tires JEEP GRAND CHEROKEE 2017 WK2 / 4.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2017 WK2 / 4.GPages: 372

Page 147 of 372

WARNING!

clutch pedal (if present) to check for

interference. If your floor mat interferes

with the operation of any pedal, or is not

secure to the floor, remove the floor mat

from the vehicle and place the floor mat

in your trunk.

• ONLY use the passenger’s side floor mat

on the passenger’s side floor area.

• ALWAYS make sure objects cannot fall

or slide into the driver’s side floor area

when the vehicle is moving. Objects can

become trapped under accelerator,

brake, or clutch pedals and could cause

a loss of vehicle control.

• NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These ob-

jects could change the position of the

floor mat and may cause interference

with the accelerator, brake, or clutch

pedals.

• If the vehicle carpet has been removed

and re-installed, always properly attach

WARNING!

carpet to the floor and check the floor

mat fasteners are secure to the vehicle

carpet. Fully depress each pedal to

check for interference with the accelera-

tor, brake, or clutch pedals then re-

install the floor mats.

• It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat

has been properly installed and is se-

cured to your vehicle using the floor mat

fasteners by lightly pulling mat.

Periodic Safety Checks You Should Make

Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones,

nails, glass, or other objects lodged in the

tread or sidewall. Inspect the tread for cuts and cracks. Inspect sidewalls for cuts,

cracks, and bulges. Check the wheel nuts for

tightness. Check the tires (including spare)

for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and lock-

ing.

Fluid Leaks

Check area under vehicle after overnight

parking for fuel, engine coolant, oil, or other

fluid leaks. Also, if gasoline fumes are de-

tected or if fuel, power steering fluid (if

equipped), or brake fluid leaks are sus-

pected. The cause should be located and

corrected immediately.

145

Page 164 of 372

Quadra-Trac II Operating Instructions/

Precautions — If Equipped

The Quadra-Trac II transfer case is fully au-

tomatic in the normal driving 4WD AUTO

mode. The Quadra-Trac II transfer case pro-

vides three mode positions:

• 4WD HI

• NEUTRAL

• 4WD LOW

This transfer case is fully automatic in the

4WD HI mode.

When additional traction is required, the

4WD LOW position can be used to lock the

front and rear driveshafts together and force

the front and rear wheels to rotate at the

same speed. The 4WD LOW position is in-

tended for loose, slippery road surfaces only.

Driving in the 4WD LOW position on dry,

hard-surfaced roads may cause increased tire

wear and damage to driveline components.When operating your vehicle in 4WD LOW,

the engine speed is approximately three

times that of the 4WD HI position at a given

road speed. Take care not to overspeed the

engine and do not exceed 25 mph (40 km/h).

Proper operation of four-wheel drive vehicles

depends on tires of equal size, type, and

circumference on each wheel. Any difference

will adversely affect shifting and cause dam-

age to the transfer case.

Because four-wheel drive provides improved

traction, there is a tendency to exceed safe

turning and stopping speeds. Do not go faster

than road conditions permit.

WARNING!

You or others could be injured or killed if

you leave the vehicle unattended with the

transfer case in the NEUTRAL position

without first fully engaging the parking

brake. The transfer case NEUTRAL posi-

tion disengages both the front and rear

drive shafts from the powertrain and will

allow the vehicle to roll, even if the trans-

mission is in PARK. The parking brake

WARNING!

should always be applied when the driver

is not in the vehicle.

Shift Positions

For additional information on the appropriate

use of each 4WD system mode position, see

the information below:

4WD AUTO

This range is used on surfaces such as ice,

snow, gravel, sand, and dry hard pavement.

NOTE:

Refer to “Selec-Terrain – If Equipped” fur-

ther on in this section for further information

on the various positions and their intended

usages.

NEUTRAL

This range disengages the driveline from the

powertrain. It is to be used for flat towing

behind another vehicle. Refer to “Recre-

ational Towing” in “Starting And Operating”

for further information.

STARTING AND OPERATING

162

Page 184 of 372

Operation With A Trailer

The operation of the sensors is automatically

deactivated when the trailer's electric plug is

inserted in the vehicle's tow hook socket. The

sensors are automatically reactivated when

the trailer's cable plug is removed.

