eco JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 346 of 1803

²the voltmeter (if equipped) does not register

properly

²an undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²accessories being left on with the engine not

running

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test in 8, Battery for more information.

INSPECTION

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the On-Board Diagnostic

(OBD) system. Some charging system circuits are

checked continuously, and some are checked only

under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Control Module; Electronic Control Modules for more

DTC information. This will include a complete list of

DTC's including DTC's for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBtscan tool. Per-form the following inspections before attaching the

scan tool.

(1) Inspect the battery condition. Refer to 8, Bat-

tery for procedures.

(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications.

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications in 7, Cooling System.

(6) Inspect automatic belt tensioner (if equipped).

Refer to 7, Cooling System for information.

(7) Inspect generator electrical connections at gen-

erator field, battery output, and ground terminal (if

equipped). Also check generator ground wire connec-

tion at engine (if equipped). They should all be clean

and tight. Repair as required.

SPECIFICATIONS

TORQUE - EXCEPT DIESEL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Generator Horizontal Mounting Bolts - 3.7L 57 42 -

Generator Vertical Mounting Bolt - 3.7L 40 29 -

Generator Mounting Bolts - 2.4L 57 42 -

B+ Terminal Nut at Top of Generator 13 - 115

Generator Decoupler 110 81 -

GENERATOR RATINGS - GAS ENGINES

TYPE PART NUMBER RATED SAE AMPS ENGINES MINIMUM TEST AMPS

DENSO 56044530AB 124 2.4L 88

DENSO 56044532AB 136 2.4L 96

DENSO 56041693AA 136 3.7L 96

DENSO 56029914AA 160 3.7L 112

KJCHARGING SYSTEM 8F - 23

CHARGING SYSTEM (Continued)

Page 347 of 1803

SPECIAL TOOLS

BATTERY TEMPERATURE

SENSOR

DESCRIPTION

The Battery Temperature Sensor (BTS) is attached

to the battery tray located under the battery.

OPERATION

The BTS is used to determine the battery temper-

ature and control battery charging rate. This temper-

ature data, along with data from monitored line

voltage, is used by the PCM to vary the battery

charging rate. System voltage will be higher at colder

temperatures and is gradually reduced at warmer

temperatures.

The PCM sends 5 volts to the sensor and is

grounded through the sensor return line. As temper-

ature increases, resistance in the sensor decreases

and the detection voltage at the PCM increases.The BTS is also used for OBD II diagnostics. Cer-

tain faults and OBD II monitors are either enabled

or disabled, depending upon BTS input (for example,

disable purge and enable Leak Detection Pump

(LDP) and O2 sensor heater tests). Most OBD II

monitors are disabled below 20 degrees F.

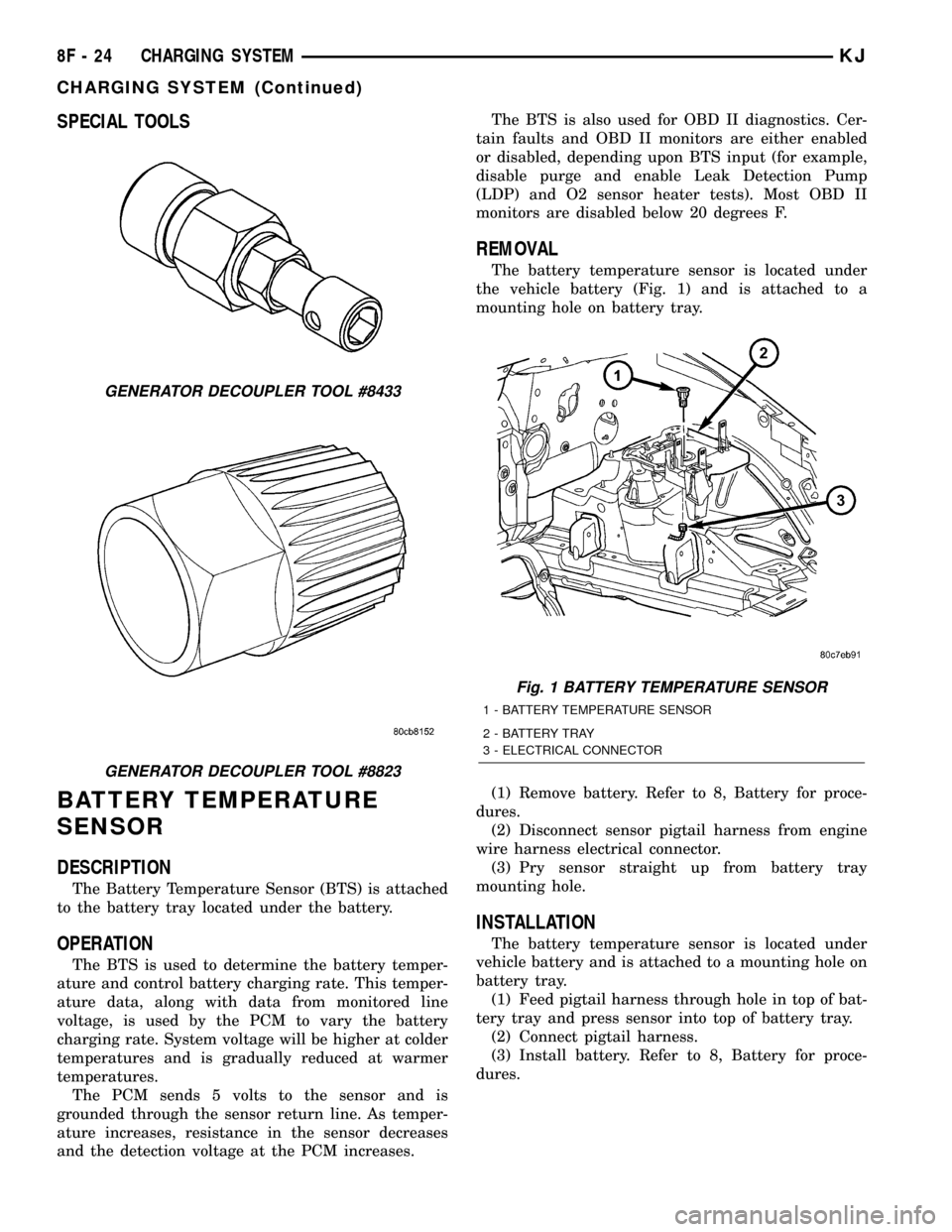

REMOVAL

The battery temperature sensor is located under

the vehicle battery (Fig. 1) and is attached to a

mounting hole on battery tray.

