spare tire JEEP WAGONEER 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: WAGONEER, Model: JEEP WAGONEER 2023Pages: 396, PDF Size: 15.17 MB

Page 8 of 396

6

SAFETY

SAFETY FEATURES........................................................... 239

Anti-Lock Brake System (ABS) ................................. 239Rear Seat Reminder Alert (RSRA) ............................ 240

Drowsy Driver Detection (DDD) — If Equipped ........ 240

Electronic Brake Control (EBC) System .................. 241

AUXILIARY DRIVING SYSTEMS ...................................... 247 Blind Spot Monitoring (BSM) .................................... 247

Forward Collision Warning (FCW)

With Mitigation .......................................................... 250

Tire Pressure Monitoring System (TPMS) ................ 252

OCCUPANT RESTRAINT SYSTEMS ................................ 256 Occupant Restraint Systems Features ................... 256Important Safety Precautions .................................. 256Seat Belt Systems .................................................... 257

Supplemental Restraint Systems (SRS) .................. 264Child Restraints ........................................................ 275

SAFETY TIPS ..................................................................... 287 Transporting Passengers .......................................... 287

Transporting Pets ...................................................... 287Connected Vehicles .................................................. 287

Safety Checks You Should Make Inside

The Vehicle ............................................................... 287

Periodic Safety Checks You Should Make

Outside The Vehicle .................................................. 289

Exhaust Gas .............................................................. 289Carbon Monoxide Warnings ..................................... 289

IN CASE OF EMERGENCY

HAZARD WARNING FLASHERS ..................................... 290

ASSIST AND SOS SYSTEM— IF EQUIPPED ................... 290

JACKING AND TIRE CHANGING...................................... 293 Preparations For Jacking ......................................... 293

Jack And Tools Location ........................................... 294Spare Tire Stowage................................................... 295

Spare Tire Removal .................................................. 295Jacking Instructions ................................................. 296

JUMP STARTING ............................................................. 300 Preparations For Jump Start .................................... 300Jump Starting Procedure.......................................... 301

REFUELING IN EMERGENCY........................................... 302

IF YOUR ENGINE OVERHEATS ........................................ 303

MANUAL PARK RELEASE .............................................. 303

FREEING A STUCK VEHICLE .......................................... 305

TOWING A DISABLED VEHICLE ..................................... 306 Rear-Wheel Drive Models......................................... 307

Four-Wheel Drive Models ......................................... 307

Emergency Tow Hooks — If Equipped ..................... 308

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS) .............................................................................. 308

EVENT DATA RECORDER (EDR) ..................................... 308

SERVICING AND MAINTENANCE

SCHEDULED SERVICING .................................................. 309 Maintenance Plan ..................................................... 310

ENGINE COMPARTMENT ................................................. 313 3.0L Engine................................................................ 313

5.7L Engine................................................................ 314

6.4L Engine................................................................ 315

Checking Oil Level — 3.0L Engines .......................... 316

Checking Oil Level — 5.7L & 6.4L Engines .............. 317

Adding Washer Fluid ................................................ 317

Maintenance-Free Battery ....................................... 318Pressure Washing ..................................................... 318

VEHICLE MAINTENANCE .................................................. 318 Engine Oil .................................................................. 319

Engine Oil Filter ....................................................... 319

Engine Air Cleaner Filter ........................................ 319Air Conditioner Maintenance ................................. 320

Accessory Drive Belt Inspection ............................... 323Body Lubrication ....................................................... 323

Windshield Wiper Blades ......................................... 324

Exhaust System ........................................................ 325

Cooling System .......................................................... 326

Brake System ........................................................... 328

Automatic Transmission ........................................... 329

Front/Rear Axle Fluid ............................................... 330Transfer Case ............................................................ 330Fuses .......................................................................... 331Bulb Replacement .................................................... 349

23_WS_OM_EN_USC_t.book Page 6

Page 9 of 396

7

TIRES ................................................................................. 349Tire Safety Information ............................................. 349

Tires — General Information ..................................... 357

Tire Types................................................................... 360

Spare Tires — If Equipped......................................... 361Wheel And Wheel Trim Care ..................................... 362

Snow Traction Devices ............................................. 364

Tire Rotation Recommendations ............................ 366

DEPARTMENT OF TRANSPORTATION UNIFORM

TIRE QUALITY GRADES ................................................... 366 Treadwear .................................................................. 367

Traction Grades ......................................................... 367

Temperature Grades................................................. 367

STORING THE VEHICLE.................................................... 368

BODYWORK ...................................................................... 368 Protection From Atmospheric Agents ...................... 368

Body And Underbody Maintenance ......................... 368Preserving The Bodywork ......................................... 368

INTERIORS ....................................................................... 369 Seats And Fabric Parts ............................................. 369

Plastic And Coated Parts .......................................... 369

Leather Surfaces....................................................... 370Glass Surfaces ......................................................... 370TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)..................... 371

BRAKE SYSTEM ............................................................... 371

WHEEL AND TIRE TORQUE SPECIFICATIONS .............. 371 Torque Specifications ............................................... 371

