JEEP PATRIOT 2019 Owner handbook (in English)

Manufacturer: JEEP, Model Year: 2019, Model line: PATRIOT, Model: JEEP PATRIOT 2019Pages: 332, PDF Size: 1.99 MB

Page 231 of 332

HAZARD WARNING FLASHERS

The Hazard Warning flasher switch is located

on the instrument panel below the climate

controls.

Push the switch to turn on the Hazard

Warning flasher. When the switch is

activated, all directional turn signals

will flash on and off to warn oncoming traffic of

an emergency. Push the switch a second time

to turn off the Hazard Warning flashers.

This is an emergency warning system and it

should not be used when the vehicle is in

motion. Use it when your vehicle is disabled and

it is creating a safety hazard for other motorists.

When you must leave the vehicle to seek assis-

tance, the Hazard Warning flashers will con-

tinue to operate even though the ignition is

placed in the OFF position.

NOTE:

With extended use the Hazard Warning

flashers may wear down your battery.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can

reduce the potential for overheating by taking

the appropriate action.

•On the highways — slow down.

•In city traffic — while stopped, place the

transmission in NEUTRAL, but do not in-

crease engine idle speed.

NOTE:

There are steps that you can take to slow

down an impending overheat condition:

•If your air conditioner (A/C) is on, turn it

off. The A/C system adds heat to the

engine cooling system and turning the

A/C off can help remove this heat.

•You can also turn the temperature control

to maximum heat, the mode control to

floor and the blower control to high. This

allows the heater core to act as a supple-

ment to the radiator and aids in removing

heat from the engine cooling system.CAUTION!

Driving with a hot cooling system could dam-

age your vehicle. If the pointer rises to the

H(red) mark, the instrument cluster will

sound a chime. When safe, pull over and

stop the vehicle with the engine at idle. Turn

off the air conditioning and wait until the

pointer drops back into the normal range. If

the pointer remains on theH(red) mark for

more than a minute, turn the engine off

immediately and call for service.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam com-

ing from under the hood, do not open the

hood until the radiator has had time to cool.

Never try to open a cooling system pressure

cap when the radiator or coolant bottle is hot.

227

Page 232 of 332

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle the lug

nuts/bolts should be torqued using a properly

calibrated torque wrench.

