spare tire JEEP WAGONEER 2023 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: WAGONEER, Model: JEEP WAGONEER 2023Pages: 396, PDF Size: 15.17 MB

Page 298 of 396

296IN CASE OF EMERGENCY

(Continued)

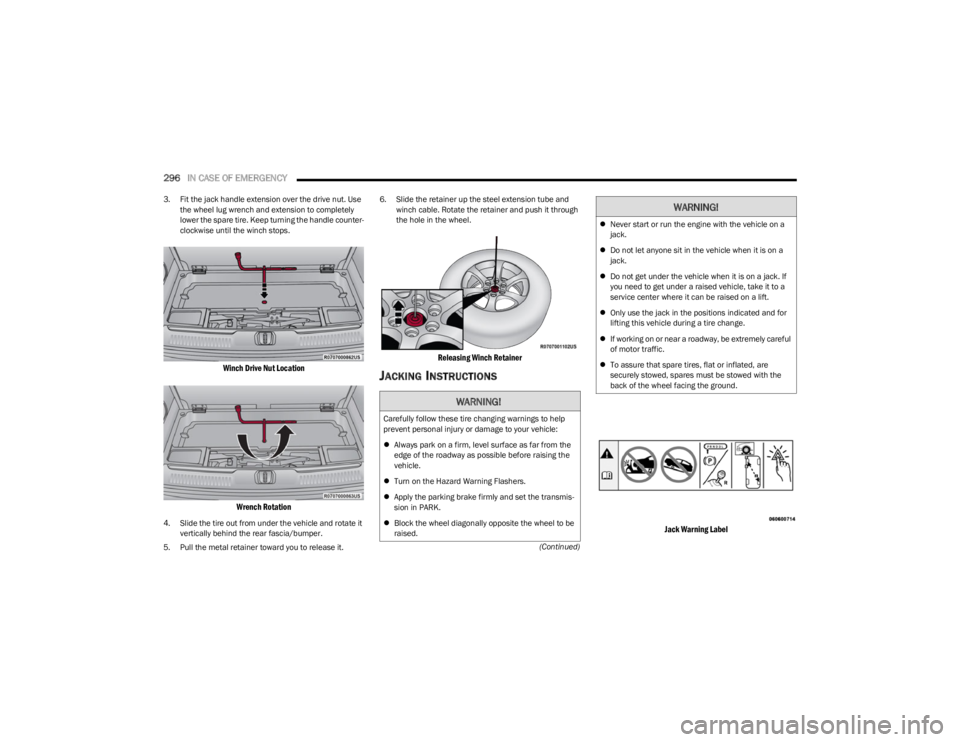

3. Fit the jack handle extension over the drive nut. Use

the wheel lug wrench and extension to completely

lower the spare tire. Keep turning the handle counter -

clockwise until the winch stops.

Winch Drive Nut Location

Wrench Rotation

4. Slide the tire out from under the vehicle and rotate it vertically behind the rear fascia/bumper.

5. Pull the metal retainer toward you to release it. 6. Slide the retainer up the steel extension tube and

winch cable. Rotate the retainer and push it through

the hole in the wheel.

Releasing Winch Retainer

JACKING INSTRUCTIONS

Jack Warning Label

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the transmis -

sion in PARK.

Block the wheel diagonally opposite the wheel to be

raised.

Never start or run the engine with the vehicle on a

jack.

Do not let anyone sit in the vehicle when it is on a

jack.

Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

If working on or near a roadway, be extremely careful

of motor traffic.

To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

back of the wheel facing the ground.

WARNING!