FUEL REQUIREMENTS ..................................................... 372 3.0L Standard Output Engine .................................. 372

3.0L High Output Engine .......................................... 3725.7L Engine ............................................................... 3726.4L Engine ............................................................... 373Reformulated Gasoline ............................................ 373

Materials Added To Fuel .......................................... 373Gasoline/Oxygenate Blends .................................... 373Do Not Use E-85 In Non-Flex Fuel Vehicles ............ 374

CNG And LP Fuel System Modifications.................. 374

Methylcyclopentadienyl Manganese

Tricarbonyl (MMT) In Gasoline ................................. 374

Fuel System Cautions ............................................... 374

FLUID CAPACITIES ........................................................... 375

ENGINE FLUIDS AND LUBRICANTS ............................... 376

CHASSIS FLUIDS AND LUBRICANTS ............................. 377

CUSTOMER ASSISTANCE

SUGGESTIONS FOR OBTAINING SERVICE FOR YOUR

VEHICLE ............................................................................378 Prepare For The Appointment .................................. 378

Prepare A List ............................................................ 378Be Reasonable With Requests ................................. 378

IF YOU NEED ASSISTANCE .............................................378 Roadside Assistance ................................................. 378

FCA US LLC Customer Center ................................... 379

Wagoneer Client Services Canada ........................... 379

Mexico ........................................................................ 380

Puerto Rico And US Virgin Islands............................ 380

Customer Assistance For The Hearing Or Speech

Impaired (TDD/TTY)................................................... 380

Service Contract ....................................................... 380

WARRANTY INFORMATION.............................................380

MOPAR® PARTS ..............................................................381

REPORTING SAFETY DEFECTS ......................................381 In The 50 United States And Washington, D.C........ 381

In Canada................................................................... 381

PUBLICATION ORDER FORMS .......................................381

CHANGE OF OWNERSHIP OR ADDRESS.......................382

GENERAL INFORMATION................................................. 382

23_WS_OM_EN_USC_t.book Page 7

Page 116 of 396

114GETTING TO KNOW YOUR INSTRUMENT PANEL

Tire Pressure Monitoring System (TPMS)

Warning Light

The warning light switches on and a message is

displayed to indicate that the tire pressure is

lower than the recommended value and/or

that slow pressure loss is occurring. In these

cases, optimal tire duration and fuel consumption may not

be guaranteed.

Should one or more tires be in the condition mentioned

previously, the display will show the indications

corresponding to each tire.

Each tire, including the spare (if provided), should be

checked monthly when cold and inflated to the inflation

pressure recommended by the vehicle manufacturer on

the vehicle placard or tire inflation pressure label. If your

vehicle has tires of a different size than the size indicated

on the vehicle placard or tire inflation pressure label, you

should determine the proper tire inflation pressure for

those tires. As an added safety feature, your vehicle has been

equipped with a TPMS that illuminates a low tire pressure

telltale when one or more of your tires is significantly

underinflated. Accordingly, when the low tire pressure

telltale illuminates, you should stop and check your tires

as soon as possible, and inflate them to the proper

pressure. Driving on a significantly underinflated tire

causes the tire to overheat and can lead to tire failure.

Underinflation also reduces fuel efficiency and tire tread

life, and may affect the vehicle’s handling and stopping

ability.

Please note that the TPMS is not a substitute for proper

tire maintenance, and it is the driver’s responsibility to

maintain correct tire pressure, even if underinflation has

not reached the level to trigger illumination of the TPMS

low tire pressure telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is not

operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the

system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously

illuminated. This sequence will continue upon subsequent

vehicle start-ups as long as the malfunction exists. When

the malfunction indicator is illuminated, the system may

not be able to detect or signal low tire pressure as

intended. TPMS malfunctions may occur for a variety of

reasons, including the installation of replacement or

alternate tires or wheels on the vehicle that prevent the

TPMS from functioning properly. Always check the TPMS

malfunction telltale after replacing one or more tires or

wheels on your vehicle to ensure that the replacement or

alternate tires and wheels allow the TPMS to continue to

function properly

Úpage 252.

Towing Hook Breakdown Warning Light —

If Equipped

This light illuminates when there is a failure

with the tow hook. Contact an authorized

dealer for service.

YELLOW INDICATOR LIGHTS

4WD Low Indicator Light — If Equipped

This light alerts the driver that the vehicle is in

the 4WD Low mode. The front and rear

driveshafts are mechanically locked together

forcing the front and rear wheels to rotate at

the same speed. Low range provides a greater gear

reduction ratio to provide increased torque at the wheels

Úpage 129.

CAUTION!

Do not continue driving with one or more flat tires as

handling may be compromised. Stop the vehicle,

avoiding sharp braking and steering. If a tire puncture

occurs, repair immediately using the dedicated tire

repair kit and contact an authorized dealer as soon as

possible.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size

equipped on your vehicle. Undesirable system

operation or sensor damage may result when using

replacement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Using aftermarket tire sealants may

cause the Tire Pressure Monitoring System (TPMS)

sensor to become inoperable. After using an

aftermarket tire sealant it is recommended that you

take your vehicle to an authorized dealer to have your

sensor function checked.

