Panel JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 5 of 2199

FASTENER USAGE

DESCRIPTION - FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Fasteners and torque specifications references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

DESCRIPTION - THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

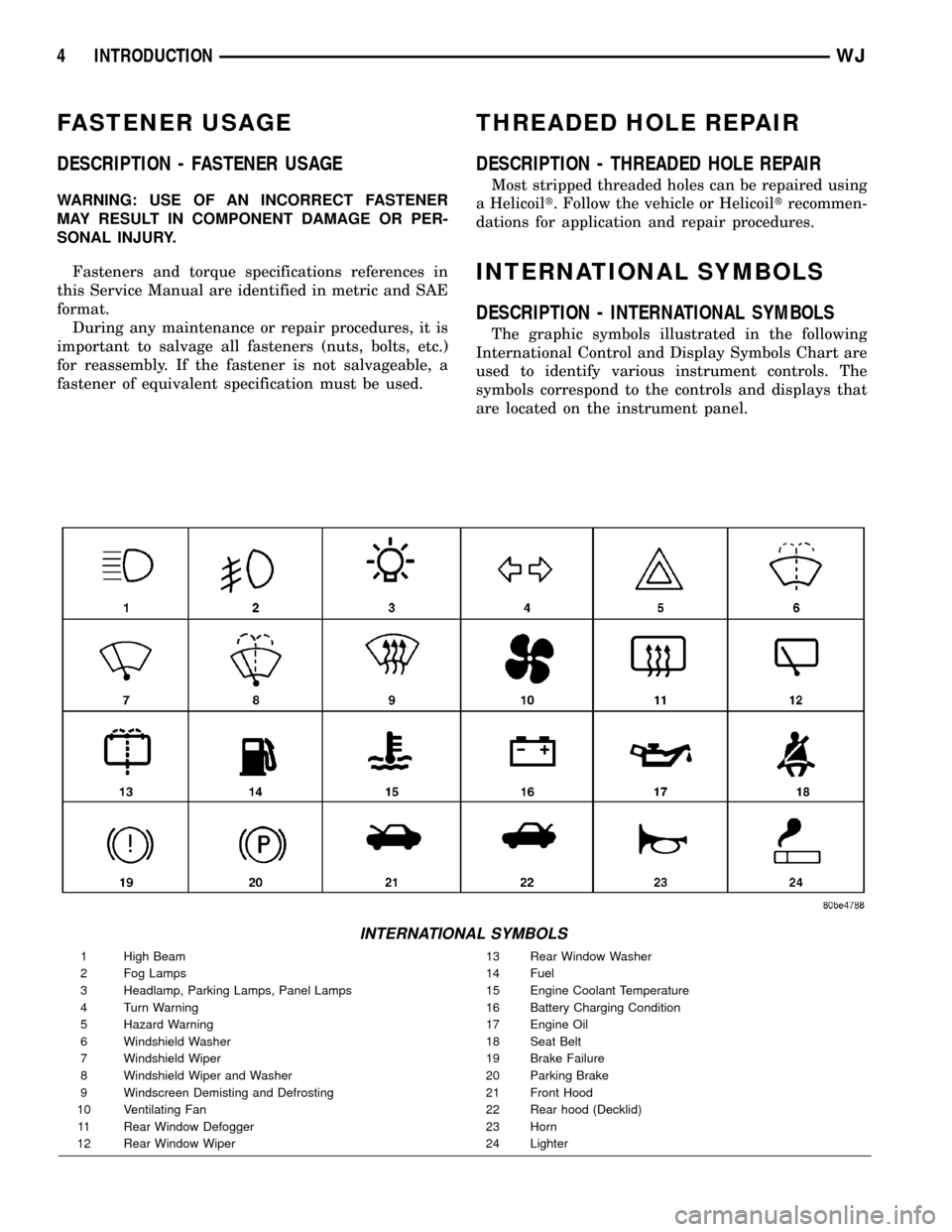

INTERNATIONAL SYMBOLS

DESCRIPTION - INTERNATIONAL SYMBOLS

The graphic symbols illustrated in the following

International Control and Display Symbols Chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

INTERNATIONAL SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

4 INTRODUCTIONWJ

Page 9 of 2199

VEHICLE EMISSION CONTROL

INFORMATION (VECI)

