Lines JEEP LIBERTY 2002 KJ / 1.G Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1404 of 1803

of the firing of the fuel injectors. It isnot usedas a

fuel pressure regulator. The fuel pressure regulator is

not mountedto the fuel rail on any engine. It is

located on the fuel tank mounted fuel pump module.

Refer to Fuel Pressure Regulator for additional infor-

mation.

The fuel rail is not repairable.

A quick-connect fitting with a safety latch is used

to attach the fuel line to the fuel rail.

3.7L

High pressure fuel from the fuel pump is routed to

the fuel rail. The fuel rail then supplies the neces-

sary fuel to each individual fuel injector.

A quick-connect fitting with a safety latch is used

to attach the fuel line to the fuel rail.

The fuel rail is not repairable.

REMOVAL

2.4L

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

The fuel rail can be removed without removing the

intake manifold if the following procedures are fol-

lowed.(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body.

(5) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(6) Remove necessary vacuum lines at throttle

body.

(7) Drain engine coolant and remove thermostat

and thermostat housing.

(8) Remove PCV hose and valve at valve cover.

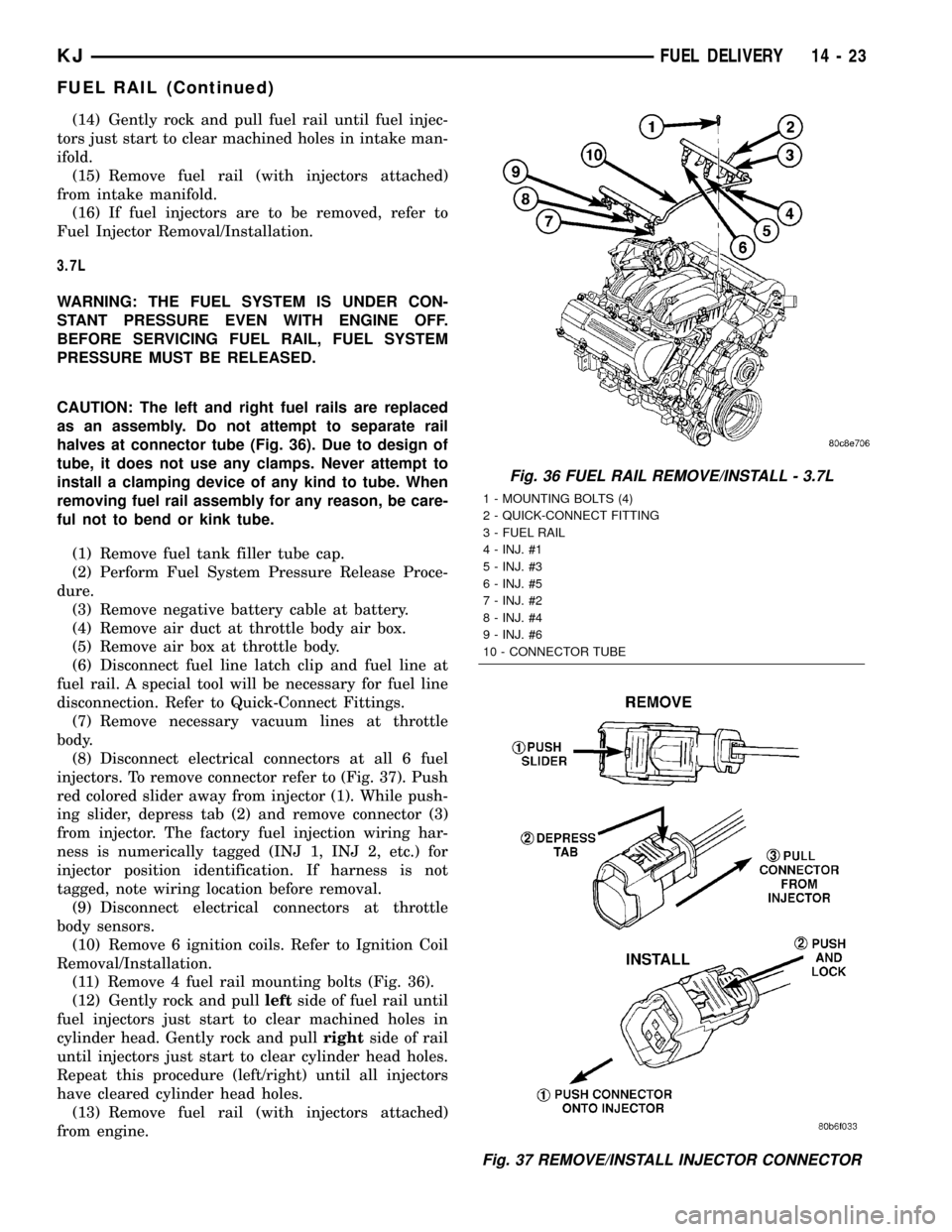

(9) Remove 3 upper intake manifold mounting

bolts (Fig. 35), but only loosen 2 lower bolts about 2

turns.

