fuse panel JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 429 of 1803

On or Start positions, the trip odometer will be reset

to 0.0 kilometers (miles). The VFD must be display-

ing the trip odometer information in order for the

trip odometer information to be reset.

²Warning Display- The odometer or trip odom-

eter information will be toggled at two second inter-

vals with a warning display when certain monitored

conditions are active. If multiple conditions are

active, the VFD will toggle each active warning and

the odometer/trip odometer information at two sec-

ond intervals. Once the vehicle is moving and a vehi-

cle speed input is received by the instrument cluster,

each active warning will be displayed for three two-

second intervals before the VFD reverts to displaying

only the selected odometer or trip odometer informa-

tion. The warnings and monitored conditions include:

²ªdoorº- A door is open or not fully latched.

²ªgateº- The tailgate is open or not fully

latched.

²ªglassº- The rear flip-up glass is open or not

fully latched.

²ªlowashº- The fluid level in the washer reser-

voir is low.

²ªno busº- The instrument cluster can detect no

PCI bus communication. This message is illuminated

solid when there is no PCI bus communication, and

will override the display of all other active warning

displays.

²Communication Error- If the cluster fails to

receive a distance message during normal operation,

it will hold and display the last data received until

the ignition switch is turned to the Off position. If

the cluster does not receive a distance message

within one second after the ignition switch is turned

to the On position, it will display the last distance

message stored in the cluster memory. If the cluster

is unable to display distance information due to an

error internal to the cluster, ªerrorº will be displayed

in the VFD.

²Actuator Test- Each time the cluster is put

through the actuator test, the VFD will step sequen-

tially through a display of ª111111 ºthrough ª999999º,

then display the cluster software version number to

confirm the functionality of the VFD and the cluster

control circuitry.

The PCM continually monitors the vehicle speed

pulse information received from the Body Control

Module (BCM), then sends the proper distance mes-

sages to the instrument cluster. For further diagnosis

of the odometer/trip odometer or the instrument clus-

ter circuitry that controls these functions, (Refer to 8

- ELECTRICAL/INSTRUMENT CLUSTER - DIAG-

NOSIS AND TESTING). For proper diagnosis of the

vehicle speed sensor, the BCM, the PCM, the PCI

data bus, or the electronic message inputs to the

instrument cluster that control the odometer/tripodometer, a DRBIIItscan tool is required. Refer to

the appropriate diagnostic information.

OVERDRIVE OFF INDICATOR

DESCRIPTION

An overdrive off indicator is standard equipment

on all instrument clusters, but is only functional on

vehicles equipped with the optional overdrive auto-

matic transmission. The overdrive off indicator is

located above the fuel gauge and to the left of the

tachometer in the instrument cluster. The overdrive

off indicator consists of a stencil-like cutout of the

text ªO/D OFFº in the opaque layer of the instrument

cluster overlay. The dark outer layer of the overlay

prevents the indicator from being clearly visible

when it is not illuminated. An amber Light Emitting

Diode (LED) behind the cutout in the opaque layer of

the overlay causes the ªO/D OFFº text to appear in

amber through the translucent outer layer of the

overlay when it is illuminated from behind by the

LED, which is soldered onto the instrument cluster

electronic circuit board. When the exterior lighting is

turned On, the illumination intensity of the overdrive

off indicator is dimmable, which is adjusted using the

panel lamps dimmer control ring on the left control

stalk of the multi-function switch. The overdrive off

indicator is serviced as a unit with the instrument

cluster.

OPERATION

The overdrive off indicator gives an indication to

the vehicle operator when the Off position of the

overdrive off switch has been selected, disabling the

electronically controlled overdrive feature of the auto-

matic transmission. This indicator is controlled by a

transistor on the instrument cluster electronic circuit

board based upon the cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus. The

overdrive off indicator Light Emitting Diode (LED) is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the LED will

always be off when the ignition switch is in any posi-

tion except On or Start. The LED only illuminates

when it is provided a path to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the overdrive off indicator for the following

reasons:

²Overdrive Off Lamp-On Message- Each time

the cluster receives an overdrive off lamp-on message

8J - 26 INSTRUMENT CLUSTERKJ

ODOMETER (Continued)

Page 430 of 1803

from the PCM indicating that the Off position of the

overdrive off switch has been selected, the overdrive

off indicator will be illuminated. The indicator

remains illuminated until the cluster receives an

overdrive off lamp-off message from the PCM or until

the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the overdrive off indicator

will be turned on, then off again during the bulb

check portion of the test in order to confirm the func-

tionality of the LED and the cluster control circuitry.

The PCM continually monitors the overdrive off

switch to determine the proper outputs to the auto-

matic transmission. The PCM then sends the proper

overdrive off lamp-on and lamp-off messages to the

instrument cluster. For further diagnosis of the over-

drive off indicator or the instrument cluster circuitry

that controls the indicator, (Refer to 8 - ELECTRI-

CAL/INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the overdrive con-

trol system, the PCM, the PCI data bus, or the elec-

tronic message inputs to the instrument cluster that

control the overdrive off indicator, a DRBIIItscan

tool is required. Refer to the appropriate diagnostic

information.

