Power distribution unit JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 726 of 1803

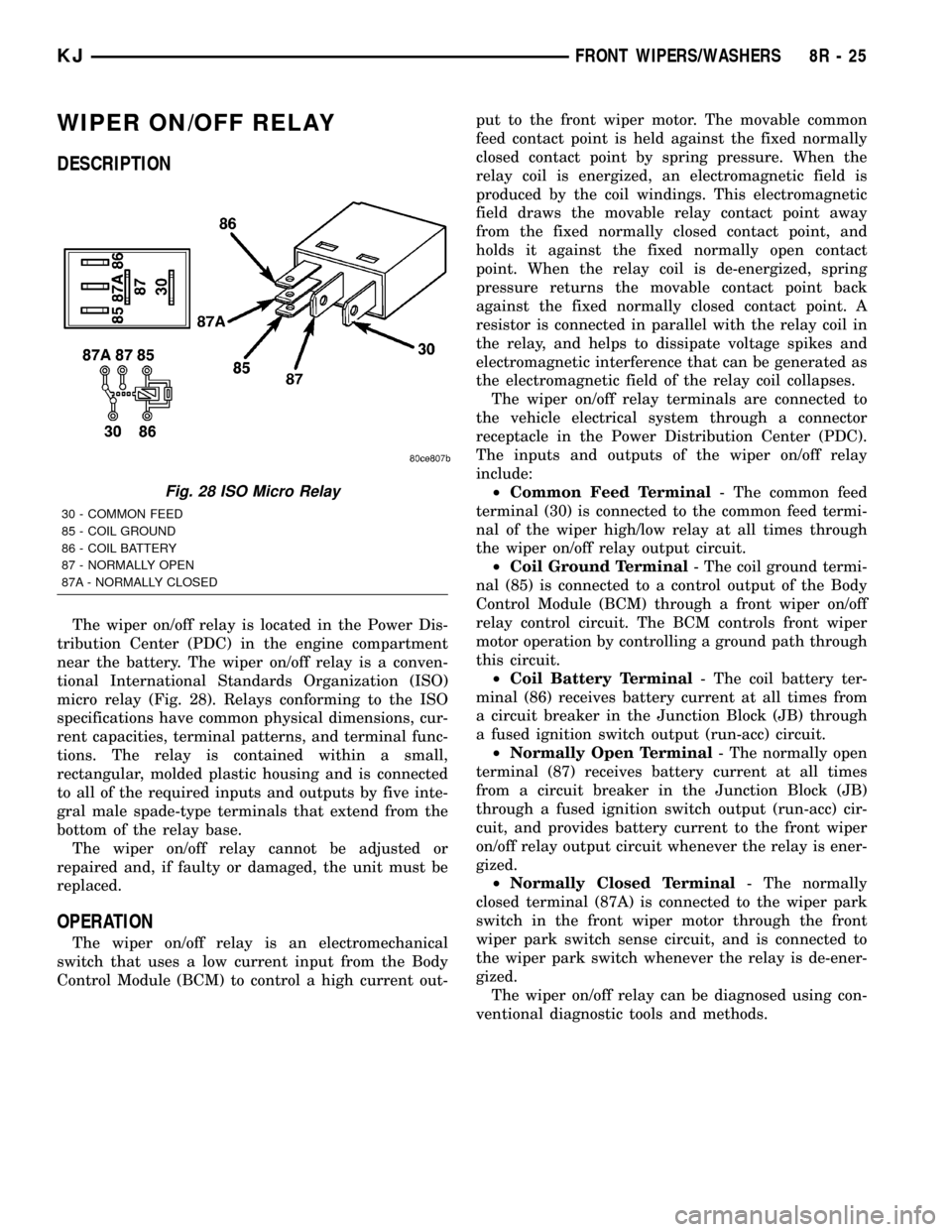

WIPER ON/OFF RELAY

DESCRIPTION

The wiper on/off relay is located in the Power Dis-

tribution Center (PDC) in the engine compartment

near the battery. The wiper on/off relay is a conven-

tional International Standards Organization (ISO)

micro relay (Fig. 28). Relays conforming to the ISO

specifications have common physical dimensions, cur-

rent capacities, terminal patterns, and terminal func-

tions. The relay is contained within a small,

rectangular, molded plastic housing and is connected

to all of the required inputs and outputs by five inte-

gral male spade-type terminals that extend from the

bottom of the relay base.

The wiper on/off relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper on/off relay is an electromechanical

switch that uses a low current input from the Body

Control Module (BCM) to control a high current out-put to the front wiper motor. The movable common

feed contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The wiper on/off relay terminals are connected to

the vehicle electrical system through a connector

receptacle in the Power Distribution Center (PDC).

The inputs and outputs of the wiper on/off relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the common feed termi-

nal of the wiper high/low relay at all times through

the wiper on/off relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Body

Control Module (BCM) through a front wiper on/off

relay control circuit. The BCM controls front wiper

motor operation by controlling a ground path through

this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a circuit breaker in the Junction Block (JB) through

a fused ignition switch output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) receives battery current at all times

from a circuit breaker in the Junction Block (JB)

through a fused ignition switch output (run-acc) cir-

cuit, and provides battery current to the front wiper

on/off relay output circuit whenever the relay is ener-

gized.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to the wiper park

switch in the front wiper motor through the front

wiper park switch sense circuit, and is connected to

the wiper park switch whenever the relay is de-ener-

gized.

The wiper on/off relay can be diagnosed using con-

ventional diagnostic tools and methods.

Fig. 28 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJFRONT WIPERS/WASHERS 8R - 25

Page 1668 of 1803

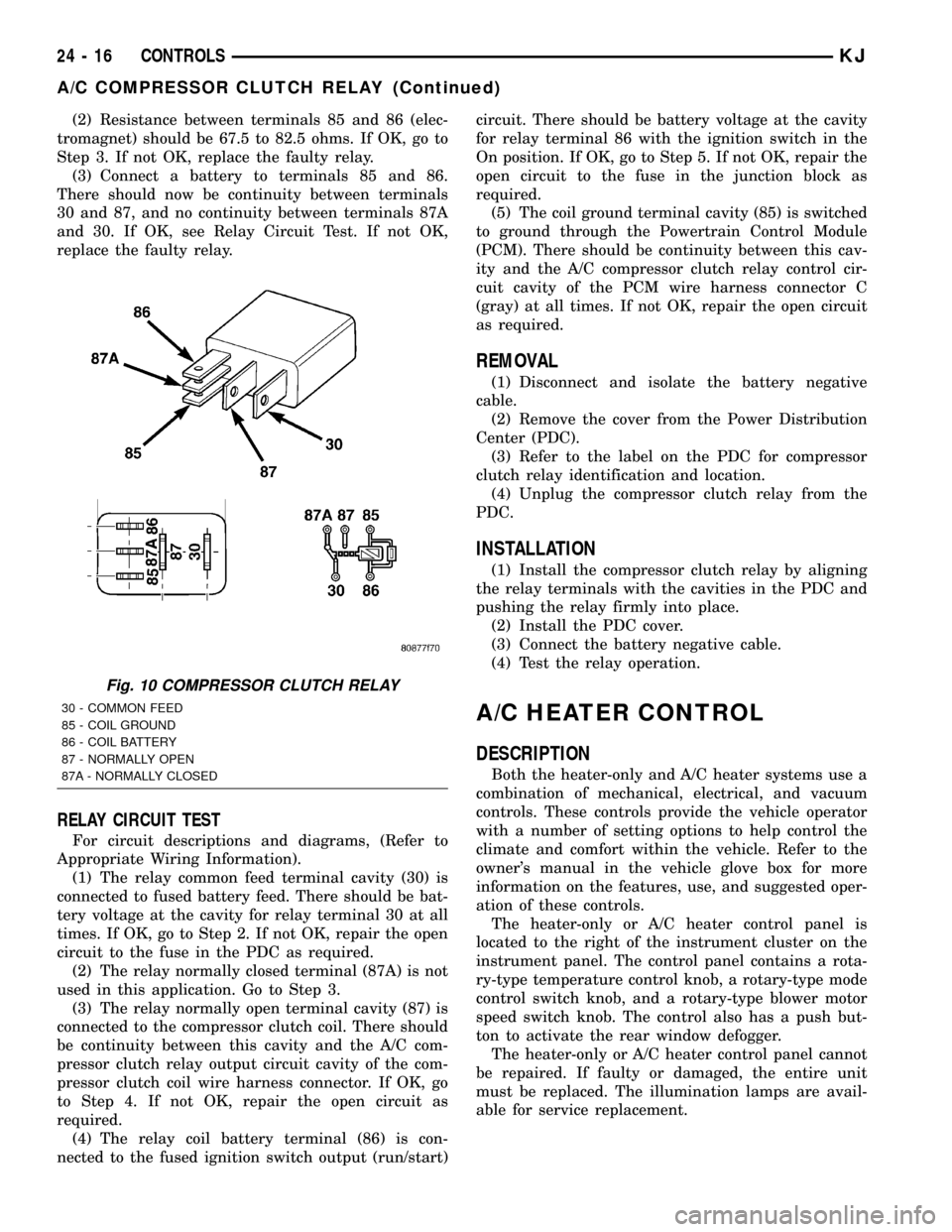

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 67.5 to 82.5 ohms. If OK, go to

Step 3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see Relay Circuit Test. If not OK,

replace the faulty relay.

