Index JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1775 of 1803

RELAY - DIAGNOSIS AND TESTING,

FRONT FOG LAMP....................8L-23

RELAY - DIAGNOSIS AND TESTING,

HEADLAMP HIGH BEAM...............8L-34

RELAY - DIAGNOSIS AND TESTING,

HEADLAMP LOW BEAM...............8L-40

RELAY - DIAGNOSIS AND TESTING,

PARK LAMP.........................8L-55

RELAY - DIAGNOSIS AND TESTING,

REAR FOG LAMP.....................8L-57

RELAY - DIAGNOSIS AND TESTING,

TRAILER TOW.......................8L-62

RELAY - INSTALLATION, DAYTIME

RUNNING LAMP.....................8L-21

RELAY - INSTALLATION, FRONT FOG

LAMP..............................8L-24

RELAY - INSTALLATION, HEADLAMP

HIGH BEAM.........................8L-35

RELAY - INSTALLATION, HEADLAMP

LOW BEAM.........................8L-41

RELAY - INSTALLATION, PARK LAMP.....8L-56

RELAY - INSTALLATION, REAR FOG

LAMP..............................8L-58

RELAY - INSTALLATION, TRAILER TOW . . . 8L-63

RELAY - OPERATION, DAYTIME

RUNNING LAMP.....................8L-20

RELAY - OPERATION, FRONT FOG LAMP . . 8L-22

RELAY - OPERATION, HEADLAMP HIGH

BEAM..............................8L-33

RELAY - OPERATION, HEADLAMP LOW

BEAM..............................8L-39

RELAY - OPERATION, PARK LAMP.......8L-54

RELAY - OPERATION, REAR FOG LAMP . . . 8L-57

RELAY - OPERATION, TRAILER TOW.....8L-62

RELAY - REMOVAL, DAYTIME RUNNING

LAMP..............................8L-21

RELAY - REMOVAL, FRONT FOG LAMP . . . 8L-24

RELAY - REMOVAL, HEADLAMP HIGH

BEAM..............................8L-34

RELAY - REMOVAL, HEADLAMP LOW

BEAM..............................8L-40

RELAY - REMOVAL, PARK LAMP........8L-55

RELAY - REMOVAL, REAR FOG LAMP....8L-58

RELAY - REMOVAL, TRAILER TOW.......8L-63

REMOVAL - CLEANING.................9-55

REMOVAL - INSPECTION...............9-28

REMOVAL, 2.4L.......................7-20

REMOVAL, 2.4L.......................9-19

REMOVAL, 2.4L ENGINE....7-14,7-16,7-22,7-27

REMOVAL, BALANCE SHAFT.............9-60

REMOVAL, BALANCE SHAFT CARRIER.....9-64

REMOVAL, BALANCE SHAFT CHAIN.......9-64

REMOVAL, BRAKE LAMP SWITCH.......8L-17

REMOVAL, CAMSHAFT OIL SEAL(S).......9-22

REMOVAL, CAMSHAFT(S)...............9-24

REMOVAL, CATALYTIC CONVERTER.......11-2

REMOVAL, CENTER HIGH MOUNTED

STOP LAMP BULB....................8L-18

REMOVAL, CENTER HIGH MOUNTED

STOP LAMP UNIT....................8L-19

REMOVAL, CLEVIS BRACKET BUSHING.....2-2

REMOVAL, CRANKSHAFT...............9-33

REMOVAL, CRANKSHAFT OIL SEAL -

FRONT..............................9-37

REMOVAL, CRANKSHAFT OIL SEAL -

REAR...............................9-38

REMOVAL, CRANKSHAFT SPROCKET......9-55

REMOVAL, CROSS-OVER PIPE...........11-4

REMOVAL, CYLINDER HEAD.............9-20

REMOVAL, CYLINDER HEAD COVER.......9-26

REMOVAL, CYLINDER HEAD OFF.........9-27

REMOVAL, CYLINDER HEAD ON..........9-27

REMOVAL, DAYTIME RUNNING LAMP

RELAY.............................8L-21

REMOVAL, ENGINE ASSEMBLY...........9-12

REMOVAL, ENGINE COOLANT

TEMPERATURE SENSOR................7-21

REMOVAL, EXHAUST MANIFOLD.........9-53

REMOVAL, FRONT FOG LAMP BULB......8L-21

REMOVAL, FRONT FOG LAMP RELAY.....8L-24

REMOVAL, FRONT FOG LAMP UNIT......8L-24

REMOVAL, FRONT LAMP BULB.........8L-27

REMOVAL, FRONT LAMP UNIT

..........8L-27

REMOVAL, FRONT MOUNT

..............9-44

REMOVAL, FRONT POSITION LAMP

BULB

..............................8L-28

REMOVAL, HAZARD SWITCH

...........8L-29

REMOVAL, HEADLAMP BULB

...........8L-30REMOVAL, HEADLAMP HIGH BEAM

RELAY.............................8L-34

REMOVAL, HEADLAMP LEVELING

MOTOR............................8L-36

REMOVAL, HEADLAMP LEVELING

SWITCH............................8L-38