(1) Remove battery. Refer to 8, Battery for proce-

dures.

(2) Disconnect sensor pigtail harness from engine

wire harness electrical connector.

(3) Pry sensor straight up from battery tray

mounting hole.

INSTALLATION

The battery temperature sensor is located under

vehicle battery and is attached to a mounting hole on

battery tray.

(1) Feed pigtail harness through hole in top of bat-

tery tray and press sensor into top of battery tray.

(2) Connect pigtail harness.

(3) Install battery. Refer to 8, Battery for proce-

dures.

GENERATOR DECOUPLER TOOL #8433

GENERATOR DECOUPLER TOOL #8823

Fig. 1 BATTERY TEMPERATURE SENSOR

1 - BATTERY TEMPERATURE SENSOR

2 - BATTERY TRAY

3 - ELECTRICAL CONNECTOR

8F - 24 CHARGING SYSTEMKJ

CHARGING SYSTEM (Continued)

Page 349 of 1803

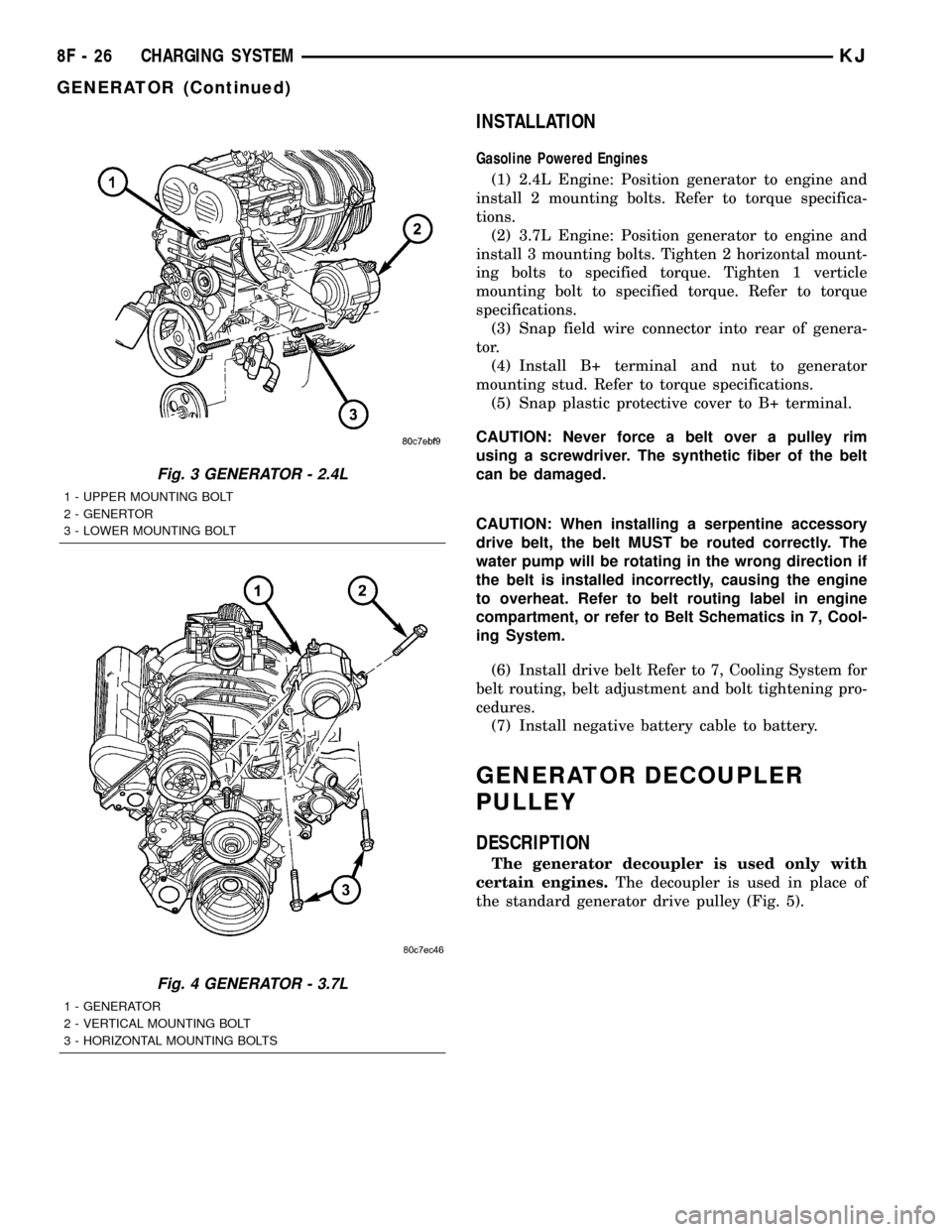

INSTALLATION

Gasoline Powered Engines

(1) 2.4L Engine: Position generator to engine and

install 2 mounting bolts. Refer to torque specifica-

tions.