RELAY CIRCUIT TEST

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed. There should be bat-

tery voltage at the cavity for relay terminal 30 at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is not

used in this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the compressor clutch coil. There should

be continuity between this cavity and the A/C com-

pressor clutch relay output circuit cavity of the com-

pressor clutch coil wire harness connector. If OK, go

to Step 4. If not OK, repair the open circuit as

required.

(4) The relay coil battery terminal (86) is con-

nected to the fused ignition switch output (run/start)circuit. There should be battery voltage at the cavity

for relay terminal 86 with the ignition switch in the

On position. If OK, go to Step 5. If not OK, repair the

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

Both the heater-only and A/C heater systems use a

combination of mechanical, electrical, and vacuum

controls. These controls provide the vehicle operator

with a number of setting options to help control the

climate and comfort within the vehicle. Refer to the

owner's manual in the vehicle glove box for more

information on the features, use, and suggested oper-

ation of these controls.

The heater-only or A/C heater control panel is

located to the right of the instrument cluster on the

instrument panel. The control panel contains a rota-

ry-type temperature control knob, a rotary-type mode

control switch knob, and a rotary-type blower motor

speed switch knob. The control also has a push but-

ton to activate the rear window defogger.

The heater-only or A/C heater control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The illumination lamps are avail-

able for service replacement.

Fig. 10 COMPRESSOR CLUTCH RELAY

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

24 - 16 CONTROLSKJ

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 1675 of 1803

BLOWER MOTOR SWITCH

DESCRIPTION

The heater-only or A/C Heater blower motor is con-

trolled by a four position rotary-type blower motor

switch, mounted in the A/C Heater control panel. The

switch allows the selection of one of four blower

motor speeds, but can only be turned off by selecting

the Off position with the heater-only or A/C Heater

mode control switch knob.

OPERATION

The blower motor switch directs the blower motor

ground path through the mode control switch to the

blower motor resistor, or directly to ground, as

required to achieve the selected blower motor speed.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire heater-only or A/C

Heater control unit must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

SWITCH

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check for battery voltage at the fuse in the

Power Distribution Center (PDC). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the A/C Heater control from the instrument

panel. Check for continuity between the ground cir-

cuit cavity of the A/C Heater control wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 3. If not OK, repair the open

circuit to ground as required.

(3) With the A/C Heater control wire harness con-

nector unplugged, place the A/C Heater mode control

switch knob in any position except the Off position.

Check for continuity between the ground circuit ter-minal and each of the blower motor driver circuit ter-

minals of the A/C Heater control as you move the

blower motor switch knob to each of the four speed

positions. There should be continuity at each driver

circuit terminal in only one blower motor switch

speed position. If OK, test and repair the blower

driver circuits between the A/C Heater control con-

nector and the blower motor resistor as required. If

not OK, replace the faulty A/C Heater control unit.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire heater-only or A/C

Heater control unit must be replaced. (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - REMOVAL)

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) The blower motor switch cannot be repaired

and, if faulty or damaged the entire heater-only or

A/C heater control unit must be replaced(Refer to 24

- HEATING & AIR CONDITIONING/CONTROLS/

A/C HEATER CONTROL - INSTALLATION).

KJCONTROLS 24 - 23

Page 1682 of 1803

BLOWER MOTOR

DESCRIPTION

The blower motor and blower wheel are located in

the passenger side end of the HVAC housing, below

the glove box. The blower motor controls the velocity

of air flowing through the HVAC housing by spinning

a squirrel cage-type blower wheel within the housing

at the selected speed. The blower motor and wheel

can be removed from the housing inside the vehicle

without removing the dash or HVAC housing assem-

bly.

OPERATION

The blower motor will only operate when the igni-

tion switch is in the On position, and the A/C Heater

mode control switch knob is in any position, except

Off. The blower motor receives a fused battery feed

through the blower motor relay whenever the igni-

tion switch is in the On position. The blower motor

battery feed circuit is protected by a fuse in the

Power Distribution Center (PDC). Blower motor

speed is controlled by regulating the ground path

through the A/C Heater control blower motor switch

and the blower motor resistor.

The blower motor and blower motor wheel cannot

be repaired and, if faulty or damaged, they must be

replaced. The blower motor and blower wheel are ser-

viced only as a unit.

DIAGNOSIS AND TESTING - BLOWER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). Possible causes of

an inoperative blower motor include:²Faulty fuse

²Faulty blower motor circuit wiring or wire har-

ness connectors

²Faulty blower motor resistor

²Faulty blower motor relay

²Faulty blower motor switch

²Faulty A/C Heater mode control switch

²Faulty blower motor.

Possible causes of the blower motor not operating

in all speeds include:

²Faulty blower motor switch

²Faulty blower motor resistor

²Faulty blower motor circuit wiring or wire har-

ness connectors.

VIBRATION

Possible causes of blower motor vibration include:

²Improper blower motor mounting

²Improper blower wheel mounting

²Blower wheel out of balance or bent

²Blower motor faulty.

NOISE

To verify that the blower is the source of the noise,

unplug the blower motor wire harness connector and

operate the HVAC system. If the noise goes away,

possible causes include:

²Foreign material in the HVAC housing

²Improper blower motor mounting

²Improper blower wheel mounting

²Blower motor faulty.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

24 - 30 DISTRIBUTIONKJ

Page 1733 of 1803

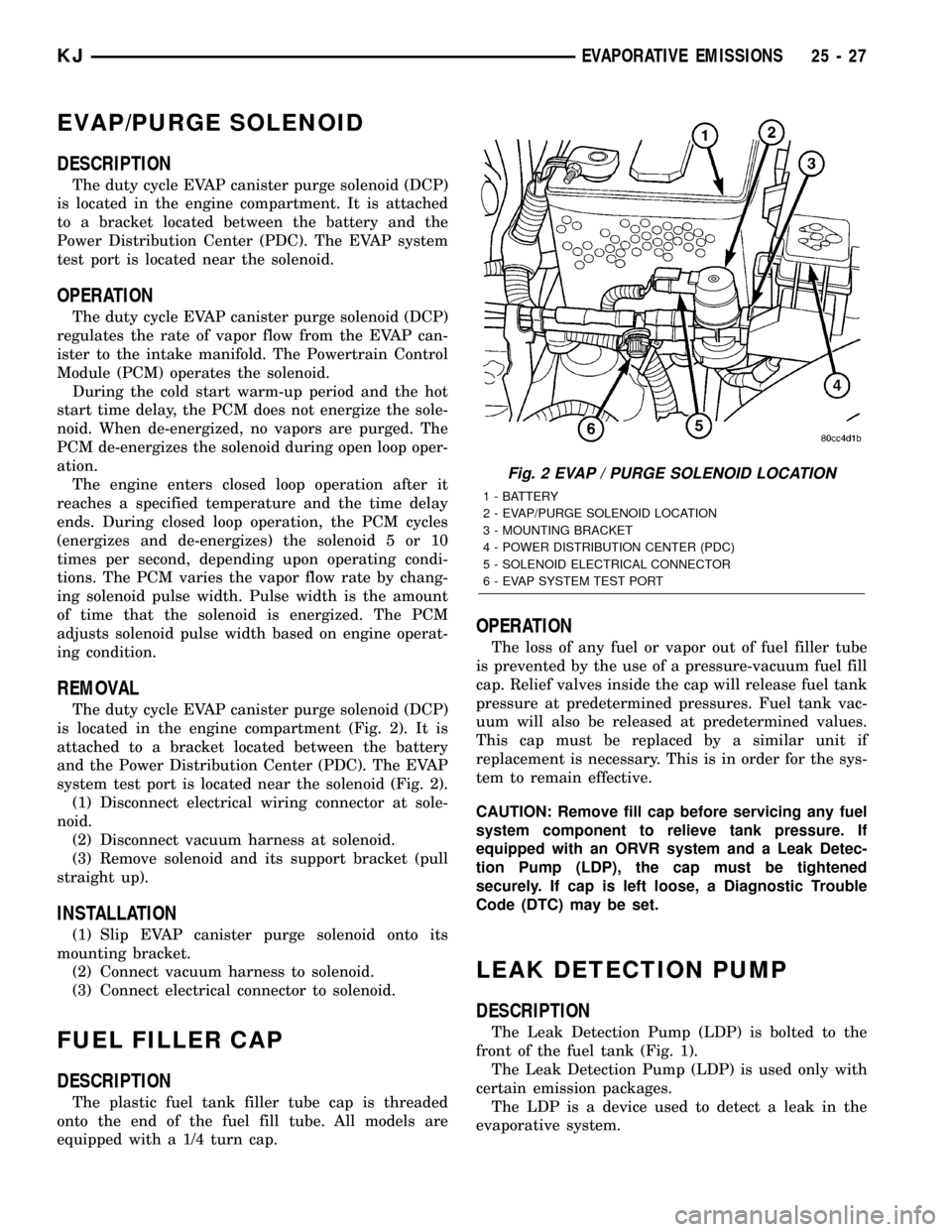

EVAP/PURGE SOLENOID

DESCRIPTION

The duty cycle EVAP canister purge solenoid (DCP)

is located in the engine compartment. It is attached

to a bracket located between the battery and the

Power Distribution Center (PDC). The EVAP system

test port is located near the solenoid.