REMOVAL, HEADLAMP LOW BEAM

RELAY.............................8L-40

REMOVAL, HEADLAMP UNIT...........8L-41

REMOVAL, HYDRAULIC LIFTERS.........9-29

REMOVAL, INTAKE MANIFOLD...........9-52

REMOVAL, LAMP....................8L-66

REMOVAL, LAMP BAR................8L-65

REMOVAL, LAMP BAR SWITCH.........8L-67

REMOVAL, LICENSE PLATE LAMP BULB . . 8L-44

REMOVAL, LICENSE PLATE LAMP UNIT . . . 8L-45

REMOVAL, LOWER BALL JOINT...........2-5

REMOVAL, LOWER CONTROL ARM

BUSHING.............................2-2

REMOVAL, LOWER SUSPENSION ARM

BUSHING.............................2-7

REMOVAL, MUFFLER...................11-4

REMOVAL, MULTI-FUNCTION SWITCH....8L-53

REMOVAL, OIL FILTER.................9-47

REMOVAL, OIL PAN...................9-48

REMOVAL, OIL PUMP..................9-49

REMOVAL, PARK LAMP RELAY..........8L-55

REMOVAL, PISTON & CONNECTING ROD . . . 9-40

REMOVAL, RADIATOR..................7-22

REMOVAL, RADIATOR FAN - ELECTRIC....7-26

REMOVAL, REAR FOG LAMP RELAY......8L-58

REMOVAL, REAR LAMP BULB..........8L-59

REMOVAL, REAR LAMP UNIT...........8L-59

REMOVAL, REAR MOUNT...............9-45

REMOVAL, REPEATER LAMP BULB.......8L-60

REMOVAL, REPEATER LAMP UNIT.......8L-61

REMOVAL, RHD........................5-1

REMOVAL, ROCKER ARMS..............9-29

REMOVAL, STRUCTURAL COLLAR........9-44

REMOVAL, TIMING BELT................9-55

REMOVAL, TIMING BELT COVER(S).......9-53

REMOVAL, TIMING BELT TENSIONER &

PULLEY.............................9-59

REMOVAL, TRAILER TOW CONNECTOR . . . 8L-61

REMOVAL, TRAILER TOW RELAY........8L-63

REMOVAL, UPPER BALL JOINT...........2-6

REMOVAL, UPPER CONTROL ARM

BUSHINGS............................2-3

REMOVAL, UPPER SUSPENSION ARM

BUSHING.............................2-7

REMOVAL, VIBRATION DAMPER..........9-43

REPAIR OF DAMAGED OR WORN

THREADS - STANDARD PROCEDURE.......9-9

REPEATER LAMP BULB - INSTALLATION . . 8L-60

REPEATER LAMP BULB - REMOVAL......8L-60

REPEATER LAMP UNIT - INSTALLATION . . 8L-61

REPEATER LAMP UNIT - REMOVAL......8L-61

REVERSE FLUSHING - STANDARD

PROCEDURE, COOLING SYSTEM.........7-12

RHD - INSTALLATION...................5-1

RHD - REMOVAL.......................5-1

RING, FITTING - PISTON................9-42

ROCKER ARMS - INSPECTION...........9-30

ROCKER ARMS - INSTALLATION.........9-30

ROCKER ARMS - REMOVAL.............9-29

ROD - DESCRIPTION, PISTON &

CONNECTING.........................9-40

ROD - INSTALLATION, PISTON &

CONNECTING.........................9-41

ROD - OPERATION, PISTON &

CONNECTING.........................9-40

ROD - REMOVAL, PISTON &

CONNECTING.........................9-40

ROD, FITTING - CONNECTING............9-32

RUNNING LAMP RELAY - DESCRIPTION,

DAYTIME...........................8L-20

RUNNING LAMP RELAY - INSTALLATION,

DAYTIME...........................8L-21

RUNNING LAMP RELAY - OPERATION,

DAYTIME

...........................8L-20

RUNNING LAMP RELAY - REMOVAL,

DAYTIME

...........................8L-21

SEAL - FRONT - INSTALLATION,

CRANKSHAFT OIL

.....................9-37

SEAL - FRONT - REMOVAL,

CRANKSHAFT OIL

.....................9-37

SEAL - REAR - INSTALLATION,

CRANKSHAFT OIL

.....................9-39SEAL - REAR - REMOVAL, CRANKSHAFT

OIL ................................9-38

SEALERS - STANDARD PROCEDURE,

FORM-IN-PLACE GASKETS..............9-10

SEAL(S) - INSTALLATION, CAMSHAFT

OIL ................................9-22

SEAL(S) - REMOVAL, CAMSHAFT OIL.....9-22

SEATS - CLEANING, INTAKE/EXHAUST

VALVES .............................9-27

SEATS - DESCRIPTION, INTAKE/

EXHAUST VALVES.....................9-27

SENSOR - DESCRIPTION, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - INSTALLATION, ENGINE

