eco JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 329 of 1803

(4) Clean the battery thermal guard with a sodium

bicarbonate (baking soda) and warm water cleaning

solution using a stiff bristle parts cleaning brush to

remove any acid film.

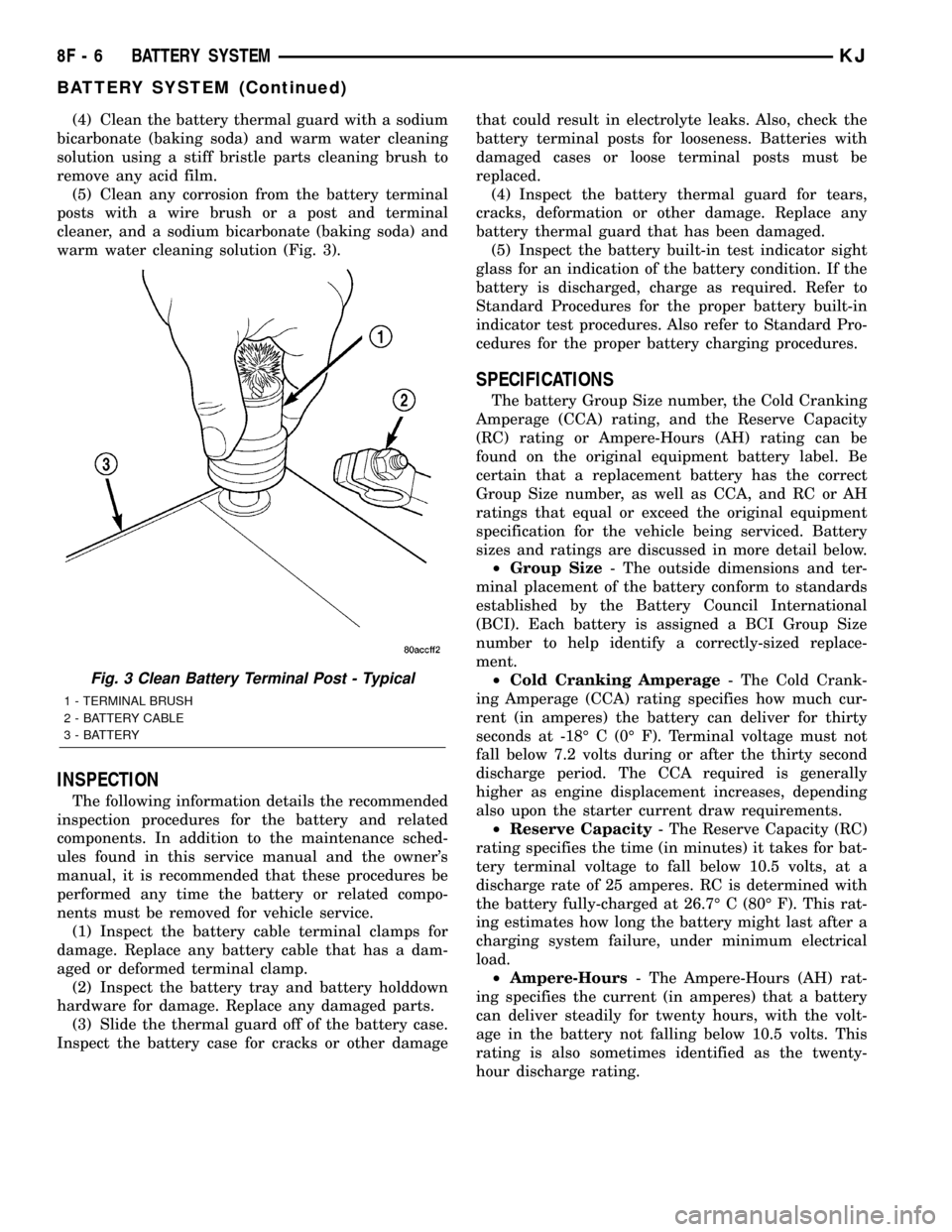

(5) Clean any corrosion from the battery terminal

posts with a wire brush or a post and terminal

cleaner, and a sodium bicarbonate (baking soda) and

warm water cleaning solution (Fig. 3).

INSPECTION

The following information details the recommended

inspection procedures for the battery and related

components. In addition to the maintenance sched-

ules found in this service manual and the owner's

manual, it is recommended that these procedures be

performed any time the battery or related compo-

nents must be removed for vehicle service.

(1) Inspect the battery cable terminal clamps for

damage. Replace any battery cable that has a dam-

aged or deformed terminal clamp.

(2) Inspect the battery tray and battery holddown

hardware for damage. Replace any damaged parts.

(3) Slide the thermal guard off of the battery case.

Inspect the battery case for cracks or other damagethat could result in electrolyte leaks. Also, check the

battery terminal posts for looseness. Batteries with

damaged cases or loose terminal posts must be

replaced.

(4) Inspect the battery thermal guard for tears,

cracks, deformation or other damage. Replace any

battery thermal guard that has been damaged.

(5) Inspect the battery built-in test indicator sight

glass for an indication of the battery condition. If the

battery is discharged, charge as required. Refer to

Standard Procedures for the proper battery built-in

indicator test procedures. Also refer to Standard Pro-

cedures for the proper battery charging procedures.

SPECIFICATIONS

The battery Group Size number, the Cold Cranking

Amperage (CCA) rating, and the Reserve Capacity

(RC) rating or Ampere-Hours (AH) rating can be

found on the original equipment battery label. Be

certain that a replacement battery has the correct

Group Size number, as well as CCA, and RC or AH

ratings that equal or exceed the original equipment

specification for the vehicle being serviced. Battery

sizes and ratings are discussed in more detail below.

²Group Size- The outside dimensions and ter-

minal placement of the battery conform to standards

established by the Battery Council International

(BCI). Each battery is assigned a BCI Group Size

number to help identify a correctly-sized replace-

ment.

²Cold Cranking Amperage- The Cold Crank-

ing Amperage (CCA) rating specifies how much cur-

rent (in amperes) the battery can deliver for thirty

seconds at -18É C (0É F). Terminal voltage must not

fall below 7.2 volts during or after the thirty second

discharge period. The CCA required is generally

higher as engine displacement increases, depending

also upon the starter current draw requirements.

²Reserve Capacity- The Reserve Capacity (RC)

rating specifies the time (in minutes) it takes for bat-

tery terminal voltage to fall below 10.5 volts, at a

discharge rate of 25 amperes. RC is determined with

the battery fully-charged at 26.7É C (80É F). This rat-

ing estimates how long the battery might last after a

charging system failure, under minimum electrical

load.

²Ampere-Hours- The Ampere-Hours (AH) rat-

ing specifies the current (in amperes) that a battery

can deliver steadily for twenty hours, with the volt-

age in the battery not falling below 10.5 volts. This

rating is also sometimes identified as the twenty-

hour discharge rating.

Fig. 3 Clean Battery Terminal Post - Typical

1 - TERMINAL BRUSH

2 - BATTERY CABLE

3 - BATTERY

8F - 6 BATTERY SYSTEMKJ

BATTERY SYSTEM (Continued)

Page 331 of 1803

battery reduces battery gassing and water loss, at

normal charge and discharge rates. Therefore, the

battery should not require additional water in nor-

mal service. If the electrolyte level in this battery

does become low, water must be added. However,

rapid loss of electrolyte can be caused by an over-

charging condition. Be certain to diagnose the charg-

ing system after replenishing the water in the

battery for a low electrolyte condition and before

returning the vehicle to service. Refer to Charging

System for the proper charging system diagnosis and

testing procedures.