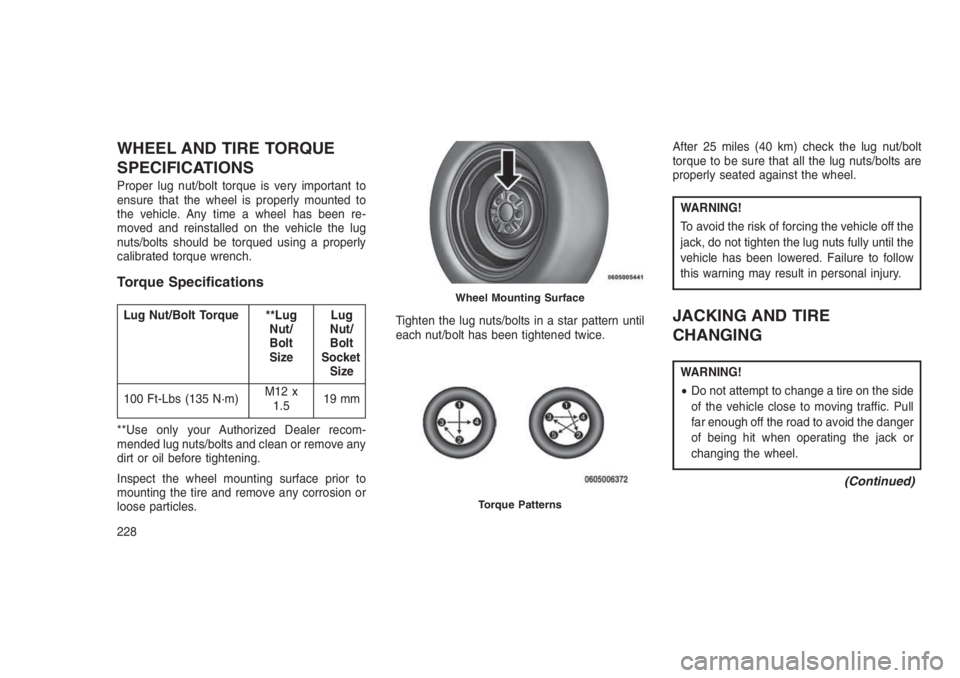

Torque Specifications

Lug Nut/Bolt Torque **Lug

Nut/

Bolt

SizeLug

Nut/

Bolt

Socket

Size

100 Ft-Lbs (135 N·m)M12 x

1.519 mm

**Use only your Authorized Dealer recom-

mended lug nuts/bolts and clean or remove any

dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.Tighten the lug nuts/bolts in a star pattern until

each nut/bolt has been tightened twice.After 25 miles (40 km) check the lug nut/bolt

torque to be sure that all the lug nuts/bolts are

properly seated against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts fully until the

vehicle has been lowered. Failure to follow

this warning may result in personal injury.

JACKING AND TIRE

CHANGING

WARNING!

•Do not attempt to change a tire on the side

of the vehicle close to moving traffic. Pull

far enough off the road to avoid the danger

of being hit when operating the jack or

changing the wheel.

(Continued)

Wheel Mounting Surface

Torque Patterns

228

Page 233 of 332

WARNING!(Continued)

•Being under a jacked-up vehicle is danger-

ous. The vehicle could slip off the jack and

fall on you. You could be crushed. Never

put any part of your body under a vehicle

that is on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

•Never start or run the engine while the

vehicle is on a jack.

•The jack is designed to be used as a tool

for changing tires only. The jack should not

be used to lift the vehicle for service pur-

poses. The vehicle should be jacked on a

firm level surface only. Avoid ice or slippery

areas.

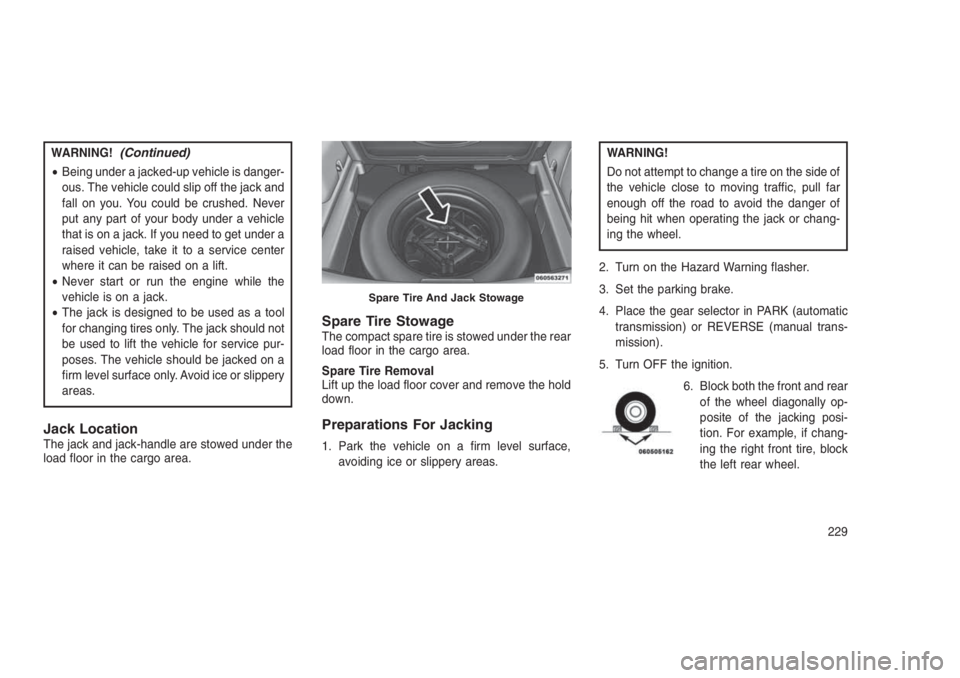

Jack LocationThe jack and jack-handle are stowed under the

load floor in the cargo area.

Spare Tire StowageThe compact spare tire is stowed under the rear

load floor in the cargo area.