OPERATION

The duty cycle EVAP canister purge solenoid (DCP)

regulates the rate of vapor flow from the EVAP can-

ister to the intake manifold. The Powertrain Control

Module (PCM) operates the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged. The

PCM de-energizes the solenoid during open loop oper-

ation.

The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM cycles

(energizes and de-energizes) the solenoid 5 or 10

times per second, depending upon operating condi-

tions. The PCM varies the vapor flow rate by chang-

ing solenoid pulse width. Pulse width is the amount

of time that the solenoid is energized. The PCM

adjusts solenoid pulse width based on engine operat-

ing condition.

REMOVAL

The duty cycle EVAP canister purge solenoid (DCP)

is located in the engine compartment (Fig. 2). It is

attached to a bracket located between the battery

and the Power Distribution Center (PDC). The EVAP

system test port is located near the solenoid (Fig. 2).

(1) Disconnect electrical wiring connector at sole-

noid.

(2) Disconnect vacuum harness at solenoid.

(3) Remove solenoid and its support bracket (pull

straight up).

INSTALLATION

(1) Slip EVAP canister purge solenoid onto its

mounting bracket.

(2) Connect vacuum harness to solenoid.

(3) Connect electrical connector to solenoid.

FUEL FILLER CAP

DESCRIPTION

The plastic fuel tank filler tube cap is threaded

onto the end of the fuel fill tube. All models are

equipped with a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube

is prevented by the use of a pressure-vacuum fuel fill

cap. Relief valves inside the cap will release fuel tank

pressure at predetermined pressures. Fuel tank vac-

uum will also be released at predetermined values.

This cap must be replaced by a similar unit if

replacement is necessary. This is in order for the sys-

tem to remain effective.

CAUTION: Remove fill cap before servicing any fuel

system component to relieve tank pressure. If

equipped with an ORVR system and a Leak Detec-

tion Pump (LDP), the cap must be tightened

securely. If cap is left loose, a Diagnostic Trouble

Code (DTC) may be set.

LEAK DETECTION PUMP

DESCRIPTION

The Leak Detection Pump (LDP) is bolted to the

front of the fuel tank (Fig. 1).

The Leak Detection Pump (LDP) is used only with

certain emission packages.

The LDP is a device used to detect a leak in the

evaporative system.

Fig. 2 EVAP / PURGE SOLENOID LOCATION

1 - BATTERY

2 - EVAP/PURGE SOLENOID LOCATION

3 - MOUNTING BRACKET

4 - POWER DISTRIBUTION CENTER (PDC)

5 - SOLENOID ELECTRICAL CONNECTOR

6 - EVAP SYSTEM TEST PORT

KJEVAPORATIVE EMISSIONS 25 - 27

Page 1741 of 1803

ANTENNA BODY & CABLE - OPERATION . . . 8A-5

ANTENNA BODY & CABLE - REMOVAL.....8A-6

ANTENNA BODY AND CABLE -

DIAGNOSIS AND TESTING..............8A-5

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL..................8A-8

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL..................8A-7

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER.......................8E-10