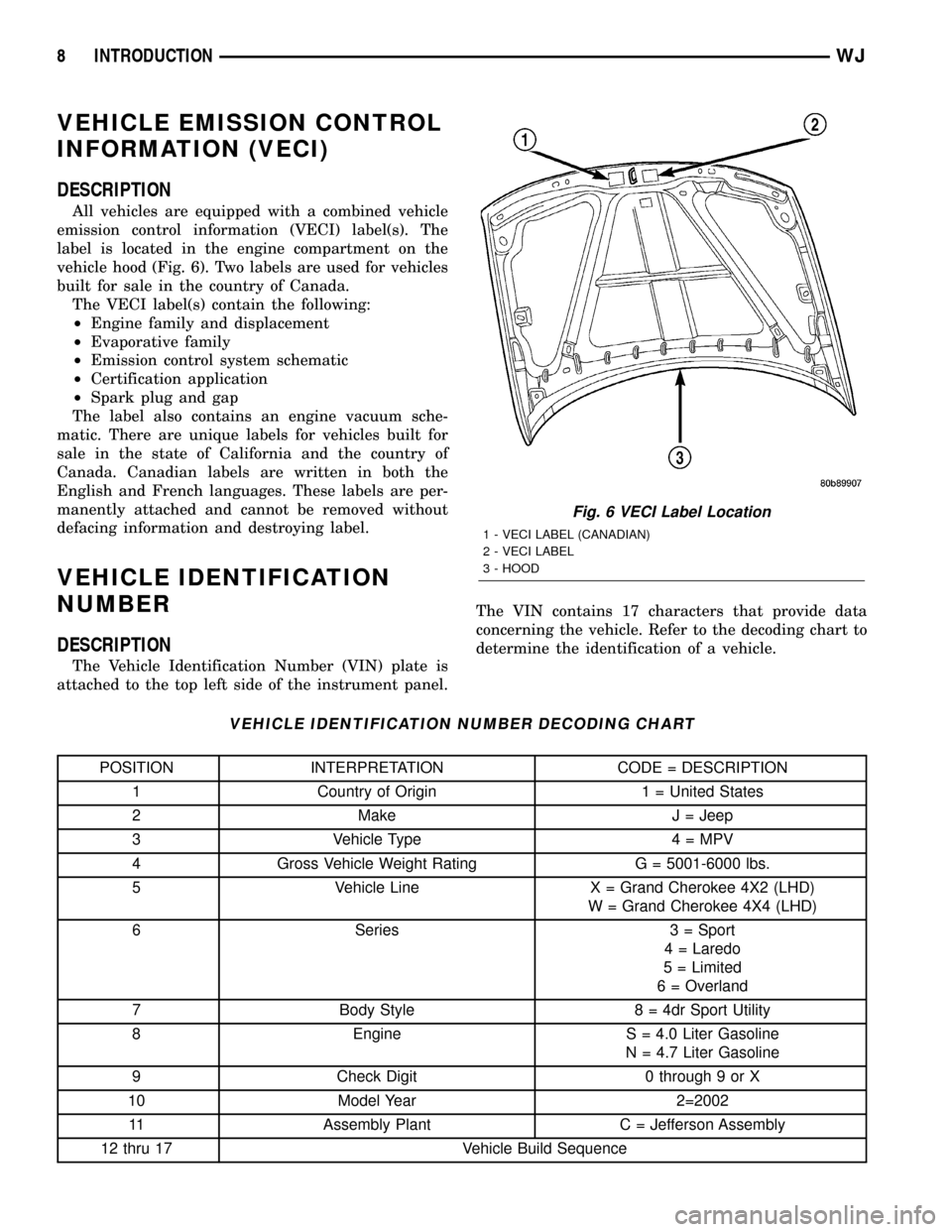

DESCRIPTION

All vehicles are equipped with a combined vehicle

emission control information (VECI) label(s). The

label is located in the engine compartment on the

vehicle hood (Fig. 6). Two labels are used for vehicles

built for sale in the country of Canada.

The VECI label(s) contain the following:

²Engine family and displacement

²Evaporative family

²Emission control system schematic

²Certification application

²Spark plug and gap

The label also contains an engine vacuum sche-

matic. There are unique labels for vehicles built for

sale in the state of California and the country of

Canada. Canadian labels are written in both the

English and French languages. These labels are per-

manently attached and cannot be removed without

defacing information and destroying label.

VEHICLE IDENTIFICATION

NUMBER

DESCRIPTION

The Vehicle Identification Number (VIN) plate is

attached to the top left side of the instrument panel.The VIN contains 17 characters that provide data

concerning the vehicle. Refer to the decoding chart to

determine the identification of a vehicle.

VEHICLE IDENTIFICATION NUMBER DECODING CHART

POSITION INTERPRETATION CODE = DESCRIPTION

1 Country of Origin 1 = United States

2 Make J = Jeep

3 Vehicle Type 4 = MPV

4 Gross Vehicle Weight Rating G = 5001-6000 lbs.

5 Vehicle Line X = Grand Cherokee 4X2 (LHD)

W = Grand Cherokee 4X4 (LHD)

6 Series 3 = Sport

4 = Laredo

5 = Limited

6 = Overland

7 Body Style 8 = 4dr Sport Utility

8 Engine S = 4.0 Liter Gasoline

N = 4.7 Liter Gasoline

9 Check Digit 0 through 9 or X

10 Model Year 2=2002

11 Assembly Plant C = Jefferson Assembly

12 thru 17 Vehicle Build Sequence

Fig. 6 VECI Label Location

1 - VECI LABEL (CANADIAN)

2 - VECI LABEL

3 - HOOD

8 INTRODUCTIONWJ

Page 20 of 2199

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.

²Do not attach tow chains, T-hooks, or J-hooks to

a bumper, steering linkage, drive shafts or a non-re-

inforced frame hole.

²Do not tow a heavily loaded vehicle. Use a flat-

bed device to transport a loaded vehicle.

TWO-WHEEL-DRIVE VEHICLE TOWING

DaimlerChrysler Corporation recommends that a

vehicle be towed with the rear end lifted, whenever

possible.

WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION (AUTO-

MATIC TRANSMISSION) OR A FORWARD DRIVE

GEAR (MANUAL TRANSMISSION).

WARNING: ENSURE VEHICLE IS ON A LEVEL SUR-

FACE OR THE WHEELS ARE BLOCKED TO PRE-

VENT VEHICLE FROM ROLLING.

TWO WHEEL DRIVE TOWING-REAR END LIFTED

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

2WD vehicles can be towed with the front wheels

on the surface for extended distances at speeds not

exceeding 48 km/h (30 mph).

(1) Attach wheel lift device to rear wheels.

(2) Place the transmission in neutral.

(3) Raise vehicle to towing position.

(4) Attach safety chains. Route chains so not to

interfere with tail pipe when vehicle is lifted.

(5) Turn the ignition switch to the OFF position to

unlock the steering wheel.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(6) Secure steering wheel in straight ahead posi-

tion with a clamp device designed for towing.

(7) Place transmission in park.

TWO WHEEL DRIVE TOWING-FRONT END LIFTED

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

(1) Attach wheel lift device to rear wheels.

(2) Place the transmission in neutral.

(3) Raise the rear of the vehicle off the ground and

install tow dollies under rear wheels.

(4) Attach wheel lift device to front wheels and

raise vehicle to towing position.

(5) Attach the safety chains.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

(7) Secure steering wheel in straight ahead posi-

tion with a clamp device designed for towing.

(8) Place transmission in park.

FOUR-WHEEL-DRIVE VEHICLE TOWING

DaimlerChrysler Corporation recommends that a

4WD vehicle be transported on a flat-bed device. A

Wheel-lift device can be used providedthe trailing

wheels are off the ground and positioned in

tow dollies.

WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION.

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

FOUR WHEEL DRIVE TOWINGÐREAR END LIFTED

WARNING: ENSURE VEHICLE IS ON A LEVEL SUR-

FACE OR THE WHEELS ARE BLOCKED TO PRE-

VENT VEHICLE FROM ROLLING.

(1) Attach wheel lift device to front wheels.

(2) Place the transmission in neutral.

(3) Raise the front of the vehicle off the ground

and install tow dollies under front wheels.

(4) Attach wheel lift device to rear wheels and

raise vehicle to towing position.

(5) Attach safety chains. Route chains so not to

interfere with tail pipe when vehicle is lifted.