23_WS_OM_EN_USC_t.book Page 114

Page 135 of 396

STARTING AND OPERATING133

Normal Ride Height (NRH) – This is the standard posi -

tion of the suspension and is meant for normal driving.

Off-Road 1 (OR1) (Raises the vehicle approximately

1.2 inches [30 mm]) – This is the primary position for

all off-road driving until OR2 is needed. A smoother and

more comfortable ride will result. Push the toggle

switch forward once from the NRH position while the

vehicle speed is below 38 mph (61 km/h). When in the

OR1 position, if the vehicle speed remains between

40 mph (64 km/h) and 50 mph (80 km/h) for greater than 20 seconds or if the vehicle speed exceeds

50 mph (80 km/h), the vehicle will be automatically

lowered to NRH

Úpage 193. OR1 is unavailable on

4x2 air suspension vehicles.

Off-Road 2 (OR2) (Raises the vehicle approximately

2.0 inches [51 mm]) – This position is intended for

off-roading use only where maximum ground clearance

is required. To enter OR2, push the toggle switch

forward twice from the NRH position or once from the

OR1 position while vehicle speed is below 20 mph

(32 km/h). While in OR2, if the vehicle speed exceeds

25 mph (40 km/h) the vehicle height will be automati -

cally lowered to OR1

Úpage 193. OR2 is unavailable

on 4x2 air suspension vehicles.

Aero Height (Lowers the vehicle approximately

-0.6 inches [-15 mm]) – This position provides

improved aerodynamics by lowering the vehicle. The

vehicle will automatically enter Aero Height when the

vehicle speed remains between 62 mph (100 km/h)

and 66 mph (106 km/h) for greater than 20 seconds

or if the vehicle speed exceeds 66 mph (106 km/h). The vehicle will return to Default Ride Height from Aero

Height if the vehicle speed remains between 30 mph

(48 km/h) and 35 mph (56 km/h) for greater than

20 seconds or if the vehicle speed falls below 30 mph

(48 km/h). The vehicle will enter Aero Height, regard

-

less of vehicle speed if the vehicle is in “SPORT” mode.

Entry/Exit Height (Lowers the vehicle approximately

-1.6 inches [-40 mm]) – This position lowers the

vehicle for easier passenger entry and exit as well as

lowering the rear of the vehicle for easier loading and

unloading of cargo. To enter Entry/Exit Height, push the

toggle switch down twice from NRH while the vehicle

speed is below 6 mph (10 km/h). To exit Entry/Exit

Height, push the UP button once while in Entry/Exit

Height or drive the vehicle over 4 mph (6 km/h).

NOTE:Automatic lowering of the vehicle into Entry/Exit Height

can be enabled through the Uconnect Touchscreen Radio.

If this feature is enabled, the vehicle will only lower if the

gear selector is in PARK, the terrain switch is in AUTO, the

transfer case is in AUTO and the vehicle level is either in

Normal or Aero Height. The vehicle will not automatically

lower if the air suspension level is in OR2 or OR1. When

towing, the automatic Entry/Exit feature may be disabled

through the Uconnect Touchscreen Radio to prevent

vehicle and trailer movement when gear selector is moved

to PARK. The Selec-Terrain system will automatically change the

vehicle to the proper height based on the position of the

Selec-Terrain switch. The height can be changed from the

default Selec-Terrain setting by normal use of the air

suspension buttons

Úpage 131.

The system requires that the engine be running for all

changes. When lowering the vehicle all of the doors,

including the liftgate, must be closed. If a door is opened

at any time while the vehicle is lowering the change will not

be completed until the open door(s) is/are closed.

The Quadra-Lift Air Suspension system uses a lifting and

lowering pattern which keeps the headlights from

incorrectly shining into oncoming traffic. When raising the

vehicle, the rear of the vehicle will move up first and then

the front. When lowering the vehicle, the front will move

down first and then the rear.

After the engine is turned off, it may be noticed that the air

suspension system operates briefly; this is normal. The

system is correcting the position of the vehicle to ensure a

proper appearance.

To assist with changing a spare tire, the Quadra-Lift Air

Suspension system has a feature which allows the

automatic leveling to be disabled

Úpage 197.