DIAGNOSIS AND TESTING - BATTERY

The battery must be completely charged and the

top, posts and terminal clamps should be properly

cleaned and inspected before diagnostic procedures

are performed. Refer to Battery System Cleaning for

the proper cleaning procedures, and Battery System

Inspection for the proper battery inspection proce-

dures. Refer to Standard Procedures for the proper

battery charging procedures.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS ARE IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

The condition of a battery is determined by two cri-

teria:

²State-Of-Charge- This can be determined by

checking the specific gravity of the battery electrolyte

(built-in indicator test or hydrometer test), or bychecking the battery voltage (open-circuit voltage

test).

²Cranking Capacity- This can be determined

by performing a battery load test, which measures

the ability of the battery to supply high-amperage

current.

First, determine the battery state-of-charge. This

can be done in one of three ways. If the battery has a

built-in test indicator, perform the built-in indicator

test to determine the state-of-charge. If the battery

has no built-in test indicator but does have remov-

able cell caps, perform the hydrometer test to deter-

mine the state-of-charge. If the battery cell caps are

not removable, or a hydrometer is not available, per-

form the open-circuit voltage test to determine the

state-of-charge. Refer to open-circuit voltage test in

the Standard Procedures section of this group.

Second, determine the battery cranking capacity by

performing a load test. The battery must be charged

before proceeding with a load test if:

²The battery built-in test indicator has a black or

dark color visible.

²The temperature corrected specific gravity of the

battery electrolyte is less than 1.235.

²The battery open-circuit voltage is less than 12.4

volts.

A battery that will not accept a charge is faulty,

and must be replaced. Further testing is not

required. A fully-charged battery must be load tested

to determine its cranking capacity. A battery that is

fully-charged, but does not pass the load test, is

faulty and must be replaced.

NOTE: Completely discharged batteries may take

several hours to accept a charge. Refer to Standard

Procedures for the proper battery charging proce-

dures.

A battery is fully-charged when:

²All battery cells are gassing freely during charg-

ing.

²A green color is visible in the sight glass of the

battery built-in test indicator.

²Three corrected specific gravity tests, taken at

one-hour intervals, indicate no increase in the spe-

cific gravity of the battery electrolyte.

²Open-circuit voltage of the battery is 12.4 volts

or greater.

STANDARD PROCEDURE

STANDARD PROCEDURE - BATTERY

CHARGING

Battery charging can be performed fast or slow, it

terms of time.Slowbattery charging is the best

means of restoring a battery to full potential. Fast

8F - 8 BATTERY SYSTEMKJ

BATTERY (Continued)

Page 334 of 1803

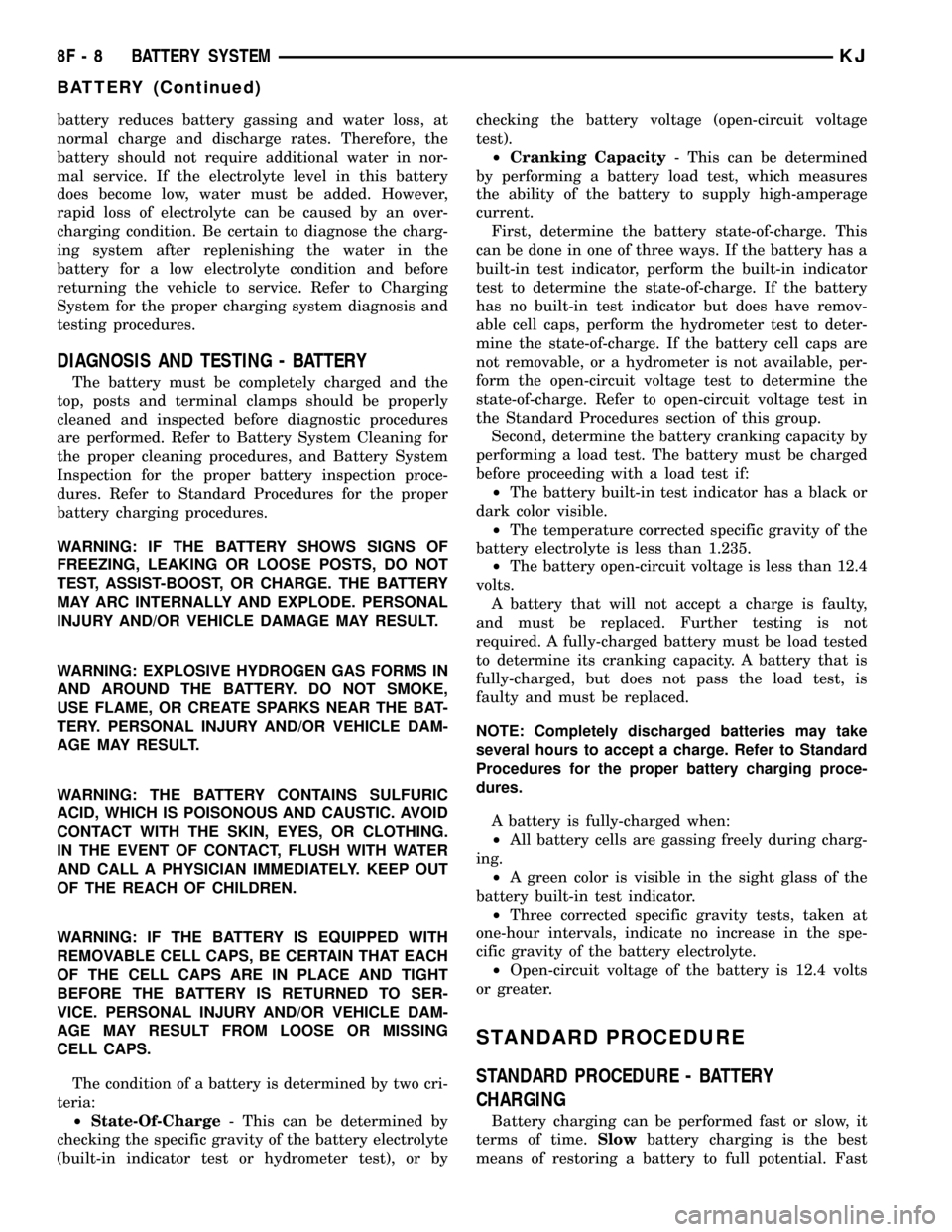

To read the built-in indicator, look into the sight

glass and note the color of the indication (Fig. 8). The

battery condition that each color indicates is

described in the following list:

²Green- Indicates 75% to 100% battery state-of-

charge. The battery is adequately charged for further

testing or return to service. If the starter will not

crank for a minimum of fifteen seconds with a fully-

charged battery, the battery must be load tested.

Refer to Standard Procedures for the proper battery

load test procedures.

²Black or Dark- Indicates 0% to 75% battery

state-of-charge. The battery is inadequately charged

and must be charged until a green indication is visi-

ble in the sight glass (12.4 volts or more), before the

battery is tested further or returned to service. Refer

to Standard Procedures for the proper battery charg-

ing procedures. Also refer to Diagnosis and Testing

for more information on the possible causes of the

discharged battery condition.

²Clear or Bright- Indicates a low battery elec-

trolyte level. The electrolyte level in the battery is

below the built-in indicator. A maintenance-free bat-

tery with non-removable cell caps must be replaced if

the electrolyte level is low. Water must be added to a

low-maintenance battery with removable cell caps

before it is charged. Refer to Standard Procedures for

the proper battery filling procedures. A low electro-

lyte level may be caused by an overcharging condi-

tion. Refer to Charging System for the proper

charging system diagnosis and testing procedures.

STANDARD PROCEDURE - HYDROMETER TEST

The hydrometer test reveals the battery state-of-

charge by measuring the specific gravity of the elec-

trolyte.This test cannot be performed on

maintenance-free batteries with non-removable

cell caps.If the battery has non-removable cell caps,

refer to Diagnosis and Testing for alternate methods

of determining the battery state-of-charge.

