warning light JEEP RENEGADE 2023 Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: RENEGADE, Model: JEEP RENEGADE 2023Pages: 364, PDF Size: 18.65 MB

Page 290 of 364

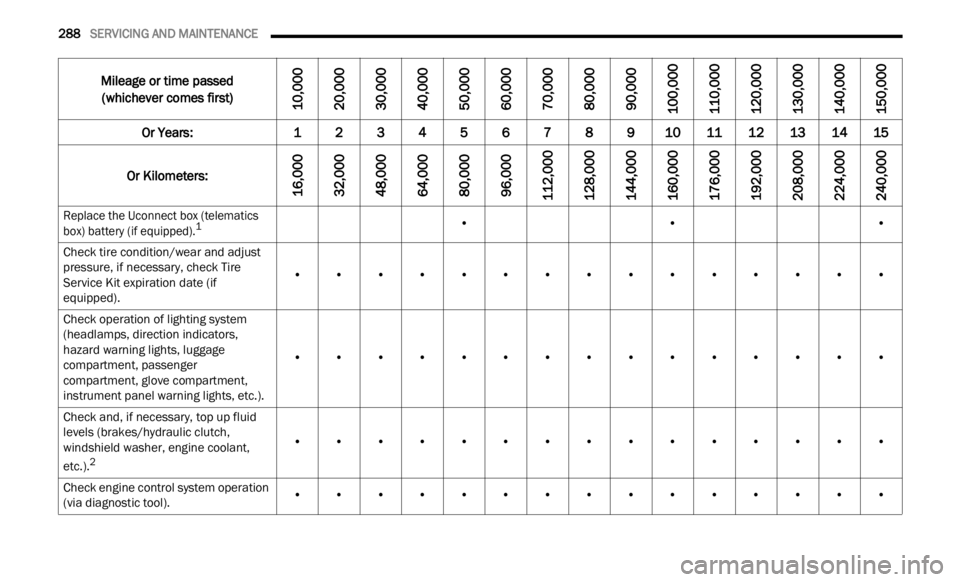

288 SERVICING AND MAINTENANCE

Mileage or time passed

(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 12345678910 1112131415

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Replace the Uconnect box (telematics

box) battery (if equipped).1

• ••

Check tire condition/wear and adjust

press u

re, if necessary, check Tire

Service Kit expiration date (if

equipped). •

••••••••••••••

Check operation of lighting system

(head l

amps, direction indicators,

hazard warning lights, luggage

compartment, passenger

compartment, glove compartment,

instrument panel warning lights, etc.). •

••••••••••••••

Check and, if necessary, top up fluid

l evel

s

(brakes/hydraulic clutch,

windshield washer, engine coolant,

etc.).

