removing JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1248 of 1803

(19) Install oil fill housing onto cylinder head.

(20) Refill the cooling system.

(21) Raise the vehicle.

(22) Install the exhaust pipe onto the right

exhaust manifold.

(23) Lower the vehicle.

(24) Reconnect battery negitive cable.

(25) Start the engine and check for leaks.

CAMSHAFT(S)

DESCRIPTION

The camshafts consist of powdered metal steel

lobes which are sinter-bonded to a steel tube. Four

bearing journals are machined into the camshaft.

Camshaft end play is controlled by two thrust walls

that border the nose piece journal. Engine oil enters

the hollow camshafts at the third journal and lubri-

cates every intake lobe rocker through a drilled pas-

sage in the intake lobe.

REMOVAL

CAUTION: When the timing chain is removed and

the cylinder heads are still installed, DO NOT force-

fully rotate the camshafts or crankshaft indepen-

dently of each other. Severe valve and/or piston

damage can occur.

CAUTION: When removing the cam sprocket, timing

chains or camshaft, Failure to use special tool 8379

will result in hydraulic tensioner ratchet over exten-

sion, Requiring timing chain cover removal to re-set

the tensioner ratchet.

(1) Remove the cylinder head cover. Refer to CYL-

INDER HEAD COVER in this section.

(2) Set engine to TDC cylinder #1, camshaft

sprocket V6 marks at the 12 o'clock position.

(3) Mark one link on the secondary timing chain

on both sides of the V6 mark on the camshaft

sprocket to aid in installation.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason, Severe damage will occur

to the target wheel. A damaged target wheel could

cause a vehicle no start condition.

(4) Loosen butDO NOTremove the camshaft

sprocket retaining bolt. Leave bolt snug against

sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-ers to extend, requiring timing chain cover removal

in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest

point between the chain strands. Damage to the

tensioners may occur.

(5) Position Special Tool 8379 timing chain wedge

between the timing chain strands. Tap the tool to

securely wedge the timing chain against the ten-

sioner arm and guide.

(6) Remove the camshaft position sensor.

(7) Hold the camshaft with Special Tool 8428 Cam-

shaft Wrench, while removing the camshaft sprocket

bolt and sprocket.

(8) Starting at the outside working inward, loosen

the camshaft bearing cap retaining bolts 1/2 turn at

a time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

(9) Remove the camshaft bearing caps and the

camshaft.

INSTALLATION

(1) Lubricate camshaft journals with clean engine

oil.

NOTE: Position the right side camshaft so that the

camshaft sprocket dowel is near the 10 o'clock

position, This will place the camshaft at the neutral

position easing the installation of the camshaft

bearing caps.

(2) Position the camshaft into the cylinder head.

(3) Install the camshaft bearing caps, hand tighten

the retaining bolts.

NOTE: Caps should be installed so that the

stamped numbers on the caps are in numerical

order, ( 1 thru 4 ) from the front to the rear of the

engine. All caps should be installed so that the

stamped arrows on the caps point toward the front

of the engine.

(4) Working in 1/2 turn increments, tighten the

bearing cap retaining bolts starting with the middle

cap working outward (Fig. 23).

(5) Torque the camshaft bearing cap retaining

bolts to 11 N´m (100 in. lbs.).

KJENGINE - 3.7L 9 - 33

CYLINDER HEAD - RIGHT (Continued)

Page 1251 of 1803

NOTE: Check for sharp edges on the keeper

grooves. Remove any burrs from the valve stem

before removing the valve from the cylinder head.

(7) Remove the valve from the cylinder head.

NOTE: The valve stem seals are common between

intake and exhaust.

(8) Remove the valve stem seal. Mark the valve for

proper installation.

TESTING VALVE SPRINGS

NOTE: Whenever the valves are removed from the

cylinder head it is recommended that the valve

springs be inspected and tested for reuse.