COOLANT TEMPERATURE...............7-22

SENSOR - OPERATION, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - REMOVAL, ENGINE COOLANT

TEMPERATURE.......................7-21

SENSOR/SWITCH - DESCRIPTION, OIL

PRESSURE..........................9-48

SENSOR/SWITCH - OPERATION, OIL

PRESSURE..........................9-48

SERPENTINE DRIVE BELT DIAGNOSIS -

DIAGNOSIS AND TESTING..............7-15

SHAFT - DESCRIPTION, BALANCE........9-59

SHAFT - OPERATION, BALANCE..........9-59

SHAFT - REMOVAL, BALANCE...........9-60

SHAFT CARRIER - INSTALLATION,

BALANCE............................9-64

SHAFT CARRIER - REMOVAL, BALANCE....9-64

SHAFT CHAIN - INSTALLATION,

BALANCE............................9-64

SHAFT CHAIN - REMOVAL, BALANCE......9-64

SHAFT TIMING, INSTALLATION -

BALANCE............................9-61

SHIELDS - DESCRIPTION, HEAT..........11-4

SPECIAL TOOLS - 2.4L ENGINE..........9-17

SPECIAL TOOLS - COOLING.............7-13

SPECIAL TOOLS - FRONT SUSPENSION.....2-1

SPECIAL TOOLS - REAR SUSPENSION......2-6

SPECIFICATIONS - TORQUE.............7-13

SPECIFICATIONS, 2.4L ENGINE...........9-13

SPECIFICATIONS, LAMPS/LIGHTING -

EXTERIOR..........................8L-15

SPECIFICATIONS, TORQUE..............9-16

SPROCKET - INSTALLATION,

CRANKSHAFT........................9-56

SPROCKET - REMOVAL, CRANKSHAFT.....9-55

STANDARD PROCEDURE - CLEANING.....9-31

STANDARD PROCEDURE - ENGINE OIL

LEVEL CHECK........................9-47

STANDARD PROCEDURE - INSPECTION....9-32

STANDARD PROCEDURE, CAMSHAFT

END-PLAY...........................9-23

STANDARD PROCEDURE, COOLING

