ECU JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 315 of 1803

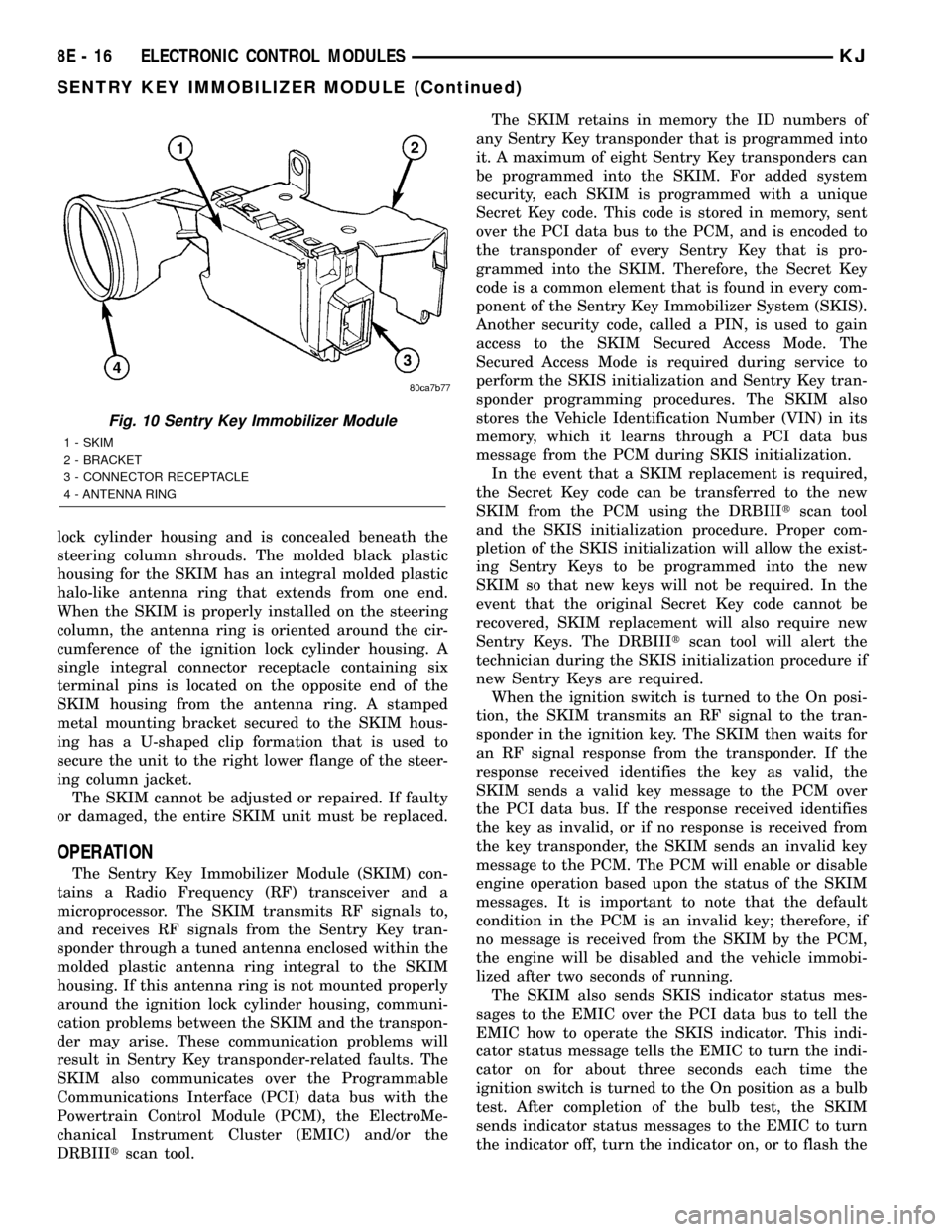

lock cylinder housing and is concealed beneath the

steering column shrouds. The molded black plastic

housing for the SKIM has an integral molded plastic

halo-like antenna ring that extends from one end.

When the SKIM is properly installed on the steering

column, the antenna ring is oriented around the cir-

cumference of the ignition lock cylinder housing. A

single integral connector receptacle containing six

terminal pins is located on the opposite end of the

SKIM housing from the antenna ring. A stamped

metal mounting bracket secured to the SKIM hous-

ing has a U-shaped clip formation that is used to

secure the unit to the right lower flange of the steer-

ing column jacket.

The SKIM cannot be adjusted or repaired. If faulty

or damaged, the entire SKIM unit must be replaced.

OPERATION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a

microprocessor. The SKIM transmits RF signals to,

and receives RF signals from the Sentry Key tran-

sponder through a tuned antenna enclosed within the

molded plastic antenna ring integral to the SKIM

housing. If this antenna ring is not mounted properly

around the ignition lock cylinder housing, communi-

cation problems between the SKIM and the transpon-

der may arise. These communication problems will

result in Sentry Key transponder-related faults. The

SKIM also communicates over the Programmable

Communications Interface (PCI) data bus with the

Powertrain Control Module (PCM), the ElectroMe-

chanical Instrument Cluster (EMIC) and/or the

DRBIIItscan tool.The SKIM retains in memory the ID numbers of

any Sentry Key transponder that is programmed into

it. A maximum of eight Sentry Key transponders can

be programmed into the SKIM. For added system

security, each SKIM is programmed with a unique

Secret Key code. This code is stored in memory, sent

over the PCI data bus to the PCM, and is encoded to

the transponder of every Sentry Key that is pro-

grammed into the SKIM. Therefore, the Secret Key

code is a common element that is found in every com-

ponent of the Sentry Key Immobilizer System (SKIS).

Another security code, called a PIN, is used to gain

access to the SKIM Secured Access Mode. The

Secured Access Mode is required during service to

perform the SKIS initialization and Sentry Key tran-

sponder programming procedures. The SKIM also

stores the Vehicle Identification Number (VIN) in its

memory, which it learns through a PCI data bus

message from the PCM during SKIS initialization.

In the event that a SKIM replacement is required,

the Secret Key code can be transferred to the new

SKIM from the PCM using the DRBIIItscan tool

and the SKIS initialization procedure. Proper com-

pletion of the SKIS initialization will allow the exist-

ing Sentry Keys to be programmed into the new

SKIM so that new keys will not be required. In the

event that the original Secret Key code cannot be

recovered, SKIM replacement will also require new

Sentry Keys. The DRBIIItscan tool will alert the

technician during the SKIS initialization procedure if

new Sentry Keys are required.

When the ignition switch is turned to the On posi-

tion, the SKIM transmits an RF signal to the tran-

sponder in the ignition key. The SKIM then waits for

an RF signal response from the transponder. If the

response received identifies the key as valid, the

SKIM sends a valid key message to the PCM over

the PCI data bus. If the response received identifies

the key as invalid, or if no response is received from

the key transponder, the SKIM sends an invalid key

message to the PCM. The PCM will enable or disable

engine operation based upon the status of the SKIM

messages. It is important to note that the default

condition in the PCM is an invalid key; therefore, if

no message is received from the SKIM by the PCM,

the engine will be disabled and the vehicle immobi-

lized after two seconds of running.

