removal JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 503 of 1803

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The relay is

contained within a small, rectangular, molded plastic

housing and is connected to all of the required inputs

and outputs by five integral male spade-type termi-

nals that extend from the bottom of the relay base.

The trailer tow relays cannot be adjusted or

repaired and, if faulty or damaged, the inoperative

relay must be replaced.

OPERATION

The trailer tow relays are electromechanical

switches. The relays each use an input from the cir-

cuit that they isolate from the trailer wiring to con-

trol a high current output to the trailer. The movable

common feed contact point is held against the fixed

normally closed contact point by spring pressure.

When the relay coil is energized, an electromagnetic

field is produced by the coil windings. This electro-

magnetic field draws the movable relay contact point

away from the fixed normally closed contact point,

and holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The terminals of each trailer tow relay are con-

nected to the vehicle electrical system through a con-nector bank in the rear lighting wire harness above

the right rear wheelhouse. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds. The trailer tow relays can be diagnosed

using conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - TRAILER TOW

RELAY

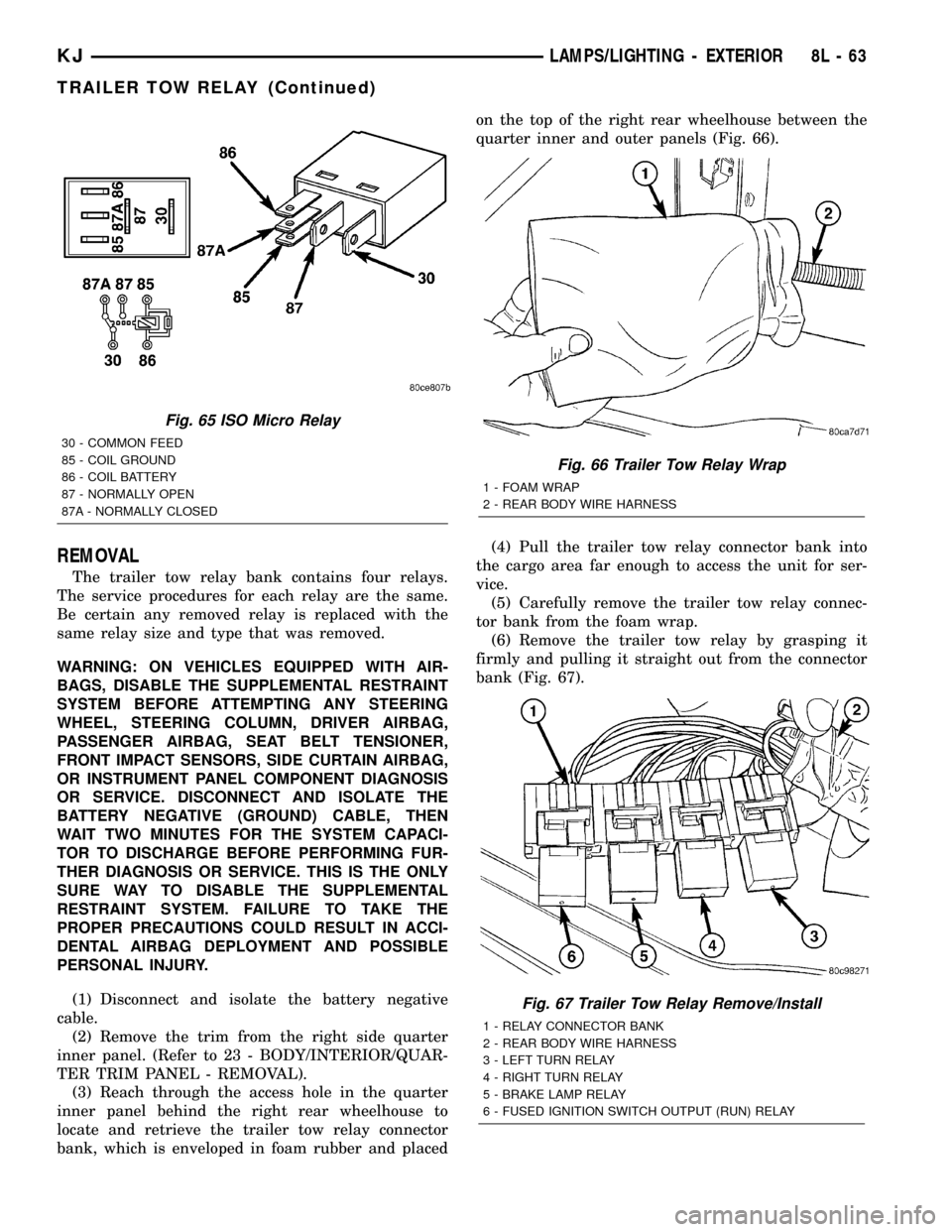

The trailer tow relays (Fig. 65) are located in a

connector bank above the right rear wheelhouse.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the trailer tow relay from the connec-

tor bank. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/TRAILER TOW RELAY -

REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, test the input and output circuits of

the relay. Refer to the appropriate wiring informa-

tion.