General Warnings

If “PARKSENSE UNAVAILABLE WIPE REAR

SENSORS" or "PARKSENSE UNAVAILABLE

WIPE FRONT SENSORS” appears in the in-

strument cluster display, clean the

ParkSense sensors with water, car wash soap

and a soft cloth. Do not use rough or hard

cloths. Do not scratch or poke the sensors.

Otherwise, you could damage the sensors.

PARKSENSE ACTIVE PARK

ASSIST SYSTEM — IF

EQUIPPED

The ParkSense Active Park Assist system is

intended to assist the driver during parallel

and perpendicular parking maneuvers by

identifying a proper parking space, providing

audible/visual instructions, and controllingthe steering wheel. The ParkSense Active

Park Assist system is defined as “semi-

automatic” since the driver maintains control

of the accelerator, gear selector and brakes.

Depending on the driver's parking maneuver

selection, the ParkSense Active Park Assist

system is capable of maneuvering a vehicle

into a parallel or a perpendicular parking

space on either side (i.e., driver side or pas-

senger side).

NOTE:

• The driver is always responsible for con-

trolling the vehicle, responsible for any

surrounding objects, and must intervene

as required.

• The system is provided to assist the driver and not to substitute the driver.

• During a semi-automatic maneuver, if the driver touches the steering wheel after

being instructed to remove their hands

from the steering wheel, the system will

cancel, and the driver will be required to

manually complete the parking maneuver. • The system may not work in all conditions

(e.g. environmental conditions such as

heavy rain, snow, etc., or if searching for a

parking space that has surfaces that will

absorb the ultrasonic sensor waves).

• New vehicles from the dealership must have at least 30 miles (48 km) accumu-

lated before the ParkSense Active Park

Assist system is fully calibrated and per-

forms accurately. This is due to the sys-

tem’s dynamic vehicle calibration to im-

prove the performance of the feature. The

system will also continuously perform the

dynamic vehicle calibration to account for

differences such as over or under inflated

tires and new tires.

Enabling And Disabling The ParkSense Active

Park Assist System

The ParkSense Active Park Assist system can

be enabled and disabled with the ParkSense

Active Park Assist switch, located on the

switch panel below the Uconnect display.