4

23_WS_OM_EN_USC_t.book Page 133

Page 136 of 396

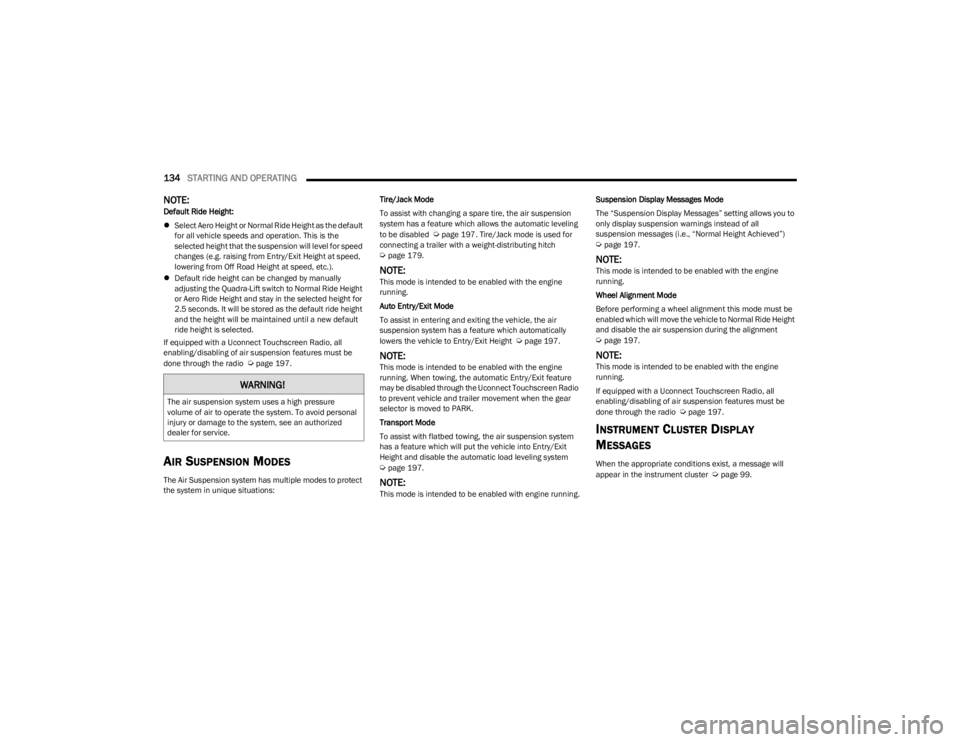

134STARTING AND OPERATING

NOTE:Default Ride Height:

Select Aero Height or Normal Ride Height as the default

for all vehicle speeds and operation. This is the

selected height that the suspension will level for speed

changes (e.g. raising from Entry/Exit Height at speed,

lowering from Off Road Height at speed, etc.).

Default ride height can be changed by manually

adjusting the Quadra-Lift switch to Normal Ride Height

or Aero Ride Height and stay in the selected height for

2.5 seconds. It will be stored as the default ride height

and the height will be maintained until a new default

ride height is selected.

If equipped with a Uconnect Touchscreen Radio, all

enabling/disabling of air suspension features must be

done through the radio

Úpage 197.

AIR SUSPENSION MODES

The Air Suspension system has multiple modes to protect

the system in unique situations: Tire/Jack Mode

To assist with changing a spare tire, the air suspension

system has a feature which allows the automatic leveling

to be disabled

Úpage 197. Tire/Jack mode is used for

connecting a trailer with a weight-distributing hitch

Úpage 179.

NOTE:This mode is intended to be enabled with the engine

running.

Auto Entry/Exit Mode

To assist in entering and exiting the vehicle, the air

suspension system has a feature which automatically

lowers the vehicle to Entry/Exit Height

Úpage 197.

NOTE:This mode is intended to be enabled with the engine

running. When towing, the automatic Entry/Exit feature

may be disabled through the Uconnect Touchscreen Radio

to prevent vehicle and trailer movement when the gear

selector is moved to PARK.

Transport Mode

To assist with flatbed towing, the air suspension system

has a feature which will put the vehicle into Entry/Exit

Height and disable the automatic load leveling system

Úpage 197.

NOTE:This mode is intended to be enabled with engine running. Suspension Display Messages Mode

The “Suspension Display Messages” setting allows you to

only display suspension warnings instead of all

suspension messages (i.e., “Normal Height Achieved”)

Úpage 197.

NOTE:This mode is intended to be enabled with the engine

running.

Wheel Alignment Mode

Before performing a wheel alignment this mode must be

enabled which will move the vehicle to Normal Ride Height

and disable the air suspension during the alignment

Úpage 197.

NOTE:This mode is intended to be enabled with the engine

running.

If equipped with a Uconnect Touchscreen Radio, all

enabling/disabling of air suspension features must be

done through the radio

Úpage 197.

INSTRUMENT CLUSTER DISPLAY

M

ESSAGES

When the appropriate conditions exist, a message will

appear in the instrument cluster Úpage 99.

WARNING!

The air suspension system uses a high pressure

volume of air to operate the system. To avoid personal

injury or damage to the system, see an authorized

dealer for service.

