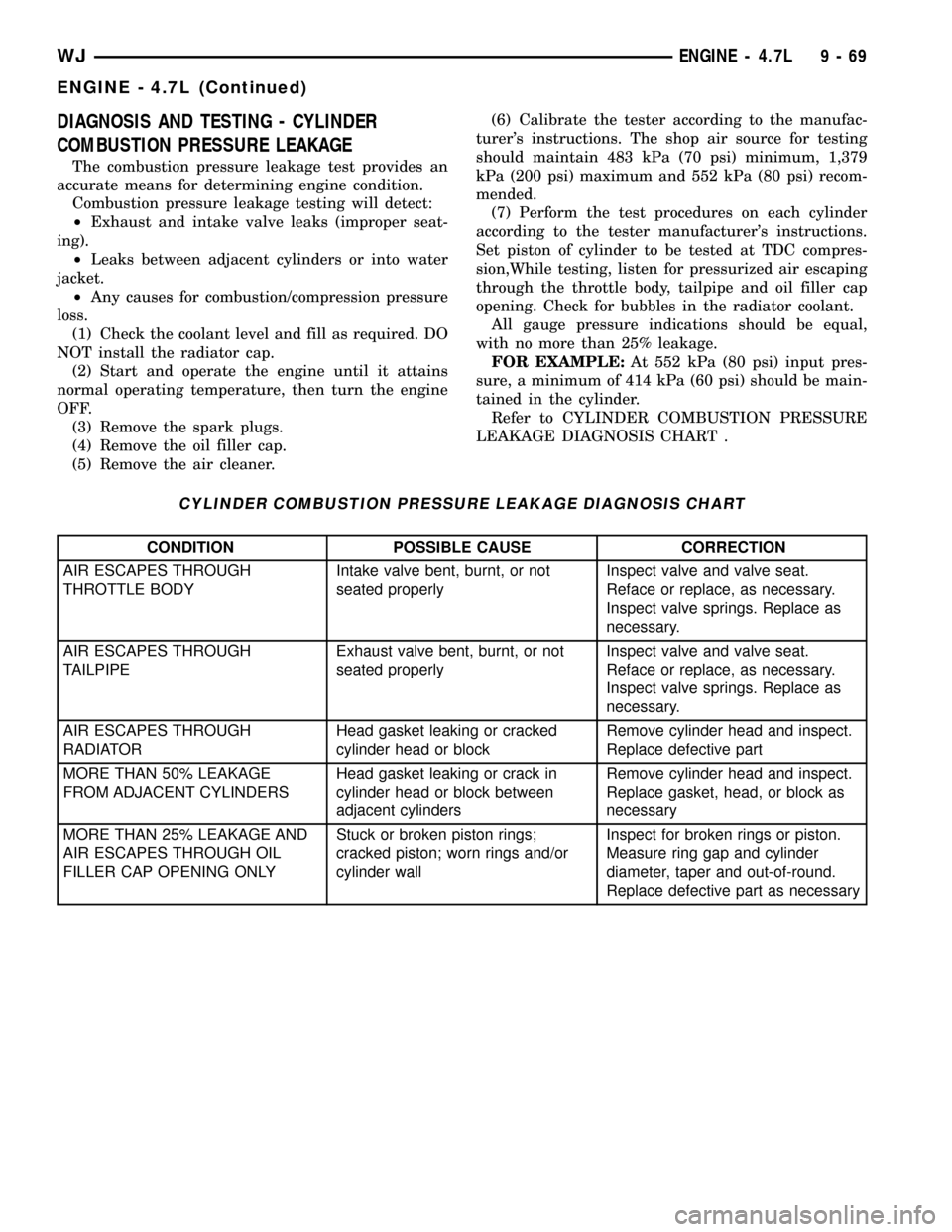

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

WJENGINE - 4.7L 9 - 69

ENGINE - 4.7L (Continued)

Page 1313 of 2199

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of airwhen squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

