JEEP WAGONEER 2023 Owners Manual

Manufacturer: JEEP, Model Year: 2023, Model line: WAGONEER, Model: JEEP WAGONEER 2023Pages: 396, PDF Size: 15.17 MB

Page 331 of 396

SERVICING AND MAINTENANCE329

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against using any

special additives in the transmission. Automatic

Transmission Fluid (ATF) is an engineered product and its

performance may be impaired by supplemental additives.

Therefore, do not add any fluid additives to the

transmission. Avoid using transmission sealers as they

may adversely affect seals.

Fluid Level Check

The fluid level is preset at the factory and does not require

adjustment under normal operating conditions. Routine

fluid level checks are not required; therefore the

transmission has no dipstick. An authorized dealer can

check your transmission fluid level using special service

tools. If you notice fluid leakage or transmission

malfunction, visit an authorized dealer immediately to

have the transmission fluid level checked. Operating the

vehicle with an improper fluid level can cause severe

transmission damage.

Fluid And Filter Changes

Under normal operating conditions, the fluid installed at

the factory will provide satisfactory lubrication for the life

of the vehicle.

Routine fluid and filter changes are not required. However,

change the fluid and filter if the fluid becomes

contaminated (with water, etc.), or if the transmission is

disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid to

ensure optimum transmission performance and life. Use

only the manufacturer's specified transmission fluid

Úpage 377. It is important to maintain the transmission

fluid at the correct level using the recommended fluid.

NOTE:No chemical flushes should be used in any transmission;

only the approved lubricant should be used.

To avoid contamination from foreign matter or mois -

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master

cylinder reservoir cap secured at all times. Brake

fluid in an open container absorbs moisture from the

air resulting in a lower boiling point. This may cause

it to boil unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This could

result in a collision.

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum-based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

WARNING!CAUTION!

Do not use chemical flushes in your transmission as the

chemicals can damage your transmission components.

Such damage is not covered by the New Vehicle Limited

Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an authorized

dealer immediately. Severe transmission damage may

occur. An authorized dealer has the proper tools to

adjust the fluid level accurately.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/or torque

converter shudder.8

23_WS_OM_EN_USC_t.book Page 329

Page 332 of 396

330SERVICING AND MAINTENANCE

FRONT/REAR AXLE FLUID

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons

the exterior surfaces of the axle assembly should be

inspected. If gear oil leakage is suspected inspect the fluid

level.

Front Axle Fluid Level Check

The front axle oil level needs to be no lower than 1/8 inch

(3 mm) below the bottom of the fill hole.

The front axle fill and drain plugs should be tightened to

22 to 29 ft-lb (30 to 40 N·m).

Rear Axle Fluid Level Check

The rear axle oil level needs to be no lower than 1/8 inch

(3 mm) below the bottom of the fill hole.

The rear axle fill and drain plugs should be tightened to

22 to 29 ft-lb (30 to 40 N·m).

Selection Of Lubricant

Use only the manufacturer's recommended fluid Úpage 377.

TRANSFER CASE

Fluid Level Check

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons

the exterior surfaces of the transfer case assembly should

be inspected. If oil leakage is suspected inspect the fluid

level.

Adding Fluid

Add fluid at the filler hole, until it runs out of the hole, when

the vehicle is in a level position.

Drain

First remove fill plug, then remove drain plug.

Recommended tightening torque for drain and fill plugs is

15 to 25 ft-lb (20 to 34 N·m).

Selection Of Lubricant

Use only the manufacturer's recommended fluid Úpage 377.

CAUTION!

Do not overtighten the plugs as it could damage them

and cause them to leak.

CAUTION!

Do not overtighten the plugs as it could damage them

and cause them to leak.CAUTION!

When installing plugs, do not overtighten. You could

damage them and cause them to leak.

23_WS_OM_EN_USC_t.book Page 330

Page 333 of 396

SERVICING AND MAINTENANCE331

FUSES

General Information

The fuses protect electrical systems against excessive

current.

When a device does not work, you must check the fuse

element inside the blade fuse for a break/melt.

Also, please be aware that using power outlets for

extended periods of time with the engine off may result in

vehicle battery discharge.