2

• ••••••••••••••

Check engine control system operation

(via d

iagnostic tool). •

••••••••••••••

Page 293 of 364

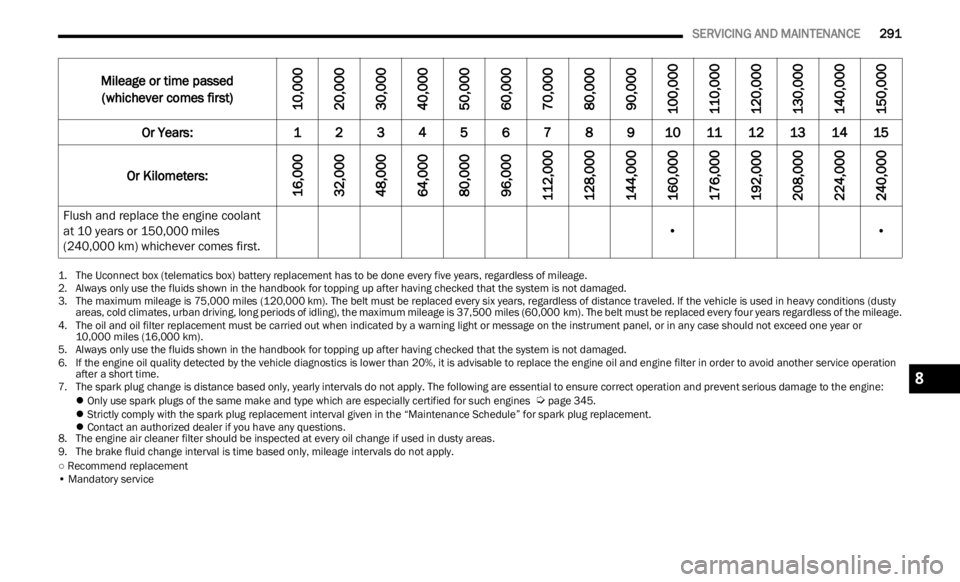

SERVICING AND MAINTENANCE 291

○ Recommend replacement

• Mandatory service

Flush and replace the engine coolant

at 10 years or 150,000 miles

(240,000 km) whichever comes first. •

•

1. The Uconnect box (telematics box) battery replacement has to be done every five years, regardless of mileage.2. Always only use the fluids shown in the handbook for topping up after having checked that the system is not damaged.

3. The maximum mileage is 75,000 mile s (120,000 km). The belt must be replaced every six years, regardless of distance traveled. If the vehicle is used in heavy conditions (dusty

areas,

cold climates, urban driving, long periods of idling), the maximum mileage is 37,500 miles (60,000 km). The belt must be replaced every four years regardless of the mileage.

4. The oil and oil filter replacement must be carried out when indicated by a warning light or message on the instrument panel, or in any case should not exceed one year or

10,0 0

0 miles (16,000 km).

5. Always only use the fluids shown in the handbook for topping up after having checked that the system is not damaged.

6. If

the engine oil quality detected by the vehicle diagnostics is lower than 20%, it is advisable to replace the engine oil and engine filter in order to avoid another service operation

afte r

a short time.

7. The spark plug change is distance based only, yearly intervals do not apply. The following are essential to ensure correct operation and prevent serious damage to the engine:

Only use spark plugs of the same make and type which are especially certified for such engines

Ú page 345 .

Strictly comply with the spark plug replacement interval given in the “Maintenance Schedule” for spark plug replacement.

Contact an authorized dealer if you have any questions.

8. Th e

engine air cleaner filter should be inspected at every oil change if used in dusty areas.

9. The brake fluid change interval is time based only, mileage intervals do not apply.

Mileage or time passed

(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

8

Page 304 of 364

302 SERVICING AND MAINTENANCE

(Continued)

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces-

sary, install ONLY the correct type thermostat.

O ther

designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically Ú page 287.

Brake Master Cylinder

The fluid level in the master cylinder should be

checked when performing under hood services, or

immediately if the Brake Warning Light is on.

Be sure to clean the top of the master cylinder area

before

removing the cap. If necessary, add fluid to

bring the fluid level up to the requirements

described on the brake fluid reservoir. Fluid level

can be expected to fall as the brake pads wear. The

brake fluid level should be checked when the pads

are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.

Use only manufacturer's recommended brake fluid

Ú page 345.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. Riding

the brakes may also reduce braking capacity in

an emergency.WARNING!

Use only manufacturer’s recommended brake

fluid

Ú page 345. Using the wrong type of

brake fluid can severely damage your brake

system

and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

CAUTION!

Use of improper brake fluids will affect overall

clutch system performance. Improper brake

fluids may damage the clutch system resulting in

loss of clutch function and the ability to shift the

transmission.

WARNING!