The SKIM also sends SKIS indicator status mes-

sages to the EMIC over the PCI data bus to tell the

EMIC how to operate the SKIS indicator. This indi-

cator status message tells the EMIC to turn the indi-

cator on for about three seconds each time the

ignition switch is turned to the On position as a bulb

test. After completion of the bulb test, the SKIM

sends indicator status messages to the EMIC to turn

the indicator off, turn the indicator on, or to flash the

Fig. 10 Sentry Key Immobilizer Module

1 - SKIM

2 - BRACKET

3 - CONNECTOR RECEPTACLE

4 - ANTENNA RING

8E - 16 ELECTRONIC CONTROL MODULESKJ

SENTRY KEY IMMOBILIZER MODULE (Continued)

Page 316 of 1803

indicator on and off. If the SKIS indicator flashes

upon ignition On or stays on solid after the bulb test,

it signifies a SKIS fault. If the SKIM detects a sys-

tem malfunction and/or the SKIS has become inoper-

ative, the SKIS indicator will stay on solid. If the

SKIM detects an invalid key or if a key transponder-

related fault exists, the SKIS indicator will flash. If

the vehicle is equipped with the Customer Learn

transponder programming feature, the SKIM will

also send messages to the EMIC to flash the SKIS

indicator and to generate a single audible chime tone

whenever the Customer Learn programming mode is

being utilized. (Refer to 8 - ELECTRICAL/VEHICLE

THEFT SECURITY - STANDARD PROCEDURE -

SENTRY KEY TRANSPONDER PROGRAMMING).

The SKIS performs a self-test each time the igni-

tion switch is turned to the On position, and will

store fault information in the form of Diagnostic

Trouble Codes (DTC's) in SKIM memory if a system

malfunction is detected. The SKIM can be diagnosed,

and any stored DTC's can be retrieved using a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) If the vehicle is equipped with the optional tilt

steering column, move the tilt steering column to the

fully lowered position and leave the tilt release lever

in the released (down) position.

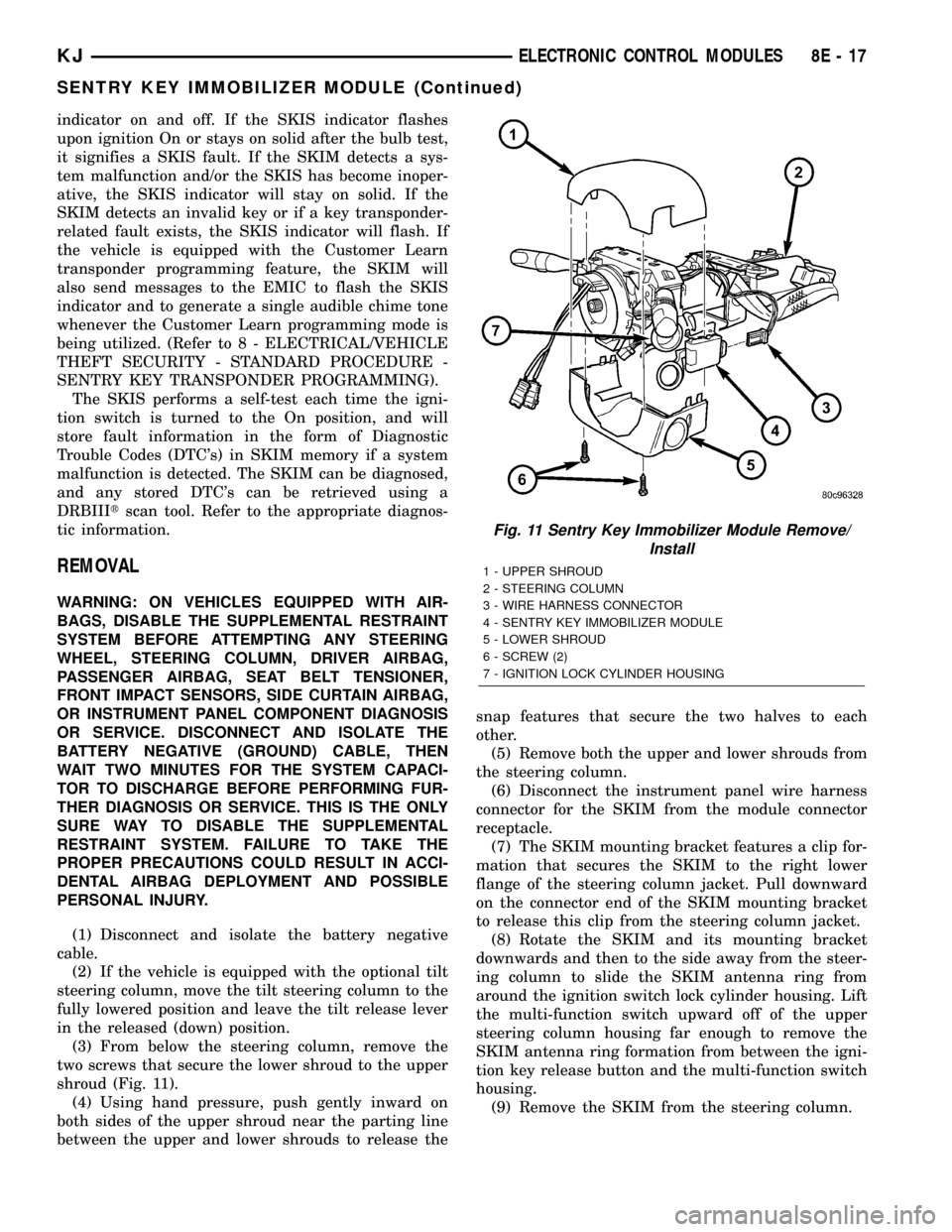

(3) From below the steering column, remove the

two screws that secure the lower shroud to the upper

shroud (Fig. 11).

(4) Using hand pressure, push gently inward on

both sides of the upper shroud near the parting line

between the upper and lower shrouds to release thesnap features that secure the two halves to each

other.

(5) Remove both the upper and lower shrouds from

the steering column.

(6) Disconnect the instrument panel wire harness

connector for the SKIM from the module connector

receptacle.

(7) The SKIM mounting bracket features a clip for-

mation that secures the SKIM to the right lower

flange of the steering column jacket. Pull downward

on the connector end of the SKIM mounting bracket

to release this clip from the steering column jacket.

(8) Rotate the SKIM and its mounting bracket

downwards and then to the side away from the steer-

ing column to slide the SKIM antenna ring from

around the ignition switch lock cylinder housing. Lift

the multi-function switch upward off of the upper

steering column housing far enough to remove the

SKIM antenna ring formation from between the igni-

tion key release button and the multi-function switch

housing.

(9) Remove the SKIM from the steering column.

Fig. 11 Sentry Key Immobilizer Module Remove/

Install

1 - UPPER SHROUD

2 - STEERING COLUMN

3 - WIRE HARNESS CONNECTOR

4 - SENTRY KEY IMMOBILIZER MODULE

5 - LOWER SHROUD

6 - SCREW (2)

7 - IGNITION LOCK CYLINDER HOUSING

KJELECTRONIC CONTROL MODULES 8E - 17

SENTRY KEY IMMOBILIZER MODULE (Continued)

Page 317 of 1803

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the Sentry Key Immobilizer Module

(SKIM) to the right side of the steering column (Fig.

11). Lift the multi-function switch upward off of the

upper steering column housing far enough to insert

the SKIM antenna ring formation between the igni-

tion key release button and the multi-function switch

housing.

(2) Slide the SKIM antenna ring around the igni-

tion switch lock cylinder housing, then rotate the

SKIM and its mounting bracket upwards and toward

the steering column.

(3) Align the SKIM mounting bracket clip forma-

tion with the right lower flange of the steering col-

umn jacket and, using hand pressure, push upward

firmly and evenly on the connector end of the SKIM

mounting bracket to engage this clip with the steer-

ing column jacket.