Specific gravity is a comparison of the density of

the battery electrolyte to the density of pure water.Pure water has a specific gravity of 1.000, and sulfu-

ric acid has a specific gravity of 1.835. Sulfuric acid

makes up approximately 35% of the battery electro-

lyte by weight, or 24% by volume. In a fully-charged

battery the electrolyte will have a temperature-cor-

rected specific gravity of 1.260 to 1.290. However, a

specific gravity of 1.235 or above is satisfactory for

the battery to be load tested and/or returned to ser-

vice.

Before testing, visually inspect the battery for any

damage (a cracked case or cover, loose posts, etc.)

that would cause the battery to be faulty. Then

remove the battery cell caps and check the electrolyte

level. Add distilled water if the electrolyte level is

below the top of the battery plates. Refer to Battery

System Cleaning for the proper battery inspection

procedures.

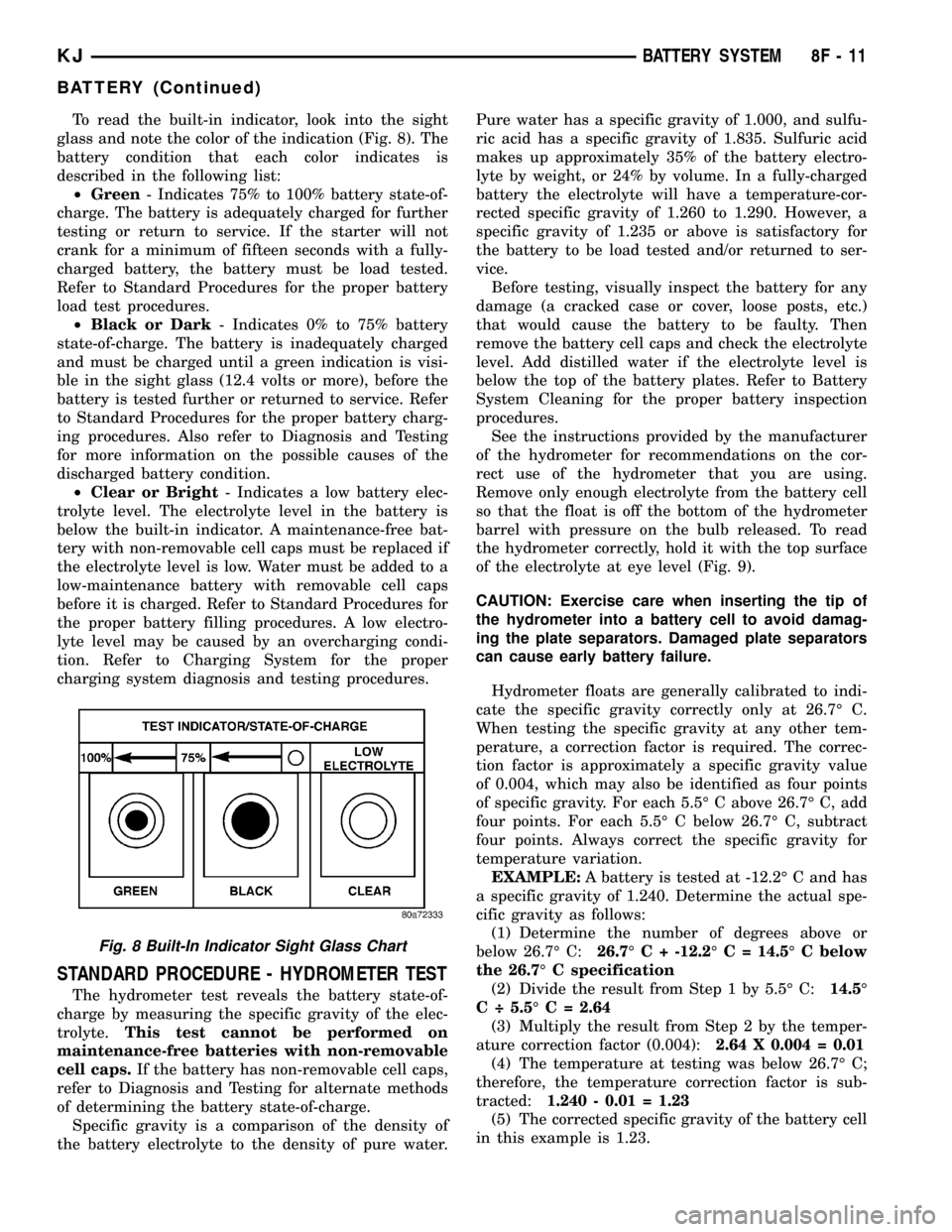

See the instructions provided by the manufacturer

of the hydrometer for recommendations on the cor-

rect use of the hydrometer that you are using.

Remove only enough electrolyte from the battery cell

so that the float is off the bottom of the hydrometer

barrel with pressure on the bulb released. To read

the hydrometer correctly, hold it with the top surface

of the electrolyte at eye level (Fig. 9).

CAUTION: Exercise care when inserting the tip of

the hydrometer into a battery cell to avoid damag-

ing the plate separators. Damaged plate separators

can cause early battery failure.

Hydrometer floats are generally calibrated to indi-

cate the specific gravity correctly only at 26.7É C.

When testing the specific gravity at any other tem-

perature, a correction factor is required. The correc-

tion factor is approximately a specific gravity value

of 0.004, which may also be identified as four points

of specific gravity. For each 5.5É C above 26.7É C, add

four points. For each 5.5É C below 26.7É C, subtract

four points. Always correct the specific gravity for

temperature variation.

EXAMPLE:A battery is tested at -12.2É C and has

a specific gravity of 1.240. Determine the actual spe-

cific gravity as follows:

(1) Determine the number of degrees above or

below 26.7É C:26.7É C + -12.2É C = 14.5É C below

the 26.7É C specification

(2) Divide the result from Step 1 by 5.5É C:14.5É

C ÷ 5.5É C = 2.64

(3) Multiply the result from Step 2 by the temper-

ature correction factor (0.004):2.64 X 0.004 = 0.01

(4) The temperature at testing was below 26.7É C;

therefore, the temperature correction factor is sub-

tracted:1.240 - 0.01 = 1.23

(5) The corrected specific gravity of the battery cell

in this example is 1.23.

Fig. 8 Built-In Indicator Sight Glass Chart

KJBATTERY SYSTEM 8F - 11

BATTERY (Continued)

Page 335 of 1803

Test the specific gravity of the electrolyte in each

battery cell. If the specific gravity of all cells is above

1.235, but the variation between cells is more than

fifty points (0.050), the battery should be replaced. If

the specific gravity of one or more cells is less than

1.235, charge the battery at a rate of approximately

five amperes. Continue charging the battery until

three consecutive specific gravity tests, taken at one-

hour intervals, are constant. If the cell specific grav-

ity variation is more than fifty points (0.050) at the

end of the charge period, replace the battery.

When the specific gravity of all cells is above 1.235,

and the cell variation is less than fifty points (0.050),

the battery may be load tested to determine its

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures.