WJLUBRICATION & MAINTENANCE 0 - 9

TOWING (Continued)

Page 183 of 2199

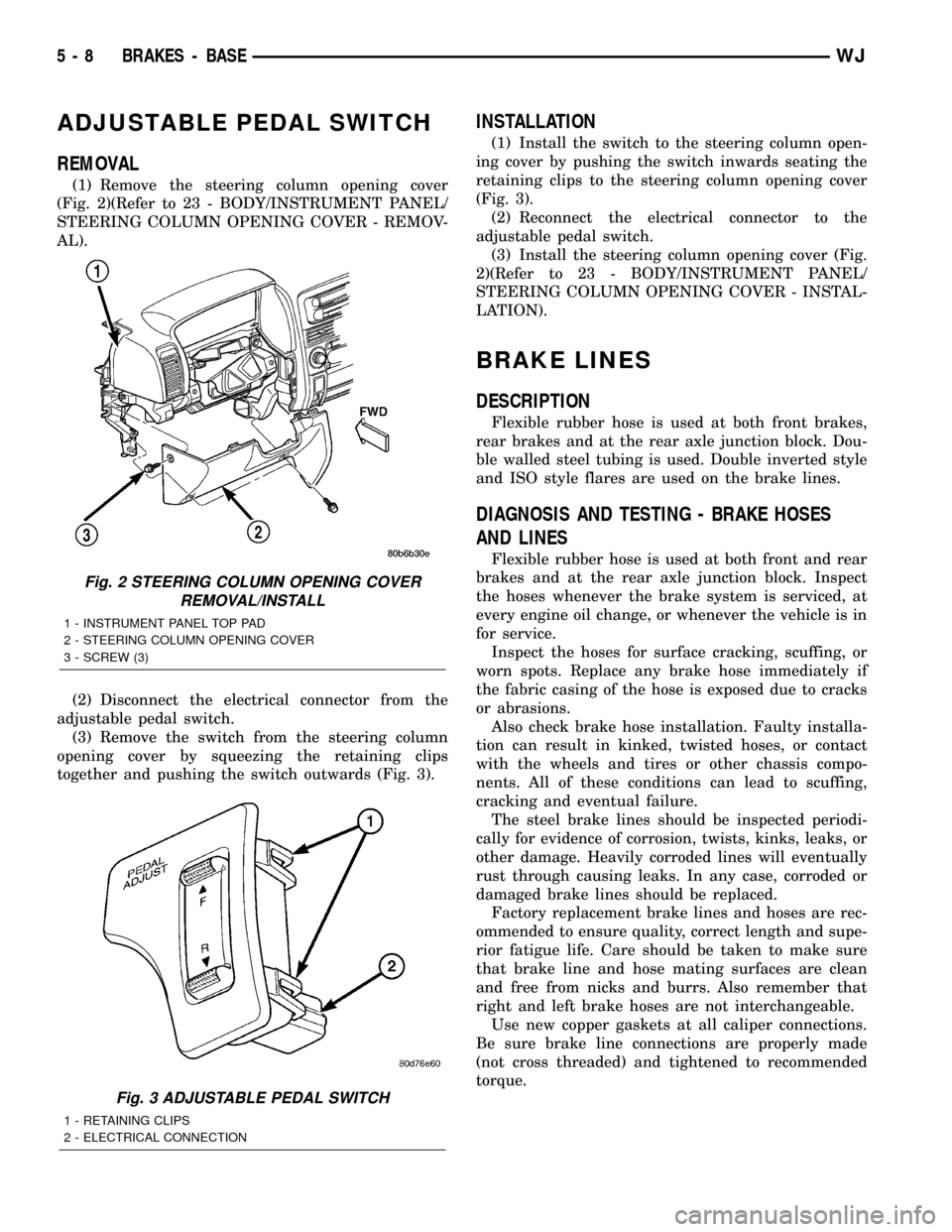

ADJUSTABLE PEDAL SWITCH

REMOVAL

(1) Remove the steering column opening cover

(Fig. 2)(Refer to 23 - BODY/INSTRUMENT PANEL/

STEERING COLUMN OPENING COVER - REMOV-

AL).

(2) Disconnect the electrical connector from the

adjustable pedal switch.

(3) Remove the switch from the steering column

opening cover by squeezing the retaining clips

together and pushing the switch outwards (Fig. 3).

INSTALLATION

(1) Install the switch to the steering column open-

ing cover by pushing the switch inwards seating the

retaining clips to the steering column opening cover

(Fig. 3).

(2) Reconnect the electrical connector to the

adjustable pedal switch.

(3) Install the steering column opening cover (Fig.

2)(Refer to 23 - BODY/INSTRUMENT PANEL/

STEERING COLUMN OPENING COVER - INSTAL-

LATION).

BRAKE LINES

DESCRIPTION

Flexible rubber hose is used at both front brakes,

rear brakes and at the rear axle junction block. Dou-

ble walled steel tubing is used. Double inverted style

and ISO style flares are used on the brake lines.

DIAGNOSIS AND TESTING - BRAKE HOSES

AND LINES

Flexible rubber hose is used at both front and rear

brakes and at the rear axle junction block. Inspect

the hoses whenever the brake system is serviced, at

every engine oil change, or whenever the vehicle is in

for service.

Inspect the hoses for surface cracking, scuffing, or

worn spots. Replace any brake hose immediately if

the fabric casing of the hose is exposed due to cracks

or abrasions.

Also check brake hose installation. Faulty installa-

tion can result in kinked, twisted hoses, or contact

with the wheels and tires or other chassis compo-

nents. All of these conditions can lead to scuffing,

cracking and eventual failure.

The steel brake lines should be inspected periodi-

cally for evidence of corrosion, twists, kinks, leaks, or

other damage. Heavily corroded lines will eventually

rust through causing leaks. In any case, corroded or

damaged brake lines should be replaced.

Factory replacement brake lines and hoses are rec-

ommended to ensure quality, correct length and supe-

rior fatigue life. Care should be taken to make sure

that brake line and hose mating surfaces are clean

and free from nicks and burrs. Also remember that

right and left brake hoses are not interchangeable.

Use new copper gaskets at all caliper connections.

Be sure brake line connections are properly made

(not cross threaded) and tightened to recommended

torque.