(4) Reconnect the instrument panel wire harness

connector for the SKIM to the module connector

receptacle.

(5) Position both the upper and lower shrouds onto

the steering column.

(6) Align the snap features on the lower shroud

with the receptacles on the upper shroud and apply

hand pressure to snap them together.

(7) From below the steering column, install and

tighten the two screws that secure the lower shroud

to the upper shroud. Tighten the screws to 2 N´m (18

in. lbs.).

(8) If the vehicle is equipped with the optional tilt

steering column, move the tilt steering column to the

fully raised position and secure it in place by moving

the tilt release lever back to the locked (up) position.

(9) Reconnect the battery negative cable.NOTE: If the SKIM has been replaced with a new

unit, the Sentry Key Immobilizer System (SKIS)

MUST be initialized before the vehicle can be oper-

ated. (Refer to 8 - ELECTRICAL/VEHICLE THEFT

SECURITY - STANDARD PROCEDURE - SKIS INI-

TIALIZATION).

TRANSMISSION CONTROL

MODULE

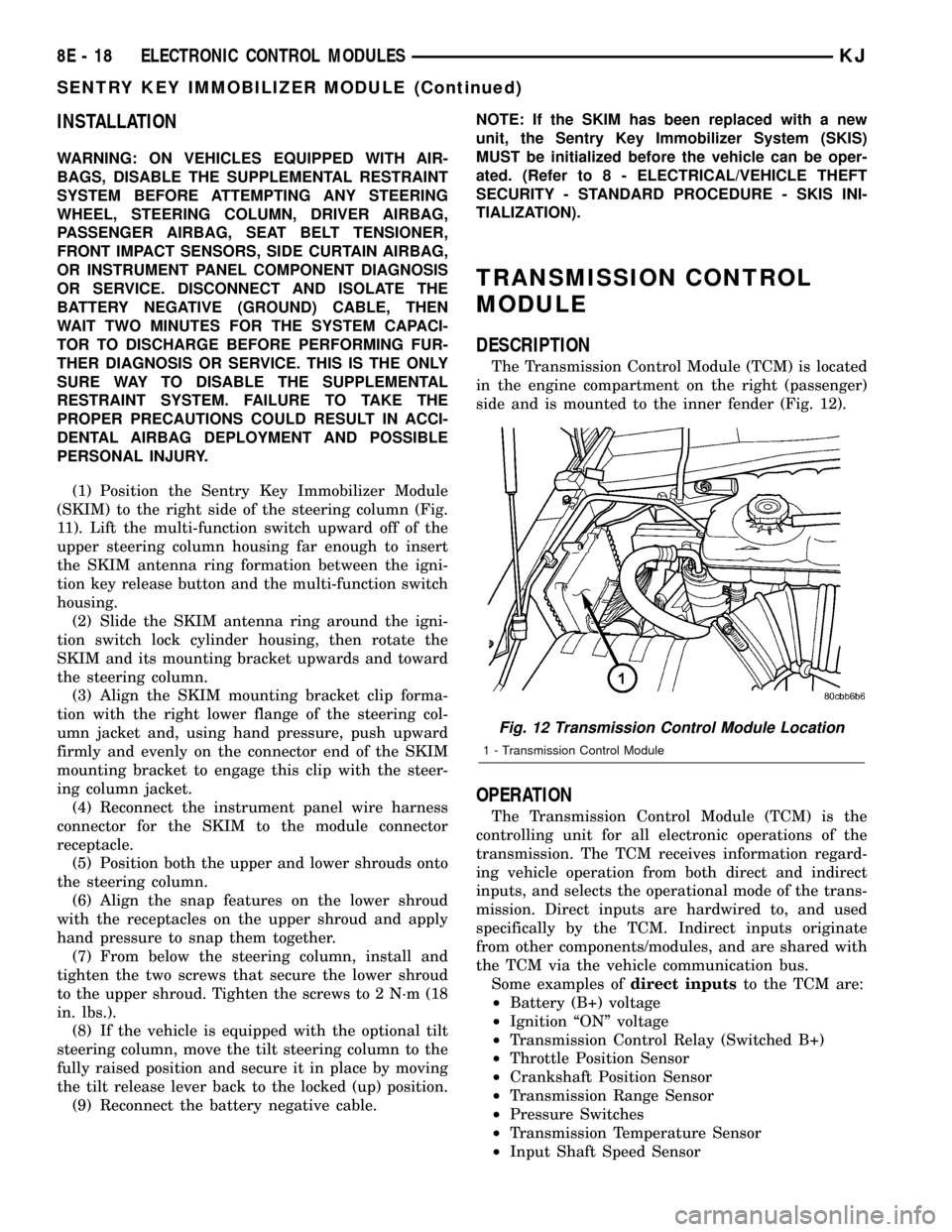

DESCRIPTION

The Transmission Control Module (TCM) is located

in the engine compartment on the right (passenger)

side and is mounted to the inner fender (Fig. 12).

OPERATION

The Transmission Control Module (TCM) is the

controlling unit for all electronic operations of the

transmission. The TCM receives information regard-

ing vehicle operation from both direct and indirect

inputs, and selects the operational mode of the trans-

mission. Direct inputs are hardwired to, and used

specifically by the TCM. Indirect inputs originate

from other components/modules, and are shared with

the TCM via the vehicle communication bus.

Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor

²Transmission Range Sensor

²Pressure Switches

²Transmission Temperature Sensor

²Input Shaft Speed Sensor

Fig. 12 Transmission Control Module Location

1 - Transmission Control Module

8E - 18 ELECTRONIC CONTROL MODULESKJ

SENTRY KEY IMMOBILIZER MODULE (Continued)

Page 320 of 1803

Schedule Condition Expected Operation

OverheatOil temperature above 240É F or

engine coolant temperature above

244É F- Delayed 2-3 upshift

- Delayed 3-4 upshift

- 3rd gear FEMCC from 30-48 mph

- 3rd gear PEMCC above 35 mph

- Above 25 mph the torque

converter will not unlock unless the

throttle is closed or if a wide open

throttle 2nd PEMCC to 1 kickdown

is made

STANDARD PROCEDURE - TCM QUICK LEARN

The quick learn procedure requires the use of the

DRBtscan tool.

This program allows the electronic transmission

system to recalibrate itself. This will provide the

proper transmission operation. The quick learn pro-

cedure should be performed if any of the following

procedures are performed:

²Transmission Assembly Replacement

²Transmission Control Module Replacement

²Solenoid Pack Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

²The shift lever position must stay in PARK until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the DRBt

indicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É

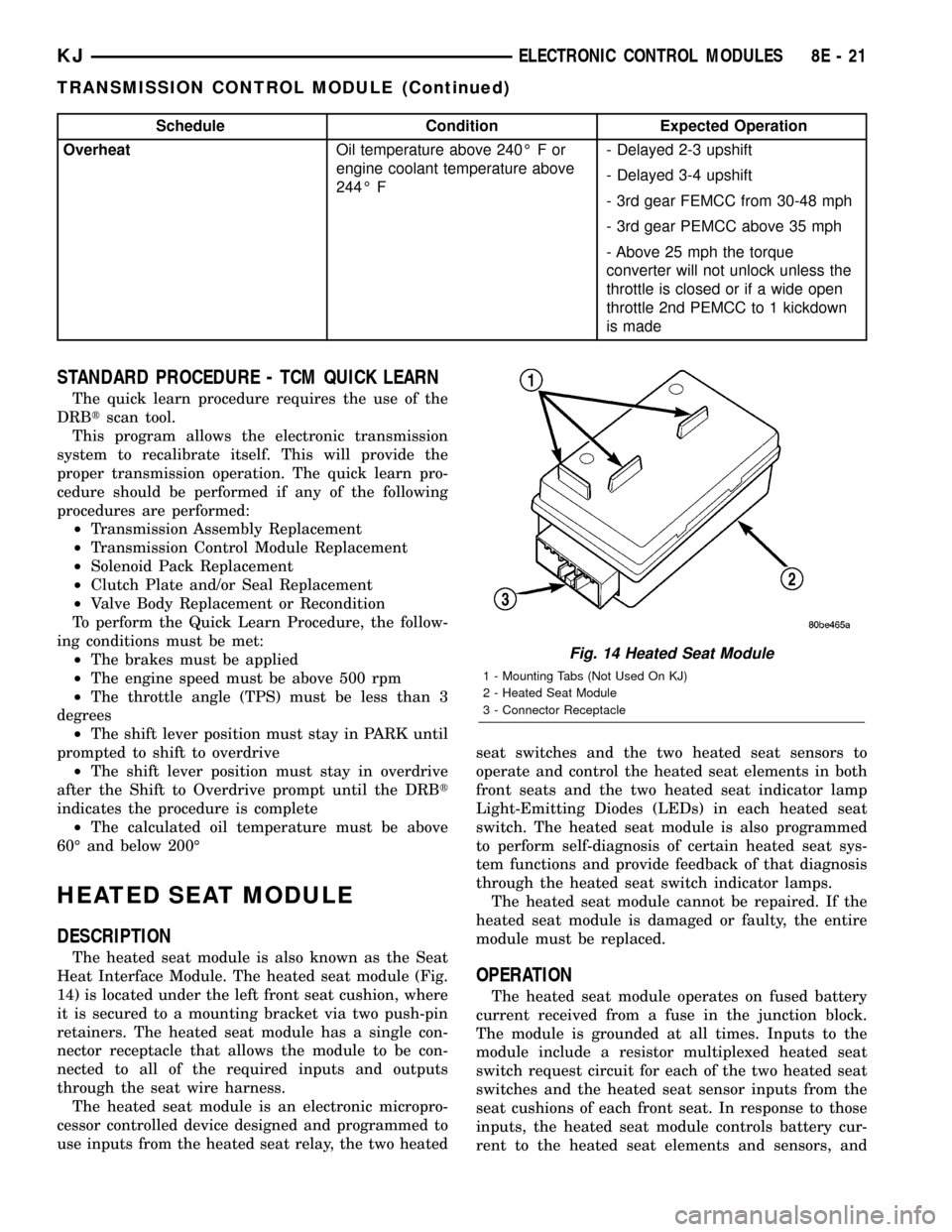

HEATED SEAT MODULE

DESCRIPTION

The heated seat module is also known as the Seat

Heat Interface Module. The heated seat module (Fig.

14) is located under the left front seat cushion, where

it is secured to a mounting bracket via two push-pin

retainers. The heated seat module has a single con-

nector receptacle that allows the module to be con-

nected to all of the required inputs and outputs

through the seat wire harness.

The heated seat module is an electronic micropro-

cessor controlled device designed and programmed to

use inputs from the heated seat relay, the two heatedseat switches and the two heated seat sensors to

operate and control the heated seat elements in both

front seats and the two heated seat indicator lamp

Light-Emitting Diodes (LEDs) in each heated seat

switch. The heated seat module is also programmed

to perform self-diagnosis of certain heated seat sys-

tem functions and provide feedback of that diagnosis

through the heated seat switch indicator lamps.

The heated seat module cannot be repaired. If the

heated seat module is damaged or faulty, the entire

module must be replaced.

OPERATION

The heated seat module operates on fused battery

current received from a fuse in the junction block.

The module is grounded at all times. Inputs to the

module include a resistor multiplexed heated seat

switch request circuit for each of the two heated seat

switches and the heated seat sensor inputs from the

seat cushions of each front seat. In response to those

inputs, the heated seat module controls battery cur-

rent to the heated seat elements and sensors, and

Fig. 14 Heated Seat Module

1 - Mounting Tabs (Not Used On KJ)

2 - Heated Seat Module

3 - Connector Receptacle

KJELECTRONIC CONTROL MODULES 8E - 21

TRANSMISSION CONTROL MODULE (Continued)

Page 324 of 1803

ENGINE SYSTEMS

TABLE OF CONTENTS

page page

BATTERY SYSTEM......................... 1

CHARGING SYSTEM....................... 22STARTING SYSTEM....................... 32

BATTERY SYSTEM

TABLE OF CONTENTS

page page

BATTERY SYSTEM

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - BATTERY

SYSTEM.............................2

CLEANING.............................5

INSPECTION...........................6

SPECIFICATIONS........................6

SPECIAL TOOLS........................7

BATTERY

DESCRIPTION..........................7

DIAGNOSIS AND TESTING - BATTERY.......8

STANDARD PROCEDURE

STANDARD PROCEDURE - BATTERY

CHARGING...........................8

STANDARD PROCEDURE - BUILT-IN

INDICATOR TEST.....................10

STANDARD PROCEDURE - HYDROMETER

TEST...............................11

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST.......................12

STANDARD PROCEDURE - LOAD TEST....12

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST.........................14STANDARD PROCEDURE - USING

MIDTRONICS ELECTRICAL TESTER.......15

REMOVAL.............................16

INSTALLATION.........................16

BATTERY HOLDDOWN

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................17

BATTERY CABLES

DESCRIPTION.........................18

OPERATION...........................18

DIAGNOSIS AND TESTING - BATTERY

CABLES............................19

THERMAL GUARD

DESCRIPTION.........................20

OPERATION...........................20

REMOVAL.............................20

INSTALLATION.........................20

BATTERY TRAY

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................21

BATTERY SYSTEM

DESCRIPTION

A single 12-volt battery system is standard factory-

installed equipment on this model. All of the compo-

nents of the battery system are located within the

engine compartment of the vehicle. The service infor-

mation for the battery system in this vehicle covers

the following related components, which are covered

in further detail elsewhere in this service manual:²Battery- The storage battery provides a reli-

able means of storing a renewable source of electrical

energy within the vehicle.

²Battery Cable- The battery cables connect the

battery terminal posts to the vehicle electrical sys-

tem.

²Battery Holddown- The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

KJENGINE SYSTEMS 8F - 1

Page 325 of 1803

²Battery Thermal Guard- The battery thermal

guard insulates the battery to protect it from engine

compartment temperature extremes.

²Battery Tray- The battery tray provides a

secure mounting location in the vehicle for the bat-

tery and an anchor point for the battery holddown

hardware.

For battery system maintenance schedules and

jump starting procedures, see the owner's manual in

the vehicle glove box. Optionally, refer to Lubrication

and Maintenance for the proper battery jump start-

ing procedures. While battery charging can be consid-

ered a maintenance procedure, the battery charging

procedures and related information are located in the

service procedures section of this service manual.

This was done because the battery must be fully-

charged before any battery system diagnosis or test-

ing procedures can be performed. Refer to Standard

Procedures for the proper battery charging proce-

dures.