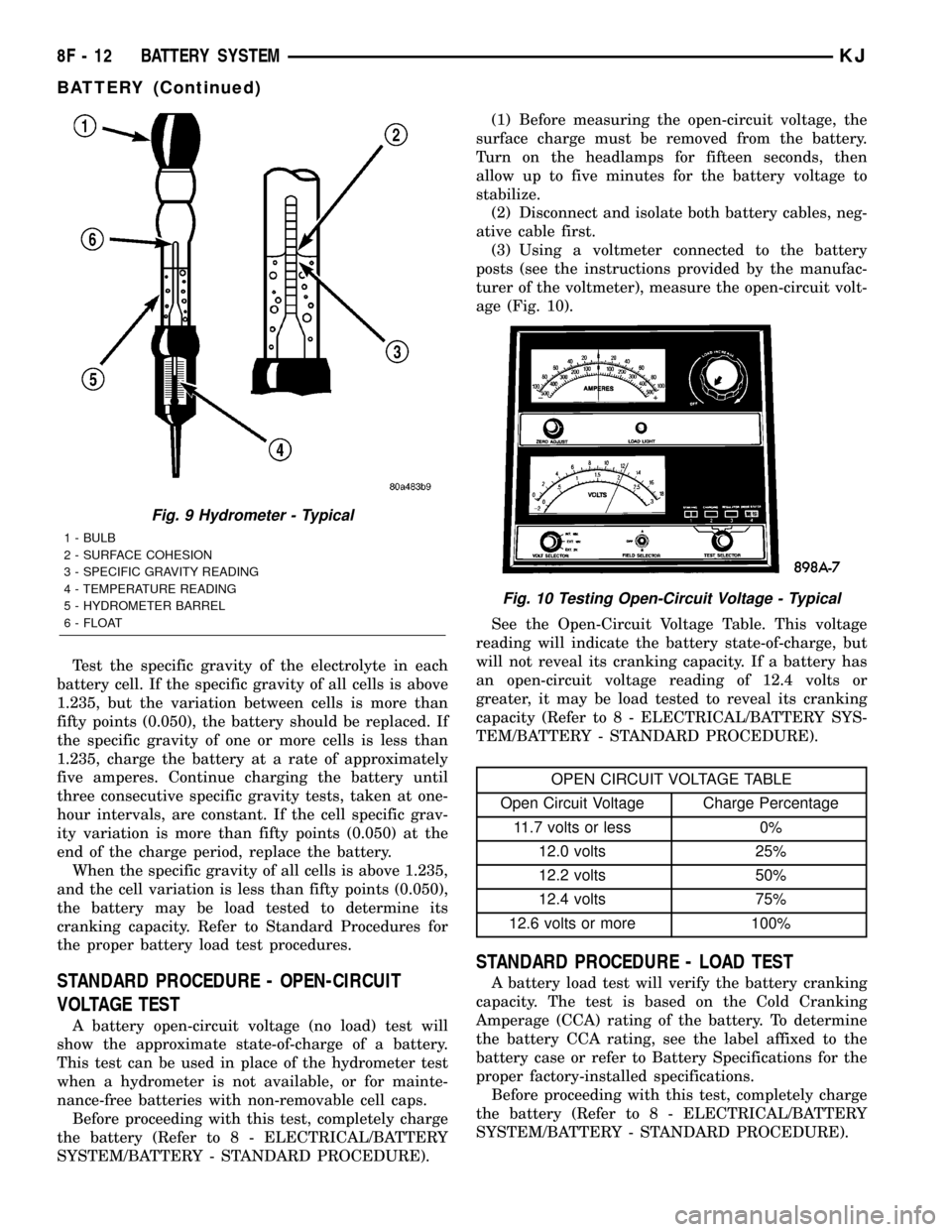

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST

A battery open-circuit voltage (no load) test will

show the approximate state-of-charge of a battery.

This test can be used in place of the hydrometer test

when a hydrometer is not available, or for mainte-

nance-free batteries with non-removable cell caps.

Before proceeding with this test, completely charge

the battery (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE).(1) Before measuring the open-circuit voltage, the

surface charge must be removed from the battery.

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, neg-

ative cable first.

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 10).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE).

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

STANDARD PROCEDURE - LOAD TEST

A battery load test will verify the battery cranking

capacity. The test is based on the Cold Cranking

Amperage (CCA) rating of the battery. To determine

the battery CCA rating, see the label affixed to the

battery case or refer to Battery Specifications for the

proper factory-installed specifications.

Before proceeding with this test, completely charge

the battery (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE).

Fig. 9 Hydrometer - Typical

1 - BULB

2 - SURFACE COHESION

3 - SPECIFIC GRAVITY READING

4 - TEMPERATURE READING

5 - HYDROMETER BARREL

6 - FLOAT

Fig. 10 Testing Open-Circuit Voltage - Typical

8F - 12 BATTERY SYSTEMKJ

BATTERY (Continued)

Page 336 of 1803

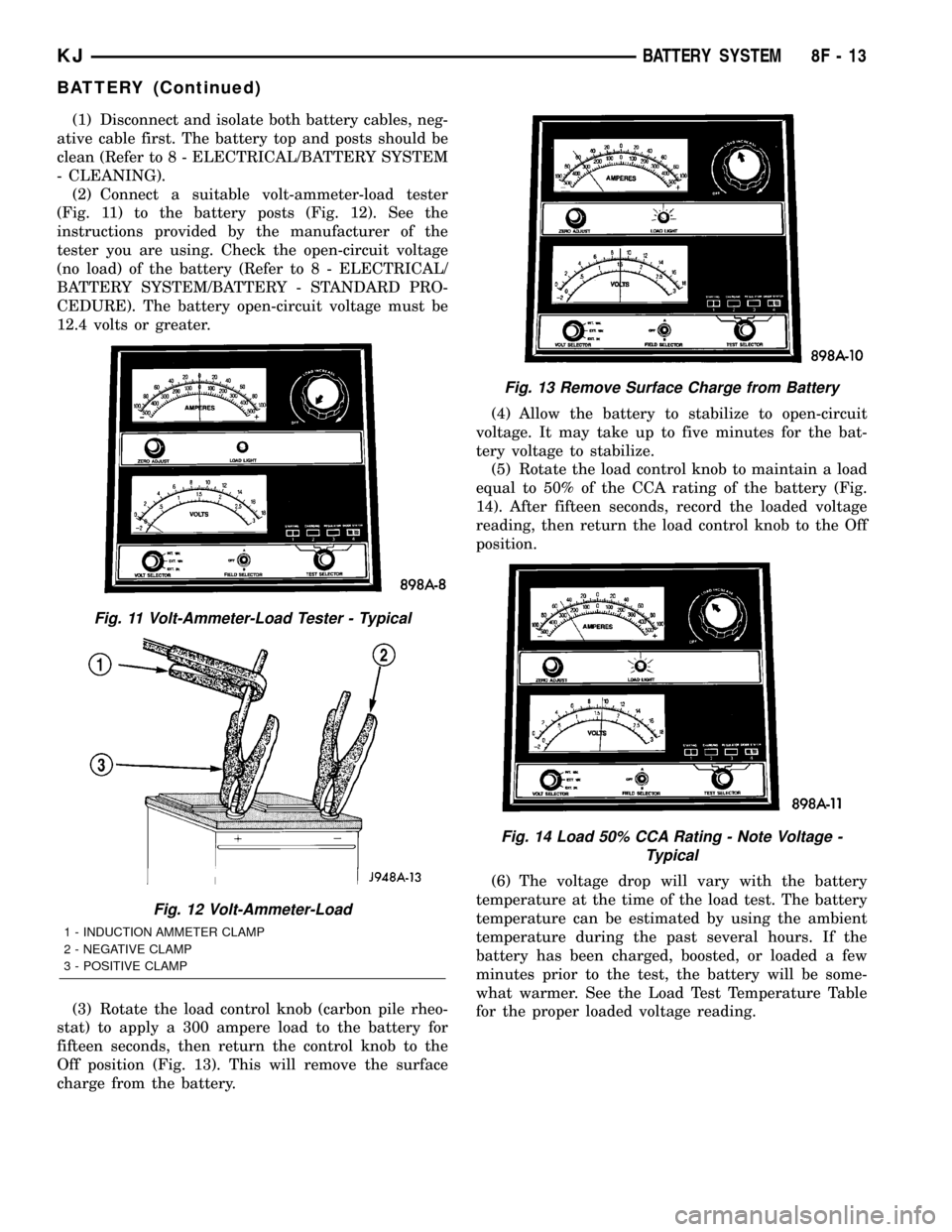

(1) Disconnect and isolate both battery cables, neg-

ative cable first. The battery top and posts should be

clean (Refer to 8 - ELECTRICAL/BATTERY SYSTEM

- CLEANING).