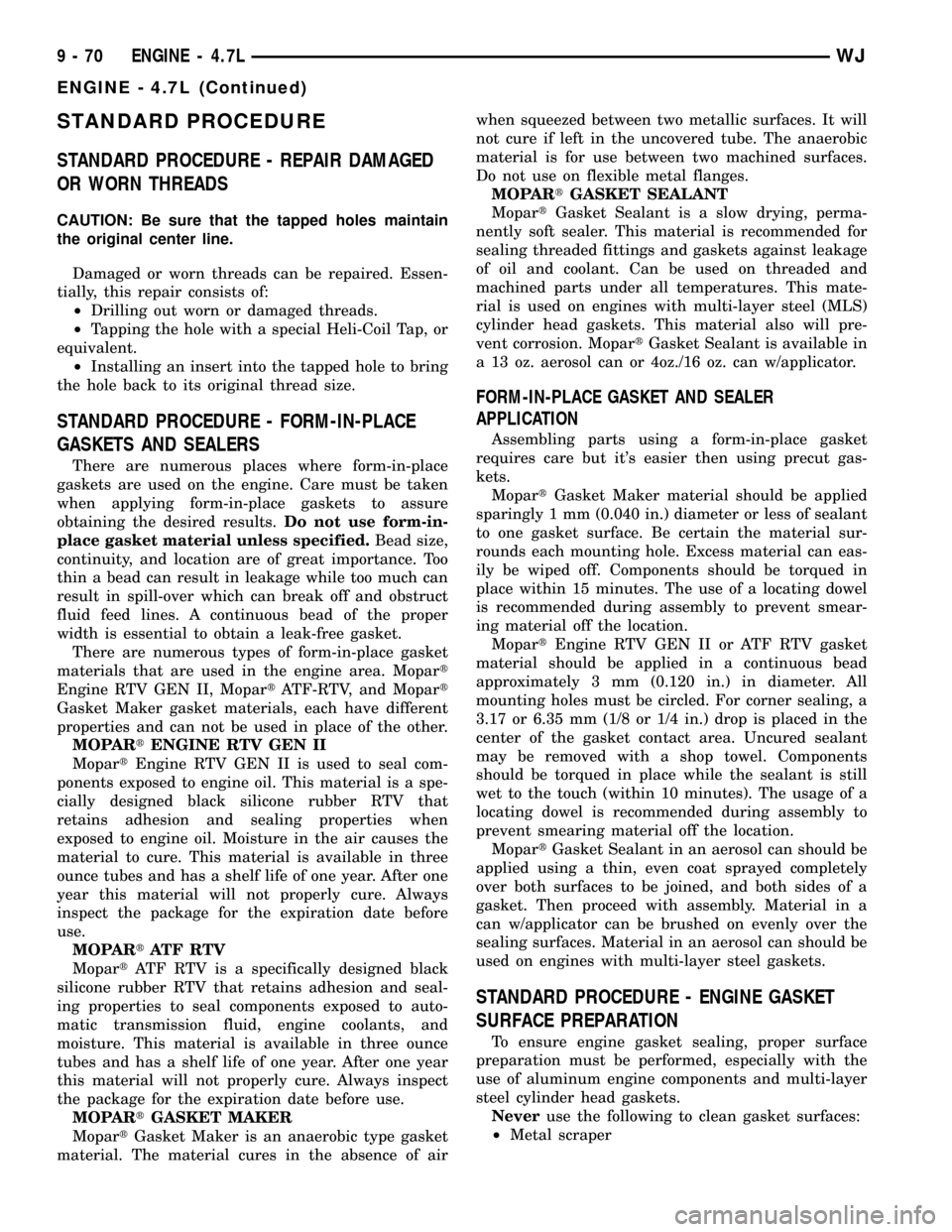

Neveruse the following to clean gasket surfaces:

²Metal scraper

9 - 70 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1314 of 2199

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 2)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 2)

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 2)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

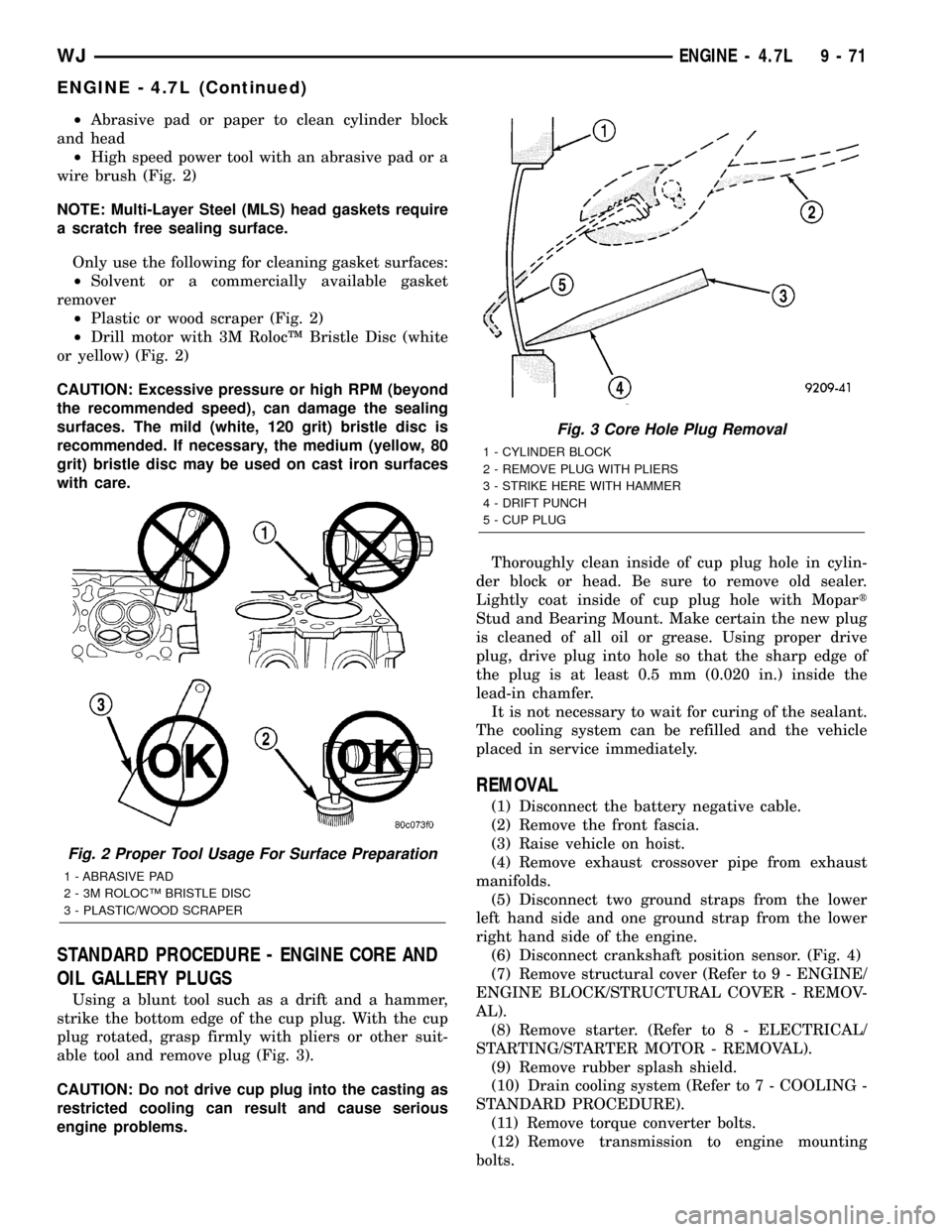

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 3).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the front fascia.

(3) Raise vehicle on hoist.

(4) Remove exhaust crossover pipe from exhaust

manifolds.

(5) Disconnect two ground straps from the lower

left hand side and one ground strap from the lower

right hand side of the engine.

(6) Disconnect crankshaft position sensor. (Fig. 4)

(7) Remove structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - REMOV-

AL).

(8) Remove starter. (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

(9) Remove rubber splash shield.

(10) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Remove torque converter bolts.

(12) Remove transmission to engine mounting

bolts.