OPERATION

The battery system is designed to provide a safe,

efficient, reliable and mobile means of delivering and

storing electrical energy. This electrical energy is

required to operate the engine starting system, as

well as to operate many of the other vehicle acces-

sory systems for limited durations while the engine

and/or the charging system are not operating. The

battery system is also designed to provide a reserve

of electrical energy to supplement the charging sys-

tem for short durations while the engine is running

and the electrical current demands of the vehicle

exceed the output of the charging system. In addition

to delivering, and storing electrical energy for the

vehicle, the battery system serves as a capacitor and

voltage stabilizer for the vehicle electrical system. It

absorbs most abnormal or transient voltages caused

by the switching of any of the electrical components

or circuits in the vehicle.

DIAGNOSIS AND TESTING - BATTERY SYSTEM

The battery, starting, and charging systems in the

vehicle operate with one another and must be testedas a complete system. In order for the engine to start

and the battery to maintain its charge properly, all of

the components that are used in these systems must

perform within specifications. It is important that

the battery, starting, and charging systems be thor-

oughly tested and inspected any time a battery needs

to be charged or replaced. The cause of abnormal bat-

tery discharge, overcharging or early battery failure

must be diagnosed and corrected before a battery is

replaced and before a vehicle is returned to service.

The service information for these systems has been

separated within this service manual to make it eas-

ier to locate the specific information you are seeking.

However, when attempting to diagnose any of these

systems, it is important that you keep their interde-

pendency in mind.

The diagnostic procedures used for the battery,

starting, and charging systems include the most

basic conventional diagnostic methods, to the more

sophisticated On-Board Diagnostics (OBD) built into

the Powertrain Control Module (PCM). Use of an

induction-type milliampere ammeter, a volt/ohmme-

ter, a battery charger, a carbon pile rheostat (load

tester) and a 12-volt test lamp may be required. All

OBD-sensed systems are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for any failure it detects. Refer to

Charging System for the proper charging system on-

board diagnostic test procedures.

MIDTRONICS ELECTRICAL SYSTEM TESTER

The Midtronicstautomotive battery and charging

system tester is designed to help the dealership tech-

nicians diagnose the cause of a defective battery or

charging system. Follow the instruction manual sup-

plied with the tester to properly diagnose a vehicle. If

the instruction manual is not available refer to the

standard procedure in this section, which includes

the directions for using the midtronics electrical sys-

tem tester.

8F - 2 BATTERY SYSTEMKJ

BATTERY SYSTEM (Continued)

Page 335 of 1803

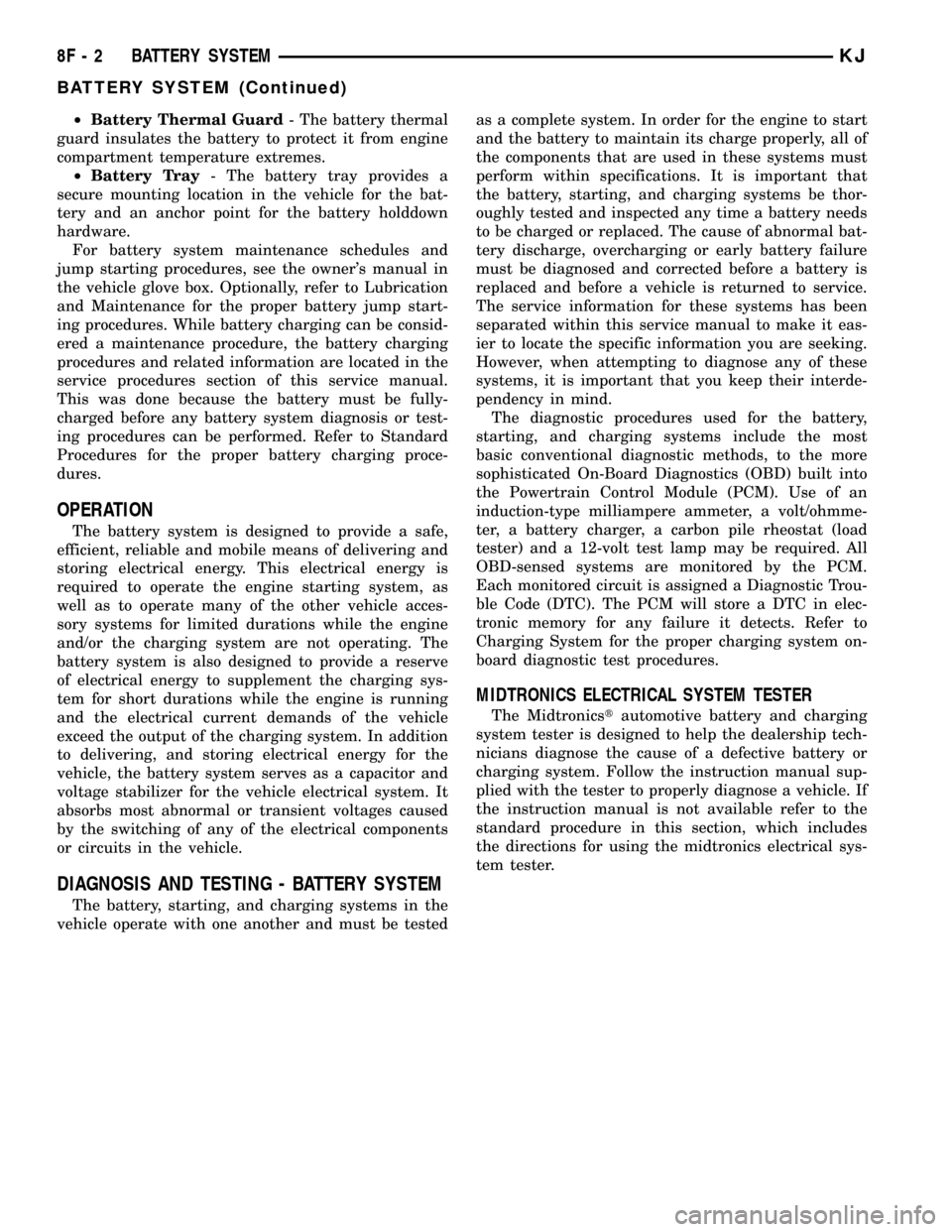

Test the specific gravity of the electrolyte in each

battery cell. If the specific gravity of all cells is above

1.235, but the variation between cells is more than

fifty points (0.050), the battery should be replaced. If

the specific gravity of one or more cells is less than

1.235, charge the battery at a rate of approximately

five amperes. Continue charging the battery until

three consecutive specific gravity tests, taken at one-

hour intervals, are constant. If the cell specific grav-

ity variation is more than fifty points (0.050) at the

end of the charge period, replace the battery.

When the specific gravity of all cells is above 1.235,

and the cell variation is less than fifty points (0.050),

the battery may be load tested to determine its

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures.