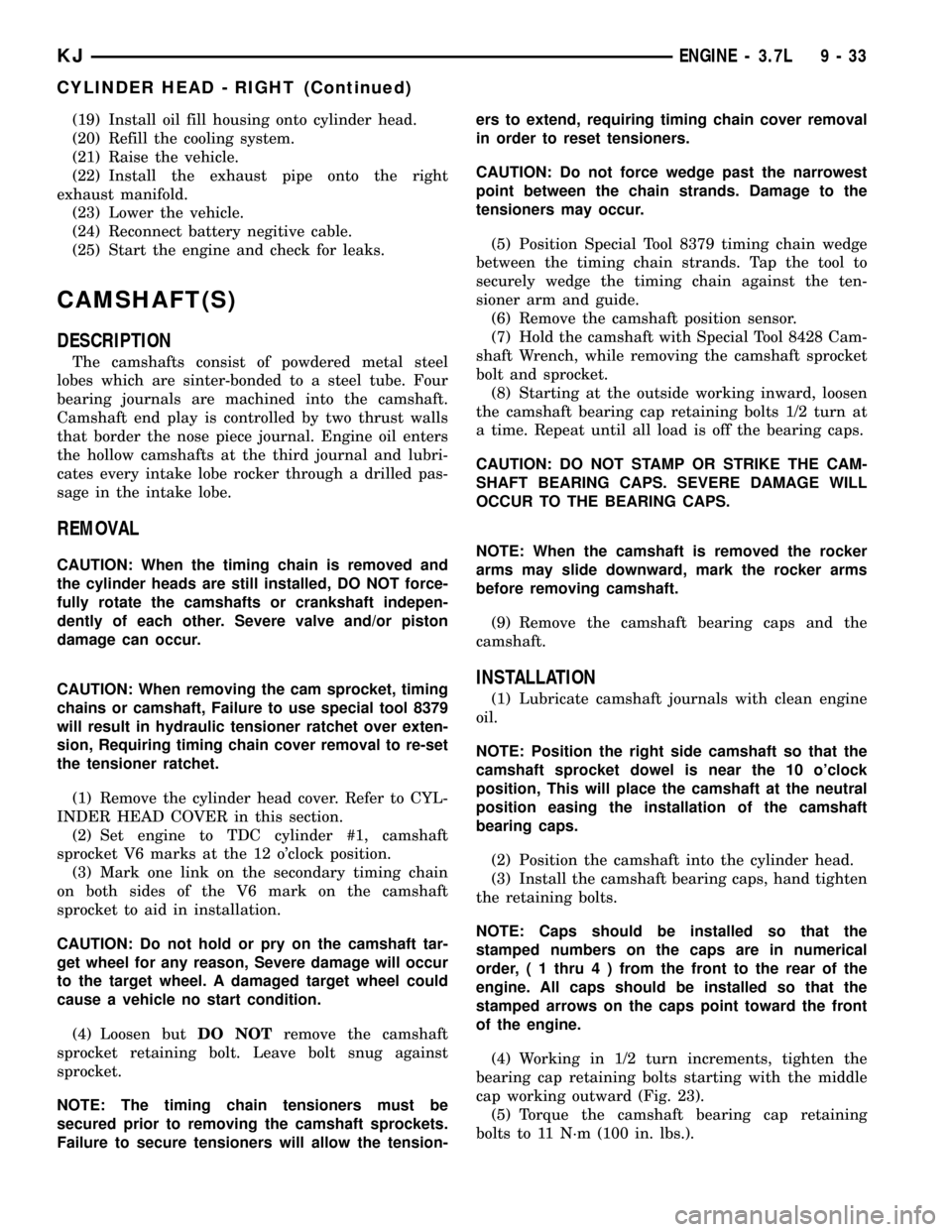

Inspect the valve springs for physical signs of wear

or damage. Turn table of tool C-647 until surface is

in line with the 40.69 mm (1.602 in.) mark on the

threaded stud and the zero mark on the front. Place

spring over the stud on the table and lift compress-

ing lever to set tone device. Pull on torque wrench

until Ping is heard. Take reading on torque wrench

at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional

measurements are indicated on the table for finer

adjustments. Refer to Specifications Section to obtain

specified height and allowable tensions. Replace any

springs that do not meet specifications (Fig. 26).

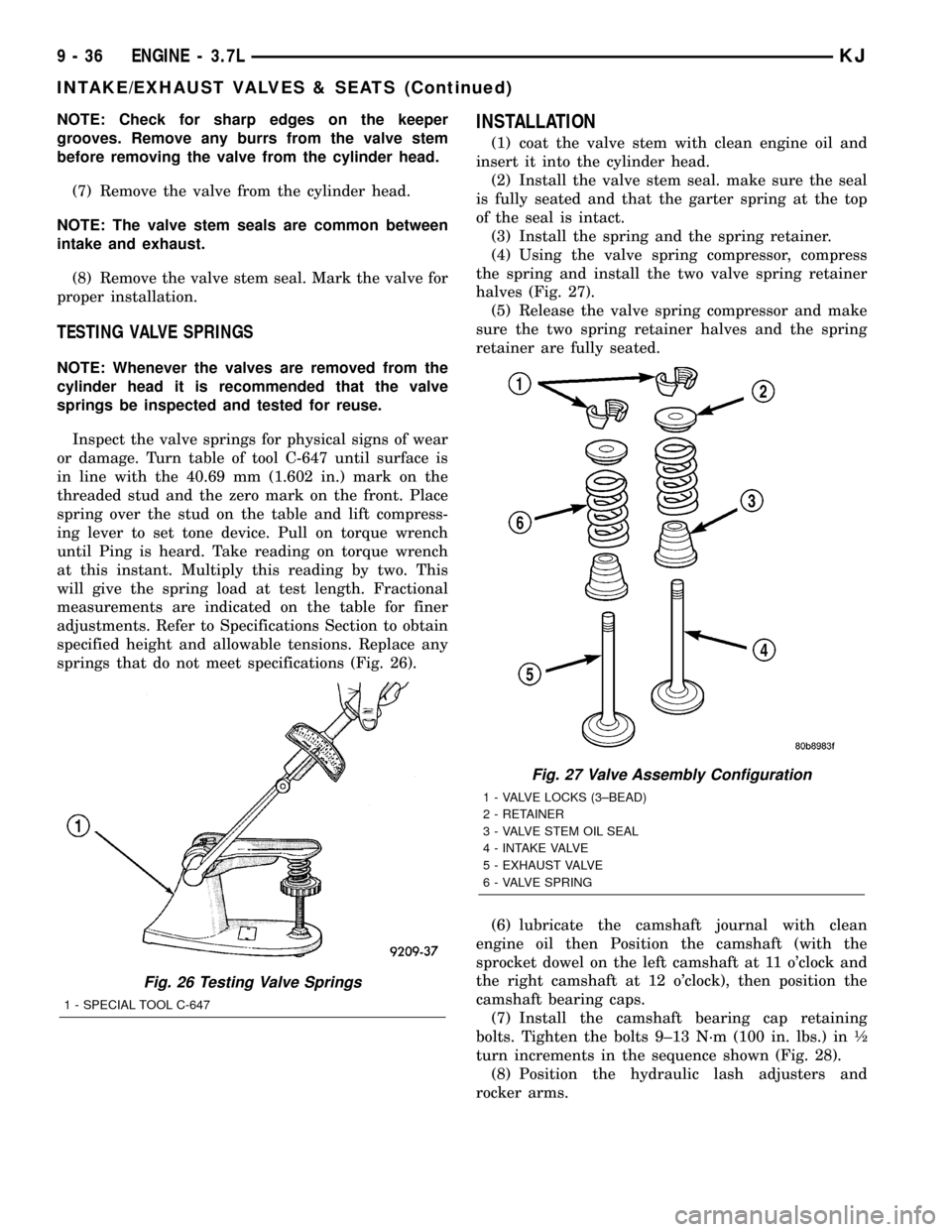

INSTALLATION

(1) coat the valve stem with clean engine oil and

insert it into the cylinder head.

(2) Install the valve stem seal. make sure the seal

is fully seated and that the garter spring at the top

of the seal is intact.

(3) Install the spring and the spring retainer.

(4) Using the valve spring compressor, compress

the spring and install the two valve spring retainer

halves (Fig. 27).

(5) Release the valve spring compressor and make

sure the two spring retainer halves and the spring

retainer are fully seated.

(6) lubricate the camshaft journal with clean

engine oil then Position the camshaft (with the

sprocket dowel on the left camshaft at 11 o'clock and

the right camshaft at 12 o'clock), then position the

camshaft bearing caps.

(7) Install the camshaft bearing cap retaining

bolts. Tighten the bolts 9±13 N´m (100 in. lbs.) in ó

turn increments in the sequence shown (Fig. 28).

(8) Position the hydraulic lash adjusters and

rocker arms.