(2) Connect a suitable volt-ammeter-load tester

(Fig. 11) to the battery posts (Fig. 12). See the

instructions provided by the manufacturer of the

tester you are using. Check the open-circuit voltage

(no load) of the battery (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - STANDARD PRO-

CEDURE). The battery open-circuit voltage must be

12.4 volts or greater.

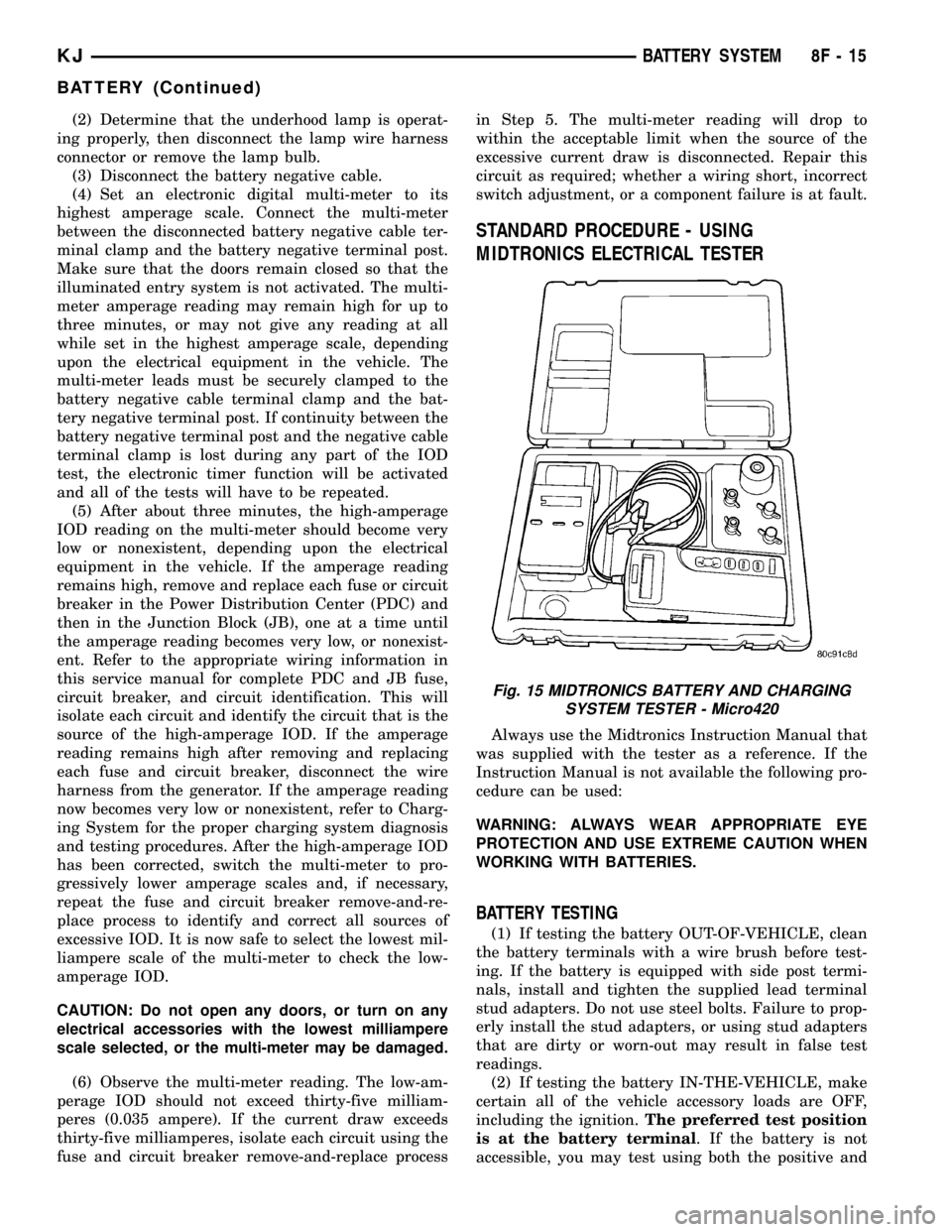

(3) Rotate the load control knob (carbon pile rheo-

stat) to apply a 300 ampere load to the battery for

fifteen seconds, then return the control knob to the

Off position (Fig. 13). This will remove the surface

charge from the battery.(4) Allow the battery to stabilize to open-circuit

voltage. It may take up to five minutes for the bat-

tery voltage to stabilize.