(2) 3.7L Engine: Position generator to engine and

install 3 mounting bolts. Tighten 2 horizontal mount-

ing bolts to specified torque. Tighten 1 verticle

mounting bolt to specified torque. Refer to torque

specifications.

(3) Snap field wire connector into rear of genera-

tor.

(4) Install B+ terminal and nut to generator

mounting stud. Refer to torque specifications.

(5) Snap plastic protective cover to B+ terminal.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump will be rotating in the wrong direction if

the belt is installed incorrectly, causing the engine

to overheat. Refer to belt routing label in engine

compartment, or refer to Belt Schematics in 7, Cool-

ing System.

(6) Install drive belt Refer to 7, Cooling System for

belt routing, belt adjustment and bolt tightening pro-

cedures.

(7) Install negative battery cable to battery.

GENERATOR DECOUPLER

PULLEY

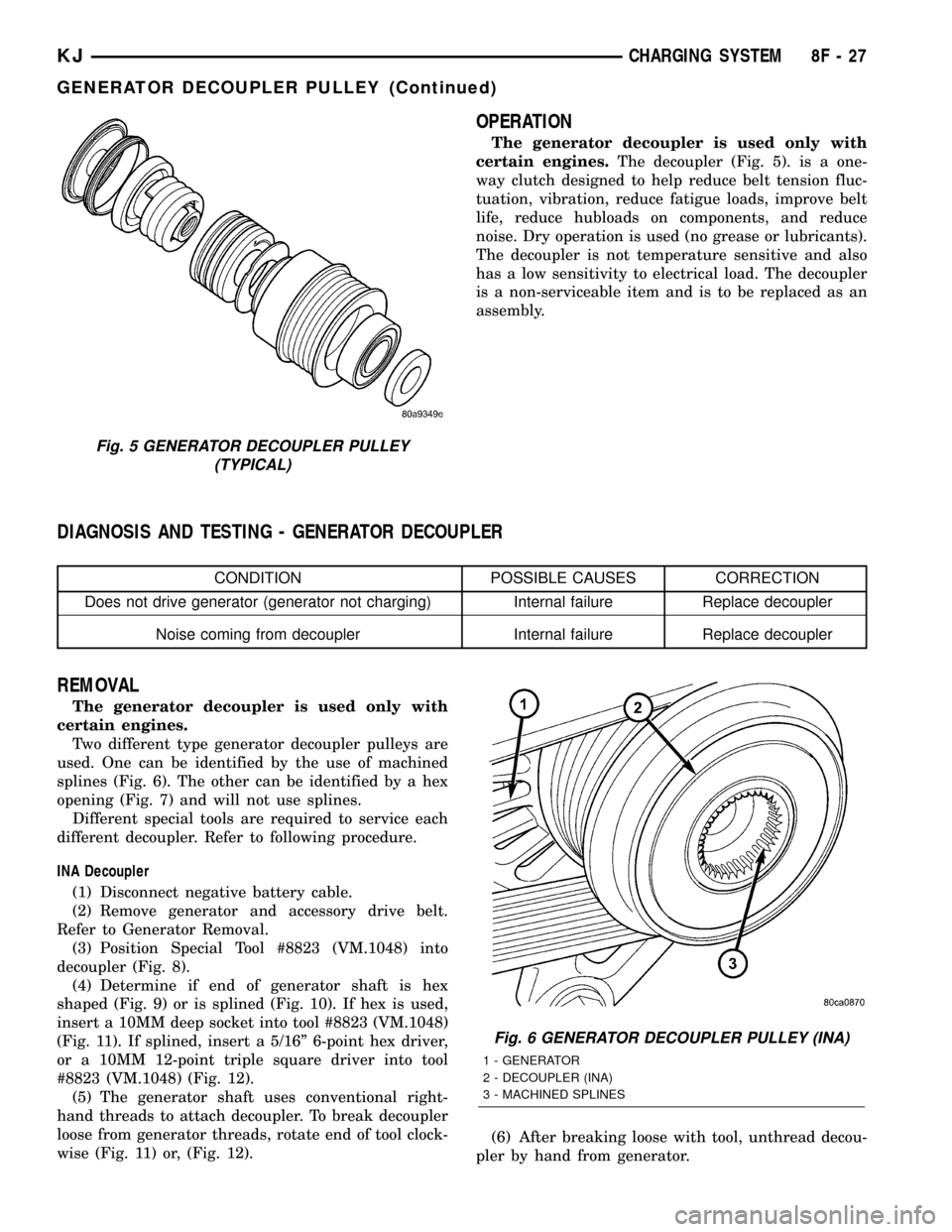

DESCRIPTION

The generator decoupler is used only with

certain engines.The decoupler is used in place of

the standard generator drive pulley (Fig. 5).

Fig. 3 GENERATOR - 2.4L

1 - UPPER MOUNTING BOLT

2 - GENERTOR

3 - LOWER MOUNTING BOLT

Fig. 4 GENERATOR - 3.7L

1 - GENERATOR

2 - VERTICAL MOUNTING BOLT

3 - HORIZONTAL MOUNTING BOLTS

8F - 26 CHARGING SYSTEMKJ

GENERATOR (Continued)

Page 350 of 1803

OPERATION

The generator decoupler is used only with

certain engines.The decoupler (Fig. 5). is a one-

way clutch designed to help reduce belt tension fluc-

tuation, vibration, reduce fatigue loads, improve belt

life, reduce hubloads on components, and reduce

noise. Dry operation is used (no grease or lubricants).

The decoupler is not temperature sensitive and also

has a low sensitivity to electrical load. The decoupler

is a non-serviceable item and is to be replaced as an

assembly.