Page 310 of 364

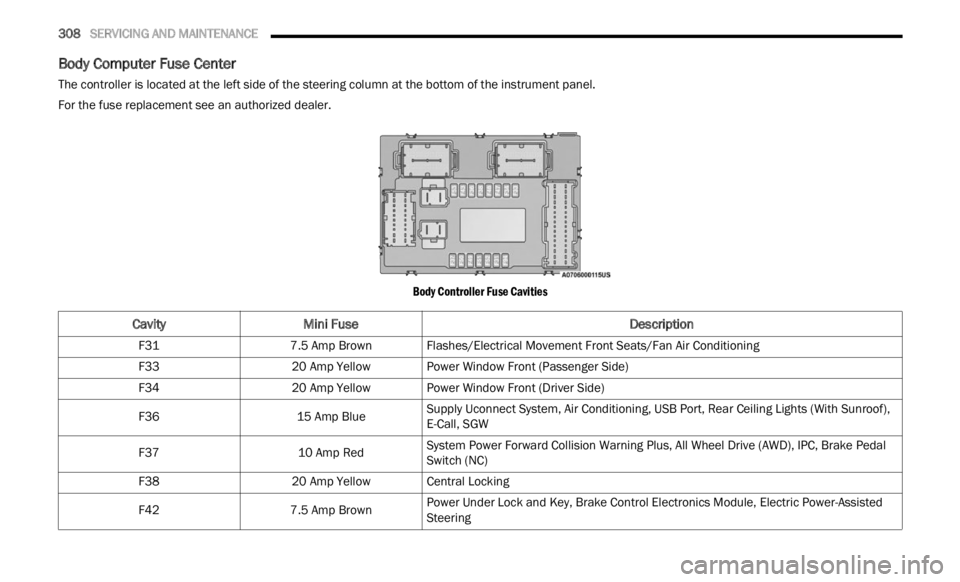

308 SERVICING AND MAINTENANCE

Body Computer Fuse Center

The controller is located at the left side of the steering column at the bottom of the instrument panel.

For the fuse replacement see an authorized dealer.

Body Controller Fuse Cavities

CavityMini Fuse Description

F317.5 Amp BrownFlashes/Electrical Movement Front Seats/Fan Air Conditioning

F33 20 Amp YellowPower Window Front (Passenger Side)

F34 20 Amp YellowPower Window Front (Driver Side)

F36 15 Amp BlueSupply Uconnect System, Air Conditioning, USB Port, Rear Ceiling Lights (With Sunroof),

E-Call

, SGW

F37 10 Amp RedSystem Power Forward Collision Warning Plus, All Wheel Drive (AWD), IPC, Brake Pedal

Switc

h

(NC)

F38 20 Amp YellowCentral Locking

F42 7.5 Amp BrownPower Under Lock and Key, Brake Control Electronics Module, Electric Power-Assisted