Spare Tire Removal

Lift up the load floor cover and remove the hold

down.

Preparations For Jacking

1. Park the vehicle on a firm level surface,

avoiding ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic, pull far

enough off the road to avoid the danger of

being hit when operating the jack or chang-

ing the wheel.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the gear selector in PARK (automatic

transmission) or REVERSE (manual trans-

mission).

5. Turn OFF the ignition.

6. Block both the front and rear

of the wheel diagonally op-

posite of the jacking posi-

tion. For example, if chang-

ing the right front tire, block

the left rear wheel.

Spare Tire And Jack Stowage

229

Page 234 of 332

NOTE:

Passengers should not remain in the vehicle

while the vehicle is being jacked.

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

•Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

•Turn on the Hazard Warning flasher.

•Block the wheel diagonally opposite the

wheel to be raised.

•Set the parking brake firmly and set an

automatic transmission in PARK; a manual

transmission in REVERSE.

•Never start or run the engine with the

vehicle on a jack.

(Continued)

WARNING!(Continued)

•Do not let anyone sit in the vehicle when it

is on a jack.

•Do not get under the vehicle when it is on

a jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

•Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

•If working on or near a roadway, be ex-

tremely careful of motor traffic.

•To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.NOTE:

Refer to “Tires — General Information” in

“Starting And Operating” for further infor-

mation about the spare tire, it’s use, and

operation.

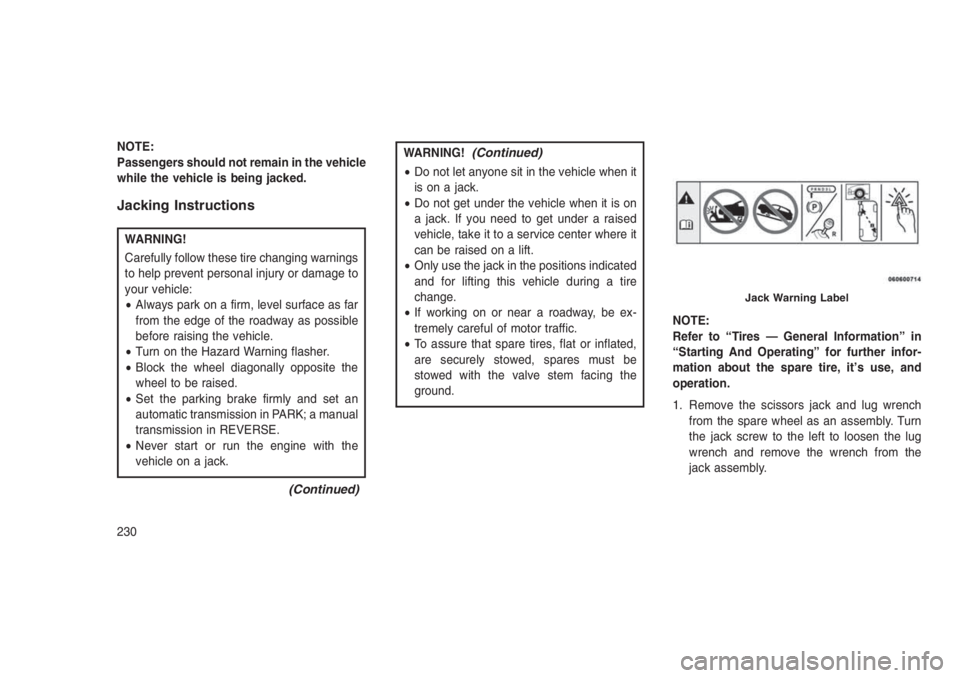

1. Remove the scissors jack and lug wrench

from the spare wheel as an assembly. Turn

the jack screw to the left to loosen the lug

wrench and remove the wrench from the

jack assembly.