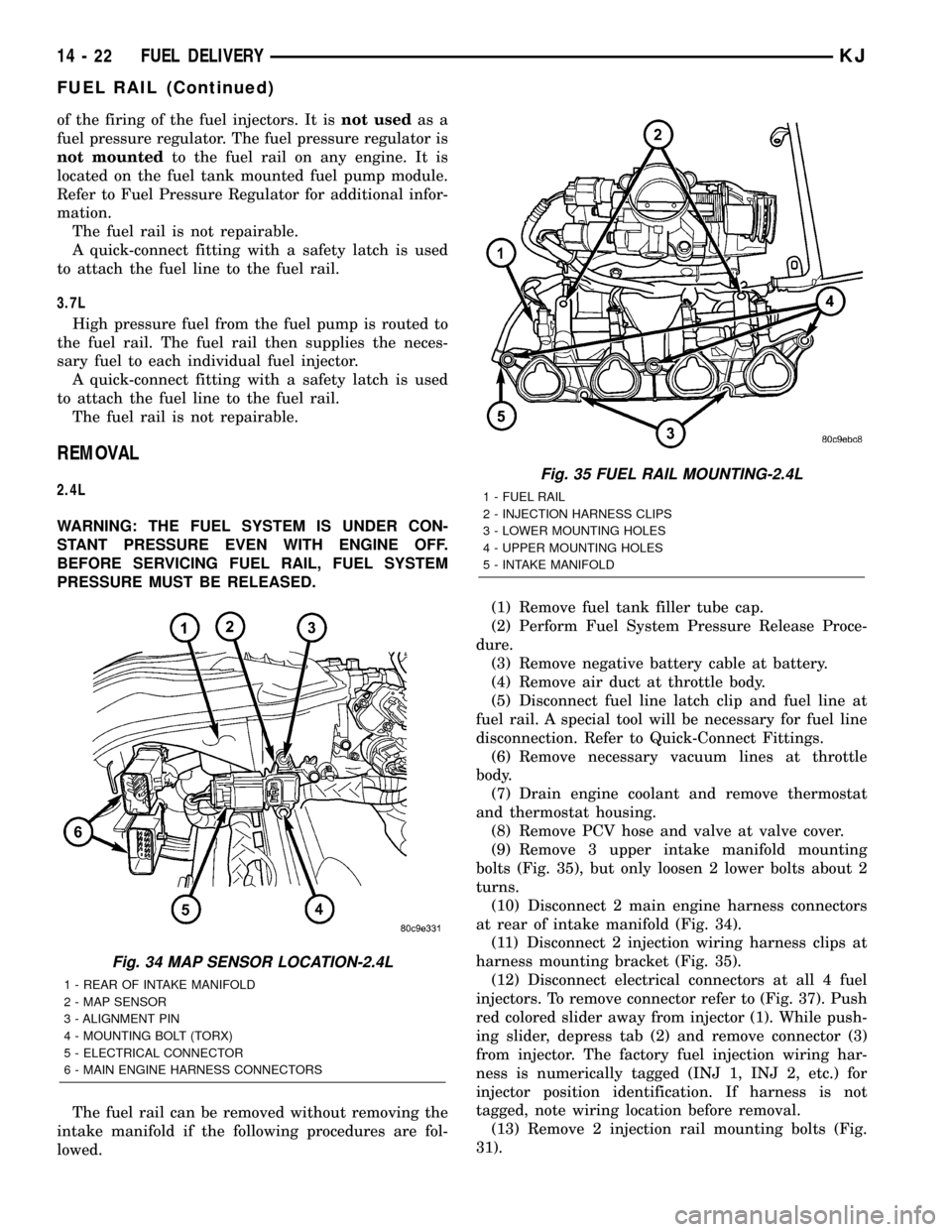

(10) Disconnect 2 main engine harness connectors

at rear of intake manifold (Fig. 34).

(11) Disconnect 2 injection wiring harness clips at

harness mounting bracket (Fig. 35).

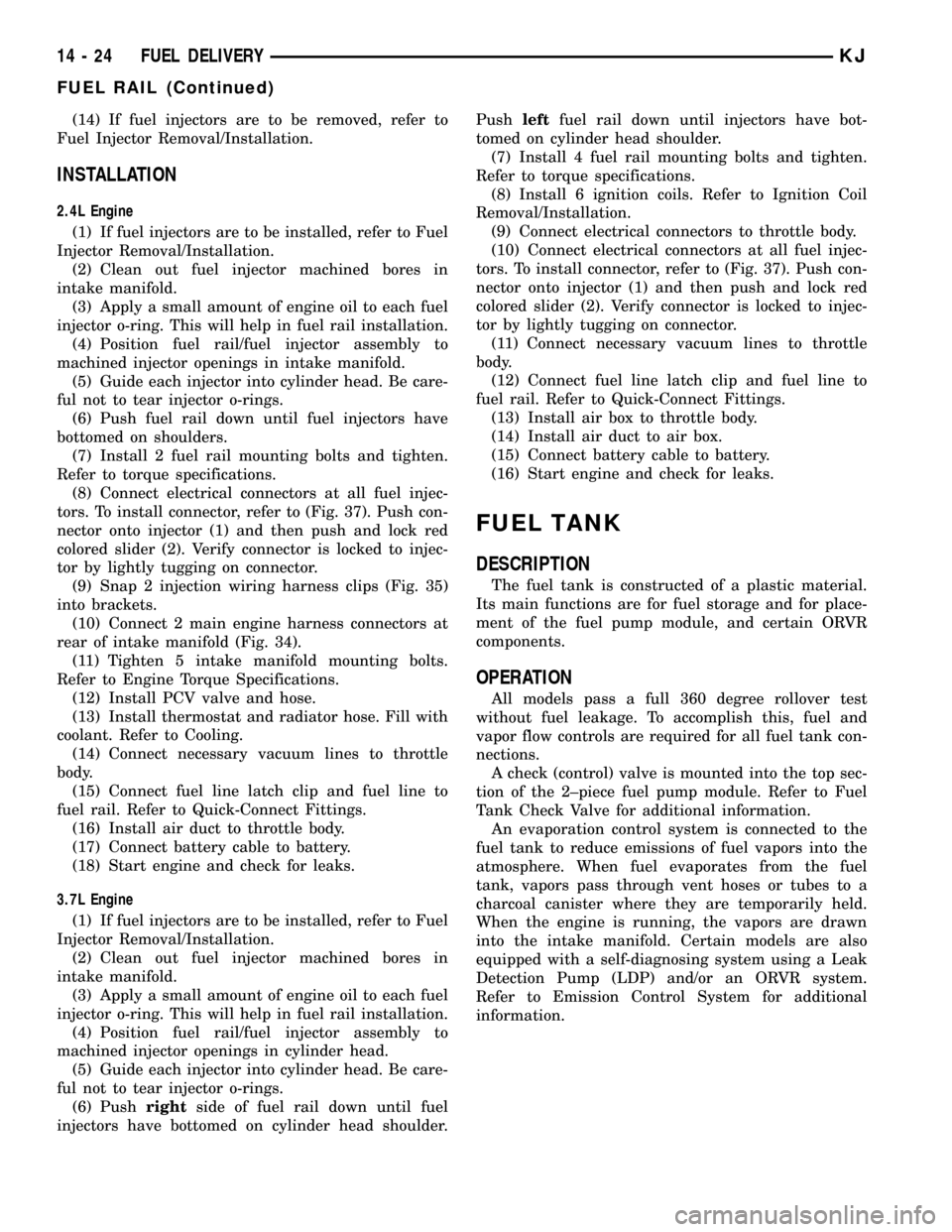

(12) Disconnect electrical connectors at all 4 fuel

injectors. To remove connector refer to (Fig. 37). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(13) Remove 2 injection rail mounting bolts (Fig.

31).

Fig. 34 MAP SENSOR LOCATION-2.4L

1 - REAR OF INTAKE MANIFOLD

2 - MAP SENSOR

3 - ALIGNMENT PIN

4 - MOUNTING BOLT (TORX)

5 - ELECTRICAL CONNECTOR

6 - MAIN ENGINE HARNESS CONNECTORS

Fig. 35 FUEL RAIL MOUNTING-2.4L

1 - FUEL RAIL

2 - INJECTION HARNESS CLIPS

3 - LOWER MOUNTING HOLES

4 - UPPER MOUNTING HOLES

5 - INTAKE MANIFOLD

14 - 22 FUEL DELIVERYKJ

FUEL RAIL (Continued)

Page 1405 of 1803

(14) Gently rock and pull fuel rail until fuel injec-

tors just start to clear machined holes in intake man-

ifold.

(15) Remove fuel rail (with injectors attached)

from intake manifold.

(16) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

3.7L

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tube (Fig. 36). Due to design of

tube, it does not use any clamps. Never attempt to

install a clamping device of any kind to tube. When

removing fuel rail assembly for any reason, be care-

ful not to bend or kink tube.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body air box.

(5) Remove air box at throttle body.

(6) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(7) Remove necessary vacuum lines at throttle

body.

(8) Disconnect electrical connectors at all 6 fuel

injectors. To remove connector refer to (Fig. 37). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(9) Disconnect electrical connectors at throttle

body sensors.

(10) Remove 6 ignition coils. Refer to Ignition Coil

Removal/Installation.

(11) Remove 4 fuel rail mounting bolts (Fig. 36).

(12) Gently rock and pullleftside of fuel rail until

fuel injectors just start to clear machined holes in

cylinder head. Gently rock and pullrightside of rail

until injectors just start to clear cylinder head holes.

Repeat this procedure (left/right) until all injectors

have cleared cylinder head holes.

(13) Remove fuel rail (with injectors attached)

from engine.

