ESP JEEP RENEGADE 2014 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2014, Model line: RENEGADE, Model: JEEP RENEGADE 2014 1.GPages: 212, PDF Size: 17.48 MB

Page 115 of 212

The sensors are automatically

reactivated when the trailer's cable plug

is removed. Before using thePark-

Sense® system, it is recommended to

remove the tow hook ball assembly and

the relevant attachment from the vehi-

cle when the latter is not used for tow-

ing operations. Failure to comply with

this prescription may cause personal

injuries or damages to vehicles or

obstacles since, when the continuous

acoustic signal is emitted, the tow hook

ball is already in a position that is much

closer to the obstacle than the rear

bumper.

In addition, the sensors may detect the

tow hook ball assembly and the

relevant attachment (depending on its

size and shape), providing a false

indication of the presence of an

obstacle in the area behind the vehicle.

GENERAL WARNINGS

Some conditions may influence the

performance of the parking system:

❒reduced sensor sensitivity and a

reduction in the parking assistance

system performance could be due to

the presence of: ice, snow, mud, thick

paint, on the surface of the sensor;

❒the sensor may detect a non-existent

obstacle ("echo interference") due to

mechanical interference, for example

when washing the vehicle, in rain

(strong wind), hail;❒the signals sent by the sensor can

also be altered by the presence of

ultrasonic systems (e.g. pneumatic

brake systems of trucks or pneumatic

drills) near the vehicle;

❒Parking assistance system

performance can also be influenced by

the position of the sensors, for example

due to a change in the ride setting

(caused by wear to the shock

absorbers, suspension), or by changing

tyres, overloading the vehicle or

carrying out specific tuning operations

that require the vehicle to be lowered.

❒the presence of a tow hook without

trailer, which may interfere with the

correct operation of the parking

sensors.

❒the presence of adhesives on the

sensors. Thus take care not to place

adhesives on the sensors.

WARNING

126)Parking and other potentially

dangerous manoeuvres are, however,

always the driver’s responsibility. When

performing these operations, always make

sure that there are no other people

(especially children) or animals on the route

you want to drive into. The parking

sensors are an aid for the driver, but the

driver must never allow their attention

to lapse during potentially dangerous

manoeuvres, even those executed at low

speeds.

WARNING

42)The sensors must be clean of mud,

dirt, snow or ice in order for the system to

operate correctly. Be careful not to scratch

or damage the sensors while cleaning

them. Avoid using dry, rough or hard

cloths. The sensors should be washed

using clean water with the addition of car

shampoo if necessary. When using special

washing equipment such as high pressure

jets or steam cleaning, clean the sensors

very quickly keeping the jet more than

10 cm away.

43)Only have interventions on the bumper

in the area of the sensors carried out by

a Jeep Dealership. Interventions on the

bumper that are not carried out properly

may compromise the operation of the

parking sensors.

113

Page 116 of 212

LANESENSE

SYSTEM (lane

crossing warning)

DESCRIPTION

44) 45) 46) 47) 48) 49)

The LaneSense system makes use of a

camera located on the windscreen to

detect the lane limits and calculate

the position of the vehicle within such

limits, in order to make sure that it

remains inside the lane.

When both limits of the lane are

detected and the vehicle crosses one of

them without the awareness of the

driver (direction indicator off), the

system provides a tactile warning by

applying torque to the steering wheel,

signalling the driver that he must take

an action to remain into the lane.

If the vehicle continues going beyond

the line of the lane without any

intervention from the driver, the

warning light (or the corresponding

graphic icon on the reconfigurable

multifunction display) will be displayed

on the instrument panel to urge the

driver to bring the vehicle back into the

limits of the lane.IMPORTANT The system monitors the

presence of the driver's hands on

the steering wheel. If they are

not detected, the system emits an

acoustic signal and deactivates until it is

reactivated by pressing the dedicated

button.

When one limit of the lane is detected

and the vehicle crosses it (direction

indicator off), warning light

(or the

icon on the reconfigurable multifunction

display) will be displayed on the

instrument panel to urge the driver to

bring the vehicle back into the lane.

In this case, the tactile warning (torque

on the steering wheel) is not provided.