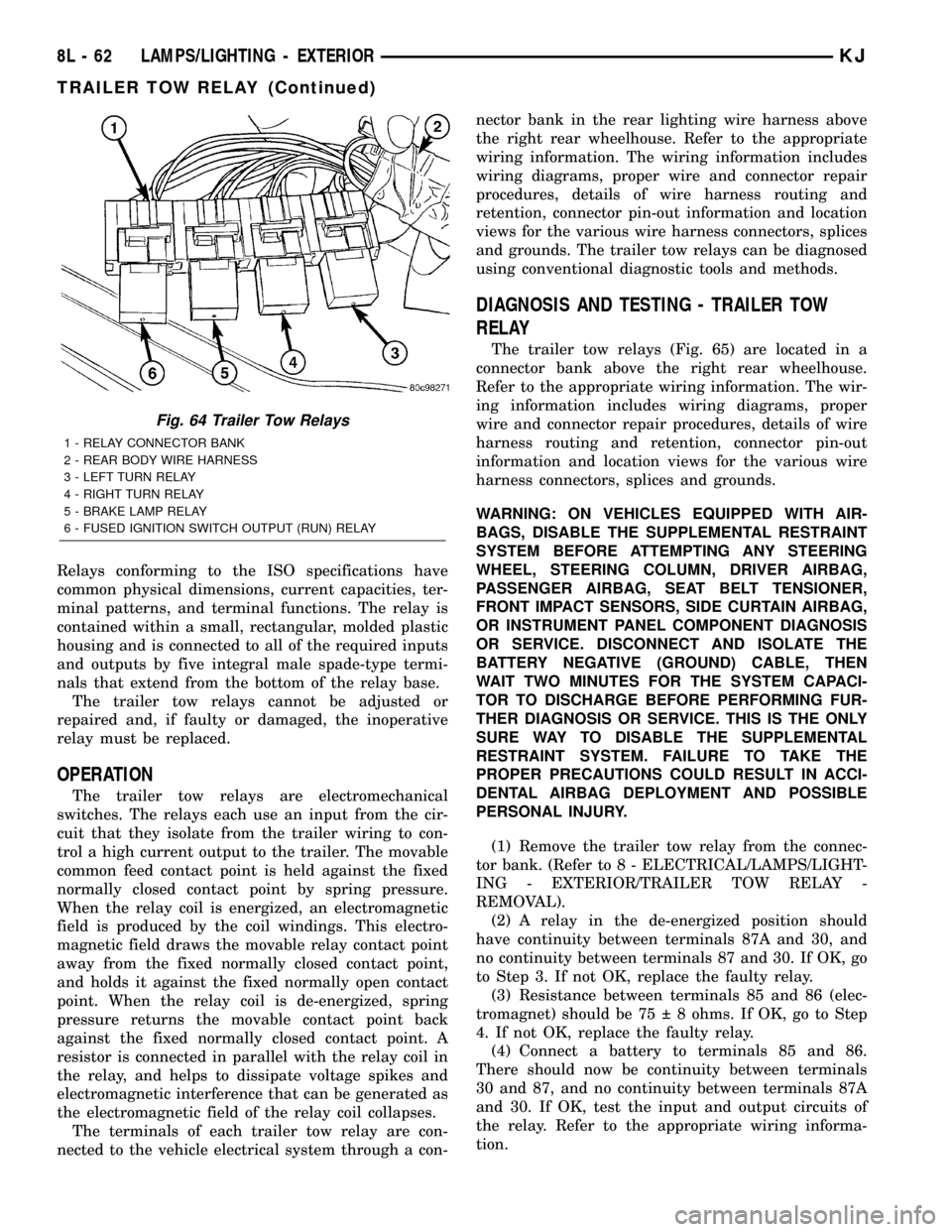

Fig. 64 Trailer Tow Relays

1 - RELAY CONNECTOR BANK

2 - REAR BODY WIRE HARNESS

3 - LEFT TURN RELAY

4 - RIGHT TURN RELAY

5 - BRAKE LAMP RELAY

6 - FUSED IGNITION SWITCH OUTPUT (RUN) RELAY

8L - 62 LAMPS/LIGHTING - EXTERIORKJ

TRAILER TOW RELAY (Continued)

Page 504 of 1803

REMOVAL

The trailer tow relay bank contains four relays.

The service procedures for each relay are the same.

Be certain any removed relay is replaced with the

same relay size and type that was removed.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim from the right side quarter

inner panel. (Refer to 23 - BODY/INTERIOR/QUAR-

TER TRIM PANEL - REMOVAL).

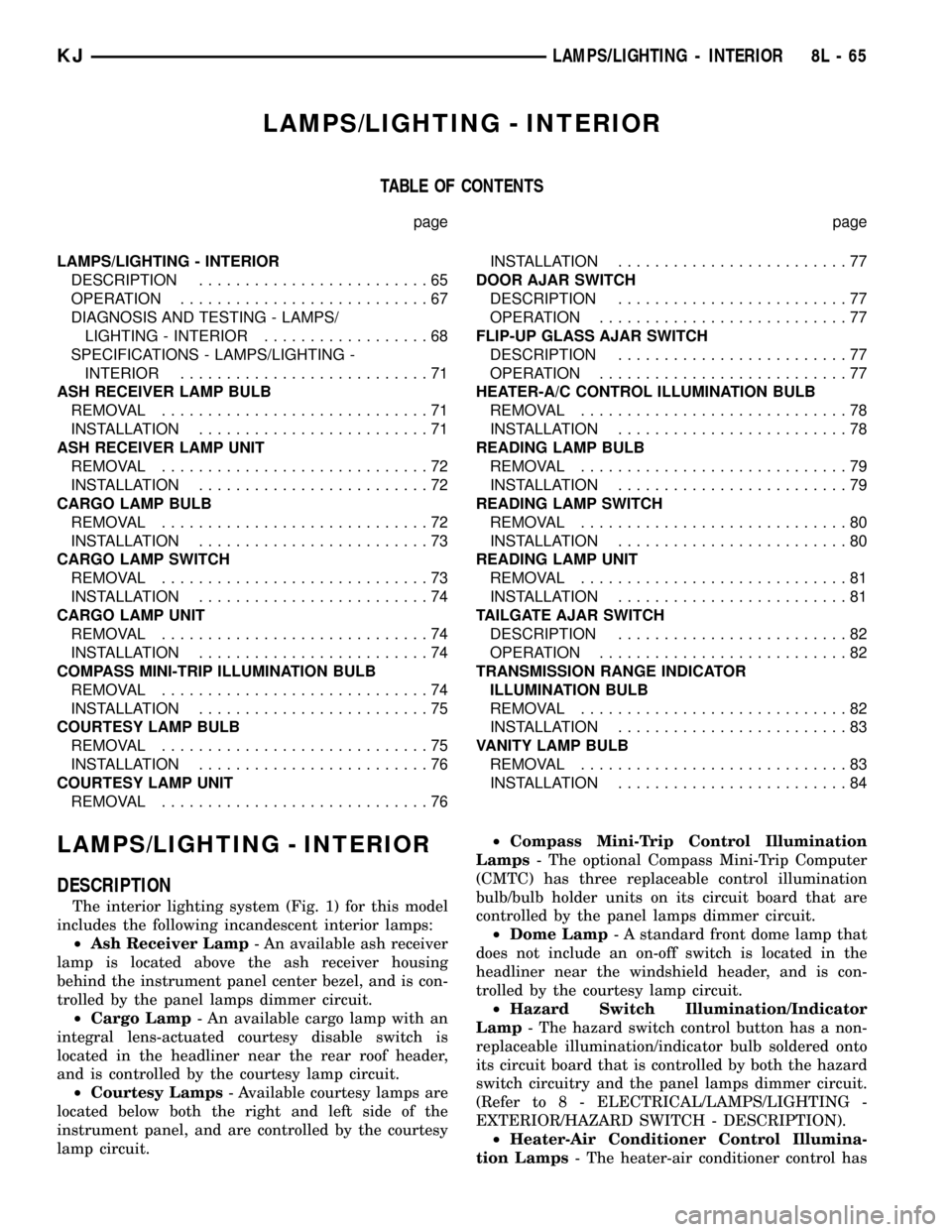

(3) Reach through the access hole in the quarter

inner panel behind the right rear wheelhouse to

locate and retrieve the trailer tow relay connector

bank, which is enveloped in foam rubber and placedon the top of the right rear wheelhouse between the

quarter inner and outer panels (Fig. 66).

(4) Pull the trailer tow relay connector bank into

the cargo area far enough to access the unit for ser-

vice.

(5) Carefully remove the trailer tow relay connec-

tor bank from the foam wrap.

(6) Remove the trailer tow relay by grasping it

firmly and pulling it straight out from the connector

bank (Fig. 67).