Fig. 36 FUEL RAIL REMOVE/INSTALL - 3.7L

1 - MOUNTING BOLTS (4)

2 - QUICK-CONNECT FITTING

3 - FUEL RAIL

4 - INJ. #1

5 - INJ. #3

6 - INJ. #5

7 - INJ. #2

8 - INJ. #4

9 - INJ. #6

10 - CONNECTOR TUBE

Fig. 37 REMOVE/INSTALL INJECTOR CONNECTOR

KJFUEL DELIVERY 14 - 23

FUEL RAIL (Continued)

Page 1406 of 1803

(14) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

INSTALLATION

2.4L Engine

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in intake manifold.

(5) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.

(6) Push fuel rail down until fuel injectors have

bottomed on shoulders.

(7) Install 2 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 37). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(9) Snap 2 injection wiring harness clips (Fig. 35)

into brackets.

(10) Connect 2 main engine harness connectors at

rear of intake manifold (Fig. 34).

(11) Tighten 5 intake manifold mounting bolts.

Refer to Engine Torque Specifications.

(12) Install PCV valve and hose.

(13) Install thermostat and radiator hose. Fill with

coolant. Refer to Cooling.

(14) Connect necessary vacuum lines to throttle

body.

(15) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(16) Install air duct to throttle body.

(17) Connect battery cable to battery.

(18) Start engine and check for leaks.

3.7L Engine

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(5) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.Pushleftfuel rail down until injectors have bot-

tomed on cylinder head shoulder.

(7) Install 4 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Install 6 ignition coils. Refer to Ignition Coil

Removal/Installation.

(9) Connect electrical connectors to throttle body.

(10) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 37). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(11) Connect necessary vacuum lines to throttle

body.

(12) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(13) Install air box to throttle body.

(14) Install air duct to air box.

(15) Connect battery cable to battery.

(16) Start engine and check for leaks.

FUEL TANK

DESCRIPTION

The fuel tank is constructed of a plastic material.

Its main functions are for fuel storage and for place-

ment of the fuel pump module, and certain ORVR

components.

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank con-

nections.

A check (control) valve is mounted into the top sec-

tion of the 2±piece fuel pump module. Refer to Fuel

Tank Check Valve for additional information.

An evaporation control system is connected to the

fuel tank to reduce emissions of fuel vapors into the

atmosphere. When fuel evaporates from the fuel

tank, vapors pass through vent hoses or tubes to a

charcoal canister where they are temporarily held.

When the engine is running, the vapors are drawn

into the intake manifold. Certain models are also

equipped with a self-diagnosing system using a Leak

Detection Pump (LDP) and/or an ORVR system.

Refer to Emission Control System for additional

information.

14 - 24 FUEL DELIVERYKJ

FUEL RAIL (Continued)

Page 1407 of 1803

REMOVAL

Fuel Tank Draining

WARNING: THE FUEL SYSTEM MAY BE UNDER

CONSTANT FUEL PRESSURE EVEN WITH THE

ENGINE OFF. THIS PRESSURE MUST BE

RELEASED BEFORE SERVICING FUEL TANK.

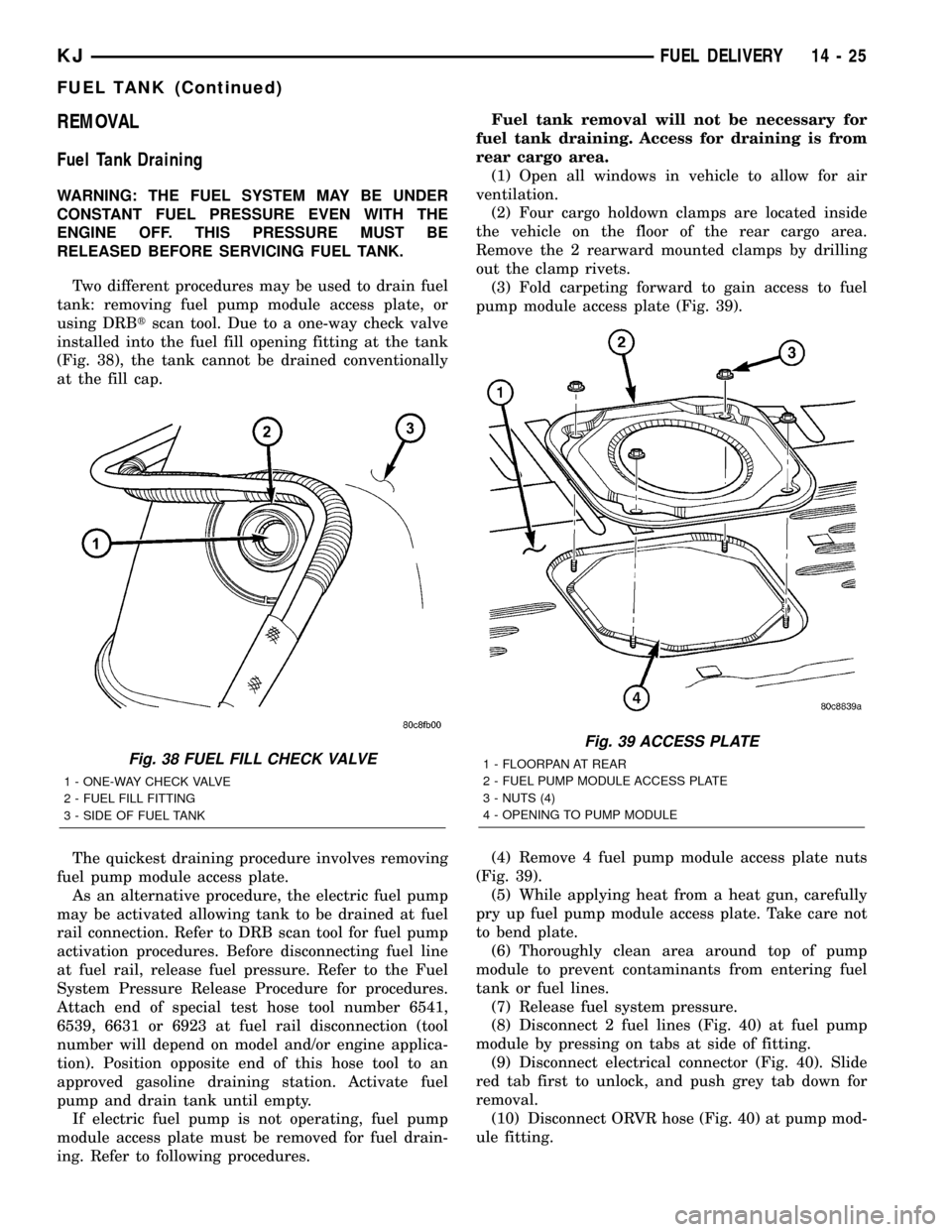

Two different procedures may be used to drain fuel

tank: removing fuel pump module access plate, or

using DRBtscan tool. Due to a one-way check valve

installed into the fuel fill opening fitting at the tank

(Fig. 38), the tank cannot be drained conventionally

at the fill cap.

The quickest draining procedure involves removing

fuel pump module access plate.

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRB scan tool for fuel pump

activation procedures. Before disconnecting fuel line

at fuel rail, release fuel pressure. Refer to the Fuel

System Pressure Release Procedure for procedures.

Attach end of special test hose tool number 6541,

6539, 6631 or 6923 at fuel rail disconnection (tool

number will depend on model and/or engine applica-

tion). Position opposite end of this hose tool to an

approved gasoline draining station. Activate fuel

pump and drain tank until empty.

If electric fuel pump is not operating, fuel pump

module access plate must be removed for fuel drain-

ing. Refer to following procedures.Fuel tank removal will not be necessary for

fuel tank draining. Access for draining is from

rear cargo area.