Fig. 2 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

Fig. 3 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

WJENGINE - 4.7L 9 - 71

ENGINE - 4.7L (Continued)

Page 1326 of 2199

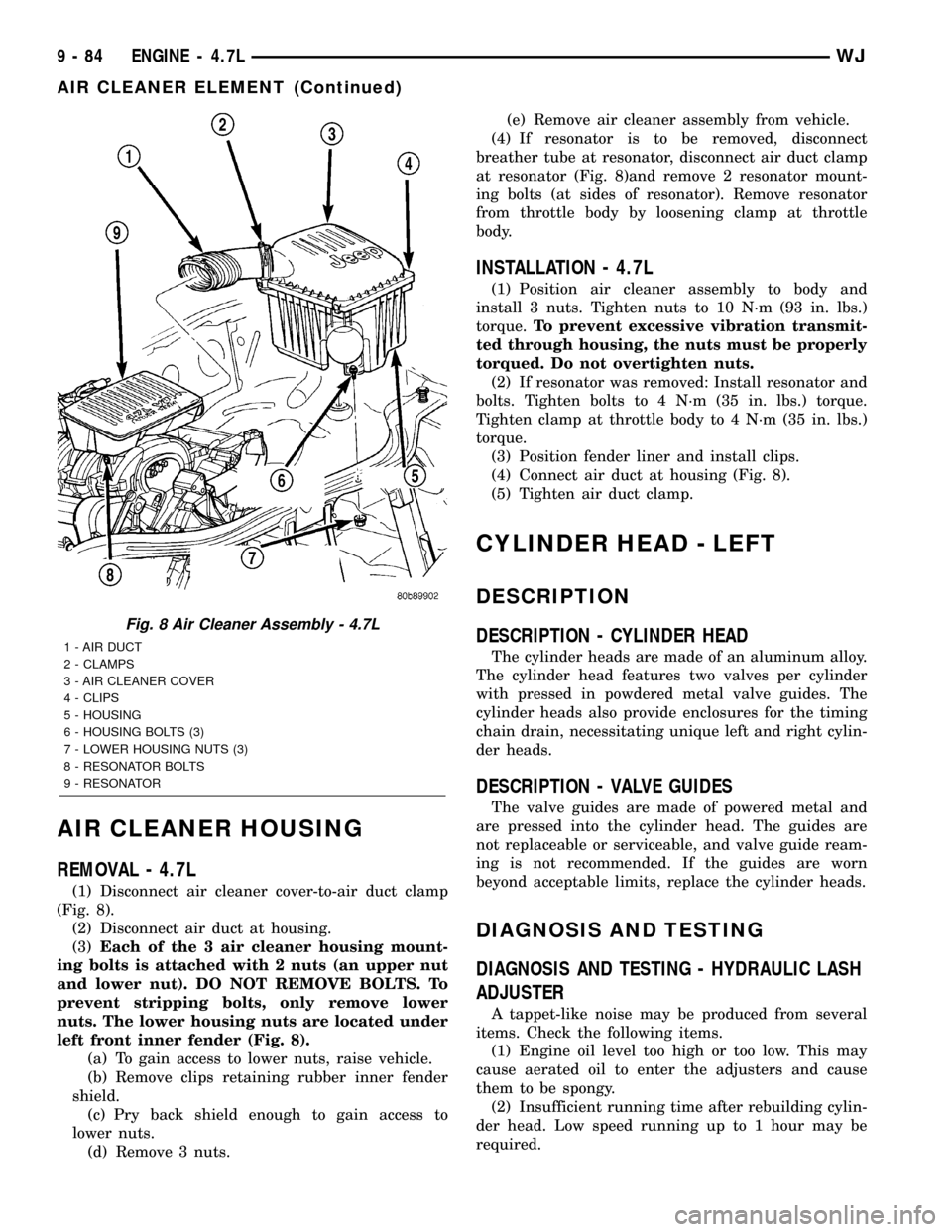

AIR CLEANER ELEMENT

REMOVAL - 4.7L

(1) Unlatch four clips retaining air cleaner cover to

air cleaner housing (Fig. 8).

(2) Lift cover up and position to the side.

(3) Remove air cleaner element.

INSTALLATION - 4.7L

(1) Clean inside of air cleaner housing before

installing new element.

(2) Install air cleaner element into housing.

(3) Latch clips and clamp cover down to secure. Be

sure air cleaner cover is properly seated to air

cleaner housing.