Fig. 2 STEERING COLUMN OPENING COVER

REMOVAL/INSTALL

1 - INSTRUMENT PANEL TOP PAD

2 - STEERING COLUMN OPENING COVER

3 - SCREW (3)

Fig. 3 ADJUSTABLE PEDAL SWITCH

1 - RETAINING CLIPS

2 - ELECTRICAL CONNECTION

5 - 8 BRAKES - BASEWJ

Page 200 of 2199

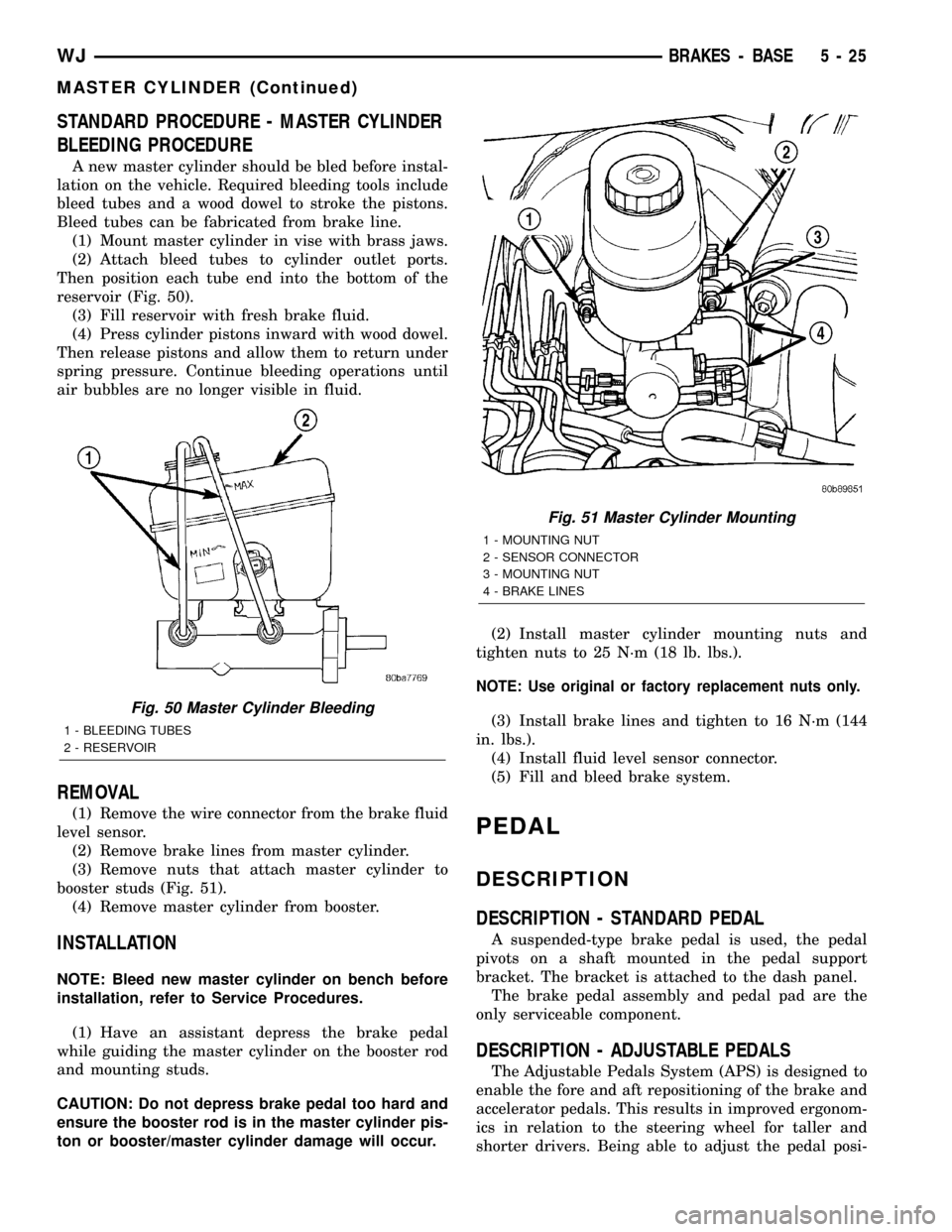

STANDARD PROCEDURE - MASTER CYLINDER

BLEEDING PROCEDURE

A new master cylinder should be bled before instal-

lation on the vehicle. Required bleeding tools include

bleed tubes and a wood dowel to stroke the pistons.

Bleed tubes can be fabricated from brake line.

(1) Mount master cylinder in vise with brass jaws.

(2) Attach bleed tubes to cylinder outlet ports.

Then position each tube end into the bottom of the

reservoir (Fig. 50).

(3) Fill reservoir with fresh brake fluid.

(4) Press cylinder pistons inward with wood dowel.

Then release pistons and allow them to return under

spring pressure. Continue bleeding operations until

air bubbles are no longer visible in fluid.