23_WS_OM_EN_USC_t.book Page 296

Page 300 of 396

298IN CASE OF EMERGENCY

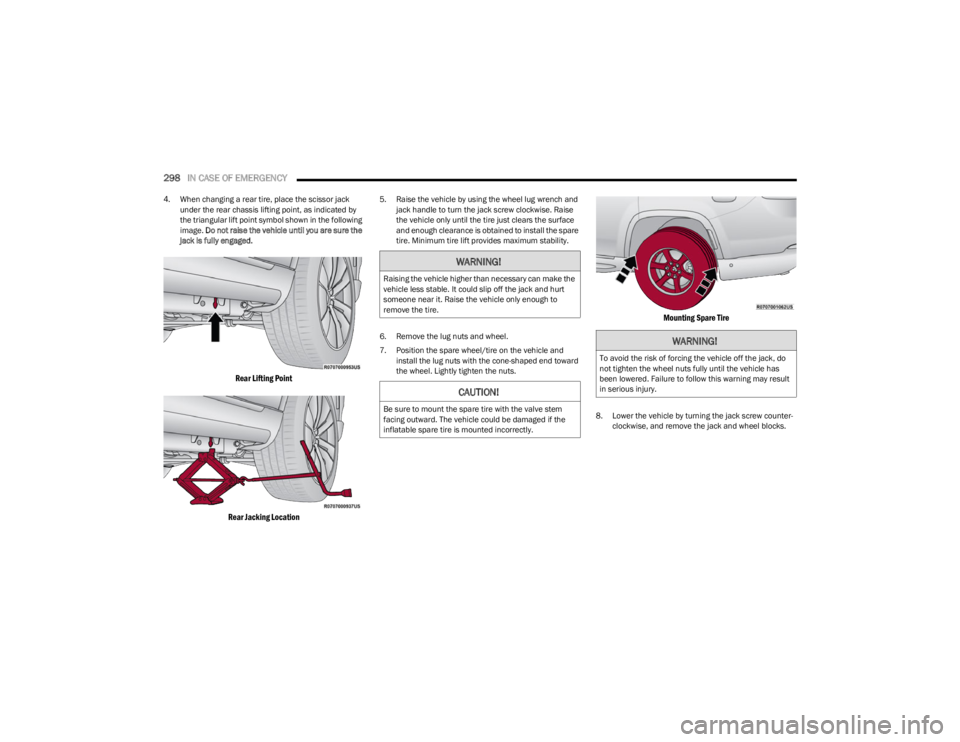

4. When changing a rear tire, place the scissor jack

under the rear chassis lifting point, as indicated by

the triangular lift point symbol shown in the following

image. Do not raise the vehicle until you are sure the

jack is fully engaged.

Rear Lifting Point

Rear Jacking Location

5. Raise the vehicle by using the wheel lug wrench and jack handle to turn the jack screw clockwise. Raise

the vehicle only until the tire just clears the surface

and enough clearance is obtained to install the spare

tire. Minimum tire lift provides maximum stability.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the vehicle and install the lug nuts with the cone-shaped end toward

the wheel. Lightly tighten the nuts.

Mounting Spare Tire

8. Lower the vehicle by turning the jack screw counter -

clockwise, and remove the jack and wheel blocks.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

inflatable spare tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may result

in serious injury.