REAR FOG LAMP INDICATOR

DESCRIPTION

A rear fog lamp indicator is standard equipment on

all instrument clusters, but is only functional on

vehicles equipped with the optional rear fog lamps,

which are available only in certain markets where

they are required. The rear fog lamp indicator is

located above the engine temperature gauge and to

the right of the speedometer in the instrument clus-

ter. The rear fog lamp indicator consists of a stencil-

like cutout of the International Control and Display

Symbol icon for ªRear Fog Lightº in the opaque layer

of the instrument cluster overlay. The dark outer

layer of the overlay prevents the indicator from being

clearly visible when it is not illuminated. An amber

Light Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

in amber through the translucent outer layer of the

overlay when it is illuminated from behind by the

LED, which is soldered onto the instrument cluster

electronic circuit board. When the exterior lighting is

turned On, the illumination intensity of the rear fog

lamp indicator is dimmable, which is adjusted using

the panel lamps dimmer control ring on the left con-

trol stalk of the multi-function switch. The rear fog

lamp indicator is serviced as a unit with the instru-

ment cluster.

OPERATION

The rear fog lamp indicator gives an indication to

the vehicle operator whenever the rear fog lamps are

illuminated. This indicator is controlled by a transis-

tor on the instrument cluster electronic circuit board

based upon the cluster programming and electronic

messages received by the cluster from the Body Con-

trol Module (BCM) over the Programmable Commu-

nications Interface (PCI) data bus. The rear fog lamp

indicator Light Emitting Diode (LED) is completely

controlled by the instrument cluster logic circuit, and

that logic will allow this indicator to operate when-

ever the instrument cluster receives a battery cur-

rent input on the fused B(+) circuit. Therefore, the

LED can be illuminated regardless of the ignition

switch position. The LED only illuminates when it is

provided a path to ground by the instrument cluster

transistor. The instrument cluster will turn on the

rear fog lamp indicator for the following reasons:

²Rear Fog Lamp-On Message- Each time the

cluster receives a rear fog lamp-on message from the

BCM indicating the rear fog lamps are turned On,

the rear fog lamp indicator will be illuminated. The

indicator remains illuminated until the cluster

receives a rear fog lamp-off message from the BCM.

²Actuator Test- Each time the cluster is put

through the actuator test, the rear fog lamp indicator

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

The BCM continually monitors the exterior light-

ing (multi-function) switch to determine the proper

outputs to the rear fog lamp relay. The BCM then

sends the proper rear fog lamp indicator lamp-on and

lamp-off messages to the instrument cluster. For fur-

ther diagnosis of the rear fog lamp indicator or the

instrument cluster circuitry that controls the indica-

tor, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). For

proper diagnosis of the rear fog lamp system, the

BCM, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the rear

fog lamp indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

SEATBELT INDICATOR

DESCRIPTION

A seatbelt indicator is standard equipment on all

instrument clusters. The seatbelt indicator is located

above the fuel gauge and to the right of the tachom-

eter in the instrument cluster. The seatbelt indicator

consists of a stencil-like cutout of the International

Control and Display Symbol icon for ªSeat Beltº in

the opaque layer of the instrument cluster overlay.

KJINSTRUMENT CLUSTER 8J - 27

OVERDRIVE OFF INDICATOR (Continued)

Page 435 of 1803

message from the SKIM or until the ignition switch

is turned to the Off position, whichever occurs first.

²Communication Error- If the cluster receives

no SKIS lamp-on or lamp-off messages from the

SKIM for twenty consecutive seconds, the SKIS indi-

cator is illuminated by the instrument cluster. The

indicator remains controlled and illuminated by the

cluster until a valid SKIS lamp-on or lamp-off mes-

sage is received from the SKIM.

²Actuator Test- Each time the cluster is put

through the actuator test, the SKIS indicator will be

turned on, then off again during the bulb check por-

tion of the test to confirm the functionality of the

LED and the cluster control circuitry.

The SKIM performs a self-test each time the igni-

tion switch is turned to the On position to decide

whether the system is in good operating condition

and whether a valid key is present in the ignition

lock cylinder. The SKIM then sends the proper SKIS

lamp-on or lamp-off messages to the instrument clus-

ter. For further diagnosis of the SKIS indicator or the

instrument cluster circuitry that controls the indica-

tor, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). If the

instrument cluster flashes the SKIS indicator upon

ignition On, or turns on the SKIS indicator solid

after the bulb test, it indicates that a SKIS malfunc-

tion has occurred or that the SKIS is inoperative. For

proper diagnosis of the SKIS, the PCI data bus, or

the electronic message inputs to the instrument clus-

ter that control the SKIS indicator, a DRBIIItscan

tool is required. Refer to the appropriate diagnostic

information.

SPEEDOMETER

DESCRIPTION

A speedometer is standard equipment on all instru-

ment clusters. The speedometer is located to the

right of the tachometer in the instrument cluster.

The speedometer consists of a movable gauge needle

or pointer controlled by the instrument cluster cir-

cuitry, and a fixed 255 degree primary scale on the

gauge dial face that reads left-to-right either from 0

to 120 mph, or from 0 to 240 km/h, depending upon

the market for which the vehicle is manufactured.