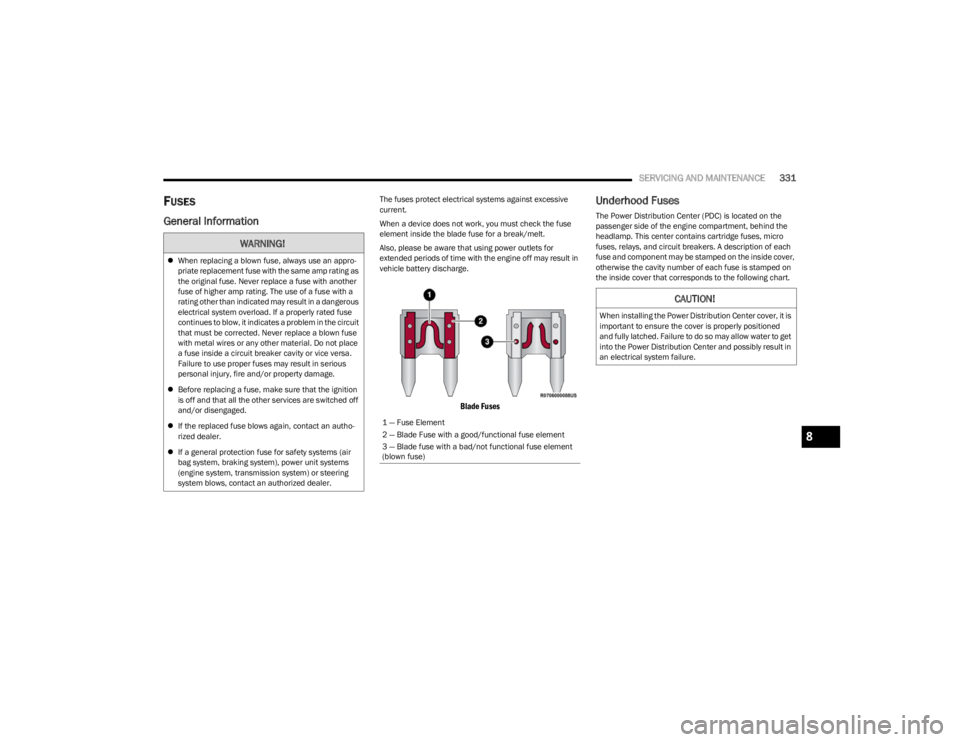

Blade Fuses

Underhood Fuses

The Power Distribution Center (PDC) is located on the

passenger side of the engine compartment, behind the

headlamp. This center contains cartridge fuses, micro

fuses, relays, and circuit breakers. A description of each

fuse and component may be stamped on the inside cover,

otherwise the cavity number of each fuse is stamped on

the inside cover that corresponds to the following chart.

WARNING!

When replacing a blown fuse, always use an appro -

priate replacement fuse with the same amp rating as

the original fuse. Never replace a fuse with another

fuse of higher amp rating. The use of a fuse with a

rating other than indicated may result in a dangerous

electrical system overload. If a properly rated fuse

continues to blow, it indicates a problem in the circuit

that must be corrected. Never replace a blown fuse

with metal wires or any other material. Do not place

a fuse inside a circuit breaker cavity or vice versa.

Failure to use proper fuses may result in serious

personal injury, fire and/or property damage.

Before replacing a fuse, make sure that the ignition

is off and that all the other services are switched off

and/or disengaged.

If the replaced fuse blows again, contact an autho -

rized dealer.

If a general protection fuse for safety systems (air

bag system, braking system), power unit systems

(engine system, transmission system) or steering

system blows, contact an authorized dealer.

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse element

3 — Blade fuse with a bad/not functional fuse element

(blown fuse)

CAUTION!

When installing the Power Distribution Center cover, it is

important to ensure the cover is properly positioned

and fully latched. Failure to do so may allow water to get

into the Power Distribution Center and possibly result in

an electrical system failure.