SYSTEM ACTIVATION/

DEACTIVATION

When the engine is started the system

is activated (LED on button

fig. 98

off). Each time the engine is started, the

system keeps the activation status

there was when it was previously

switched off.

Activation conditions

Once switched on, the system

becomes active only if the following

conditions are met:

❒the driver always keeps at least one

hand on the steering wheel;❒vehicle speed ranges within 60 km/h

and 180 km/h (or equivalent values in

miles);

❒the lane limit lines are perfectly visible

on both sides;

❒there are suitable visibility conditions;

❒the road is straight or with wide

radius bends;

❒a suitable distance is kept from the

vehicle in front;

❒the direction indicator (for leaving the

lane) is not active;

❒the lane limit lines are perfectly visible

on both sides (for activation of the

tactile warning only).

NOTE The system does not apply

torque to the steering wheel every time

a safety system is activated (brakes,

ABS, ASR system, ESC system,

Forward Collision Warning Plus system,

etc.).

98J0A0052C

114

STARTING AND DRIVING

Page 118 of 212

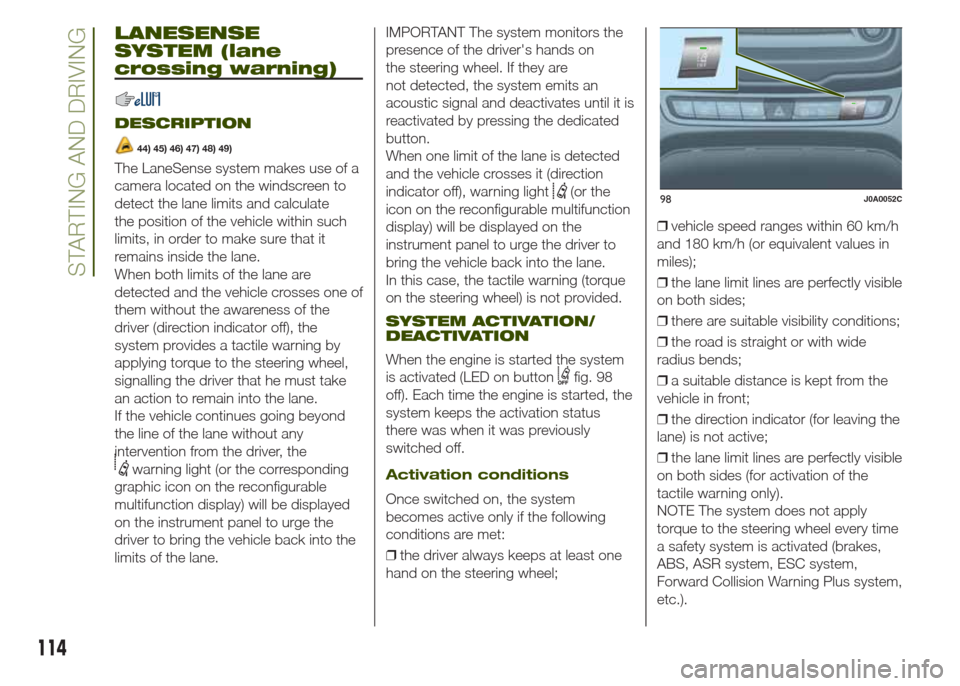

A superimposed central broken line

indicates the centre of the vehicle

to facilitate parking manoeuvres or tow

hook alignment.

The various coloured areas indicate the

distance from the rear of the vehicle.

Area (reference

fig. 100)Distance from the

rear of the vehicle

Red (A) 0–30 cm

Yellow (B) 30–100 cm

Green (C) 1 m or more

IMPORTANT When parking, take the

utmost care over obstacles that may be

above or under the camera range.

WARNING

127)Parking and other potentially

dangerous manoeuvres are, however,

always the driver’s responsibility. While

carrying out these manoeuvres, always

make sure that no people (especially

children) or animals are in the area

concerned. The camera is an aid for the

driver, but the driver must never allow

his/her attention to lapse during potentially

dangerous manoeuvres, even those

executed at low speeds. Always keep a

slow speed, so as to promptly brake in the

case of obstacles.