SYSTEM - REVERSE FLUSHING..........7-12

STANDARD PROCEDURE, CRANKSHAFT

END PLAY ...........................9-33

STANDARD PROCEDURE, CYLINDER

BORE HONING........................9-31

STANDARD PROCEDURE, DRAINING

COOLING SYSTEM....................7-11

STANDARD PROCEDURE, ENGINE CORE

AND OIL GALLERY PLUGS...............9-9

STANDARD PROCEDURE, ENGINE

GASKET SURFACE PREPARATION.........9-11

STANDARD PROCEDURE, ENGINE OIL

AND FILTER CHANGE..................9-47

STANDARD PROCEDURE, FLUSHING

COOLERS AND TUBES.................7-30

STANDARD PROCEDURE, FORM-IN-

PLACE GASKETS AND SEALERS..........9-10

STANDARD PROCEDURE, HYDROSTATIC

LOCKED ENGINE.......................9-9

STANDARD PROCEDURE, LAMP BAR

AIMING............................8L-65

STANDARD PROCEDURE, MAIN BEARING

- FITTING

............................9-35

STANDARD PROCEDURE, MEASURING

BEARING CLEARANCE USING

PLASTIGAGE

.........................9-11

STANDARD PROCEDURE, PISTON TO

CYLINDER BORE FITTING

...............9-30

STANDARD PROCEDURE, REFILLING

COOLING SYSTEM

....................7-11

STANDARD PROCEDURE, REPAIR OF

DAMAGED OR WORN THREADS

...........9-9

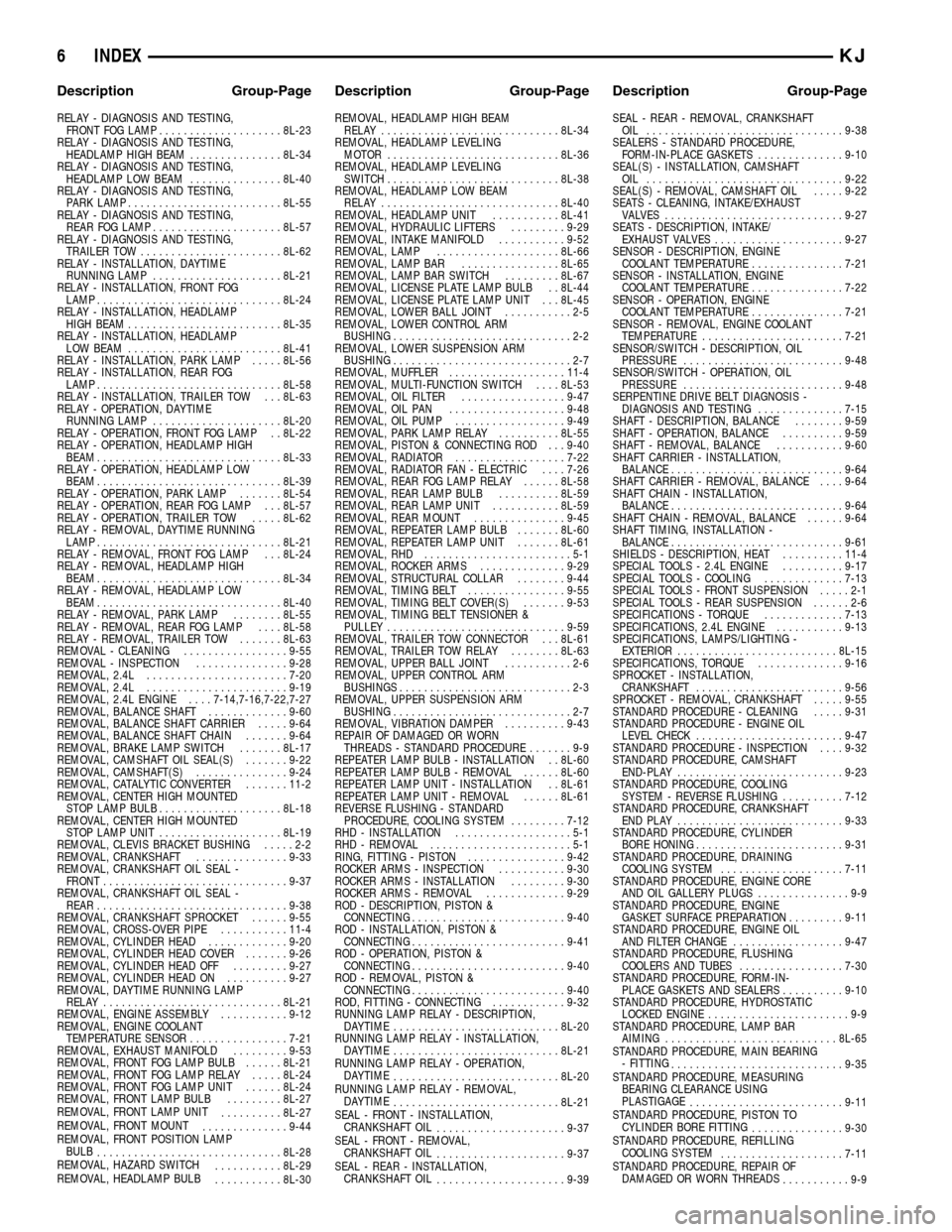

6 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1776 of 1803

STOP LAMP BULB - INSTALLATION,

CENTER HIGH MOUNTED..............8L-19

STOP LAMP BULB - REMOVAL, CENTER

HIGH MOUNTED.....................8L-18

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED..............8L-19

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED.....................8L-19