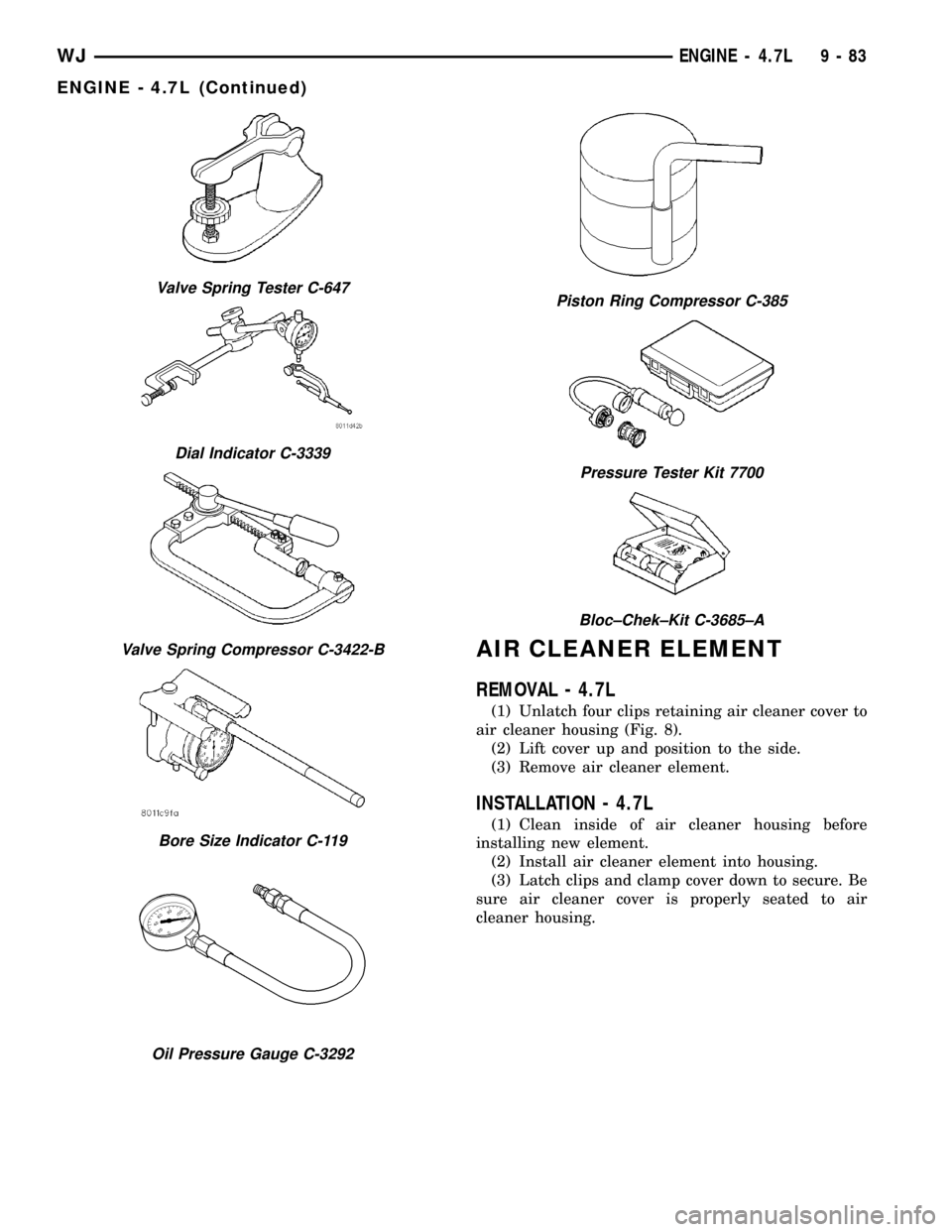

Valve Spring Tester C-647

Dial Indicator C-3339

Valve Spring Compressor C-3422-B

Bore Size Indicator C-119

Oil Pressure Gauge C-3292

Piston Ring Compressor C-385

Pressure Tester Kit 7700

Bloc±Chek±Kit C-3685±A

WJENGINE - 4.7L 9 - 83

ENGINE - 4.7L (Continued)

Page 1327 of 2199

AIR CLEANER HOUSING

REMOVAL - 4.7L

(1) Disconnect air cleaner cover-to-air duct clamp

(Fig. 8).

(2) Disconnect air duct at housing.

(3)Each of the 3 air cleaner housing mount-

ing bolts is attached with 2 nuts (an upper nut

and lower nut). DO NOT REMOVE BOLTS. To

prevent stripping bolts, only remove lower

nuts. The lower housing nuts are located under

left front inner fender (Fig. 8).

(a) To gain access to lower nuts, raise vehicle.

(b) Remove clips retaining rubber inner fender

shield.

(c) Pry back shield enough to gain access to

lower nuts.

(d) Remove 3 nuts.(e) Remove air cleaner assembly from vehicle.

(4) If resonator is to be removed, disconnect

breather tube at resonator, disconnect air duct clamp

at resonator (Fig. 8)and remove 2 resonator mount-

ing bolts (at sides of resonator). Remove resonator

from throttle body by loosening clamp at throttle

body.

INSTALLATION - 4.7L

(1) Position air cleaner assembly to body and

install 3 nuts. Tighten nuts to 10 N´m (93 in. lbs.)

torque.To prevent excessive vibration transmit-

ted through housing, the nuts must be properly

torqued. Do not overtighten nuts.

(2) If resonator was removed: Install resonator and

bolts. Tighten bolts to 4 N´m (35 in. lbs.) torque.

Tighten clamp at throttle body to 4 N´m (35 in. lbs.)

torque.

(3) Position fender liner and install clips.

(4) Connect air duct at housing (Fig. 8).

(5) Tighten air duct clamp.

CYLINDER HEAD - LEFT

DESCRIPTION

DESCRIPTION - CYLINDER HEAD

The cylinder heads are made of an aluminum alloy.

The cylinder head features two valves per cylinder

with pressed in powdered metal valve guides. The

cylinder heads also provide enclosures for the timing

chain drain, necessitating unique left and right cylin-

der heads.

DESCRIPTION - VALVE GUIDES

The valve guides are made of powered metal and

are pressed into the cylinder head. The guides are

not replaceable or serviceable, and valve guide ream-

ing is not recommended. If the guides are worn

beyond acceptable limits, replace the cylinder heads.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HYDRAULIC LASH

ADJUSTER

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

Fig. 8 Air Cleaner Assembly - 4.7L

1 - AIR DUCT

2 - CLAMPS

3 - AIR CLEANER COVER

4 - CLIPS

5 - HOUSING

6 - HOUSING BOLTS (3)

7 - LOWER HOUSING NUTS (3)

8 - RESONATOR BOLTS

9 - RESONATOR

9 - 84 ENGINE - 4.7LWJ

AIR CLEANER ELEMENT (Continued)