(1) Open all windows in vehicle to allow for air

ventilation.

(2) Four cargo holdown clamps are located inside

the vehicle on the floor of the rear cargo area.

Remove the 2 rearward mounted clamps by drilling

out the clamp rivets.

(3) Fold carpeting forward to gain access to fuel

pump module access plate (Fig. 39).

(4) Remove 4 fuel pump module access plate nuts

(Fig. 39).

(5) While applying heat from a heat gun, carefully

pry up fuel pump module access plate. Take care not

to bend plate.

(6) Thoroughly clean area around top of pump

module to prevent contaminants from entering fuel

tank or fuel lines.

(7) Release fuel system pressure.

(8) Disconnect 2 fuel lines (Fig. 40) at fuel pump

module by pressing on tabs at side of fitting.

(9) Disconnect electrical connector (Fig. 40). Slide

red tab first to unlock, and push grey tab down for

removal.

(10) Disconnect ORVR hose (Fig. 40) at pump mod-

ule fitting.

Fig. 38 FUEL FILL CHECK VALVE

1 - ONE-WAY CHECK VALVE

2 - FUEL FILL FITTING

3 - SIDE OF FUEL TANK

Fig. 39 ACCESS PLATE

1 - FLOORPAN AT REAR

2 - FUEL PUMP MODULE ACCESS PLATE

3 - NUTS (4)

4 - OPENING TO PUMP MODULE

KJFUEL DELIVERY 14 - 25

FUEL TANK (Continued)

Page 1409 of 1803

(14) Continue lowering tank while guiding remain-

ing hoses and lines.

(15) If fuel tank is to be replaced, remove LDP,

fuel filter and fuel pump module from tank. Refer to

Leak Detection Pump, Fuel Filter and Fuel Pump

Module Removal/Installation procedures.

INSTALLATION

(1) If fuel tank is to be replaced, install LDP, fuel

filter and fuel pump module to tank. Refer to Leak

Detection Pump, Fuel Filter and Fuel Pump Module

Removal/Installation procedures.

(2) Position fuel tank to hydraulic jack.

(3) Raise tank while carefully guiding vent tubes/

hoses through frame rail and crossmember. Before

tank reaches body, connect electrical connector to

Leak Detection Pump (LDP).

(4) Continue raising tank until positioned to body.

(5) Attach two fuel tank mounting straps and 4

mounting bolts. Tighten bolts to 61 N´m (45 ft. lbs.)

torque.

(6) Connect 2 hoses to body retention clip at left/

front of tank.

(7) Connect fuel filter fuel line to main fuel line

(snaps together). After connecting, snap this line into

body retention clip. Also connect LDP vacuum hose

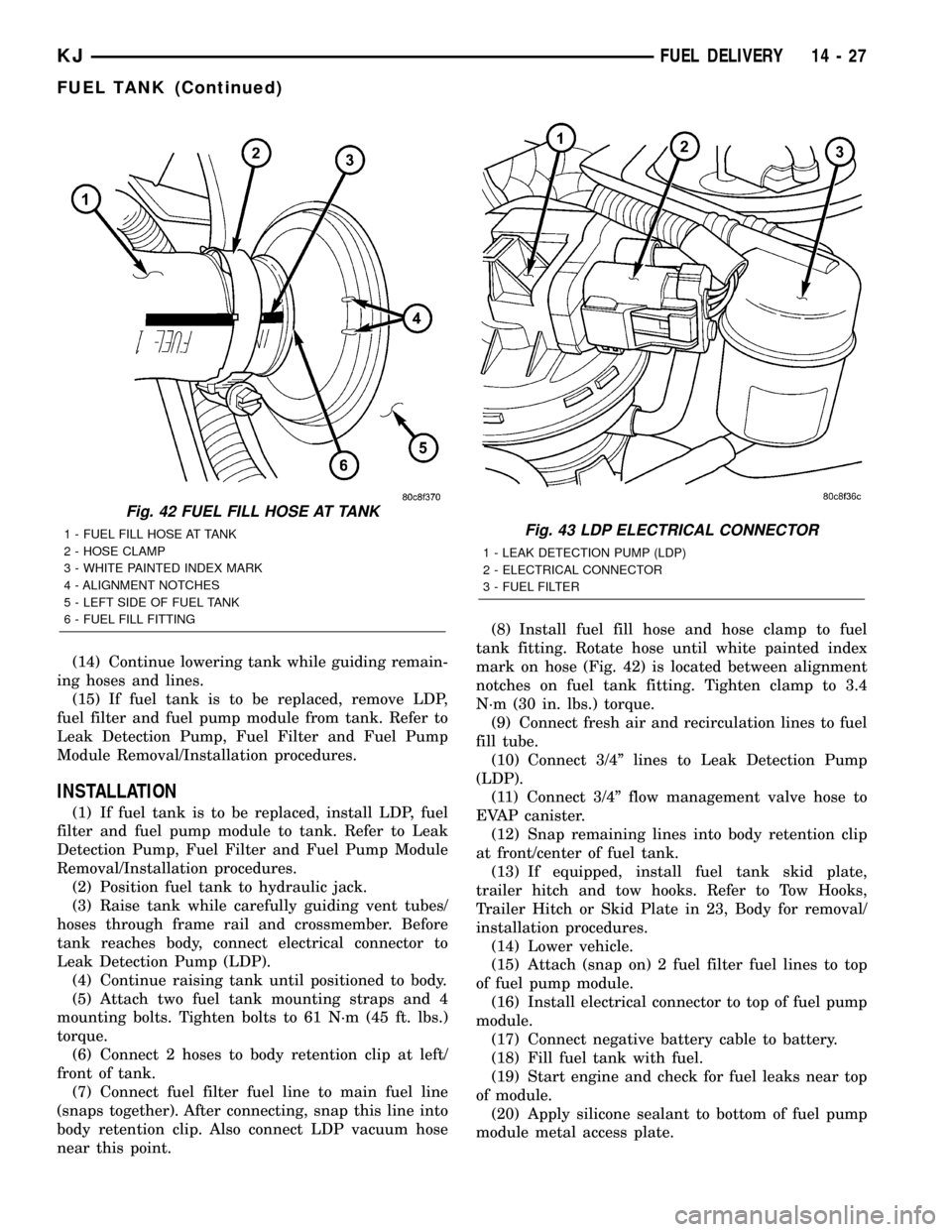

near this point.(8) Install fuel fill hose and hose clamp to fuel

tank fitting. Rotate hose until white painted index

mark on hose (Fig. 42) is located between alignment

notches on fuel tank fitting. Tighten clamp to 3.4

N´m (30 in. lbs.) torque.

(9) Connect fresh air and recirculation lines to fuel

fill tube.

(10) Connect 3/4º lines to Leak Detection Pump

(LDP).

(11) Connect 3/4º flow management valve hose to

EVAP canister.

(12) Snap remaining lines into body retention clip

at front/center of fuel tank.

(13) If equipped, install fuel tank skid plate,

trailer hitch and tow hooks. Refer to Tow Hooks,

Trailer Hitch or Skid Plate in 23, Body for removal/

installation procedures.

(14) Lower vehicle.

(15) Attach (snap on) 2 fuel filter fuel lines to top

of fuel pump module.

(16) Install electrical connector to top of fuel pump

module.

(17) Connect negative battery cable to battery.

(18) Fill fuel tank with fuel.

(19) Start engine and check for fuel leaks near top

of module.

(20) Apply silicone sealant to bottom of fuel pump

module metal access plate.