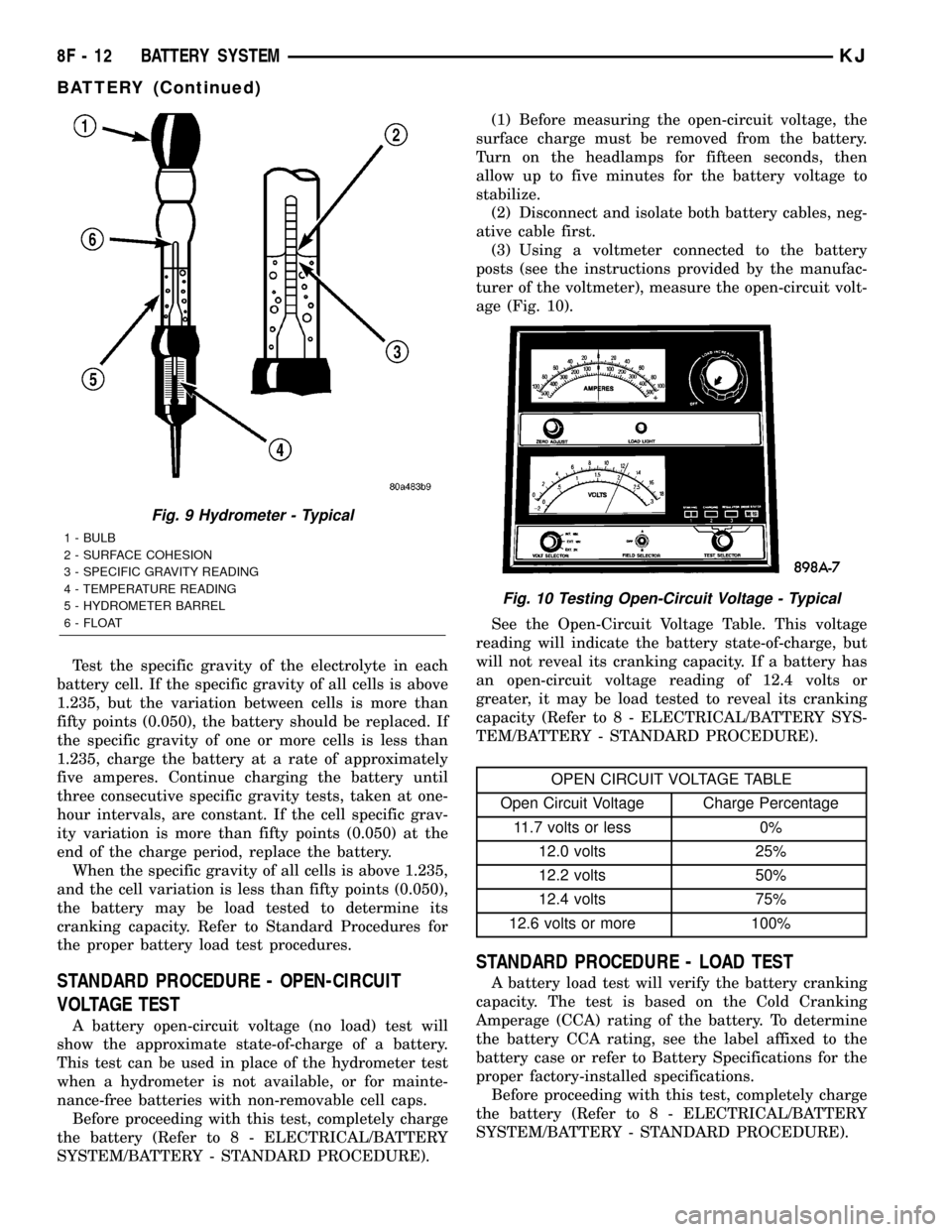

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST

A battery open-circuit voltage (no load) test will

show the approximate state-of-charge of a battery.

This test can be used in place of the hydrometer test

when a hydrometer is not available, or for mainte-

nance-free batteries with non-removable cell caps.

Before proceeding with this test, completely charge

the battery (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE).(1) Before measuring the open-circuit voltage, the

surface charge must be removed from the battery.

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, neg-

ative cable first.

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 10).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE).

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

STANDARD PROCEDURE - LOAD TEST

A battery load test will verify the battery cranking

capacity. The test is based on the Cold Cranking

Amperage (CCA) rating of the battery. To determine

the battery CCA rating, see the label affixed to the

battery case or refer to Battery Specifications for the

proper factory-installed specifications.

Before proceeding with this test, completely charge

the battery (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE).

Fig. 9 Hydrometer - Typical

1 - BULB

2 - SURFACE COHESION

3 - SPECIFIC GRAVITY READING

4 - TEMPERATURE READING

5 - HYDROMETER BARREL

6 - FLOAT

Fig. 10 Testing Open-Circuit Voltage - Typical

8F - 12 BATTERY SYSTEMKJ

BATTERY (Continued)

Page 338 of 1803

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect the lamp wire harness

connector or remove the lamp bulb.

(3) Disconnect the battery negative cable.

(4) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.

(5) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Power Distribution Center (PDC) and

then in the Junction Block (JB), one at a time until

the amperage reading becomes very low, or nonexist-

ent. Refer to the appropriate wiring information in

this service manual for complete PDC and JB fuse,

circuit breaker, and circuit identification. This will

isolate each circuit and identify the circuit that is the

source of the high-amperage IOD. If the amperage

reading remains high after removing and replacing

each fuse and circuit breaker, disconnect the wire

harness from the generator. If the amperage reading

now becomes very low or nonexistent, refer to Charg-

ing System for the proper charging system diagnosis

and testing procedures. After the high-amperage IOD

has been corrected, switch the multi-meter to pro-

gressively lower amperage scales and, if necessary,

repeat the fuse and circuit breaker remove-and-re-

place process to identify and correct all sources of

excessive IOD. It is now safe to select the lowest mil-

liampere scale of the multi-meter to check the low-

amperage IOD.

CAUTION: Do not open any doors, or turn on any

electrical accessories with the lowest milliampere

scale selected, or the multi-meter may be damaged.

(6) Observe the multi-meter reading. The low-am-

perage IOD should not exceed thirty-five milliam-

peres (0.035 ampere). If the current draw exceeds

thirty-five milliamperes, isolate each circuit using the

fuse and circuit breaker remove-and-replace processin Step 5. The multi-meter reading will drop to

within the acceptable limit when the source of the

excessive current draw is disconnected. Repair this

circuit as required; whether a wiring short, incorrect

switch adjustment, or a component failure is at fault.