WARNING

50)It is vital, for correct operation, that the

camera is always kept clean and free

from mud, dirt, snow or ice. Be careful not

to scratch or damage the camera while

cleaning it. Avoid using dry, rough or hard

cloths. The camera must be washed

using clean water, with the addition of car

shampoo if necessary. In washing stations

which use steam or high-pressure jets,

clean the camera quickly, keeping the

nozzle more than 10 cm away from the

sensors. Do not apply stickers to the

camera.

100J0A0103C

116

STARTING AND DRIVING

Page 121 of 212

Key

1 – Housing pipe

2 – Ball head tow bar

3 – Locking balls

4 – Release ball

5 – Release lever

6 – Knob

7 – Cap

8 – Key

9 – Red marking (knob)

10 – Green marking (knob)

11 – Green marking (tow bar)

12 – Symbol (control release)

13 – Closing cap

14 – Engagement pin

15 – Absence of slots between 2 and 6

16 – Slot of 5 mm approx.

A: locked position (driving)

B: released position (removed)

Installing the ball head tow

bar

Remove the plug from the mounting

pipe.

The ball head tow bar is usually in the

released position when taken out from

the luggage compartment. This can

be observed by the knob spaced from

the tow bar, corresponding to a slot

of approximately 5 mm (see fig. 101)

and by the red mark on the knob

directed to the green mark on the tow

bar. The tow bar can be installed only

when in these conditions.If the locking mechanism of the tow bar

is disengaged before the installation,

or at any other time, and is in the

locked position, it must be pre-loaded.

The locked position can be identified

by the green mark of the knob

coinciding with the green mark of the

tow bar and by the knob in the stop

position on the tow bar, namely without

slot (see figure).

The locking mechanism is pre-loaded

as follows:

❒with key inserted and lock open,

extract the knob following the direction

of arrow A fig. 101;

❒then follow the direction of arrow B,

until it stops.

The release ball is pre-loaded and the

locking mechanism remains in the

pre-loading position even when the

knob is released.

The release lever is engaged and the

locking mechanism remains in the

pre-loading position even when the

knob is released.

The tow bar must be inserted in the

housing pipe with the coupling pin for

the installation. Insert from the bottom

and push upwards: the mechanism

locks automatically.

IMPORTANT To prevent injury to limbs,

keep hands away from the knob when

locking.Close the lock and always remove the

key. The key cannot be removed when

the lock is released. Then fit the

protection cap on the lock.

Removing the tow bar

Proceed as follows:

❒remove the protection cap from the

lock and press it on the key grip. Open

the lock with the key;

❒grip the tow bar firmly, remove the

knob following the direction of arrow A

fig. 101, then rotate in the direction

of arrow B until it stops, in order to

release it in unlocked position. Then

remove the tow bar from the housing

pipe. The knob can then be released (it

will automatically stop in released

position);

❒arrange the tow bar in the luggage

compartment so that it cannot be

dirtied and/or damaged by other

transported objects;

❒finally, insert the dedicated plug in the

mounting pipe.

Important

Apply the plate in a highly visible point

of the vehicle, near the mounting pipe

or inside the luggage compartment.