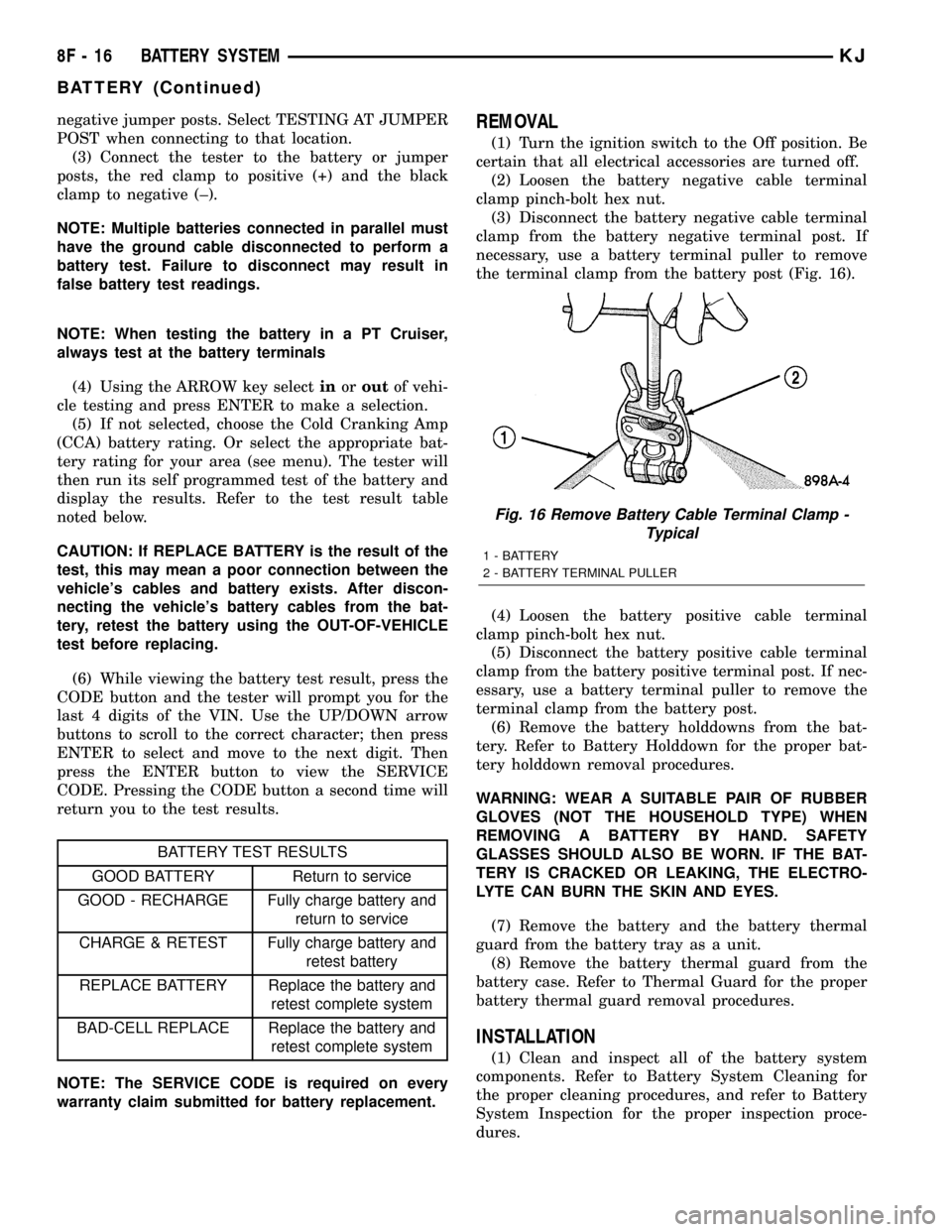

(5) Rotate the load control knob to maintain a load

equal to 50% of the CCA rating of the battery (Fig.

14). After fifteen seconds, record the loaded voltage

reading, then return the load control knob to the Off

position.

(6) The voltage drop will vary with the battery

temperature at the time of the load test. The battery

temperature can be estimated by using the ambient

temperature during the past several hours. If the

battery has been charged, boosted, or loaded a few

minutes prior to the test, the battery will be some-

what warmer. See the Load Test Temperature Table

for the proper loaded voltage reading.

Fig. 11 Volt-Ammeter-Load Tester - Typical

Fig. 12 Volt-Ammeter-Load

1 - INDUCTION AMMETER CLAMP

2 - NEGATIVE CLAMP

3 - POSITIVE CLAMP

Fig. 13 Remove Surface Charge from Battery

Fig. 14 Load 50% CCA Rating - Note Voltage -

Typical

KJBATTERY SYSTEM 8F - 13

BATTERY (Continued)

Page 338 of 1803

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect the lamp wire harness

connector or remove the lamp bulb.

(3) Disconnect the battery negative cable.

(4) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.

(5) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Power Distribution Center (PDC) and

then in the Junction Block (JB), one at a time until

the amperage reading becomes very low, or nonexist-

ent. Refer to the appropriate wiring information in

this service manual for complete PDC and JB fuse,

circuit breaker, and circuit identification. This will

isolate each circuit and identify the circuit that is the

source of the high-amperage IOD. If the amperage

reading remains high after removing and replacing

each fuse and circuit breaker, disconnect the wire

harness from the generator. If the amperage reading

now becomes very low or nonexistent, refer to Charg-

ing System for the proper charging system diagnosis

and testing procedures. After the high-amperage IOD

has been corrected, switch the multi-meter to pro-

gressively lower amperage scales and, if necessary,

repeat the fuse and circuit breaker remove-and-re-

place process to identify and correct all sources of

excessive IOD. It is now safe to select the lowest mil-

liampere scale of the multi-meter to check the low-

amperage IOD.

CAUTION: Do not open any doors, or turn on any

electrical accessories with the lowest milliampere

scale selected, or the multi-meter may be damaged.

(6) Observe the multi-meter reading. The low-am-

perage IOD should not exceed thirty-five milliam-

peres (0.035 ampere). If the current draw exceeds

thirty-five milliamperes, isolate each circuit using the

fuse and circuit breaker remove-and-replace processin Step 5. The multi-meter reading will drop to

within the acceptable limit when the source of the

excessive current draw is disconnected. Repair this

circuit as required; whether a wiring short, incorrect

switch adjustment, or a component failure is at fault.

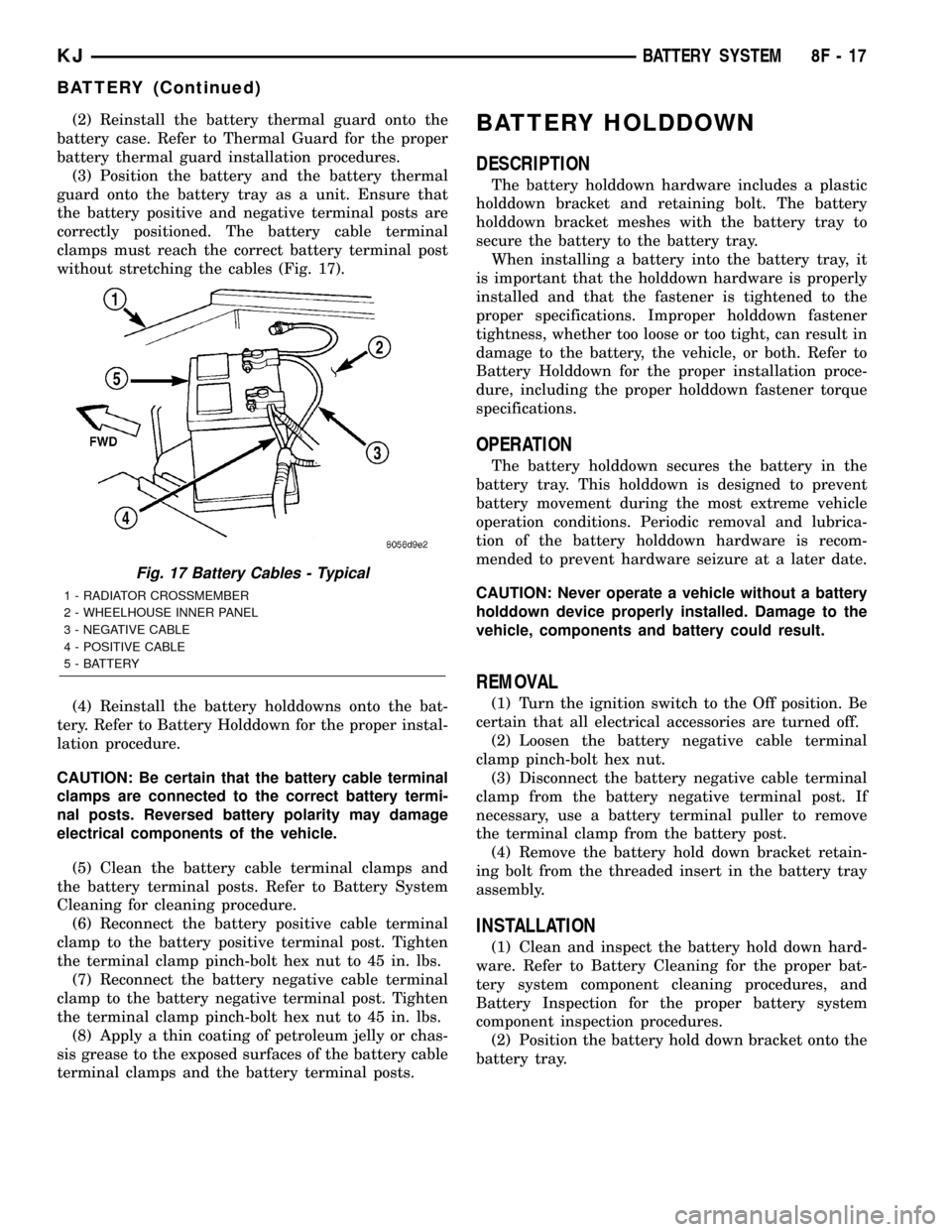

STANDARD PROCEDURE - USING

MIDTRONICS ELECTRICAL TESTER

Always use the Midtronics Instruction Manual that

was supplied with the tester as a reference. If the

Instruction Manual is not available the following pro-

cedure can be used:

WARNING: ALWAYS WEAR APPROPRIATE EYE

PROTECTION AND USE EXTREME CAUTION WHEN

WORKING WITH BATTERIES.