Most models also have a smaller secondary inner

scale on the gauge dial face that provides the equiv-

alent opposite measurement units from the primary

scale. Text appearing on the cluster overlay just

below the hub of the speedometer needle abbreviates

the unit of measure for the primary scale first (i.e.:

MPH or km/h), followed by the unit of measure for

the secondary scale (i.e.: MPH or km/h). The speed-

ometer graphics are dark blue (primary scale) andlight blue (secondary scale) against a beige field,

making them clearly visible within the instrument

cluster in daylight. When illuminated from behind by

the panel lamps dimmer controlled cluster illumina-

tion lighting with the exterior lamps turned On, both

the dark blue and light blue graphics retain their

blue colors. The orange gauge needle is internally

illuminated. Gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. The speedometer is serviced as a unit with the

instrument cluster.

OPERATION

The speedometer gives an indication to the vehicle

operator of the vehicle road speed. This gauge is con-

trolled by the instrument cluster electronic circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus. The

speedometer is an air core magnetic unit that

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (run-start) circuit whenever the igni-

tion switch is in the On or Start positions. The clus-

ter is programmed to move the gauge needle back to

the low end of the scale after the ignition switch is

turned to the Off position. The instrument cluster

circuitry controls the gauge needle position and pro-

vides the following features:

²Vehicle Speed Message- Each time the clus-

ter receives a vehicle speed message from the PCM it

will calculate the correct vehicle speed reading and

position the gauge needle at that speed position on

the gauge scale. The cluster will receive a new vehi-

cle speed message and reposition the gauge pointer

accordingly about every 86 milliseconds. The gauge

needle will continue to be positioned at the actual

vehicle speed position on the gauge scale until the

ignition switch is turned to the Off position.

²Communication Error- If the cluster fails to

receive a speedometer message, it will hold the gauge

needle at the last indication for about six seconds, or

until the ignition switch is turned to the Off position,

whichever occurs first. If a new speed message is not

received after about six seconds, the gauge needle

will return to the far left (low) end of the scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scale

in sequence in order to confirm the functionality of

the gauge and the cluster control circuitry.

The PCM continually monitors the vehicle speed

information received from the Body Control Module

(BCM) to determine the vehicle road speed, then

8J - 32 INSTRUMENT CLUSTERKJ

SKIS INDICATOR (Continued)

Page 436 of 1803

sends the proper vehicle speed messages to the

instrument cluster. For further diagnosis of the

speedometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the BCM, the PCM, the

PCI data bus, or the electronic message inputs to the

instrument cluster that control the speedometer, a

DRBIIItscan tool is required. Refer to the appropri-

ate diagnostic information.

TACHOMETER

DESCRIPTION

A tachometer is standard equipment on all instru-

ment clusters. The tachometer is located to the left of

the speedometer in the instrument cluster. The

tachometer consists of a movable gauge needle or

pointer controlled by the instrument cluster circuitry,

and a fixed 255 degree scale on the gauge dial face

that reads left-to-right from 0 to 7 for gasoline

engines, or from 0 to 5 for diesel engines. The text

ªRPM X 1000º imprinted on the cluster overlay

directly below the hub of the tachometer needle iden-

tifies that each number on the tachometer scale is to

be multiplied by 1000 rpm. The gasoline engine

tachometer has a red zone beginning at 5800 RPM,

while the red zone for the diesel engine tachometer

begins at 4300 RPM. The tachometer graphics are

dark blue and red against a beige field, making them

clearly visible within the instrument cluster in day-

light. When illuminated from behind by the panel

lamps dimmer controlled cluster illumination lighting

with the exterior lamps turned On, the dark blue

graphics appear blue and the red graphics appear

red. The orange gauge needle is internally illumi-

nated. Gauge illumination is provided by replaceable

incandescent bulb and bulb holder units located on

the instrument cluster electronic circuit board. The

tachometer is serviced as a unit with the instrument

cluster.

OPERATION

The tachometer gives an indication to the vehicle

operator of the engine speed. This gauge is controlled

by the instrument cluster electronic circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Powertrain

Control Module (PCM) over the Programmable Com-

munications Interface (PCI) data bus. The tachome-

ter is an air core magnetic unit that receives battery

current on the instrument cluster electronic circuit

board through the fused ignition switch output (run-

start) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed tomove the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Engine Speed Message- Each time the cluster

receives an engine speed message from the PCM it

will calculate the correct engine speed reading and

position the gauge needle at that speed position on

the gauge scale. The cluster will receive a new

engine speed message and reposition the gauge

pointer accordingly about every 86 milliseconds. The

gauge needle will continue to be positioned at the

actual engine speed position on the gauge scale until

the ignition switch is turned to the Off position.

²Communication Error- If the cluster fails to

receive an engine speed message, it will hold the

gauge needle at the last indication for about six sec-

onds, or until the ignition switch is turned to the Off

position, whichever occurs first. If a new engine

speed message is not received after about six sec-

onds, the gauge needle will return to the far left

(low) end of the scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scale

in sequence in order to confirm the functionality of

the gauge and the cluster control circuitry.