Page 1329 of 2199

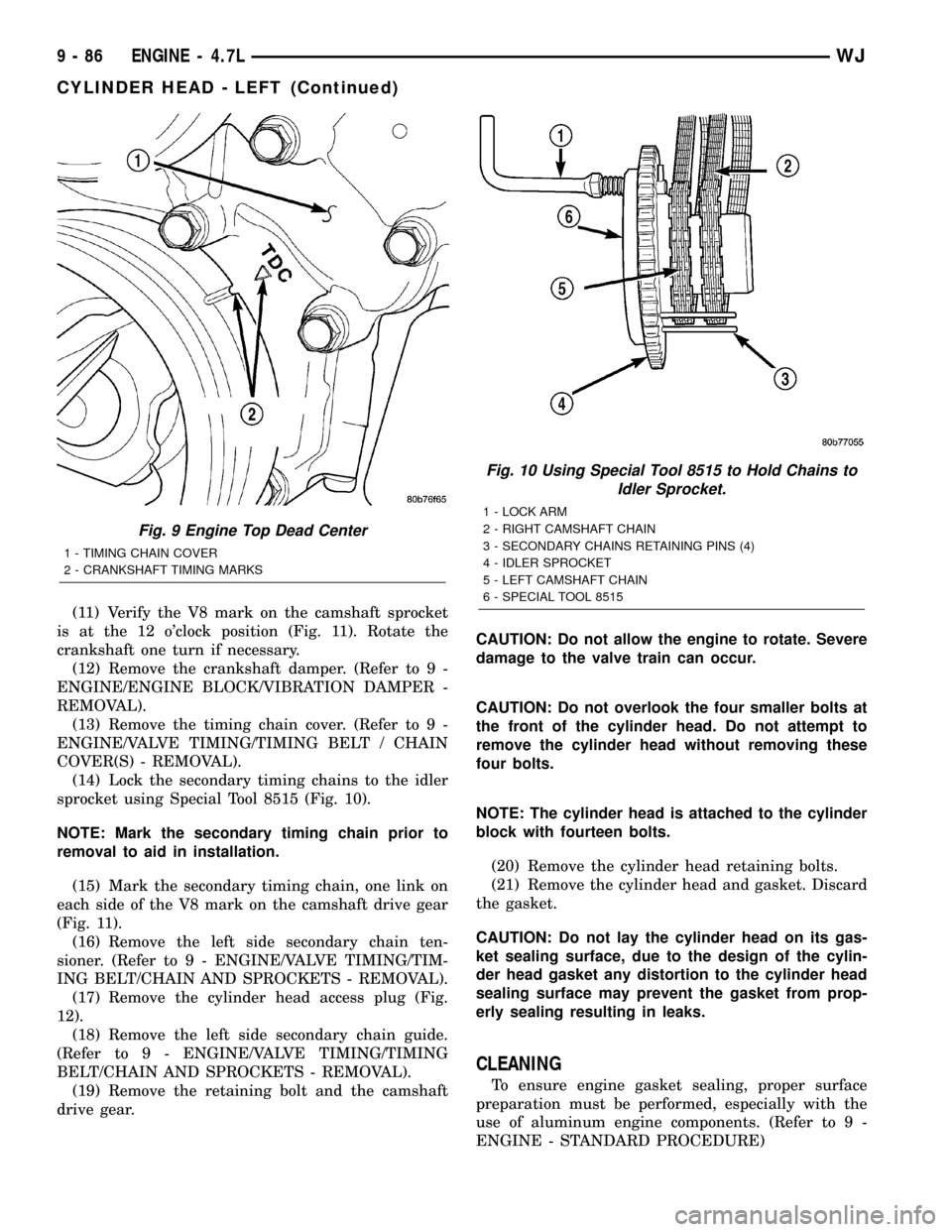

(11) Verify the V8 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 11). Rotate the

crankshaft one turn if necessary.

(12) Remove the crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(13) Remove the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(14) Lock the secondary timing chains to the idler

sprocket using Special Tool 8515 (Fig. 10).

NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(15) Mark the secondary timing chain, one link on

each side of the V8 mark on the camshaft drive gear

(Fig. 11).

(16) Remove the left side secondary chain ten-

sioner. (Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING BELT/CHAIN AND SPROCKETS - REMOVAL).

(17) Remove the cylinder head access plug (Fig.

12).

(18) Remove the left side secondary chain guide.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

(19) Remove the retaining bolt and the camshaft

drive gear.CAUTION: Do not allow the engine to rotate. Severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

NOTE: The cylinder head is attached to the cylinder

block with fourteen bolts.

(20) Remove the cylinder head retaining bolts.

(21) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, due to the design of the cylin-

der head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

Fig. 9 Engine Top Dead Center

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

Fig. 10 Using Special Tool 8515 to Hold Chains to

Idler Sprocket.

1 - LOCK ARM

2 - RIGHT CAMSHAFT CHAIN

3 - SECONDARY CHAINS RETAINING PINS (4)

4 - IDLER SPROCKET

5 - LEFT CAMSHAFT CHAIN

6 - SPECIAL TOOL 8515

9 - 86 ENGINE - 4.7LWJ

CYLINDER HEAD - LEFT (Continued)