BATTERY TESTING

(1) If testing the battery OUT-OF-VEHICLE, clean

the battery terminals with a wire brush before test-

ing. If the battery is equipped with side post termi-

nals, install and tighten the supplied lead terminal

stud adapters. Do not use steel bolts. Failure to prop-

erly install the stud adapters, or using stud adapters

that are dirty or worn-out may result in false test

readings.

(2) If testing the battery IN-THE-VEHICLE, make

certain all of the vehicle accessory loads are OFF,

including the ignition.The preferred test position

is at the battery terminal. If the battery is not

accessible, you may test using both the positive and

Fig. 15 MIDTRONICS BATTERY AND CHARGING

SYSTEM TESTER - Micro420

KJBATTERY SYSTEM 8F - 15

BATTERY (Continued)

Page 339 of 1803

negative jumper posts. Select TESTING AT JUMPER

POST when connecting to that location.

(3) Connect the tester to the battery or jumper

posts, the red clamp to positive (+) and the black

clamp to negative (±).

NOTE: Multiple batteries connected in parallel must

have the ground cable disconnected to perform a

battery test. Failure to disconnect may result in

false battery test readings.

NOTE: When testing the battery in a PT Cruiser,

always test at the battery terminals

(4) Using the ARROW key selectinoroutof vehi-

cle testing and press ENTER to make a selection.

(5) If not selected, choose the Cold Cranking Amp

(CCA) battery rating. Or select the appropriate bat-

tery rating for your area (see menu). The tester will

then run its self programmed test of the battery and

display the results. Refer to the test result table

noted below.

CAUTION: If REPLACE BATTERY is the result of the

test, this may mean a poor connection between the

vehicle's cables and battery exists. After discon-

necting the vehicle's battery cables from the bat-

tery, retest the battery using the OUT-OF-VEHICLE

test before replacing.

(6) While viewing the battery test result, press the

CODE button and the tester will prompt you for the

last 4 digits of the VIN. Use the UP/DOWN arrow

buttons to scroll to the correct character; then press

ENTER to select and move to the next digit. Then

press the ENTER button to view the SERVICE

CODE. Pressing the CODE button a second time will

return you to the test results.

BATTERY TEST RESULTS

GOOD BATTERY Return to service

GOOD - RECHARGE Fully charge battery and

return to service

CHARGE & RETEST Fully charge battery and

retest battery

REPLACE BATTERY Replace the battery and

retest complete system

BAD-CELL REPLACE Replace the battery and

retest complete system

NOTE: The SERVICE CODE is required on every

warranty claim submitted for battery replacement.

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post (Fig. 16).

(4) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post.

(6) Remove the battery holddowns from the bat-

tery. Refer to Battery Holddown for the proper bat-

tery holddown removal procedures.

WARNING: WEAR A SUITABLE PAIR OF RUBBER

GLOVES (NOT THE HOUSEHOLD TYPE) WHEN

REMOVING A BATTERY BY HAND. SAFETY

GLASSES SHOULD ALSO BE WORN. IF THE BAT-

TERY IS CRACKED OR LEAKING, THE ELECTRO-

LYTE CAN BURN THE SKIN AND EYES.

(7) Remove the battery and the battery thermal

guard from the battery tray as a unit.

(8) Remove the battery thermal guard from the

battery case. Refer to Thermal Guard for the proper

battery thermal guard removal procedures.

INSTALLATION

(1) Clean and inspect all of the battery system

components. Refer to Battery System Cleaning for

the proper cleaning procedures, and refer to Battery

System Inspection for the proper inspection proce-

dures.

Fig. 16 Remove Battery Cable Terminal Clamp -

Typical

1 - BATTERY

2 - BATTERY TERMINAL PULLER

8F - 16 BATTERY SYSTEMKJ

BATTERY (Continued)

Page 340 of 1803

(2) Reinstall the battery thermal guard onto the

battery case. Refer to Thermal Guard for the proper

battery thermal guard installation procedures.

(3) Position the battery and the battery thermal

guard onto the battery tray as a unit. Ensure that

the battery positive and negative terminal posts are

correctly positioned. The battery cable terminal

clamps must reach the correct battery terminal post

without stretching the cables (Fig. 17).

(4) Reinstall the battery holddowns onto the bat-

tery. Refer to Battery Holddown for the proper instal-

lation procedure.

CAUTION: Be certain that the battery cable terminal

clamps are connected to the correct battery termi-

nal posts. Reversed battery polarity may damage

electrical components of the vehicle.

(5) Clean the battery cable terminal clamps and

the battery terminal posts. Refer to Battery System

Cleaning for cleaning procedure.

(6) Reconnect the battery positive cable terminal

clamp to the battery positive terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 45 in. lbs.

(7) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 45 in. lbs.

(8) Apply a thin coating of petroleum jelly or chas-

sis grease to the exposed surfaces of the battery cable

terminal clamps and the battery terminal posts.BATTERY HOLDDOWN

DESCRIPTION

The battery holddown hardware includes a plastic

holddown bracket and retaining bolt. The battery

holddown bracket meshes with the battery tray to

secure the battery to the battery tray.

When installing a battery into the battery tray, it

is important that the holddown hardware is properly

installed and that the fastener is tightened to the

proper specifications. Improper holddown fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle, or both. Refer to

Battery Holddown for the proper installation proce-

dure, including the proper holddown fastener torque

specifications.

OPERATION

The battery holddown secures the battery in the

battery tray. This holddown is designed to prevent

battery movement during the most extreme vehicle

operation conditions. Periodic removal and lubrica-

tion of the battery holddown hardware is recom-

mended to prevent hardware seizure at a later date.

CAUTION: Never operate a vehicle without a battery

holddown device properly installed. Damage to the

vehicle, components and battery could result.

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post.

(4) Remove the battery hold down bracket retain-

ing bolt from the threaded insert in the battery tray

assembly.

INSTALLATION

(1) Clean and inspect the battery hold down hard-

ware. Refer to Battery Cleaning for the proper bat-

tery system component cleaning procedures, and

Battery Inspection for the proper battery system

component inspection procedures.

(2) Position the battery hold down bracket onto the

battery tray.

Fig. 17 Battery Cables - Typical

1 - RADIATOR CROSSMEMBER

2 - WHEELHOUSE INNER PANEL

3 - NEGATIVE CABLE

4 - POSITIVE CABLE

5 - BATTERY

KJBATTERY SYSTEM 8F - 17

BATTERY (Continued)

Page 341 of 1803

(3) Install and tighten the battery hold down

bracket retaining bolt. Tighten the bolt to 4 N´m (20

in. lbs.).

(4) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 8.4 N´m (75

in. lbs.).