The PCM continually monitors the crankshaft posi-

tion sensor to determine the engine speed, then

sends the proper engine speed messages to the

instrument cluster. For further diagnosis of the

tachometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the crankshaft position

sensor, the PCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the tachometer, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

TRANS TEMP INDICATOR

DESCRIPTION

A transmission over-temperature indicator is stan-

dard equipment on all instrument clusters, but is

only functional on vehicles equipped with an optional

automatic transmission. The transmission over-tem-

perature indicator is located near the lower edge of

the instrument cluster, between the tachometer and

the speedometer. The transmission over-temperature

indicator consists of a stencil-like cutout of the words

ªTRANS TEMPº in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

KJINSTRUMENT CLUSTER 8J - 33

SPEEDOMETER (Continued)

Page 439 of 1803

OPERATION

The washer fluid indicator gives an indication to

the vehicle operator that the fluid level in the washer

reservoir is low. This indicator is controlled by the

instrument cluster electronic circuit board based

upon cluster programming and a hard wired input

received by the cluster from the washer fluid level

switch mounted on the washer reservoir. The washer

fluid indicator function of the Vacuum Fluorescent

Display (VFD) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the LED will always be off when the ignition switch

is in any position except On or Start. The instrument

cluster will turn on the washer fluid indicator for the

following reasons:

²Washer Fluid Level Switch Input- Each time

the cluster detects ground on the low washer fluid

sense circuit (washer fluid level switch closed =

washer fluid level low) the cluster applies an algo-

rithm to confirm that the input is correct and not the

result of fluid sloshing in the washer reservoir. The

cluster tests the status of the circuit about seven mil-

liseconds after ignition On, and about once every sec-

ond thereafter, then uses an internal counter to

count up or down. When the counter accumulates

thirty ground inputs on the circuit, the washer fluid

indicator will be illuminated. If the vehicle is not

moving when the washer fluid level switch input

counter reaches thirty, the VFD will repeatedly and

sequentially cycle its indication in two second inter-

vals with the odometer/trip odometer information,

the low washer fluid warning, and any other active

warnings including: door ajar, gate ajar, and glass

ajar. If the vehicle is moving, or once the cluster of a

non-moving vehicle receives an electronic vehicle

speed message from the Powertrain Control Module

(PCM) indicating a speed greater than zero, the

warning sequence will consist of three complete dis-

play cycles, then revert to only the odometer/trip

odometer display. Once the washer fluid indicator

warning has completed, the washer fluid indicator is

extinguished and will not repeat until the ignition

switch is cycled.

The instrument cluster continually monitors the

washer fluid level switch in the washer reservoir to

determine the status of the washer fluid level. For

further diagnosis of the washer fluid indicator or the

instrument cluster circuitry that controls the indica-

tor, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). The

washer fluid level switch and circuits can be diag-

nosed using conventional diagnostic tools and meth-

ods. The washer fluid level switch also features a 3.3kilohm diagnostic resistor connected in parallel

between the switch input and output to provide the

cluster with verification that the low washer fluid

sense circuit is not open or shorted. This input can

be monitored using a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

DIAGNOSIS AND TESTING - WASHER FLUID

INDICATOR

The diagnosis found here addresses an inoperative

washer fluid indicator condition. If the problem being

diagnosed is related to indicator accuracy, be certain

to confirm that the problem is with the indicator or

washer fluid level switch input and not with a dam-

aged or empty washer fluid reservoir, or inoperative

instrument cluster indicator control circuitry. Inspect

the washer fluid reservoir for proper fluid level and

signs of damage or distortion that could affect

washer fluid level switch performance and perform

the instrument cluster actuator test before you pro-

ceed with the following diagnosis. If no washer fluid

reservoir or instrument cluster control circuitry prob-

lem is found, the following procedure will help to

locate a short or open in the washer fluid switch

sense circuit. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

INDICATOR DOES NOT ILLUMINATE WITH WASHER

RESERVOIR EMPTY

(1) Disconnect and isolate the battery negative

cable. Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the washer fluid level switch connector receptacle.

Check for continuity between the ground circuit cav-

8J - 36 INSTRUMENT CLUSTERKJ

WASHER FLUID INDICATOR (Continued)

Page 440 of 1803

ity of the headlamp and dash wire harness connector

for the washer fluid level switch and a good ground.

There should be continuity. If OK, go to Step 2. If not

OK, repair the open ground circuit to ground (G111)

as required.

(2) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the washer

fluid sense circuit cavities of the headlamp and dash

wire harness connector for the washer fluid level

switch and the instrument panel wire harness con-

nector (Connector C2) for the instrument cluster. If

OK, replace the faulty washer fluid level switch. If

not OK, repair the open washer fluid switch sense

circuit between the washer fluid level switch and the

instrument cluster as required.

INDICATOR STAYS ILLUMINATED WITH WASHER

RESERVOIR FULL

(1) Disconnect and isolate the battery negative

cable. Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the washer fluid level switch connector receptacle.

Check for continuity between the ground circuit ter-

minal and the washer fluid sense terminal in the

washer fluid level switch connector receptacle. There

should be no continuity. If OK, go to Step 2. If not

OK, replace the faulty washer fluid level switch.

(2) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the washer

fluid sense circuit cavity of the headlamp and dash

wire harness connector for the washer fluid level

switch and a good ground. There should be no conti-

nuity. If not OK, repair the shorted washer fluid

switch sense circuit between the washer fluid level

switch and the instrument cluster as required.