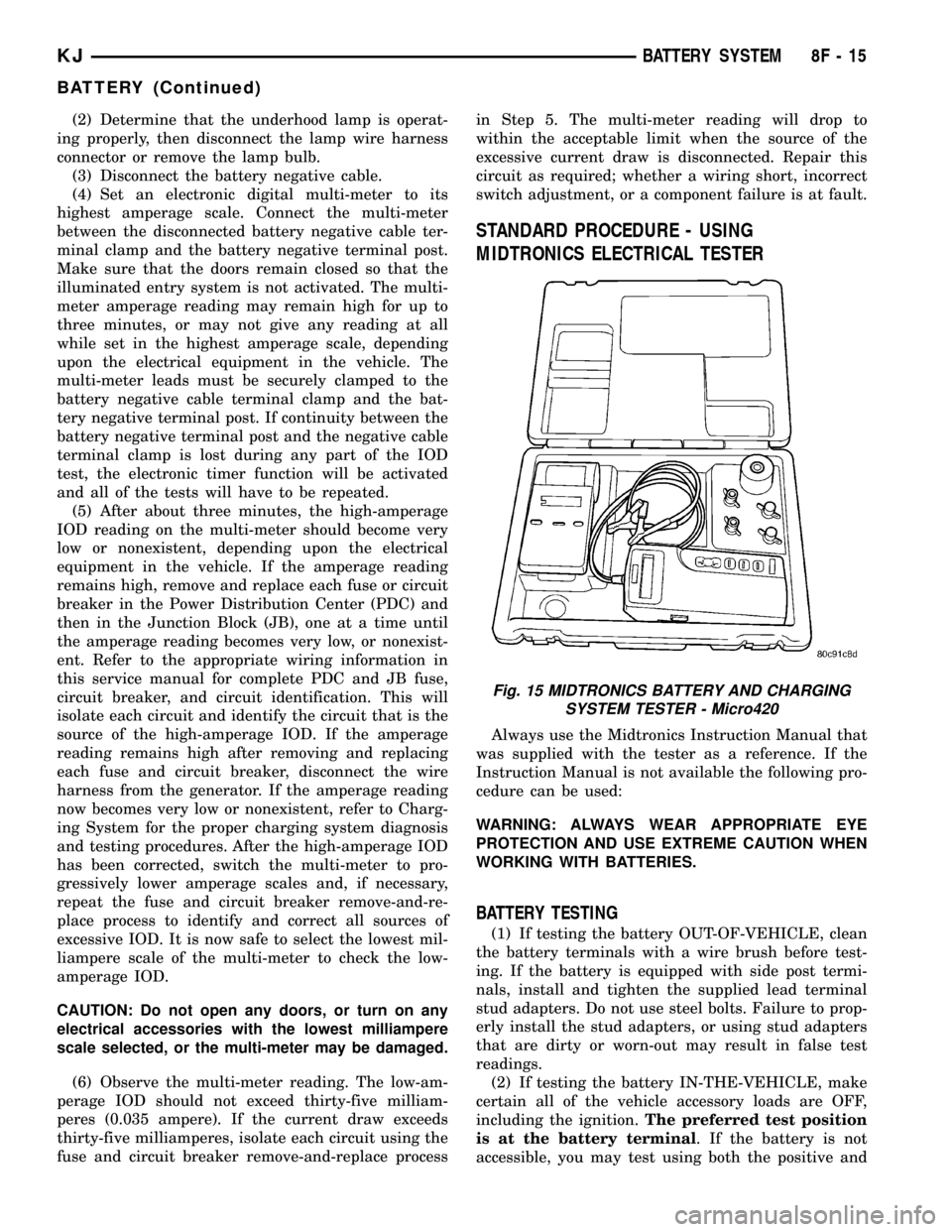

STANDARD PROCEDURE - USING

MIDTRONICS ELECTRICAL TESTER

Always use the Midtronics Instruction Manual that

was supplied with the tester as a reference. If the

Instruction Manual is not available the following pro-

cedure can be used:

WARNING: ALWAYS WEAR APPROPRIATE EYE

PROTECTION AND USE EXTREME CAUTION WHEN

WORKING WITH BATTERIES.

BATTERY TESTING

(1) If testing the battery OUT-OF-VEHICLE, clean

the battery terminals with a wire brush before test-

ing. If the battery is equipped with side post termi-

nals, install and tighten the supplied lead terminal

stud adapters. Do not use steel bolts. Failure to prop-

erly install the stud adapters, or using stud adapters

that are dirty or worn-out may result in false test

readings.

(2) If testing the battery IN-THE-VEHICLE, make

certain all of the vehicle accessory loads are OFF,

including the ignition.The preferred test position

is at the battery terminal. If the battery is not

accessible, you may test using both the positive and

Fig. 15 MIDTRONICS BATTERY AND CHARGING

SYSTEM TESTER - Micro420

KJBATTERY SYSTEM 8F - 15

BATTERY (Continued)

Page 340 of 1803

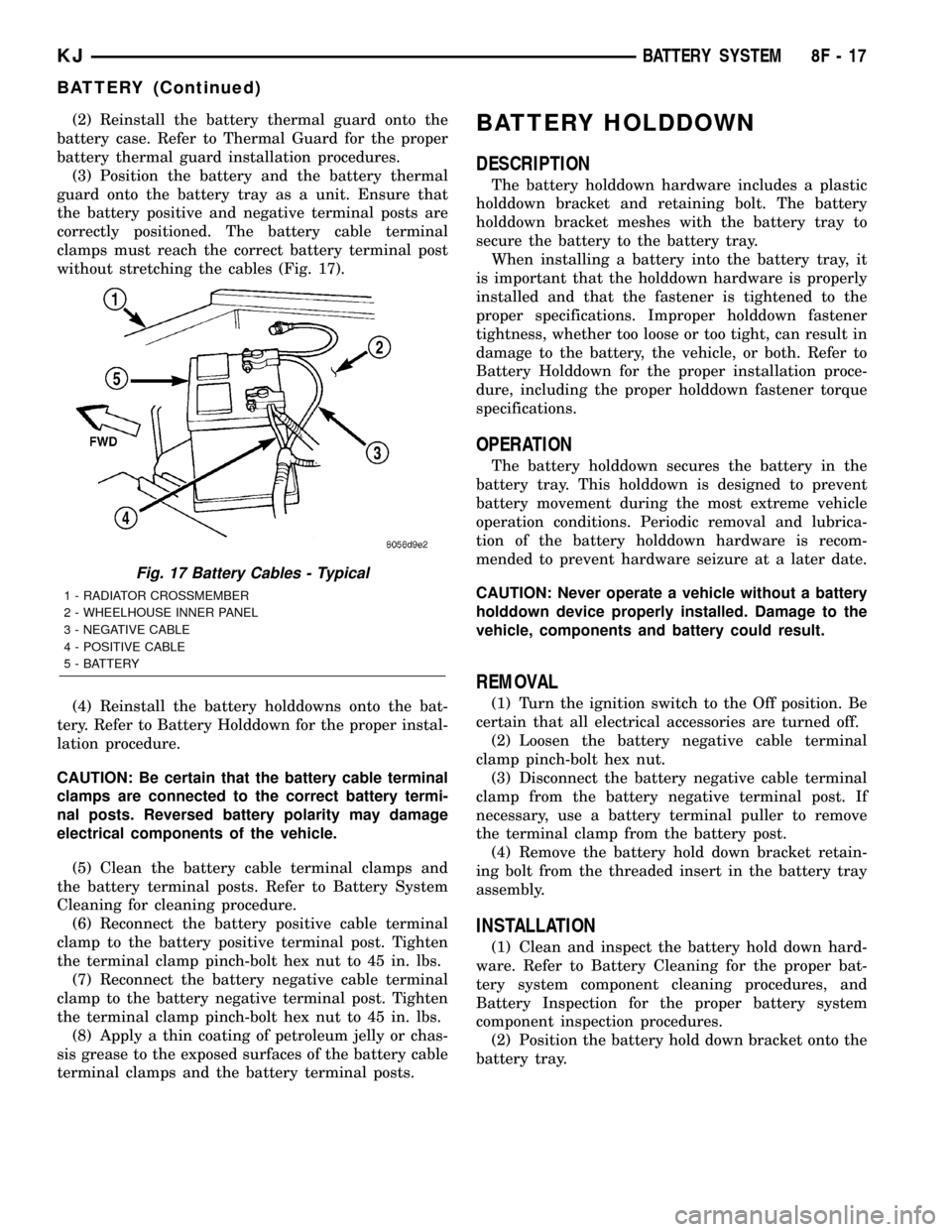

(2) Reinstall the battery thermal guard onto the

battery case. Refer to Thermal Guard for the proper

battery thermal guard installation procedures.

(3) Position the battery and the battery thermal

guard onto the battery tray as a unit. Ensure that

the battery positive and negative terminal posts are

correctly positioned. The battery cable terminal

clamps must reach the correct battery terminal post

without stretching the cables (Fig. 17).

(4) Reinstall the battery holddowns onto the bat-

tery. Refer to Battery Holddown for the proper instal-

lation procedure.

CAUTION: Be certain that the battery cable terminal

clamps are connected to the correct battery termi-

nal posts. Reversed battery polarity may damage

electrical components of the vehicle.

(5) Clean the battery cable terminal clamps and

the battery terminal posts. Refer to Battery System

Cleaning for cleaning procedure.