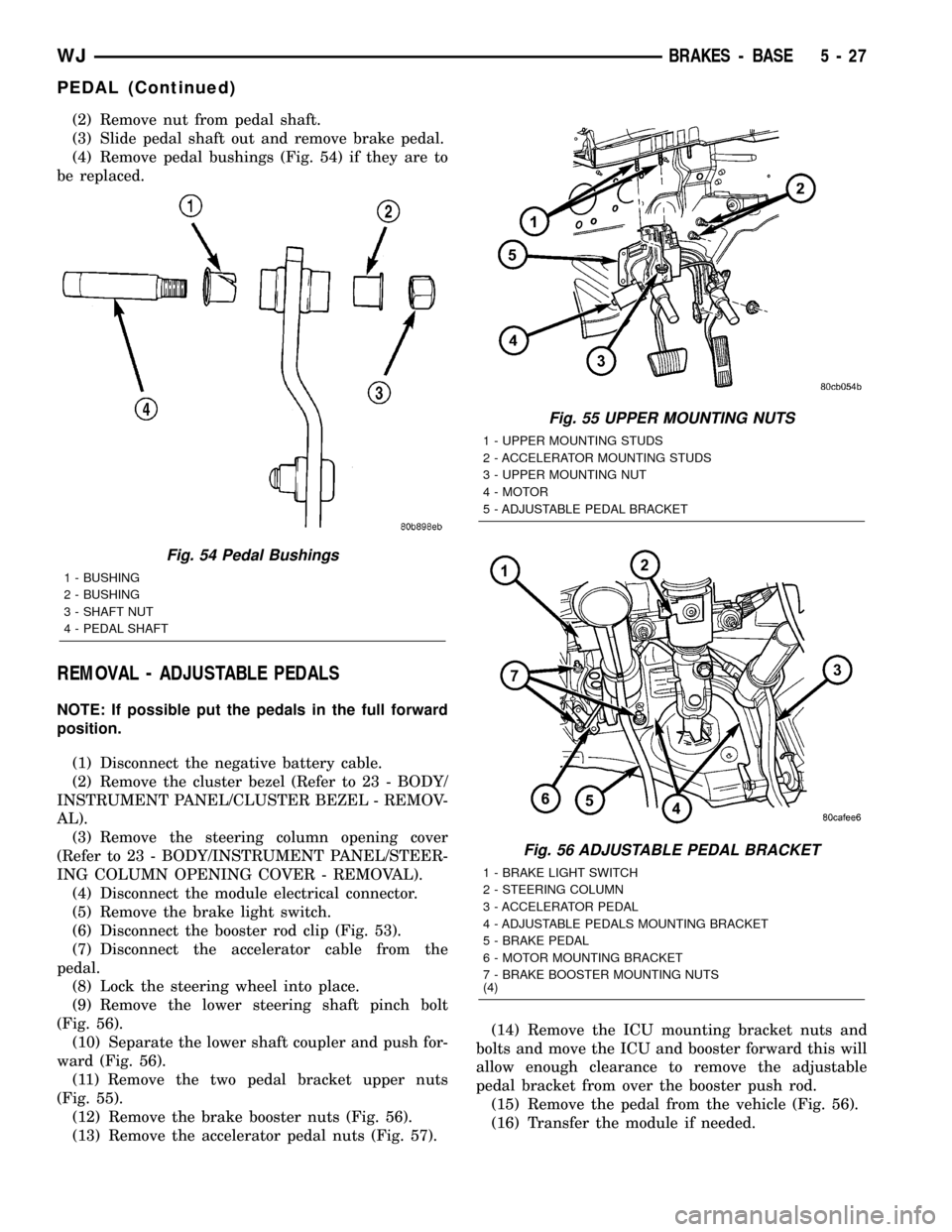

REMOVAL

(1) Remove the wire connector from the brake fluid

level sensor.

(2) Remove brake lines from master cylinder.

(3) Remove nuts that attach master cylinder to

booster studs (Fig. 51).

(4) Remove master cylinder from booster.

INSTALLATION

NOTE: Bleed new master cylinder on bench before

installation, refer to Service Procedures.

(1) Have an assistant depress the brake pedal

while guiding the master cylinder on the booster rod

and mounting studs.

CAUTION: Do not depress brake pedal too hard and

ensure the booster rod is in the master cylinder pis-

ton or booster/master cylinder damage will occur.(2) Install master cylinder mounting nuts and

tighten nuts to 25 N´m (18 lb. lbs.).

NOTE: Use original or factory replacement nuts only.

(3) Install brake lines and tighten to 16 N´m (144

in. lbs.).

(4) Install fluid level sensor connector.

(5) Fill and bleed brake system.

PEDAL

DESCRIPTION

DESCRIPTION - STANDARD PEDAL

A suspended-type brake pedal is used, the pedal

pivots on a shaft mounted in the pedal support

bracket. The bracket is attached to the dash panel.

The brake pedal assembly and pedal pad are the

only serviceable component.

DESCRIPTION - ADJUSTABLE PEDALS

The Adjustable Pedals System (APS) is designed to

enable the fore and aft repositioning of the brake and

accelerator pedals. This results in improved ergonom-

ics in relation to the steering wheel for taller and

shorter drivers. Being able to adjust the pedal posi-

Fig. 50 Master Cylinder Bleeding

1 - BLEEDING TUBES

2 - RESERVOIR

Fig. 51 Master Cylinder Mounting

1 - MOUNTING NUT

2 - SENSOR CONNECTOR

3 - MOUNTING NUT

4 - BRAKE LINES

WJBRAKES - BASE 5 - 25

MASTER CYLINDER (Continued)

Page 202 of 2199

(2) Remove nut from pedal shaft.

(3) Slide pedal shaft out and remove brake pedal.

(4) Remove pedal bushings (Fig. 54) if they are to

be replaced.