Page 1337 of 2199

INTAKE/EXHAUST VALVES &

SEATS

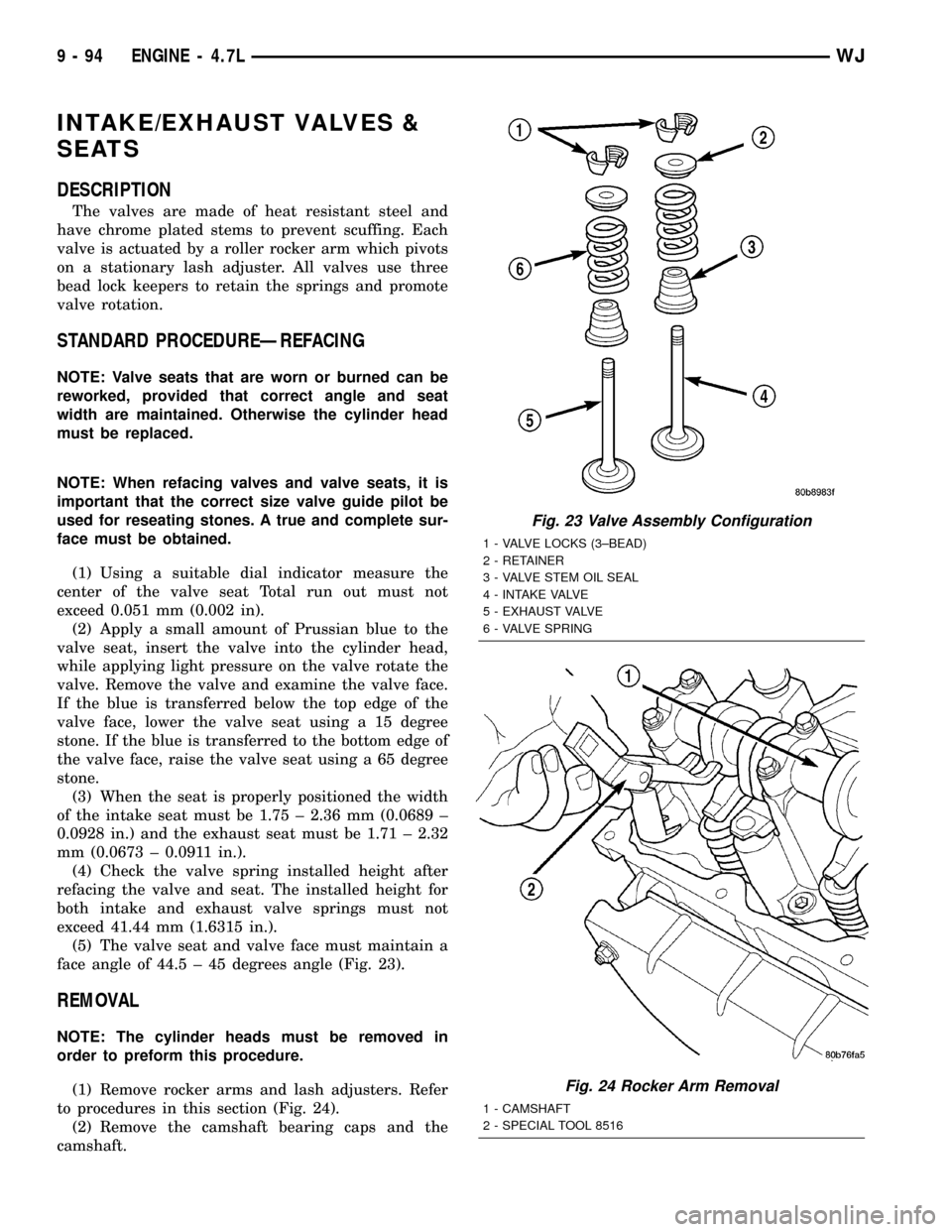

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. Each

valve is actuated by a roller rocker arm which pivots

on a stationary lash adjuster. All valves use three

bead lock keepers to retain the springs and promote

valve rotation.

STANDARD PROCEDUREÐREFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.75 ± 2.36 mm (0.0689 ±

0.0928 in.) and the exhaust seat must be 1.71 ± 2.32

mm (0.0673 ± 0.0911 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 41.44 mm (1.6315 in.).

(5) The valve seat and valve face must maintain a

face angle of 44.5 ± 45 degrees angle (Fig. 23).

REMOVAL

NOTE: The cylinder heads must be removed in

order to preform this procedure.

(1) Remove rocker arms and lash adjusters. Refer

to procedures in this section (Fig. 24).

(2) Remove the camshaft bearing caps and the

camshaft.

Fig. 23 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

Fig. 24 Rocker Arm Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

9 - 94 ENGINE - 4.7LWJ

Page 1338 of 2199

NOTE: All eight valve springs and valves are

removed in the same manner; this procedure only

covers one valve and valve spring.

(3) Using Special Tool C-3422±B or C-3422±C

Valve Spring Compressor and Special tool 8519

Adapter, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(4) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(5) Remove the valve spring compressor.

(6) Remove the spring retainer, and the spring.

NOTE: Check for sharp edges on the keeper

grooves. Remove any burrs from the valve stem

before removing the valve from the cylinder head.

(7) Remove the valve from the cylinder head.

NOTE: The valve stem seals are common between

intake and exhaust.

(8) Remove the valve stem seal. Mark the valve for

proper installation.

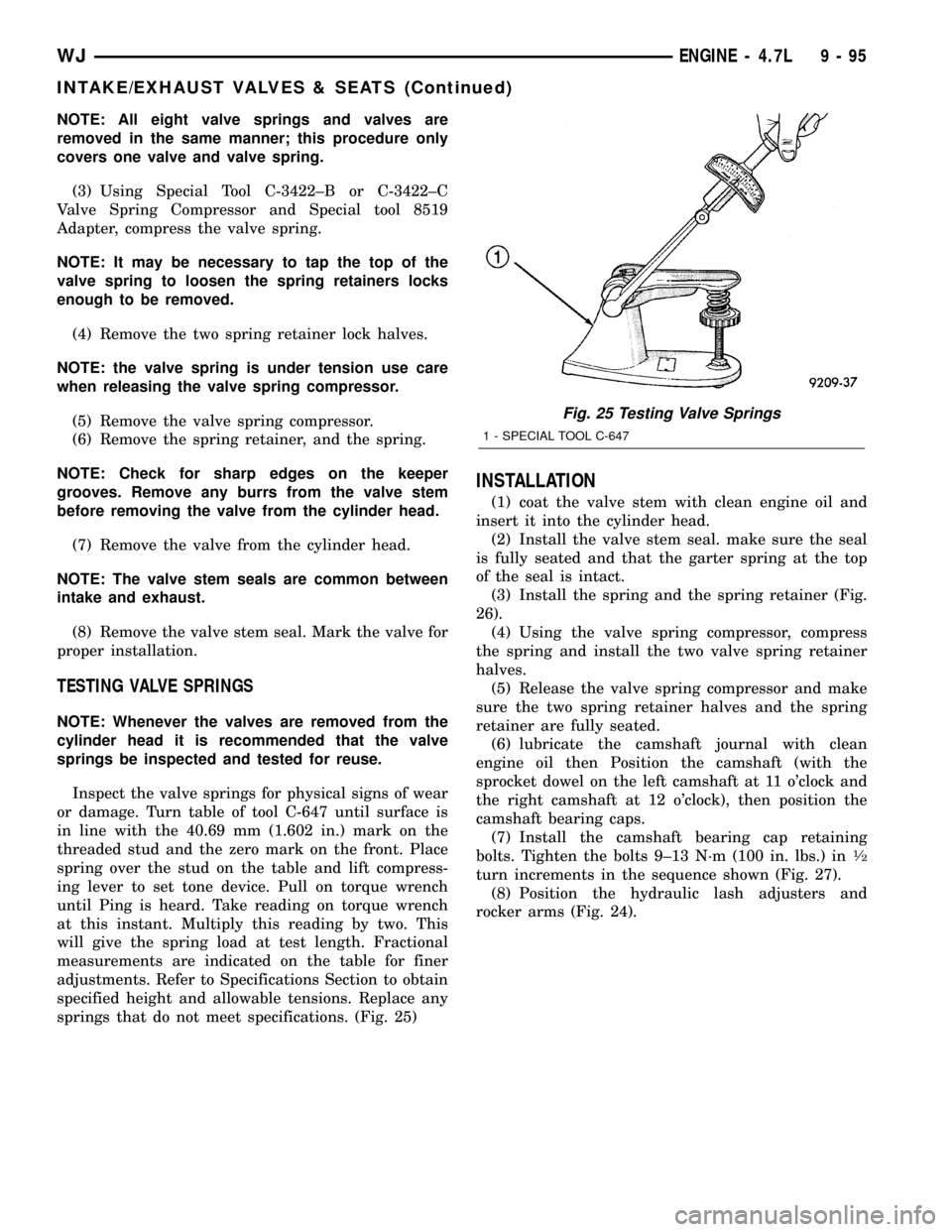

TESTING VALVE SPRINGS

NOTE: Whenever the valves are removed from the

cylinder head it is recommended that the valve

springs be inspected and tested for reuse.