Fig. 26 Testing Valve Springs

1 - SPECIAL TOOL C-647

Fig. 27 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

9 - 36 ENGINE - 3.7LKJ

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1254 of 1803

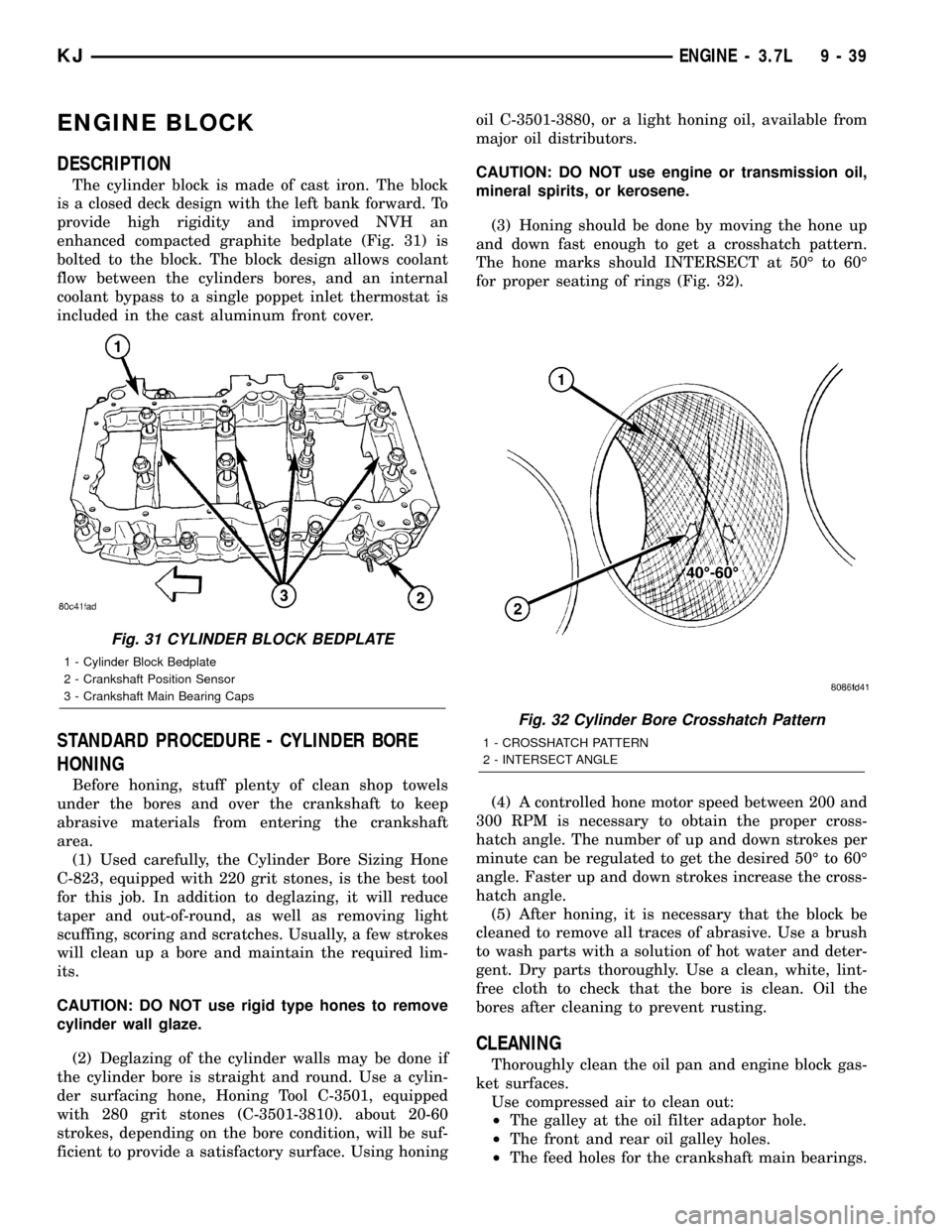

ENGINE BLOCK

DESCRIPTION

The cylinder block is made of cast iron. The block

is a closed deck design with the left bank forward. To

provide high rigidity and improved NVH an

enhanced compacted graphite bedplate (Fig. 31) is

bolted to the block. The block design allows coolant

flow between the cylinders bores, and an internal

coolant bypass to a single poppet inlet thermostat is

included in the cast aluminum front cover.

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honingoil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

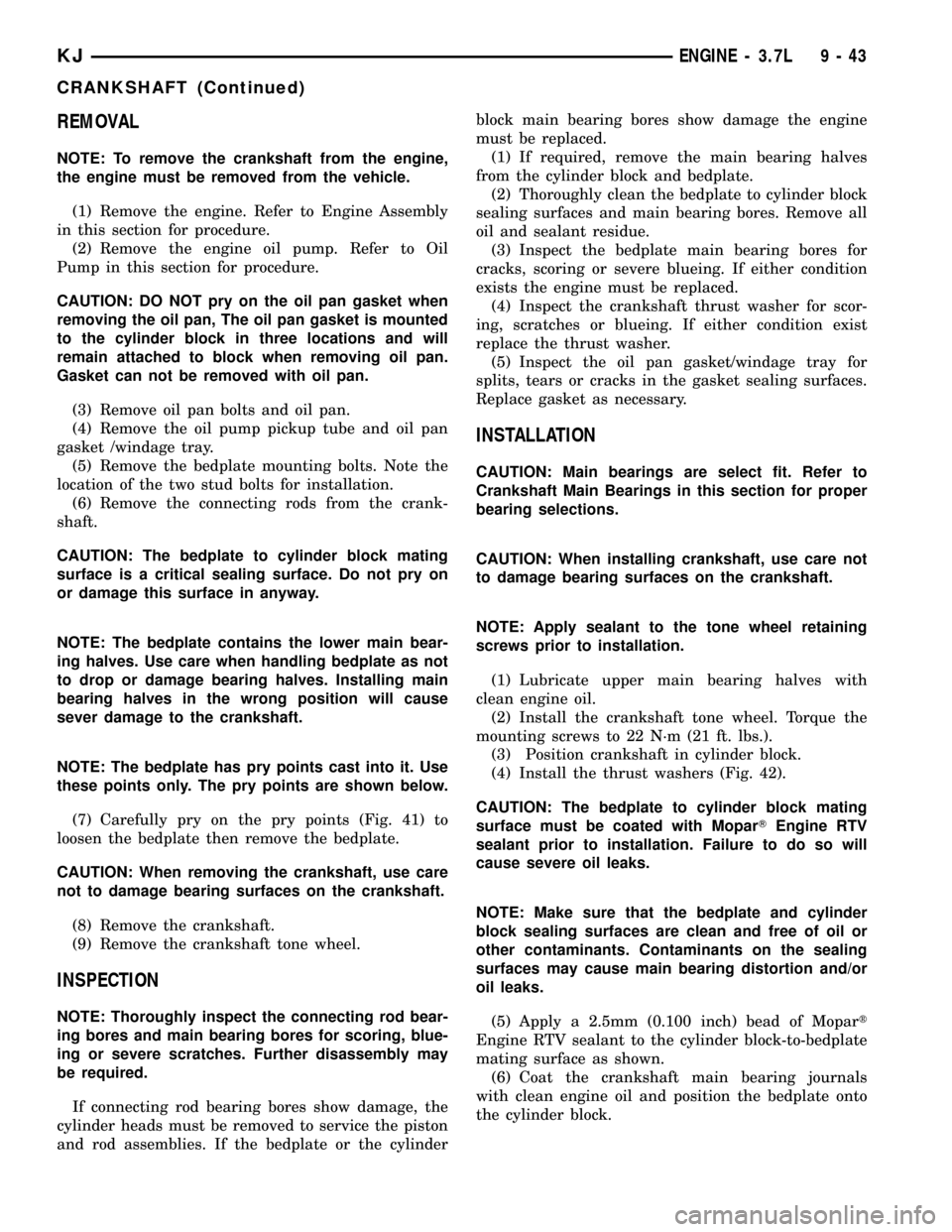

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 32).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Fig. 31 CYLINDER BLOCK BEDPLATE