8

23_WS_OM_EN_USC_t.book Page 331

Page 334 of 396

332SERVICING AND MAINTENANCE

Power Distribution Center

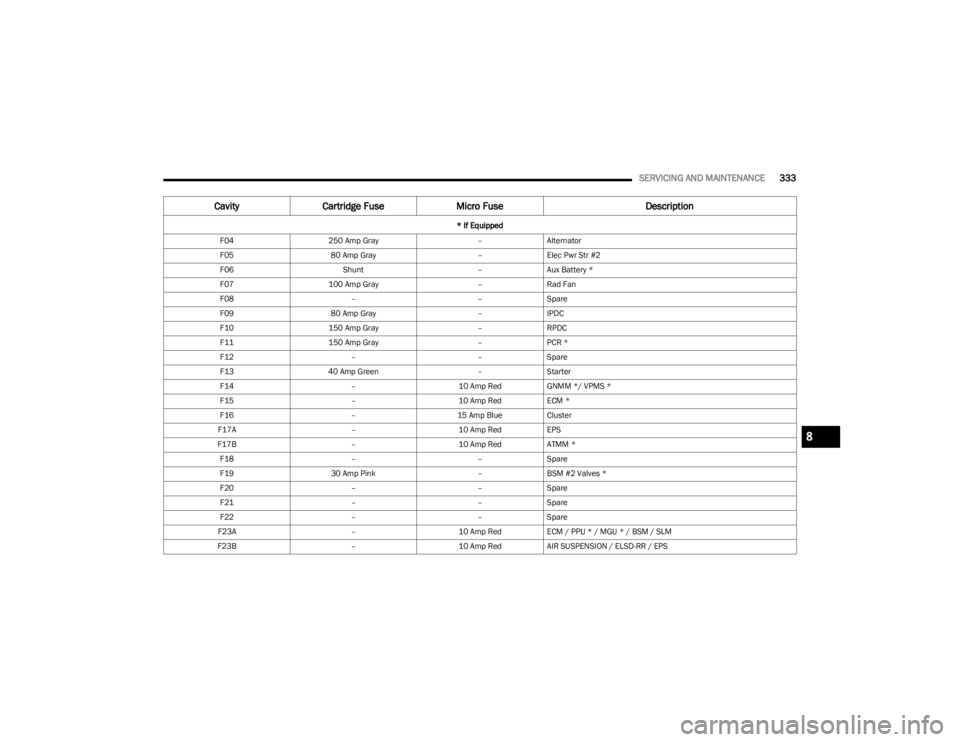

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

F01 ––Crank Batt

F02 80 Amp Gray –Elec Pwr Str #1

F03 500 Amp Gray –Starter

23_WS_OM_EN_USC_t.book Page 332

Page 335 of 396

SERVICING AND MAINTENANCE333

F04250 Amp Gray –Alternator

F05 80 Amp Gray –Elec Pwr Str #2

F06 Shunt –Aux Battery *

F07 100 Amp Gray –Rad Fan

F08 ––Spare

F09 80 Amp Gray –IPDC

F10 150 Amp Gray –RPDC

F11 150 Amp Gray –PCR *

F12 ––Spare

F13 40 Amp Green –Starter

F14 –10 Amp RedGNMM */ VPMS *

F15 –10 Amp RedECM *

F16 –15 Amp BlueCluster

F17A –10 Amp RedEPS

F17B –10 Amp RedATMM *

F18 ––Spare

F19 30 Amp Pink –BSM #2 Valves *

F20 ––Spare

F21 ––Spare

F22 ––Spare

F23A –10 Amp RedECM / PPU * / MGU * / BSM / SLM

F23B –10 Amp RedAIR SUSPENSION / ELSD-RR / EPS