Jack Warning Label

230

Page 235 of 332

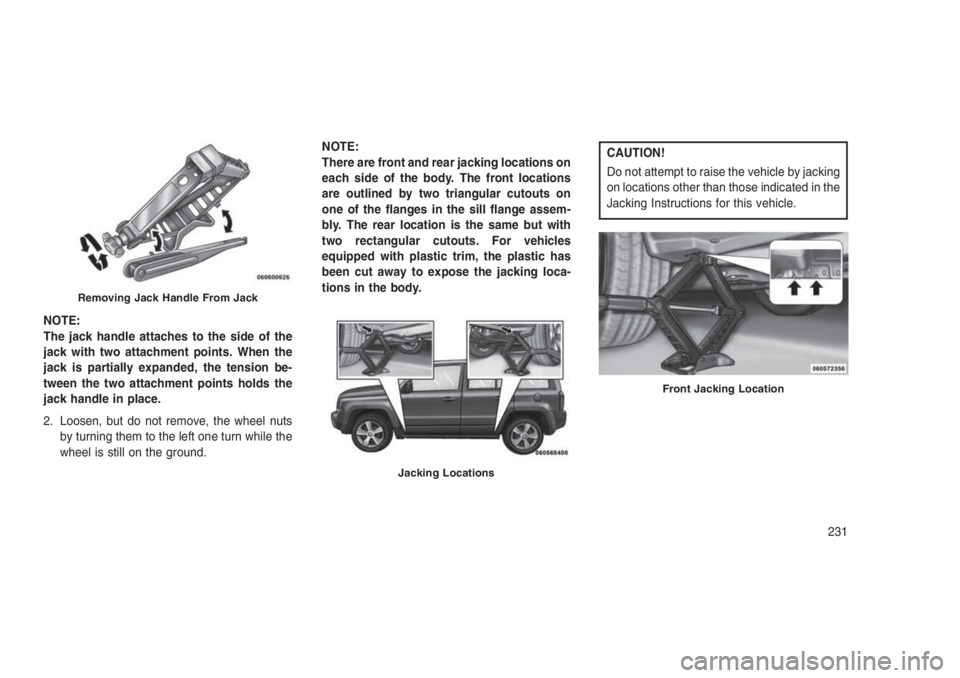

NOTE:

The jack handle attaches to the side of the

jack with two attachment points. When the

jack is partially expanded, the tension be-

tween the two attachment points holds the

jack handle in place.

2. Loosen, but do not remove, the wheel nuts

by turning them to the left one turn while the

wheel is still on the ground.NOTE:

There are front and rear jacking locations on

each side of the body. The front locations

are outlined by two triangular cutouts on

one of the flanges in the sill flange assem-

bly. The rear location is the same but with

two rectangular cutouts. For vehicles

equipped with plastic trim, the plastic has

been cut away to expose the jacking loca-

tions in the body.