Fig. 65 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 66 Trailer Tow Relay Wrap

1 - FOAM WRAP

2 - REAR BODY WIRE HARNESS

Fig. 67 Trailer Tow Relay Remove/Install

1 - RELAY CONNECTOR BANK

2 - REAR BODY WIRE HARNESS

3 - LEFT TURN RELAY

4 - RIGHT TURN RELAY

5 - BRAKE LAMP RELAY

6 - FUSED IGNITION SWITCH OUTPUT (RUN) RELAY

KJLAMPS/LIGHTING - EXTERIOR 8L - 63

TRAILER TOW RELAY (Continued)

Page 506 of 1803

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

DESCRIPTION.........................65

OPERATION...........................67

DIAGNOSIS AND TESTING - LAMPS/

LIGHTING - INTERIOR..................68

SPECIFICATIONS - LAMPS/LIGHTING -

INTERIOR...........................71

ASH RECEIVER LAMP BULB

REMOVAL.............................71

INSTALLATION.........................71

ASH RECEIVER LAMP UNIT

REMOVAL.............................72

INSTALLATION.........................72

CARGO LAMP BULB

REMOVAL.............................72

INSTALLATION.........................73

CARGO LAMP SWITCH

REMOVAL.............................73

INSTALLATION.........................74

CARGO LAMP UNIT

REMOVAL.............................74

INSTALLATION.........................74

COMPASS MINI-TRIP ILLUMINATION BULB

REMOVAL.............................74

INSTALLATION.........................75

COURTESY LAMP BULB

REMOVAL.............................75

INSTALLATION.........................76

COURTESY LAMP UNIT

REMOVAL.............................76INSTALLATION.........................77

DOOR AJAR SWITCH

DESCRIPTION.........................77

OPERATION...........................77

FLIP-UP GLASS AJAR SWITCH

DESCRIPTION.........................77

OPERATION...........................77

HEATER-A/C CONTROL ILLUMINATION BULB

REMOVAL.............................78

INSTALLATION.........................78

READING LAMP BULB

REMOVAL.............................79

INSTALLATION.........................79

READING LAMP SWITCH

REMOVAL.............................80

INSTALLATION.........................80

READING LAMP UNIT

REMOVAL.............................81

INSTALLATION.........................81

TAILGATE AJAR SWITCH

DESCRIPTION.........................82

OPERATION...........................82

TRANSMISSION RANGE INDICATOR

ILLUMINATION BULB

REMOVAL.............................82

INSTALLATION.........................83

VANITY LAMP BULB

REMOVAL.............................83

INSTALLATION.........................84

LAMPS/LIGHTING - INTERIOR

DESCRIPTION

The interior lighting system (Fig. 1) for this model

includes the following incandescent interior lamps:

²Ash Receiver Lamp- An available ash receiver

lamp is located above the ash receiver housing

behind the instrument panel center bezel, and is con-

trolled by the panel lamps dimmer circuit.

²Cargo Lamp- An available cargo lamp with an

integral lens-actuated courtesy disable switch is

located in the headliner near the rear roof header,

and is controlled by the courtesy lamp circuit.

²Courtesy Lamps- Available courtesy lamps are

located below both the right and left side of the

instrument panel, and are controlled by the courtesy

lamp circuit.²Compass Mini-Trip Control Illumination

Lamps- The optional Compass Mini-Trip Computer

(CMTC) has three replaceable control illumination

bulb/bulb holder units on its circuit board that are

controlled by the panel lamps dimmer circuit.

²Dome Lamp- A standard front dome lamp that

does not include an on-off switch is located in the

headliner near the windshield header, and is con-

trolled by the courtesy lamp circuit.

²Hazard Switch Illumination/Indicator

Lamp- The hazard switch control button has a non-

replaceable illumination/indicator bulb soldered onto

its circuit board that is controlled by both the hazard

switch circuitry and the panel lamps dimmer circuit.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/HAZARD SWITCH - DESCRIPTION).

²Heater-Air Conditioner Control Illumina-

tion Lamps- The heater-air conditioner control has

KJLAMPS/LIGHTING - INTERIOR 8L - 65

Page 512 of 1803

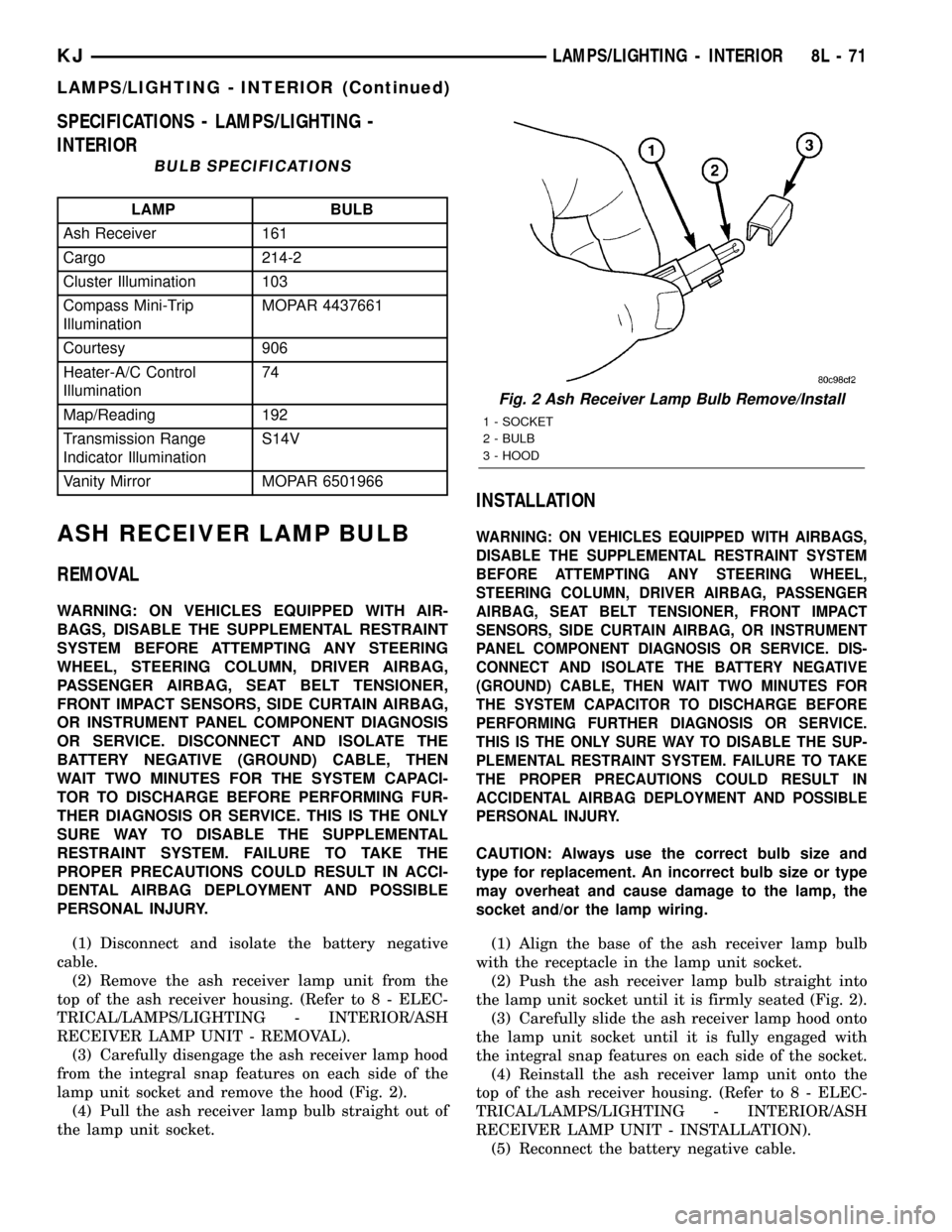

SPECIFICATIONS - LAMPS/LIGHTING -

INTERIOR

BULB SPECIFICATIONS

LAMP BULB

Ash Receiver 161

Cargo 214-2

Cluster Illumination 103

Compass Mini-Trip

IlluminationMOPAR 4437661

Courtesy 906

Heater-A/C Control

Illumination74

Map/Reading 192

Transmission Range

Indicator IlluminationS14V

Vanity Mirror MOPAR 6501966

ASH RECEIVER LAMP BULB

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the ash receiver lamp unit from the

top of the ash receiver housing. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - INTERIOR/ASH

RECEIVER LAMP UNIT - REMOVAL).