Fig. 42 FUEL FILL HOSE AT TANK

1 - FUEL FILL HOSE AT TANK

2 - HOSE CLAMP

3 - WHITE PAINTED INDEX MARK

4 - ALIGNMENT NOTCHES

5 - LEFT SIDE OF FUEL TANK

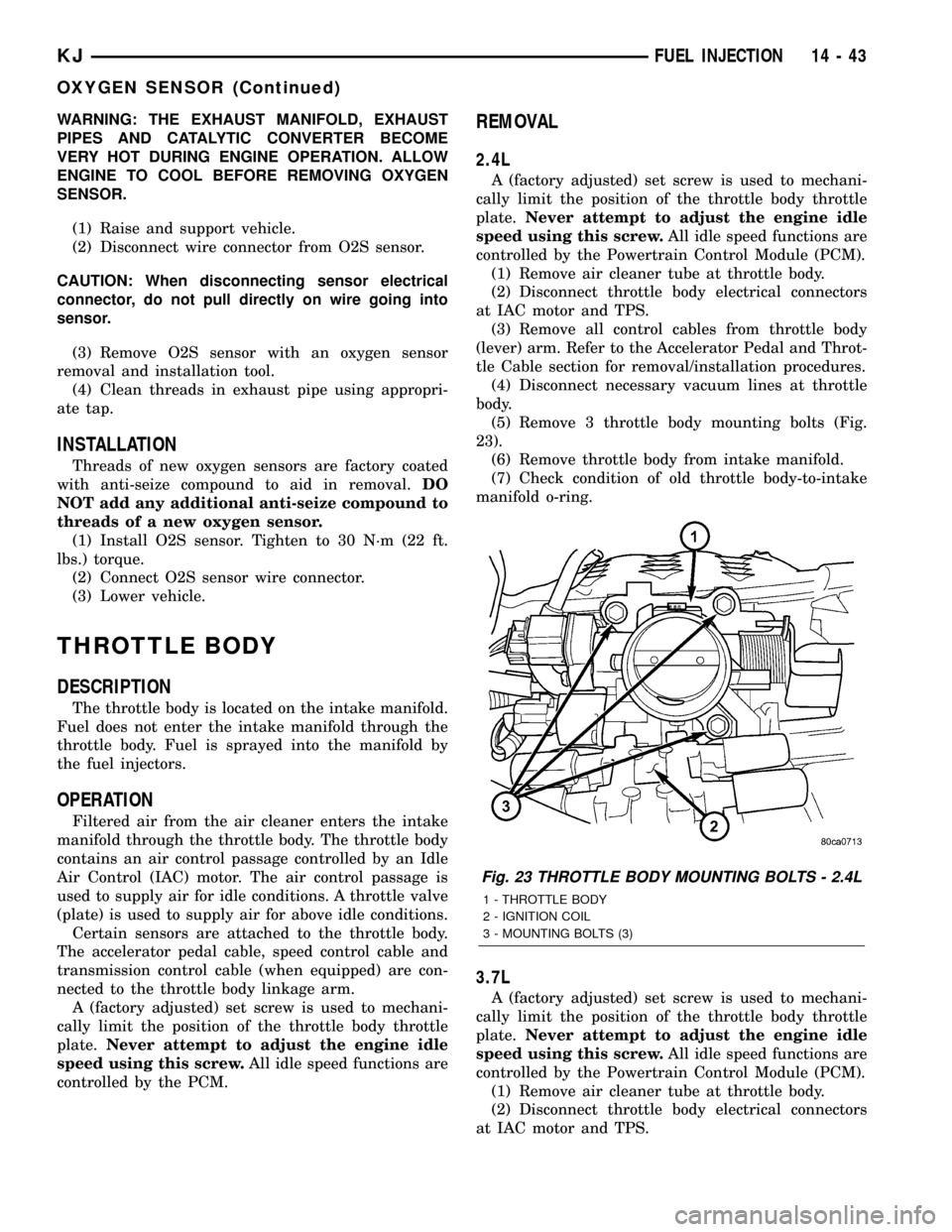

6 - FUEL FILL FITTINGFig. 43 LDP ELECTRICAL CONNECTOR

1 - LEAK DETECTION PUMP (LDP)

2 - ELECTRICAL CONNECTOR

3 - FUEL FILTER

KJFUEL DELIVERY 14 - 27

FUEL TANK (Continued)

Page 1425 of 1803

WARNING: THE EXHAUST MANIFOLD, EXHAUST

PIPES AND CATALYTIC CONVERTER BECOME

VERY HOT DURING ENGINE OPERATION. ALLOW

ENGINE TO COOL BEFORE REMOVING OXYGEN

SENSOR.

(1) Raise and support vehicle.

(2) Disconnect wire connector from O2S sensor.

CAUTION: When disconnecting sensor electrical

connector, do not pull directly on wire going into

sensor.

(3) Remove O2S sensor with an oxygen sensor

removal and installation tool.

(4) Clean threads in exhaust pipe using appropri-

ate tap.

INSTALLATION

Threads of new oxygen sensors are factory coated

with anti-seize compound to aid in removal.DO

NOT add any additional anti-seize compound to

threads of a new oxygen sensor.

(1) Install O2S sensor. Tighten to 30 N´m (22 ft.

lbs.) torque.

(2) Connect O2S sensor wire connector.

(3) Lower vehicle.

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold.

Fuel does not enter the intake manifold through the

throttle body. Fuel is sprayed into the manifold by

the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle body

contains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable and

transmission control cable (when equipped) are con-

nected to the throttle body linkage arm.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

REMOVAL

2.4L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Remove air cleaner tube at throttle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS.

(3) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section for removal/installation procedures.

(4) Disconnect necessary vacuum lines at throttle

body.