119

Page 126 of 212

HAZARD WARNING

LIGHTS

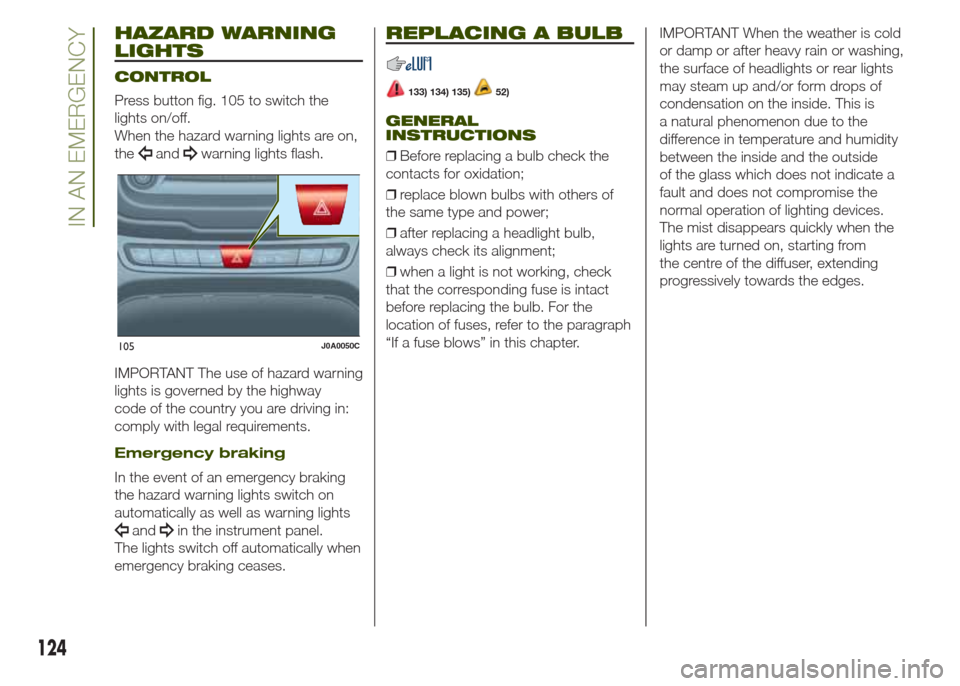

CONTROL

Press button fig. 105 to switch the

lights on/off.

When the hazard warning lights are on,

the

andwarning lights flash.

IMPORTANT The use of hazard warning

lights is governed by the highway

code of the country you are driving in:

comply with legal requirements.

Emergency braking

In the event of an emergency braking

the hazard warning lights switch on

automatically as well as warning lights

andin the instrument panel.

The lights switch off automatically when

emergency braking ceases.

REPLACING A BULB

133) 134) 135)52)

GENERAL

INSTRUCTIONS

❒Before replacing a bulb check the

contacts for oxidation;

❒replace blown bulbs with others of

the same type and power;

❒after replacing a headlight bulb,

always check its alignment;

❒when a light is not working, check

that the corresponding fuse is intact

before replacing the bulb. For the

location of fuses, refer to the paragraph

“If a fuse blows” in this chapter.IMPORTANT When the weather is cold

or damp or after heavy rain or washing,

the surface of headlights or rear lights

may steam up and/or form drops of

condensation on the inside. This is

a natural phenomenon due to the

difference in temperature and humidity

between the inside and the outside

of the glass which does not indicate a

fault and does not compromise the

normal operation of lighting devices.

The mist disappears quickly when the

lights are turned on, starting from

the centre of the diffuser, extending

progressively towards the edges.