(3) Carefully disengage the ash receiver lamp hood

from the integral snap features on each side of the

lamp unit socket and remove the hood (Fig. 2).

(4) Pull the ash receiver lamp bulb straight out of

the lamp unit socket.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, DRIVER AIRBAG, PASSENGER

AIRBAG, SEAT BELT TENSIONER, FRONT IMPACT

SENSORS, SIDE CURTAIN AIRBAG, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE. DIS-

CONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE SUP-

PLEMENTAL RESTRAINT SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the base of the ash receiver lamp bulb

with the receptacle in the lamp unit socket.

(2) Push the ash receiver lamp bulb straight into

the lamp unit socket until it is firmly seated (Fig. 2).

(3) Carefully slide the ash receiver lamp hood onto

the lamp unit socket until it is fully engaged with

the integral snap features on each side of the socket.

(4) Reinstall the ash receiver lamp unit onto the

top of the ash receiver housing. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - INTERIOR/ASH

RECEIVER LAMP UNIT - INSTALLATION).

(5) Reconnect the battery negative cable.

Fig. 2 Ash Receiver Lamp Bulb Remove/Install

1 - SOCKET

2 - BULB

3 - HOOD

KJLAMPS/LIGHTING - INTERIOR 8L - 71

LAMPS/LIGHTING - INTERIOR (Continued)

Page 513 of 1803

ASH RECEIVER LAMP UNIT

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

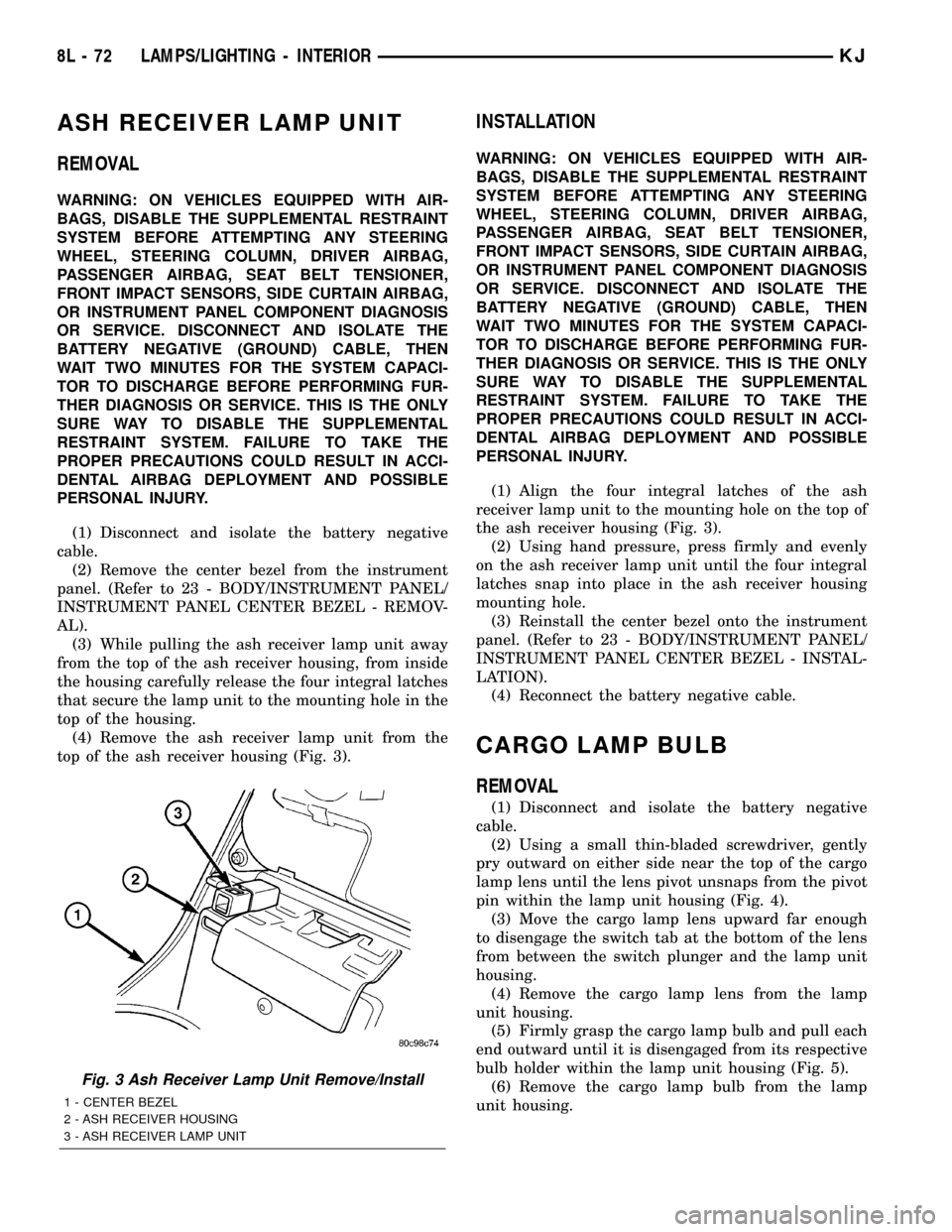

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL).

(3) While pulling the ash receiver lamp unit away

from the top of the ash receiver housing, from inside

the housing carefully release the four integral latches

that secure the lamp unit to the mounting hole in the

top of the housing.

(4) Remove the ash receiver lamp unit from the

top of the ash receiver housing (Fig. 3).

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Align the four integral latches of the ash

receiver lamp unit to the mounting hole on the top of

the ash receiver housing (Fig. 3).

(2) Using hand pressure, press firmly and evenly

on the ash receiver lamp unit until the four integral

latches snap into place in the ash receiver housing

mounting hole.

(3) Reinstall the center bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(4) Reconnect the battery negative cable.