23_WS_OM_EN_USC_t.book Page 134

Page 188 of 396

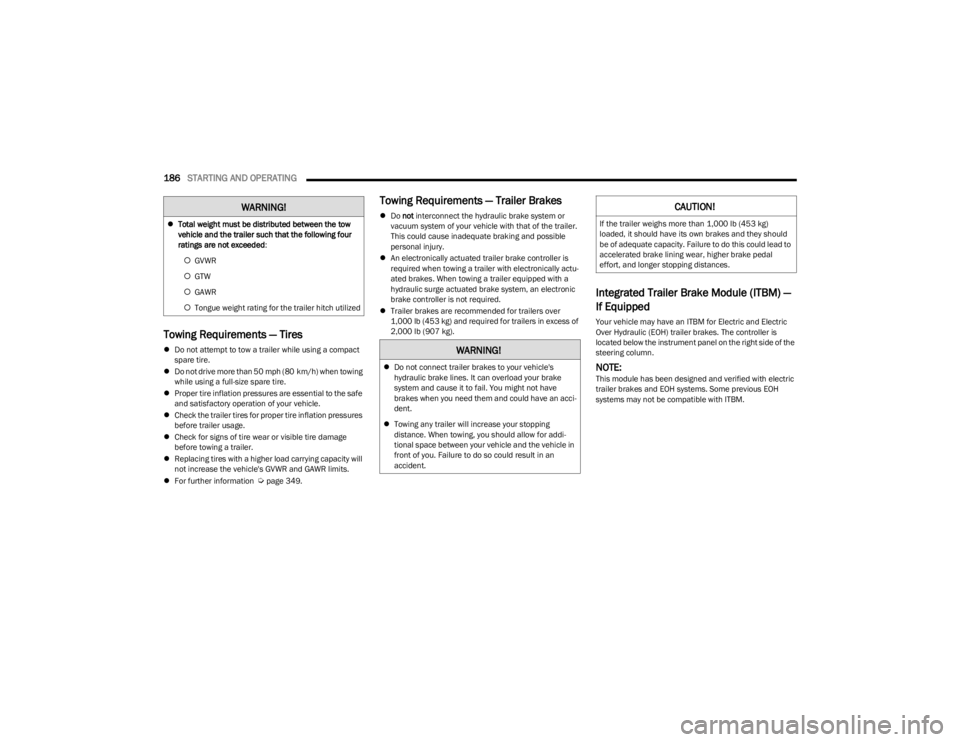

186STARTING AND OPERATING

Towing Requirements — Tires

Do not attempt to tow a trailer while using a compact

spare tire.

Do not drive more than 50 mph (80 km/h) when towing

while using a full-size spare tire.

Proper tire inflation pressures are essential to the safe

and satisfactory operation of your vehicle.

Check the trailer tires for proper tire inflation pressures

before trailer usage.

Check for signs of tire wear or visible tire damage

before towing a trailer.

Replacing tires with a higher load carrying capacity will

not increase the vehicle's GVWR and GAWR limits.

For further information

Úpage 349.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake system or

vacuum system of your vehicle with that of the trailer.

This could cause inadequate braking and possible

personal injury.

An electronically actuated trailer brake controller is

required when towing a trailer with electronically actu -

ated brakes. When towing a trailer equipped with a

hydraulic surge actuated brake system, an electronic

brake controller is not required.

Trailer brakes are recommended for trailers over

1,000 lb (453 kg) and required for trailers in excess of

2,000 lb (907 kg).

Integrated Trailer Brake Module (ITBM) —

If Equipped

Your vehicle may have an ITBM for Electric and Electric

Over Hydraulic (EOH) trailer brakes. The controller is

located below the instrument panel on the right side of the

steering column.

NOTE:This module has been designed and verified with electric

trailer brakes and EOH systems. Some previous EOH

systems may not be compatible with ITBM.

Total weight must be distributed between the tow

vehicle and the trailer such that the following four

ratings are not exceeded :

GVWR

GTW

GAWR

Tongue weight rating for the trailer hitch utilized

WARNING!

WARNING!

Do not connect trailer brakes to your vehicle's

hydraulic brake lines. It can overload your brake

system and cause it to fail. You might not have

brakes when you need them and could have an acci -

dent.

Towing any trailer will increase your stopping

distance. When towing, you should allow for addi -

tional space between your vehicle and the vehicle in

front of you. Failure to do so could result in an

accident.

CAUTION!

If the trailer weighs more than 1,000 lb (453 kg)

loaded, it should have its own brakes and they should

be of adequate capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake pedal

effort, and longer stopping distances.