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

Removing Jack Handle From Jack

Jacking Locations

Front Jacking Location

231

Page 236 of 332

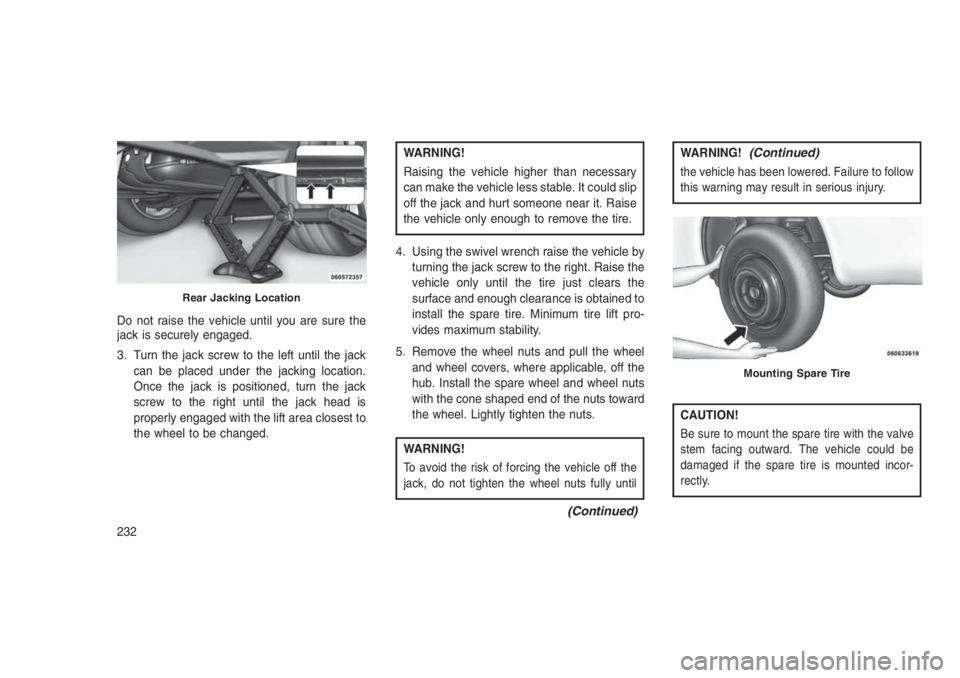

Do not raise the vehicle until you are sure the

jack is securely engaged.

3. Turn the jack screw to the left until the jack

can be placed under the jacking location.

Once the jack is positioned, turn the jack

screw to the right until the jack head is

properly engaged with the lift area closest to

the wheel to be changed.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could slip

off the jack and hurt someone near it. Raise

the vehicle only enough to remove the tire.

4. Using the swivel wrench raise the vehicle by

turning the jack screw to the right. Raise the

vehicle only until the tire just clears the

surface and enough clearance is obtained to

install the spare tire. Minimum tire lift pro-

vides maximum stability.

5. Remove the wheel nuts and pull the wheel

and wheel covers, where applicable, off the

hub. Install the spare wheel and wheel nuts

with the cone shaped end of the nuts toward

the wheel. Lightly tighten the nuts.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

(Continued)

WARNING!(Continued)

the vehicle has been lowered. Failure to follow

this warning may result in serious injury.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted incor-

rectly.

Rear Jacking Location

Mounting Spare Tire

232

Page 237 of 332

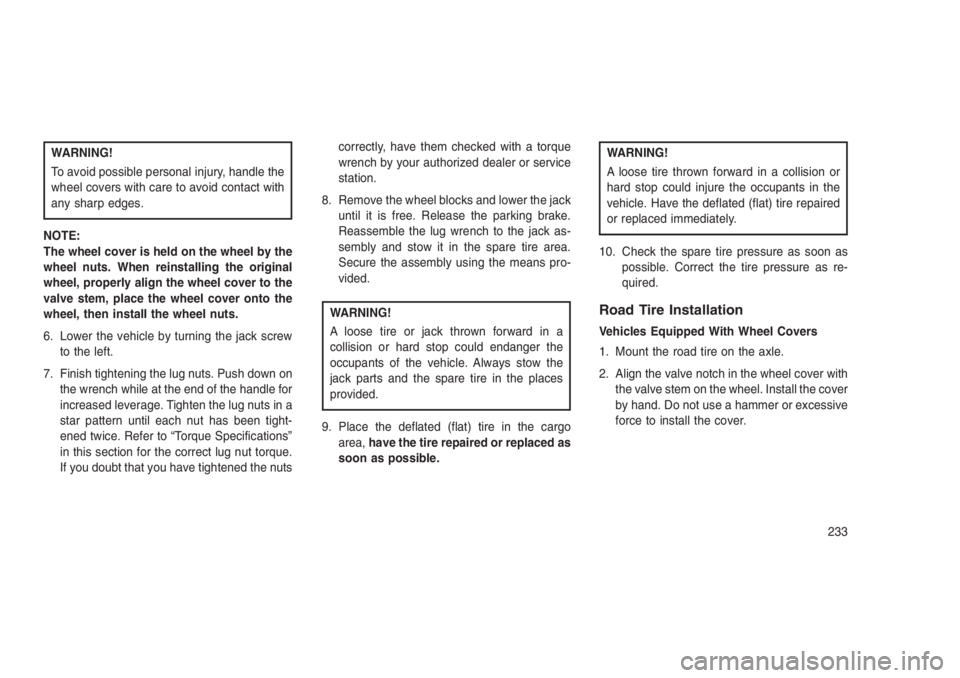

WARNING!

To avoid possible personal injury, handle the

wheel covers with care to avoid contact with

any sharp edges.

NOTE:

The wheel cover is held on the wheel by the

wheel nuts. When reinstalling the original

wheel, properly align the wheel cover to the

valve stem, place the wheel cover onto the

wheel, then install the wheel nuts.