CARGO LAMP BULB

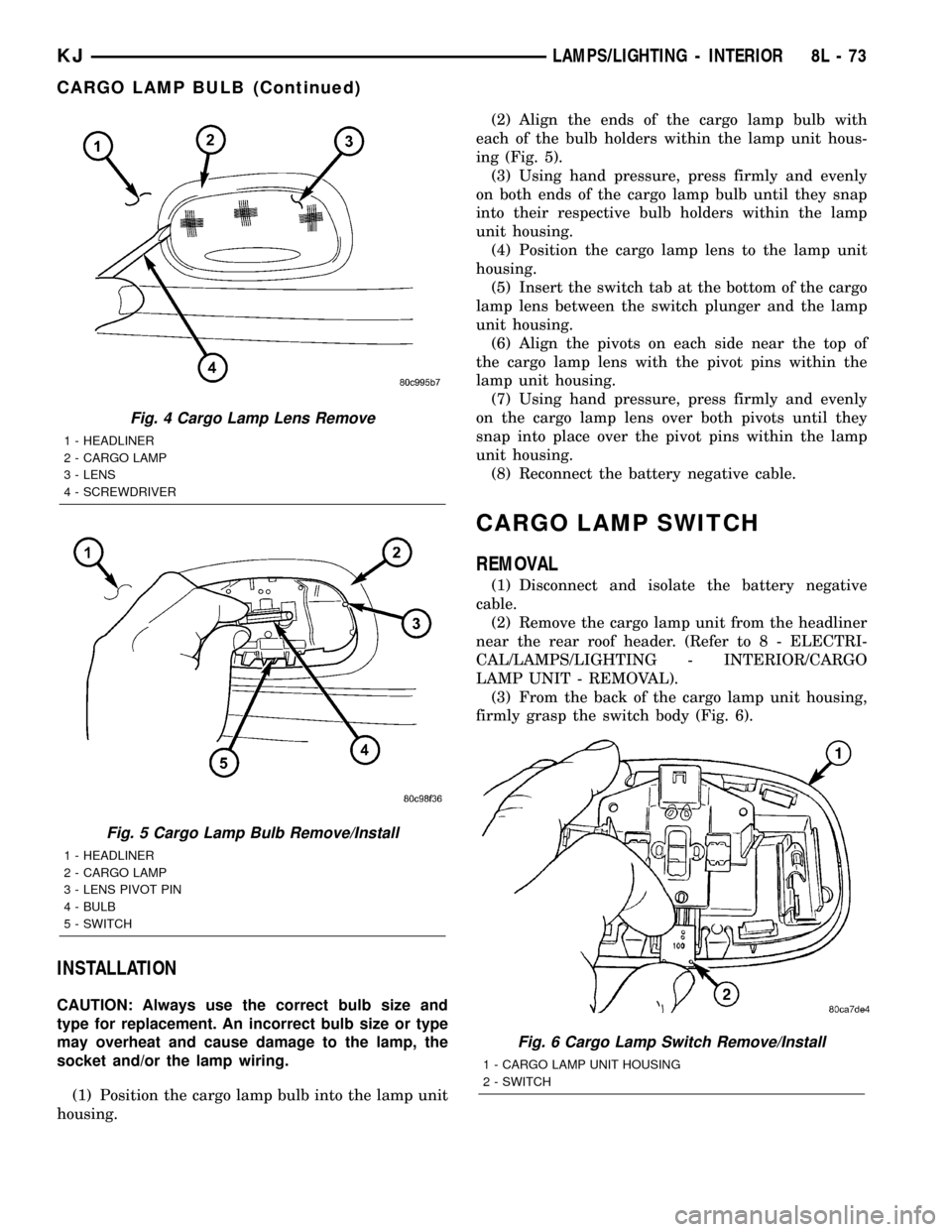

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a small thin-bladed screwdriver, gently

pry outward on either side near the top of the cargo

lamp lens until the lens pivot unsnaps from the pivot

pin within the lamp unit housing (Fig. 4).

(3) Move the cargo lamp lens upward far enough

to disengage the switch tab at the bottom of the lens

from between the switch plunger and the lamp unit

housing.

(4) Remove the cargo lamp lens from the lamp

unit housing.

(5) Firmly grasp the cargo lamp bulb and pull each

end outward until it is disengaged from its respective

bulb holder within the lamp unit housing (Fig. 5).

(6) Remove the cargo lamp bulb from the lamp

unit housing.

Fig. 3 Ash Receiver Lamp Unit Remove/Install

1 - CENTER BEZEL

2 - ASH RECEIVER HOUSING

3 - ASH RECEIVER LAMP UNIT

8L - 72 LAMPS/LIGHTING - INTERIORKJ

Page 514 of 1803

INSTALLATION

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Position the cargo lamp bulb into the lamp unit

housing.(2) Align the ends of the cargo lamp bulb with

each of the bulb holders within the lamp unit hous-

ing (Fig. 5).

(3) Using hand pressure, press firmly and evenly

on both ends of the cargo lamp bulb until they snap

into their respective bulb holders within the lamp

unit housing.

(4) Position the cargo lamp lens to the lamp unit

housing.

(5) Insert the switch tab at the bottom of the cargo

lamp lens between the switch plunger and the lamp

unit housing.

(6) Align the pivots on each side near the top of

the cargo lamp lens with the pivot pins within the

lamp unit housing.

(7) Using hand pressure, press firmly and evenly

on the cargo lamp lens over both pivots until they

snap into place over the pivot pins within the lamp

unit housing.

(8) Reconnect the battery negative cable.

CARGO LAMP SWITCH

REMOVAL

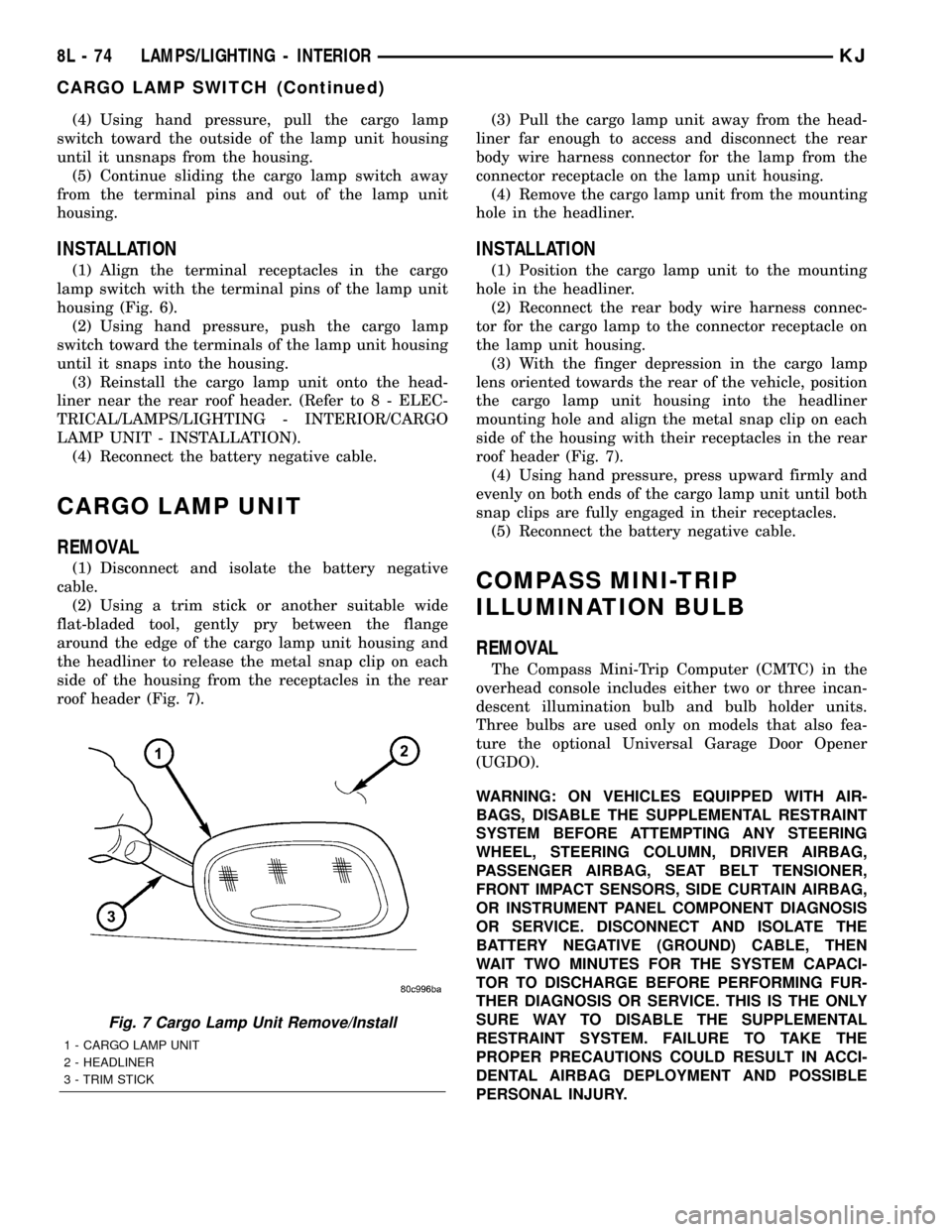

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cargo lamp unit from the headliner

near the rear roof header. (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - INTERIOR/CARGO

LAMP UNIT - REMOVAL).