Steer

i

ng

Page 311 of 364

SERVICING AND MAINTENANCE 309

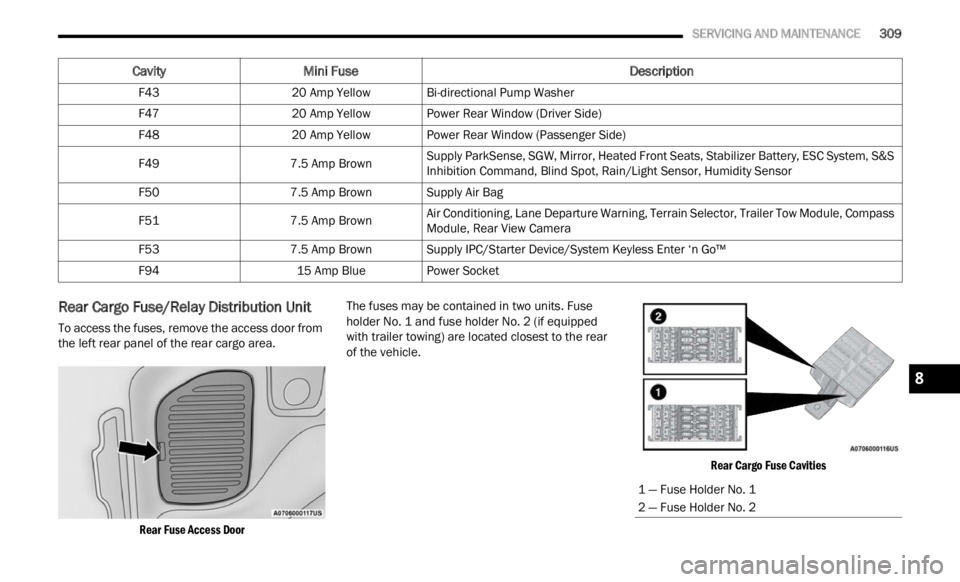

Rear Cargo Fuse/Relay Distribution Unit

To access the fuses, remove the access door from

the left rear panel of the rear cargo area.

Rear Fuse Access Door

The fuses may be contained in two units. Fuse

holder

No. 1 and fuse holder No. 2 (if equipped

with trailer towing) are located closest to the rear

of the vehicle.

Rear Cargo Fuse Cavities

F43

20 Amp YellowBi-directional Pump Washer

F47 20 Amp YellowPower Rear Window (Driver Side)

F48 20 Amp YellowPower Rear Window (Passenger Side)

F49 7.5 Amp BrownSupply ParkSense, SGW, Mirror, Heated Front Seats, Stabilizer Battery, ESC System, S&S

Inhib

i

tion Command, Blind Spot, Rain/Light Sensor, Humidity Sensor

F50 7.5 Amp BrownSupply Air Bag

F51 7.5 Amp BrownAir Conditioning, Lane Departure Warning, Terrain Selector, Trailer Tow Module, Compass

Module

,

Rear View Camera

F53 7.5 Amp BrownSupply IPC/Starter Device/System Keyless Enter ‘n Go™

F94 15 Amp BluePower Socket

Cavity Mini Fuse Description

1 — Fuse Holder No. 1

2 — Fuse Holder No. 2

8

Page 315 of 364

SERVICING AND MAINTENANCE 313

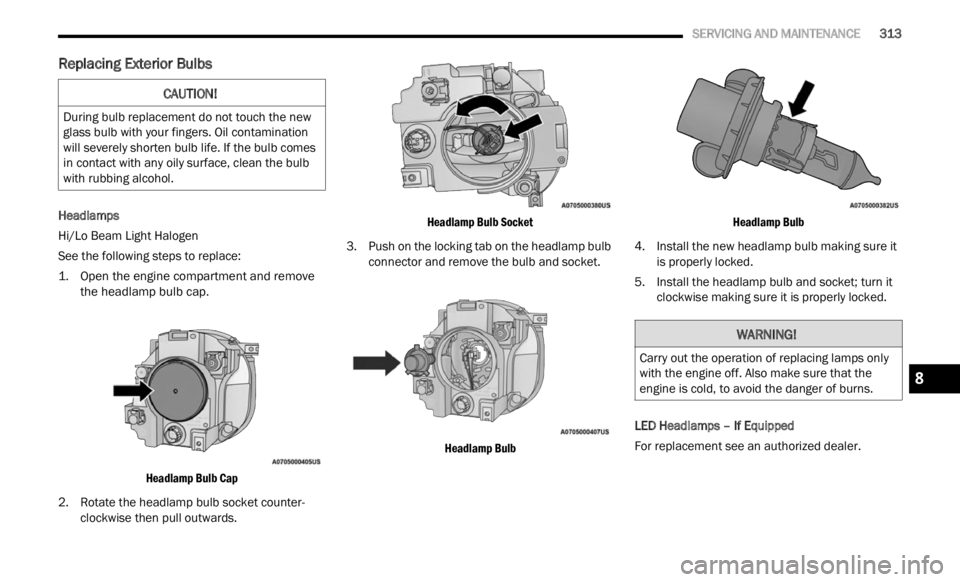

Replacing Exterior Bulbs

Headlamps

Hi/Lo Beam Light Halogen

See the following steps to replace:

1. O

pen the engine compartment and remove

the he a

dlamp bulb cap.