BATTERY CABLES

DESCRIPTION

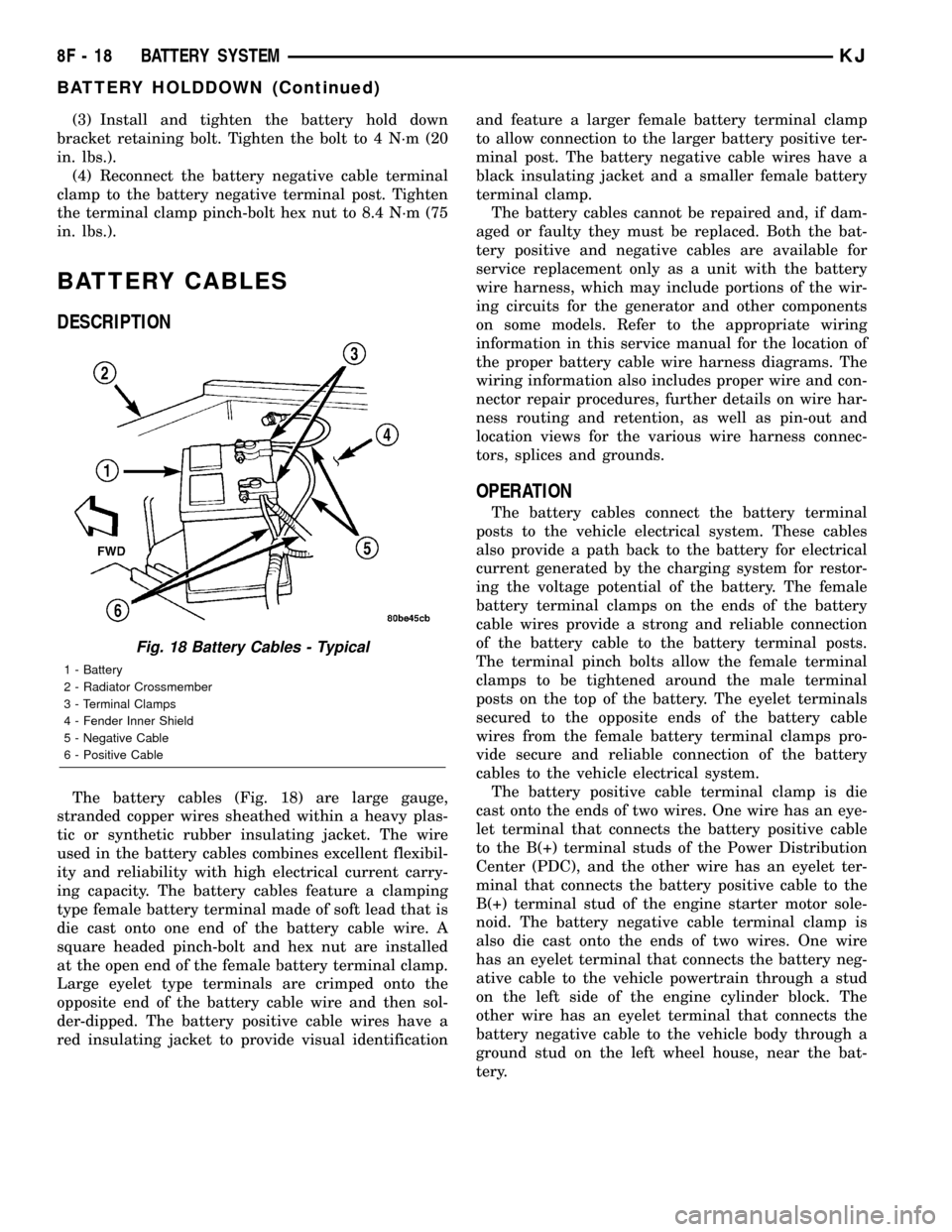

The battery cables (Fig. 18) are large gauge,

stranded copper wires sheathed within a heavy plas-

tic or synthetic rubber insulating jacket. The wire

used in the battery cables combines excellent flexibil-

ity and reliability with high electrical current carry-

ing capacity. The battery cables feature a clamping

type female battery terminal made of soft lead that is

die cast onto one end of the battery cable wire. A

square headed pinch-bolt and hex nut are installed

at the open end of the female battery terminal clamp.

Large eyelet type terminals are crimped onto the

opposite end of the battery cable wire and then sol-

der-dipped. The battery positive cable wires have a

red insulating jacket to provide visual identificationand feature a larger female battery terminal clamp

to allow connection to the larger battery positive ter-

minal post. The battery negative cable wires have a

black insulating jacket and a smaller female battery

terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer to the appropriate wiring

information in this service manual for the location of

the proper battery cable wire harness diagrams. The

wiring information also includes proper wire and con-

nector repair procedures, further details on wire har-

ness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is die

cast onto the ends of two wires. One wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal studs of the Power Distribution

Center (PDC), and the other wire has an eyelet ter-

minal that connects the battery positive cable to the

B(+) terminal stud of the engine starter motor sole-

noid. The battery negative cable terminal clamp is

also die cast onto the ends of two wires. One wire

has an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the left side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground stud on the left wheel house, near the bat-

tery.

Fig. 18 Battery Cables - Typical

1 - Battery

2 - Radiator Crossmember

3 - Terminal Clamps

4 - Fender Inner Shield

5 - Negative Cable

6 - Positive Cable

8F - 18 BATTERY SYSTEMKJ

BATTERY HOLDDOWN (Continued)

Page 345 of 1803

CHARGING SYSTEM

TABLE OF CONTENTS

page page

CHARGING SYSTEM

DESCRIPTION.........................22

OPERATION...........................22

DIAGNOSIS AND TESTING - CHARGING

SYSTEM............................22

SPECIFICATIONS

TORQUE - EXCEPT DIESEL.............23

GENERATOR RATINGS - GAS ENGINES . . . 23

SPECIAL TOOLS.......................24

BATTERY TEMPERATURE SENSOR

DESCRIPTION.........................24

OPERATION...........................24

REMOVAL.............................24

INSTALLATION.........................24

GENERATOR

DESCRIPTION.........................25OPERATION...........................25

REMOVAL.............................25

INSTALLATION.........................26

GENERATOR DECOUPLER PULLEY

DESCRIPTION.........................26

OPERATION...........................27

DIAGNOSIS AND TESTING - GENERATOR

DECOUPLER.........................27

REMOVAL.............................27

INSTALLATION.........................30

VOLTAGE REGULATOR

DESCRIPTION.........................31

OPERATION...........................31

CHARGING SYSTEM

DESCRIPTION

The charging system consists of:

²Generator

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM)

²Ignition switch

²Battery (refer to 8, Battery for information)

²Battery temperature sensor

²Generator Lamp (if equipped)

²Check Gauges Lamp (if equipped)

²Wiring harness and connections (refer to 8, Wir-

ing for information)

OPERATION

The charging system is turned on and off with the

ignition switch. The system is on when the engine is

running and the ASD relay is energized. When the

ASD relay is on, voltage is supplied to the ASD relay

sense circuit at the PCM. This voltage is connected

through the PCM and supplied to one of the genera-

tor field terminals (Gen. Source +) at the back of the

generator.

The amount of DC current produced by the gener-

ator is controlled by the EVR (field control) circuitry

contained within the PCM. This circuitry is con-

nected in series with the second rotor field terminal

and ground.

A battery temperature sensor, located in the bat-

tery tray housing, is used to sense battery tempera-ture. This temperature data, along with data from

monitored line voltage, is used by the PCM to vary

the battery charging rate. This is done by cycling the

ground path to control the strength of the rotor mag-

netic field. The PCM then compensates and regulates

generator current output accordingly.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including EVR

(field control) circuitry, are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for certain failures it detects. Refer to

Diagnostic Trouble Codes in; Powertrain Control

Module; Electronic Control Modules for more DTC

information.

The Check Gauges Lamp (if equipped) monitors:

charging system voltage,engine coolant tempera-

ture and engine oil pressure. If an extreme condition

is indicated, the lamp will be illuminated. This is

done as reminder to check the three gauges. The sig-

nal to activate the lamp is sent via the CCD bus cir-

cuits. The lamp is located on the instrument panel.

Refer to 8, Instrument Cluster for additional infor-

mation.

DIAGNOSIS AND TESTING - CHARGING

SYSTEM

The following procedures may be used to diagnose

the charging system if:

²the check gauges lamp (if equipped) is illumi-

nated with the engine running

8F - 22 CHARGING SYSTEMKJ