(3) From the back of the cargo lamp unit housing,

firmly grasp the switch body (Fig. 6).

Fig. 4 Cargo Lamp Lens Remove

1 - HEADLINER

2 - CARGO LAMP

3 - LENS

4 - SCREWDRIVER

Fig. 5 Cargo Lamp Bulb Remove/Install

1 - HEADLINER

2 - CARGO LAMP

3 - LENS PIVOT PIN

4 - BULB

5 - SWITCH

Fig. 6 Cargo Lamp Switch Remove/Install

1 - CARGO LAMP UNIT HOUSING

2 - SWITCH

KJLAMPS/LIGHTING - INTERIOR 8L - 73

CARGO LAMP BULB (Continued)

Page 515 of 1803

(4) Using hand pressure, pull the cargo lamp

switch toward the outside of the lamp unit housing

until it unsnaps from the housing.

(5) Continue sliding the cargo lamp switch away

from the terminal pins and out of the lamp unit

housing.

INSTALLATION

(1) Align the terminal receptacles in the cargo

lamp switch with the terminal pins of the lamp unit

housing (Fig. 6).

(2) Using hand pressure, push the cargo lamp

switch toward the terminals of the lamp unit housing

until it snaps into the housing.

(3) Reinstall the cargo lamp unit onto the head-

liner near the rear roof header. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - INTERIOR/CARGO

LAMP UNIT - INSTALLATION).

(4) Reconnect the battery negative cable.

CARGO LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry between the flange

around the edge of the cargo lamp unit housing and

the headliner to release the metal snap clip on each

side of the housing from the receptacles in the rear

roof header (Fig. 7).(3) Pull the cargo lamp unit away from the head-

liner far enough to access and disconnect the rear

body wire harness connector for the lamp from the

connector receptacle on the lamp unit housing.

(4) Remove the cargo lamp unit from the mounting

hole in the headliner.

INSTALLATION

(1) Position the cargo lamp unit to the mounting

hole in the headliner.

(2) Reconnect the rear body wire harness connec-

tor for the cargo lamp to the connector receptacle on

the lamp unit housing.

(3) With the finger depression in the cargo lamp

lens oriented towards the rear of the vehicle, position

the cargo lamp unit housing into the headliner

mounting hole and align the metal snap clip on each

side of the housing with their receptacles in the rear

roof header (Fig. 7).

(4) Using hand pressure, press upward firmly and

evenly on both ends of the cargo lamp unit until both

snap clips are fully engaged in their receptacles.

(5) Reconnect the battery negative cable.

COMPASS MINI-TRIP

ILLUMINATION BULB

REMOVAL

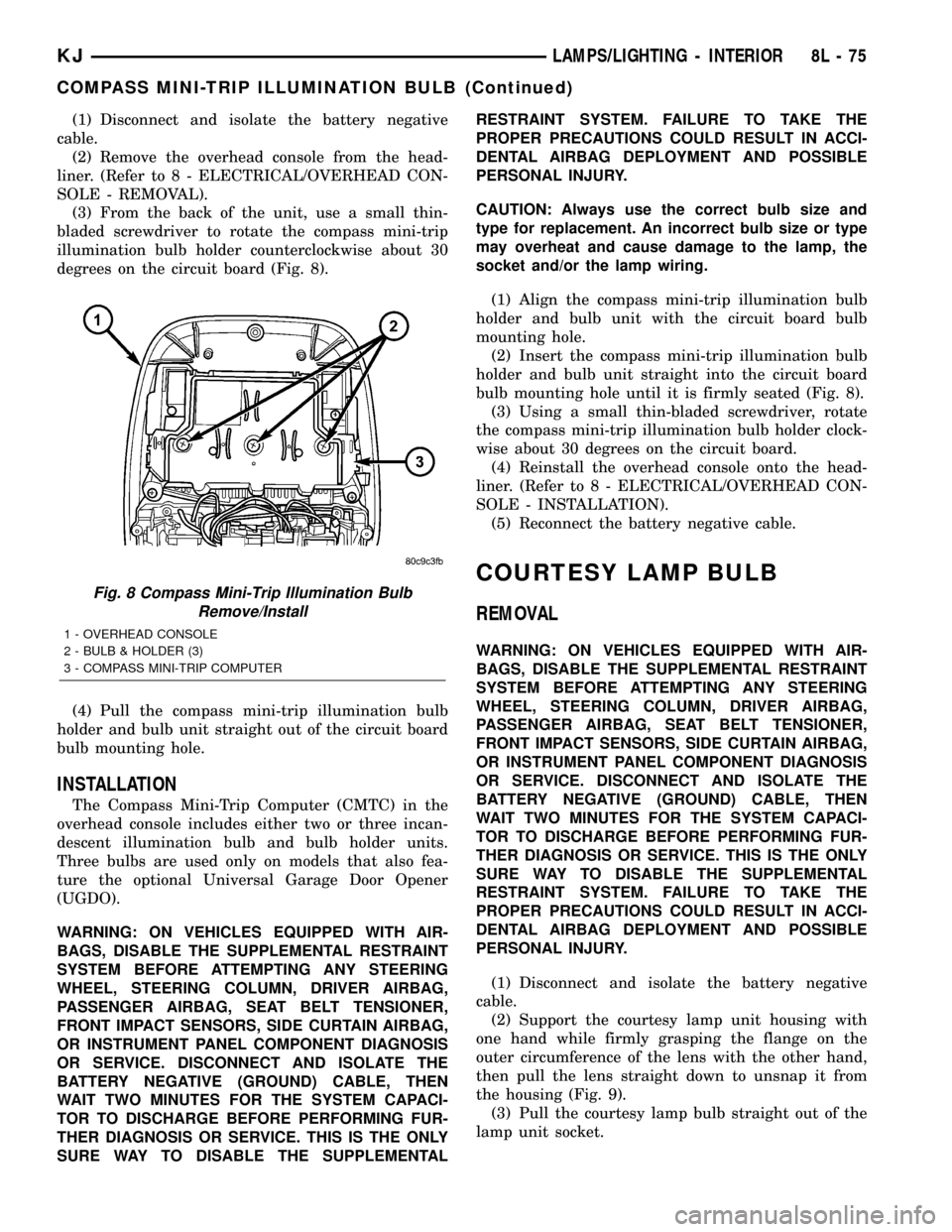

The Compass Mini-Trip Computer (CMTC) in the

overhead console includes either two or three incan-

descent illumination bulb and bulb holder units.