DIAGNOSIS AND TESTING - GENERATOR DECOUPLER

CONDITION POSSIBLE CAUSES CORRECTION

Does not drive generator (generator not charging) Internal failure Replace decoupler

Noise coming from decoupler Internal failure Replace decoupler

REMOVAL

The generator decoupler is used only with

certain engines.

Two different type generator decoupler pulleys are

used. One can be identified by the use of machined

splines (Fig. 6). The other can be identified by a hex

opening (Fig. 7) and will not use splines.

Different special tools are required to service each

different decoupler. Refer to following procedure.

INA Decoupler

(1) Disconnect negative battery cable.

(2) Remove generator and accessory drive belt.

Refer to Generator Removal.

(3) Position Special Tool #8823 (VM.1048) into

decoupler (Fig. 8).

(4) Determine if end of generator shaft is hex

shaped (Fig. 9) or is splined (Fig. 10). If hex is used,

insert a 10MM deep socket into tool #8823 (VM.1048)

(Fig. 11). If splined, insert a 5/16º 6-point hex driver,

or a 10MM 12-point triple square driver into tool

#8823 (VM.1048) (Fig. 12).

(5) The generator shaft uses conventional right-

hand threads to attach decoupler. To break decoupler

loose from generator threads, rotate end of tool clock-

wise (Fig. 11) or, (Fig. 12).(6) After breaking loose with tool, unthread decou-

pler by hand from generator.

Fig. 5 GENERATOR DECOUPLER PULLEY

(TYPICAL)

Fig. 6 GENERATOR DECOUPLER PULLEY (INA)

1 - GENERATOR

2 - DECOUPLER (INA)

3 - MACHINED SPLINES

KJCHARGING SYSTEM 8F - 27

GENERATOR DECOUPLER PULLEY (Continued)

Page 351 of 1803

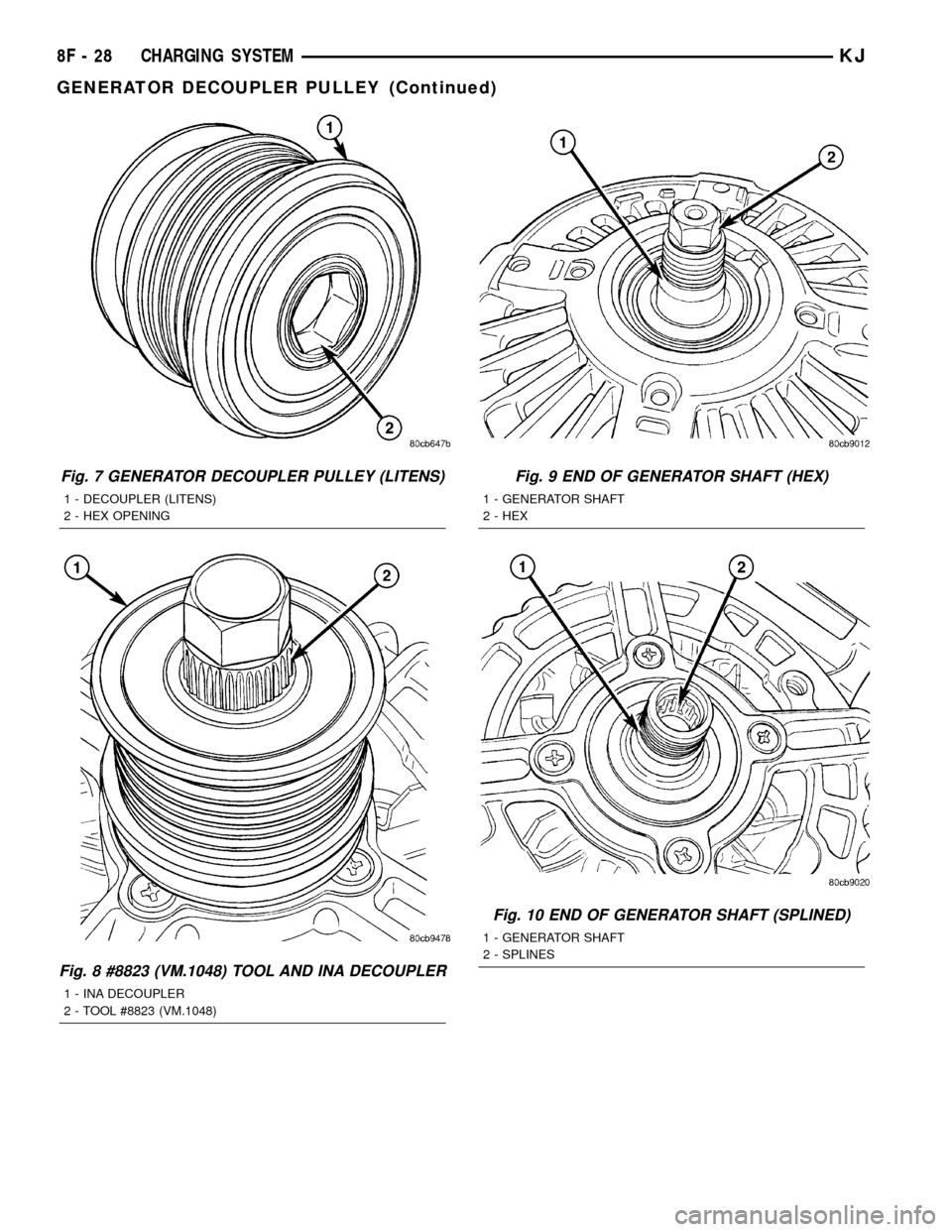

Fig. 7 GENERATOR DECOUPLER PULLEY (LITENS)

1 - DECOUPLER (LITENS)