1 - Cylinder Block Bedplate

2 - Crankshaft Position Sensor

3 - Crankshaft Main Bearing Caps

Fig. 32 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

KJENGINE - 3.7L 9 - 39

Page 1258 of 1803

REMOVAL

NOTE: To remove the crankshaft from the engine,

the engine must be removed from the vehicle.

(1) Remove the engine. Refer to Engine Assembly

in this section for procedure.

(2) Remove the engine oil pump. Refer to Oil

Pump in this section for procedure.

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when removing oil pan.

Gasket can not be removed with oil pan.

(3) Remove oil pan bolts and oil pan.

(4) Remove the oil pump pickup tube and oil pan

gasket /windage tray.

(5) Remove the bedplate mounting bolts. Note the

location of the two stud bolts for installation.

(6) Remove the connecting rods from the crank-

shaft.

CAUTION: The bedplate to cylinder block mating

surface is a critical sealing surface. Do not pry on

or damage this surface in anyway.

NOTE: The bedplate contains the lower main bear-

ing halves. Use care when handling bedplate as not

to drop or damage bearing halves. Installing main

bearing halves in the wrong position will cause

sever damage to the crankshaft.

NOTE: The bedplate has pry points cast into it. Use

these points only. The pry points are shown below.

(7) Carefully pry on the pry points (Fig. 41) to

loosen the bedplate then remove the bedplate.

CAUTION: When removing the crankshaft, use care

not to damage bearing surfaces on the crankshaft.

(8) Remove the crankshaft.

(9) Remove the crankshaft tone wheel.

INSPECTION

NOTE: Thoroughly inspect the connecting rod bear-

ing bores and main bearing bores for scoring, blue-

ing or severe scratches. Further disassembly may

be required.

If connecting rod bearing bores show damage, the

cylinder heads must be removed to service the piston

and rod assemblies. If the bedplate or the cylinderblock main bearing bores show damage the engine

must be replaced.

(1) If required, remove the main bearing halves

from the cylinder block and bedplate.

(2) Thoroughly clean the bedplate to cylinder block

sealing surfaces and main bearing bores. Remove all

oil and sealant residue.

(3) Inspect the bedplate main bearing bores for

cracks, scoring or severe blueing. If either condition

exists the engine must be replaced.

(4) Inspect the crankshaft thrust washer for scor-

ing, scratches or blueing. If either condition exist

replace the thrust washer.

(5) Inspect the oil pan gasket/windage tray for

splits, tears or cracks in the gasket sealing surfaces.

Replace gasket as necessary.

INSTALLATION

CAUTION: Main bearings are select fit. Refer to

Crankshaft Main Bearings in this section for proper

bearing selections.

CAUTION: When installing crankshaft, use care not

to damage bearing surfaces on the crankshaft.

NOTE: Apply sealant to the tone wheel retaining

screws prior to installation.

(1) Lubricate upper main bearing halves with

clean engine oil.

(2) Install the crankshaft tone wheel. Torque the

mounting screws to 22 N´m (21 ft. lbs.).

(3) Position crankshaft in cylinder block.

(4) Install the thrust washers (Fig. 42).

CAUTION: The bedplate to cylinder block mating

surface must be coated with MoparTEngine RTV

sealant prior to installation. Failure to do so will

cause severe oil leaks.

NOTE: Make sure that the bedplate and cylinder

block sealing surfaces are clean and free of oil or

other contaminants. Contaminants on the sealing

surfaces may cause main bearing distortion and/or

oil leaks.

(5) Apply a 2.5mm (0.100 inch) bead of Mopart

Engine RTV sealant to the cylinder block-to-bedplate

mating surface as shown.

(6) Coat the crankshaft main bearing journals

with clean engine oil and position the bedplate onto

the cylinder block.

KJENGINE - 3.7L 9 - 43

CRANKSHAFT (Continued)

Page 1263 of 1803

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

NOTE: This procedure can be performed in vehicle.

(1) If being preformed in vehicle, remove the

transmission.