Headlamp Bulb Cap

2. Rotate the headlamp bulb socket counter -

clock w

ise then pull outwards.

Headlamp Bulb Socket

3. P ush on the locking tab on the headlamp bulb

conne c

tor and remove the bulb and socket.

Headlamp Bulb Headlamp Bulb

4. Install the new headlamp bulb making sure it is pr operly locked.

5. Install the headlamp bulb and socket; turn it clockw

ise making sure it is properly locked.

LED Headlamps – If Equipped

For replacement see an authorized dealer.

CAUTION!

During bulb replacement do not touch the new

glass bulb with your fingers. Oil contamination

will severely shorten bulb life. If the bulb comes

in contact with any oily surface, clean the bulb

with rubbing alcohol.

WARNING!

Carry out the operation of replacing lamps only

with the engine off. Also make sure that the

engine is cold, to avoid the danger of burns.

8

Page 323 of 364

SERVICING AND MAINTENANCE 321

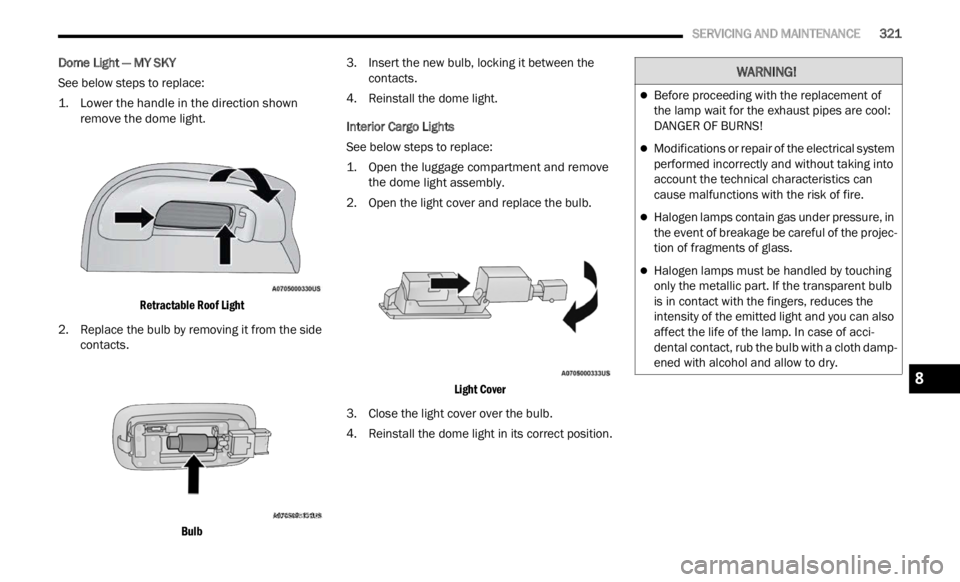

Dome Light — MY SKY

See below steps to replace:

1. L

ower the handle in the direction shown

remove

the dome light.

Retractable Roof Light

2. Replace the bulb by removing it from the side conta c

ts.

Bulb

3. I

nsert the new bulb, locking it between the

c on t

a c

ts.

4. Reinstall the dome light.

Inter

ior Cargo Lights

See below steps to replace:

1. Open the luggage compartment and remove the d o

me light assembly.

2. Open the light cover and replace the bulb.

Light

Cover

3. Close the light cover over the bulb.

4. R ein

stall the dome light in its correct position.

WARNING!

Before proceeding with the replacement of

the lamp wait for the exhaust pipes are cool:

DANGER OF BURNS!

Modifications or repair of the electrical system

performed incorrectly and without taking into

account the technical characteristics can

cause malfunctions with the risk of fire.

Halogen lamps contain gas under pressure, in

the event of breakage be careful of the projec -

tion of fragments of glass.