23_WS_OM_EN_USC_t.book Page 298

Page 301 of 396

IN CASE OF EMERGENCY299

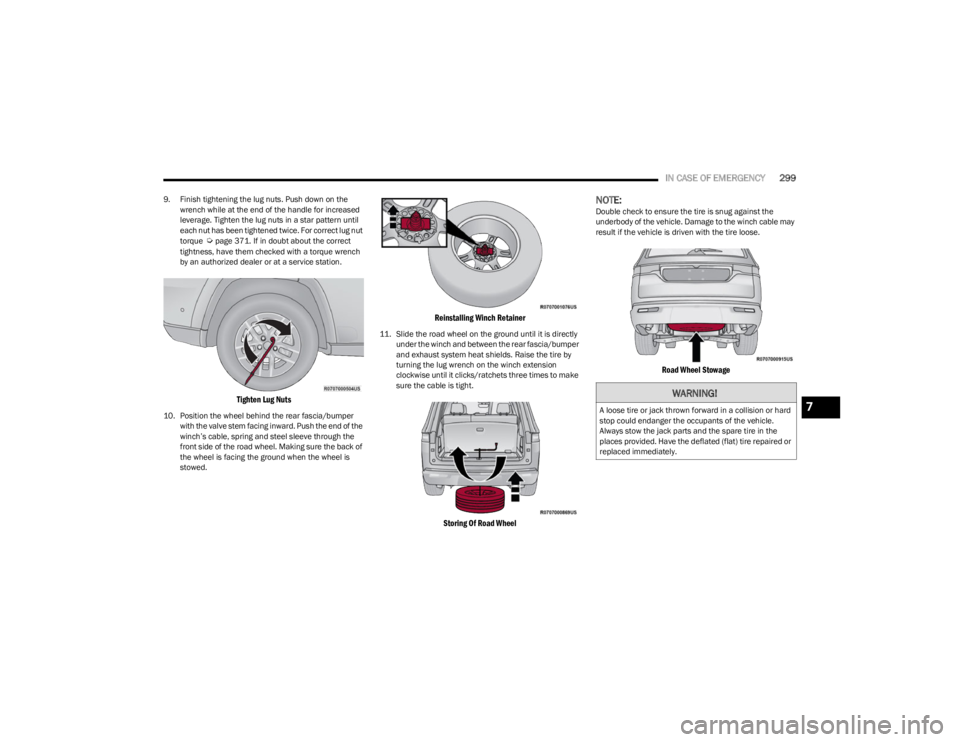

9. Finish tightening the lug nuts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. For correct lug nut

torque

Úpage 371. If in doubt about the correct

tightness, have them checked with a torque wrench

by an authorized dealer or at a service station.

Tighten Lug Nuts

10. Position the wheel behind the rear fascia/bumper with the valve stem facing inward. Push the end of the

winch’s cable, spring and steel sleeve through the

front side of the road wheel. Making sure the back of

the wheel is facing the ground when the wheel is

stowed.

Reinstalling Winch Retainer

11. Slide the road wheel on the ground until it is directly under the winch and between the rear fascia/bumper

and exhaust system heat shields. Raise the tire by

turning the lug wrench on the winch extension

clockwise until it clicks/ratchets three times to make

sure the cable is tight.

Storing Of Road Wheel

NOTE:Double check to ensure the tire is snug against the

underbody of the vehicle. Damage to the winch cable may

result if the vehicle is driven with the tire loose.

Road Wheel Stowage

WARNING!

A loose tire or jack thrown forward in a collision or hard

stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or

replaced immediately.7

23_WS_OM_EN_USC_t.book Page 299

Page 302 of 396

300IN CASE OF EMERGENCY

12. Lower the jack to the fully closed position.

13. Return the Jack and tools back into the jack storage

bin. Reinstall the jack storage cover by firmly pushing

down until the clips lock into position.

14. After 25 miles (40 km), check the lug nut torque with a torque wrench to ensure that all lug nuts are

properly seated against the wheel.

15. Have the road wheel and tire repaired as soon as possible and properly secure the spare tire, jack and

tool kit.

NOTE:Do not drive with the spare tire installed for more than

50 miles (80 km) at a max speed of 50 mph (80 km/h).

JUMP STARTING

If your vehicle has a discharged battery, it can be jump

started using a set of jumper cables and a battery in

another vehicle, or by using a portable battery booster

pack. Jump starting can be dangerous if done improperly,

so please follow the procedures in this section carefully.

NOTE:When using a portable battery booster pack, follow the

manufacturer's operating instructions and precautions.

PREPARATIONS FOR JUMP START

The battery in your vehicle is located in the front of the

engine compartment, behind the left headlight assembly.

Positive (+) Jump Starting Post

NOTE:The positive (+) battery post may be covered with a

protective cap. Lift up on the cap to gain access to the

positive battery post. Do not jump off fuses. Only jump

directly off positive post which has a positive (+) symbol on

or around the post.

See the following steps to prepare for jump starting:

1. Apply the parking brake, shift the automatic transmission into PARK (P) and turn the ignition OFF.

2. Turn off the heater, radio, and all electrical accessories.

3. If using another vehicle to jump start the battery, park the vehicle within the jumper cables’ reach, apply the

parking brake and make sure the ignition is OFF.

NOTE:Be sure that the disconnected cable ends do not touch

each other, or either vehicle, until properly connected for

jump starting.

WARNING!

Do not attempt jump starting if the battery is frozen. It

could rupture or explode and cause personal injury.

CAUTION!

Do not use a portable battery booster pack or any other

booster source with a system voltage greater than

12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

WARNING!

Do not allow vehicles to touch each other as this could

establish a ground connection and personal injury

could result.

23_WS_OM_EN_USC_t.book Page 300

Page 304 of 396

302IN CASE OF EMERGENCY

3. Disconnect the positive (+) end of the jumper cable

from the positive (+) post of the booster battery.