WATER-IN-FUEL INDICATOR

DESCRIPTION

A water-in-fuel indicator is only found in the

instrument clusters of vehicles equipped with an

optional diesel engine. The water-in-fuel indicator is

located above the coolant temperature gauge and to

the right of the speedometer in the instrument clus-

ter. The water-in-fuel indicator consists of a stencil-

like cutout of the International Control and Display

Symbol icon for ªWater In Fuelº in the opaque layer

of the instrument cluster overlay. The dark outer

layer of the overlay prevents the indicator from being

clearly visible when it is not illuminated. A red Light

Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

in red through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. Thewater-in-fuel indicator is serviced as a unit with the

instrument cluster.

OPERATION

The water-in-fuel indicator gives an indication to

the vehicle operator when there is excessive water in

the fuel system. This indicator is controlled by a

transistor on the instrument cluster electronic circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus. The

water-in-fuel indicator Light Emitting Diode (LED) is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the LED will

always be off when the ignition switch is in any posi-

tion except On or Start. The LED only illuminates

when it is provided a path to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the water-in-fuel indicator for the following

reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the water-in-fuel indicator

is illuminated for about three seconds as a bulb test.

²Water-In-Fuel Lamp-On Message- Each time

the cluster receives a water-in-fuel lamp-on message

from the PCM indicating there is excessive water in

the diesel fuel system, the water-in-fuel indicator will

be illuminated. The indicator remains illuminated

until the cluster receives a water-in-fuel lamp-off

message, or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the water-in-fuel indicator

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

The PCM continually monitors the water-in-fuel

sensor to determine whether there is excessive water

in the diesel fuel. The PCM then sends the proper

water-in-fuel lamp-on and lamp-off messages to the

instrument cluster. For further diagnosis of the

water-in-fuel indicator or the instrument cluster cir-

cuitry that controls the indicator, (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). For proper diagnosis of the water-

in-fuel-sensor, the PCM, the PCI data bus, or the

electronic message inputs to the instrument cluster

that control the water-in-fuel indicator, a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.

KJINSTRUMENT CLUSTER 8J - 37

WASHER FLUID INDICATOR (Continued)

Page 446 of 1803

trols for both the exterior and interior lighting sys-

tems.

²Park Lamp Relay- A park lamp relay is

located in the Junction Block (JB) of all vehicles.

²Rear Fog Lamp Relay- Vehicles manufac-

tured for certain markets where rear fog lamps are

required equipment have a rear fog lamp relay

located in the Junction Block (JB).

²Trailer Tow Adapter- Vehicles equipped with

a factory-installed trailer towing package have an

adapter provided that adapts the factory-installed

heavy duty 7-way trailer tow connector to a conven-

tional 4-way light duty connector.

²Trailer Tow Connector- Vehicles equipped

with a factory-installed trailer towing package have a

heavy duty 7-way trailer tow connector installed in a

bracket on the trailer hitch receiver.

²Trailer Tow Relays- Vehicles equipped with a

factory-installed trailer towing package have a con-

nector bank containing four relays located behind the

right quarter trim panel and over the right rear

wheel housing. The four relays are used to supply

fused ignition switch output (run), brake lamps, right

turn signal, and left turn signal outputs to a trailer

through the trailer tow wiring and connectors.

Hard wired circuitry connects the exterior lighting

system components to the electrical system of the

vehicle. These hard wired circuits are integral to sev-

eral wire harnesses, which are routed throughout the

vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the exterior lighting

system components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

OPERATION

Following are paragraphs that briefly describe the

operation of each of the major exterior lighting sys-

tems. The hard wired circuits and components of the

exterior lighting systems may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the Body

Control Module (BCM), the ElectroMechanical

Instrument Cluster (EMIC), the Powertrain Control

Module (PCM), or the Programmable Communica-

tions Interface (PCI) data bus network. The most

reliable, efficient, and accurate means to diagnose

the BCM, the EMIC, the PCM, and the PCI data busnetwork inputs and outputs related to the various

exterior lighting systems requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

BACKUP LAMPS

The backup (or reverse) lamps have a path to

ground at all times through their connection to the

rear lighting wire harness from a take out of the rear

body wire harness with an eyelet terminal connector

that is secured by a ground screw to the base of the

right D-pillar behind the quarter trim panel. The

backup lamps receive battery current from a fused

ignition switch output (run) fuse in the Junction

Block (JB) on the back-up lamp feed circuit only

when the backup lamp switch (manual transmission),

or backup lamp switch circuit of the Transmission

Range Sensor (TRS - electronic automatic transmis-

sion) is closed by the gearshift mechanism within the

transmission.

BRAKE LAMPS

The brake (or stop) lamps have a path to ground at

all times through their connection to the rear light-

ing wire harness from a take out of the rear body

wire harness with an eyelet terminal connector that

is secured by a screw to the base of the right D-pillar

behind the quarter trim panel. The Center High

Mounted Stop Lamp (CHMSL) has a path to ground

at all times through its connection to the rear body

wire harness from a take out of the rear body wire

harness with an eyelet terminal connector that is

secured by a ground screw to the driver side D-pillar

(left side D-pillar for left-hand drive, right side D-pil-

lar for right-hand drive) behind the quarter trim

panel. The brake lamps and CHMSL receive battery

current from a fused B(+) fuse in the Junction Block

(JB) on the brake lamp switch output circuit only

when the brake lamp switch circuit of the brake

lamp switch is closed by the brake pedal arm.