(6) Reconnect the battery positive cable terminal

clamp to the battery positive terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 45 in. lbs.

(7) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 45 in. lbs.

(8) Apply a thin coating of petroleum jelly or chas-

sis grease to the exposed surfaces of the battery cable

terminal clamps and the battery terminal posts.BATTERY HOLDDOWN

DESCRIPTION

The battery holddown hardware includes a plastic

holddown bracket and retaining bolt. The battery

holddown bracket meshes with the battery tray to

secure the battery to the battery tray.

When installing a battery into the battery tray, it

is important that the holddown hardware is properly

installed and that the fastener is tightened to the

proper specifications. Improper holddown fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle, or both. Refer to

Battery Holddown for the proper installation proce-

dure, including the proper holddown fastener torque

specifications.

OPERATION

The battery holddown secures the battery in the

battery tray. This holddown is designed to prevent

battery movement during the most extreme vehicle

operation conditions. Periodic removal and lubrica-

tion of the battery holddown hardware is recom-

mended to prevent hardware seizure at a later date.

CAUTION: Never operate a vehicle without a battery

holddown device properly installed. Damage to the

vehicle, components and battery could result.

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post.

(4) Remove the battery hold down bracket retain-

ing bolt from the threaded insert in the battery tray

assembly.

INSTALLATION

(1) Clean and inspect the battery hold down hard-

ware. Refer to Battery Cleaning for the proper bat-

tery system component cleaning procedures, and

Battery Inspection for the proper battery system

component inspection procedures.

(2) Position the battery hold down bracket onto the

battery tray.

Fig. 17 Battery Cables - Typical

1 - RADIATOR CROSSMEMBER

2 - WHEELHOUSE INNER PANEL

3 - NEGATIVE CABLE

4 - POSITIVE CABLE

5 - BATTERY

KJBATTERY SYSTEM 8F - 17

BATTERY (Continued)

Page 341 of 1803

(3) Install and tighten the battery hold down

bracket retaining bolt. Tighten the bolt to 4 N´m (20

in. lbs.).

(4) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 8.4 N´m (75

in. lbs.).

BATTERY CABLES

DESCRIPTION

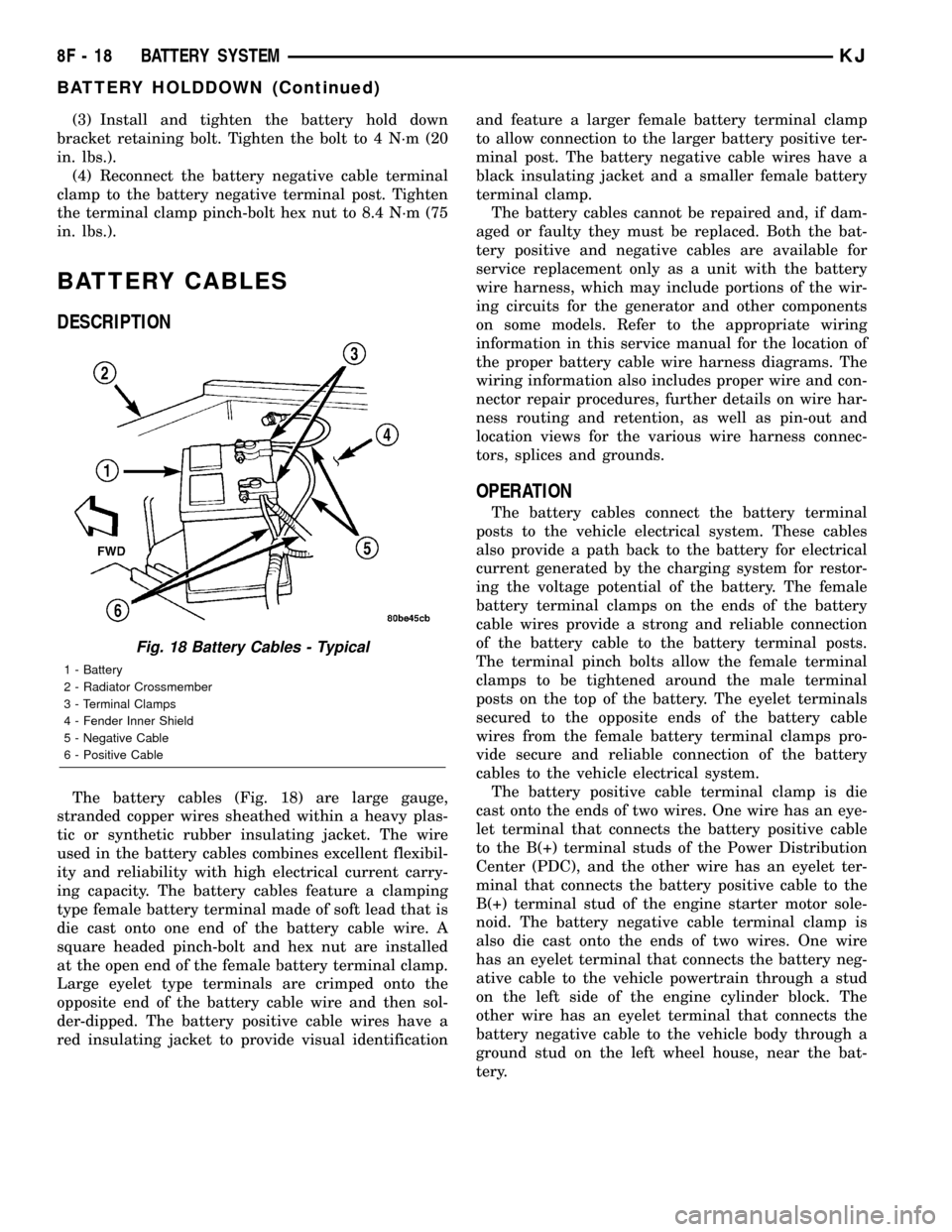

The battery cables (Fig. 18) are large gauge,

stranded copper wires sheathed within a heavy plas-

tic or synthetic rubber insulating jacket. The wire

used in the battery cables combines excellent flexibil-

ity and reliability with high electrical current carry-

ing capacity. The battery cables feature a clamping

type female battery terminal made of soft lead that is

die cast onto one end of the battery cable wire. A

square headed pinch-bolt and hex nut are installed

at the open end of the female battery terminal clamp.

Large eyelet type terminals are crimped onto the

opposite end of the battery cable wire and then sol-

der-dipped. The battery positive cable wires have a

red insulating jacket to provide visual identificationand feature a larger female battery terminal clamp

to allow connection to the larger battery positive ter-

minal post. The battery negative cable wires have a

black insulating jacket and a smaller female battery

terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer to the appropriate wiring

information in this service manual for the location of

the proper battery cable wire harness diagrams. The

wiring information also includes proper wire and con-

nector repair procedures, further details on wire har-

ness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is die

cast onto the ends of two wires. One wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal studs of the Power Distribution

Center (PDC), and the other wire has an eyelet ter-

minal that connects the battery positive cable to the

B(+) terminal stud of the engine starter motor sole-

noid. The battery negative cable terminal clamp is

also die cast onto the ends of two wires. One wire

has an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the left side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground stud on the left wheel house, near the bat-

tery.

Fig. 18 Battery Cables - Typical

1 - Battery

2 - Radiator Crossmember

3 - Terminal Clamps

4 - Fender Inner Shield

5 - Negative Cable

6 - Positive Cable

8F - 18 BATTERY SYSTEMKJ

BATTERY HOLDDOWN (Continued)