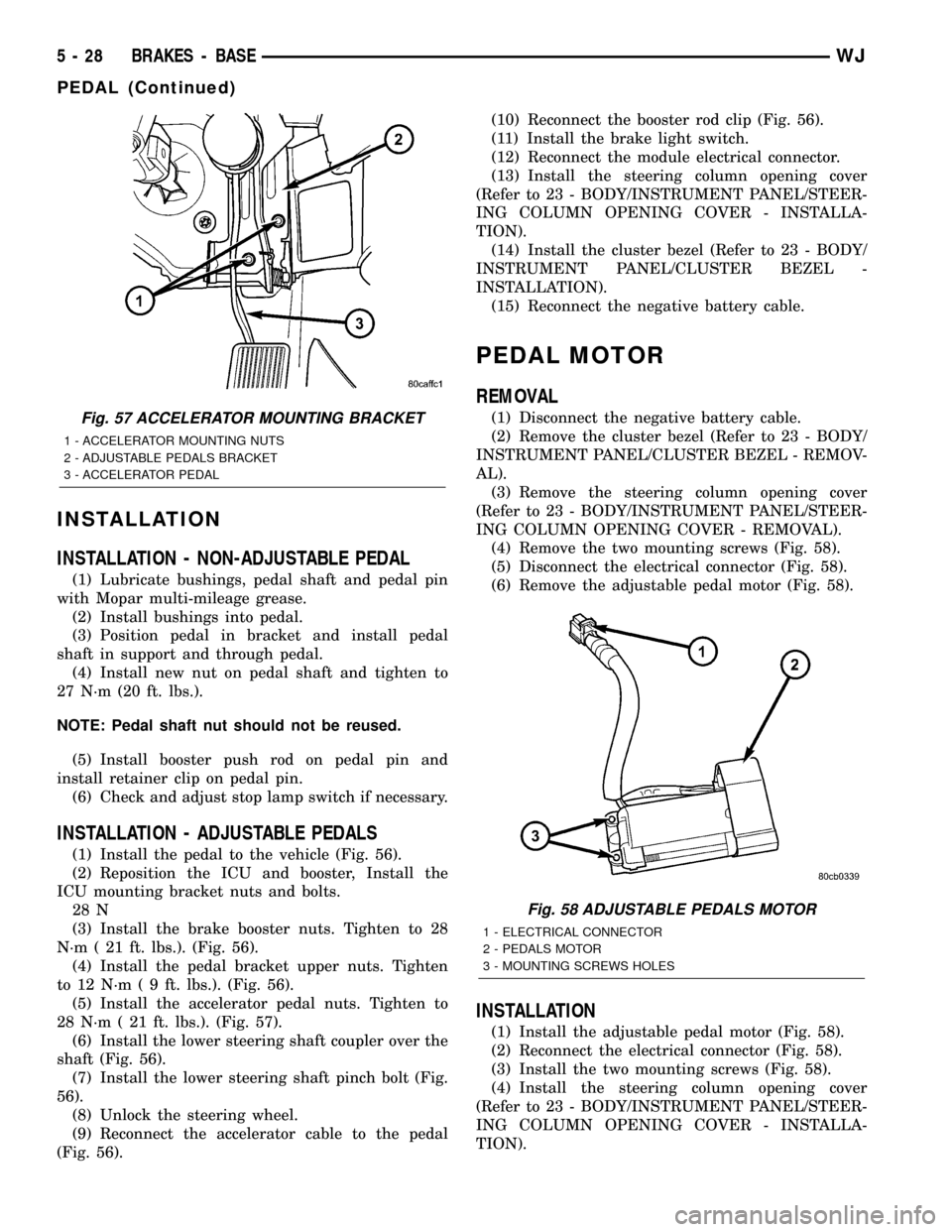

REMOVAL - ADJUSTABLE PEDALS

NOTE: If possible put the pedals in the full forward

position.

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Disconnect the module electrical connector.

(5) Remove the brake light switch.

(6) Disconnect the booster rod clip (Fig. 53).

(7) Disconnect the accelerator cable from the

pedal.

(8) Lock the steering wheel into place.

(9) Remove the lower steering shaft pinch bolt

(Fig. 56).

(10) Separate the lower shaft coupler and push for-

ward (Fig. 56).

(11) Remove the two pedal bracket upper nuts

(Fig. 55).

(12) Remove the brake booster nuts (Fig. 56).

(13) Remove the accelerator pedal nuts (Fig. 57).(14) Remove the ICU mounting bracket nuts and

bolts and move the ICU and booster forward this will

allow enough clearance to remove the adjustable

pedal bracket from over the booster push rod.

(15) Remove the pedal from the vehicle (Fig. 56).

(16) Transfer the module if needed.

Fig. 54 Pedal Bushings

1 - BUSHING

2 - BUSHING

3 - SHAFT NUT

4 - PEDAL SHAFT

Fig. 55 UPPER MOUNTING NUTS

1 - UPPER MOUNTING STUDS

2 - ACCELERATOR MOUNTING STUDS

3 - UPPER MOUNTING NUT

4 - MOTOR

5 - ADJUSTABLE PEDAL BRACKET

Fig. 56 ADJUSTABLE PEDAL BRACKET

1 - BRAKE LIGHT SWITCH

2 - STEERING COLUMN

3 - ACCELERATOR PEDAL

4 - ADJUSTABLE PEDALS MOUNTING BRACKET

5 - BRAKE PEDAL

6 - MOTOR MOUNTING BRACKET

7 - BRAKE BOOSTER MOUNTING NUTS

(4)

WJBRAKES - BASE 5 - 27

PEDAL (Continued)

Page 203 of 2199

INSTALLATION

INSTALLATION - NON-ADJUSTABLE PEDAL

(1) Lubricate bushings, pedal shaft and pedal pin

with Mopar multi-mileage grease.

(2) Install bushings into pedal.

(3) Position pedal in bracket and install pedal

shaft in support and through pedal.

(4) Install new nut on pedal shaft and tighten to

27 N´m (20 ft. lbs.).

NOTE: Pedal shaft nut should not be reused.

(5) Install booster push rod on pedal pin and

install retainer clip on pedal pin.

(6) Check and adjust stop lamp switch if necessary.

INSTALLATION - ADJUSTABLE PEDALS

(1) Install the pedal to the vehicle (Fig. 56).

(2) Reposition the ICU and booster, Install the

ICU mounting bracket nuts and bolts.

28 N

(3) Install the brake booster nuts. Tighten to 28

N´m ( 21 ft. lbs.). (Fig. 56).

(4) Install the pedal bracket upper nuts. Tighten

to 12 N´m ( 9 ft. lbs.). (Fig. 56).

(5) Install the accelerator pedal nuts. Tighten to

28 N´m ( 21 ft. lbs.). (Fig. 57).

(6) Install the lower steering shaft coupler over the

shaft (Fig. 56).

(7) Install the lower steering shaft pinch bolt (Fig.

56).

(8) Unlock the steering wheel.

(9) Reconnect the accelerator cable to the pedal

(Fig. 56).(10) Reconnect the booster rod clip (Fig. 56).

(11) Install the brake light switch.

(12) Reconnect the module electrical connector.

(13) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(14) Install the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(15) Reconnect the negative battery cable.