105J0A0050C

124

IN AN EMERGENCY

Page 129 of 212

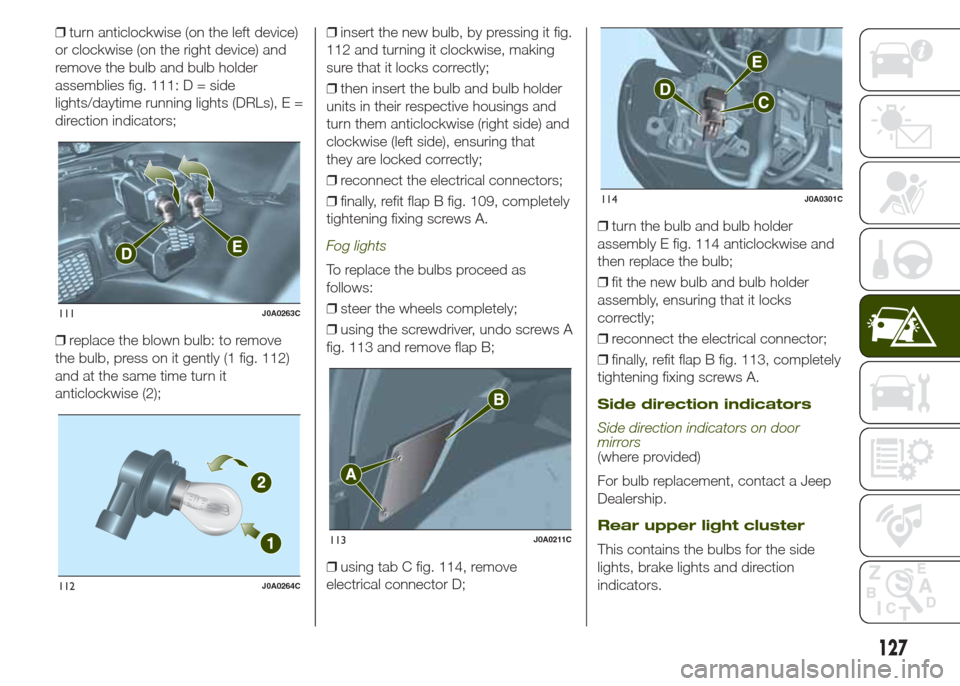

❒turn anticlockwise (on the left device)

or clockwise (on the right device) and

remove the bulb and bulb holder

assemblies fig. 111: D = side

lights/daytime running lights (DRLs), E =

direction indicators;

❒replace the blown bulb: to remove

the bulb, press on it gently (1 fig. 112)

and at the same time turn it

anticlockwise (2);❒insert the new bulb, by pressing it fig.

112 and turning it clockwise, making

sure that it locks correctly;

❒then insert the bulb and bulb holder

units in their respective housings and

turn them anticlockwise (right side) and

clockwise (left side), ensuring that

they are locked correctly;

❒reconnect the electrical connectors;

❒finally, refit flap B fig. 109, completely

tightening fixing screws A.

Fog lights

To replace the bulbs proceed as

follows:

❒steer the wheels completely;

❒using the screwdriver, undo screws A

fig. 113 and remove flap B;

❒using tab C fig. 114, remove

electrical connector D;❒turn the bulb and bulb holder

assembly E fig. 114 anticlockwise and

then replace the bulb;

❒fit the new bulb and bulb holder

assembly, ensuring that it locks

correctly;

❒reconnect the electrical connector;

❒finally, refit flap B fig. 113, completely

tightening fixing screws A.

Side direction indicators

Side direction indicators on door

mirrors

(where provided)

For bulb replacement, contact a Jeep

Dealership.

Rear upper light cluster

This contains the bulbs for the side

lights, brake lights and direction

indicators.

111J0A0263C

112J0A0264C

113J0A0211C

114J0A0301C

127

Page 132 of 212

WARNING

133)Before replacing the bulb, wait for the

exhaust ducts to cool down: RISK OF

BURNS!

134)Changes or repairs to the electrical

system carried out incorrectly and without

due consideration for the technical

specifications of the system may lead to

malfunctioning and generate a fire hazard.

135)Halogen bulbs contain pressurised

gas. If they break, glass fragments could fly

everywhere.

WARNING

52)Halogen bulbs must be handled by

holding the metallic part only. Touching the

transparent part of the bulb with your

fingers may reduce the intensity of the

emitted light and even reduce the lifespan

of the bulb. In the case of accidental

contact, rub the lamp with a cloth and

spirit and leave to dry.

REPLACING FUSES

INTRODUCTION

136) 137) 138) 139) 140)

53) 54)