2 - HEX OPENING

Fig. 8 #8823 (VM.1048) TOOL AND INA DECOUPLER

1 - INA DECOUPLER

2 - TOOL #8823 (VM.1048)

Fig. 9 END OF GENERATOR SHAFT (HEX)

1 - GENERATOR SHAFT

2 - HEX

Fig. 10 END OF GENERATOR SHAFT (SPLINED)

1 - GENERATOR SHAFT

2 - SPLINES

8F - 28 CHARGING SYSTEMKJ

GENERATOR DECOUPLER PULLEY (Continued)

Page 352 of 1803

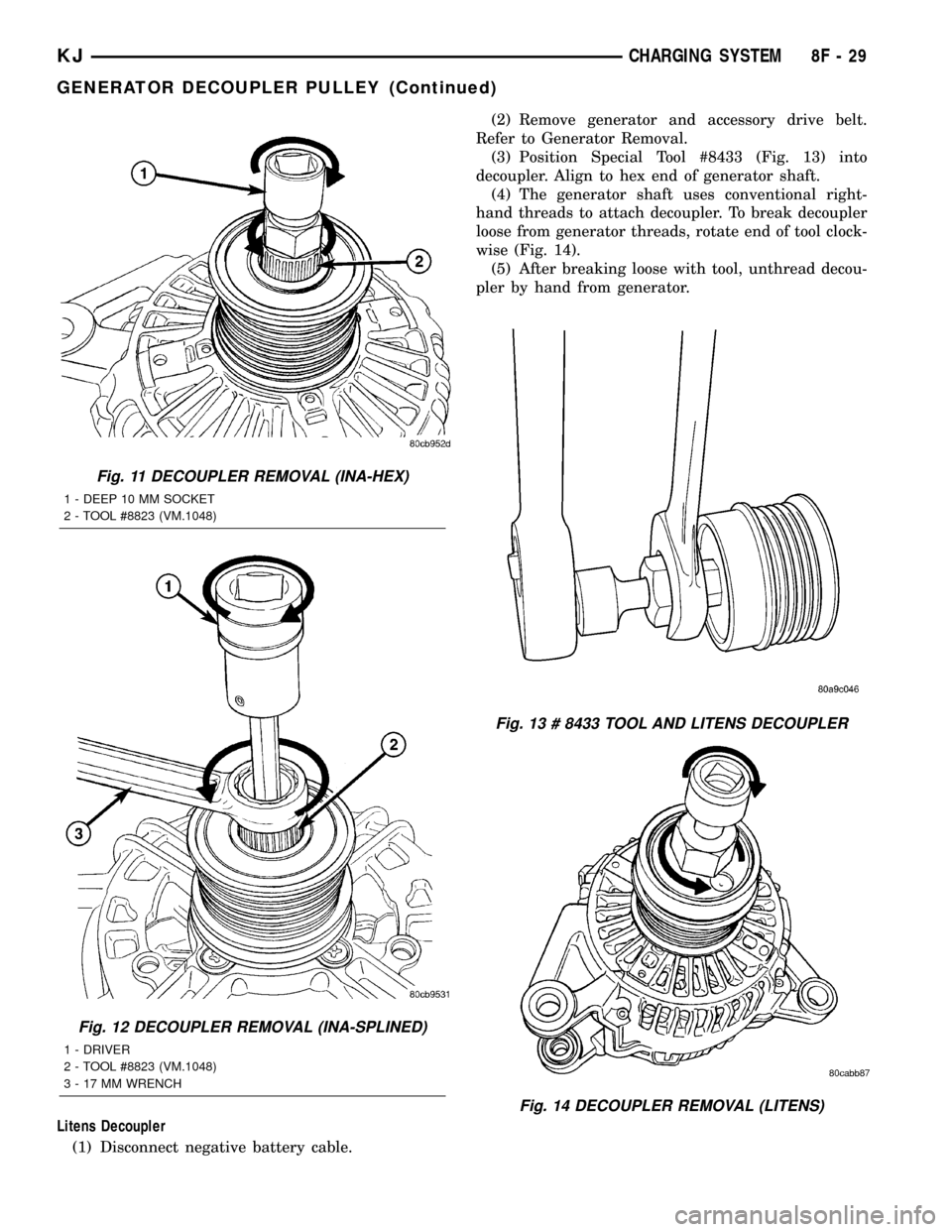

Litens Decoupler

(1) Disconnect negative battery cable.(2) Remove generator and accessory drive belt.

Refer to Generator Removal.

(3) Position Special Tool #8433 (Fig. 13) into

decoupler. Align to hex end of generator shaft.

(4) The generator shaft uses conventional right-

hand threads to attach decoupler. To break decoupler

loose from generator threads, rotate end of tool clock-

wise (Fig. 14).

(5) After breaking loose with tool, unthread decou-

pler by hand from generator.

Fig. 11 DECOUPLER REMOVAL (INA-HEX)

1 - DEEP 10 MM SOCKET

2 - TOOL #8823 (VM.1048)

Fig. 12 DECOUPLER REMOVAL (INA-SPLINED)

1 - DRIVER

2 - TOOL #8823 (VM.1048)

3 - 17 MM WRENCH

Fig. 13 # 8433 TOOL AND LITENS DECOUPLER

Fig. 14 DECOUPLER REMOVAL (LITENS)

KJCHARGING SYSTEM 8F - 29

GENERATOR DECOUPLER PULLEY (Continued)