DAYTIME RUNNING LAMPS

Vehicles manufactured for sale in Canada illumi-

nate the high beam filament at a reduced intensity

when the engine is running and the exterior lamps

are turned off. This feature is enabled by the Body

Control Module (BCM) and a solid state Daytime

Running Lamps (DRL) relay, which is installed in the

Junction Block (JB) and the high beam relay is omit-

ted. When the BCM monitors an engine speed signal

of greater than 450 RPM and the status of the exte-

rior lighting switch input from the multi-function

switch is Off, the BCM duty cycles the DRL relay to

produce illumination of the headlamp high beam fil-

aments at a reduced intensity. The BCM also pro-

vides normal headlamp high beam operation through

the DRL relay on vehicles so equipped. When the

KJLAMPS/LIGHTING - EXTERIOR 8L - 5

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 447 of 1803

DRL relay is energized, it provides battery current

from a fused B(+) fuse in the JB to the headlamp

high beam filament through the DRL relay output

circuit.

FRONT FOG LAMPS

Vehicles equipped with optional front fog lamps

have a premium Body Control Module (BCM), a front

fog lamp relay installed in the Junction Block (JB),

and a front fog lamp switch integral to the left (light-

ing) control stalk of the multi-function switch. The

front fog lamps have a path to ground at all times

through their connection to the front fascia wire har-

ness from two take outs of the headlamp and dash

wire harness with eyelet terminal connectors that

are secured by ground screws to the left inner fender

shield in the engine compartment. The BCM controls

front fog lamp operation by monitoring the exterior

lighting switch input from the multi-function switch,

then energizing or de-energizing the front fog lamp

relay control coil; and, by sending the appropriate

electronic message to the instrument cluster over the

Programmable Communications Interface (PCI) data

bus to turn the front fog lamp indicator on or off.

When the front fog lamp relay is energized, it pro-

vides battery current from a fused B(+) fuse in the

JB to the front fog lamps through the front fog lamp

relay output circuit. The BCM provides a battery

saver (load shedding) feature for the front fog lamps,

which will turn these lamps off if they are left on for

more than about eight minutes with the ignition

switch in the Off position. In certain markets where

required, the front fog lamps are also turned off by

the BCM whenever the headlamp high beams are

selected. Each front fog lamp includes an integral

adjustment screw to be used for static aiming the fog

lamp beams.

HAZARD WARNING LAMPS

With the hazard switch in the On position, the

hazard warning system is activated causing the haz-

ard switch button illumination lamp, the right and

left turn signal indicators, and the right and left turn

signal lamps to flash on and off. When the hazard

warning system is activated, the circuitry within the

hazard switch and electronic combination flasher

unit will repeatedly energize and de-energize two

internal relays that switch battery current from a

fused B(+) fuse in the Junction Block (JB) to the

right side and left side turn signal indicators, and

turn signal lamps through the right and left turn sig-

nal circuits. The flashing of the hazard switch button

illumination lamp is performed internally by the haz-

ard switch and combination flasher unit circuit

board. The hazard warning lamps can also be ener-

gized by the Body Control Module (BCM) through ahazard lamp control circuit input to the hazard

switch and combination flasher unit.

HEADLAMPS

The headlamp system includes the Body Control

Module (BCM), a low beam relay installed in the

Junction Block (JB), a high beam relay installed in

the JB (except Canada), a solid state Daytime Run-

ning Lamps (DRL) relay installed in the JB (Canada

only), and the exterior lighting (headlamp and dim-

mer) switches integral to the left (lighting) control

stalk of the multi-function switch. The headlamp

bulbs have a path to ground at all times through

their connection to the grille opening reinforcement

wire harness from two take outs of the headlamp and

dash wire harness with eyelet terminal connectors

that are secured by ground screws to the left inner

fender shield in the engine compartment. The BCM

controls the headlamp operation by monitoring the

exterior lighting switch inputs from the multi-func-

tion switch, then energizing or de-energizing the con-

trol coils of the low beam relay, the high beam relay,

or the solid state circuitry of the DRL relay; and, by

sending the appropriate electronic message to the

instrument cluster over the Programmable Commu-

nications Interface (PCI) data bus to turn the high

beam indicator on or off. When each respective relay

is energized, it provides battery current from a fused

B(+) fuse in the Power Distribution Center (PDC)

through a relay (low beam, high beam, or DRL) out-

put circuit and four separate fuses in the JB through

individual fused right and left, low and high beam

output circuits to the appropriate headlamp bulb fil-

aments. The BCM provides a battery saver (load

shedding) feature for the headlamps, which will turn

these lamps off if they are left on for more than

about eight minutes with the ignition switch in the

Off position; and, a headlamp delay feature with a

DRBIIItscan tool programmable delay interval.

Each headlamp includes an integral adjustment

screw to be used for static aiming of the headlamp

beams.