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

8

23_WS_OM_EN_USC_t.book Page 333

Page 336 of 396

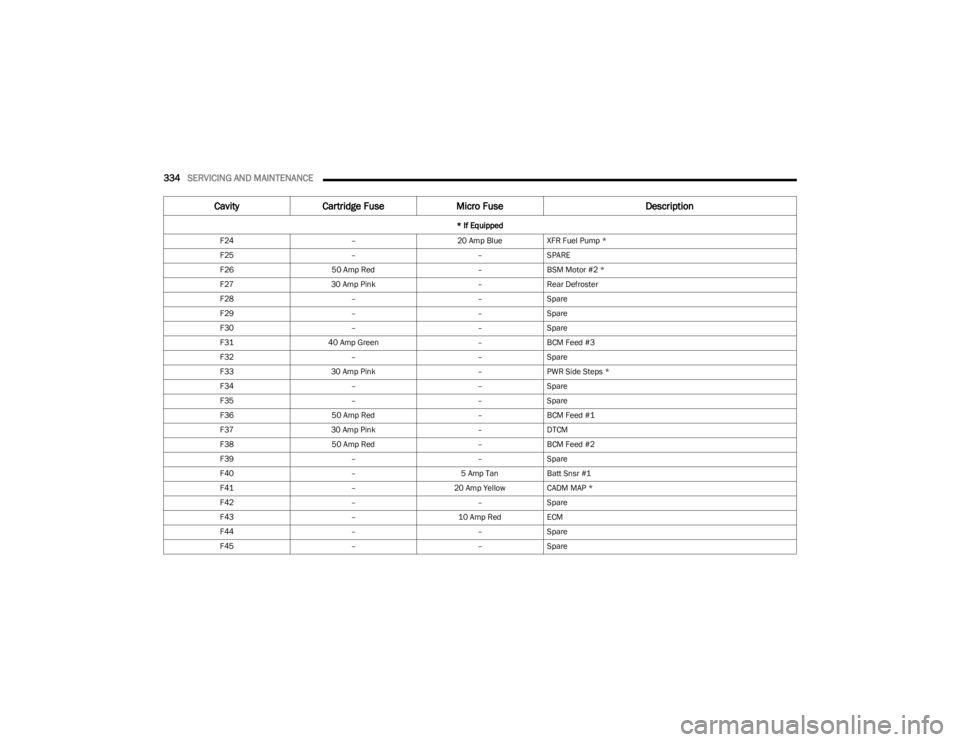

334SERVICING AND MAINTENANCE

F24 –20 Amp BlueXFR Fuel Pump *

F25 ––SPARE

F26 50 Amp Red –BSM Motor #2 *

F27 30 Amp Pink –Rear Defroster

F28 ––Spare

F29 ––Spare

F30 ––Spare

F31 40 Amp Green –BCM Feed #3

F32 ––Spare

F33 30 Amp Pink –PWR Side Steps *

F34 ––Spare

F35 ––Spare

F36 50 Amp Red –BCM Feed #1

F37 30 Amp Pink –DTCM

F38 50 Amp Red –BCM Feed #2

F39 ––Spare

F40 –5 Amp TanBatt Snsr #1

F41 –20 Amp Yellow CADM MAP *

F42 ––Spare

F43 –10 Amp RedECM

F44 ––Spare

F45 ––Spare

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

23_WS_OM_EN_USC_t.book Page 334

Page 337 of 396

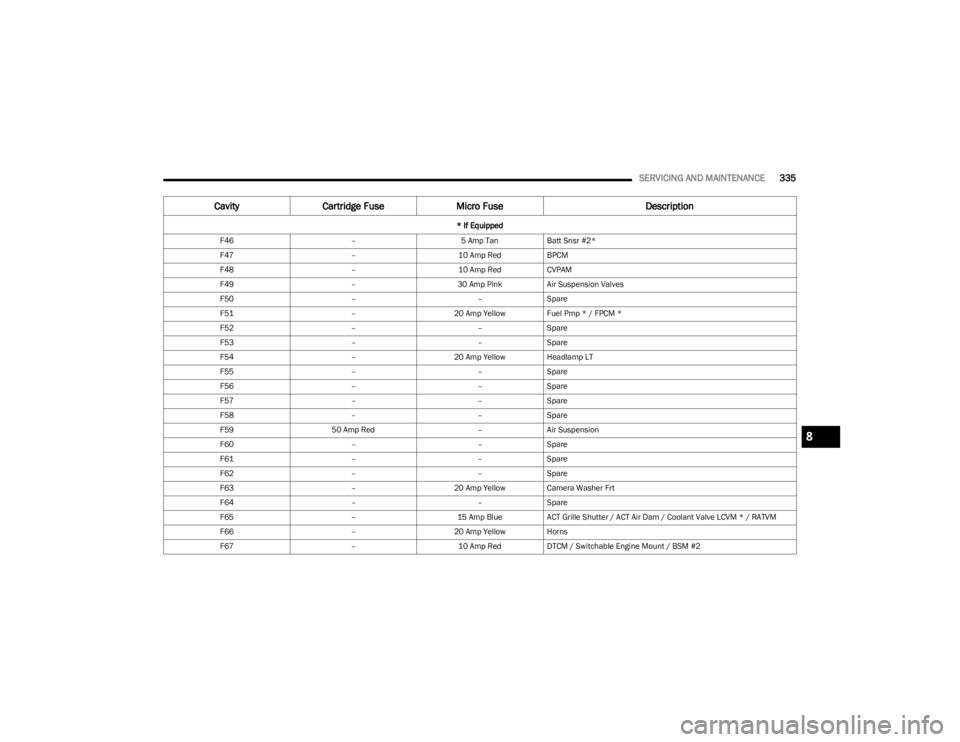

SERVICING AND MAINTENANCE335

F46 –5 Amp TanBatt Snsr #2*

F47 –10 Amp RedBPCM

F48 –10 Amp RedCVPAM

F49 –30 Amp PinkAir Suspension Valves