STARTING AND OPERATING

182

Page 196 of 372

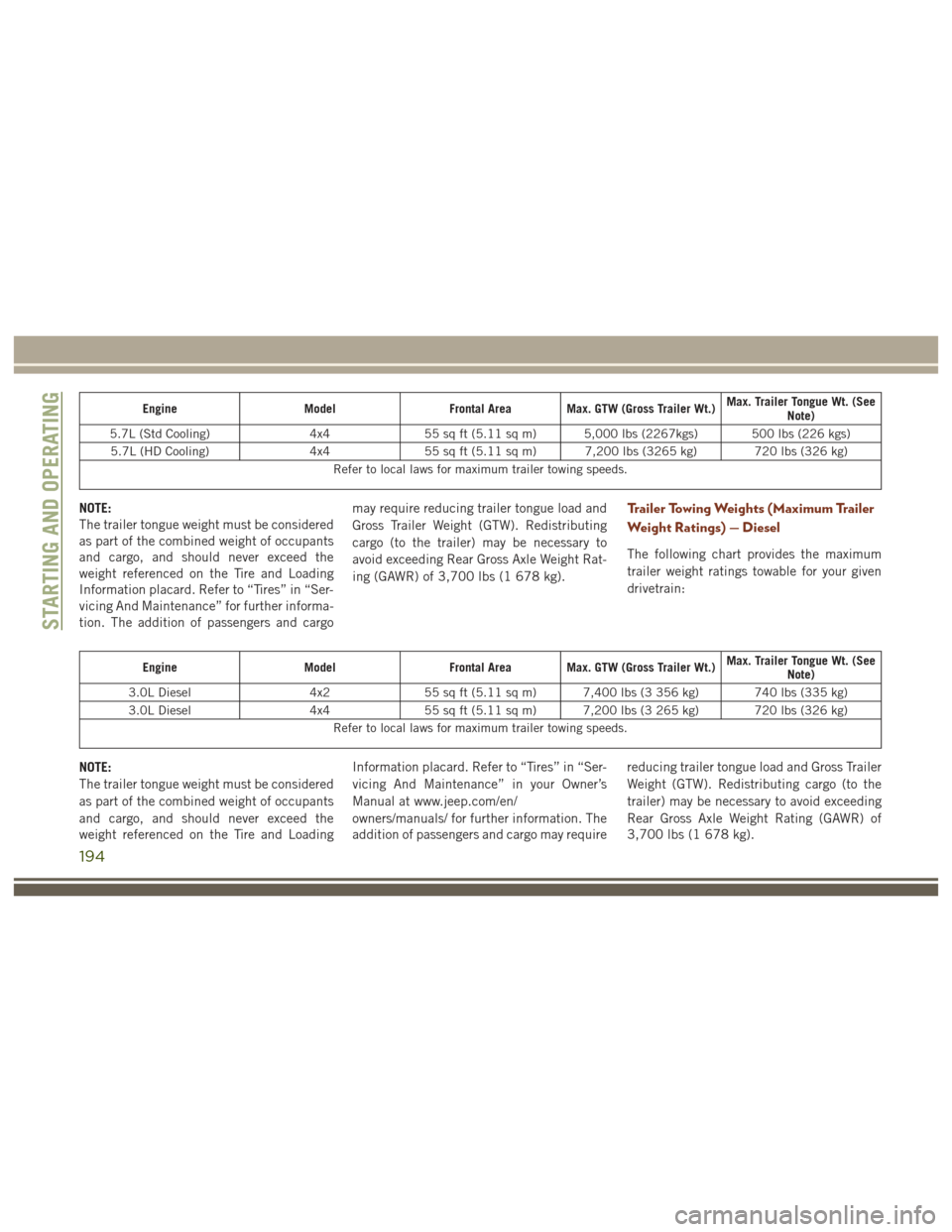

EngineModelFrontal Area Max. GTW (Gross Trailer Wt.) Max. Trailer Tongue Wt. (See

Note)

5.7L (Std Cooling) 4x455 sq ft (5.11 sq m) 5,000 lbs (2267kgs) 500 lbs (226 kgs)

5.7L (HD Cooling) 4x455 sq ft (5.11 sq m) 7,200 lbs (3265 kg) 720 lbs (326 kg)

Refer to local laws for maximum trailer towing speeds.

NOTE:

The trailer tongue weight must be considered

as part of the combined weight of occupants

and cargo, and should never exceed the

weight referenced on the Tire and Loading

Information placard. Refer to “Tires” in “Ser-

vicing And Maintenance” for further informa-

tion. The addition of passengers and cargo may require reducing trailer tongue load and

Gross Trailer Weight (GTW). Redistributing

cargo (to the trailer) may be necessary to

avoid exceeding Rear Gross Axle Weight Rat-

ing (GAWR) of 3,700 lbs (1 678 kg).Trailer Towing Weights (Maximum Trailer

Weight Ratings) — Diesel

The following chart provides the maximum

trailer weight ratings towable for your given

drivetrain:

Engine

ModelFrontal Area Max. GTW (Gross Trailer Wt.) Max. Trailer Tongue Wt. (See

Note)

3.0L Diesel 4x255 sq ft (5.11 sq m) 7,400 lbs (3 356 kg) 740 lbs (335 kg)

3.0L Diesel 4x455 sq ft (5.11 sq m) 7,200 lbs (3 265 kg) 720 lbs (326 kg)

Refer to local laws for maximum trailer towing speeds.

NOTE:

The trailer tongue weight must be considered

as part of the combined weight of occupants

and cargo, and should never exceed the

weight referenced on the Tire and Loading Information placard. Refer to “Tires” in “Ser-

vicing And Maintenance” in your Owner’s

Manual at www.jeep.com/en/

owners/manuals/ for further information. The

addition of passengers and cargo may require reducing trailer tongue load and Gross Trailer

Weight (GTW). Redistributing cargo (to the

trailer) may be necessary to avoid exceeding

Rear Gross Axle Weight Rating (GAWR) of

3,700 lbs (1 678 kg).