4. Disconnect the opposite end of the positive (+)

jumper cable from the positive (+) post of the

discharged vehicle.

5. Reinstall the protective cover over the positive (+)

post of the discharged vehicle.

If frequent jump starting is required to start your vehicle

have the battery and charging system tested at an

authorized dealer.

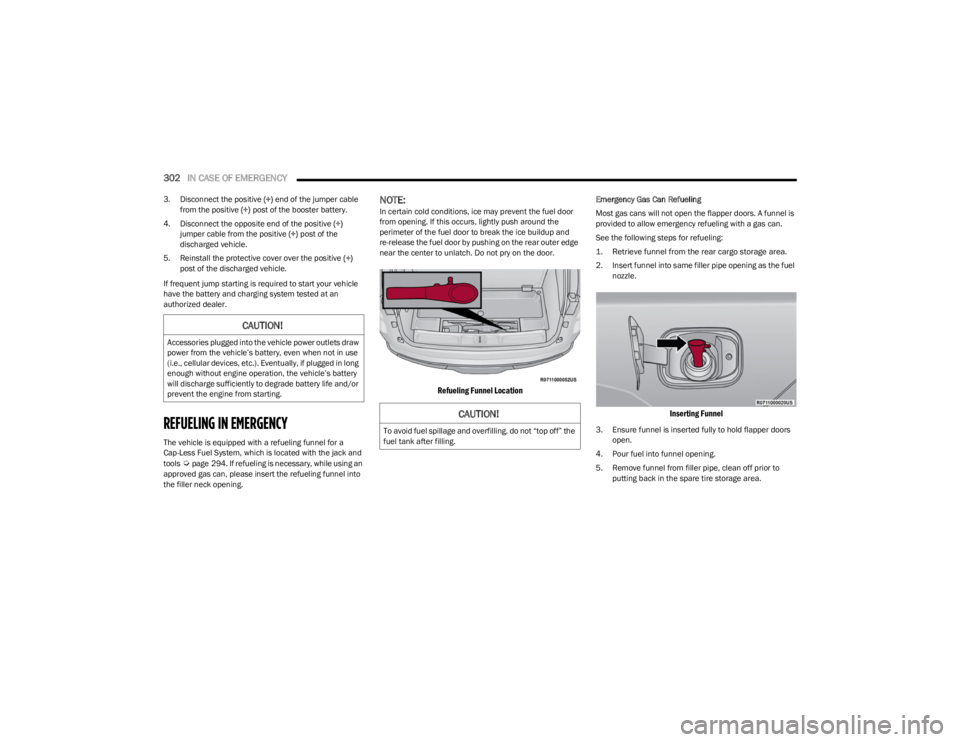

REFUELING IN EMERGENCY

The vehicle is equipped with a refueling funnel for a

Cap-Less Fuel System, which is located with the jack and

tools

Úpage 294. If refueling is necessary, while using an

approved gas can, please insert the refueling funnel into

the filler neck opening.

NOTE:In certain cold conditions, ice may prevent the fuel door

from opening. If this occurs, lightly push around the

perimeter of the fuel door to break the ice buildup and

re-release the fuel door by pushing on the rear outer edge

near the center to unlatch. Do not pry on the door.

Refueling Funnel Location

Emergency Gas Can Refueling

Most gas cans will not open the flapper doors. A funnel is

provided to allow emergency refueling with a gas can.

See the following steps for refueling:

1. Retrieve funnel from the rear cargo storage area.

2. Insert funnel into same filler pipe opening as the fuel nozzle.

Inserting Funnel

3. Ensure funnel is inserted fully to hold flapper doors open.

4. Pour fuel into funnel opening.

5. Remove funnel from filler pipe, clean off prior to putting back in the spare tire storage area.

CAUTION!

Accessories plugged into the vehicle power outlets draw

power from the vehicle’s battery, even when not in use

(i.e., cellular devices, etc.). Eventually, if plugged in long

enough without engine operation, the vehicle’s battery

will discharge sufficiently to degrade battery life and/or

prevent the engine from starting.

CAUTION!

To avoid fuel spillage and overfilling, do not “top off” the

fuel tank after filling.