F50 ––Spare

F51 –20 Amp Yellow Fuel Pmp * / FPCM *

F52 ––Spare

F53 ––Spare

F54 –20 Amp Yellow Headlamp LT

F55 ––Spare

F56 ––Spare

F57 ––Spare

F58 ––Spare

F59 50 Amp Red –Air Suspension

F60 ––Spare

F61 ––Spare

F62 ––Spare

F63 –20 Amp Yellow Camera Washer Frt

F64 ––Spare

F65 –15 Amp BlueACT Grille Shutter / ACT Air Dam / Coolant Valve LCVM * / RATVM

F66 –20 Amp Yellow Horns

F67 –10 Amp RedDTCM / Switchable Engine Mount / BSM #2

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

8

23_WS_OM_EN_USC_t.book Page 335

Page 338 of 396

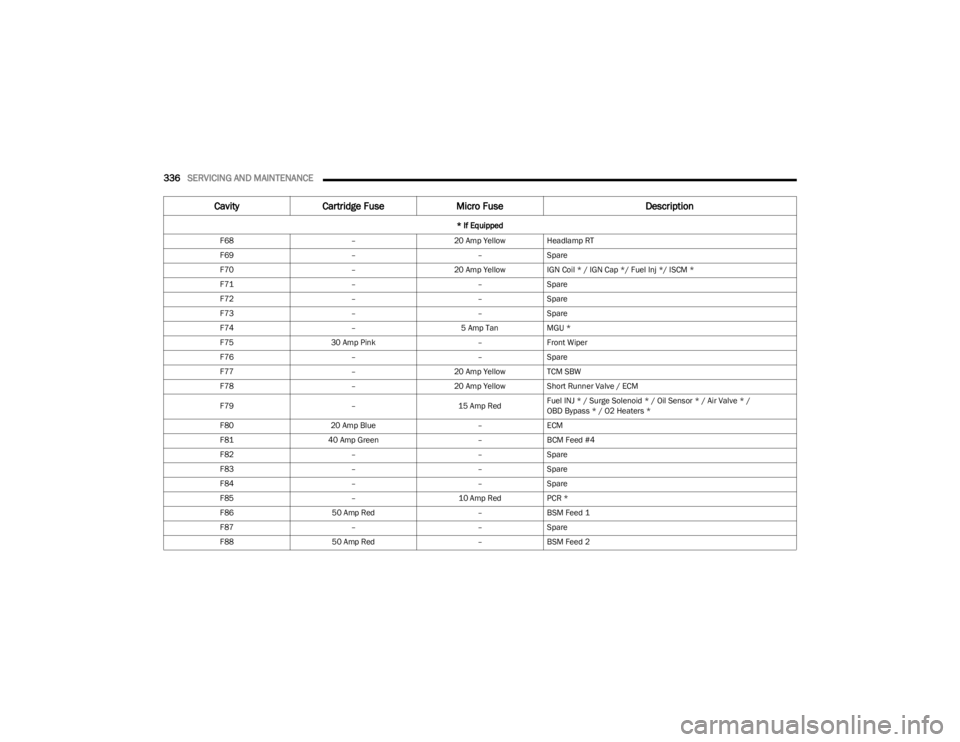

336SERVICING AND MAINTENANCE

F68 –20 Amp Yellow Headlamp RT

F69 ––Spare

F70 –20 Amp Yellow IGN Coil * / IGN Cap */ Fuel Inj */ ISCM *

F71 ––Spare

F72 ––Spare

F73 ––Spare

F74 –5 Amp TanMGU *

F75 30 Amp Pink –Front Wiper

F76 ––Spare

F77 –20 Amp Yellow TCM SBW

F78 –20 Amp Yellow Short Runner Valve / ECM