23_WS_OM_EN_USC_t.book Page 186

Page 217 of 396

MULTIMEDIA215

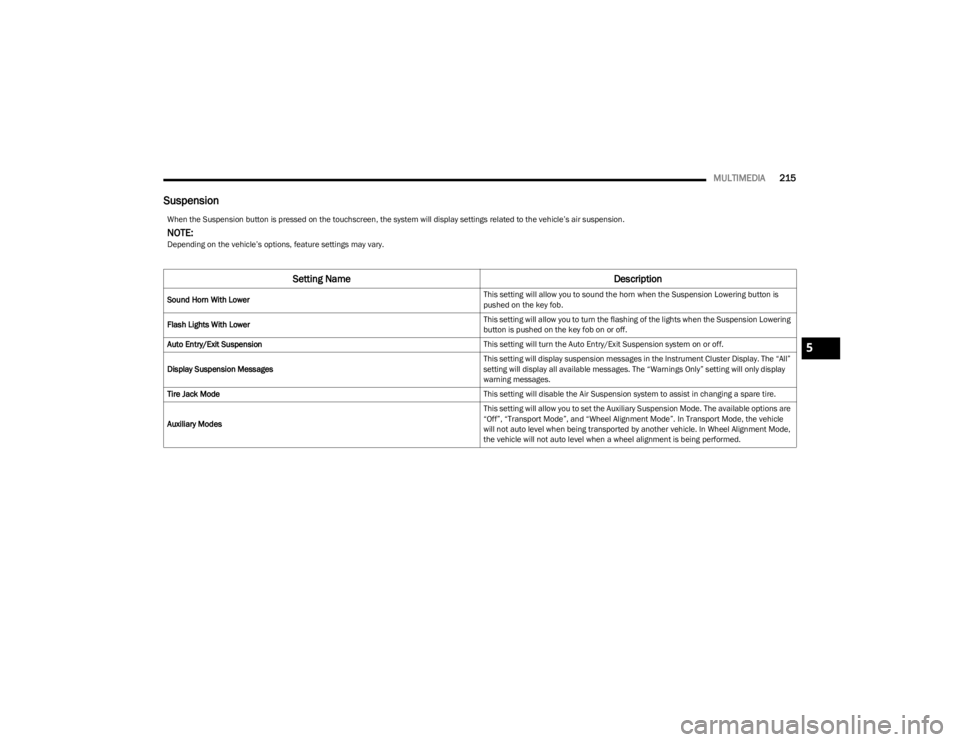

Suspension

When the Suspension button is pressed on the touchscreen, the system will display settings related to the vehicle’s air suspension.

NOTE:Depending on the vehicle’s options, feature settings may vary.

Setting Name Description

Sound Horn With Lower This setting will allow you to sound the horn when the Suspension Lowering button is

pushed on the key fob.

Flash Lights With Lower This setting will allow you to turn the flashing of the lights when the Suspension Lowering

button is pushed on the key fob on or off.

Auto Entry/Exit Suspension This setting will turn the Auto Entry/Exit Suspension system on or off.

Display Suspension Messages This setting will display suspension messages in the Instrument Cluster Display. The “All”

setting will display all available messages. The “Warnings Only” setting will only display

warning messages.

Tire Jack Mode This setting will disable the Air Suspension system to assist in changing a spare tire.

Auxiliary Modes This setting will allow you to set the Auxiliary Suspension Mode. The available options are

“Off”, “Transport Mode”, and “Wheel Alignment Mode”. In Transport Mode, the vehicle

will not auto level when being transported by another vehicle. In Wheel Alignment Mode,

the vehicle will not auto level when a wheel alignment is being performed.

5

23_WS_OM_EN_USC_t.book Page 215

Page 257 of 396

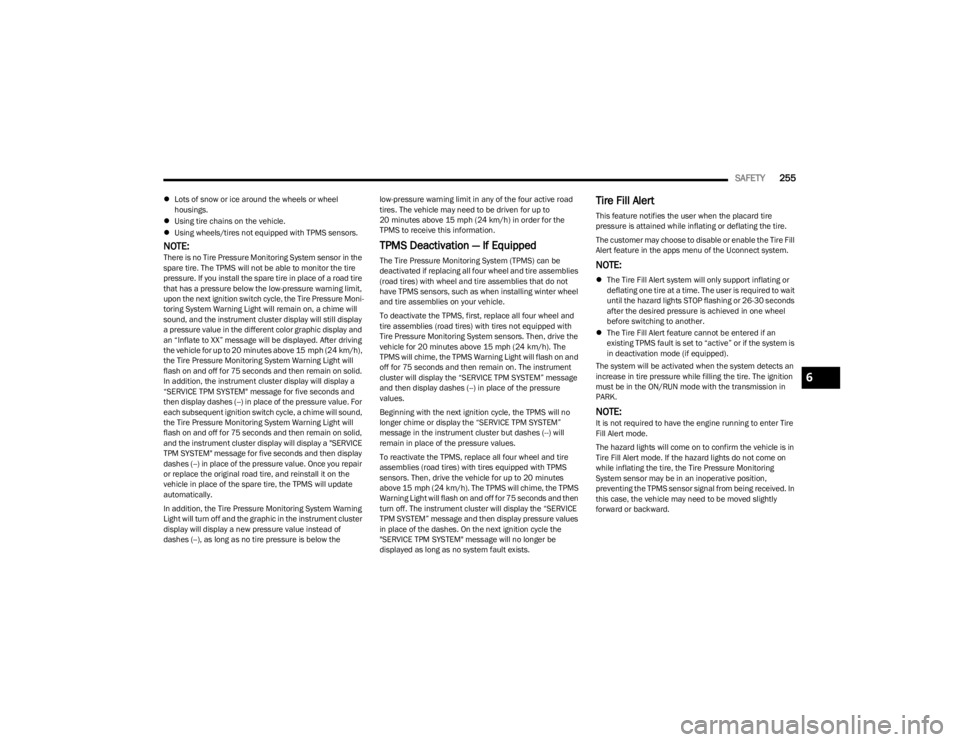

SAFETY255

Lots of snow or ice around the wheels or wheel

housings.