6. Lower the vehicle by turning the jack screw

to the left.

7. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle for

increased leverage. Tighten the lug nuts in a

star pattern until each nut has been tight-

ened twice. Refer to “Torque Specifications”

in this section for the correct lug nut torque.

If you doubt that you have tightened the nutscorrectly, have them checked with a torque

wrench by your authorized dealer or service

station.

8. Remove the wheel blocks and lower the jack

until it is free. Release the parking brake.

Reassemble the lug wrench to the jack as-

sembly and stow it in the spare tire area.

Secure the assembly using the means pro-

vided.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

9. Place the deflated (flat) tire in the cargo

area,have the tire repaired or replaced as

soon as possible.

WARNING!

A loose tire thrown forward in a collision or

hard stop could injure the occupants in the

vehicle. Have the deflated (flat) tire repaired

or replaced immediately.

10. Check the spare tire pressure as soon as

possible. Correct the tire pressure as re-

quired.

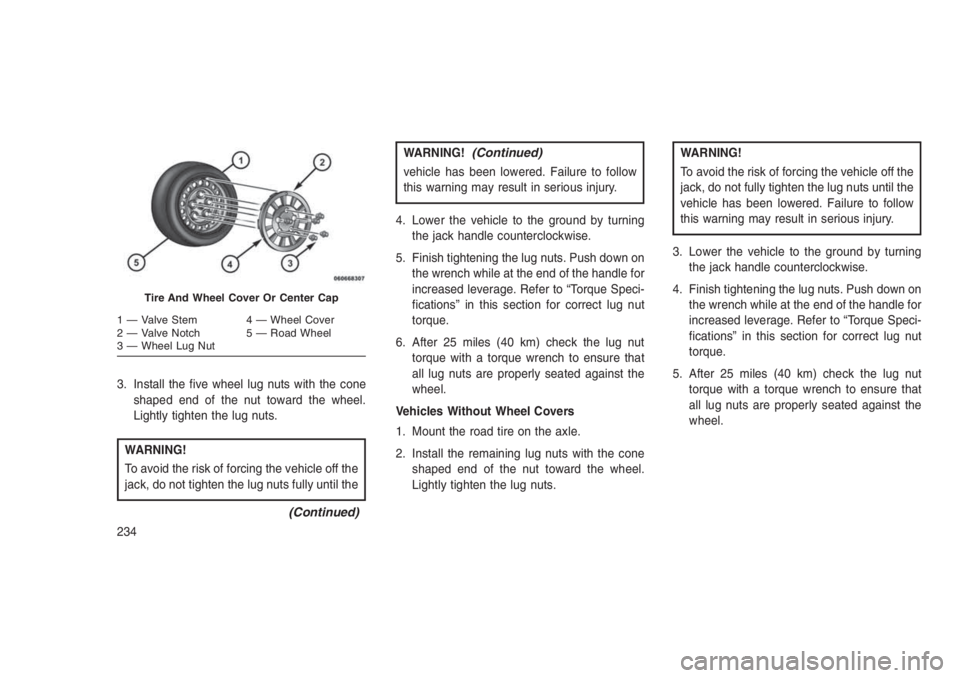

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. Align the valve notch in the wheel cover with

the valve stem on the wheel. Install the cover

by hand. Do not use a hammer or excessive

force to install the cover.

233

Page 238 of 332

3. Install the five wheel lug nuts with the cone

shaped end of the nut toward the wheel.

Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts fully until the

(Continued)

WARNING!(Continued)

vehicle has been lowered. Failure to follow

this warning may result in serious injury.

4. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

5. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle for

increased leverage. Refer to “Torque Speci-

fications” in this section for correct lug nut

torque.

6. After 25 miles (40 km) check the lug nut

torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone

shaped end of the nut toward the wheel.

Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not fully tighten the lug nuts until the

vehicle has been lowered. Failure to follow

this warning may result in serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle for

increased leverage. Refer to “Torque Speci-

fications” in this section for correct lug nut

torque.