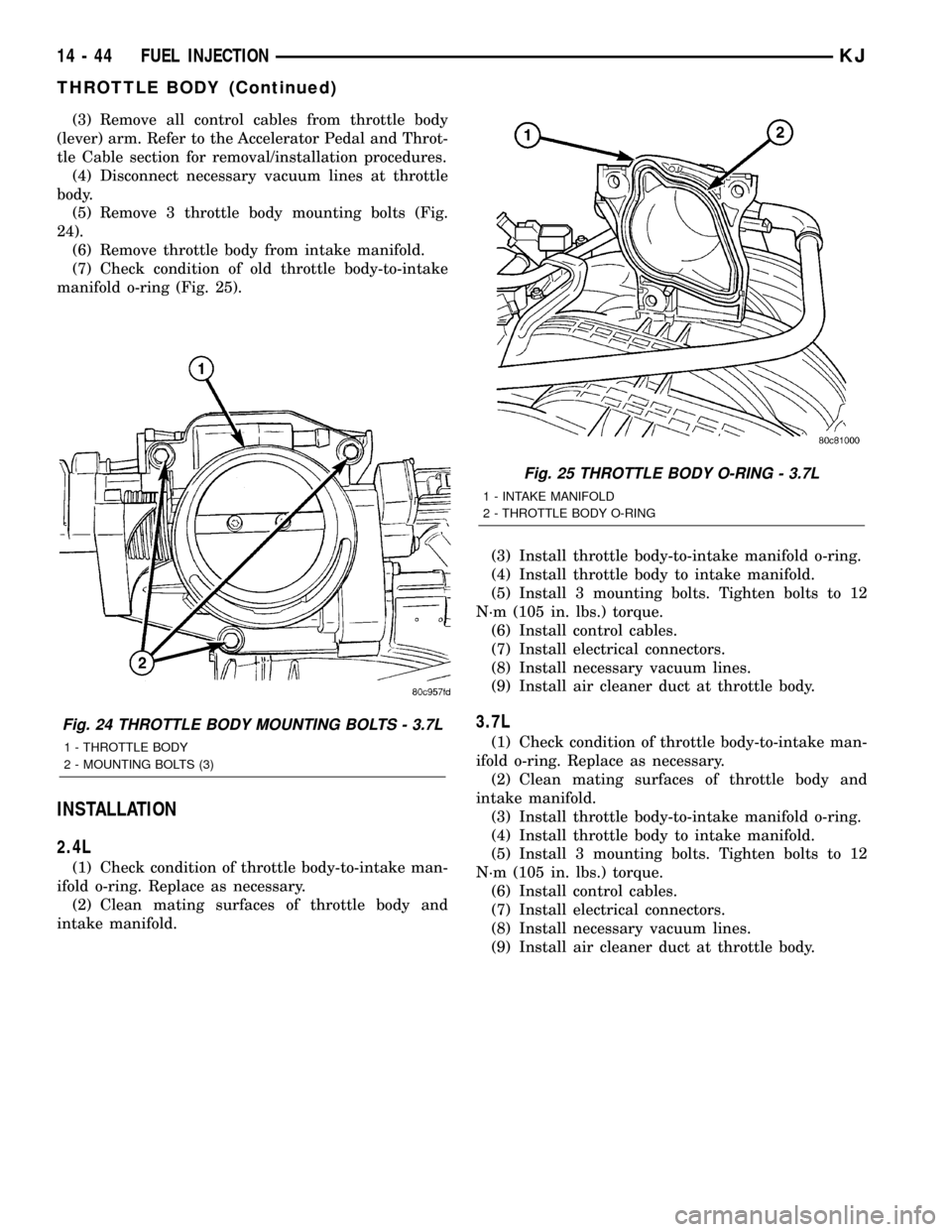

(5) Remove 3 throttle body mounting bolts (Fig.

23).

(6) Remove throttle body from intake manifold.

(7) Check condition of old throttle body-to-intake

manifold o-ring.

3.7L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Remove air cleaner tube at throttle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS.

Fig. 23 THROTTLE BODY MOUNTING BOLTS - 2.4L

1 - THROTTLE BODY

2 - IGNITION COIL

3 - MOUNTING BOLTS (3)

KJFUEL INJECTION 14 - 43

OXYGEN SENSOR (Continued)

Page 1426 of 1803

(3) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section for removal/installation procedures.

(4) Disconnect necessary vacuum lines at throttle

body.

(5) Remove 3 throttle body mounting bolts (Fig.

24).

(6) Remove throttle body from intake manifold.

(7) Check condition of old throttle body-to-intake

manifold o-ring (Fig. 25).

INSTALLATION

2.4L

(1) Check condition of throttle body-to-intake man-

ifold o-ring. Replace as necessary.

(2) Clean mating surfaces of throttle body and

intake manifold.(3) Install throttle body-to-intake manifold o-ring.

(4) Install throttle body to intake manifold.

(5) Install 3 mounting bolts. Tighten bolts to 12

N´m (105 in. lbs.) torque.

(6) Install control cables.

(7) Install electrical connectors.

(8) Install necessary vacuum lines.

(9) Install air cleaner duct at throttle body.

3.7L

(1) Check condition of throttle body-to-intake man-

ifold o-ring. Replace as necessary.

(2) Clean mating surfaces of throttle body and

intake manifold.

(3) Install throttle body-to-intake manifold o-ring.

(4) Install throttle body to intake manifold.

(5) Install 3 mounting bolts. Tighten bolts to 12

N´m (105 in. lbs.) torque.

(6) Install control cables.

(7) Install electrical connectors.

(8) Install necessary vacuum lines.

(9) Install air cleaner duct at throttle body.

Fig. 24 THROTTLE BODY MOUNTING BOLTS - 3.7L

1 - THROTTLE BODY

2 - MOUNTING BOLTS (3)

Fig. 25 THROTTLE BODY O-RING - 3.7L

1 - INTAKE MANIFOLD

2 - THROTTLE BODY O-RING

14 - 44 FUEL INJECTIONKJ

THROTTLE BODY (Continued)