Three bulbs are used only on models that also fea-

ture the optional Universal Garage Door Opener

(UGDO).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 7 Cargo Lamp Unit Remove/Install

1 - CARGO LAMP UNIT

2 - HEADLINER

3 - TRIM STICK

8L - 74 LAMPS/LIGHTING - INTERIORKJ

CARGO LAMP SWITCH (Continued)

Page 516 of 1803

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the overhead console from the head-

liner. (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(3) From the back of the unit, use a small thin-

bladed screwdriver to rotate the compass mini-trip

illumination bulb holder counterclockwise about 30

degrees on the circuit board (Fig. 8).

(4) Pull the compass mini-trip illumination bulb

holder and bulb unit straight out of the circuit board

bulb mounting hole.

INSTALLATION

The Compass Mini-Trip Computer (CMTC) in the

overhead console includes either two or three incan-

descent illumination bulb and bulb holder units.

Three bulbs are used only on models that also fea-

ture the optional Universal Garage Door Opener

(UGDO).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTALRESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the compass mini-trip illumination bulb

holder and bulb unit with the circuit board bulb

mounting hole.

(2) Insert the compass mini-trip illumination bulb

holder and bulb unit straight into the circuit board

bulb mounting hole until it is firmly seated (Fig. 8).

(3) Using a small thin-bladed screwdriver, rotate

the compass mini-trip illumination bulb holder clock-

wise about 30 degrees on the circuit board.

(4) Reinstall the overhead console onto the head-

liner. (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - INSTALLATION).

(5) Reconnect the battery negative cable.

COURTESY LAMP BULB

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

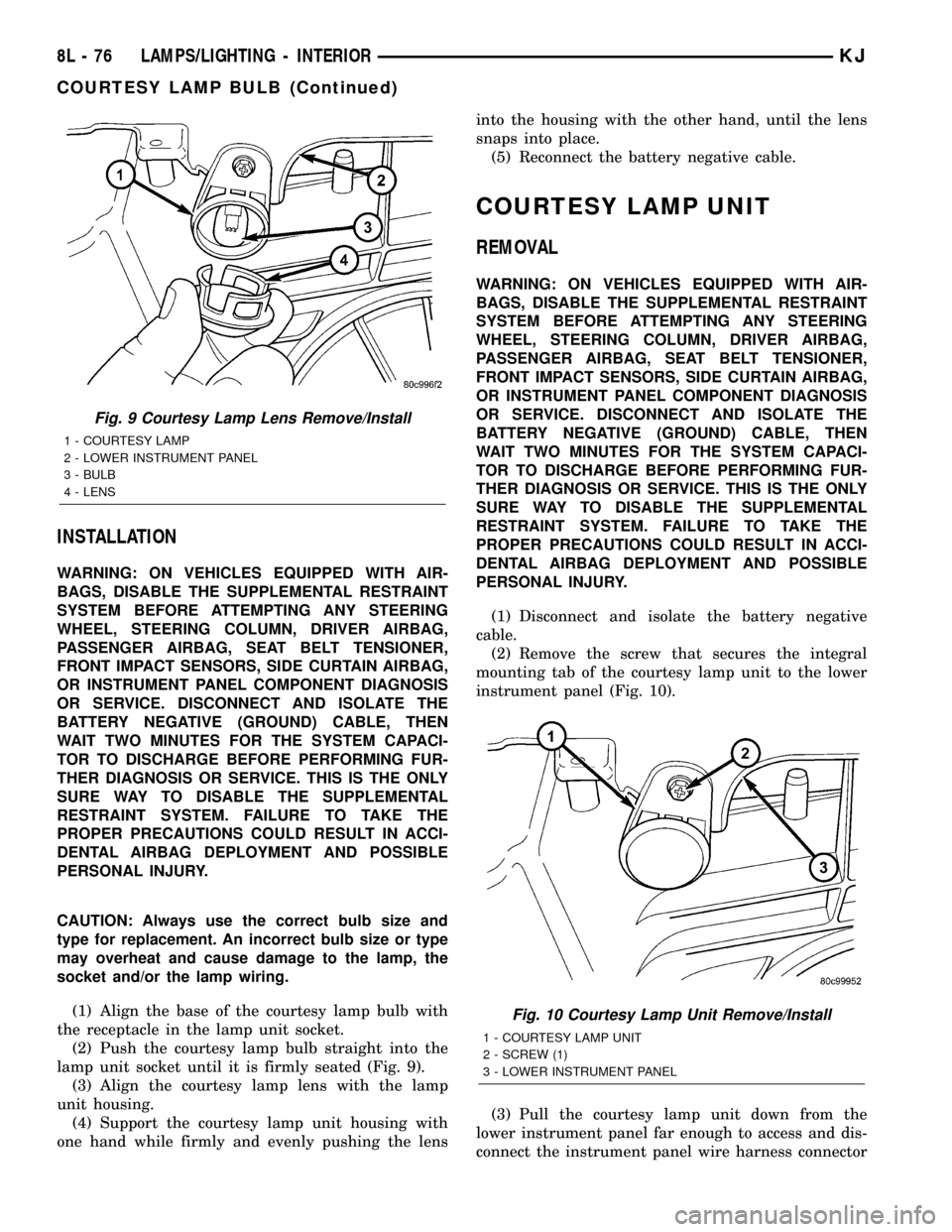

(2) Support the courtesy lamp unit housing with

one hand while firmly grasping the flange on the

outer circumference of the lens with the other hand,

then pull the lens straight down to unsnap it from

the housing (Fig. 9).

(3) Pull the courtesy lamp bulb straight out of the

lamp unit socket.

Fig. 8 Compass Mini-Trip Illumination Bulb

Remove/Install

1 - OVERHEAD CONSOLE

2 - BULB & HOLDER (3)

3 - COMPASS MINI-TRIP COMPUTER

KJLAMPS/LIGHTING - INTERIOR 8L - 75

COMPASS MINI-TRIP ILLUMINATION BULB (Continued)

Page 517 of 1803

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the base of the courtesy lamp bulb with

the receptacle in the lamp unit socket.

(2) Push the courtesy lamp bulb straight into the

lamp unit socket until it is firmly seated (Fig. 9).

(3) Align the courtesy lamp lens with the lamp

unit housing.

(4) Support the courtesy lamp unit housing with

one hand while firmly and evenly pushing the lensinto the housing with the other hand, until the lens

snaps into place.

(5) Reconnect the battery negative cable.