Page 353 of 1803

INSTALLATION

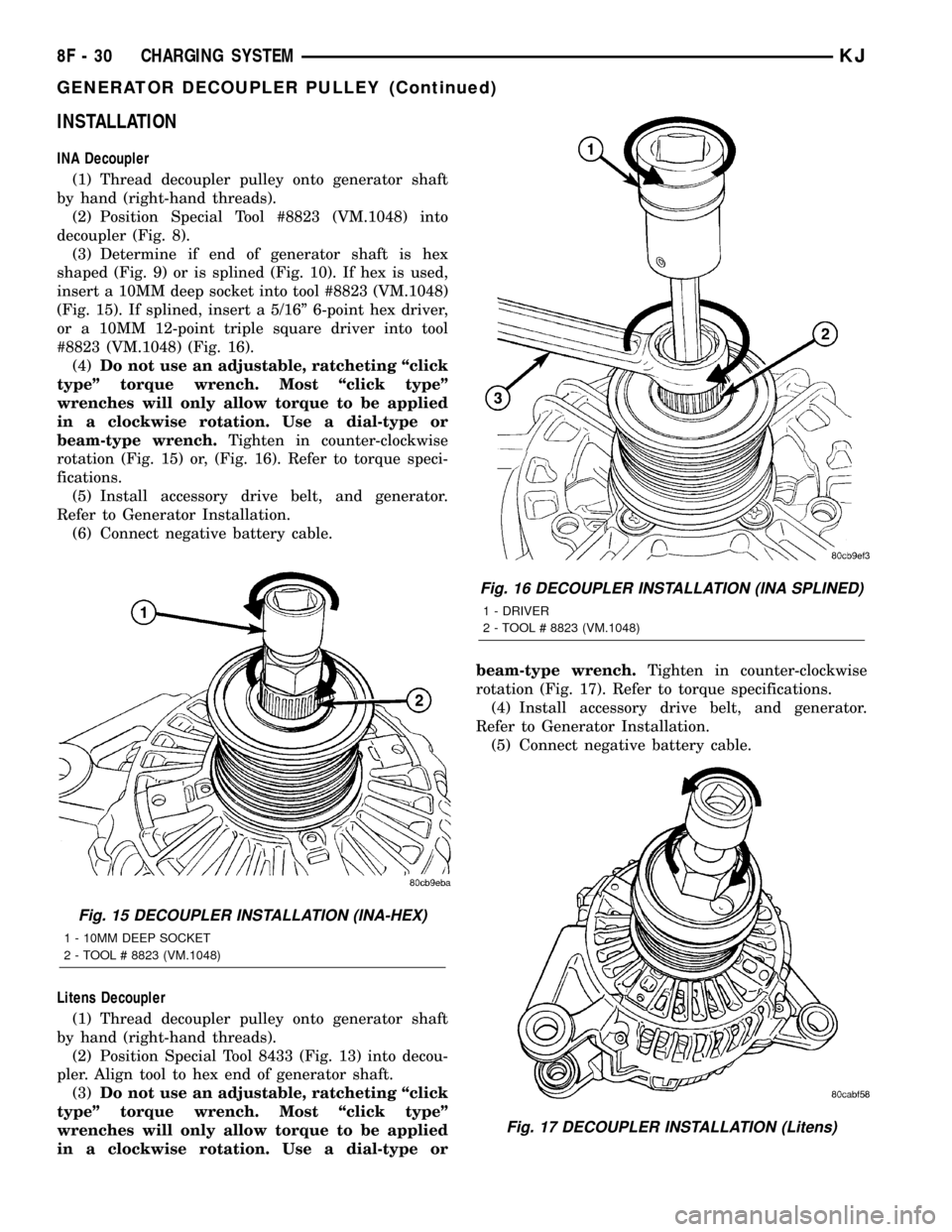

INA Decoupler

(1) Thread decoupler pulley onto generator shaft

by hand (right-hand threads).

(2) Position Special Tool #8823 (VM.1048) into

decoupler (Fig. 8).

(3) Determine if end of generator shaft is hex

shaped (Fig. 9) or is splined (Fig. 10). If hex is used,

insert a 10MM deep socket into tool #8823 (VM.1048)

(Fig. 15). If splined, insert a 5/16º 6-point hex driver,

or a 10MM 12-point triple square driver into tool

#8823 (VM.1048) (Fig. 16).

(4)Do not use an adjustable, ratcheting ªclick

typeº torque wrench. Most ªclick typeº

wrenches will only allow torque to be applied

in a clockwise rotation. Use a dial-type or

beam-type wrench.Tighten in counter-clockwise

rotation (Fig. 15) or, (Fig. 16). Refer to torque speci-

fications.

(5) Install accessory drive belt, and generator.

Refer to Generator Installation.

(6) Connect negative battery cable.

Litens Decoupler

(1) Thread decoupler pulley onto generator shaft

by hand (right-hand threads).

(2) Position Special Tool 8433 (Fig. 13) into decou-

pler. Align tool to hex end of generator shaft.

(3)Do not use an adjustable, ratcheting ªclick

typeº torque wrench. Most ªclick typeº

wrenches will only allow torque to be applied

in a clockwise rotation. Use a dial-type orbeam-type wrench.Tighten in counter-clockwise

rotation (Fig. 17). Refer to torque specifications.

(4) Install accessory drive belt, and generator.

Refer to Generator Installation.

(5) Connect negative battery cable.

Fig. 15 DECOUPLER INSTALLATION (INA-HEX)

1 - 10MM DEEP SOCKET

2 - TOOL # 8823 (VM.1048)

Fig. 16 DECOUPLER INSTALLATION (INA SPLINED)

1 - DRIVER

2 - TOOL # 8823 (VM.1048)

Fig. 17 DECOUPLER INSTALLATION (Litens)

8F - 30 CHARGING SYSTEMKJ

GENERATOR DECOUPLER PULLEY (Continued)

Page 354 of 1803

VOLTAGE REGULATOR

DESCRIPTION

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the Powertrain Control

Module (PCM). The EVR is not serviced separately. If

replacement is necessary, the PCM must be replaced.