5. After 25 miles (40 km) check the lug nut

torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Road Wheel

3 — Wheel Lug Nut

234

Page 239 of 332

TIRE SERVICE KIT — IF

EQUIPPED

Small punctures up to 1/4 inch (6 mm) in the tire

tread can be sealed with Tire Service Kit. For-

eign objects (e.g., screws or nails) should not be

removed from the tire. Tire Service Kit can be

used in outside temperatures down to approxi-

mately -4°F (-20°C).

This kit will provide a temporary tire seal, allow-

ing you to drive your vehicle up to 100 miles

(160 km) with a maximum speed of 55 mph

(90 km/h).

Tire Service Kit StorageThe Tire Service Kit is located under the load

floor in the cargo area.

Tire Service Kit Components And

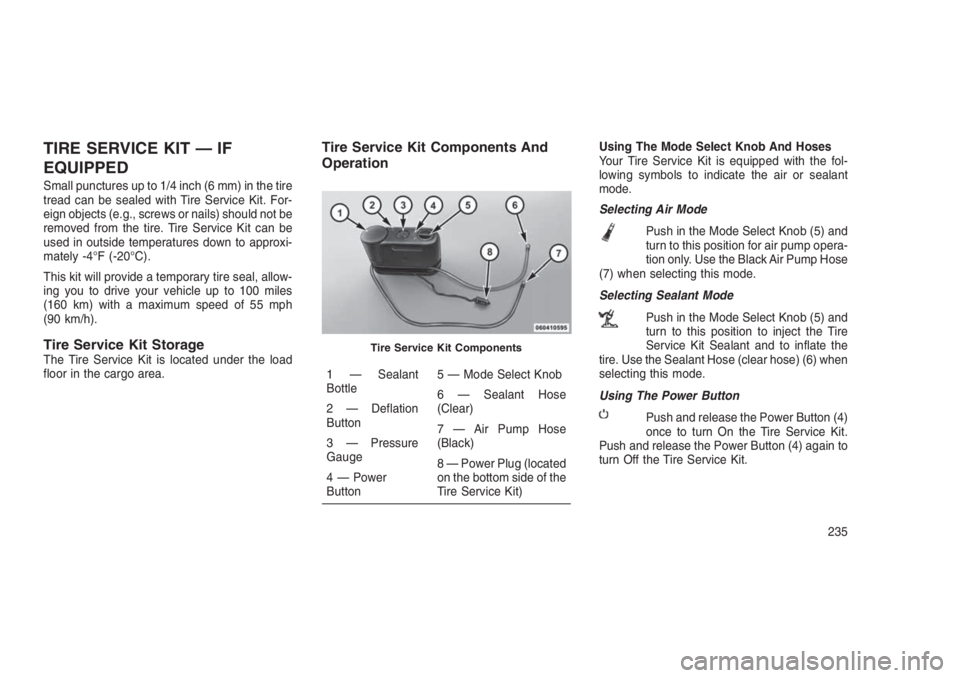

OperationUsing The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the fol-

lowing symbols to indicate the air or sealant

mode.

Selecting Air Mode

Push in the Mode Select Knob (5) and

turn to this position for air pump opera-

tion only. Use the Black Air Pump Hose

(7) when selecting this mode.

Selecting Sealant Mode

Push in the Mode Select Knob (5) and

turn to this position to inject the Tire

Service Kit Sealant and to inflate the

tire. Use the Sealant Hose (clear hose) (6) when

selecting this mode.

Using The Power Button

Push and release the Power Button (4)

once to turn On the Tire Service Kit.

Push and release the Power Button (4) again to

turn Off the Tire Service Kit.

Tire Service Kit Components

1 — Sealant

Bottle5 — Mode Select Knob

2 — Deflation

Button6 — Sealant Hose

(Clear)

3 — Pressure

Gauge7 — Air Pump Hose

(Black)

4 — Power

Button8 — Power Plug (located

on the bottom side of the

Tire Service Kit)

235

Page 240 of 332

Using The Deflation Button

Push the Deflation Button (2) to reduce

the air pressure in the tire if it becomes

over-inflated.