HEADLAMP LEVELING

In certain markets where required, a headlamp

leveling system is provided on the vehicle. The head-

lamp leveling system includes unique headlamp units

equipped with a headlamp leveling actuator motor,

and a rotary thumbwheel actuated headlamp leveling

switch on the instrument panel. The headlamp level-

ing system allows the headlamp beams to be

adjusted to one of four vertical positions to compen-

sate for changes in inclination caused by the loading

of the vehicle suspension. The actuator motors are

mechanically connected through an integral pushrod

to an adjustable headlamp reflector. The headlamp

8L - 6 LAMPS/LIGHTING - EXTERIORKJ

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 448 of 1803

leveling switch is a resistor multiplexed unit that

provides one of four voltage outputs to the headlamp

leveling motors. The headlamp leveling motors will

move the headlamps to the selected position based

upon the voltage input received from the switch. The

headlamp leveling motors and switch have a path to

ground at all times. The headlamp leveling compo-

nents operate on battery current received through

the fused park lamp relay output circuit so that the

system will only operate when the exterior lighting is

turned on.

PARK LAMPS

The park lamps system includes the Body Control

Module (BCM), a park lamp relay installed in the

Junction Block (JB), and the exterior lighting switch

integral to the left (lighting) control stalk of the

multi-function switch. The front park lamp and side

marker or, if equipped, the front position lamp bulbs

each have a path to ground at all times through their

connections to the grille opening reinforcement wire

harness from two take outs of the headlamp and

dash wire harness with eyelet terminal connectors

that are secured by ground screws to the left inner

fender shield in the engine compartment. The rear

park lamp bulbs and license plate lamp have a path

to ground at all times through their connection to the

rear lighting wire harness from a take out of the rear

body wire harness with an eyelet terminal connector

that is secured by a ground screw to the base of the

right D-pillar behind the quarter trim panel. The

BCM controls the park lamp operation by monitoring

the exterior lighting switch inputs from the multi-

function switch, then energizing or de-energizing the

control coil of the park lamp relay. When the park

lamp relay is energized, it provides battery current

from a fused B(+) fuse in the Power Distribution

Center (PDC) through a park lamp relay output cir-

cuit and a separate fuse in the JB through a fused

park lamp relay output circuit to the appropriate

lamp bulb filaments. The BCM provides a battery

saver (load shedding) feature for the park lamps,

which will turn these lamps off if they are left on for

more than about eight minutes with the ignition

switch in the Off position.

REAR FOG LAMPS

Rear fog lamps are installed on vehicles manufac-

tured for certain markets where they are required.

The rear fog lamp system includes a premium Body

Control Module (BCM), a rear fog lamp relay

installed in the Junction Block (JB), and a rear fog

lamp switch integral to the left (lighting) control

stalk of the multi-function switch. The rear fog lamps

have a path to ground at all times through their con-

nection to the rear lighting wire harness from a takeout of the rear body wire harness with an eyelet ter-

minal connector that is secured by a ground screw to

the base of the right D-pillar behind the quarter trim

panel. The BCM controls rear fog lamp operation by

monitoring the exterior lighting switch input from

the multi-function switch, then energizing or de-ener-

gizing the rear fog lamp relay control coil; and, by

sending the appropriate electronic message to the

instrument cluster over the Programmable Commu-

nications Interface (PCI) data bus to turn the rear

fog lamp indicator on or off. When the rear fog lamp

relay is energized, it provides battery current from a

fused B(+) fuse in the JB to the rear fog lamps

through the rear fog lamp relay output circuit. The

BCM provides a battery saver (load shedding) feature

for the rear fog lamps, which will turn these lamps

off if they are left on for more than about eight min-

utes with the ignition switch in the Off position.

TURN SIGNAL LAMPS

When the left control stalk of the multi-function

switch is moved up (right turn) or down (left turn),

the turn signal system is activated causing the

selected right or left turn signal indicator, and right

or left turn signal lamps to flash on and off. When

the turn signal system is activated, the circuitry

within the turn signal switch and the hazard switch/

electronic combination flasher unit will repeatedly

energize and de-energize one of two internal relays

that switch battery current from a fused ignition

switch output (run) fuse in the Junction Block (JB) to

the right side or left side turn signal indicators and

turn signal lamps through the right or left turn sig-

nal circuits. The ElectroMechanical Instrument Clus-

ter (EMIC) chime tone generator will generate an

audible turn signal cancel warning each time the

vehicle is driven for a distance of about 3.2 kilome-

ters (about two miles) with a turn signal indicator

flashing. The EMIC uses Programmable Communica-

tions Interface (PCI) data bus distance messages

from the Powertrain Control Module (PCM) and a

hard wired input from the turn signal switch cir-

cuitry of the multi-function switch to determine when

to sound the turn signal cancel warning.

DIAGNOSIS AND TESTING - LAMPS/LIGHTING

- EXTERIOR

The hard wired circuits and components of the

exterior lighting systems may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the Body

Control Module (BCM), the ElectroMechanical

Instrument Cluster (EMIC), the Powertrain Control

Module (PCM), or the Programmable Communica-

tions Interface (PCI) data bus network. The most

KJLAMPS/LIGHTING - EXTERIOR 8L - 7

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 449 of 1803

reliable, efficient, and accurate means to diagnose

the BCM, the EMIC, the PCM, and the PCI data bus

network inputs and outputs related to the various

exterior lighting systems requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

When diagnosing the exterior lighting circuits,

remember that high generator output can burn out

bulbs rapidly and repeatedly; and, that dim or flick-

ering bulbs can be caused by low generator output or

poor battery condition. If one of these symptoms is a

problem on the vehicle being diagnosed, be certain to

diagnose and repair the battery and charging system

as required. Also keep in mind that a good ground is

necessary for proper lighting operation. If a lighting

problem is being diagnosed that involves multiple

symptoms, systems, or components the problem can

often be traced to a loose, corroded, or open ground.