STARTING AND OPERATING

194

Page 197 of 372

Trailer Towing Weights (Maximum Trailer Weight Ratings) — SRT

Engine/TransmissionGCWR (Gross Combined Wt.

Rating) Frontal Area Max. GTW (Gross Trailer Wt.) Max. Trailer Tongue Wt. (See

Note)

6.4L Automatic 12,600 lbs (5 715 kg) 55 sq ft (5.11 sq m) 7,200 lbs (3 265 kg) 720 lbs (327 kg) Refer to local laws for maximum trailer towing speeds.

NOTE:

• The trailer tongue weight must be consid-ered as part of the combined weight of

occupants and cargo, and should never

exceed the weight referenced on the Tire

and Loading Information placard. Refer to

“Tires” in “Servicing And Maintenance” in

your Owner’s Manual at

www.jeep.com/en/owners/manuals/ for

further information.

• The manufacturer does not recommend using the run flat feature while driving a

vehicle loaded at full capacity or towing a

trailer.Trailer Hitch Receiver Cover Removal

(Summit Models) — If Equipped

Your vehicle may be equipped with a trailer

hitch receiver cover, this must be removed to

access the trailer hitch receiver (if equipped).

This hitch receiver cover is located at the

bottom center of the rear fascia.

1. Turn the two locking retainers located at

the bottom of the hitch receiver cover a

1/4 turn counterclockwise.

NOTE:

Use a suitable tool such as a coin in the

slot of the locking retainer if needed for

added leverage.