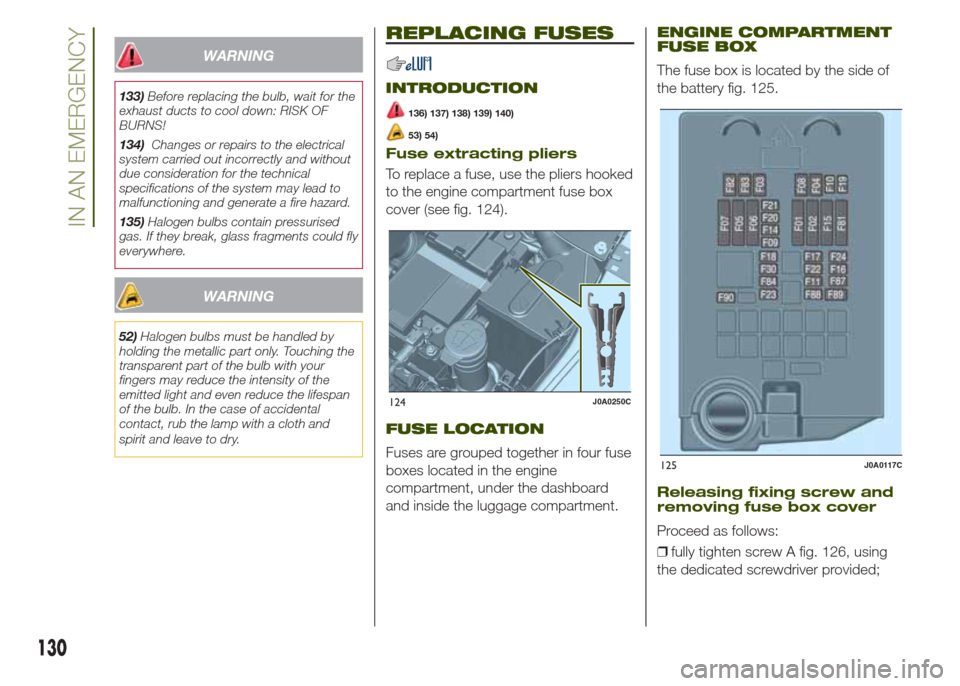

Fuse extracting pliers

To replace a fuse, use the pliers hooked

to the engine compartment fuse box

cover (see fig. 124).

FUSE LOCATION

Fuses are grouped together in four fuse

boxes located in the engine

compartment, under the dashboard

and inside the luggage compartment.

ENGINE COMPARTMENT

FUSE BOX

The fuse box is located by the side of

the battery fig. 125.

Releasing fixing screw and

removing fuse box cover

Proceed as follows:

❒fully tighten screw A fig. 126, using

the dedicated screwdriver provided;

124J0A0250C

125J0A0117C

130

IN AN EMERGENCY

Page 133 of 212

❒slowly rotate the screw anticlockwise,

until resistance is encountered (do not

overtighten);

❒slowly release the screw;

❒opening is indicated by the entire

screw head coming out of its housing;

❒remove cover B fig. 126, sliding it

completely upwards, as indicated in the

figure.

The number identifying the electrical

component corresponding to each fuse

is shown on the cover. After replacing

a fuse, make sure that you have closed

cover B correctly.

Fitting fuse box cover and

locking screw

Proceed as follows:

❒fix cover B fig. 126 to the box

correctly, sliding it down completely

from the top;❒fully tighten screw A fig. 126, using

the dedicated screwdriver provided;

❒slowly rotate the screw clockwise,

until resistance is encountered (do not

overtighten);

❒slowly release the screw;

❒closure is indicated by the securing

of the entire screw head in its housing.