ANTILOCK BRAKE - REMOVAL,

CONTROLLER.......................8E-10

ANTILOCK BRAKING SYSTEM -

DIAGNOSIS AND TESTING..............5-33

A-PILLAR SEAL - INSTALLATION.......23-185

A-PILLAR SEAL - REMOVAL...........23-185

A-PILLAR TRIM AND GRAB HANDLE -

INSTALLATION......................23-156

A-PILLAR TRIM AND GRAB HANDLE -

REMOVAL.........................23-156

A-PILLAR WEATHERSTRIP/RETAINER -

INSTALLATION, WINDSHIELD..........23-187

A-PILLAR WEATHERSTRIP/RETAINER -

REMOVAL, WINDSHIELD..............23-186

APPLICATION TABLE, SPECIFICATIONS -

A/C ................................24-9

AREA LEAKS - DIAGNOSIS AND

TESTING, REAR SEAL..................9-61

ARM - DESCRIPTION, FRONT WIPER.....8R-12

ARM - DESCRIPTION, LOWER CONTROL . . . 2-21

ARM - DESCRIPTION, REAR WIPER......8R-37

ARM - DESCRIPTION, ROCKER......9-29,9-37

ARM - INSTALLATION, FRONT WIPER....8R-13

ARM - INSTALLATION, LOWER CONTROL . . 2-10,

2-21

ARM - INSTALLATION, REAR WIPER.....8R-38

ARM - INSTALLATION, ROCKER..........9-37

ARM - INSTALLATION, UPPER CONTROL . . . 2-21

ARM - OPERATION, FRONT WIPER......8R-12

ARM - OPERATION, LOWER CONTROL.....2-21

ARM - OPERATION, REAR WIPER.......8R-38

ARM - REMOVAL, FRONT WIPER........8R-12

ARM - REMOVAL, LOWER CONTROL . . 2-10,2-21

ARM - REMOVAL, REAR WIPER.........8R-38

ARM - REMOVAL, ROCKER..............9-37

ARM - REMOVAL, UPPER CONTROL......2-20

ARM, BUSHINGS, AND BALL JOINT -

DESCRIPTION, UPPER SUSPENSION......2-20

ARM, BUSHINGS, AND BALL JOINT -

OPERATION, UPPER SUSPENSION........2-20

ARM PARK RAMP - INSTALLATION,

WIPER.............................8R-43

ARM PARK RAMP - REMOVAL, WIPER . . . 8R-43

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-4

ASD SENSE - PCM INPUT - OPERATION....8I-4

ASH RECEIVER LAMP BULB -

INSTALLATION.......................8L-71

ASH RECEIVER LAMP BULB - REMOVAL . . 8L-71

ASH RECEIVER LAMP UNIT -

INSTALLATION.......................8L-72

ASH RECEIVER LAMP UNIT - REMOVAL . . 8L-72

ASSEMBLY - ASSEMBLY, INPUT CLUTCH . 21-138

ASSEMBLY - DESCRIPTION, INPUT

CLUTCH...........................21-133

ASSEMBLY - DESCRIPTION,

TRANSMISSION SOLENOID/TRS........21-169

ASSEMBLY - DISASSEMBLY, INPUT

CLUTCH...........................21-135

ASSEMBLY - INSTALLATION.........8W-97-11

ASSEMBLY - INSTALLATION, GUIDE.....23-179

ASSEMBLY - INSTALLATION,

INSTRUMENT PANEL.................23-151

ASSEMBLY - INSTALLATION, MODULE . . . 23-181

ASSEMBLY - INSTALLATION,

TRANSMISSION SOLENOID/TRS........21-170

ASSEMBLY - OPERATION, INPUT

CLUTCH...........................21-135

ASSEMBLY - OPERATION,

TRANSMISSION SOLENOID/TRS........21-169

ASSEMBLY - POWER DISTRIBUTION

CENTER ASSEMBLY

...............8W-97-10

ASSEMBLY - REMOVAL, GUIDE

........23-179

ASSEMBLY - REMOVAL, INSTRUMENT

PANEL

............................23-149

ASSEMBLY - REMOVAL, MODULE

......23-181

ASSEMBLY - REMOVAL, TRANSMISSION

SOLENOID/TRS

.....................21-170ASSEMBLY, 4C RETAINER/BULKHEAD....21-123

ASSEMBLY, ASSEMBLY - POWER

DISTRIBUTION CENTER............8W-97-10

ASSEMBLY, DIAGNOSIS AND TESTING....21-90

ASSEMBLY, DIFFERENTIAL.........3-105,3-41

ASSEMBLY, DIFFERENTIAL - TRAC-LOK . . . 3-109,

3-77

ASSEMBLY, DISC BRAKE CALIPERS.......5-16

ASSEMBLY, HVAC HOUSING............24-34

ASSEMBLY, INPUT CLUTCH ASSEMBLY . . 21-138

ASSEMBLY, INSTRUMENT CLUSTER......8J-10

ASSEMBLY, LOW/REVERSE CLUTCH.....21-146

ASSEMBLY, MANUAL - NV1500.........21-13

ASSEMBLY, MANUAL - NV3550.........21-48

ASSEMBLY, OIL PUMP.................9-67

ASSEMBLY, OIL PUMP...............21-151

ASSEMBLY, PLANETARY GEARTRAIN....21-160

ASSEMBLY, SINGLE CARDAN

UNIVERSAL JOINTS....................3-9

ASSEMBLY, TRANSFER CASE - NV231 . . . 21-194

ASSEMBLY, TRANSFER CASE - NV242 . . . 21-230

ASSEMBLY, VALVE BODY.............21-176

ASSEMBLY, WHEEL CYLINDERS..........5-29

ASSEMBLY WINDOW DEFOGGER

FUNCTION - DIAGNOSIS AND TESTING,

REAR HVAC CONTROL.................8G-9

ASSIST HANDLE - INSTALLATION.......23-157

ASSIST HANDLE - REMOVAL............23-157

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-1

AUTOMATIC TRANSMISSION - 45RFE -

DESCRIPTION.......................21-76

AUTOMATIC TRANSMISSION - 45RFE -

OPERATION.........................21-77

AUTOMATIC TRANSMISSION -

DIAGNOSIS AND TESTING.............21-77

AUTOMATIC TRANSMISSION FLUID -

DESCRIPTION.........................0-2

AUTOMATIC TRANSMISSION FLUID -

OPERATION...........................0-4

AXLE - 186FIA - ADJUSTMENTS, FRONT . . . 3-25

AXLE - 186FIA - DESCRIPTION, FRONT....3-19

AXLE - 186FIA - INSTALLATION, FRONT....3-24

AXLE - 186FIA - OPERATION, FRONT......3-19

AXLE - 186FIA - REMOVAL, FRONT.......3-24

AXLE - 198RBI - DESCRIPTION, REAR.....3-49

AXLE - 198RBI - INSTALLATION, REAR....3-54

AXLE - 198RBI - OPERATION, REAR.......3-49

AXLE - 198RBI - REMOVAL, REAR........3-54

AXLE - 8 1/4 - ADJUSTMENTS, REAR.....3-92

AXLE - 8 1/4 - DESCRIPTION, REAR......3-86

AXLE - 8 1/4 - INSTALLATION, REAR......3-91

AXLE - 8 1/4 - OPERATION, REAR........3-86

AXLE - 8 1/4 - REMOVAL, REAR..........3-91

AXLE - DESCRIPTION...................0-2

AXLE - DIAGNOSIS AND TESTING....3-20,3-51,

3-88

AXLE - INSTALLATION, 198 RBI..........5-28

AXLE - INSTALLATION, 8 1/4............5-28

AXLE - REMOVAL, 198 RBI..............5-27

AXLE - REMOVAL, 8 1/4................5-27

AXLE - SPECIFICATIONS, FRONT.........3-33

AXLE - SPECIFICATIONS, REAR..........3-62

AXLE BEARINGS - INSTALLATION....3-102,3-38

AXLE BEARINGS - REMOVAL.......3-102,3-38

AXLE BEARING/SEAL - INSTALLATION.....3-67

AXLE BEARING/SEAL - REMOVAL.........3-66

AXLE SHAFT SEALS - INSTALLATION . 3-102,3-38

AXLE SHAFT SEALS - REMOVAL....3-101,3-37

AXLE SHAFTS - INSTALLATION . . 3-101,3-37,3-65

AXLE SHAFTS - REMOVAL.....3-101,3-37,3-65

AXLE, SPECIAL TOOLS - 8 1/4 ...........3-98

AXLE, SPECIAL TOOLS - FRONT..........3-34

AXLE, SPECIAL TOOLS - REAR...........3-63

AXLE, SPECIFICATIONS - REAR..........3-98

BACK - FRONT - INSTALLATION, SEAT . . . 23-166

BACK - FRONT - REMOVAL, SEAT.......23-166

BACK - REAR - INSTALLATION, SEAT....23-168

BACK - REAR - REMOVAL, SEAT.......23-168

BACK COVER - FRONT - INSTALLATION,

SEAT

.............................23-167

BACK COVER - FRONT - REMOVAL, SEAT

. 23-166

BACK COVER - REAR - INSTALLATION,

SEAT

.............................23-169

BACK COVER - REAR - REMOVAL, SEAT

. 23-169

BACK CUSHION - FRONT -

INSTALLATION, SEAT

.................23-167BACK CUSHION - FRONT - REMOVAL,

SEAT .............................23-167

BACK CUSHION - REAR - INSTALLATION,

SEAT .............................23-170

BACK CUSHION - REAR - REMOVAL,

SEAT .............................23-170

BACK FRAME - REAR - INSTALLATION,

SEAT .............................23-171

BACK FRAME - REAR - REMOVAL, SEAT . 23-171

BACK LATCH / LOCK - INSTALLATION,

FOLDING REAR SEAT................23-170

BACK LATCH / LOCK - REMOVAL,

FOLDING REAR SEAT................23-170

BACK LATCH STRIKER - INSTALLATION,

REAR SEAT........................23-171

BACK LATCH STRIKER - REMOVAL,

REAR SEAT........................23-170

BACK RECLINER - FRONT -

INSTALLATION, SEAT.................23-166

BACK RECLINER - FRONT - REMOVAL,

SEAT .............................23-166

BACKUP LAMP SWITCH - DESCRIPTION . . 8L-15

BACKUP LAMP SWITCH - DIAGNOSIS

AND TESTING.......................8L-15

BACKUP LAMP SWITCH - OPERATION....8L-15

BAFFLE SEAL - INSTALLATION,

COWL/PLENUM WINDOW.............23-187

BAFFLE SEAL - REMOVAL, COWL/

PLENUM WINDOW..................23-187

BALANCE SHAFT - INSTALLATION........9-74

BALANCE SHAFT - REMOVAL............9-74

BALANCING - STANDARD PROCEDURE,

WHEEL.............................22-4

BALL JOINT - DESCRIPTION, UPPER

SUSPENSION ARM, BUSHINGS..........2-20

BALL JOINT - DIAGNOSIS AND TESTING,

LOWER.............................2-10

BALL JOINT - INSTALLATION, UPPER.....2-20

BALL JOINT - OPERATION, UPPER

SUSPENSION ARM, BUSHINGS..........2-20

BALL JOINT - REMOVAL, UPPER.........2-20

BAR - INSTALLATION, STABILIZER....2-14,2-19

BAR - REMOVAL, STABILIZER.......2-14,2-19

BAR BUSHINGS - INSTALLATION,

STABILIZER...........................2-9

BAR BUSHINGS - REMOVAL, STABILIZER . . . 2-9

BARRELS - INSTALLATION, PANEL

OUTLET............................24-29

BARRELS - REMOVAL, PANEL OUTLET . . . 24-29

BASE - DESCRIPTION, BRAKES...........5-2

BASE - WARNING, BRAKES..............5-2

BASE BRAKE SYSTEM - DIAGNOSIS AND

TESTING.............................5-3

BASE BRAKES, SPECIAL TOOLS...........5-7

BASE COAT/CLEAR COAT FINISH -

DESCRIPTION......................23-162

BATTERIES - STANDARD PROCEDURE,

RKE TRANSMITTER...................8N-8

BATTERY - DESCRIPTION...............8F-7

BATTERY - DIAGNOSIS AND TESTING.....8F-8

BATTERY CABLES - DESCRIPTION.......8F-18