Hitch Receiver Cover

1 — Hitch Receiver Cover Tab Loca-

tions

2 — Locking Retainers

195

Page 205 of 372

IN CASE OF EMERGENCY

HAZARD WARNING

FLASHERS................204

Control....................204

BULB REPLACEMENT ........204

Replacement Bulbs.............204

Bulb Replacement .............206

FUSES ...................209

General Information.............209

Underhood Fuses ..............209

JACKING AND TIRE

CHANGING............... .214

Run Flat Tires — SRT Models .......214

Jack/Spare Tire Stowage ..........215

Changing Procedure ............221

JUMP-STARTING............221

Preparations For Jump-Starting ......221

Jump-Starting Procedure .........222

REFUELING IN EMERGENCY . . .224

IF YOUR ENGINE OVERHEATS .224 MANUAL PARK RELEASE

.....224

FREEING A STUCK VEHICLE . . .226

TOWING A DISABLED

VEHICLE ................ .227

Two-Wheel Drive Models..........228

Four-Wheel Drive Models .........229

ENHANCED ACCIDENT RESPONSE

SYSTEM(EARS) ........... .229

EVENT DATA RECORDER

(EDR)................... .229

IN CASE OF EMERGENCY

203

Page 216 of 372

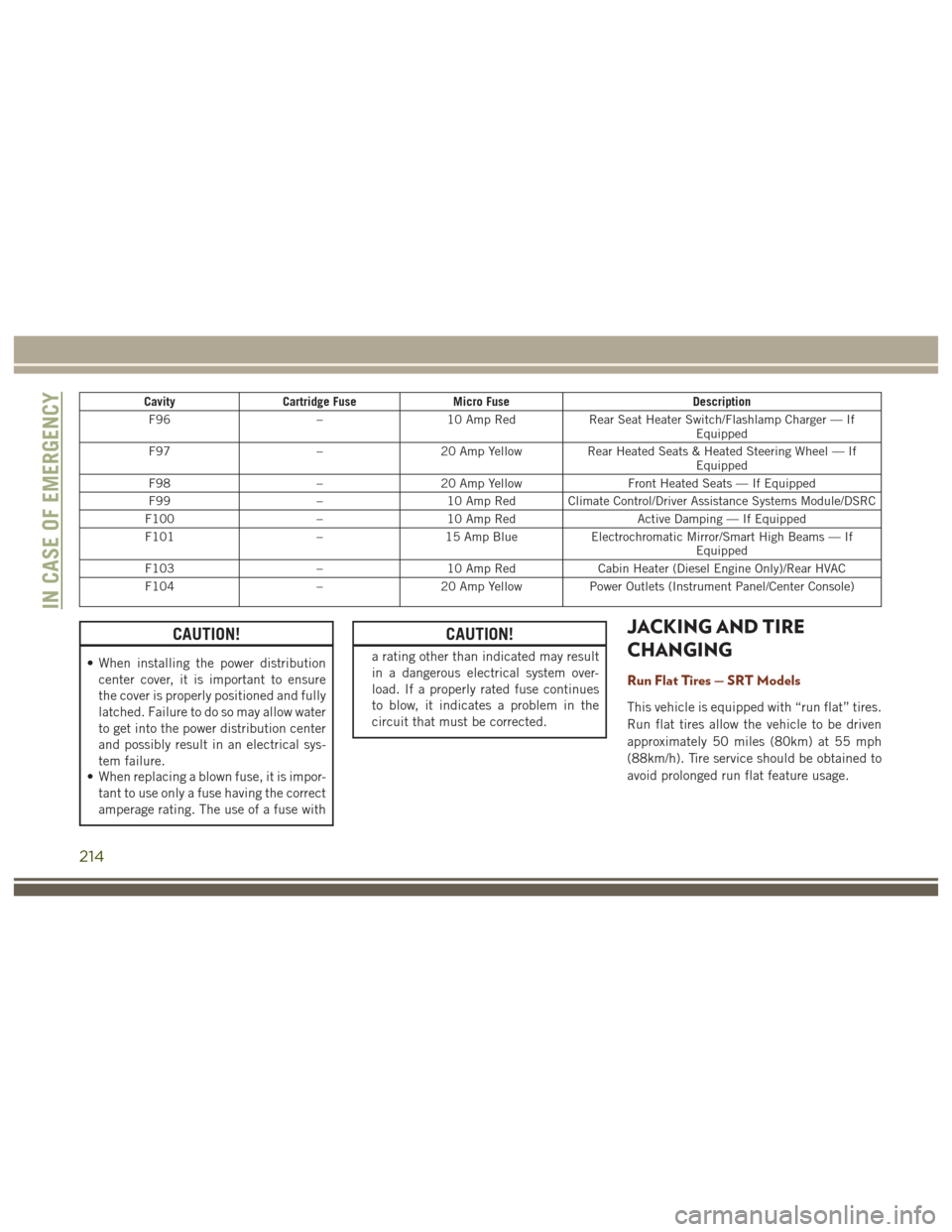

CavityCartridge Fuse Micro Fuse Description

F96 –10 Amp Red Rear Seat Heater Switch/Flashlamp Charger — If

Equipped

F97 –20 Amp Yellow Rear Heated Seats & Heated Steering Wheel — If

Equipped

F98 –20 Amp Yellow Front Heated Seats — If Equipped

F99 –10 Amp Red Climate Control/Driver Assistance Systems Module/DSRC

F100 –10 Amp Red Active Damping — If Equipped

F101 –15 Amp Blue Electrochromatic Mirror/Smart High Beams — If

Equipped

F103 –10 Amp Red Cabin Heater (Diesel Engine Only)/Rear HVAC

F104 –20 Amp Yellow Power Outlets (Instrument Panel/Center Console)

CAUTION!

• When installing the power distribution

center cover, it is important to ensure

the cover is properly positioned and fully

latched. Failure to do so may allow water

to get into the power distribution center

and possibly result in an electrical sys-

tem failure.

• When replacing a blown fuse, it is impor-

tant to use only a fuse having the correct

amperage rating. The use of a fuse with

CAUTION!

a rating other than indicated may result

in a dangerous electrical system over-

load. If a properly rated fuse continues

to blow, it indicates a problem in the

circuit that must be corrected.

JACKING AND TIRE

CHANGING

Run Flat Tires — SRT Models

This vehicle is equipped with “run flat” tires.

Run flat tires allow the vehicle to be driven

approximately 50 miles (80km) at 55 mph

(88km/h). Tire service should be obtained to

avoid prolonged run flat feature usage.

IN CASE OF EMERGENCY

214

Page 219 of 372

Jacking Instructions

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface asfar from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Chock the wheel diagonally opposite the

wheel to be raised.