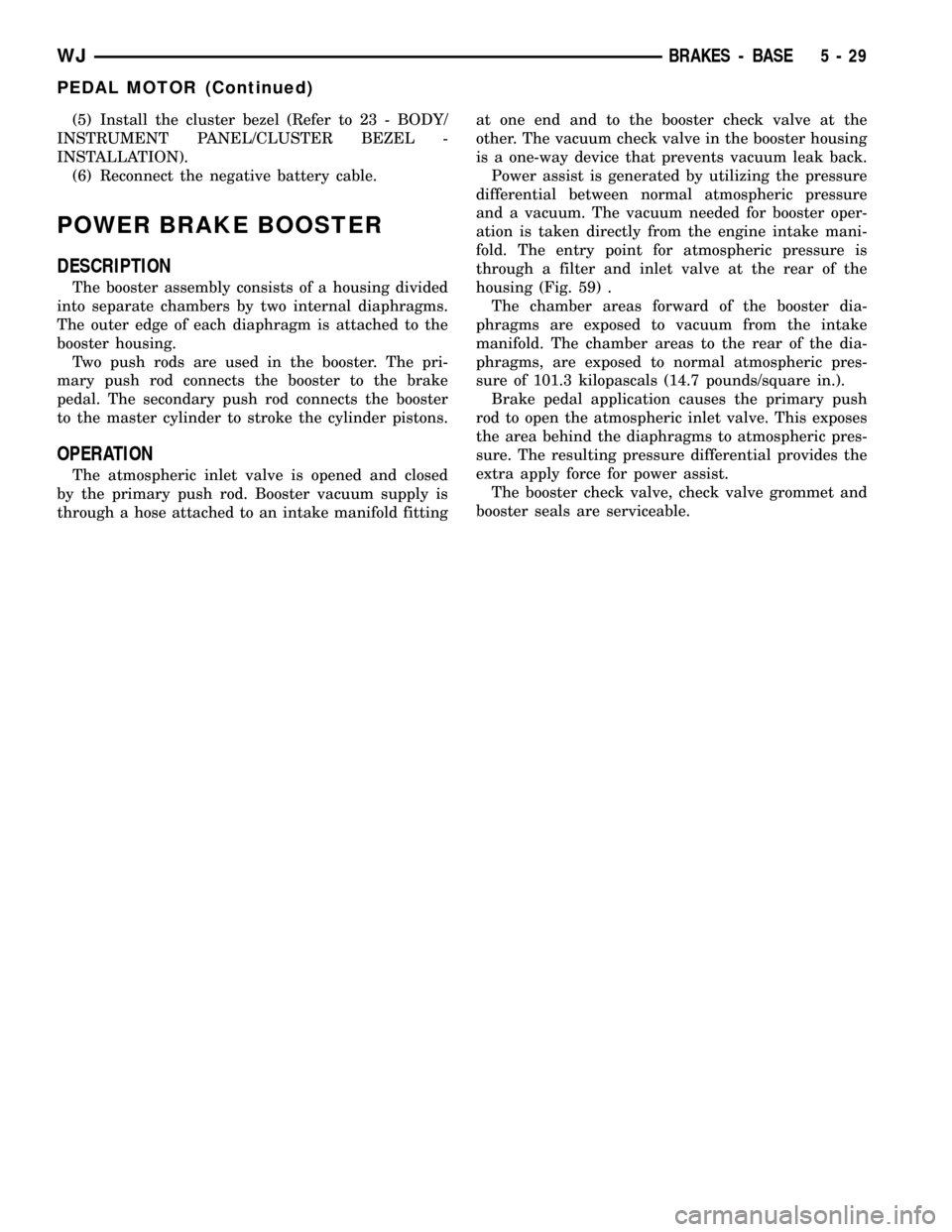

PEDAL MOTOR

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Remove the two mounting screws (Fig. 58).

(5) Disconnect the electrical connector (Fig. 58).

(6) Remove the adjustable pedal motor (Fig. 58).

INSTALLATION

(1) Install the adjustable pedal motor (Fig. 58).

(2) Reconnect the electrical connector (Fig. 58).

(3) Install the two mounting screws (Fig. 58).

(4) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

Fig. 57 ACCELERATOR MOUNTING BRACKET

1 - ACCELERATOR MOUNTING NUTS

2 - ADJUSTABLE PEDALS BRACKET

3 - ACCELERATOR PEDAL

Fig. 58 ADJUSTABLE PEDALS MOTOR

1 - ELECTRICAL CONNECTOR

2 - PEDALS MOTOR

3 - MOUNTING SCREWS HOLES

5 - 28 BRAKES - BASEWJ

PEDAL (Continued)

Page 204 of 2199

(5) Install the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(6) Reconnect the negative battery cable.

POWER BRAKE BOOSTER

DESCRIPTION

The booster assembly consists of a housing divided

into separate chambers by two internal diaphragms.

The outer edge of each diaphragm is attached to the

booster housing.

Two push rods are used in the booster. The pri-

mary push rod connects the booster to the brake

pedal. The secondary push rod connects the booster

to the master cylinder to stroke the cylinder pistons.

OPERATION

The atmospheric inlet valve is opened and closed

by the primary push rod. Booster vacuum supply is

through a hose attached to an intake manifold fittingat one end and to the booster check valve at the

other. The vacuum check valve in the booster housing

is a one-way device that prevents vacuum leak back.

Power assist is generated by utilizing the pressure

differential between normal atmospheric pressure

and a vacuum. The vacuum needed for booster oper-

ation is taken directly from the engine intake mani-

fold. The entry point for atmospheric pressure is

through a filter and inlet valve at the rear of the

housing (Fig. 59) .

The chamber areas forward of the booster dia-

phragms are exposed to vacuum from the intake

manifold. The chamber areas to the rear of the dia-

phragms, are exposed to normal atmospheric pres-

sure of 101.3 kilopascals (14.7 pounds/square in.).

Brake pedal application causes the primary push

rod to open the atmospheric inlet valve. This exposes

the area behind the diaphragms to atmospheric pres-

sure. The resulting pressure differential provides the

extra apply force for power assist.

The booster check valve, check valve grommet and

booster seals are serviceable.

WJBRAKES - BASE 5 - 29

PEDAL MOTOR (Continued)