Tire Service Kit Usage Precautions

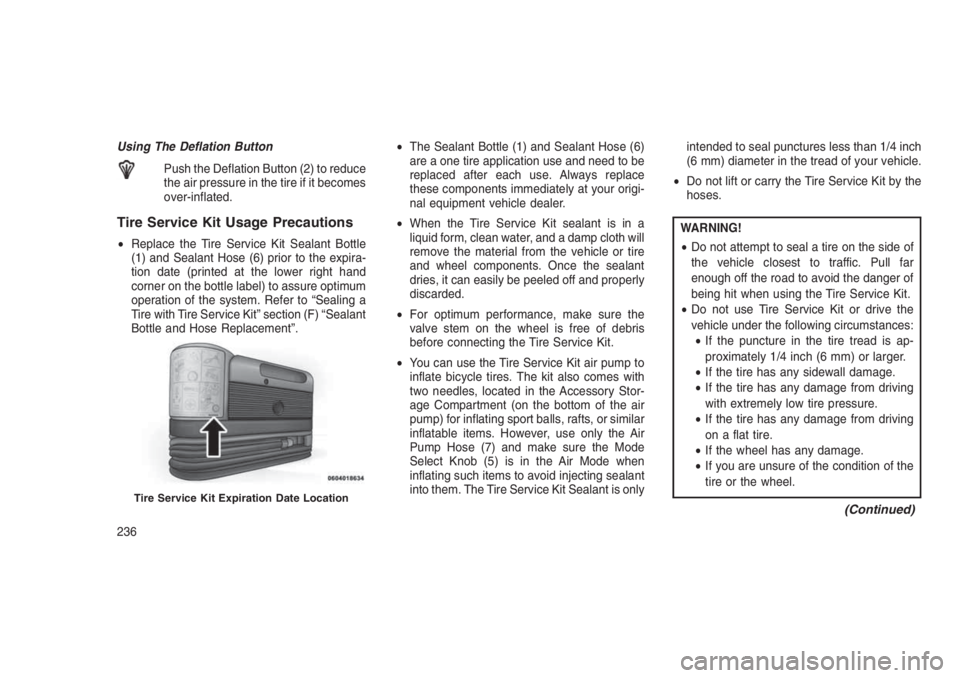

•Replace the Tire Service Kit Sealant Bottle

(1) and Sealant Hose (6) prior to the expira-

tion date (printed at the lower right hand

corner on the bottle label) to assure optimum

operation of the system. Refer to “Sealing a

Tire with Tire Service Kit” section (F) “Sealant

Bottle and Hose Replacement”.•The Sealant Bottle (1) and Sealant Hose (6)

are a one tire application use and need to be

replaced after each use. Always replace

these components immediately at your origi-

nal equipment vehicle dealer.

•When the Tire Service Kit sealant is in a

liquid form, clean water, and a damp cloth will

remove the material from the vehicle or tire

and wheel components. Once the sealant

dries, it can easily be peeled off and properly

discarded.

•For optimum performance, make sure the

valve stem on the wheel is free of debris

before connecting the Tire Service Kit.

•You can use the Tire Service Kit air pump to

inflate bicycle tires. The kit also comes with

two needles, located in the Accessory Stor-

age Compartment (on the bottom of the air

pump) for inflating sport balls, rafts, or similar

inflatable items. However, use only the Air

Pump Hose (7) and make sure the Mode

Select Knob (5) is in the Air Mode when

inflating such items to avoid injecting sealant

into them. The Tire Service Kit Sealant is onlyintended to seal punctures less than 1/4 inch

(6 mm) diameter in the tread of your vehicle.

•Do not lift or carry the Tire Service Kit by the

hoses.WARNING!

•Do not attempt to seal a tire on the side of

the vehicle closest to traffic. Pull far

enough off the road to avoid the danger of

being hit when using the Tire Service Kit.

•Do not use Tire Service Kit or drive the

vehicle under the following circumstances:

•If the puncture in the tire tread is ap-

proximately 1/4 inch (6 mm) or larger.

•If the tire has any sidewall damage.

•If the tire has any damage from driving

with extremely low tire pressure.

•If the tire has any damage from driving

on a flat tire.

•If the wheel has any damage.

•If you are unsure of the condition of the

tire or the wheel.

(Continued)Tire Service Kit Expiration Date Location

236