23_WS_OM_EN_USC_t.book Page 302

Page 346 of 396

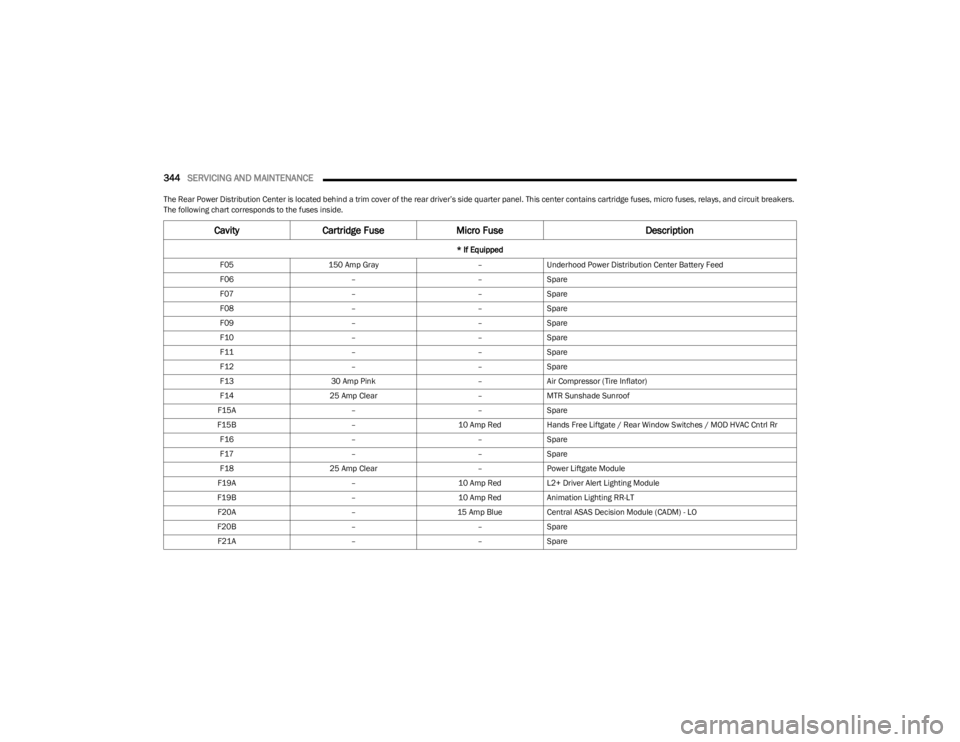

344SERVICING AND MAINTENANCE

The Rear Power Distribution Center is located behind a trim cover of the rear driver’s side quarter panel. This center contains cartridge fuses, micro fuses, relays, and circuit breakers.

The following chart corresponds to the fuses inside.

CavityCartridge Fuse Micro Fuse Description

* If Equipped

F05 150 Amp Gray –Underhood Power Distribution Center Battery Feed

F06 ––Spare

F07 ––Spare

F08 ––Spare

F09 ––Spare

F10 ––Spare

F11 ––Spare

F12 ––Spare

F13 30 Amp Pink –Air Compressor (Tire Inflator)