COURTESY LAMP UNIT

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

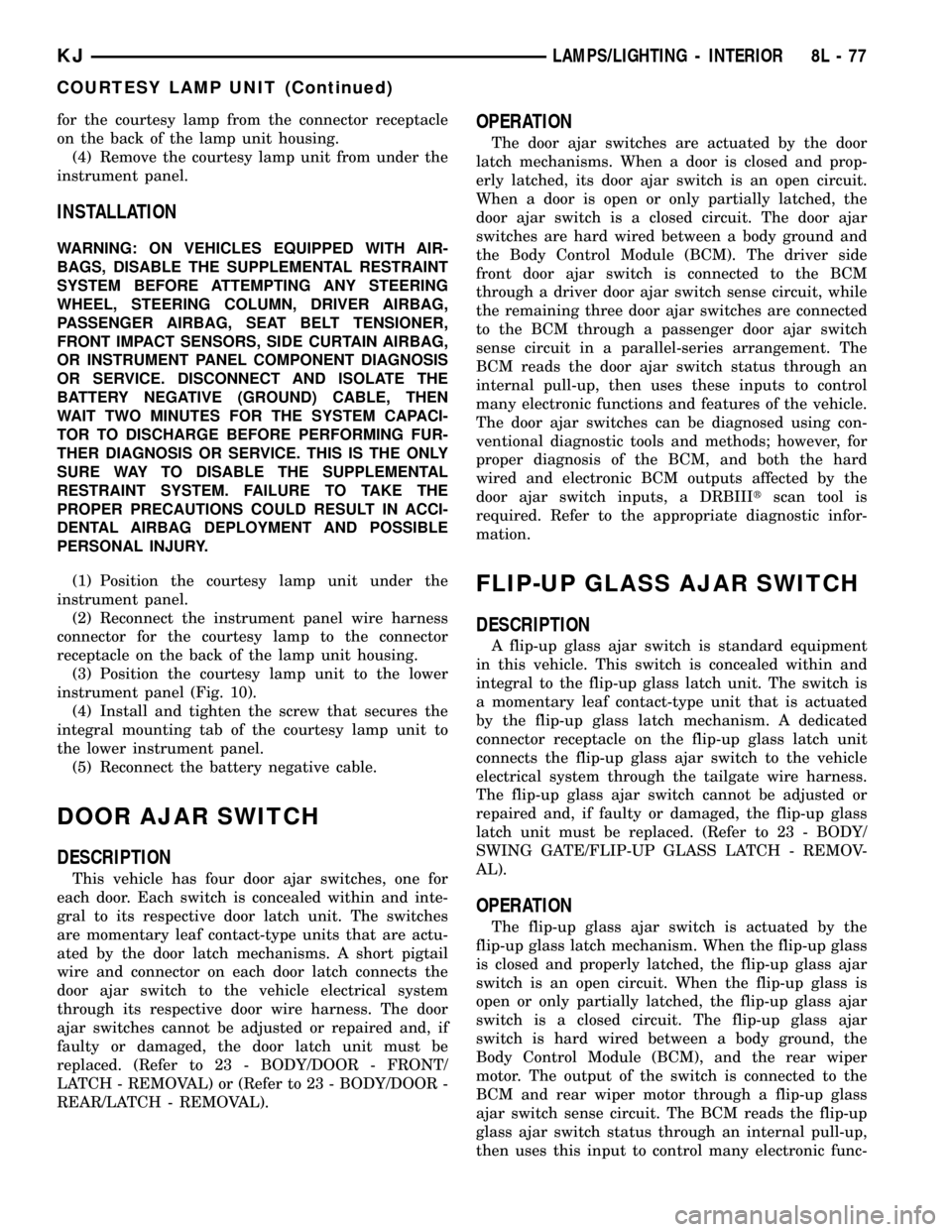

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the screw that secures the integral

mounting tab of the courtesy lamp unit to the lower

instrument panel (Fig. 10).

(3) Pull the courtesy lamp unit down from the

lower instrument panel far enough to access and dis-

connect the instrument panel wire harness connector

Fig. 9 Courtesy Lamp Lens Remove/Install

1 - COURTESY LAMP

2 - LOWER INSTRUMENT PANEL

3 - BULB

4 - LENS

Fig. 10 Courtesy Lamp Unit Remove/Install

1 - COURTESY LAMP UNIT

2 - SCREW (1)

3 - LOWER INSTRUMENT PANEL

8L - 76 LAMPS/LIGHTING - INTERIORKJ

COURTESY LAMP BULB (Continued)

Page 518 of 1803

for the courtesy lamp from the connector receptacle

on the back of the lamp unit housing.

(4) Remove the courtesy lamp unit from under the

instrument panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the courtesy lamp unit under the

instrument panel.

(2) Reconnect the instrument panel wire harness

connector for the courtesy lamp to the connector

receptacle on the back of the lamp unit housing.

(3) Position the courtesy lamp unit to the lower

instrument panel (Fig. 10).

(4) Install and tighten the screw that secures the

integral mounting tab of the courtesy lamp unit to

the lower instrument panel.

(5) Reconnect the battery negative cable.

DOOR AJAR SWITCH

DESCRIPTION

This vehicle has four door ajar switches, one for

each door. Each switch is concealed within and inte-

gral to its respective door latch unit. The switches

are momentary leaf contact-type units that are actu-

ated by the door latch mechanisms. A short pigtail

wire and connector on each door latch connects the

door ajar switch to the vehicle electrical system

through its respective door wire harness. The door

ajar switches cannot be adjusted or repaired and, if

faulty or damaged, the door latch unit must be

replaced. (Refer to 23 - BODY/DOOR - FRONT/

LATCH - REMOVAL) or (Refer to 23 - BODY/DOOR -

REAR/LATCH - REMOVAL).

OPERATION

The door ajar switches are actuated by the door

latch mechanisms. When a door is closed and prop-

erly latched, its door ajar switch is an open circuit.

When a door is open or only partially latched, the

door ajar switch is a closed circuit. The door ajar

switches are hard wired between a body ground and

the Body Control Module (BCM). The driver side

front door ajar switch is connected to the BCM

through a driver door ajar switch sense circuit, while

the remaining three door ajar switches are connected

to the BCM through a passenger door ajar switch

sense circuit in a parallel-series arrangement. The

BCM reads the door ajar switch status through an

internal pull-up, then uses these inputs to control

many electronic functions and features of the vehicle.

The door ajar switches can be diagnosed using con-

ventional diagnostic tools and methods; however, for

proper diagnosis of the BCM, and both the hard

wired and electronic BCM outputs affected by the

door ajar switch inputs, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

FLIP-UP GLASS AJAR SWITCH

DESCRIPTION

A flip-up glass ajar switch is standard equipment

in this vehicle. This switch is concealed within and

integral to the flip-up glass latch unit. The switch is

a momentary leaf contact-type unit that is actuated

by the flip-up glass latch mechanism. A dedicated

connector receptacle on the flip-up glass latch unit

connects the flip-up glass ajar switch to the vehicle

electrical system through the tailgate wire harness.

The flip-up glass ajar switch cannot be adjusted or

repaired and, if faulty or damaged, the flip-up glass

latch unit must be replaced. (Refer to 23 - BODY/

SWING GATE/FLIP-UP GLASS LATCH - REMOV-

AL).

OPERATION

The flip-up glass ajar switch is actuated by the

flip-up glass latch mechanism. When the flip-up glass

is closed and properly latched, the flip-up glass ajar

switch is an open circuit. When the flip-up glass is

open or only partially latched, the flip-up glass ajar

switch is a closed circuit. The flip-up glass ajar

switch is hard wired between a body ground, the

Body Control Module (BCM), and the rear wiper

motor. The output of the switch is connected to the

BCM and rear wiper motor through a flip-up glass

ajar switch sense circuit. The BCM reads the flip-up

glass ajar switch status through an internal pull-up,

then uses this input to control many electronic func-

KJLAMPS/LIGHTING - INTERIOR 8L - 77

COURTESY LAMP UNIT (Continued)