STRUCTURAL COLLAR - INSTALLATION....9-44

STRUCTURAL COLLAR - REMOVAL.......9-44

SURFACE PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET...........9-11

SUSPENSION ARM BUSHING -

INSTALLATION, LOWER.................2-8

SUSPENSION ARM BUSHING -

INSTALLATION, UPPER..................2-8

SUSPENSION ARM BUSHING -

REMOVAL, LOWER.....................2-7

SUSPENSION ARM BUSHING -

REMOVAL, UPPER......................2-7

SUSPENSION, SPECIAL TOOLS - FRONT....2-1

SUSPENSION, SPECIAL TOOLS - REAR.....2-6

SWITCH - DESCRIPTION, BACKUP LAMP . . 8L-15

SWITCH - DESCRIPTION, BRAKE LAMP . . . 8L-16

SWITCH - DESCRIPTION, HAZARD.......8L-28

SWITCH - DESCRIPTION, HEADLAMP

LEVELING..........................8L-37

SWITCH - DESCRIPTION, LAMP BAR.....8L-67

SWITCH - DESCRIPTION, MULTI-

FUNCTION..........................8L-46

SWITCH - DIAGNOSIS AND TESTING,

BACKUP LAMP......................8L-15

SWITCH - DIAGNOSIS AND TESTING,

BRAKE LAMP.......................8L-17

SWITCH - DIAGNOSIS AND TESTING,

HEADLAMP LEVELING.................8L-37

SWITCH - DIAGNOSIS AND TESTING,

MULTI-FUNCTION....................8L-50

SWITCH - INSTALLATION, BRAKE LAMP . . 8L-18

SWITCH - INSTALLATION, HAZARD......8L-30

SWITCH - INSTALLATION, HEADLAMP

LEVELING..........................8L-38

SWITCH - INSTALLATION, LAMP BAR....8L-67

SWITCH - INSTALLATION, MULTI-

FUNCTION..........................8L-53

SWITCH - OPERATION, BACKUP LAMP . . . 8L-15

SWITCH - OPERATION, BRAKE LAMP.....8L-16

SWITCH - OPERATION, HAZARD.........8L-29

SWITCH - OPERATION, HEADLAMP

LEVELING..........................8L-37

SWITCH - OPERATION, MULTI-FUNCTION . 8L-48

SWITCH - REMOVAL, BRAKE LAMP......8L-17

SWITCH - REMOVAL, HAZARD..........8L-29

SWITCH - REMOVAL, HEADLAMP

LEVELING..........................8L-38

SWITCH - REMOVAL, LAMP BAR........8L-67

SWITCH - REMOVAL, MULTI-FUNCTION . . . 8L-53

SYSTEM - DESCRIPTION, EXHAUST.......11-1

SYSTEM - DIAGNOSIS AND TESTING,

EXHAUST............................11-2

SYSTEM - OPERATION, COOLING..........7-2

SYSTEM - REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING.......7-12

SYSTEM - STANDARD PROCEDURE,

DRAINING COOLING...................7-11

SYSTEM - STANDARD PROCEDURE,

REFILLING COOLING...................7-11

SYSTEM 2.4L ENGINE - DESCRIPTION,

COOLING.............................7-1

SYSTEM DIAGNOSIS CHART -

DIAGNOSIS AND TESTING, COOLING.......7-5

SYSTEM LEAKS - DIAGNOSIS AND

TESTING, COOLING.....................7-2

TEMPERATURE SENSOR - DESCRIPTION,

ENGINE COOLANT.....................7-21

TEMPERATURE SENSOR -

INSTALLATION, ENGINE COOLANT........7-22

TEMPERATURE SENSOR - OPERATION,

ENGINE COOLANT.....................7-21

TEMPERATURE SENSOR - REMOVAL,

ENGINE COOLANT.....................7-21TENSIONER & PULLEY - INSTALLATION,

TIMING BELT.........................9-59

TENSIONER & PULLEY - REMOVAL,

TIMING BELT.........................9-59

TEST - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE

LEAKAGE.............................9-3

TEST - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION PRESSURE......9-3

TESTING, BACKUP LAMP SWITCH -

DIAGNOSIS.........................8L-15

TESTING, BRAKE LAMP SWITCH -

DIAGNOSIS.........................8L-17

TESTING, COOLING SYSTEM DIAGNOSIS

CHART - DIAGNOSIS....................7-5

TESTING, COOLING SYSTEM LEAKS -

DIAGNOSIS...........................7-2

TESTING, CYLINDER COMBUSTION

PRESSURE LEAKAGE TEST -

DIAGNOSIS...........................9-3

TESTING, CYLINDER COMPRESSION

PRESSURE TEST - DIAGNOSIS............9-3

TESTING, CYLINDER HEAD GASKET -

DIAGNOSIS..........................9-19

TESTING, ENGINE - DIAGNOSIS...........9-5

TESTING, ENGINE DIAGNOSIS -

PERFORMANCE - DIAGNOSIS.............9-5

TESTING, ENGINE MECHANICAL -

DIAGNOSIS...........................9-7

TESTING, ENGINE OIL LEAK

INSPECTION - DIAGNOSIS...............9-4

TESTING, ENGINE OIL PRESSURE

CHECKING - DIAGNOSIS................9-46

TESTING, EXHAUST SYSTEM -

DIAGNOSIS..........................11-2

TESTING, FRONT FOG LAMP RELAY -

DIAGNOSIS.........................8L-23

TESTING, HEADLAMP HIGH BEAM

RELAY - DIAGNOSIS

..................8L-34

TESTING, HEADLAMP LEVELING SWITCH

- DIAGNOSIS

........................8L-37

TESTING, HEADLAMP LOW BEAM RELAY

- DIAGNOSIS

........................8L-40

TESTING, INTAKE MANIFOLD LEAKS -

DIAGNOSIS

..........................9-51

TESTING, LAMP BAR - DIAGNOSIS

......8L-65

TESTING, LAMPS/LIGHTING - EXTERIOR

- DIAGNOSIS

.........................8L-7

TESTING, LASH ADJUSTER (TAPPET)