(2) Remove the flexplate (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

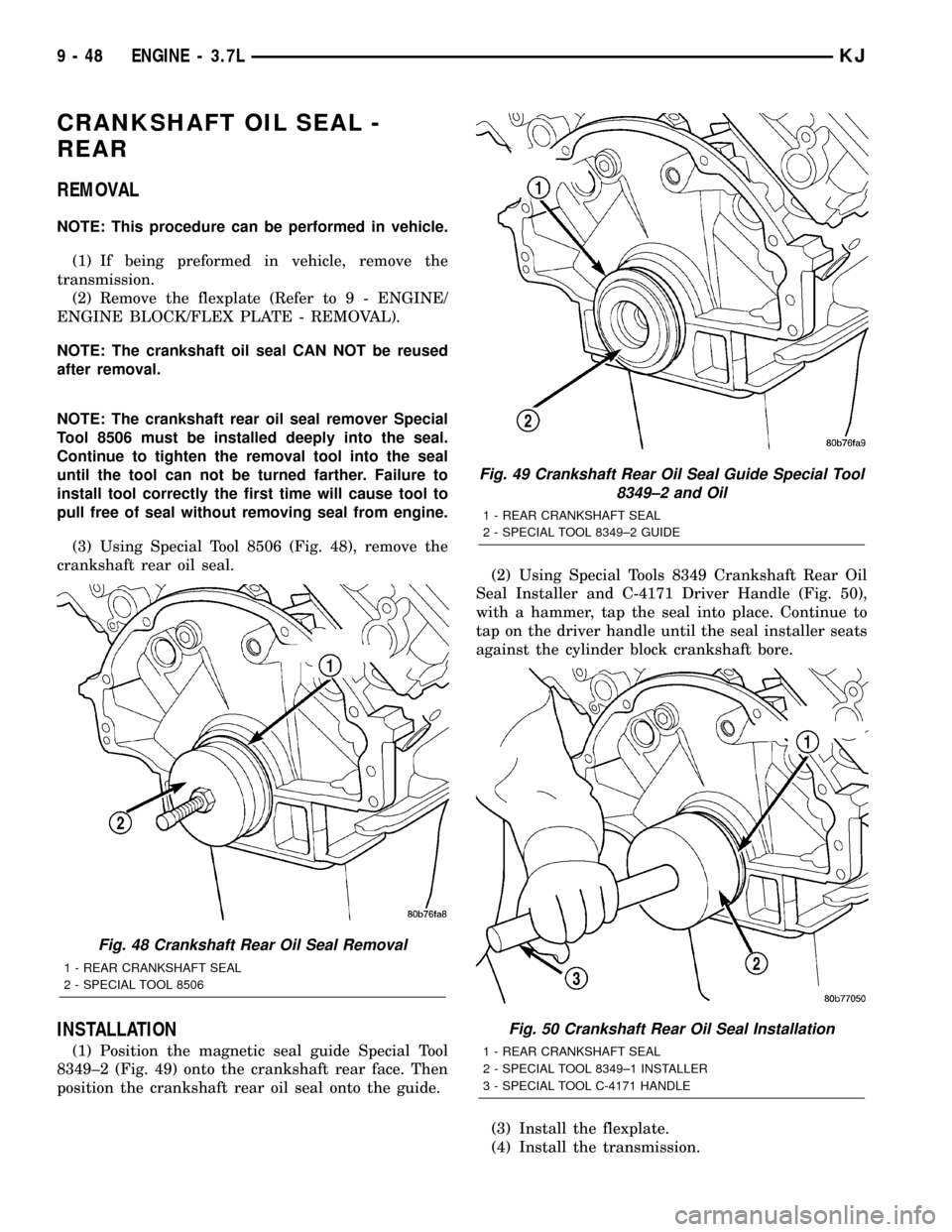

(3) Using Special Tool 8506 (Fig. 48), remove the

crankshaft rear oil seal.

INSTALLATION

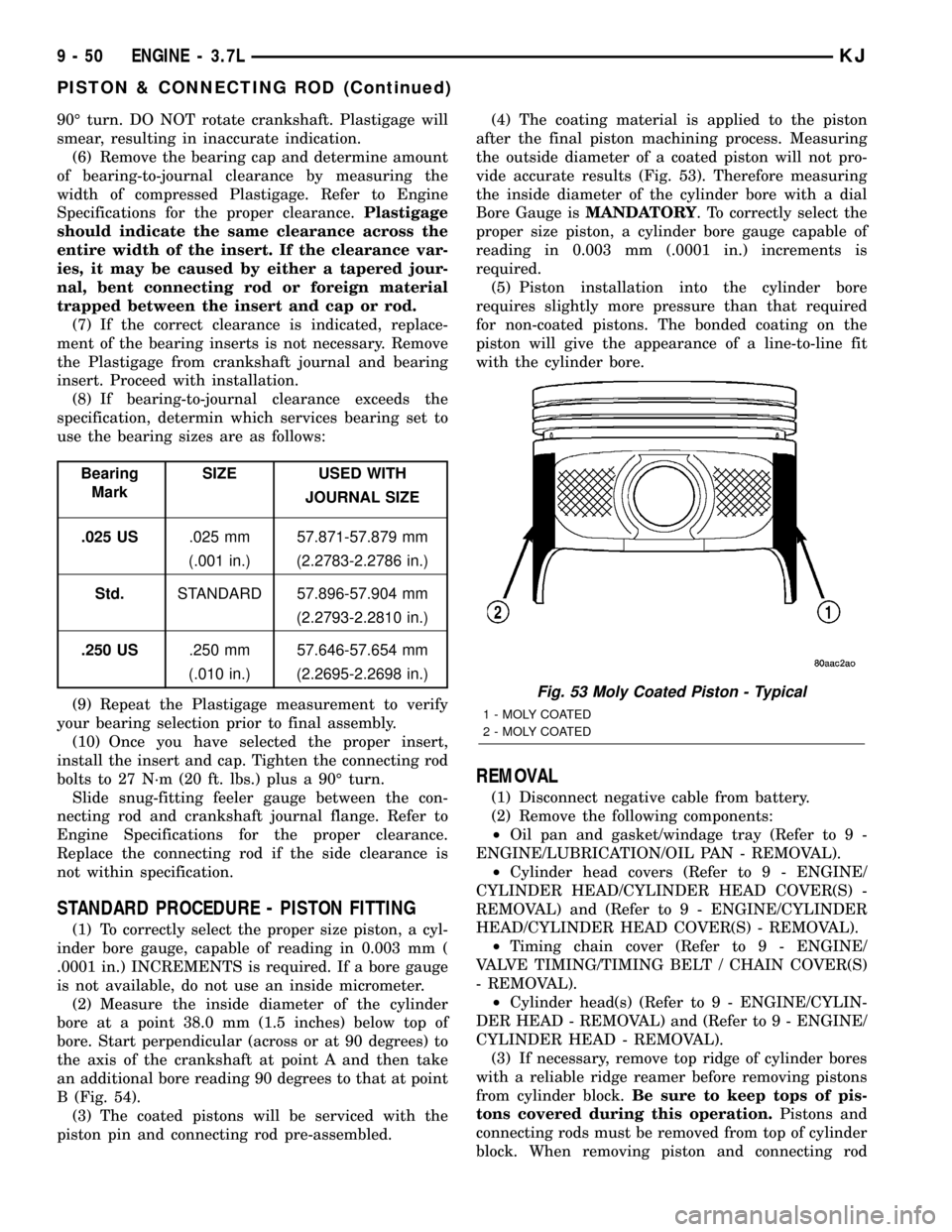

(1) Position the magnetic seal guide Special Tool

8349±2 (Fig. 49) onto the crankshaft rear face. Then

position the crankshaft rear oil seal onto the guide.(2) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle (Fig. 50),

with a hammer, tap the seal into place. Continue to

tap on the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(3) Install the flexplate.

(4) Install the transmission.

Fig. 48 Crankshaft Rear Oil Seal Removal

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8506

Fig. 49 Crankshaft Rear Oil Seal Guide Special Tool

8349±2 and Oil

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8349±2 GUIDE

Fig. 50 Crankshaft Rear Oil Seal Installation

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8349±1 INSTALLER

3 - SPECIAL TOOL C-4171 HANDLE

9 - 48 ENGINE - 3.7LKJ

Page 1265 of 1803

90É turn. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

(6) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage. Refer to Engine

Specifications for the proper clearance.Plastigage

should indicate the same clearance across the

entire width of the insert. If the clearance var-

ies, it may be caused by either a tapered jour-

nal, bent connecting rod or foreign material

trapped between the insert and cap or rod.