F79 –15 Amp RedFuel INJ * / Surge Solenoid * / Oil Sensor * / Air Valve * /

OBD Bypass * / O2 Heaters *

F80 20 Amp Blue –ECM

F81 40 Amp Green –BCM Feed #4

F82 ––Spare

F83 ––Spare

F84 ––Spare

F85 –10 Amp RedPCR *

F86 50 Amp Red –BSM Feed 1

F87 ––Spare

F88 50 Amp Red –BSM Feed 2

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

23_WS_OM_EN_USC_t.book Page 336

Page 339 of 396

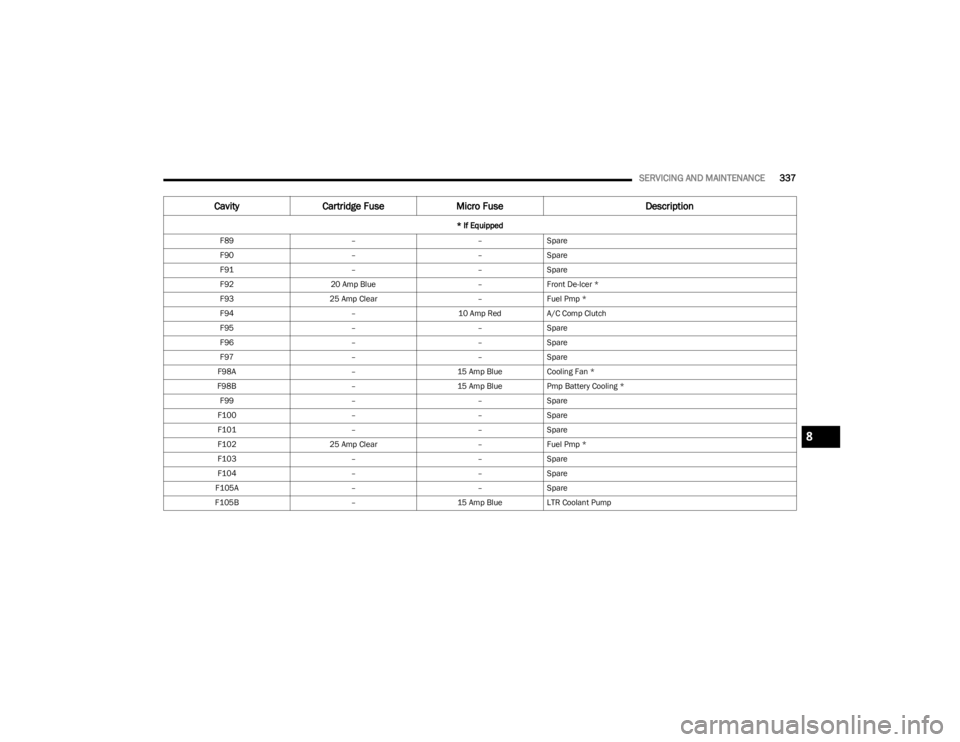

SERVICING AND MAINTENANCE337

F89 ––Spare

F90 ––Spare

F91 ––Spare

F92 20 Amp Blue –Front De-Icer *

F93 25 Amp Clear –Fuel Pmp *

F94 –10 Amp RedA/C Comp Clutch

F95 ––Spare

F96 ––Spare

F97 ––Spare

F98A –15 Amp BlueCooling Fan *

F98B –15 Amp BluePmp Battery Cooling *

F99 ––Spare

F100 ––Spare

F101 ––Spare

F102 25 Amp Clear –Fuel Pmp *

F103 ––Spare

F104 ––Spare

F105A ––Spare

F105B –15 Amp BlueLTR Coolant Pump

CavityCartridge Fuse Micro Fuse Description

* If Equipped