Inspect the valve springs for physical signs of wear

or damage. Turn table of tool C-647 until surface is

in line with the 40.69 mm (1.602 in.) mark on the

threaded stud and the zero mark on the front. Place

spring over the stud on the table and lift compress-

ing lever to set tone device. Pull on torque wrench

until Ping is heard. Take reading on torque wrench

at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional

measurements are indicated on the table for finer

adjustments. Refer to Specifications Section to obtain

specified height and allowable tensions. Replace any

springs that do not meet specifications. (Fig. 25)

INSTALLATION

(1) coat the valve stem with clean engine oil and

insert it into the cylinder head.

(2) Install the valve stem seal. make sure the seal

is fully seated and that the garter spring at the top

of the seal is intact.

(3) Install the spring and the spring retainer (Fig.

26).

(4) Using the valve spring compressor, compress

the spring and install the two valve spring retainer

halves.

(5) Release the valve spring compressor and make

sure the two spring retainer halves and the spring

retainer are fully seated.

(6) lubricate the camshaft journal with clean

engine oil then Position the camshaft (with the

sprocket dowel on the left camshaft at 11 o'clock and

the right camshaft at 12 o'clock), then position the

camshaft bearing caps.

(7) Install the camshaft bearing cap retaining

bolts. Tighten the bolts 9±13 N´m (100 in. lbs.) in

1¤2

turn increments in the sequence shown (Fig. 27).

(8) Position the hydraulic lash adjusters and

rocker arms (Fig. 24).

Fig. 25 Testing Valve Springs

1 - SPECIAL TOOL C-647

WJENGINE - 4.7L 9 - 95

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1342 of 2199

(19) Remove the retaining bolt and the camshaft

drive gear.

CAUTION: Do not allow the engine to rotate. severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason. A damaged target wheel

can result in a vehicle no start condition.

NOTE: The cylinder head is attached to the cylinder

block with fourteen bolts.

(20) Remove the cylinder head retaining bolts.

(21) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, do to the design of the cylinder

head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

INSPECTION

(1) Inspect the cylinder head for out-of-flatness,

using a straightedge and a feeler gauge. If tolerances

exceed 0.0508 mm (0.002 in.) replace the cylinder

head.

(2) Inspect the valve seats for damage. Service the

valve seats as necessary.

(3) Inspect the valve guides for wear, cracks or

looseness. If either condition exist, replace the cylin-

der head.

INSTALLATION

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are necked

down the bolts should be replaced.

Necking can be checked by holding a straight edge

against the threads. If all the threads do not contact

the scale, the bolt should be replaced (Fig. 13).

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper.

(1) Clean the cylinder head and cylinder block

mating surfaces (Refer to 9 - ENGINE - STANDARD

PROCEDURE).

(2) Position the new cylinder head gasket on the

locating dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.

(3) Position the cylinder head onto the cylinder

block. Make sure the cylinder head seats fully over

the locating dowels.

NOTE: The four smaller cylinder head mounting

bolts require sealant to be added to them before

installing. Failure to do so may cause leaks.

(4) Lubricate the cylinder head bolt threads with

clean engine oil and install the ten M10 bolts.

(5) Coat the four M8 cylinder head bolts with

Mopar Lock and Seal Adhesivethen install the

bolts.

NOTE: The cylinder head bolts are tightened using

an angle torque procedure, however, the bolts are

not a torque-to-yield design.

(6) Tighten the bolts in sequence (Fig. 30) using

the following steps and torque values:

²Step 1: Tighten bolts 1±10, 27 N´m (20 ft. lbs.).