F14 25 Amp Clear –MTR Sunshade Sunroof

F15A ––Spare

F15B –10 Amp RedHands Free Liftgate / Rear Window Switches / MOD HVAC Cntrl Rr

F16 ––Spare

F17 ––Spare

F18 25 Amp Clear –Power Liftgate Module

F19A –10 Amp RedL2+ Driver Alert Lighting Module

F19B –10 Amp RedAnimation Lighting RR-LT

F20A –15 Amp BlueCentral ASAS Decision Module (CADM) - LO

F20B ––Spare

F21A ––Spare

23_WS_OM_EN_USC_t.book Page 344

Page 350 of 396

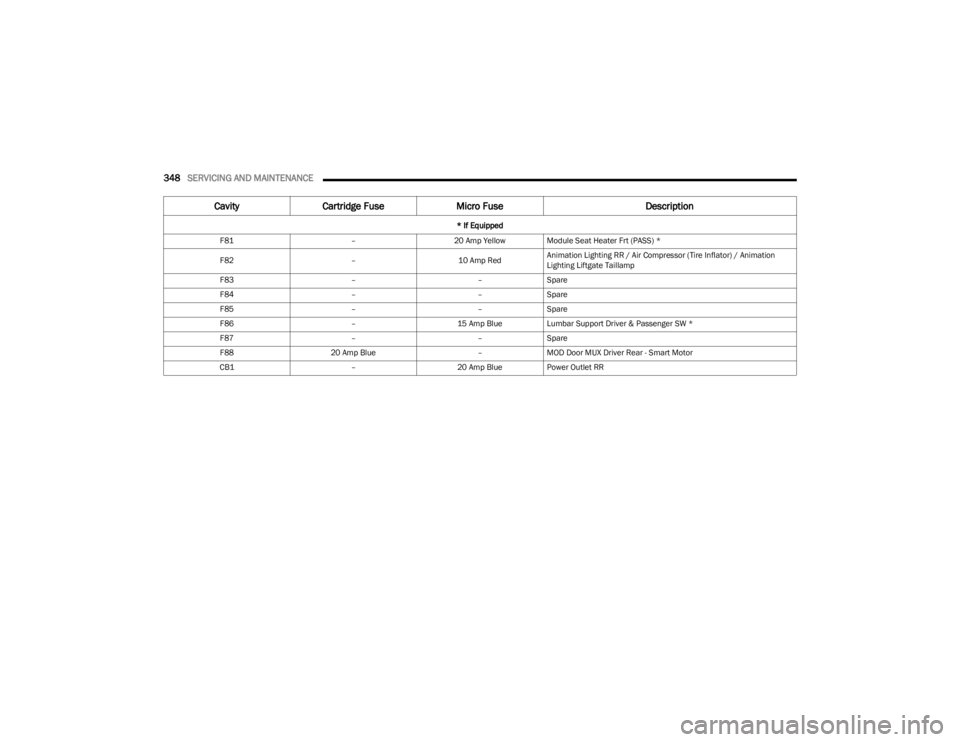

348SERVICING AND MAINTENANCE

F81 –20 Amp Yellow Module Seat Heater Frt (PASS) *

F82 –10 Amp RedAnimation Lighting RR / Air Compressor (Tire Inflator) / Animation

Lighting Liftgate Taillamp

F83 ––Spare

F84 ––Spare

F85 ––Spare

F86 –15 Amp BlueLumbar Support Driver & Passenger SW *

F87 ––Spare

F88 20 Amp Blue –MOD Door MUX Driver Rear - Smart Motor

CB1 –20 Amp BluePower Outlet RR

CavityCartridge Fuse Micro Fuse Description

* If Equipped

23_WS_OM_EN_USC_t.book Page 348

Page 351 of 396

SERVICING AND MAINTENANCE349

BULB REPLACEMENT

Replacement Bulbs, Names, And Part

Numbers

Your vehicle is equipped with LED lamps. In the event of a

light malfunction, please see an authorized dealer for LED

replacement.