8

23_WS_OM_EN_USC_t.book Page 337

Page 340 of 396

338SERVICING AND MAINTENANCE

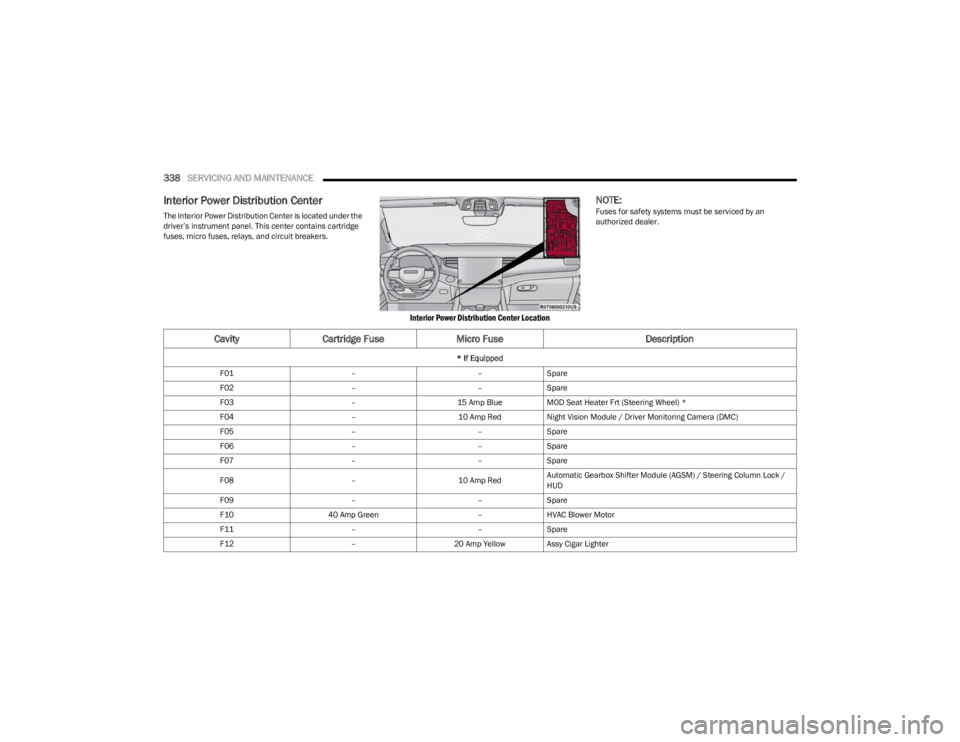

Interior Power Distribution Center

The Interior Power Distribution Center is located under the

driver’s instrument panel. This center contains cartridge

fuses, micro fuses, relays, and circuit breakers.

Interior Power Distribution Center Location

NOTE:Fuses for safety systems must be serviced by an

authorized dealer.

CavityCartridge Fuse Micro Fuse Description

* If Equipped

F01 ––Spare

F02 ––Spare

F03 –15 Amp BlueMOD Seat Heater Frt (Steering Wheel) *

F04 –10 Amp RedNight Vision Module / Driver Monitoring Camera (DMC)

F05 ––Spare

F06 ––Spare

F07 ––Spare

F08 –10 Amp RedAutomatic Gearbox Shifter Module (AGSM) / Steering Column Lock /

HUD

F09 ––Spare

F10 40 Amp Green –HVAC Blower Motor

F11 ––Spare

F12 –20 Amp Yellow Assy Cigar Lighter

23_WS_OM_EN_USC_t.book Page 338