(7) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(8) If bearing-to-journal clearance exceeds the

specification, determin which services bearing set to

use the bearing sizes are as follows:

Bearing

MarkSIZE USED WITH

JOURNAL SIZE

.025 US.025 mm 57.871-57.879 mm

(.001 in.) (2.2783-2.2786 in.)

Std.STANDARD 57.896-57.904 mm

(2.2793-2.2810 in.)

.250 US.250 mm 57.646-57.654 mm

(.010 in.) (2.2695-2.2698 in.)

(9) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(10) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 27 N´m (20 ft. lbs.) plus a 90É turn.

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange. Refer to

Engine Specifications for the proper clearance.

Replace the connecting rod if the side clearance is

not within specification.

STANDARD PROCEDURE - PISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (

.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

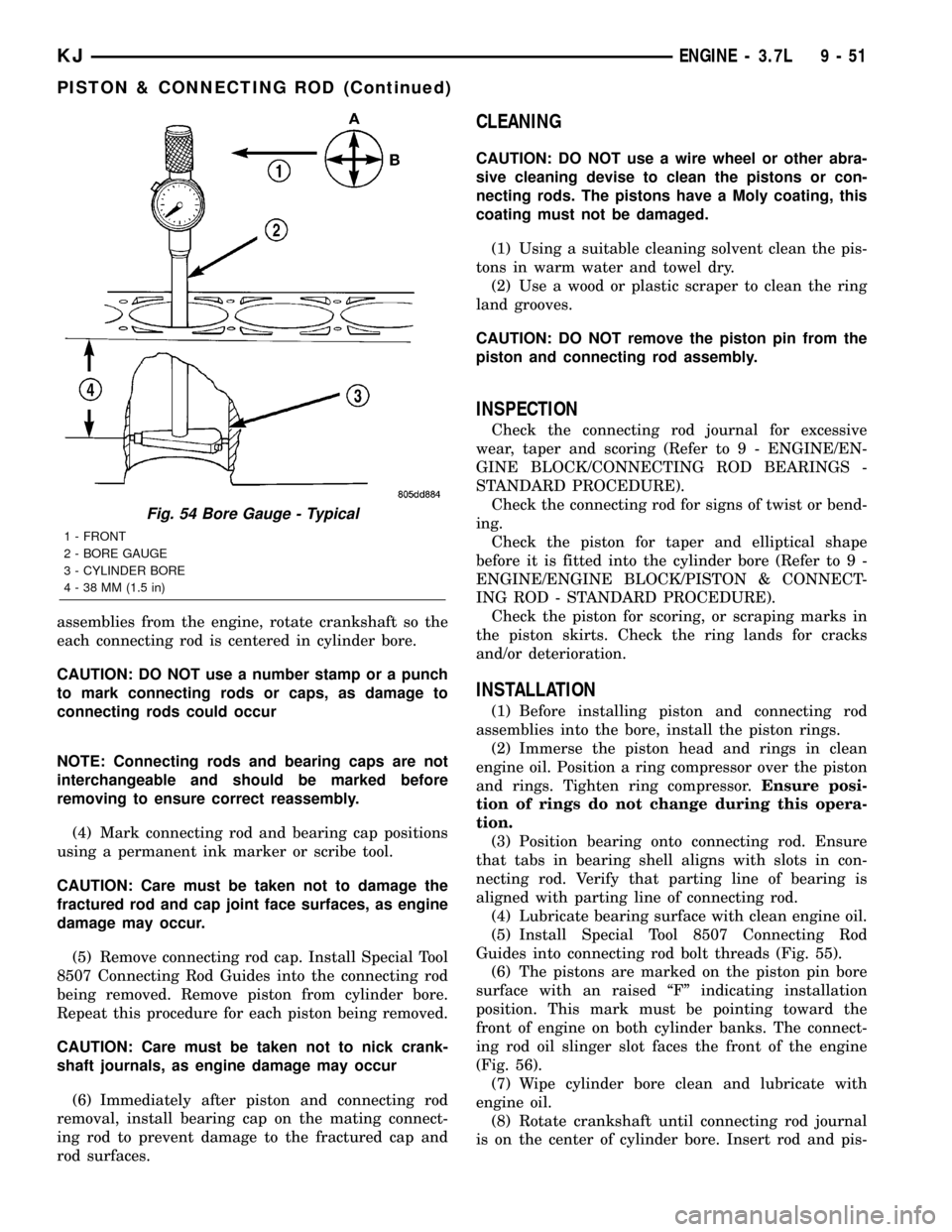

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 54).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled.(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not pro-

vide accurate results (Fig. 53). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the following components:

²Oil pan and gasket/windage tray (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - REMOVAL).

²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

²Timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- REMOVAL).

²Cylinder head(s) (Refer to 9 - ENGINE/CYLIN-

DER HEAD - REMOVAL) and (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(3) If necessary, remove top ridge of cylinder bores

with a reliable ridge reamer before removing pistons

from cylinder block.Be sure to keep tops of pis-

tons covered during this operation.Pistons and

connecting rods must be removed from top of cylinder

block. When removing piston and connecting rod

Fig. 53 Moly Coated Piston - Typical

1 - MOLY COATED

2 - MOLY COATED

9 - 50 ENGINE - 3.7LKJ

PISTON & CONNECTING ROD (Continued)

Page 1266 of 1803

assemblies from the engine, rotate crankshaft so the

each connecting rod is centered in cylinder bore.

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods or caps, as damage to

connecting rods could occur

NOTE: Connecting rods and bearing caps are not

interchangeable and should be marked before

removing to ensure correct reassembly.

(4) Mark connecting rod and bearing cap positions

using a permanent ink marker or scribe tool.

CAUTION: Care must be taken not to damage the

fractured rod and cap joint face surfaces, as engine

damage may occur.

(5) Remove connecting rod cap. Install Special Tool

8507 Connecting Rod Guides into the connecting rod

being removed. Remove piston from cylinder bore.

Repeat this procedure for each piston being removed.

CAUTION: Care must be taken not to nick crank-

shaft journals, as engine damage may occur

(6) Immediately after piston and connecting rod

removal, install bearing cap on the mating connect-

ing rod to prevent damage to the fractured cap and

rod surfaces.

CLEANING

CAUTION: DO NOT use a wire wheel or other abra-

sive cleaning devise to clean the pistons or con-

necting rods. The pistons have a Moly coating, this

coating must not be damaged.

(1) Using a suitable cleaning solvent clean the pis-

tons in warm water and towel dry.

(2) Use a wood or plastic scraper to clean the ring

land grooves.