OPERATION

The amount of DC current produced by the gener-

ator is controlled by EVR circuitry contained within

the Powertrain Control Module (PCM). This circuitry

is connected in series with the generators second

rotor field terminal and its ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. TheEVR circuitry monitors system line voltage (B+) and

battery temperature (refer to Battery Temperature

Sensor for more information). It then determines a

target charging voltage. If sensed battery voltage is

0.5 volts or lower than the target voltage, the PCM

grounds the field winding until sensed battery volt-

age is 0.5 volts above target voltage. A circuit in the

PCM cycles the ground side of the generator field up

to 100 times per second (100Hz), but has the capabil-

ity to ground the field control wire 100% of the time

(full field) to achieve the target voltage. If the charg-

ing rate cannot be monitored (limp-in), a duty cycle

of 25% is used by the PCM in order to have some

generator output. Also refer to Charging Operation

for additional information.

KJCHARGING SYSTEM 8F - 31

Page 368 of 1803

HEATED SYSTEMS

TABLE OF CONTENTS

page page

HEATED MIRRORS......................... 1

WINDOW DEFOGGER....................... 3HEATED SEAT SYSTEM.................... 10

HEATED MIRRORS

TABLE OF CONTENTS

page page

HEATED MIRRORS

DESCRIPTION..........................1

OPERATION............................1DIAGNOSIS AND TESTING - HEATED

MIRRORS............................1

HEATED MIRRORS

DESCRIPTION

Vehicles equipped with the optional heated mirror

package have an electric heating grid located behind

the mirror glass of each outside rear view mirror.

The heated mirrors are controlled by the rear win-

dow defogger switch. Electrical current is directed to

the heating grid inside the mirror only when the rear

window defogger switch is in the On position.

If the outside mirror heating grids and the rear

window heating grid are all inoperative, (Refer to 8 -

ELECTRICAL/HEATED GLASS - DIAGNOSIS AND

TESTING). If the outside mirror heating grids are

inoperative, but the rear window heating grid is

operating as designed, (Refer to 8 - ELECTRICAL/

HEATED MIRRORS - DIAGNOSIS AND TESTING).

The heating grid behind each outside mirror glass

cannot be repaired and, if faulty or damaged, the

entire power mirror unit must be replaced(Refer to 8

- ELECTRICAL/POWER MIRRORS/SIDEVIEW MIR-

ROR - REMOVAL) and (Refer to 8 - ELECTRICAL/

POWER MIRRORS/SIDEVIEW MIRROR -

INSTALLATION).

OPERATION

The heated mirror is controlled by the rear window

defogger switch. The only time that the heated mir-

ror is on is when the rear window defogger is on. The

mirror should become warm to the touch.

DIAGNOSIS AND TESTING - HEATED MIRRORS

For circuit descriptions and diagrams (Refer to

Appropriate Wiring Information).

(1) Check the fuse in the junction block. If OK, go

to Step 2. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 3. If not OK, repair the open

circuit to the ignition switch as required.

(3) Disconnect and isolate the battery negative

cable. Remove the front door trim panel on the side

of the vehicle with the inoperative mirror heating

grid. Unplug the wire harness connector at the mir-

ror. Check for continuity between the ground circuit

cavity in the body half of the power mirror wire har-

ness connector and a good ground. If OK, go to Step

4. If not OK, repair the open circuit to ground as

required.

(4) Connect the battery negative cable. Turn the

ignition switch to the On position. Turn on the rear

window defogger system. Check for battery voltage at

the rear window defogger relay output circuit cavity

in the body half of the power mirror wire harness

connector. If OK, go to Step 5. If not OK, repair the

open circuit to the rear window defogger relay as

required.

KJHEATED SYSTEMS 8G - 1

Page 378 of 1803

The heated seat module monitors inputs from the

heated seat sensors and the heated seat switches. In

response to these inputs the heated seat module uses

its internal programming to control outputs to the

heated seat elements in both front seats and to con-

trol the heated seat LED indicator lamps located in

both of the heated seat switches. The heated seat

module is also programmed to provide self-diagnostic

capability. When the module detects certain failures

within the heated seat system, it will provide a

visual indication of the failure by flashing the indica-

tor lamps in the affected heated seat switch. The

heated seat module will automatically turn off the

heated seat elements if it detects a short or open in

the heated seat element circuit or a heated seat sen-

sor value that is out of range.