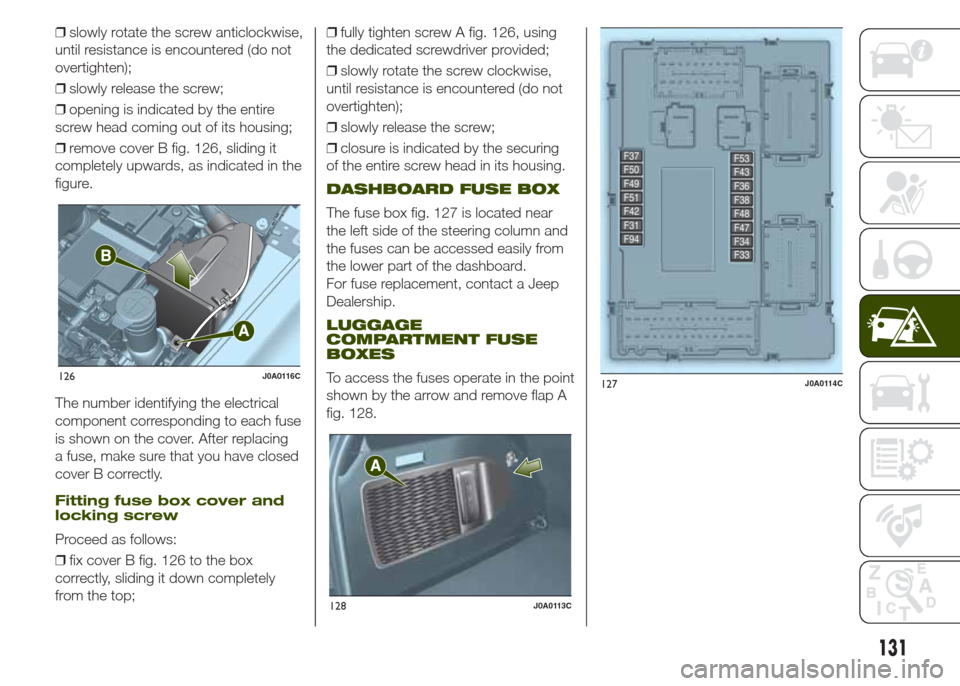

DASHBOARD FUSE BOX

The fuse box fig. 127 is located near

the left side of the steering column and

the fuses can be accessed easily from

the lower part of the dashboard.

For fuse replacement, contact a Jeep

Dealership.

LUGGAGE

COMPARTMENT FUSE

BOXES

To access the fuses operate in the point

shown by the arrow and remove flap A

fig. 128.126J0A0116C

128J0A0113C

127J0A0114C

131

Page 138 of 212

❒remove the fixing device for the jack

and the spare wheel;

❒remove the wheel chock;

❒remove the jack unit and the key for

removing the bolts from the spare

wheel. Turn the screw of the jack to

loosen the key and separate it from the

jack assembly;

❒take the spare wheel out of the

luggage compartment.

Tool box (where provided)

On versions with spare wheel there

is also, inside the luggage compartment

(right side), a tool box secured to the

luggage compartment carpet with

dedicated fastenings.

Inside the tool box are fig. 133:

❒A: the jack;

❒B: the screwdriver;

❒C: the emergency refuelling adaptor;

❒D: the wheel locating pin (where

provided, to use during the spare wheel

fitting operation);

❒E: special anti-theft nut (where

provided, to use during the wheel bolt

fitting/removal operation);

❒F: a chock for locking the wheels;

❒G: the tow hook;

❒H: the key for removing/tightening the

wheel bolts and operating the jack;❒I: the Allen key for emergency sun

roof operation (where provided).

Important information about

the jack

Please note that:

❒the weight of the jack is 2.8 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired: in the

event of a fault it must be replaced by

another original one;❒no tool other than its cranking device

may be fitted on the jack.

Then proceed as follows:

❒should it be necessary to stop the

vehicle on a road with a gradient,

especially a very high one, or on an

unstable surface, take chock A and fold

it out, as shown in the diagram in fig.

134;

❒alert any bystander that the vehicle is

about to be raised: all persons should

be kept away from the vehicle and

nobody must touch it until it has been

lowered. Nor should any occupant

remain in the vehicle;

❒if the vehicle has alloy wheels, where

the hub cap covers the bolts, use the

key with great care to remove the

hub cap before raising the vehicle;

A

C

B

D

E

I

F

G

H

133J0A0226C

134J0A0157C

136

IN AN EMERGENCY

Page 148 of 212

163)The front and rear tow hooks should

be used only for emergencies on the road.

You are allowed to tow the vehicle for

short distances using an appropriate

device in accordance with the highway

code (a rigid bar), to move the vehicle on

the road in readiness for towing or

transport via a breakdown vehicle. Tow

hooks MUST NOT be used to tow vehicles

off the road or where there are obstacles

and/or for towing operations using ropes or

other non-rigid devices. Respecting the

above conditions, towing must take place

with two vehicles (one towing, the other

towed) aligned as much as possible along

the same centre line.BROKEN-DOWN

VEHICLE TOWING

It is recommended to tow the vehicle

with all four wheels lifted from the

ground on the platform of a rescue

vehicle.

VERSIONS WITH FOUR-WHEEL

DRIVE (4WD) AND AUTOMATIC

TRANSMISSION

IMPORTANT Avoid lifting the front (or

rear) wheels only. Lifting the front (or

rear) wheels only while towing might

damage the transmission or the transfer

unit.

IMPORTANT If a vehicle is towed

without complying with the above

requirements, the transmission and/or

the transfer unit might be seriously

damaged. Damage due to an incorrect

towing will not be covered by the

warranty.

146

IN AN EMERGENCY