NOISE DIAGNOSIS - DIAGNOSIS

.........9-28

TESTING, MULTI-FUNCTION SWITCH -

DIAGNOSIS

.........................8L-50

TESTING, ON-BOARD DIAGNOSTICS

(OBD) - DIAGNOSIS

....................7-2

TESTING, PARK LAMP RELAY -

DIAGNOSIS

.........................8L-55

TESTING, PRELIMINARY CHECKS -

DIAGNOSIS

...........................7-2

TESTING, RADIATOR PRESSURE CAP -

DIAGNOSIS

..........................7-25

TESTING, REAR FOG LAMP RELAY -

DIAGNOSIS

.........................8L-57

TESTING, SERPENTINE DRIVE BELT

DIAGNOSIS - DIAGNOSIS

...............7-15

TESTING, TRAILER TOW RELAY -

DIAGNOSIS

.........................8L-62

THREADS - STANDARD PROCEDURE,

REPAIR OF DAMAGED OR WORN

..........9-9

TIMING BELT - INSTALLATION

...........9-56

TIMING BELT - REMOVAL

...............9-55

TIMING BELT COVER(S) - INSTALLATION

. . . 9-53

TIMING BELT COVER(S) - REMOVAL

......9-53

TIMING BELT TENSIONER & PULLEY -

INSTALLATION

........................9-59

TIMING BELT TENSIONER & PULLEY -

REMOVAL

...........................9-59

TIMING, INSTALLATION - BALANCE

SHAFT

..............................9-61TO CYLINDER BORE FITTING -

STANDARD PROCEDURE, PISTON........9-30

TOOLS - 2.4L ENGINE, SPECIAL..........9-17

TOOLS - COOLING, SPECIAL.............7-13

TOOLS - FRONT SUSPENSION, SPECIAL....2-1

TOOLS - REAR SUSPENSION, SPECIAL.....2-6

TORQUE - SPECIFICATIONS.............9-16

TORQUE, SPECIFICATIONS..............7-13

TOW CONNECTOR - INSTALLATION,

TRAILER...........................8L-61

TOW CONNECTOR - REMOVAL, TRAILER . . 8L-61

TOW RELAY - DESCRIPTION, TRAILER....8L-62

TOW RELAY - DIAGNOSIS AND TESTING,

TRAILER...........................8L-62

TOW RELAY - INSTALLATION, TRAILER . . . 8L-63

TOW RELAY - OPERATION, TRAILER.....8L-62

TOW RELAY - REMOVAL, TRAILER.......8L-63

TOW WIRING - DESCRIPTION, TRAILER . . 8L-64

TRAILER TOW CONNECTOR -

INSTALLATION.......................8L-61

TRAILER TOW CONNECTOR - REMOVAL . . 8L-61

TRAILER TOW RELAY - DESCRIPTION....8L-62

TRAILER TOW RELAY - DIAGNOSIS AND

TESTING...........................8L-62

TRAILER TOW RELAY - INSTALLATION . . . 8L-63

TRAILER TOW RELAY - OPERATION......8L-62

TRAILER TOW RELAY - REMOVAL.......8L-63

TRAILER TOW WIRING - DESCRIPTION . . . 8L-64

TRANS COOLER - DESCRIPTION.........7-30

TUBES - STANDARD PROCEDURE,

FLUSHING COOLERS...................7-30

UNIT - ADJUSTMENT, FRONT FOG LAMP . . 8L-25

UNIT - ADJUSTMENT, HEADLAMP.......8L-42

UNIT - INSTALLATION, CENTER HIGH

MOUNTED STOP LAMP................8L-19

UNIT - INSTALLATION, FRONT FOG

LAMP..............................8L-25

UNIT - INSTALLATION, FRONT LAMP.....8L-28

UNIT - INSTALLATION, HEADLAMP.......8L-42

UNIT - INSTALLATION, LICENSE PLATE

LAMP..............................8L-46

UNIT - INSTALLATION, REAR LAMP......8L-60