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM

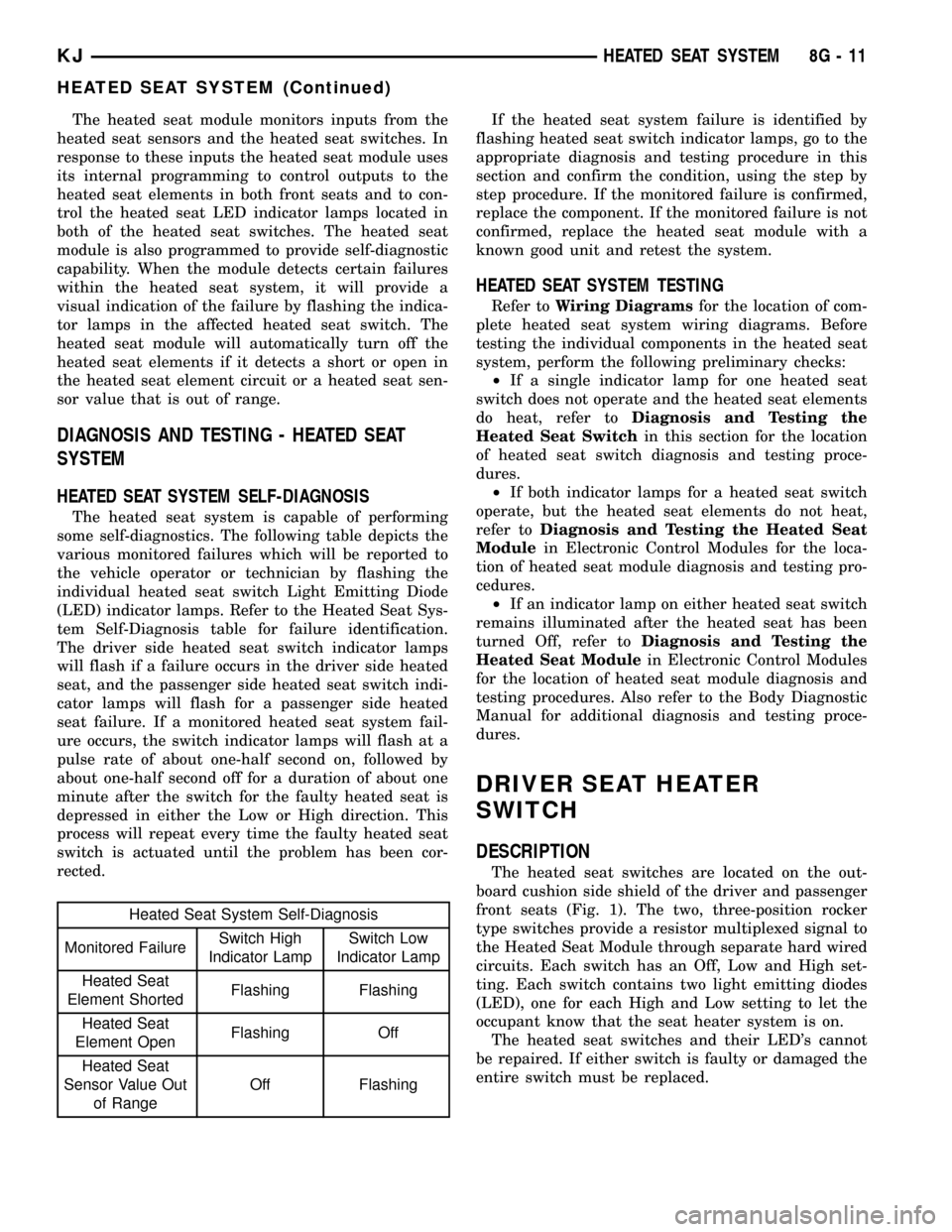

HEATED SEAT SYSTEM SELF-DIAGNOSIS

The heated seat system is capable of performing

some self-diagnostics. The following table depicts the

various monitored failures which will be reported to

the vehicle operator or technician by flashing the

individual heated seat switch Light Emitting Diode

(LED) indicator lamps. Refer to the Heated Seat Sys-

tem Self-Diagnosis table for failure identification.

The driver side heated seat switch indicator lamps

will flash if a failure occurs in the driver side heated

seat, and the passenger side heated seat switch indi-

cator lamps will flash for a passenger side heated

seat failure. If a monitored heated seat system fail-

ure occurs, the switch indicator lamps will flash at a

pulse rate of about one-half second on, followed by

about one-half second off for a duration of about one

minute after the switch for the faulty heated seat is

depressed in either the Low or High direction. This

process will repeat every time the faulty heated seat

switch is actuated until the problem has been cor-

rected.

Heated Seat System Self-Diagnosis

Monitored FailureSwitch High

Indicator LampSwitch Low

Indicator Lamp

Heated Seat

Element ShortedFlashing Flashing

Heated Seat

Element OpenFlashing Off

Heated Seat

Sensor Value Out

of RangeOff FlashingIf the heated seat system failure is identified by

flashing heated seat switch indicator lamps, go to the

appropriate diagnosis and testing procedure in this

section and confirm the condition, using the step by

step procedure. If the monitored failure is confirmed,

replace the component. If the monitored failure is not

confirmed, replace the heated seat module with a

known good unit and retest the system.

HEATED SEAT SYSTEM TESTING

Refer toWiring Diagramsfor the location of com-

plete heated seat system wiring diagrams. Before

testing the individual components in the heated seat

system, perform the following preliminary checks:

²If a single indicator lamp for one heated seat

switch does not operate and the heated seat elements

do heat, refer toDiagnosis and Testing the

Heated Seat Switchin this section for the location

of heated seat switch diagnosis and testing proce-

dures.

²If both indicator lamps for a heated seat switch

operate, but the heated seat elements do not heat,

refer toDiagnosis and Testing the Heated Seat

Modulein Electronic Control Modules for the loca-

tion of heated seat module diagnosis and testing pro-

cedures.

²If an indicator lamp on either heated seat switch

remains illuminated after the heated seat has been

turned Off, refer toDiagnosis and Testing the

Heated Seat Modulein Electronic Control Modules

for the location of heated seat module diagnosis and

testing procedures. Also refer to the Body Diagnostic

Manual for additional diagnosis and testing proce-

dures.

DRIVER SEAT HEATER

SWITCH

DESCRIPTION

The heated seat switches are located on the out-

board cushion side shield of the driver and passenger

front seats (Fig. 1). The two, three-position rocker

type switches provide a resistor multiplexed signal to

the Heated Seat Module through separate hard wired

circuits. Each switch has an Off, Low and High set-

ting. Each switch contains two light emitting diodes

(LED), one for each High and Low setting to let the

occupant know that the seat heater system is on.

The heated seat switches and their LED's cannot

be repaired. If either switch is faulty or damaged the

entire switch must be replaced.

KJHEATED SEAT SYSTEM 8G - 11

HEATED SEAT SYSTEM (Continued)