TIRES

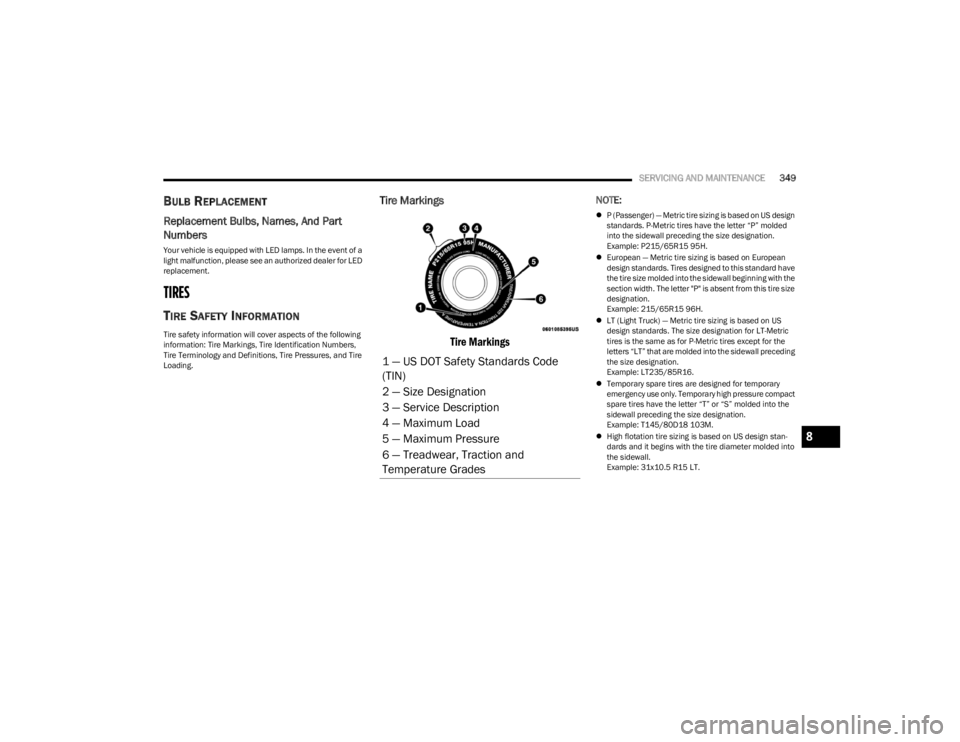

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the following

information: Tire Markings, Tire Identification Numbers,

Tire Terminology and Definitions, Tire Pressures, and Tire

Loading.

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US design

standards. P-Metric tires have the letter “P” molded

into the sidewall preceding the size designation.

Example: P215/65R15 95H.

European — Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with the

section width. The letter "P" is absent from this tire size

designation.

Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on US

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters “LT” that are molded into the sidewall preceding

the size designation.

Example: LT235/85R16.

Temporary spare tires are designed for temporary

emergency use only. Temporary high pressure compact

spare tires have the letter “T” or “S” molded into the

sidewall preceding the size designation.

Example: T145/80D18 103M.

High flotation tire sizing is based on US design stan -

dards and it begins with the tire diameter molded into

the sidewall.

Example: 31x10.5 R15 LT.