CAUTION: DO NOT remove the piston pin from the

piston and connecting rod assembly.

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

(1) Before installing piston and connecting rod

assemblies into the bore, install the piston rings.

(2) Immerse the piston head and rings in clean

engine oil. Position a ring compressor over the piston

and rings. Tighten ring compressor.Ensure posi-

tion of rings do not change during this opera-

tion.

(3) Position bearing onto connecting rod. Ensure

that tabs in bearing shell aligns with slots in con-

necting rod. Verify that parting line of bearing is

aligned with parting line of connecting rod.

(4) Lubricate bearing surface with clean engine oil.

(5) Install Special Tool 8507 Connecting Rod

Guides into connecting rod bolt threads (Fig. 55).

(6) The pistons are marked on the piston pin bore

surface with an raised ªFº indicating installation

position. This mark must be pointing toward the

front of engine on both cylinder banks. The connect-

ing rod oil slinger slot faces the front of the engine

(Fig. 56).

(7) Wipe cylinder bore clean and lubricate with

engine oil.

(8) Rotate crankshaft until connecting rod journal

is on the center of cylinder bore. Insert rod and pis-

Fig. 54 Bore Gauge - Typical

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 38 MM (1.5 in)

KJENGINE - 3.7L 9 - 51

PISTON & CONNECTING ROD (Continued)

Page 1285 of 1803

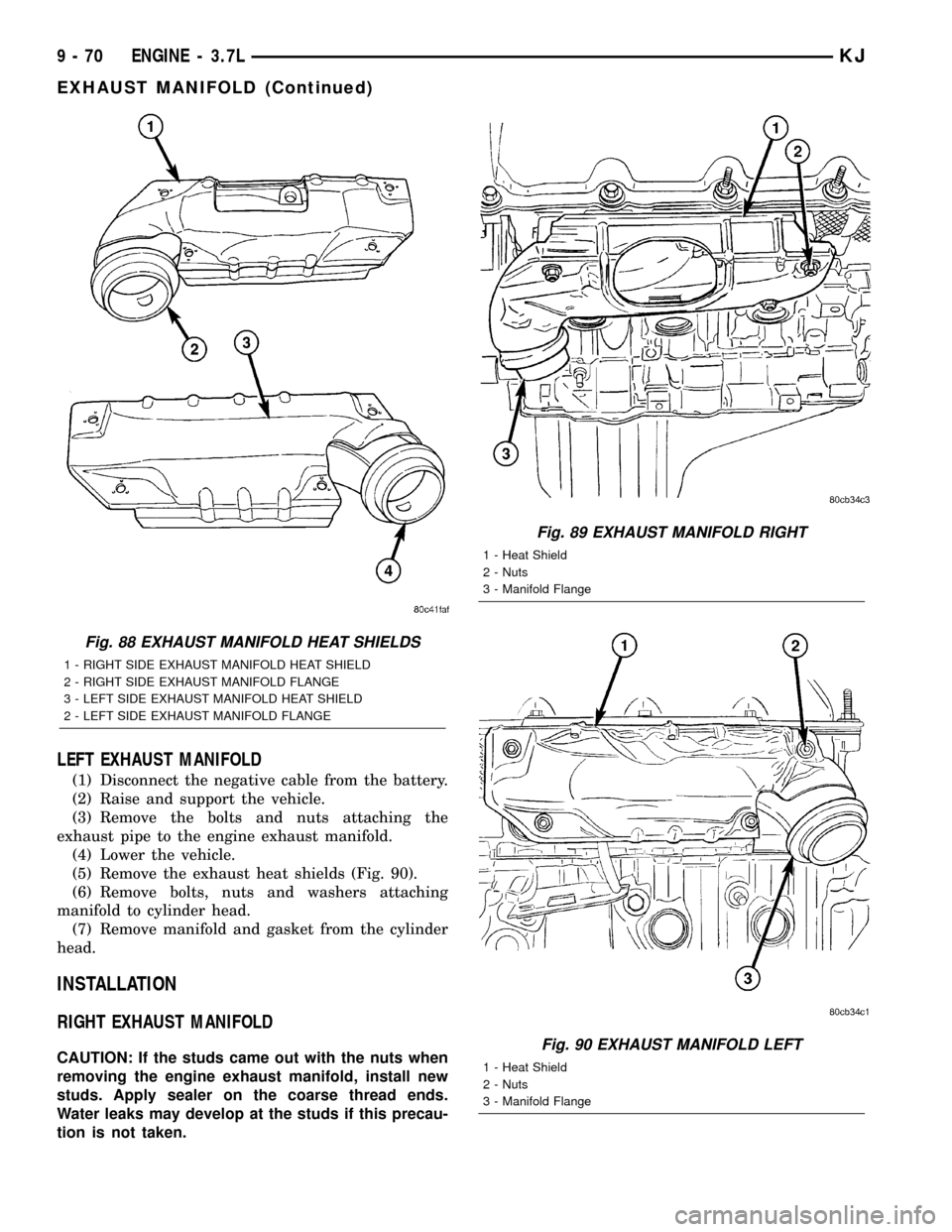

LEFT EXHAUST MANIFOLD

(1) Disconnect the negative cable from the battery.

(2) Raise and support the vehicle.

(3) Remove the bolts and nuts attaching the

exhaust pipe to the engine exhaust manifold.

(4) Lower the vehicle.

(5) Remove the exhaust heat shields (Fig. 90).

(6) Remove bolts, nuts and washers attaching

manifold to cylinder head.

(7) Remove manifold and gasket from the cylinder

head.

INSTALLATION

RIGHT EXHAUST MANIFOLD

CAUTION: If the studs came out with the nuts when

removing the engine exhaust manifold, install new

studs. Apply sealer on the coarse thread ends.

Water leaks may develop at the studs if this precau-

tion is not taken.

Fig. 88 EXHAUST MANIFOLD HEAT SHIELDS

1 - RIGHT SIDE EXHAUST MANIFOLD HEAT SHIELD

2 - RIGHT SIDE EXHAUST MANIFOLD FLANGE

3 - LEFT SIDE EXHAUST MANIFOLD HEAT SHIELD

2 - LEFT SIDE EXHAUST MANIFOLD FLANGE

Fig. 89 EXHAUST MANIFOLD RIGHT

1 - Heat Shield

2 - Nuts

3 - Manifold Flange

Fig. 90 EXHAUST MANIFOLD LEFT

1 - Heat Shield

2 - Nuts

3 - Manifold Flange

9 - 70 ENGINE - 3.7LKJ

EXHAUST MANIFOLD (Continued)

Page 1286 of 1803

(1) Position the engine exhaust manifold and gas-

ket on the two studs located on the cylinder head.

Install conical washers and nuts on these studs.