BATTERY CABLES - DIAGNOSIS AND

TESTING...........................8F-19

BATTERY CABLES - OPERATION.........8F-18

BATTERY CHARGING - STANDARD

PROCEDURE.........................8F-8

BATTERY HOLDDOWN - DESCRIPTION....8F-17

BATTERY HOLDDOWN - INSTALLATION . . . 8F-17

BATTERY HOLDDOWN - OPERATION.....8F-17

BATTERY HOLDDOWN - REMOVAL.......8F-17

BATTERY SYSTEM - CLEANING...........8F-5

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.........8F-6

BATTERY SYSTEM - OPERATION.........8F-2

BATTERY SYSTEM - SPECIAL TOOLS......8F-7

BATTERY SYSTEM - SPECIFICATIONS......8F-6

BATTERY TEMPERATURE SENSOR -

DESCRIPTION.......................8F-24

BATTERY TEMPERATURE SENSOR -

INSTALLATION

.......................8F-24

BATTERY TEMPERATURE SENSOR -

OPERATION

.........................8F-24

BATTERY TEMPERATURE SENSOR -

REMOVAL

..........................8F-24

BATTERY TRAY - DESCRIPTION

.........8F-21

BATTERY TRAY - INSTALLATION

.........8F-21

2 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1744 of 1803

CASE BEARINGS - REMOVAL,

DIFFERENTIAL...............3-110,3-43,3-79

CASE, NV231 - TRANSFER............21-206

CASE, NV242 - TRANSFER............21-244

CASE SKID PLATE - INSTALLATION,

TRANSFER...........................13-7

CASE SKID PLATE - REMOVAL,

TRANSFER...........................13-7

CASE, SPECIFICATIONS - NV242

TRANSFER.........................21-244

CASTER ADJUSTMENT - STANDARD

PROCEDURE, CAMBER..................2-5

CASTER AND TOE ADJUSTMENT -

STANDARD PROCEDURE, CAMBER........2-5

CATALYTIC CONVERTER - DESCRIPTION . . . 11-2

CATALYTIC CONVERTER - INSPECTION....11-3

CATALYTIC CONVERTER - INSTALLATION . . . 11-3

CATALYTIC CONVERTER - REMOVAL......11-2

CAUSES OF BURNT FLUID - DIAGNOSIS

AND TESTING......................21-125

CAUTION - SERVICE CAUTIONS.........24-39

CAUTION, HALF SHAFT.................3-10

CAUTION, REFRIGERANT HOSES/LINES/

TUBES PRECAUTIONS.................24-40

CAUTIONS, CAUTION - SERVICE.........24-39

CD CHANGER - DESCRIPTION...........8A-7

CD CHANGER - INSTALLATION...........8A-7

CD CHANGER - OPERATION.............8A-7

CD CHANGER - REMOVAL..............8A-7

CENTER - DESCRIPTION, POWER

DISTRIBUTION....................8W-97-6

CENTER - OPERATION, POWER

DISTRIBUTION....................8W-97-7

CENTER - REMOVAL, POWER

DISTRIBUTION....................8W-97-7

CENTER ASSEMBLY, ASSEMBLY -

POWER DISTRIBUTION.............8W-97-10

CENTER BEZEL - INSTALLATION,

INSTRUMENT PANEL.................23-154

CENTER BEZEL - REMOVAL,

INSTRUMENT PANEL.................23-154

CENTER DISASSEMBLY, DISASSEMBLY -

POWER DISTRIBUTION..............8W-97-7

CENTER HIGH MOUNTED STOP LAMP

BULB - INSTALLATION................8L-19

CENTER HIGH MOUNTED STOP LAMP

BULB - REMOVAL....................8L-18

CENTER HIGH MOUNTED STOP LAMP

UNIT - INSTALLATION.................8L-19

CENTER HIGH MOUNTED STOP LAMP

UNIT - REMOVAL....................8L-19

CENTER SEAT BELT & RETRACTOR -

INSTALLATION, REAR.................8O-33

CENTER SEAT BELT & RETRACTOR -

REMOVAL, REAR....................8O-32

CENTERING - STANDARD PROCEDURE,

CLOCKSPRING......................8O-14

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE SAFETY...................Intro.-9

CHAIN COVER(S) - INSTALLATION,

TIMING BELT.........................9-76

CHAIN COVER(S) - REMOVAL, TIMING

BELT ...............................9-74

CHAIN WEAR, STANDARD PROCEDURE -

MEASURING TIMING...................9-71

CHANGER - DESCRIPTION, CD...........8A-7

CHANGER - INSTALLATION, CD..........8A-7

CHANGER - OPERATION, CD.............8A-7

CHANGER - REMOVAL, CD..............8A-7

CHANNEL - INSTALLATION, GLASS RUN . 23-123,

23-130

CHANNEL - REMOVAL, GLASS RUN....23-123,

23-130

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-41

CHARGE CAPACITY - SPECIFICATIONS....24-42

CHARGING - STANDARD PROCEDURE,

BATTERY............................8F-8

CHARGING INDICATOR - DESCRIPTION . . . 8J-15

CHARGING INDICATOR - OPERATION.....8J-15

CHARGING SYSTEM - DESCRIPTION

.....8F-22

CHARGING SYSTEM - DIAGNOSIS AND

TESTING

...........................8F-22

CHARGING SYSTEM - OPERATION

.......8F-22

CHART - DIAGNOSIS AND TESTING,

COOLING SYSTEM DIAGNOSIS

............7-6

CHART, SPECIFICATIONS - TORQUE

.....19-15,

19-19,19-8CHART, SPECIFICATIONS - TORQUE....2-17,2-8

CHECK - STANDARD PROCEDURE, FLUID

LEVEL............................21-126

CHECK - STANDARD PROCEDURE, OIL

PUMP VOLUME.....................21-148

CHECK STRAP - INSTALLATION . . 23-121,23-128,

23-135

CHECK STRAP - REMOVAL.....23-121,23-128,

23-135

CHECK VALVE - DESCRIPTION, FRONT....8R-8

CHECK VALVE - DESCRIPTION, FUEL

TANK ..............................14-28

CHECK VALVE - DESCRIPTION, REAR....8R-34

CHECK VALVE - DESCRIPTION, VACUUM . . 24-28

CHECK VALVE - INSTALLATION, FRONT....8R-9

CHECK VALVE - INSTALLATION, FUEL

TANK ..............................14-28

CHECK VALVE - INSTALLATION, REAR....8R-35

CHECK VALVE - INSTALLATION, VACUUM . 24-28

CHECK VALVE - OPERATION, FRONT......8R-9

CHECK VALVE - OPERATION, FUEL TANK . . 14-28

CHECK VALVE - OPERATION, REAR......8R-34

CHECK VALVE - OPERATION, VACUUM....24-28

CHECK VALVE - REMOVAL, FRONT.......8R-9

CHECK VALVE - REMOVAL, FUEL TANK . . . 14-28

CHECK VALVE - REMOVAL, REAR.......8R-34

CHECK VALVE - REMOVAL, VACUUM.....24-28

CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING, AIR.......................21-80

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY.........................7-3

CHILD TETHER ANCHOR - DESCRIPTION . . 8O-13

CHILD TETHER ANCHOR - OPERATION . . . 8O-13

CHIME WARNING SYSTEM -

DESCRIPTION........................8B-1

CHIME WARNING SYSTEM - DIAGNOSIS

AND TESTING........................8B-6

CHIME WARNING SYSTEM - OPERATION . . . 8B-2

CHOKE AND RELAY - DESCRIPTION,

AMPLIFIER..........................8A-3

CHOKE AND RELAY - DIAGNOSIS AND

TESTING, AMPLIFIER..................8A-4

CHOKE AND RELAY - INSTALLATION,

AMPLIFIER..........................8A-4

CHOKE AND RELAY - OPERATION,

AMPLIFIER..........................8A-3

CHOKE AND RELAY - REMOVAL,

AMPLIFIER..........................8A-4

CIGAR LIGHTER OUTLET -

DESCRIPTION.....................8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CLEVIS BRACKET - INSTALLATION........2-13

CLEVIS BRACKET - REMOVAL...........2-13

CLOCKSPRING - DESCRIPTION.........8O-13

CLOCKSPRING - INSTALLATION.........8O-16

CLOCKSPRING - OPERATION...........8O-14

CLOCKSPRING - REMOVAL............8O-15

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-14

CLUSTER - ASSEMBLY, INSTRUMENT....8J-10

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-7

CLUSTER - DISASSEMBLY, INSTRUMENT . . . 8J-9

CLUSTER - INSTALLATION, INSTRUMENT . 8J-11

CLUSTER - OPERATION, INSTRUMENT.....8J-4

CLUSTER - REMOVAL, INSTRUMENT......8J-9

CLUSTER BEZEL - INSTALLATION.......23-147

CLUSTER BEZEL - REMOVAL..........23-147

CLUTCH - ASSEMBLY, LOW/REVERSE

. . . 21-146

CLUTCH - CLEANING, LOW/REVERSE

....21-146

CLUTCH - DESCRIPTION

.................6-1

CLUTCH - DIAGNOSIS AND TESTING

.......6-2

CLUTCH - DISASSEMBLY, LOW/REVERSE

. 21-145

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-14

CLUTCH - INSPECTION, LOW/REVERSE

. . 21-146

CLUTCH - INSTALLATION, A/C

COMPRESSOR

.......................24-14

CLUTCH - OPERATION

..................6-1

CLUTCH - REMOVAL, A/C COMPRESSOR

. . 24-13

CLUTCH - SPECIFICATIONS

...............6-5

CLUTCH - WARNING

....................6-2

CLUTCH ASSEMBLY - ASSEMBLY, INPUT

. 21-138CLUTCH ASSEMBLY - DESCRIPTION,

INPUT............................21-133

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT............................21-135

CLUTCH ASSEMBLY - OPERATION,

INPUT............................21-135

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR........24-12

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-12

CLUTCH DISC - INSTALLATION............6-6

CLUTCH DISC - REMOVAL...............6-6

CLUTCH OPERATION - DIAGNOSIS AND

TESTING, AIR CHECKING

TRANSMISSION......................21-80

CLUTCH PEDAL - INSTALLATION.........6-10

CLUTCH PEDAL - REMOVAL.............6-10

CLUTCH PEDAL POSITION SWITCH -

DESCRIPTION........................6-11

CLUTCH PEDAL POSITION SWITCH -

DIAGNOSIS AND TESTING..............6-11

CLUTCH PEDAL POSITION SWITCH -

OPERATION..........................6-11

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR.......................24-15

CLUTCH RELAY - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-15

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR.......................24-16

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR.......................24-15

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR........................24-16