Page 1443 of 1803

GEAR

TABLE OF CONTENTS

page page

GEAR

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL

REMOVAL - 4WD......................13

REMOVAL - 2WD......................14

INSTALLATION

INSTALLATION - 4WD..................14INSTALLATION - 2WD..................14

SPECIFICATIONS

TORQUE CHART......................15

SPECIAL TOOLS

OUTER TIE ROD END REMOVAL TOOL....15

GEAR

DESCRIPTION

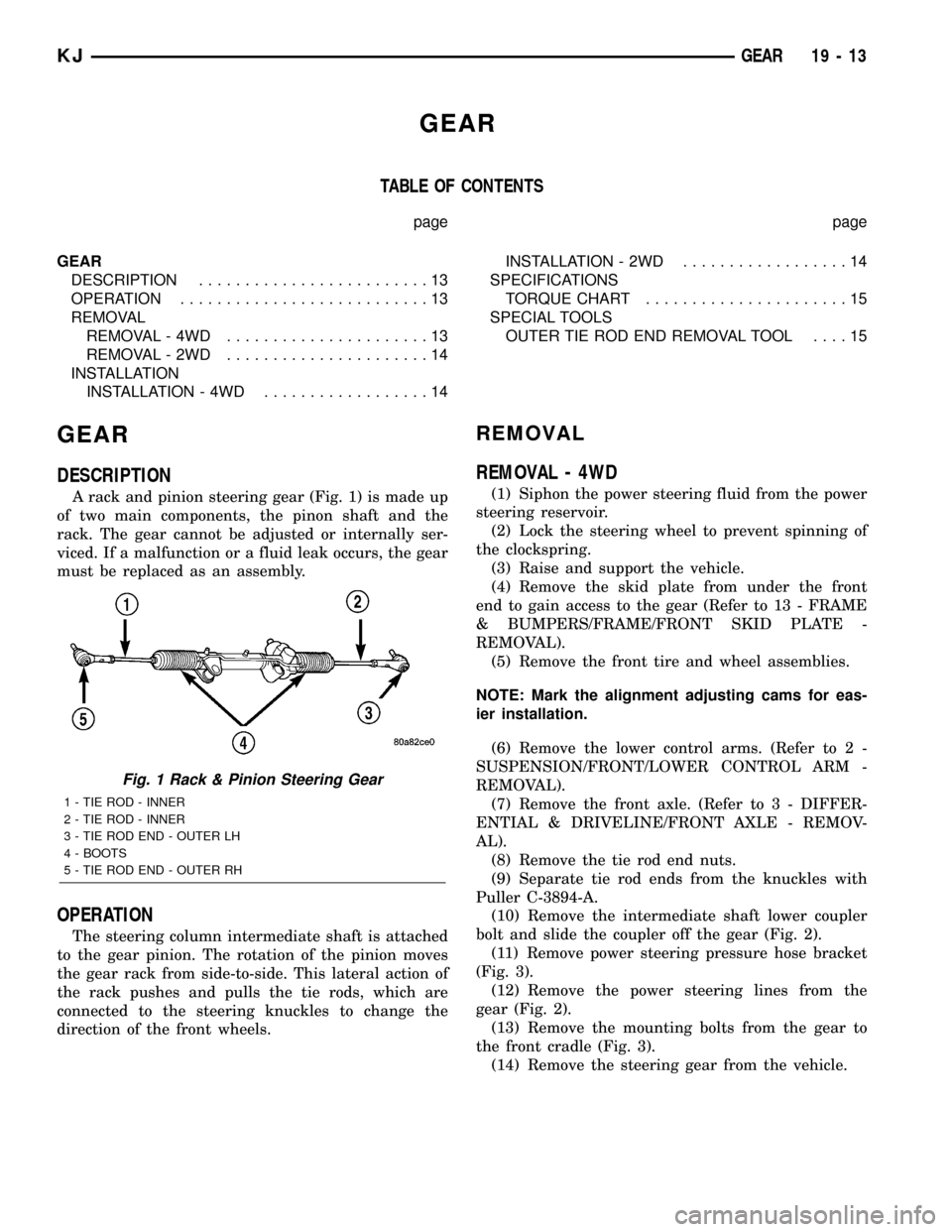

A rack and pinion steering gear (Fig. 1) is made up

of two main components, the pinon shaft and the

rack. The gear cannot be adjusted or internally ser-

viced. If a malfunction or a fluid leak occurs, the gear

must be replaced as an assembly.

OPERATION

The steering column intermediate shaft is attached

to the gear pinion. The rotation of the pinion moves

the gear rack from side-to-side. This lateral action of

the rack pushes and pulls the tie rods, which are

connected to the steering knuckles to change the

direction of the front wheels.

REMOVAL

REMOVAL - 4WD

(1) Siphon the power steering fluid from the power

steering reservoir.

(2) Lock the steering wheel to prevent spinning of

the clockspring.

(3) Raise and support the vehicle.

(4) Remove the skid plate from under the front

end to gain access to the gear (Refer to 13 - FRAME

& BUMPERS/FRAME/FRONT SKID PLATE -

REMOVAL).

(5) Remove the front tire and wheel assemblies.

NOTE: Mark the alignment adjusting cams for eas-

ier installation.

(6) Remove the lower control arms. (Refer to 2 -

SUSPENSION/FRONT/LOWER CONTROL ARM -

REMOVAL).

(7) Remove the front axle. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/FRONT AXLE - REMOV-

AL).

(8) Remove the tie rod end nuts.

(9) Separate tie rod ends from the knuckles with

Puller C-3894-A.

(10) Remove the intermediate shaft lower coupler

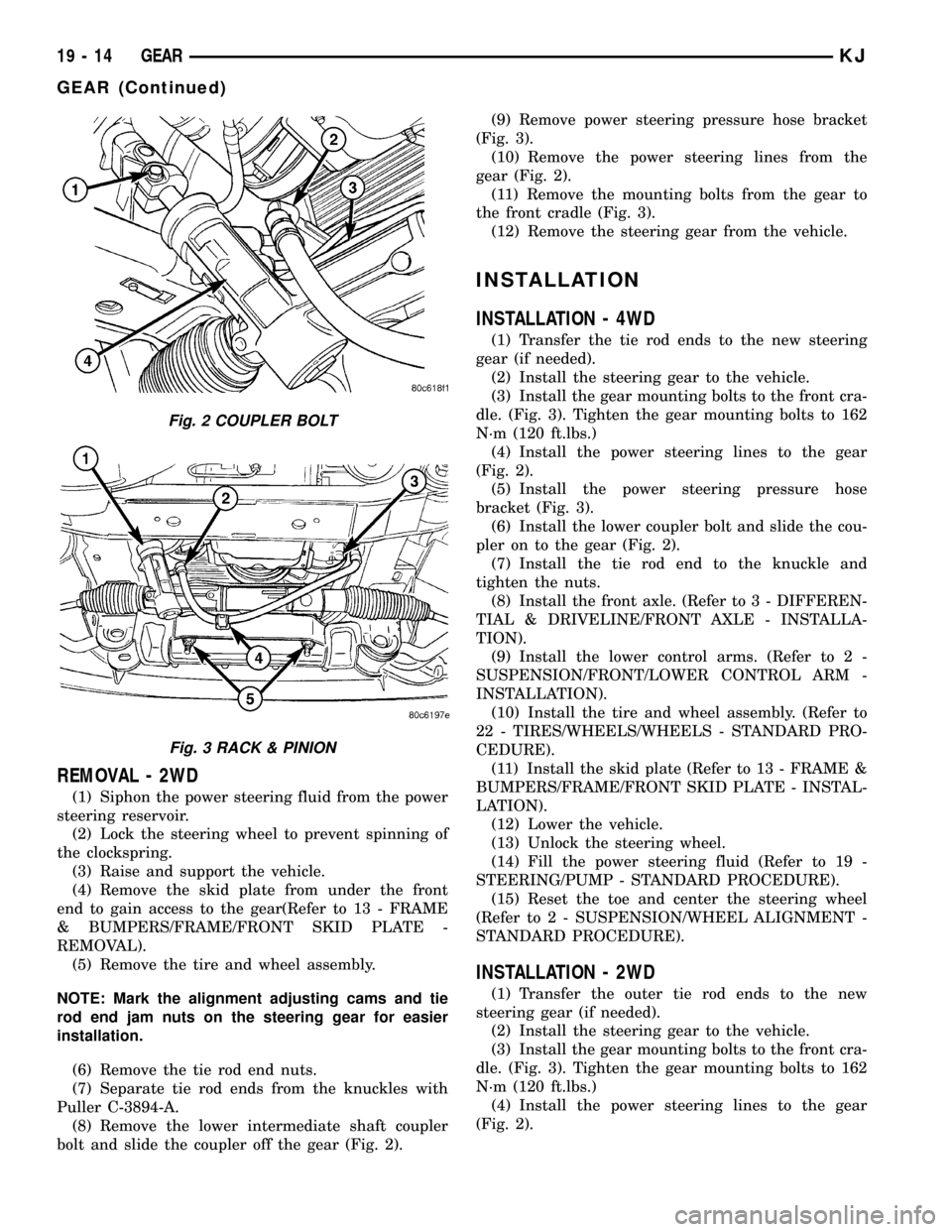

bolt and slide the coupler off the gear (Fig. 2).

(11) Remove power steering pressure hose bracket

(Fig. 3).

(12) Remove the power steering lines from the

gear (Fig. 2).

(13) Remove the mounting bolts from the gear to

the front cradle (Fig. 3).

(14) Remove the steering gear from the vehicle.

Fig. 1 Rack & Pinion Steering Gear

1 - TIE ROD - INNER

2 - TIE ROD - INNER

3 - TIE ROD END - OUTER LH

4 - BOOTS

5 - TIE ROD END - OUTER RH

KJGEAR 19 - 13

Page 1444 of 1803

REMOVAL - 2WD

(1) Siphon the power steering fluid from the power

steering reservoir.

(2) Lock the steering wheel to prevent spinning of

the clockspring.

(3) Raise and support the vehicle.

(4) Remove the skid plate from under the front

end to gain access to the gear(Refer to 13 - FRAME

& BUMPERS/FRAME/FRONT SKID PLATE -

REMOVAL).

(5) Remove the tire and wheel assembly.

NOTE: Mark the alignment adjusting cams and tie

rod end jam nuts on the steering gear for easier

installation.

(6) Remove the tie rod end nuts.

(7) Separate tie rod ends from the knuckles with

Puller C-3894-A.

(8) Remove the lower intermediate shaft coupler

bolt and slide the coupler off the gear (Fig. 2).(9) Remove power steering pressure hose bracket

(Fig. 3).