For complete circuit diagrams, refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connectorrepair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

BACKUP LAMPS

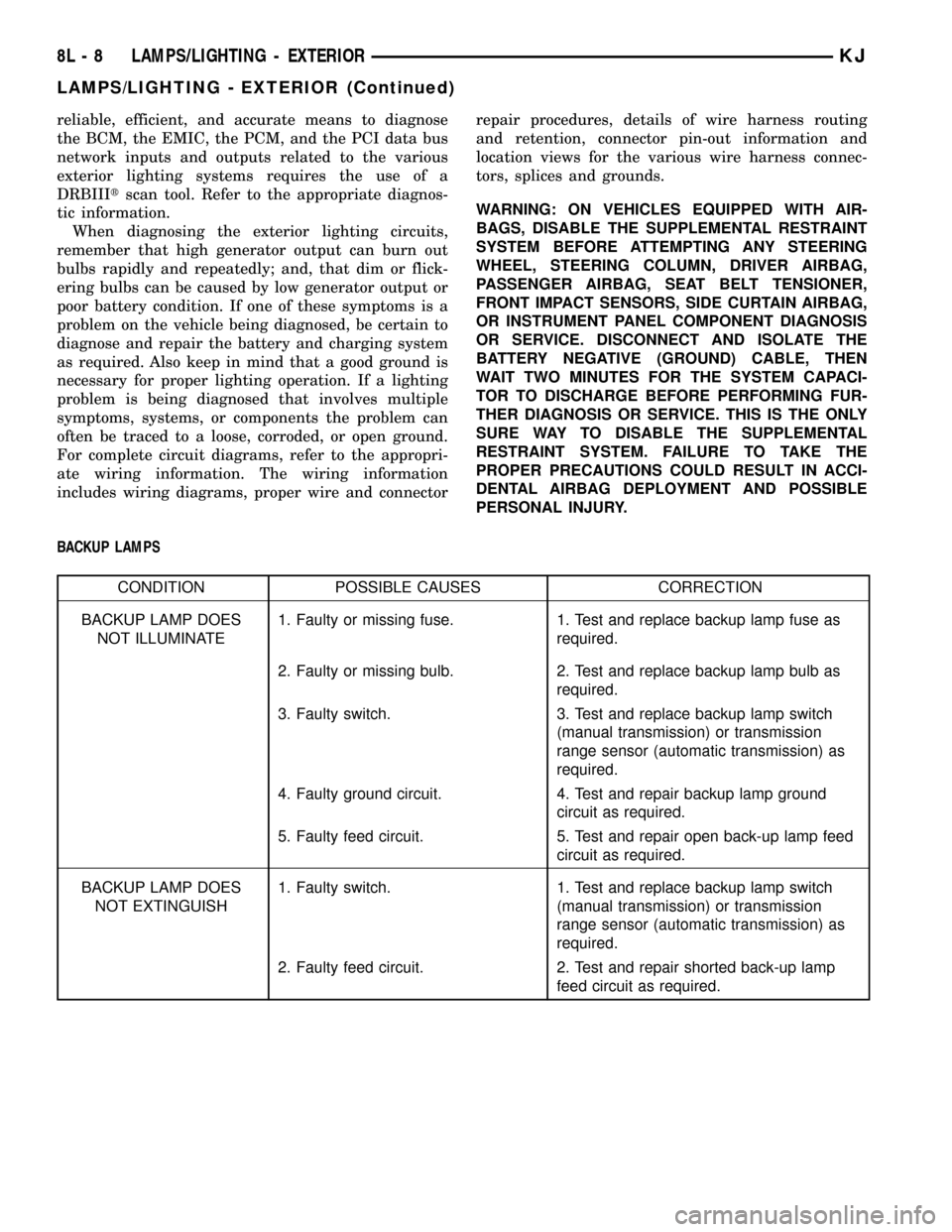

CONDITION POSSIBLE CAUSES CORRECTION

BACKUP LAMP DOES

NOT ILLUMINATE1. Faulty or missing fuse. 1. Test and replace backup lamp fuse as

required.

2. Faulty or missing bulb. 2. Test and replace backup lamp bulb as

required.

3. Faulty switch. 3. Test and replace backup lamp switch

(manual transmission) or transmission

range sensor (automatic transmission) as

required.

4. Faulty ground circuit. 4. Test and repair backup lamp ground

circuit as required.

5. Faulty feed circuit. 5. Test and repair open back-up lamp feed

circuit as required.

BACKUP LAMP DOES

NOT EXTINGUISH1. Faulty switch. 1. Test and replace backup lamp switch

(manual transmission) or transmission

range sensor (automatic transmission) as

required.

2. Faulty feed circuit. 2. Test and repair shorted back-up lamp

feed circuit as required.

8L - 8 LAMPS/LIGHTING - EXTERIORKJ

LAMPS/LIGHTING - EXTERIOR (Continued)