CLUTCH RELEASE BEARING -

INSTALLATION.........................6-6

CLUTCH RELEASE BEARING - REMOVAL....6-6

CLUTCH SWITCH OVERRIDE RELAY -

DESCRIPTION........................6-10

CLUTCH SWITCH OVERRIDE RELAY -

INSTALLATION........................6-10

CLUTCH SWITCH OVERRIDE RELAY -

OPERATION..........................6-10

CLUTCH SWITCH OVERRIDE RELAY -

REMOVAL...........................6-10

CLUTCHES - DESCRIPTION, HOLDING . . . 21-131

CLUTCHES - OPERATION, HOLDING.....21-132

CMTC LAMP REPLACEMENT -

STANDARD PROCEDURE...............8M-2

COAT FINISH - DESCRIPTION, BASE

COAT/CLEAR.......................23-162

COAT/CLEAR COAT FINISH -

DESCRIPTION, BASE.................23-162

CODE - DESCRIPTION, PAINT..........23-162

CODES - DESCRIPTION, DIAGNOSTIC

TROUBLE............................25-2

CODES - SPECIFICATIONS, PAINT.......23-162

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER...............8M-8

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER...............8M-9

COIL - DESCRIPTION, IGNITION..........8I-9

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-12

COIL - INSTALLATION, IGNITION.........8I-10

COIL - OPERATION, IGNITION............8I-9

COIL - REMOVAL, IGNITION............8I-10

COIL CAPACITOR - DESCRIPTION,

IGNITION...........................8I-16

COIL CAPACITOR - INSTALLATION,

IGNITION...........................8I-16

COIL CAPACITOR - OPERATION,

IGNITION...........................8I-16

COIL CAPACITOR - REMOVAL, IGNITION . . . 8I-16

COIL RESISTANCE, 2.4L - IGNITION

.......8I-2

COIL RESISTANCE, 3.7L V-6 - IGNITION

....8I-3

COLLAPSIBLE SPACER - INSTALLATION

....3-70

COLLAPSIBLE SPACER - REMOVAL

.......3-70

COLUMN - DESCRIPTION

...............19-5

COLUMN - INSTALLATION

...............19-7

COLUMN - REMOVAL

..................19-5

COLUMN, SPECIAL TOOLS - STEERING

....19-8

COMBINATION FLASHER - DESCRIPTION

. . 8L-19

COMBINATION FLASHER - OPERATION

. . . 8L-19

COMBUSTION PRESSURE LEAKAGE -

DIAGNOSIS AND TESTING, CYLINDER

......9-8

COMMUNICATION - DESCRIPTION

........8E-8

COMMUNICATION - OPERATION

..........8E-8

KJINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 1758 of 1803

PLATE LAMP UNIT - INSTALLATION,

LICENSE...........................8L-46

PLATE LAMP UNIT - REMOVAL, LICENSE . . 8L-45

PLATES - INSTALLATION, EXTERIOR

NAME............................23-141

PLATES - REMOVAL, EXTERIOR NAME . . . 23-140

PLUG - CLEANING SPARK PLUGS,

SPARK .............................8I-15

PLUG - DESCRIPTION, SPARK...........8I-12

PLUG - INSTALLATION, SPARK..........8I-15

PLUG - OPERATION, SPARK............8I-12

PLUG - REMOVAL, SPARK..............8I-15

PLUG CABLE RESISTANCE, 2.4L - SPARK . . . 8I-3

PLUG CONDITIONS - DIAGNOSIS AND

TESTING, SPARK.....................8I-13

PLUGS - STANDARD PROCEDURE,

ENGINE CORE AND OIL GALLERY........9-10

PLUGS, SPARK PLUG - CLEANING

SPARK .............................8I-15

PLUGS, SPECIFICATIONS - SPARK........8I-3

POLISHING - DESCRIPTION, FINESSE

SANDING/BUFFING..................23-163

PORT - DESCRIPTION, REFRIGERANT

SYSTEM SERVICE.....................24-2

PORT - OPERATION, REFRIGERANT

SYSTEM SERVICE.....................24-2

POSITION LAMP BULB - INSTALLATION,

FRONT.............................8L-28

POSITION LAMP BULB - REMOVAL,

FRONT.............................8L-28

POSITION SENSOR - DESCRIPTION . 21-209,21-247

POSITION SENSOR - DESCRIPTION,

CRANKSHAFT.......................14-30

POSITION SENSOR - DESCRIPTION,

THROTTLE..........................14-47

POSITION SENSOR - INSTALLATION....21-210,

21-247

POSITION SENSOR - INSTALLATION,

CRANKSHAFT.......................14-32

POSITION SENSOR - INSTALLATION,

THROTTLE..........................14-48

POSITION SENSOR - OPERATION . 21-209,21-247

POSITION SENSOR - OPERATION,

CRANKSHAFT.......................14-31

POSITION SENSOR - OPERATION,

THROTTLE..........................14-47

POSITION SENSOR - REMOVAL . . 21-210,21-247

POSITION SENSOR - REMOVAL,

CRANKSHAFT.......................14-31

POSITION SENSOR - REMOVAL,

THROTTLE..........................14-47

POSITION SWITCH - DESCRIPTION,

CLUTCH PEDAL.......................6-11

POSITION SWITCH - DIAGNOSIS AND

TESTING, CLUTCH PEDAL...............6-11

POSITION SWITCH - OPERATION,

CLUTCH PEDAL.......................6-11

POTENTIAL - STANDARD PROCEDURE,

TESTING OF VOLTAGE..............8W-01-9

POWER BRAKE BOOSTER -

DESCRIPTION........................5-21

POWER BRAKE BOOSTER -

INSTALLATION........................5-23

POWER BRAKE BOOSTER - OPERATION . . . 5-21

POWER BRAKE BOOSTER - REMOVAL.....5-22

POWER DISTRIBUTION - DESCRIPTION . 8W-97-1

POWER DISTRIBUTION - OPERATION . . 8W-97-1

POWER DISTRIBUTION CENTER -

DESCRIPTION.....................8W-97-6

POWER DISTRIBUTION CENTER -

OPERATION.......................8W-97-7

POWER DISTRIBUTION CENTER -

REMOVAL........................8W-97-7

POWER DISTRIBUTION CENTER

ASSEMBLY, ASSEMBLY.............8W-97-10

POWER DISTRIBUTION CENTER

DISASSEMBLY, DISASSEMBLY........8W-97-7

POWER DISTRIBUTION SYSTEMS,

SPECIAL TOOLS...................8W-97-2

POWER GROUNDS - DESCRIPTION......8E-13

POWER LOCKS - DESCRIPTION

..........8N-1

POWER LOCKS - DIAGNOSIS AND

TESTING

............................8N-3

POWER LOCKS - OPERATION

............8N-3

POWER MIRROR SWITCH - DIAGNOSIS

AND TESTING

.......................8N-12

POWER MIRROR SWITCH -

INSTALLATION

......................8N-13POWER MIRROR SWITCH - REMOVAL . . . 8N-13

POWER MIRRORS - DESCRIPTION......8N-11

POWER MIRRORS - DIAGNOSIS AND

TESTING...........................8N-11

POWER MIRRORS - OPERATION........8N-11

POWER OUTLET - DESCRIPTION.....8W-97-11

POWER OUTLET - DIAGNOSIS AND

TESTING........................8W-97-11

POWER OUTLET - INSTALLATION....8W-97-13

POWER OUTLET - OPERATION.......8W-97-11

POWER OUTLET - REMOVAL........8W-97-12

POWER SEAT SWITCH - DESCRIPTION,

LEFT..............................8N-16

POWER SEAT SWITCH - DESCRIPTION,

RIGHT.............................8N-19

POWER SEAT SWITCH - DIAGNOSIS

AND TESTING, LEFT..................8N-17

POWER SEAT SWITCH - DIAGNOSIS

AND TESTING, RIGHT.................8N-19

POWER SEAT SWITCH - INSTALLATION,

LEFT..............................8N-18

POWER SEAT SWITCH - INSTALLATION,

RIGHT.............................8N-20

POWER SEAT SWITCH - OPERATION,

LEFT..............................8N-17

POWER SEAT SWITCH - OPERATION,

RIGHT.............................8N-19

POWER SEAT SWITCH - REMOVAL, LEFT . 8N-18

POWER SEAT SWITCH - REMOVAL,

RIGHT.............................8N-20

POWER SEATS - DESCRIPTION...........8N-14

POWER SEATS - DIAGNOSIS AND

TESTING...........................8N-15

POWER SEATS - OPERATION...........8N-15

POWER STEERING FLOW AND

PRESSURE - DIAGNOSIS AND

TESTING............................19-3

POWER STEERING PRESSURE SWITCH -

DESCRIPTION.......................19-22

POWER STEERING PRESSURE SWITCH -

INSTALLATION.......................19-22

POWER STEERING PRESSURE SWITCH -

OPERATION.........................19-22

POWER STEERING PRESSURE SWITCH -

REMOVAL..........................19-22

POWER STEERING PUMP - INITIAL

OPERATION - STANDARD PROCEDURE . . . 19-18

POWER STEERING PUMP, SPECIAL

TOOLS.............................19-20

POWER STEERING SYSTEM -

DIAGNOSIS AND TESTING..............19-1