Using tire chains on the vehicle.

Using wheels/tires not equipped with TPMS sensors.

NOTE:There is no Tire Pressure Monitoring System sensor in the

spare tire. The TPMS will not be able to monitor the tire

pressure. If you install the spare tire in place of a road tire

that has a pressure below the low-pressure warning limit,

upon the next ignition switch cycle, the Tire Pressure Moni -

toring System Warning Light will remain on, a chime will

sound, and the instrument cluster display will still display

a pressure value in the different color graphic display and

an “Inflate to XX” message will be displayed. After driving

the vehicle for up to 20 minutes above 15 mph (24 km/h),

the Tire Pressure Monitoring System Warning Light will

flash on and off for 75 seconds and then remain on solid.

In addition, the instrument cluster display will display a

“SERVICE TPM SYSTEM" message for five seconds and

then display dashes (--) in place of the pressure value. For

each subsequent ignition switch cycle, a chime will sound,

the Tire Pressure Monitoring System Warning Light will

flash on and off for 75 seconds and then remain on solid,

and the instrument cluster display will display a "SERVICE

TPM SYSTEM" message for five seconds and then display

dashes (--) in place of the pressure value. Once you repair

or replace the original road tire, and reinstall it on the

vehicle in place of the spare tire, the TPMS will update

automatically.

In addition, the Tire Pressure Monitoring System Warning

Light will turn off and the graphic in the instrument cluster

display will display a new pressure value instead of

dashes (--), as long as no tire pressure is below the low-pressure warning limit in any of the four active road

tires. The vehicle may need to be driven for up to

20 minutes above 15 mph (24 km/h) in order for the

TPMS to receive this information.TPMS Deactivation — If Equipped

The Tire Pressure Monitoring System (TPMS) can be

deactivated if replacing all four wheel and tire assemblies

(road tires) with wheel and tire assemblies that do not

have TPMS sensors, such as when installing winter wheel

and tire assemblies on your vehicle.

To deactivate the TPMS, first, replace all four wheel and

tire assemblies (road tires) with tires not equipped with

Tire Pressure Monitoring System sensors. Then, drive the

vehicle for 20 minutes above 15 mph (24 km/h). The TPMS will chime, the TPMS Warning Light will flash on and

off for 75 seconds and then remain on. The instrument

cluster will display the “SERVICE TPM SYSTEM” message

and then display dashes (--) in place of the pressure

values.

Beginning with the next ignition cycle, the TPMS will no

longer chime or display the “SERVICE TPM SYSTEM”

message in the instrument cluster but dashes (--) will

remain in place of the pressure values.

To reactivate the TPMS, replace all four wheel and tire

assemblies (road tires) with tires equipped with TPMS

sensors. Then, drive the vehicle for up to 20 minutes

above 15 mph (24 km/h). The TPMS will chime, the TPMS

Warning Light will flash on and off for 75 seconds and then

turn off. The instrument cluster will display the “SERVICE

TPM SYSTEM” message and then display pressure values

in place of the dashes. On the next ignition cycle the

"SERVICE TPM SYSTEM" message will no longer be

displayed as long as no system fault exists.

Tire Fill Alert

This feature notifies the user when the placard tire

pressure is attained while inflating or deflating the tire.

The customer may choose to disable or enable the Tire Fill

Alert feature in the apps menu of the Uconnect system.

NOTE:

The Tire Fill Alert system will only support inflating or

deflating one tire at a time. The user is required to wait

until the hazard lights STOP flashing or 26-30 seconds

after the desired pressure is achieved in one wheel

before switching to another.

The Tire Fill Alert feature cannot be entered if an

existing TPMS fault is set to “active” or if the system is

in deactivation mode (if equipped).

The system will be activated when the system detects an

increase in tire pressure while filling the tire. The ignition

must be in the ON/RUN mode with the transmission in

PARK.

NOTE:It is not required to have the engine running to enter Tire

Fill Alert mode.

The hazard lights will come on to confirm the vehicle is in

Tire Fill Alert mode. If the hazard lights do not come on

while inflating the tire, the Tire Pressure Monitoring

System sensor may be in an inoperative position,

preventing the TPMS sensor signal from being received. In

this case, the vehicle may need to be moved slightly

forward or backward.

6

23_WS_OM_EN_USC_t.book Page 255

Page 291 of 396

SAFETY289

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts, cracks, and bulges.

Check the lug nut/bolt torque for tightness. Check the

tires (including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake lights and

exterior lights while you work the controls. Check turn

signal and high beam indicator lights on the instrument

panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight parking for

fuel, coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel or brake fluid leaks are

suspected, the cause should be located and corrected

immediately.

EXHAUST GAS

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system. Whenever a change is noticed in the sound of the exhaust

system, when exhaust fumes can be detected inside the

vehicle, or when the underside or rear of the vehicle is

damaged, have an authorized dealer inspect the complete

exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts. Open

seams or loose connections could permit exhaust fumes

to seep into the passenger compartment. In addition,

inspect the exhaust system each time the vehicle is raised

for lubrication or oil change. Replace as required.