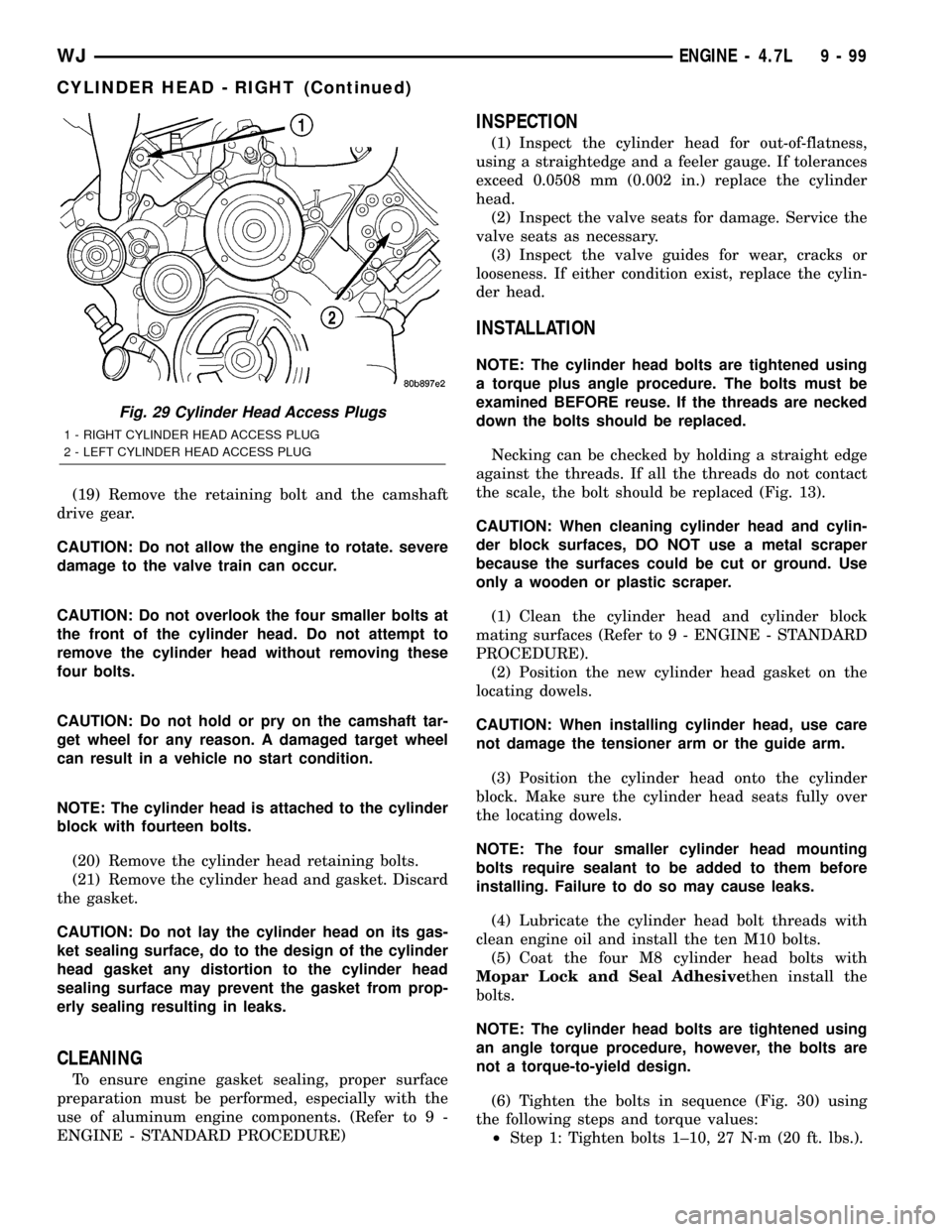

Fig. 29 Cylinder Head Access Plugs

1 - RIGHT CYLINDER HEAD ACCESS PLUG

2 - LEFT CYLINDER HEAD ACCESS PLUG

WJENGINE - 4.7L 9 - 99

CYLINDER HEAD - RIGHT (Continued)

Page 1348 of 2199

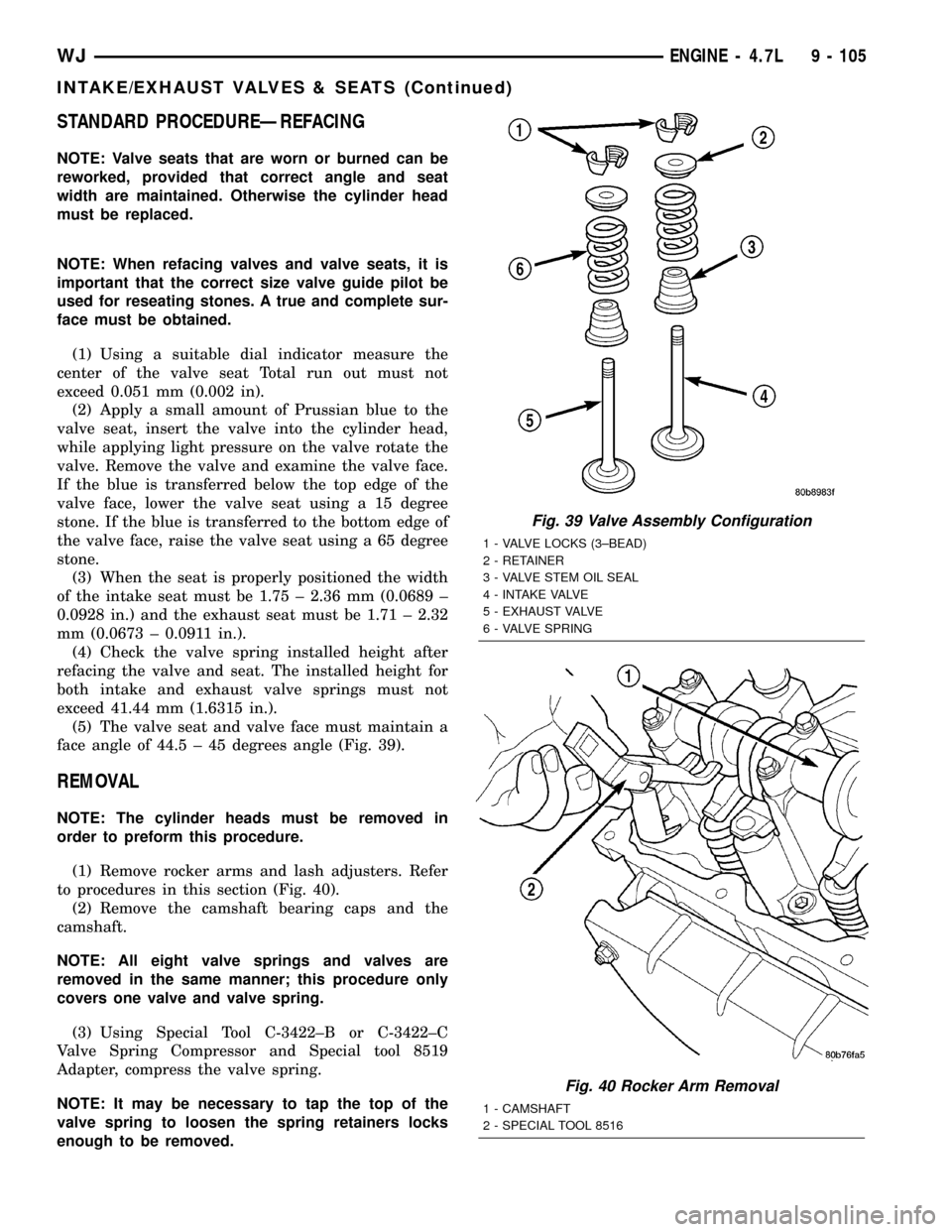

STANDARD PROCEDUREÐREFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.75 ± 2.36 mm (0.0689 ±

0.0928 in.) and the exhaust seat must be 1.71 ± 2.32

mm (0.0673 ± 0.0911 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 41.44 mm (1.6315 in.).

(5) The valve seat and valve face must maintain a

face angle of 44.5 ± 45 degrees angle (Fig. 39).

REMOVAL

NOTE: The cylinder heads must be removed in

order to preform this procedure.

(1) Remove rocker arms and lash adjusters. Refer

to procedures in this section (Fig. 40).

(2) Remove the camshaft bearing caps and the

camshaft.

NOTE: All eight valve springs and valves are

removed in the same manner; this procedure only

covers one valve and valve spring.

(3) Using Special Tool C-3422±B or C-3422±C

Valve Spring Compressor and Special tool 8519

Adapter, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

Fig. 39 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

Fig. 40 Rocker Arm Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

WJENGINE - 4.7L 9 - 105

INTAKE/EXHAUST VALVES & SEATS (Continued)