Halogen lamps must be handled by touching

only the metallic part. If the transparent bulb

is in contact with the fingers, reduces the

intensity of the emitted light and you can also

affect the life of the lamp. In case of acci -

dental contact, rub the bulb with a cloth damp -

ened with alcohol and allow to dry.

8

Page 334 of 364

332 SERVICING AND MAINTENANCE

Keep dismounted tires in a cool, dry place with as

little exposure to light as possible. Protect tires

from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of

many characteristics. They should be inspected

regularly for wear and correct cold tire inflation

pressures. The manufacturer strongly

recommends that you use tires equivalent to the

originals in size, quality and performance when

replacement is needed

Ú page 331. Refer to the

Tire and Loading Information placard or the

Vehic l

e Certification Label for the size designation

of your tire. The Load Index and Speed Symbol for

your tire will be found on the original equipment

tire sidewall.

See the Tire Sizing Chart example for more

inform a

tion relating to the Load Index and Speed

Symbol of a tire Ú page 323.

It is recommended to replace the two front tires or

two re a

r tires as a pair. Replacing just one tire can

seriously affect your vehicle’s handling. If you ever

replace a wheel, make sure that the wheel’s

specifications match those of the original wheels.

It is recommended you contact an authorized tire

deale r

or original equipment dealer with any

questions you may have on tire specifications or capability. Failure to use equivalent replacement

tires may adversely affect the safety, handling, and

ride of your vehicle.

TIRE TYPES

All Season Tires — If Equipped

All Season tires provide traction for all seasons

(Spring, Summer, Autumn, and Winter). Traction

levels may vary between different all season tires.

All season tires can be identified by the M+S, M&S,

M/S or MS designation on the tire sidewall. Use all

season tires only in sets of four; failure to do so

may adversely affect the safety and handling of

your vehicle.

Summer Or Three Season Tires —

If Equipped

Summer tires provide traction in both wet and dry

conditions, and are not intended to be driven in

snow or on ice. If your vehicle is equipped with

Summer tires, be aware these tires are not

designed for Winter or cold driving conditions.

Install Winter tires on your vehicle when ambient

temperatures are less than 40°F (5°C) or if roads

are covered with ice or snow. For more

information, contact an authorized dealer.

WARNING!

Do not use a tire, wheel size, load rating, or

speed rating other than that specified for your

vehicle. Some combinations of unapproved

tires and wheels may change suspension

dimensions and performance characteristics,

resulting in changes to steering, handling, and

braking of your vehicle. This can cause unpre -

dictable handling and stress to steering and

suspe n

sion components. You could lose

control and have a collision resulting in

serious injury or death. Use only the tire and

wheel sizes with load ratings approved for

your vehicle.

Never use a tire with a smaller load index or

capacity, other than what was originally

equipped on your vehicle. Using a tire with a

smaller load index could result in tire over -

loading and failure. You could lose control and

h ave a

collision.

Failure to equip your vehicle with tires having

adequate speed capability can result in

sudden tire failure and loss of vehicle control.

CAUTION!

Replacing original tires with tires of a different

size may result in false speedometer and

odometer readings.

Page 343 of 364

341

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is stamped on a plate located on the left

front corner of the instrument panel cover, which is

visible from outside the car through the

windshield.

Vehicle Identification Number (VIN)

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic brake

systems. If either of the two hydraulic systems lose

normal capability, the remaining system will still

function. However, there will be some loss of

overall braking effectiveness. You may notice

increased pedal travel during application, greater

pedal force required to slow or stop, and potential

activation of the Brake Warning Light.