• Set the parking brake firmly and set an

automatic transmission in PARK.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

WARNING!

• If working on or near a roadway, beextremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

1. Remove the spare tire, jack, and tools from storage. 2. Loosen (but do not remove) the wheel lug

nuts by turning them to the left, one turn,

while the wheel is still on the ground.

3. Assemble the jack and jacking tools.

Warning Label

Jack And Tools Assembled

217

Page 228 of 372

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand

or snow, it can often be moved using a rock-

ing motion. Turn the steering wheel right and

left to clear the area around the front wheels.

Push and hold the lock button on the gear

selector. Then shift back and forth between

DRIVE and REVERSE while gently pressing

the accelerator.

NOTE:

Shifts between DRIVE and REVERSE can

only be achieved at wheel speeds of 5 mph

(8 km/h) or less. Whenever the transmission

remains in NEUTRAL for more than two sec-

onds, you must press the brake pedal to

engage DRIVE or REVERSE.

Use the least amount of accelerator pedal

pressure that will maintain the rocking mo-

tion without spinning the wheels or racing the

engine.NOTE:

Push the "ESC Off" switch (if necessary), to

place the Electronic Stability Control (ESC)

system in "Partial Off" mode, before rocking

the vehicle. Refer to “Electronic Brake Con-

trol” in “Safety” in the Owners Manual at

www.jeep.com/en/owners/manuals/ for fur-

ther information. Once the vehicle has been

freed, push the "ESC Off" switch again to

restore "ESC On" mode.

WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even failure,

of the axle and tires. A tire could explode

and injure someone. Do not spin your

vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you

are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

CAUTION!

• Racing the engine or spinning the

wheels may lead to transmission over-

heating and failure. Allow the engine to

idle with the transmission in NEUTRAL

for at least one minute after every five

rocking-motion cycles. This will mini-

mize overheating and reduce the risk of

transmission failure during prolonged

efforts to free a stuck vehicle.

• When “rocking” a stuck vehicle by shift-

ing between DRIVE and REVERSE, do

not spin the wheels faster than 15 mph

(24 km/h), or drivetrain damage may

result.

• Revving the engine or spinning the

wheels too fast may lead to transmission

overheating and failure. It can also dam-

age the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear

(no transmission shifting occurring).

IN CASE OF EMERGENCY

226

Page 233 of 372

SERVICING AND MAINTENANCE

SCHEDULED SERVICING NON-

SRT......................232

Maintenance Plan Non-SRT........233

Heavy Duty Use Of The Vehicle ......234

SCHEDULED SERVICING – SRT .235

Maintenance Plan – SRT..........236

SCHEDULED SERVICING — DIESEL

ENGINE.................. .239

Maintenance Plan — Diesel Fuel Up To

B5 Biodiesel.................241

Additional Maintenance — B6 To

B20 Biodiesel ................242

ENGINE COMPARTMENT .....244

3.6L Engine.................244

5.7L Engine .................245

6.4L Engine .................246 3.0L Diesel Engine

.............247

Checking Oil Level — Gasoline Engine .248

Checking Oil Level — Diesel Engine . . .248

Adding Washer Fluid ............248

Brake System ................249

Automatic Transmission ..........250

Maintenance-Free Battery ........250

DEALERSERVICE .......... .251

Air Conditioner Maintenance.......251

Windshield Wiper Blades .........253

Cooling System ...............257

RAISINGTHEVEHICLE .......258

TIRES................... .258

Tire Safety Information..........258

Wheel And Wheel Trim Care .......264

Tire Chains (Traction Devices) .......265Tire Rotation Recommendations

.....265

DEPARTMENT OF TRANSPORTA-

TION UNIFORM TIRE QUALITY

GRADES................. .266

Treadwear...................266

Traction Grades ...............266

Temperature Grades .............267

STORINGTHEVEHICLE.......267

BODYWORK...............268

Body And Underbody Maintenance . . .268

Preserving The Bodywork .........268

INTERIORS............... .269

Seats And Fabric Parts...........269

Plastic And Coated Parts ..........270

Leather Parts .................270

SERVICING AND MAINTENANCE

231