(2) Install remaining conical washers. Starting at

the center arm and working outward, tighten the

bolts and nuts to 25 N´m (18 ft. lbs.) torque.

(3) Install the exhaust heat shields.

(4) Raise and support the vehicle.

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(5) Assemble exhaust pipe to manifold and secure

with bolts, nuts and retainers. Tighten the bolts and

nuts to 34 N´m (25 ft. lbs.) torque.

LEFT EXHAUST MANIFOLD

CAUTION: If the studs came out with the nuts when

removing the engine exhaust manifold, install new

studs. Apply sealer on the coarse thread ends.

Water leaks may develop at the studs if this precau-

tion is not taken.

(1) Position the engine exhaust manifold and gas-

ket on the two studs located on the cylinder head.

Install conical washers and nuts on these studs.

(2) Install remaining conical washers. Starting at

the center arm and working outward, tighten the

bolts and nuts to 25 N´m (18 ft. lbs.) torque.

(3) Install the exhaust heat shields.

(4) Raise and support the vehicle.

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(5) Assemble exhaust pipe to manifold and secure

with bolts, nuts and retainers. Tighten the bolts and

nuts to 34 N´m (25 ft. lbs.) torque.

VALVE TIMING

DESCRIPTION

The timing drive system has been designed to pro-

vide quiet performance and reliability to support a

non-free wheelingengine. Specifically the intake

valves are non-free wheeling and can be easily dam-

aged with forceful engine rotation if camshaft-to-

crankshaft timing is incorrect. The timing drive

system consists of a primary chain, two secondary

timing chain drives and a counterbalance shaft drive.

OPERATION

The primary timing chain is a single inverted tooth

chain type. The primary chain drives the large 40

tooth idler sprocket directly from a 20 tooth crank-shaft sprocket. Primary chain motion is controlled by

a pivoting leaf spring tensioner arm and a fixed

guide. The arm and the guide both use nylon plastic

wear faces for low friction and long wear. The pri-

mary chain receives oil splash lubrication from the

secondary chain drive and designed oil pump leak-

age. The idler sprocket assembly connects the pri-

mary chain drive, secondary chain drives, and the

counterbalance shaft. The idler sprocket assembly

consists of two integral 26 tooth sprockets a 40 tooth

sprocket and a helical gear that is press-fit to the

assembly. The spline joint for the 40 tooth sprocket is

a non ± serviceable press fit anti rattle type. A spiral

ring is installed on the outboard side of the fifty

tooth sprocket to prevent spline disengagement. The

idler sprocket assembly spins on a stationary idler

shaft. The idler shaft is a light press-fit into the cyl-

inder block. A large washer on the idler shaft bolt

and the rear flange of the idler shaft are used to con-

trol sprocket thrust movement. Pressurized oil is

routed through the center of the idler shaft to pro-

vide lubrication for the two bushings used in the

idler sprocket assembly.

There are two secondary drive chains, both are

roller type, one to drive the camshaft in each SOHC

cylinder head. There are no shaft speed changes in

the secondary chain drive system. Each secondary

chain drives a 26 tooth cam sprocket directly from

the 26 tooth sprocket on the idler sprocket assembly.

A fixed chain guide and a hydraulic oil damped ten-

sioner are used to maintain tension in each second-

ary chain system. The hydraulic tensioners for the

secondary chain systems are fed pressurized oil from

oil reservoir pockets in the block. Each tensioner

incorprates a controled leak path through a device

known as a vent disc located in the nose of the piston

to manage chain loads. Each tensioner also has a

mechanical ratchet system that limits chain slack if

the tensioner piston bleeds down after engine shut

down. The tensioner arms and guides also utilize

nylon wear faces for low friction and long wear. The

secondary timing chains receive lubrication from a

small orifice in the tensioners. This orifice is pro-

tected from clogging by a fine mesh screen which is

located on the back of the hydraulic tensioners.

STANDARD PROCEDURE

MEASURING TIMING CHAIN WEAR

NOTE: This procedure must be performed with the

timing chain cover removed.

(1) Remove the timing chain cover. Refer to Timing

Chain Cover in this section for procedure.

KJENGINE - 3.7L 9 - 71

EXHAUST MANIFOLD (Continued)

Page 1292 of 1803

IDLER SHAFT

REMOVAL

(1) Remove the primary and secondary timing

chains and sprockets. Refer to procedure in this sec-

tion.

NOTE: To remove the idler shaft, it is necessary to

tap threads into the shaft, to install the removal

tool.

(2) Using a 12 mm X 1.75 tap, cut threads in the

idler shaft center bore.

(3) Cover the radiator core with a suitable cover.

CAUTION: Use care when removing the idler shaft,

Do not strike the radiator cooling fins with the slide

hammer.

(4) Using Special Tool 8517 Slide Hammer, remove

the idler shaft.

INSTALLATION

(1) Thoroughly clean the idler shaft bore.

(2) Position the idler shaft in the bore.

NOTE: The two lubrication holes in the idler shaft

do not require any special alignment.

NOTE: Before using the retaining bolt to install the

idler shaft, coat the threads and the pilot on the

idler shaft, with clean engine oil.

(3) Using the primary idler sprocket retaining bolt

and washer, carefully draw the idler shaft into the

bore until fully seated.

(4) Coat the idler shaft with clean engine oil.

(5) Install the timing chains and sprockets. Refer

to procedure in this section.

TIMING BELT/CHAIN AND

SPROCKET(S

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system. Refer to COOLING SYS-

TEM for procedures.

(3) Remove right and left cylinder head covers.

Refer to CYLINDER HEAD COVER.

(4) Remove radiator fan shroud. Refer to COOL-

ING SYSTEM for procedure.

(5) Rotate engine until timing mark on crankshaft

damper aligns with TDC mark on timing chain cover

(Fig. 103) (#1 cylinder exhaust stroke) and the cam-

shaft sprocket ªV6º marks are at the 12 o'clock posi-

tion (Fig. 102).

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed

retorque nut to 5 N´m (44 in. lbs.).

(6) Remove power steering pump. Refer to STEER-

ING for procedure.

(7) Remove access plug from left and right cylinder

heads for access to chain guide fasteners (Fig. 104).

(8) Remove the oil fill housing to gain access to the

right side tensioner arm fastener.

(9) Remove crankshaft damper and timing chain

cover. Refer to procedures.

(10) Collapse and pin primary chain tensioner.

CAUTION: Plate behind left secondary chain ten-

sioner could fall into oil pan. Therefore, cover pan

opening.

(11) Remove secondary chain tensioners.

(12) Remove camshaft position and crankshaft

position sensors (Fig. 105) and (Fig. 106).

KJENGINE - 3.7L 9 - 77