In the event power assist is lost for any reason (i.e.,

repea t

ed brake applications with the engine OFF)

the brakes will still function. However, the effort

required to brake the vehicle will be much greater

than that required with the power system

operating.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts should

be torqued using a properly calibrated torque

wrench using a six-sided (hex) deep wall socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Wheel Bolt Torque**Wheel Bolt Size Wheel Bolt

Socket Size

89 Ft-Lb

(120 N·

m) M12 x 1.25

17 mm

9

Page 344 of 364

342 TECHNICAL SPECIFICATIONS

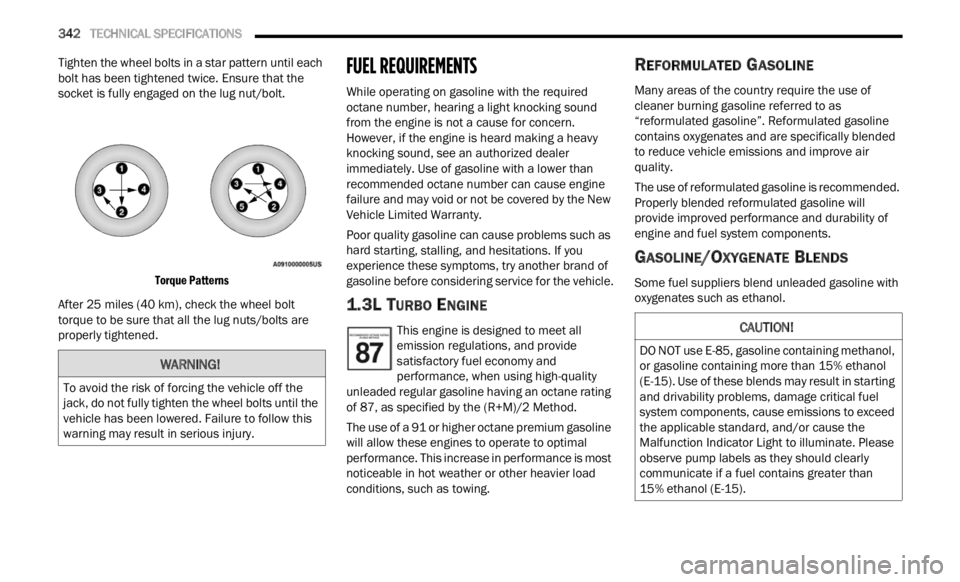

Tighten the wheel bolts in a star pattern until each

bolt has been tightened twice. Ensure that the

socket is fully engaged on the lug nut/bolt.

Torque Patterns

After 25 miles (40 km), check the wheel bolt

torque

to be sure that all the lug nuts/bolts are

properly tightened.

FUEL REQUIREMENTS

While operating on gasoline with the required

octane number, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see an authorized dealer

immediately. Use of gasoline with a lower than

recommended octane number can cause engine

failure and may void or not be covered by the New

Vehicle Limited Warranty.

Poor quality gasoline can cause problems such as

hard s

tarting, stalling, and hesitations. If you

experience these symptoms, try another brand of

gasoline before considering service for the vehicle.

1.3L TURBO ENGINE

This engine is designed to meet all

emission regulations, and provide

s a t

is

f

actory fuel economy and

performance, when using high-quality

unleaded regular gasoline having an octane rating

of 87, as specified by the (R+M)/2 Method.

The use of a 91 or higher octane premium gasoline

will a

llow these engines to operate to optimal

performance. This increase in performance is most

noticeable in hot weather or other heavier load

conditions, such as towing.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner burning gasoline referred to as

“reformulated gasoline”. Reformulated gasoline

contains oxygenates and are specifically blended

to reduce vehicle emissions and improve air

quality.

The use of reformulated gasoline is recommended.

Proper l

y blended reformulated gasoline will

provide improved performance and durability of

engine and fuel system components.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as ethanol.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not fully tighten the wheel bolts until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

CAUTION!

DO NOT use E-85, gasoline containing methanol,

or gasoline containing more than 15% ethanol

(E-15). Use of these blends may result in starting

and drivability problems, damage critical fuel

system components, cause emissions to exceed

the applicable standard, and/or cause the

Malfunction Indicator Light to illuminate. Please

observe pump labels as they should clearly

communicate if a fuel contains greater than

15% ethanol (E-15).