POWER WINDOWS - DESCRIPTION......8N-21

POWER WINDOWS - DIAGNOSIS AND

TESTING...........................8N-21

POWER WINDOWS - OPERATION........8N-21

POWERED - STARTER MOTOR, GAS......8F-39

POWERED - TORQUE, GAS.............8F-38

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-9

PRECAUTIONS - CAUTION,

REFRIGERANT HOSES/LINES/TUBES

......24-40

PRECAUTIONS - OPERATION, SERVICE

....19-5

PRECAUTIONS AND WARNINGS,

WARNING - SAFETY

...................23-1

PRECAUTIONS, WARNING -

WINDSHIELD SAFETY

................23-173

PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER

CUSTOMER

..........................8N-8

PRELIMINARY - DIAGNOSIS AND

TESTING

...........................21-78

PRELIMINARY CHECKS - DIAGNOSIS

AND TESTING

.........................7-3

PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET

SURFACE

.............................9-9

PRESS CONTAINER - DESCRIPTION,

COOLANT RECOVERY

..................7-19

PRESS CONTAINER - OPERATION,

COOLANT RECOVERY

..................7-19

PRESSURE - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION

...............9-8

PRESSURE - DIAGNOSIS AND TESTING,

ENGINE OIL

..........................9-60

PRESSURE - DIAGNOSIS AND TESTING,

POWER STEERING FLOW

...............19-3PRESSURE BLEEDING - STANDARD

PROCEDURE..........................5-5

PRESSURE CAP - CLEANING, RADIATOR . . . 7-25

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-25

PRESSURE CAP - DIAGNOSIS AND

TESTING, RADIATOR...................7-25

PRESSURE CAP - INSPECTION,

RADIATOR...........................7-25

PRESSURE CAP - OPERATION,

RADIATOR...........................7-25

PRESSURE HOSE - INSTALLATION.......19-21

PRESSURE HOSE - REMOVAL..........19-21

PRESSURE INDICATOR - DESCRIPTION,

LOW OIL ...........................8J-23

PRESSURE INDICATOR - OPERATION,

LOW OIL ...........................8J-23

PRESSURE LEAK DOWN TEST -

DIAGNOSIS AND TESTING, FUEL.........14-3

PRESSURE LEAKAGE - DIAGNOSIS AND

TESTING, CYLINDER COMBUSTION........9-8

PRESSURE (LP) SENSOR -

DESCRIPTION, LINE.................21-144

PRESSURE (LP) SENSOR -

INSTALLATION, LINE.................21-144

PRESSURE (LP) SENSOR - OPERATION,

LINE..............................21-144

PRESSURE (LP) SENSOR - REMOVAL,

LINE..............................21-144

PRESSURE REGULATOR - DESCRIPTION,

FUEL..............................14-13

PRESSURE REGULATOR -

INSTALLATION, FUEL...................14-14

PRESSURE REGULATOR - OPERATION,

FUEL..............................14-14

PRESSURE REGULATOR - REMOVAL,

FUEL..............................14-14

PRESSURE RELEASE - STANDARD

PROCEDURE, FUEL SYSTEM.............14-4

PRESSURE RELIEF VALVE -

DESCRIPTION, HIGH..................24-42

PRESSURE RELIEF VALVE - OPERATION,

HIGH..............................24-42

PRESSURE SENSOR/SWITCH -

DESCRIPTION, OIL....................9-65

PRESSURE SENSOR/SWITCH -

INSTALLATION, OIL....................9-65

PRESSURE SENSOR/SWITCH -

OPERATION, OIL......................9-65

PRESSURE SENSOR/SWITCH -

REMOVAL, OIL.......................9-65

PRESSURE, SPECIFICATIONS - FUEL

SYSTEM............................14-5

PRESSURE SWITCH - DESCRIPTION, A/C

HIGH..............................24-17

PRESSURE SWITCH - DESCRIPTION, A/C

LOW ..............................24-18

PRESSURE SWITCH - DESCRIPTION,

POWER STEERING...................19-22

PRESSURE SWITCH - DIAGNOSIS AND

TESTING, A/C HIGH...................24-18

PRESSURE SWITCH - DIAGNOSIS AND

TESTING, A/C LOW

...................24-19

PRESSURE SWITCH - INSTALLATION,

A/C HIGH

...........................24-18

PRESSURE SWITCH - INSTALLATION,

A/C LOW

...........................24-19

PRESSURE SWITCH - INSTALLATION,

POWER STEERING

...................19-22

PRESSURE SWITCH - OPERATION, A/C

HIGH

..............................24-18

PRESSURE SWITCH - OPERATION, A/C

LOW

..............................24-18

PRESSURE SWITCH - OPERATION,

POWER STEERING

...................19-22

PRESSURE SWITCH - REMOVAL, A/C

HIGH

..............................24-18

PRESSURE SWITCH - REMOVAL, A/C

LOW

..............................24-19

PRESSURE SWITCH - REMOVAL,

POWER STEERING

...................19-22

PRESSURE TEST - DIAGNOSIS AND

TESTING, FUEL PUMP

.................14-15

PRESSURE TEST - DIAGNOSIS AND

TESTING, HYDRAULIC

.................21-79

PRIMARY WEATHERSTRIP -

INSTALLATION, DOOR

................23-185

KJINDEX 19

Description Group-Page Description Group-Page Description Group-Page

Page 1764 of 1803

SPARK PLUG - OPERATION.............8I-12

SPARK PLUG - REMOVAL..............8I-15

SPARK PLUG CABLE RESISTANCE, 2.4L....8I-3

SPARK PLUG CONDITIONS - DIAGNOSIS

AND TESTING........................8I-13

SPARK PLUGS, SPARK PLUG -

CLEANING..........................8I-15

SPARK PLUGS, SPECIFICATIONS..........8I-3

SPEAKER - DESCRIPTION..............8A-13

SPEAKER - INSTALLATION.............8A-15

SPEAKER - OPERATION...............8A-14

SPEAKER - REMOVAL.................8A-14

SPECIAL TOOLS - 3.7L ENGINE..........9-15

SPECIAL TOOLS - 8 1/4 AXLE...........3-98

SPECIAL TOOLS - BASE BRAKES..........5-7

SPECIAL TOOLS - BODY................23-5

SPECIAL TOOLS - COOLING.............7-14

SPECIAL TOOLS - FRONT AXLE..........3-34

SPECIAL TOOLS - FRONT SUSPENSION.....2-8

SPECIAL TOOLS - FUEL SYSTEM.........14-6

SPECIAL TOOLS - OUTER TIE ROD END

REMOVAL TOOL.....................19-15

SPECIAL TOOLS - POWER

DISTRIBUTION SYSTEMS............8W-97-2

SPECIAL TOOLS - POWER STEERING

PUMP.............................19-20

SPECIAL TOOLS - REAR AXLE...........3-63

SPECIAL TOOLS - RFE TRANSMISSION....21-120

SPECIAL TOOLS - STEERING COLUMN....19-8

SPECIAL TOOLS - WIRING/TERMINAL . 8W-01-10

SPECIAL TOOLS, BATTERY SYSTEM.......8F-7

SPECIFICATIONS, BATTERY SYSTEM......8F-6

SPECIFICATIONS, BRAKES - ABS.........5-33

SPECIFICATIONS, CHARGE CAPACITY.....24-42

SPECIFICATIONS, CLUTCH...............6-5

SPECIFICATIONS, DIAGNOSIS AND

TESTING............................22-8

SPECIFICATIONS, FLUID CAPACITIES.......0-4

SPECIFICATIONS, FRAME DIMENSIONS....13-3

SPECIFICATIONS, FRONT AXLE...........3-33

SPECIFICATIONS, GAP AND FLUSH.....23-116

SPECIFICATIONS, IGNITION TIMING.......8I-2

SPECIFICATIONS, LAMPS/LIGHTING -

EXTERIOR..........................8L-15

SPECIFICATIONS, LAMPS/LIGHTING -

INTERIOR..........................8L-71

SPECIFICATIONS, NV1500..............21-30

SPECIFICATIONS, OPENING DIMENSIONS . 23-111

SPECIFICATIONS, PAINT CODES........23-162

SPECIFICATIONS, REAR AXLE............3-62

SPECIFICATIONS, REMOTE KEYLESS

ENTRY TRANSMITTER.................8N-9

SPECIFICATIONS, SEALER LOCATIONS....23-87

SPECIFICATIONS, SPECIFICATIONS.......24-10

SPECIFICATIONS, STANDARD

PROCEDURE.........................23-4

SPECIFICATIONS, TORQUE..............13-6

SPECIFICATIONS, WELD AND

STRUCTURAL ADHESIVE LOCATIONS......23-9

SPEED CONTROL - DESCRIPTION........8P-1

SPEED CONTROL - OPERATION..........8P-1

SPEED CONTROL - TORQUE.............8P-2

SPEED SENSOR - DESCRIPTION, INPUT . 21-143

SPEED SENSOR - DESCRIPTION,

OUTPUT...........................21-152

SPEED SENSOR - INSTALLATION, FRONT

WHEEL.............................5-34

SPEED SENSOR - INSTALLATION, INPUT . 21-143

SPEED SENSOR - INSTALLATION,

OUTPUT...........................21-152

SPEED SENSOR - INSTALLATION, REAR