CARBON MONOXIDE WARNINGS

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide (CO), which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing (CO), follow

these safety tips:

Do not run the engine in a closed garage or in

confined areas any longer than needed to move your

vehicle in or out of the area.

If you are required to drive with the trunk/liftgate/

rear doors open, make sure that all windows are

closed and the climate control BLOWER switch is set

at high speed. DO NOT use the recirculation mode.

If it is necessary to sit in a parked vehicle with the

engine running, adjust your heating or cooling

controls to force outside air into the vehicle. Set the

blower at high speed.

WARNING!

Carbon monoxide (CO) in exhaust gases is deadly.

Follow the precautions below to prevent carbon

monoxide poisoning:

Do not inhale exhaust gases. They contain carbon

monoxide, a colorless and odorless gas, which can

kill. Never run the engine in a closed area, such as a

garage, and never sit in a parked vehicle with the

engine running for an extended period. If the vehicle

is stopped in an open area with the engine running

for more than a short period, adjust the ventilation

system to force fresh, outside air into the vehicle.

Guard against carbon monoxide with proper mainte -

nance. Have the exhaust system inspected every

time the vehicle is raised. Have any abnormal condi -

tions repaired promptly. Until repaired, drive with all

side windows fully open.

6

23_WS_OM_EN_USC_t.book Page 289

Page 297 of 396

IN CASE OF EMERGENCY295

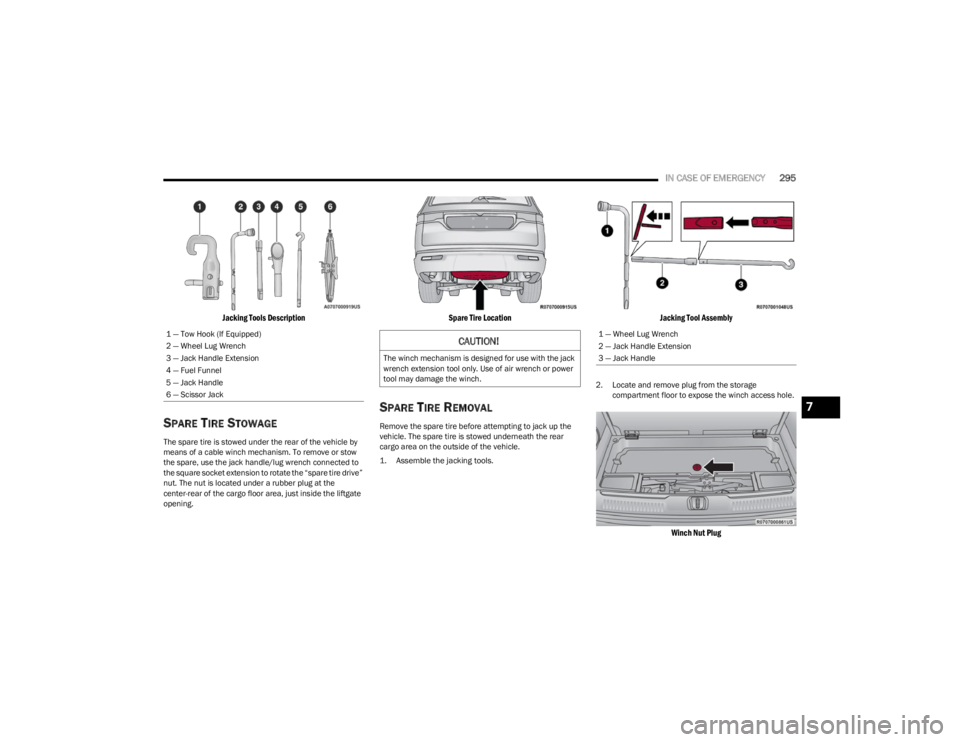

Jacking Tools Description

SPARE TIRE STOWAGE

The spare tire is stowed under the rear of the vehicle by

means of a cable winch mechanism. To remove or stow

the spare, use the jack handle/lug wrench connected to

the square socket extension to rotate the “spare tire drive”

nut. The nut is located under a rubber plug at the

center-rear of the cargo floor area, just inside the liftgate

opening.

Spare Tire Location

SPARE TIRE REMOVAL

Remove the spare tire before attempting to jack up the

vehicle. The spare tire is stowed underneath the rear

cargo area on the outside of the vehicle.

1. Assemble the jacking tools.

Jacking Tool Assembly

2. Locate and remove plug from the storage

compartment floor to expose the winch access hole.

Winch Nut Plug

1 — Tow Hook (If Equipped)

2 — Wheel Lug Wrench

3 — Jack Handle Extension

4 — Fuel Funnel

5 — Jack Handle

6 — Scissor JackCAUTION!

The winch mechanism is designed for use with the jack

wrench extension tool only. Use of air wrench or power

tool may damage the winch.

1 — Wheel Lug Wrench

2 — Jack Handle Extension

3 — Jack Handle

7

23_WS_OM_EN_USC_t.book Page 295