1 — US DOT Safety Standards Code

(TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and

Temperature Grades

8

23_WS_OM_EN_USC_t.book Page 349

Page 352 of 396

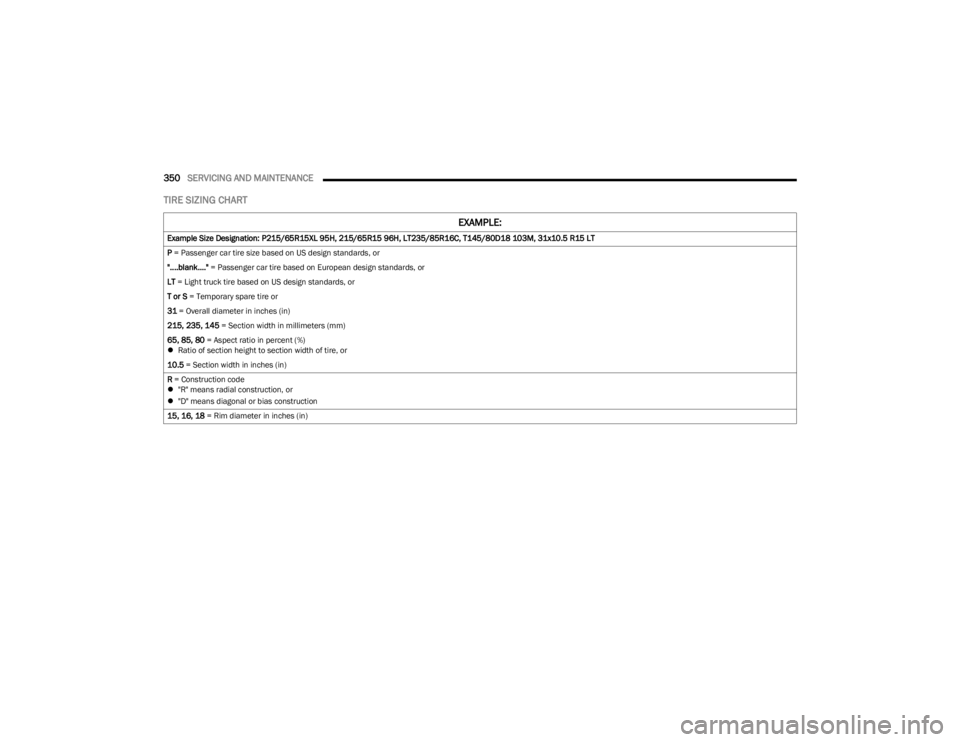

350SERVICING AND MAINTENANCE

TIRE SIZING CHART

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

23_WS_OM_EN_USC_t.book Page 350

Page 356 of 396

354SERVICING AND MAINTENANCE

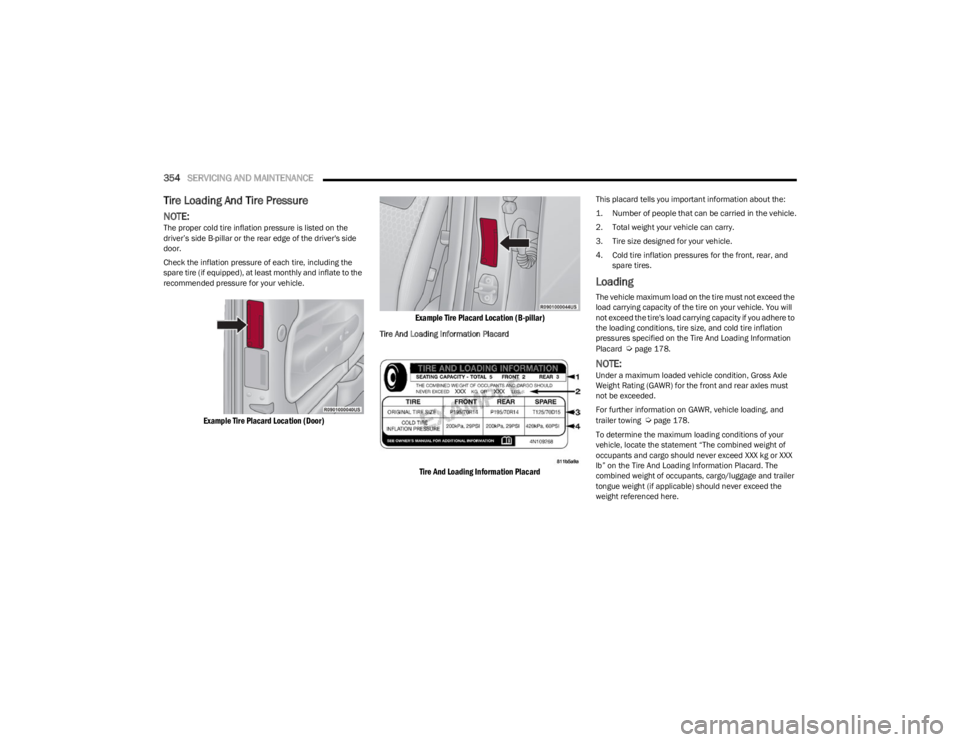

Tire Loading And Tire Pressure

NOTE:The proper cold tire inflation pressure is listed on the

driver’s side B-pillar or the rear edge of the driver's side

door.

Check the inflation pressure of each tire, including the

spare tire (if equipped), at least monthly and inflate to the

recommended pressure for your vehicle.

Example Tire Placard Location (Door) Example Tire Placard Location (B-pillar)

Tire And Loading Information Placard

Tire And Loading Information Placard

This placard tells you important information about the:

1. Number of people that can be carried in the vehicle.

2. Total weight your vehicle can carry.

3. Tire size designed for your vehicle.

4. Cold tire inflation pressures for the front, rear, and

spare tires.

Loading

The vehicle maximum load on the tire must not exceed the

load carrying capacity of the tire on your vehicle. You will

not exceed the tire's load carrying capacity if you adhere to

the loading conditions, tire size, and cold tire inflation

pressures specified on the Tire And Loading Information

Placard

Úpage 178.

NOTE:Under a maximum loaded vehicle condition, Gross Axle

Weight Rating (GAWR) for the front and rear axles must

not be exceeded.

For further information on GAWR, vehicle loading, and

trailer towing

Úpage 178.

To determine the maximum loading conditions of your

vehicle, locate the statement “The combined weight of

occupants and cargo should never exceed XXX kg or XXX

lb” on the Tire And Loading Information Placard. The

combined weight of occupants, cargo/luggage and trailer

tongue weight (if applicable) should never exceed the

weight referenced here.

23_WS_OM_EN_USC_t.book Page 354