Page 206 of 2199

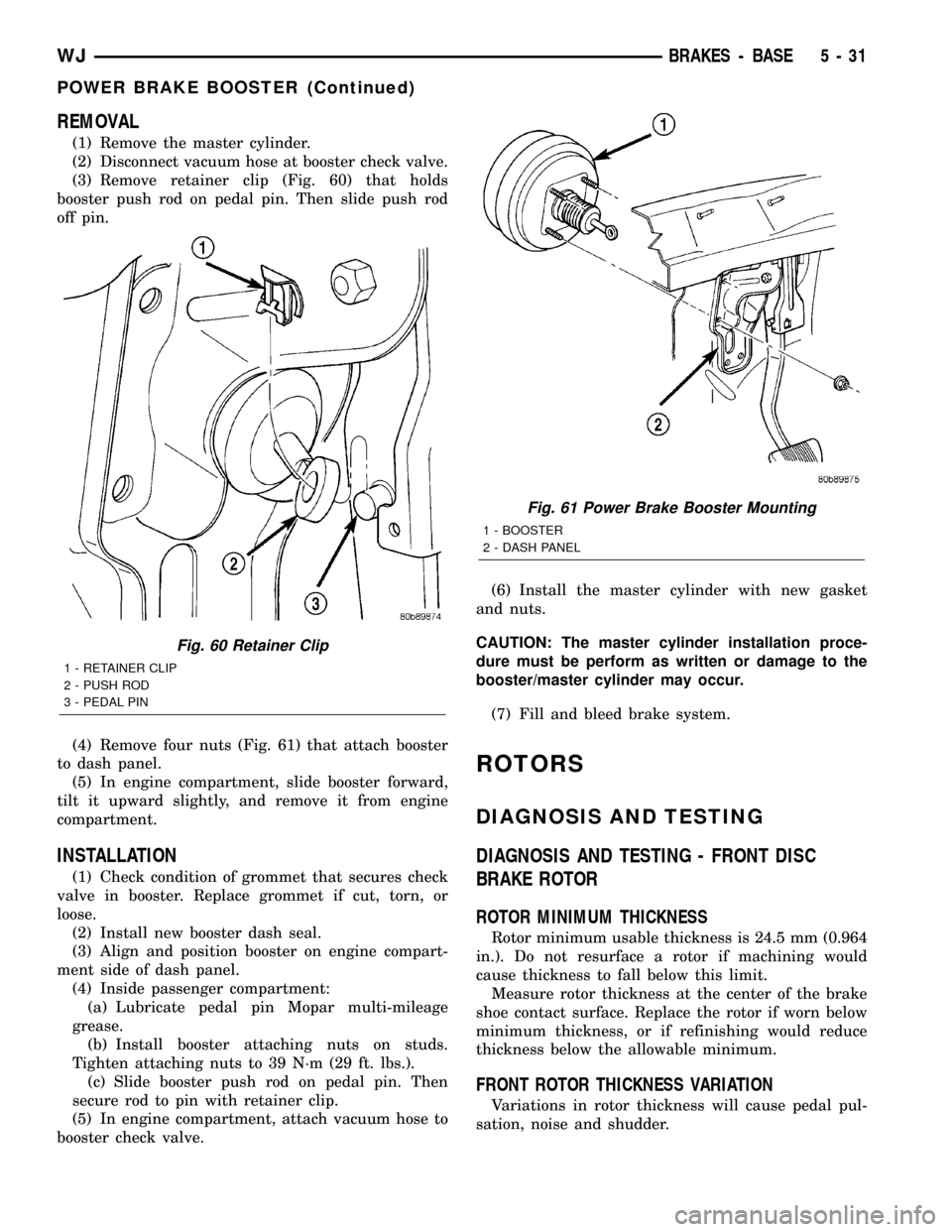

REMOVAL

(1) Remove the master cylinder.

(2) Disconnect vacuum hose at booster check valve.

(3) Remove retainer clip (Fig. 60) that holds

booster push rod on pedal pin. Then slide push rod

off pin.

(4) Remove four nuts (Fig. 61) that attach booster

to dash panel.

(5) In engine compartment, slide booster forward,

tilt it upward slightly, and remove it from engine

compartment.

INSTALLATION

(1) Check condition of grommet that secures check

valve in booster. Replace grommet if cut, torn, or

loose.

(2) Install new booster dash seal.

(3) Align and position booster on engine compart-

ment side of dash panel.

(4) Inside passenger compartment:

(a) Lubricate pedal pin Mopar multi-mileage

grease.

(b) Install booster attaching nuts on studs.

Tighten attaching nuts to 39 N´m (29 ft. lbs.).

(c) Slide booster push rod on pedal pin. Then

secure rod to pin with retainer clip.

(5) In engine compartment, attach vacuum hose to

booster check valve.(6) Install the master cylinder with new gasket

and nuts.

CAUTION: The master cylinder installation proce-

dure must be perform as written or damage to the

booster/master cylinder may occur.

(7) Fill and bleed brake system.

ROTORS

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FRONT DISC

BRAKE ROTOR

ROTOR MINIMUM THICKNESS

Rotor minimum usable thickness is 24.5 mm (0.964

in.). Do not resurface a rotor if machining would

cause thickness to fall below this limit.

Measure rotor thickness at the center of the brake

shoe contact surface. Replace the rotor if worn below

minimum thickness, or if refinishing would reduce

thickness below the allowable minimum.

FRONT ROTOR THICKNESS VARIATION

Variations in rotor thickness will cause pedal pul-

sation, noise and shudder.

Fig. 60 Retainer Clip

1 - RETAINER CLIP

2 - PUSH ROD

3 - PEDAL PIN

Fig. 61 Power Brake Booster Mounting

1 - BOOSTER

2 - DASH PANEL

WJBRAKES - BASE 5 - 31

POWER BRAKE BOOSTER (Continued)

Page 280 of 2199

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION..........................2

OPERATION............................3

DIAGNOSIS AND TESTING - AUDIO..........3

SPECIAL TOOLS

AUDIO SYSTEMS......................6

AMPLIFIER

DESCRIPTION..........................6

OPERATION............................6

DIAGNOSIS AND TESTING - AMPLIFIER......6

REMOVAL.............................6

INSTALLATION..........................6

ANTENNA BODY & CABLE

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE..........................7

REMOVAL.............................9

INSTALLATION.........................10

ANTENNA MODULE - EXPORT

DESCRIPTION.........................10

OPERATION...........................11

DIAGNOSIS AND TESTING - ANTENNA

MODULE - EXPORT....................11

REMOVAL.............................12

INSTALLATION.........................12

CD CHANGER

DESCRIPTION.........................12

OPERATION...........................13

DIAGNOSIS AND TESTING - CD CHANGER . . . 13

REMOVAL.............................14

INSTALLATION.........................14

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL.............................15

INSTALLATION.........................15

QUARTER GLASS INTEGRAL ANTENNA -

EXPORT

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING - QUARTER

GLASS INTEGRAL ANTENNA - EXPORT....16RADIO

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING - RADIO.........16

REMOVAL.............................17

INSTALLATION.........................18

RADIO NOISE SUPPRESSION GROUND STRAP

DESCRIPTION.........................18

REMOVAL

REMOVAL - ENGINE-TO-BODY GROUND

STRAP.............................18

REMOVAL - EXHAUST-TO-BODY GROUND

STRAP.............................19

INSTALLATION

INSTALLATION - ENGINE TO BODY

GROUND STRAP......................19

INSTALLATION - EXHAUST-TO-BODY

GROUND STRAP......................19

REMOTE SWITCHES

DESCRIPTION.........................19

OPERATION...........................20

DIAGNOSIS AND TESTING - REMOTE

SWITCHES..........................20

REMOVAL.............................21

INSTALLATION.........................21

SPEAKER

DESCRIPTION.........................22

OPERATION...........................22

DIAGNOSIS AND TESTING - SPEAKER......23

REMOVAL

REAR DOOR SPEAKER................24

INSTRUMENT PANEL SPEAKER..........24

FRONT DOOR SPEAKER...............24

INSTALLATION

INSTALLATION - REAR DOOR SPEAKER . . . 25

INSTALLATION - INSTRUMENT PANEL

SPEAKER...........................25

INSTALLATION - FRONT DOOR SPEAKER . . 25

WJAUDIO 8A - 1