(10) Remove the power steering lines from the

gear (Fig. 2).

(11) Remove the mounting bolts from the gear to

the front cradle (Fig. 3).

(12) Remove the steering gear from the vehicle.

INSTALLATION

INSTALLATION - 4WD

(1) Transfer the tie rod ends to the new steering

gear (if needed).

(2) Install the steering gear to the vehicle.

(3) Install the gear mounting bolts to the front cra-

dle. (Fig. 3). Tighten the gear mounting bolts to 162

N´m (120 ft.lbs.)

(4) Install the power steering lines to the gear

(Fig. 2).

(5) Install the power steering pressure hose

bracket (Fig. 3).

(6) Install the lower coupler bolt and slide the cou-

pler on to the gear (Fig. 2).

(7) Install the tie rod end to the knuckle and

tighten the nuts.

(8) Install the front axle. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/FRONT AXLE - INSTALLA-

TION).

(9) Install the lower control arms. (Refer to 2 -

SUSPENSION/FRONT/LOWER CONTROL ARM -

INSTALLATION).

(10) Install the tire and wheel assembly. (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(11) Install the skid plate (Refer to 13 - FRAME &

BUMPERS/FRAME/FRONT SKID PLATE - INSTAL-

LATION).

(12) Lower the vehicle.

(13) Unlock the steering wheel.

(14) Fill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

(15) Reset the toe and center the steering wheel

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE).

INSTALLATION - 2WD

(1) Transfer the outer tie rod ends to the new

steering gear (if needed).

(2) Install the steering gear to the vehicle.

(3) Install the gear mounting bolts to the front cra-

dle. (Fig. 3). Tighten the gear mounting bolts to 162

N´m (120 ft.lbs.)

(4) Install the power steering lines to the gear

(Fig. 2).

Fig. 2 COUPLER BOLT

Fig. 3 RACK & PINION

19 - 14 GEARKJ

GEAR (Continued)

Page 1657 of 1803

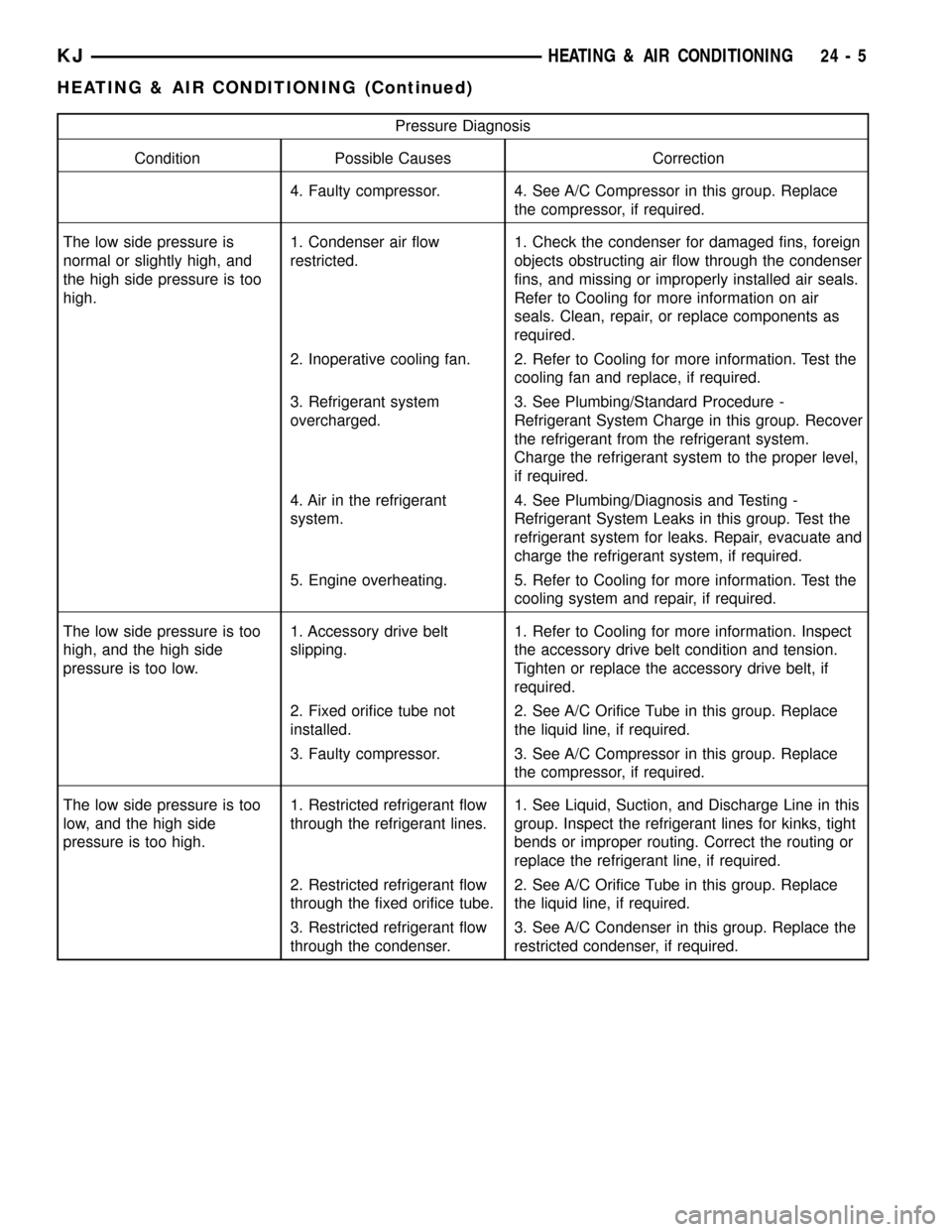

Pressure Diagnosis

Condition Possible Causes Correction

4. Faulty compressor. 4. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is

normal or slightly high, and

the high side pressure is too

high.1. Condenser air flow

restricted.1. Check the condenser for damaged fins, foreign

objects obstructing air flow through the condenser

fins, and missing or improperly installed air seals.

Refer to Cooling for more information on air

seals. Clean, repair, or replace components as

required.

2. Inoperative cooling fan. 2. Refer to Cooling for more information. Test the

cooling fan and replace, if required.

3. Refrigerant system

overcharged.3. See Plumbing/Standard Procedure -

Refrigerant System Charge in this group. Recover

the refrigerant from the refrigerant system.

Charge the refrigerant system to the proper level,

if required.

4. Air in the refrigerant

system.4. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

5. Engine overheating. 5. Refer to Cooling for more information. Test the

cooling system and repair, if required.

The low side pressure is too

high, and the high side

pressure is too low.1. Accessory drive belt

slipping.1. Refer to Cooling for more information. Inspect

the accessory drive belt condition and tension.

Tighten or replace the accessory drive belt, if

required.

2. Fixed orifice tube not

installed.2. See A/C Orifice Tube in this group. Replace

the liquid line, if required.

3. Faulty compressor. 3. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is too

low, and the high side

pressure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid, Suction, and Discharge Line in this

group. Inspect the refrigerant lines for kinks, tight

bends or improper routing. Correct the routing or

replace the refrigerant line, if required.

2. Restricted refrigerant flow

through the fixed orifice tube.2. See A/C Orifice Tube in this group. Replace

the liquid line, if required.

3. Restricted refrigerant flow

through the condenser.3. See A/C Condenser in this group. Replace the

restricted condenser, if required.

KJHEATING & AIR CONDITIONING 24 - 5

HEATING & AIR CONDITIONING (Continued)