WHEEL.............................5-35

SPEED SENSOR - OPERATION, INPUT . . . 21-143

SPEED SENSOR - OPERATION, OUTPUT . . 21-152

SPEED SENSOR - REMOVAL, FRONT

WHEEL.............................5-34

SPEED SENSOR - REMOVAL, INPUT.....21-143

SPEED SENSOR - REMOVAL, OUTPUT . . . 21-152

SPEED SENSOR - REMOVAL, REAR

WHEEL.............................5-35

SPEEDOMETER - DESCRIPTION

.........8J-32

SPEEDOMETER - OPERATION

...........8J-32

SPLASH SHIELD - INSTALLATION,

FRONT WHEELHOUSE

................23-143

SPLASH SHIELD - INSTALLATION, REAR

WHEELHOUSE

......................23-144

SPLASH SHIELD - REMOVAL, FRONT

WHEELHOUSE

......................23-143SPLASH SHIELD - REMOVAL, REAR

WHEELHOUSE......................23-144

SPLICE INFORMATION - DESCRIPTION,

CONNECTOR, GROUND..............8W-01-7

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-14

SPRING - INSTALLATION...........2-13,2-18

SPRING - REMOVAL...............2-13,2-18

SPRINGS - DESCRIPTION, VALVE.....9-29,9-38

SPRINGS - INSTALLATION, VALVE....9-29,9-38

SPRINGS - REMOVAL, VALVE........9-29,9-38

STABILIZER BAR - INSTALLATION....2-14,2-19

STABILIZER BAR - REMOVAL........2-14,2-19

STABILIZER BAR BUSHINGS -

INSTALLATION.........................2-9

STABILIZER BAR BUSHINGS - REMOVAL....2-9

STABILIZER LINK - INSTALLATION........2-14

STABILIZER LINK - REMOVAL............2-14

STAKING - STANDARD PROCEDURE,

HEAT ...............................23-3

STARTER MOTOR - DIAGNOSIS AND

TESTING...........................8F-39

STARTER MOTOR - INSTALLATION.......8F-41

STARTER MOTOR - REMOVAL..........8F-39

STARTER MOTOR, GAS POWERED.......8F-39

STARTER MOTOR RELAY - DESCRIPTION . 8F-41

STARTER MOTOR RELAY -

INSTALLATION.......................8F-43

STARTER MOTOR RELAY - OPERATION.....8F-42

STARTER MOTOR RELAY - REMOVAL.....8F-43

STARTER RELAY - DIAGNOSIS AND

TESTING...........................8F-42

STARTING PROCEDURE - STANDARD

PROCEDURE, JUMP....................0-5

STARTING SYSTEM - DESCRIPTION......8F-32

STARTING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-33

STARTING SYSTEM - INSPECTION.......8F-37

STARTING SYSTEM - OPERATION........8F-32

STATE DISPLAY TEST MODE -

DESCRIPTION........................25-2

STEERING - DESCRIPTION..............19-1

STEERING - OPERATION................19-1

STEERING COLUMN, SPECIAL TOOLS.....19-8

STEERING FLOW AND PRESSURE -

DIAGNOSIS AND TESTING, POWER.......19-3

STEERING LINKAGE - STANDARD

PROCEDURE........................19-16

STEERING PRESSURE SWITCH -

DESCRIPTION, POWER................19-22

STEERING PRESSURE SWITCH -

INSTALLATION, POWER...............19-22

STEERING PRESSURE SWITCH -

OPERATION, POWER..................19-22

STEERING PRESSURE SWITCH -

REMOVAL, POWER...................19-22

STEERING PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-18

STEERING PUMP, SPECIAL TOOLS -

POWER............................19-20

STEERING SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................19-1

STEERING SYSTEM - DIAGNOSIS AND

TESTING, SUSPENSION.................2-1

STEERING WHEEL - INSTALLATION......19-12

STEERING WHEEL - REMOVAL..........19-12

STOP LAMP BULB - INSTALLATION,

CENTER HIGH MOUNTED..............8L-19

STOP LAMP BULB - REMOVAL, CENTER

HIGH MOUNTED.....................8L-18

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED..............8L-19

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED.....................8L-19

STRAP - DESCRIPTION, RADIO NOISE

SUPPRESSION GROUND................8A-9

STRAP - INSTALLATION, CHECK . 23-121,23-128,

23-135

STRAP - INSTALLATION, RADIO NOISE

SUPPRESSION GROUND

...............8A-11

STRAP - OPERATION, RADIO NOISE

SUPPRESSION GROUND

...............8A-10

STRAP - REMOVAL, CHECK

.....23-121,23-128,

23-135

STRAP - REMOVAL, RADIO NOISE

SUPPRESSION GROUND

...............8A-10

STRIKER - INSTALLATION, GLOVE BOX

LATCH

............................23-149STRIKER - INSTALLATION, HOOD AJAR

SWITCH............................8Q-14

STRIKER - INSTALLATION, LATCH......23-124,

23-132,23-137

STRIKER - INSTALLATION, REAR SEAT

BACK LATCH.......................23-171

STRIKER - REMOVAL, GLOVE BOX

LATCH ............................23-148

STRIKER - REMOVAL, HOOD AJAR

SWITCH............................8Q-13

STRIKER - REMOVAL, LATCH . . . 23-124,23-132,

23-137

STRIKER - REMOVAL, REAR SEAT BACK

LATCH ............................23-170

STRUCTURAL ADHESIVE LOCATIONS -

SPECIFICATIONS, WELD................23-9

STRUCTURAL COVER - DESCRIPTION.....9-55

STRUCTURAL COVER - INSTALLATION.....9-55

STRUCTURAL COVER - OPERATION.......9-55

STRUCTURAL COVER - REMOVAL........9-55

STUDS - INSTALLATION...............22-11

STUDS - REMOVAL...................22-11

SUCTION LINE - INSTALLATION, A/C.....24-49

SUCTION LINE - REMOVAL, A/C.........24-48

SUN VISOR - INSTALLATION..........23-160

SUN VISOR - REMOVAL..............23-160

SUN VISOR SUPPORT - INSTALLATION . . 23-160

SUN VISOR SUPPORT - REMOVAL......23-160

SUNROOF - DESCRIPTION............23-175

SUNROOF GLASS PANEL ADJUSTMENT,

ADJUSTMENTS.....................23-178

SUNSHADE - INSTALLATION...........23-179

SUNSHADE - REMOVAL..............23-179

SUPPLEMENTAL RESTRAINT

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A.........8O-6

SUPPLEMENTAL RESTRAINT SYSTEM -

DIAGNOSIS AND TESTING..............8O-6

SUPPLEMENTAL RESTRAINTS -

STANDARD PROCEDURE, HANDLING

NON-DEPLOYED......................8O-6

SUPPLIES - DESCRIPTION, 5 VOLT......8E-13

SUPPLIES - OPERATION, 5 VOLT........8E-15

SUPPORT - INSTALLATION, REAR

FASCIA..............................13-3

SUPPORT - INSTALLATION, SUN VISOR . . 23-160

SUPPORT - REMOVAL, REAR FASCIA......13-3

SUPPORT - REMOVAL, SUN VISOR.....23-160

SUPPORT BRACKET - INSTALLATION,

REARVIEW MIRROR.................23-161

SUPPORT CYLINDER - INSTALLATION . . . 23-120

SUPPORT CYLINDER - INSTALLATION,

FLIP-UP GLASS.....................23-139

SUPPORT CYLINDER - REMOVAL.......23-120

SUPPORT CYLINDER - REMOVAL,

FLIP-UP GLASS.....................23-139

SUPPRESSION GROUND STRAP -

DESCRIPTION, RADIO NOISE............8A-9

SUPPRESSION GROUND STRAP -

INSTALLATION, RADIO NOISE...........8A-11

SUPPRESSION GROUND STRAP -

OPERATION, RADIO NOISE.............8A-10

SUPPRESSION GROUND STRAP -

REMOVAL, RADIO NOISE..............8A-10

SURFACE PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET............9-9

SUSPENSION - DIAGNOSIS AND

TESTING, REAR.......................2-17

SUSPENSION AND STEERING SYSTEM -

DIAGNOSIS AND TESTING...............2-1

SUSPENSION ARM, BUSHINGS, AND

BALL JOINT - DESCRIPTION, UPPER......2-20

SUSPENSION ARM, BUSHINGS, AND

BALL JOINT - OPERATION, UPPER........2-20

SUSPENSION, SPECIAL TOOLS - FRONT....2-8

SWING GATE - INSTALLATION.........23-138

SWING GATE - REMOVAL.............23-138

SWING GATE BELTLINE WEATHERSTRIP

- INSTALLATION....................23-186

SWING GATE BELTLINE WEATHERSTRIP

- REMOVAL

........................23-186

SWING GATE OPENING WEATHERSTRIP

- INSTALLATION

....................23-186

SWING GATE OPENING WEATHERSTRIP

- REMOVAL

........................23-186

SWITCH - DESCRIPTION

................8P-5

SWITCH - DESCRIPTION, A/C HIGH

PRESSURE

.........................24-17

KJINDEX 25

Description Group-Page Description Group-Page Description Group-Page