UNIT - INSTALLATION, REPEATER LAMP . . 8L-61

UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP LAMP

................8L-19

UNIT - REMOVAL, FRONT FOG LAMP

.....8L-24

UNIT - REMOVAL, FRONT LAMP

.........8L-27

UNIT - REMOVAL, HEADLAMP

..........8L-41

UNIT - REMOVAL, LICENSE PLATE LAMP

. . 8L-45

UNIT - REMOVAL, REAR LAMP

..........8L-59

UNIT - REMOVAL, REPEATER LAMP

......8L-61

UPPER BALL JOINT - INSTALLATION

.......2-6

UPPER BALL JOINT - REMOVAL

...........2-6

UPPER CONTROL ARM BUSHINGS -

INSTALLATION

.........................2-4

UPPER CONTROL ARM BUSHINGS -

REMOVAL

............................2-3

UPPER SUSPENSION ARM BUSHING -

INSTALLATION

.........................2-8

UPPER SUSPENSION ARM BUSHING -

REMOVAL

............................2-7

USING PLASTIGAGE - STANDARD

PROCEDURE, MEASURING BEARING

CLEARANCE

..........................9-11

VALVES & SEATS - CLEANING,

INTAKE/EXHAUST

.....................9-27

VALVES & SEATS - DESCRIPTION,

INTAKE/EXHAUST

.....................9-27

VIBRATION DAMPER - INSTALLATION

.....9-43

VIBRATION DAMPER - REMOVAL

.........9-43

WATER PUMP - 2.4L - DESCRIPTION

......7-27

WATER PUMP - 2.4L - INSPECTION

.......7-28

WATER PUMP - 2.4L - OPERATION

.......7-27

WIRING - DESCRIPTION, TRAILER TOW

. . 8L-64

WORN THREADS - STANDARD

PROCEDURE, REPAIR OF DAMAGED

OR

..................................9-9

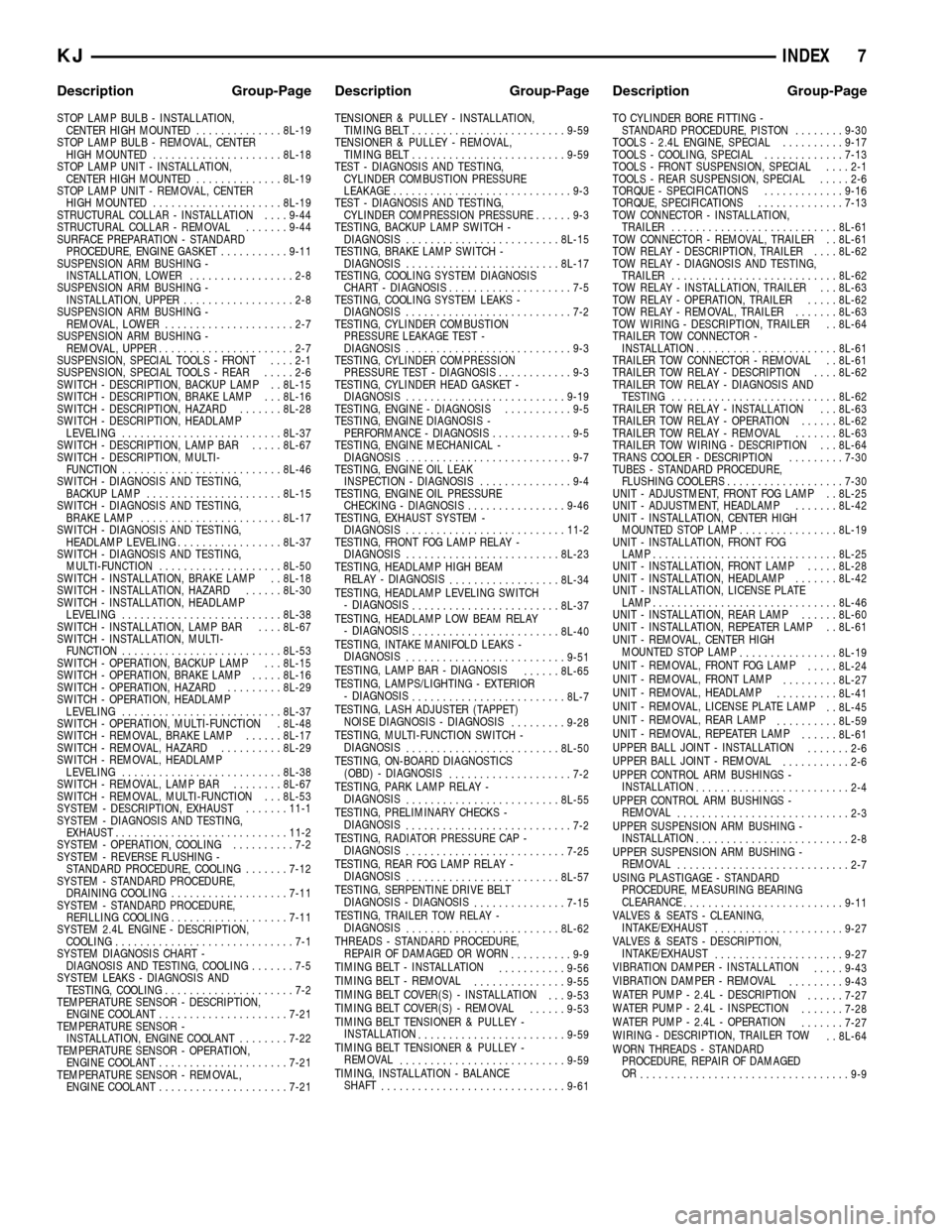

KJINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 1793 of 1803

FOREWORD

This manual is designed as a supplement to be used along with the 2002 Liberty service manual,

81-370-02060. It includes information related to the 2.4L gas engine installed in this vehicle by

DaimlerChrysler Corporation. For diagnosis or service procedures relating to other components or systems,

refer to the 2002 Liberty Service Manual.

The information contained in this service manual has been prepared for the professional automotive tech-

nician involved in daily repair operations. Information describing the operation and use of standard and

optional equipment is included in the Owner's Manual provided with the vehicle.

Information in this manual is divided into groups. These groups contain description, operation, diagnosis,

testing, adjustments, removal, installation, disassembly, and assembly procedures for the systems and compo-

nents. To assist in locating a group title page, use the Group Tab Locator on the following page. The solid bar

after the group title is aligned to a solid tab on the first page of each group. The first page of the group has

a contents section that lists major topics within the group. If you are not sure which Group contains the infor-

mation you need, look up the Component/System in the alphabetical index located in the rear of this manual.

A Service Manual Comment form is included at the rear of this manual. Use the form to provide

DaimlerChrysler Corporation with your comments and suggestions.

Tightening torques are provided as a specific value throughout this manual. This value represents the

midpoint of the acceptable engineering torque range for a given fastener application. These torque values are

intended for use in service assembly and installation procedures using the correct OEM fasteners. When

replacing fasteners, always use the same type (part number) fastener as removed.

DaimlerChrysler Corporation reserves the right to change testing procedures, specifications, diagnosis,

repair methods, or vehicle wiring at any time without prior notice or incurring obligation.

Page 1794 of 1803

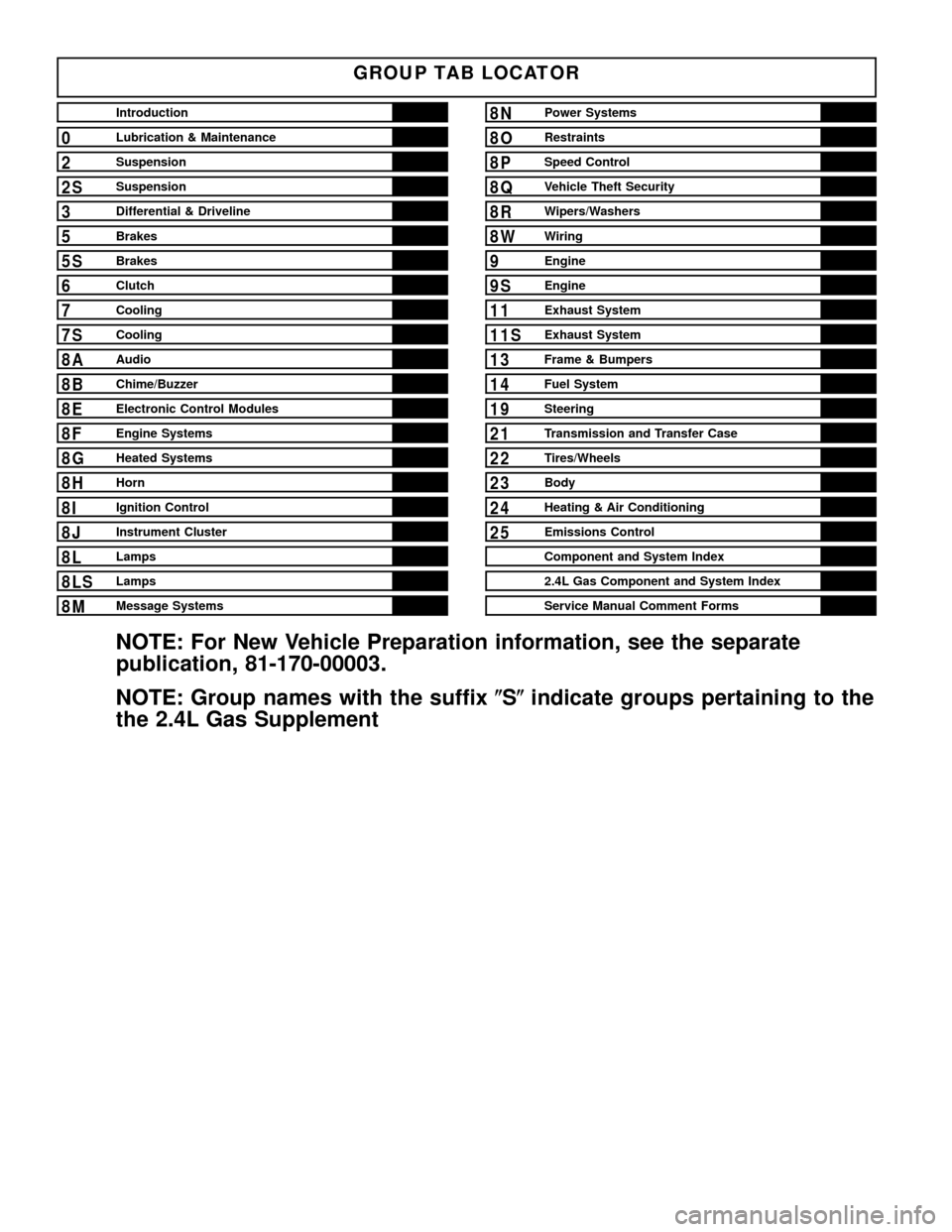

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

2SSuspension

3Differential & Driveline

5Brakes

5SBrakes

6Clutch

7Cooling

7SCooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8LSLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

9SEngine

11Exhaust System

11SExhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission and Transfer Case

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

2.4L Gas Component and System Index

Service Manual Comment Forms

NOTE: For New Vehicle Preparation information, see the separate

publication, 81-170-00003.

NOTE: Group names with the suffix(S(indicate groups pertaining to the

the 2.4L Gas Supplement